Introduction: Navigating the Global Market for rfid pet feeder

In an increasingly digital world, sourcing the right RFID pet feeder can be a daunting challenge for B2B buyers, particularly in emerging markets such as Nigeria, Brazil, and throughout the Middle East and Europe. These innovative feeding solutions not only streamline pet care but also enhance operational efficiency in pet-related businesses, from veterinary clinics to pet hotels. This guide serves as a comprehensive resource, addressing essential aspects of the RFID pet feeder market, including various types, applications, supplier vetting processes, and cost considerations.

As international buyers navigate the complexities of sourcing RFID pet feeders, understanding the technological advancements and features—such as customizable feeding schedules, real-time monitoring through app connectivity, and enhanced food preservation capabilities—becomes crucial. This guide aims to empower decision-makers with actionable insights, enabling them to make informed purchasing decisions tailored to their unique market conditions and consumer needs.

Whether you are a retailer seeking to expand your product offerings or a service provider aiming to improve operational efficiency, this guide will equip you with the knowledge necessary to effectively evaluate and select the best RFID pet feeders for your business. By focusing on the evolving trends and demands within the global pet care market, we will help you stay ahead of the competition and meet the expectations of your clientele.

Table Of Contents

- Top 5 Rfid Pet Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for rfid pet feeder

- Understanding rfid pet feeder Types and Variations

- Key Industrial Applications of rfid pet feeder

- 3 Common User Pain Points for ‘rfid pet feeder’ & Their Solutions

- Strategic Material Selection Guide for rfid pet feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for rfid pet feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘rfid pet feeder’

- Comprehensive Cost and Pricing Analysis for rfid pet feeder Sourcing

- Alternatives Analysis: Comparing rfid pet feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for rfid pet feeder

- Navigating Market Dynamics and Sourcing Trends in the rfid pet feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rfid pet feeder

- Strategic Sourcing Conclusion and Outlook for rfid pet feeder

- Important Disclaimer & Terms of Use

Understanding rfid pet feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Pet RFID Feeders | Recognizes one pet via RFID collar; schedules multiple meals. | Pet stores, veterinary clinics, shelters. | Pros: Personalized feeding; Cons: Limited to one pet. |

| Multi-Pet RFID Feeders | Can manage feeding for multiple pets with individual access. | Animal boarding facilities, multi-pet households. | Pros: Efficient for multiple pets; Cons: Higher cost. |

| Smart Wi-Fi Connected Feeders | App-controlled, features feeding logs and notifications. | Pet tech retailers, online pet supply stores. | Pros: Remote management; Cons: Requires stable internet. |

| Automated Portion Control Feeders | Customizable portions and schedules, often with large capacity. | Animal care centers, pet grooming salons. | Pros: Reduces overfeeding; Cons: Initial setup complexity. |

| Cooling and Freshness Feeders | Maintains optimal food temperature, preventing spoilage. | High-end pet boutiques, specialty pet care services. | Pros: Keeps food fresh longer; Cons: Typically more expensive. |

What Are the Characteristics of Single-Pet RFID Feeders?

Single-pet RFID feeders are designed to cater to one specific pet, utilizing an RFID collar tag for recognition. This type allows pet owners to schedule multiple meals throughout the day, providing a tailored feeding experience. B2B buyers, such as pet stores or veterinary clinics, can benefit from offering these feeders as they promote health and nutrition through controlled feeding. However, their limitation to one pet may deter businesses catering to multi-pet households.

How Do Multi-Pet RFID Feeders Work?

Multi-pet RFID feeders are equipped to recognize several pets, allowing each to access their designated meals. This technology is particularly advantageous for animal boarding facilities or homes with multiple pets, streamlining feeding processes. B2B buyers should consider the higher cost associated with these feeders, as well as their potential to enhance customer satisfaction by reducing feeding conflicts among pets.

Why Choose Smart Wi-Fi Connected Feeders?

Smart Wi-Fi connected feeders provide advanced features, including app control and feeding logs that help monitor pet diets. These feeders are suitable for tech-savvy pet owners and can be marketed by pet tech retailers or online supply stores. The primary consideration for B2B buyers is the need for a reliable internet connection, which could limit sales in regions with unstable networks.

Illustrative image related to rfid pet feeder

What Are the Benefits of Automated Portion Control Feeders?

Automated portion control feeders allow precise customization of meal sizes and schedules, making them ideal for animal care centers and grooming salons focused on pet health. They help prevent overfeeding, a common issue in pet care. B2B buyers should weigh the initial setup complexity against the long-term benefits of promoting healthy feeding practices.

What Makes Cooling and Freshness Feeders Unique?

Cooling and freshness feeders ensure that pet food is kept at optimal temperatures, preventing spoilage and maintaining freshness. This type of feeder is particularly attractive to high-end pet boutiques and specialty pet care services. While they offer significant advantages in food quality, the higher price point may limit their appeal to budget-conscious buyers, necessitating a strong value proposition.

Key Industrial Applications of rfid pet feeder

| Industry/Sector | Specific Application of rfid pet feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Automated feeding for recovering pets | Ensures proper nutrition during recovery, reducing staff workload | Compatibility with various pet sizes and dietary needs |

| Pet Boarding Facilities | Individualized feeding schedules for multiple pets | Enhances pet care quality, reduces food waste, and ensures timely feeding | Robustness for high usage, easy maintenance and cleaning |

| Pet Retailers | Smart inventory management for pet food | Tracks food consumption patterns, optimizing stock levels | Integration with existing retail management systems |

| Animal Shelters | Tailored feeding for specific dietary requirements | Improves health outcomes for rescued animals, streamlining care | Affordability, ease of use, and adaptability for various pets |

| Smart Home Integrators | Integration into smart home ecosystems for pet care | Offers convenience and enhanced pet monitoring features | Compatibility with existing smart home technologies |

How Can Veterinary Clinics Benefit from RFID Pet Feeders?

In veterinary clinics, RFID pet feeders can automate the feeding process for pets recovering from surgery or illness. These feeders can be programmed to deliver precise portions at set intervals, ensuring that pets receive the necessary nutrition without requiring constant staff oversight. This not only alleviates the burden on veterinary staff but also improves the recovery process for pets. When sourcing RFID feeders, clinics should consider the compatibility with various pet sizes and specific dietary needs to cater effectively to all patients.

How Do Pet Boarding Facilities Utilize RFID Pet Feeders?

Pet boarding facilities can implement RFID pet feeders to provide individualized feeding schedules for each animal. This technology allows for precise control over portion sizes and feeding times, accommodating the specific dietary needs of each pet. By using RFID feeders, boarding facilities can enhance the quality of care provided to pets, reduce food waste, and ensure that all animals are fed on time. Buyers in this sector should prioritize robust designs that can withstand high usage and are easy to maintain and clean.

What Role Do RFID Pet Feeders Play in Pet Retailers?

In the retail sector, RFID pet feeders can significantly enhance inventory management by tracking pet food consumption patterns. Retailers can utilize this data to optimize stock levels and reduce waste, ensuring that they meet customer demand without overstocking. This technology not only improves operational efficiency but also allows retailers to offer personalized recommendations to customers based on their pet’s eating habits. Key considerations for sourcing include the ability to integrate these feeders with existing retail management systems for seamless operations.

Illustrative image related to rfid pet feeder

How Can Animal Shelters Benefit from Tailored Feeding Solutions?

Animal shelters can leverage RFID pet feeders to provide tailored feeding solutions that cater to the specific dietary requirements of rescued animals. This technology ensures that each pet receives the right amount of food, which is crucial for their health and well-being. By streamlining the feeding process, shelters can improve health outcomes and facilitate better care for the animals in their charge. When sourcing feeders, shelters should focus on affordability, ease of use, and adaptability to accommodate various pet types.

How Do Smart Home Integrators Incorporate RFID Pet Feeders?

Smart home integrators can incorporate RFID pet feeders into broader pet care solutions, enhancing convenience and monitoring capabilities for pet owners. These feeders can be connected to home automation systems, allowing owners to manage feeding schedules remotely and receive notifications about their pet’s eating habits. This integration not only simplifies pet care but also provides peace of mind for busy pet owners. Buyers in this space should ensure that the feeders are compatible with existing smart home technologies for optimal functionality.

3 Common User Pain Points for ‘rfid pet feeder’ & Their Solutions

Scenario 1: Navigating Multi-Pet Feeding Challenges

The Problem: B2B buyers operating pet care facilities or veterinary clinics often face the challenge of feeding multiple pets with varying dietary needs. Traditional feeders lack the ability to provide individualized meals, leading to potential overfeeding, underfeeding, or food theft among pets. This situation not only frustrates pet owners but can also compromise the health of the animals, causing stress for both staff and management.

The Solution: Implementing RFID pet feeders can effectively solve this issue. These feeders are equipped with RFID technology that recognizes individual pets through their collar tags, allowing each pet to access its designated meal. Buyers should look for feeders that support multiple profiles, enabling customization of meal portions and schedules for different pets. When sourcing these devices, prioritize models with comprehensive mobile applications that track feeding history, provide alerts, and allow for remote adjustments. This ensures that pet care facilities can maintain optimal feeding practices and enhance overall pet welfare.

Scenario 2: Managing Inventory and Food Freshness

The Problem: A significant concern for B2B buyers is maintaining food quality and managing inventory levels. In environments like pet boarding facilities or shelters, bulk purchases of pet food are common, but improper storage can lead to spoilage and waste. Additionally, feeding schedules may become erratic, affecting the freshness of the food served to pets.

Illustrative image related to rfid pet feeder

The Solution: RFID pet feeders can play a crucial role in managing food inventory and ensuring freshness. Buyers should consider feeders that feature vacuum-sealed food compartments and real-time monitoring capabilities. These systems can alert users when food levels are low or nearing expiration, allowing for timely reordering and reducing waste. Additionally, incorporating a tracking system for inventory management can help streamline purchasing decisions and optimize storage practices. When selecting an RFID feeder, ensure it has robust data analytics features that can provide insights into food consumption patterns, helping buyers adjust inventory levels proactively.

Scenario 3: Ensuring User-Friendly Operations for Staff

The Problem: In many pet care facilities, staff may struggle with the usability of feeding equipment, leading to inconsistencies in meal provision and potential errors in feeding schedules. Traditional feeders can be cumbersome to set up and may lack intuitive interfaces, leading to frustration among employees who are trying to provide the best care for the animals.

The Solution: To address this pain point, B2B buyers should invest in RFID pet feeders with user-friendly designs and clear, intuitive interfaces. Look for feeders that offer easy setup processes, such as simple app integration and straightforward programming for meal schedules. Additionally, consider devices that include training resources or customer support for staff to quickly adapt to the new technology. Prioritizing feeders with features like two-way communication systems can also enhance staff interactions with pets during feeding times, allowing for a more engaging experience. By selecting RFID feeders that emphasize ease of use, facilities can improve operational efficiency and staff satisfaction while ensuring consistent care for the animals.

Strategic Material Selection Guide for rfid pet feeder

What Are the Key Materials Used in RFID Pet Feeders?

When selecting materials for RFID pet feeders, several factors come into play, including durability, functionality, and cost-effectiveness. The choice of materials directly impacts the performance, longevity, and overall user satisfaction of the product. Here, we analyze four common materials used in RFID pet feeders: plastic, stainless steel, aluminum, and glass.

Illustrative image related to rfid pet feeder

How Does Plastic Perform in RFID Pet Feeders?

Plastic is one of the most widely used materials in RFID pet feeders due to its versatility and cost-effectiveness. Key properties include lightweight characteristics and resistance to corrosion and moisture, making it suitable for various environments.

Pros: Plastic is generally low-cost, easy to mold into complex shapes, and available in a variety of colors and finishes. It is also relatively durable against impacts and scratches.

Cons: However, plastic can be less durable over time compared to metals and may become brittle under extreme temperatures. Additionally, lower-quality plastics can leach harmful chemicals, which raises concerns about pet safety.

Impact on Application: Plastic is compatible with most pet foods, but it’s essential to ensure that the chosen plastic is food-grade and BPA-free to avoid health risks.

Illustrative image related to rfid pet feeder

Considerations for International Buyers: Compliance with food safety standards such as those set by the FDA or EU regulations is crucial. Buyers from regions like Africa and South America should also consider local regulations regarding plastic use and disposal.

What Are the Benefits of Using Stainless Steel in RFID Pet Feeders?

Stainless steel is another popular choice for RFID pet feeders, particularly for components that come into direct contact with food. Its key properties include excellent corrosion resistance and high-temperature tolerance.

Pros: Stainless steel is durable, easy to clean, and resistant to rust and staining. It also provides a modern aesthetic that appeals to many consumers.

Illustrative image related to rfid pet feeder

Cons: The main drawback is the higher cost compared to plastic. Additionally, stainless steel can be heavier, which may affect portability.

Impact on Application: Stainless steel is highly compatible with various pet foods and can withstand rigorous cleaning processes, making it ideal for hygiene-sensitive applications.

Considerations for International Buyers: Compliance with international standards such as ASTM for materials is essential. Buyers should also ensure that the stainless steel used is of food-grade quality, particularly in regions with strict health regulations.

How Does Aluminum Compare for RFID Pet Feeders?

Aluminum is often used in RFID pet feeders for its lightweight and strength properties. It is resistant to corrosion and can be anodized for additional protection.

Illustrative image related to rfid pet feeder

Pros: Aluminum is lightweight, making it easy to handle and transport. It also has good thermal conductivity, which can be beneficial for temperature-sensitive applications.

Cons: While aluminum is resistant to corrosion, it can be prone to scratching and denting. It is also generally more expensive than plastic.

Impact on Application: Aluminum is suitable for food contact but should be coated or treated to prevent reactions with acidic foods.

Considerations for International Buyers: Compliance with local and international food safety standards is necessary. Buyers should be aware of aluminum recycling regulations in their regions, particularly in Europe, where recycling is heavily promoted.

Illustrative image related to rfid pet feeder

Why Is Glass a Viable Option for RFID Pet Feeders?

Glass is less common but can be used in RFID pet feeders, particularly for food storage compartments. Its key properties include excellent chemical resistance and non-reactivity.

Pros: Glass is non-toxic, easy to clean, and does not retain odors or stains. It also provides a premium look and feel.

Cons: The primary disadvantage is its fragility; glass can break easily if dropped. Additionally, it is heavier than plastic or aluminum.

Impact on Application: Glass is compatible with all pet foods and can be used for both dry and wet food storage.

Considerations for International Buyers: Buyers should ensure that the glass used meets safety standards to prevent breakage and injury. Compliance with local regulations regarding glass recycling and disposal is also important.

Illustrative image related to rfid pet feeder

Summary Table of Material Selection for RFID Pet Feeders

| Material | Typical Use Case for RFID Pet Feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Body and food storage compartments | Low cost and lightweight | May leach chemicals over time | Low |

| Stainless Steel | Food bowls and internal components | Durable and easy to clean | Higher cost and heavier | High |

| Aluminum | Structural components and frames | Lightweight and corrosion-resistant | Prone to scratching | Medium |

| Glass | Food storage compartments | Non-toxic and easy to clean | Fragile and heavy | Medium |

This analysis provides international B2B buyers with actionable insights into material selection for RFID pet feeders, ensuring they make informed decisions that align with their market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rfid pet feeder

What Are the Main Stages in the Manufacturing Process of RFID Pet Feeders?

The manufacturing process for RFID pet feeders involves several critical stages, each designed to ensure the final product is functional, reliable, and meets the needs of pet owners. Here’s a breakdown of the primary stages involved:

Material Preparation

The first stage of manufacturing involves sourcing high-quality materials that meet safety and performance standards. Common materials used in RFID pet feeders include:

- Plastics: Often used for the body and internal mechanisms due to their durability and lightweight nature.

- Electronics: Components such as RFID chips, microcontrollers, and sensors are sourced from specialized electronics suppliers.

- Stainless Steel: For food bowls and other contact surfaces, stainless steel is favored for its hygienic properties and resistance to corrosion.

Once materials are sourced, they undergo initial quality checks to ensure compliance with international standards.

Forming Processes

After material preparation, the next step is forming. This includes shaping the plastics and metals into the desired components using techniques such as:

- Injection Molding: This technique is predominantly used for creating the plastic housing and other intricate parts. It allows for high precision and the production of complex shapes.

- Stamping and Cutting: For metal components, stamping and laser cutting are used to achieve precise shapes that are then finished to remove any sharp edges.

These methods ensure that each component fits together seamlessly, which is critical for the functionality of the feeder.

Assembly

The assembly stage involves bringing together the various components produced in the earlier stages. This typically includes:

- Electronics Integration: RFID systems, sensors, and the power supply are integrated into the feeder. This requires skilled labor to ensure correct wiring and connection.

- Mechanical Assembly: Parts such as the food reservoir, dispensing mechanism, and control interface are assembled. This often includes tests to ensure that moving parts function smoothly.

During assembly, manufacturers may employ automation, such as robotic arms, for repetitive tasks, which enhances efficiency and consistency.

Finishing

The final stage of manufacturing involves finishing processes that enhance the product’s aesthetics and performance. This may include:

- Surface Treatment: Techniques like polishing or coating are applied to improve durability and appearance.

- Final Quality Checks: Each feeder undergoes a series of inspections to ensure all components function as intended, including the RFID system, electronic displays, and feeding mechanisms.

This comprehensive approach to manufacturing helps ensure that the RFID pet feeders meet the high standards expected by consumers and retailers alike.

Illustrative image related to rfid pet feeder

How Is Quality Assurance Implemented in RFID Pet Feeder Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for RFID pet feeders. It ensures that products are safe, reliable, and meet customer expectations. Here are the essential components of QA in this context:

What International Standards Guide Quality Assurance?

Manufacturers of RFID pet feeders often adhere to various international standards to ensure product quality and safety. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization seeking to improve product quality and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

- RoHS Compliance: This ensures that electronic products do not contain hazardous substances above specified levels.

These standards not only enhance product credibility but also facilitate market access across different regions.

Illustrative image related to rfid pet feeder

What Are the Key Quality Control Checkpoints?

Quality control (QC) in RFID pet feeder manufacturing typically involves several checkpoints throughout the production process:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor the quality of the production processes and components. This helps catch defects early.

- Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing to ensure it meets all operational specifications and safety standards.

These checkpoints are essential for minimizing defects and ensuring that only high-quality products reach the market.

What Common Testing Methods Are Used for RFID Pet Feeders?

To validate the performance and safety of RFID pet feeders, manufacturers typically employ a variety of testing methods, including:

Illustrative image related to rfid pet feeder

- Functional Testing: Ensures that all features, including RFID recognition and feeding mechanisms, operate as intended.

- Durability Testing: Assesses the product’s resistance to wear and tear, simulating long-term use.

- Safety Testing: Involves evaluating electrical components for safety, ensuring they do not pose a risk of shock or fire.

These tests are crucial for maintaining product integrity and consumer trust.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies to consider:

Conducting Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This can involve:

- On-site Visits: Inspecting the manufacturing facility can help assess equipment, cleanliness, and adherence to quality standards.

- Reviewing Documentation: Requesting quality control manuals, inspection reports, and compliance certificates can provide further assurance of their practices.

Requesting Quality Reports

Suppliers should be willing to provide quality assurance documentation, including:

- ISO Certifications: Proof of compliance with international quality standards.

- Testing Reports: Documentation of testing procedures and results for the specific products being purchased.

This transparency can help build confidence in the supplier’s capabilities.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can offer an independent assessment of the supplier’s quality control processes. These services can perform:

- Random Sampling Inspections: Evaluating a portion of the shipment to ensure quality standards are met before delivery.

- Compliance Checks: Ensuring that the products meet required international and regional standards.

This added layer of scrutiny can be invaluable for B2B buyers looking to mitigate risk.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions must navigate specific quality control nuances when dealing with international suppliers. This includes understanding:

- Regional Compliance Requirements: Different countries may have unique safety and quality standards that need to be adhered to, which can affect product design and labeling.

- Cultural Differences in Quality Expectations: Expectations regarding quality and service levels can vary widely by region, necessitating clear communication to align on standards.

- Logistical Challenges: International shipping can introduce risks related to product handling and storage, which should be considered during the quality assurance process.

By being aware of these factors, international buyers can make more informed decisions and establish better partnerships with suppliers.

In conclusion, understanding the manufacturing processes and quality assurance practices for RFID pet feeders is essential for B2B buyers aiming to source reliable products. By focusing on these aspects, buyers can ensure they are investing in high-quality feeders that meet the needs of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rfid pet feeder’

In the rapidly evolving pet technology market, RFID pet feeders offer a sophisticated solution for managing pet diets. This practical sourcing guide aims to assist international B2B buyers in navigating the procurement process for RFID pet feeders, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for sourcing the right RFID pet feeder. Consider factors such as meal scheduling capabilities, food storage capacity, and connectivity options (e.g., Wi-Fi, app integration). This ensures that the product not only meets the needs of your business but also caters to the preferences of end-users.

- Meal Scheduling: Look for feeders that can schedule multiple meals per day, accommodating various pet diets.

- Capacity: Assess whether a 3L or 5L storage capacity aligns with expected usage.

Step 2: Research Market Trends and Competitors

Understanding current market trends and competitor offerings can provide valuable insights. Research what features are in demand, such as smart technology integration or eco-friendly materials. This knowledge will help you position your product effectively.

- Feature Analysis: Identify trending features like real-time feeding logs and pest-proof designs.

- Competitive Landscape: Analyze competitors in your target regions to understand their pricing and product positioning.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request detailed company profiles, product samples, and references from other businesses that have sourced similar products. This due diligence will help mitigate risks associated with quality and reliability.

Illustrative image related to rfid pet feeder

- Supplier Reputation: Look for suppliers with proven track records in the pet technology market.

- Quality Assurance: Inquire about certifications and quality control processes.

Step 4: Assess Compliance and Certification Requirements

Different regions have varying compliance standards for electronic devices. Ensure that the RFID pet feeders you consider meet local regulations and certification requirements. This step is crucial to avoid legal issues and ensure product safety.

- Certification Verification: Check for certifications such as CE, FCC, or others relevant to your region.

- Safety Standards: Ensure the products comply with pet safety standards to protect both pets and users.

Step 5: Negotiate Terms and Conditions

Once you have selected potential suppliers, negotiate favorable terms and conditions. Discuss pricing, minimum order quantities, delivery timelines, and after-sales support. Clear agreements will help establish a solid working relationship.

- Pricing Strategy: Consider bulk purchase discounts or long-term partnership agreements.

- Support Services: Ensure clarity on warranty and support services to enhance customer satisfaction.

Step 6: Plan for Logistics and Distribution

Effective logistics and distribution planning are crucial for timely product delivery. Assess the logistics capabilities of your suppliers, including shipping times and costs. This is particularly important for businesses operating in regions with less developed logistics infrastructure.

- Shipping Options: Evaluate both air and sea freight options to optimize costs and delivery times.

- Inventory Management: Implement a robust inventory management system to keep track of stock levels and reorders.

Step 7: Conduct Market Testing and Feedback Collection

Before a full-scale launch, conduct market testing with select customers. Gather feedback on the product’s performance and user experience. This step is vital for refining your offering and ensuring it meets market expectations.

- Pilot Programs: Initiate pilot programs to assess product functionality and customer satisfaction.

- Feedback Mechanisms: Set up systems for collecting user feedback post-launch to inform future product iterations.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing RFID pet feeders, ensuring they make well-informed decisions that meet their operational and market needs.

Comprehensive Cost and Pricing Analysis for rfid pet feeder Sourcing

What Are the Key Cost Components for Sourcing RFID Pet Feeders?

When sourcing RFID pet feeders, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials can significantly impact costs. High-quality plastics and stainless steel are common in pet feeders, providing durability and ease of cleaning. Innovative features like vacuum-sealing and pest-proof designs may require specialized materials, leading to increased costs.

-

Labor: Labor costs vary widely depending on the manufacturing location. Countries with lower labor costs might provide a short-term savings opportunity; however, this can sometimes compromise quality. Skilled labor is essential for ensuring precise assembly, particularly for complex RFID technology.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor costs. Factories that invest in automated processes may have higher upfront costs but can lower per-unit costs over time due to increased efficiency.

-

Tooling: Initial tooling costs can be significant, especially if custom molds are required for unique designs. Buyers should inquire about amortization plans for tooling costs, particularly for larger orders.

-

Quality Control: Implementing stringent quality control measures is essential, especially for tech-driven products like RFID feeders. Costs associated with QC processes can add to the overall price, but they are vital for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping costs are influenced by the weight and dimensions of the feeders, as well as the distance to the destination. Additionally, customs duties and taxes can vary significantly by region, impacting overall pricing.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market positioning and the competitiveness of the product.

How Do Price Influencers Affect the Cost of RFID Pet Feeders?

Several factors influence the pricing of RFID pet feeders, making it essential for buyers to understand these dynamics.

Illustrative image related to rfid pet feeder

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly affect pricing. Suppliers often offer discounts for larger orders, which can significantly reduce the per-unit cost.

-

Specifications and Customization: Custom features or modifications can lead to increased costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials and Quality Certifications: Products made with higher-quality materials or those that meet specific certifications (e.g., safety standards) may come at a premium. Buyers should ensure that the quality justifies the price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for calculating total landed costs. Terms like FOB (Free On Board) and CIF (Cost, Insurance, Freight) can affect pricing strategies and overall cost management.

What Are Effective Buyer Tips for Negotiating RFID Pet Feeder Prices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings.

-

Negotiate Volume Discounts: Leverage larger orders to negotiate better prices. Suppliers are often willing to provide discounts for bulk purchases, which can enhance profitability.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also long-term operational costs, including maintenance, warranties, and potential returns. TCO analysis can provide a clearer picture of overall value.

-

Understand Pricing Nuances: Be aware of regional pricing differences influenced by local market conditions, currency fluctuations, and economic factors. This knowledge can help in negotiating more effectively.

-

Foster Relationships with Suppliers: Building strong relationships can lead to better terms and conditions. Suppliers may be more willing to offer favorable pricing to repeat customers.

-

Stay Informed on Market Trends: Keeping abreast of trends in the RFID pet feeder market can provide leverage during negotiations. Knowledge of competitor pricing and emerging technologies can aid in securing better deals.

Disclaimer

Prices and cost structures mentioned in this analysis are indicative and may vary based on specific supplier agreements, market conditions, and product specifications. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure a competitive pricing strategy.

Alternatives Analysis: Comparing rfid pet feeder With Other Solutions

When considering the adoption of an RFID pet feeder, it is essential to evaluate alternative solutions that can fulfill similar needs for pet feeding management. Understanding the differences in performance, cost, ease of implementation, and maintenance will help B2B buyers make informed decisions tailored to their operational requirements.

| Comparison Aspect | RFID Pet Feeder | Automated Gravity Feeder | Manual Pet Feeder |

|---|---|---|---|

| Performance | High precision; personalized feeding via RFID tags | Consistent feeding, but lacks customization | Manual feeding; no automation |

| Cost | High initial investment (~$440) | Moderate cost (~$100) | Low cost (~$30) |

| Ease of Implementation | Requires Wi-Fi setup and app configuration | Simple setup, no tech required | Very easy to use; no setup needed |

| Maintenance | Regular software updates; cleaning required | Minimal maintenance; easy to clean | Low maintenance; occasional cleaning |

| Best Use Case | Multi-pet households needing tailored feeding | Budget-conscious pet owners with single pets | Casual pet owners without tech needs |

What Are the Pros and Cons of Automated Gravity Feeders Compared to RFID Pet Feeders?

Automated gravity feeders are a cost-effective alternative for pet owners who prefer a simple solution. These feeders utilize gravity to dispense food consistently without requiring electricity or Wi-Fi connectivity. They are easy to set up and maintain, making them ideal for single-pet households. However, they lack the personalized feeding capabilities of RFID pet feeders, which can lead to overfeeding or underfeeding if not monitored closely.

How Do Manual Pet Feeders Stack Up Against RFID Pet Feeders?

Manual pet feeders represent the most basic feeding solution. They are affordable and require no technology, making them suitable for pet owners who prefer a hands-on approach. The simplicity of these feeders allows for easy cleaning and minimal maintenance. However, manual feeders do not offer any form of portion control or scheduling, leading to potential issues with regular feeding routines. Additionally, they do not cater to multi-pet households, where feeding management can become more complex.

How Can B2B Buyers Choose the Right Pet Feeding Solution for Their Needs?

Selecting the right pet feeding solution hinges on understanding the unique needs of your operation. For businesses that manage multiple pets or require precise feeding schedules, an RFID pet feeder offers advanced features that ensure individualized care. On the other hand, budget-conscious buyers or those managing fewer pets may find automated gravity feeders or manual feeders sufficient for their needs. Ultimately, evaluating the balance between cost, functionality, and ease of use will guide B2B buyers to the most appropriate solution for their specific circumstances.

Essential Technical Properties and Trade Terminology for rfid pet feeder

What Are the Essential Technical Properties of RFID Pet Feeders?

When considering RFID pet feeders for B2B procurement, understanding the technical specifications is vital for ensuring product quality and performance. Here are key properties to focus on:

-

Material Grade

RFID pet feeders are typically constructed from durable, food-safe materials such as BPA-free plastic or stainless steel. The material grade is crucial as it affects the longevity of the feeder, its resistance to wear and tear, and its safety for pet use. High-quality materials minimize the risk of contamination and ensure compliance with health regulations, which is particularly important in international markets. -

Capacity

The feeder’s capacity, usually measured in liters (e.g., 3L or 5L), indicates how much food it can hold. This specification is essential for B2B buyers who need to determine the suitability of the feeder for different pet sizes and feeding frequencies. A larger capacity can benefit businesses that cater to multiple pets or require less frequent refilling, ultimately saving time and labor. -

Power Source and Battery Life

RFID pet feeders may operate on AC power, rechargeable batteries, or standard batteries. Battery life is a critical factor, especially in areas with unstable electricity supply. A unit that can last several days or weeks on battery power ensures consistent operation, reducing the need for frequent maintenance and minimizing disruptions for pet owners. -

Connectivity Features

Many modern RFID feeders are equipped with Wi-Fi connectivity that allows for app integration, enabling remote management of feeding schedules and tracking pet eating habits. Understanding the connectivity options is essential for businesses looking to offer tech-savvy products that appeal to modern pet owners. It also enhances customer engagement through features like feeding logs and notifications. -

Sealing and Freshness Mechanism

The design often includes features such as quadruple sealing or vacuum-sealing to maintain food freshness. This property is critical for pet health and food safety. Buyers should consider how these mechanisms work, as they affect product reliability and customer satisfaction. A well-sealed feeder can help reduce food waste and ensure that pets receive fresh meals.

Which Trade Terminology Is Commonly Used in the RFID Pet Feeder Industry?

Familiarity with industry jargon can streamline communication and negotiations. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers to ensure they are sourcing quality products that meet their specifications, especially when dealing with custom RFID feeders. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses plan their inventory and budget effectively. It is particularly relevant for international buyers who may need to balance import costs with stock requirements. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to invite them to bid on a project. It outlines the specifications, quantities, and terms. For B2B buyers, issuing an RFQ is a vital step to gather competitive pricing and ensure that suppliers understand their needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and logistics. Familiarity with these terms helps B2B buyers understand their obligations and risks, facilitating smoother international trade. -

SKU (Stock Keeping Unit)

An SKU is a unique identifier for each distinct product and service that can be purchased. It helps businesses track inventory and sales. Understanding SKUs is essential for B2B operations, as it enhances inventory management and order processing efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing RFID pet feeders, ensuring they select products that meet their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the rfid pet feeder Sector

What Are the Key Market Drivers and Trends in the RFID Pet Feeder Sector?

The RFID pet feeder market is experiencing robust growth driven by several global factors. Increased pet ownership, particularly in emerging markets such as Africa and South America, is leading to a heightened demand for innovative pet care solutions. Urbanization and busy lifestyles are making automated feeding solutions more appealing, as they provide convenience and ensure pets receive proper nutrition even when owners are unavailable. Additionally, advancements in technology, including the integration of IoT and app connectivity, are transforming how pet owners manage feeding schedules and monitor their pets’ eating habits remotely.

Illustrative image related to rfid pet feeder

Emerging trends in the B2B sourcing landscape include a shift towards smart devices that offer real-time data analytics and remote access features. International buyers, particularly from regions like Europe and the Middle East, are increasingly interested in products that provide enhanced functionality, such as customizable feeding schedules, pet recognition through RFID technology, and integrated health monitoring systems. Furthermore, partnerships with tech companies to enhance product features, such as AI-driven feeding recommendations, are becoming common as brands aim to differentiate themselves in a competitive marketplace.

How Are Sustainability and Ethical Sourcing Influencing the RFID Pet Feeder Market?

Sustainability and ethical sourcing are now pivotal considerations for B2B buyers in the RFID pet feeder sector. The environmental impact of pet products is gaining attention, prompting manufacturers to adopt greener practices. Sustainable materials, such as biodegradable plastics and recycled components, are becoming integral to product design. International buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their carbon footprint, whether through sustainable manufacturing processes or eco-friendly packaging.

Moreover, ethical supply chains are crucial for building brand trust and customer loyalty. B2B buyers are looking for partners who can provide transparency in their sourcing practices, ensuring fair labor conditions and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and Fair Trade labels can enhance a product’s appeal in the marketplace. As consumers become more eco-conscious, the demand for RFID pet feeders that align with these values will likely continue to rise, influencing sourcing decisions.

What Is the Evolution of RFID Technology in Pet Feeding Solutions?

The evolution of RFID technology in pet feeders has significantly shaped the market landscape. Initially, RFID was primarily used for inventory management and tracking. However, its application in pet care began to emerge in the early 2000s as pet ownership surged and the demand for smarter pet care solutions grew. The integration of RFID technology allowed for personalized feeding experiences, enabling feeders to recognize individual pets and dispense the appropriate portion sizes.

Illustrative image related to rfid pet feeder

As technology advanced, RFID pet feeders evolved into sophisticated devices equipped with connectivity features, allowing owners to monitor and manage their pets’ feeding habits remotely. The introduction of mobile applications has further enhanced user experience, enabling real-time updates and alerts. This transformation reflects a broader trend towards smart living, where technology seamlessly integrates into daily routines, providing convenience and peace of mind for pet owners. As the market continues to mature, further innovations are expected, focusing on health monitoring and enhanced user engagement.

Frequently Asked Questions (FAQs) for B2B Buyers of rfid pet feeder

-

How do I solve supply chain issues when sourcing RFID pet feeders?

To address supply chain challenges, it’s essential to build strong relationships with suppliers and understand their logistics capabilities. Conduct thorough market research to identify reliable manufacturers with a proven track record in your target regions, such as Africa and South America. Additionally, consider diversifying your supplier base to mitigate risks. Implementing a Just-In-Time (JIT) inventory system can also help manage stock levels efficiently while reducing lead times. -

What is the best RFID pet feeder for multi-pet households?

For multi-pet households, look for RFID pet feeders that can accommodate multiple collar tags and schedule personalized meal times for each pet. A feeder that supports at least 10 meals per day and has a large capacity, such as 5L, would be ideal. Features like app connectivity and feeding logs can help owners monitor their pets’ eating habits, ensuring each pet receives the correct portion without overlap. -

How can I ensure the quality of RFID pet feeders from international suppliers?

To guarantee product quality, start by vetting suppliers through certifications and industry standards. Request samples to conduct quality checks and inspect for durability and functionality. Additionally, consider suppliers that offer a warranty or return policy, which indicates confidence in their products. It may also be beneficial to visit manufacturing facilities or request third-party audits to assess quality control processes. -

What customization options are available for RFID pet feeders?

Customization options can vary by supplier, but many manufacturers offer choices for color, branding, and functionality. Some may allow you to adjust the feeder’s capacity or add features such as enhanced connectivity or additional feeding schedules. When negotiating with suppliers, clearly communicate your specifications and inquire about the minimum order quantity (MOQ) for customized products to ensure they can meet your needs. -

What are the typical payment terms for purchasing RFID pet feeders internationally?

Payment terms can differ widely based on the supplier and the buyer’s relationship. Common practices include upfront payments, partial payments upon order confirmation, and balance payments before shipment. It’s advisable to negotiate favorable terms that align with your cash flow needs. Using secure payment methods, such as letters of credit or escrow services, can also protect both parties during the transaction. -

How do I handle logistics and shipping when importing RFID pet feeders?

Effective logistics management starts with selecting a reliable freight forwarder experienced in international shipping. Discuss shipping options, including air and sea freight, to determine the most cost-effective and timely method. Ensure that you understand customs regulations in your target market to avoid delays. Additionally, consider using Incoterms (International Commercial Terms) to clarify responsibilities for shipping costs and risk during transit. -

What are the most important features to look for in an RFID pet feeder?

When selecting an RFID pet feeder, prioritize features such as programmable meal schedules, app connectivity for monitoring, and RFID collar recognition to prevent food theft among pets. Durability, ease of cleaning, and pest-proof designs are also essential for long-term use. Finally, look for feeders that offer a warranty or customer support to ensure you have assistance if any issues arise. -

How can I find reputable suppliers of RFID pet feeders in Africa and South America?

To identify reputable suppliers in Africa and South America, utilize platforms like Alibaba or Global Sources, which feature verified manufacturers. Attend regional trade shows focused on pet products to network and gather firsthand information. Additionally, leveraging local business directories or chambers of commerce can help you find trusted suppliers. Always conduct background checks and request references to ensure reliability before placing orders.

Top 5 Rfid Pet Feeder Manufacturers & Suppliers List

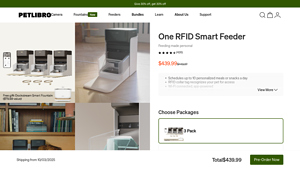

1. Petlibro – One RFID Smart Feeder

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Product Name: Petlibro One RFID Smart Feeder

Price: $439.99 (originally $449.97)

Features:

– Schedules up to 6 meals or snacks a day

– Quadruple sealed for freshness

– Dual power supply

– Available capacities: 3L or 5L

– Battery life lasts up to 180 days (batteries not included)

– Rotor design locks in freshness

– Pestproof and spillproof

– Wi-Fi connected, app-powered

– Keeps you informed with f…

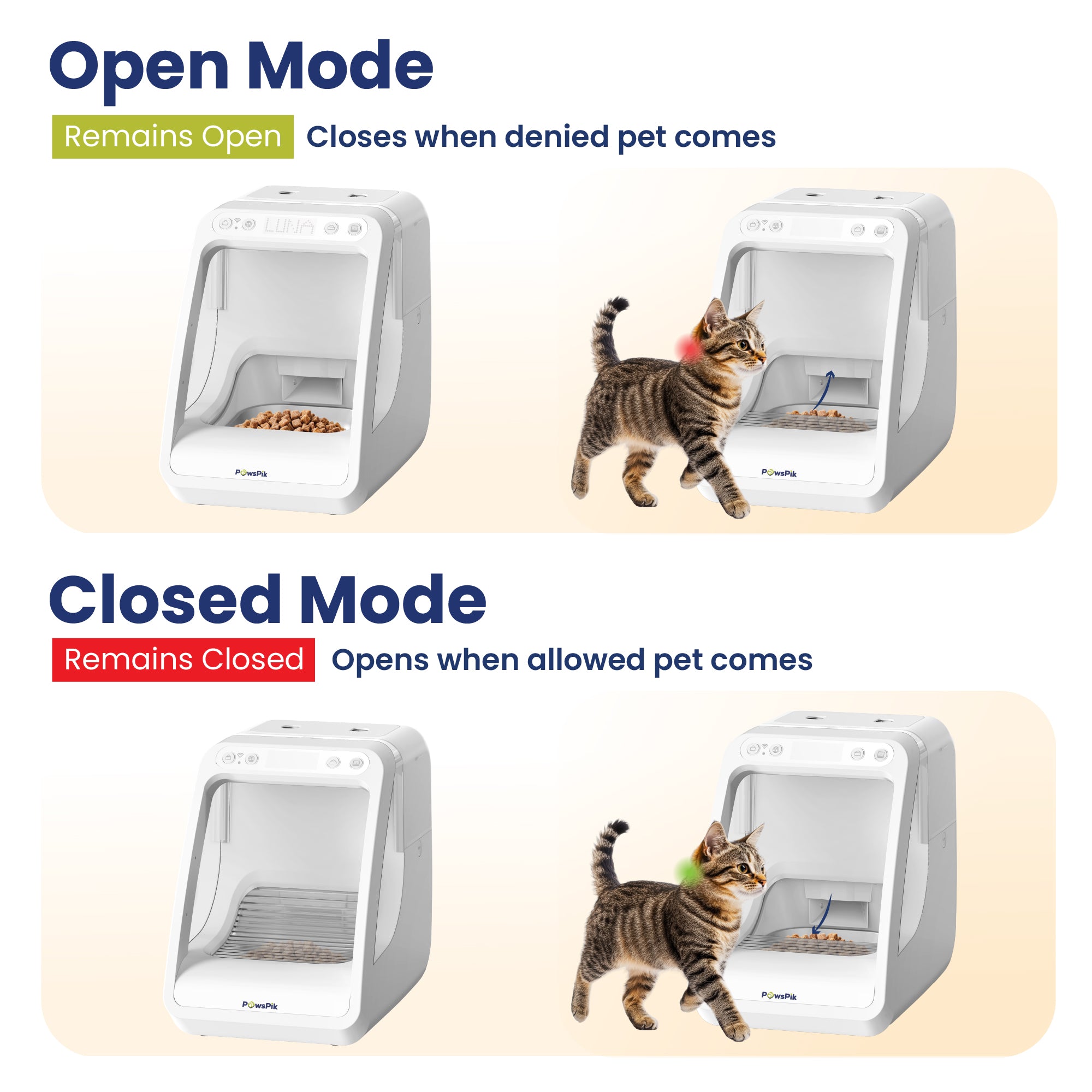

2. PawsPik® – Automatic Microchip RFID Pet Feeder

Domain: pawspik.com

Registered: 2023 (2 years)

Introduction: PawsPik® Automatic Microchip RFID Pet Feeder

– Compatible with ISO Microchips

– Compatible with PawsPik Microchip RFID Tags Only

– Pairs with One Pet Per Household

– Customized Door Access Control

– Perfect for Multi-Pet Family

– Perfect for Therapeutic Feeding

– Remote Monitoring/Control

– Scheduled Feedings

– Customizable Portions (1/8 cup to 1/2 cup per meal)

– Track Feeding Data and Share with…

3. Sure Pet Care – SureFeed Microchip Pet Feeder

Domain: surepetcare.com

Registered: 2016 (9 years)

Introduction: Product Name: SureFeed Microchip Pet Feeder

Price: $167.00 (originally $199)

Features:

– Designed for multi-pet homes to prevent food stealing

– Ensures prescription food is consumed by the right pet

– Suitable for pets on weight management diets

– Compatible with all identification microchips worldwide & SureFlap RFID collar tags

– Works with SureFlap RFID collar tag (one tag included)

– Suitable…

4. Monoprice – HDMI Cable 44326

Domain: monoprice.com

Registered: 2001 (24 years)

Introduction: {“product_name”:”Monoprice 44326″,”description”:”The Monoprice 44326 is a high-quality HDMI cable designed for reliable performance and durability. It supports 4K resolution and is compatible with various devices, making it ideal for home theater setups and gaming. The cable features gold-plated connectors for optimal signal transfer and is available in multiple lengths to suit different needs.”,”…

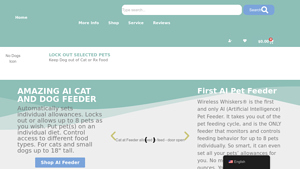

5. Wireless Whiskers – AI & RFID Pet Feeder

Domain: wirelesswhiskers.com

Registered: 2008 (17 years)

Introduction: Wireless Whiskers is the first AI and RFID pet feeder designed for up to 8 pets. It features over 30 settings and capabilities, allowing for individual diet management, including weight loss diets. The feeder automatically sets individual allowances, prevents overeating, and alerts owners if any pet is underfeeding. It controls access to different food types, making it suitable for multi-pet house…

Strategic Sourcing Conclusion and Outlook for rfid pet feeder

In the rapidly evolving market for RFID pet feeders, strategic sourcing emerges as a crucial element for international B2B buyers. The integration of advanced features such as customizable meal schedules, RFID collar recognition, and app connectivity not only enhances the pet feeding experience but also offers significant operational efficiencies. Buyers should prioritize suppliers that provide robust product quality, reliable after-sales support, and compliance with international standards, ensuring that they can meet the diverse needs of customers across regions like Africa, South America, the Middle East, and Europe.

Furthermore, as pet ownership continues to rise globally, investing in RFID technology can differentiate your offerings and appeal to tech-savvy consumers. The ability to monitor feeding habits and control portions through smart technology not only addresses convenience but also promotes pet health, aligning with the increasing consumer demand for premium pet care solutions.

Looking ahead, businesses are encouraged to explore partnerships with innovative suppliers in the RFID pet feeder space. By leveraging strategic sourcing, companies can enhance their competitive edge and better serve their markets. Embrace this opportunity to elevate your product portfolio and meet the growing expectations of pet owners worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.