Introduction: Navigating the Global Market for how do automatic litter boxes work

In an increasingly globalized market, understanding how automatic litter boxes work is essential for B2B buyers looking to enhance their pet care offerings. The challenge lies in sourcing reliable and effective products that cater to diverse consumer needs while ensuring operational efficiency. This guide delves into the intricacies of automatic litter boxes, exploring various types, their applications, and the technology behind their functionality. By examining key factors such as supplier vetting, cost considerations, and maintenance requirements, we equip international buyers from regions like Africa, South America, the Middle East, and Europe—particularly in markets like Brazil and Nigeria—with the knowledge necessary to make informed purchasing decisions.

As the demand for innovative pet care solutions continues to rise, understanding the advantages and limitations of automatic litter boxes becomes crucial. This guide not only clarifies the mechanics of these products, including how they simplify waste management and enhance user experience, but also addresses potential challenges, such as compatibility with different types of litter and user preferences. By leveraging this comprehensive insight, B2B buyers can confidently navigate the complexities of sourcing automatic litter boxes, ensuring they meet customer expectations while maximizing profitability in a competitive landscape.

Table Of Contents

- Top 4 How Do Automatic Litter Boxes Work Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do automatic litter boxes work

- Understanding how do automatic litter boxes work Types and Variations

- Key Industrial Applications of how do automatic litter boxes work

- 3 Common User Pain Points for ‘how do automatic litter boxes work’ & Their Solutions

- Strategic Material Selection Guide for how do automatic litter boxes work

- In-depth Look: Manufacturing Processes and Quality Assurance for how do automatic litter boxes work

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do automatic litter boxes work’

- Comprehensive Cost and Pricing Analysis for how do automatic litter boxes work Sourcing

- Alternatives Analysis: Comparing how do automatic litter boxes work With Other Solutions

- Essential Technical Properties and Trade Terminology for how do automatic litter boxes work

- Navigating Market Dynamics and Sourcing Trends in the how do automatic litter boxes work Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do automatic litter boxes work

- Strategic Sourcing Conclusion and Outlook for how do automatic litter boxes work

- Important Disclaimer & Terms of Use

Understanding how do automatic litter boxes work Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sifting Litter Boxes | Utilizes a rotating mechanism to sift clumps of waste. | Pet supply retailers, veterinary clinics | Pros: Reduces manual labor, easy to maintain. Cons: May require specific litter types. |

| Self-Cleaning Boxes | Automatically cleans litter after each use with sensors. | E-commerce platforms, pet grooming services | Pros: Enhances hygiene, minimizes odor. Cons: Can be noisy, may scare pets. |

| Health Monitoring Boxes | Incorporates sensors to track cat health metrics. | Veterinary practices, pet care providers | Pros: Offers health insights, alerts for issues. Cons: Higher cost, potential tech failures. |

| Disposable Litter Boxes | Designed for single-use or short-term use with minimal cleanup. | Temporary housing, shelters | Pros: Convenient, no maintenance. Cons: Not eco-friendly, recurring costs. |

| Multi-Cat Systems | Larger units designed for multiple cats with separate areas. | Pet boarding facilities, multi-pet households | Pros: Accommodates several cats, reduces conflict. Cons: Takes up more space, higher initial investment. |

What Are the Characteristics of Sifting Litter Boxes?

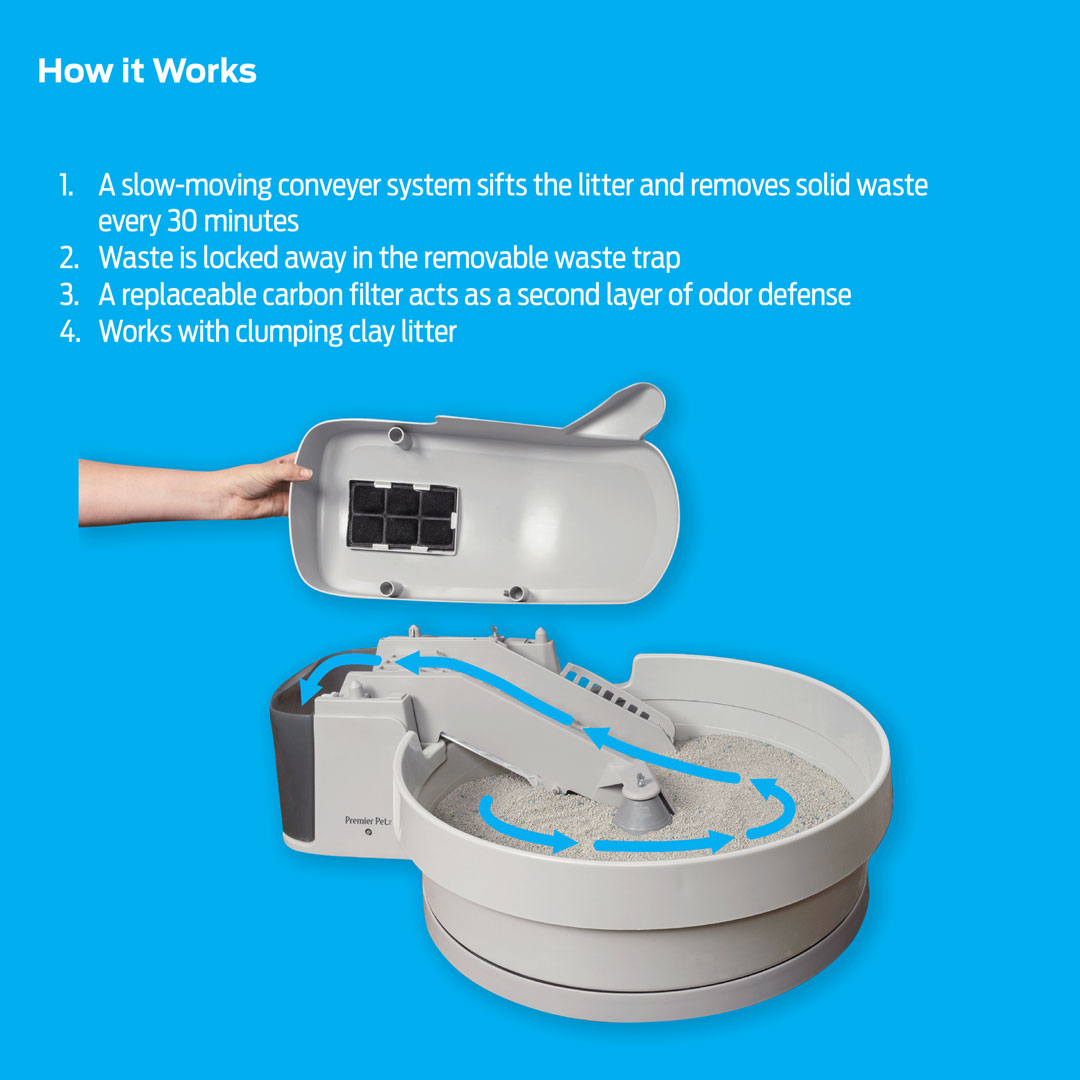

Sifting litter boxes are designed with a rotating mechanism that sifts through the litter, separating clumps of waste from clean litter. This type is popular among pet supply retailers due to its ease of maintenance and reduced need for manual scooping. B2B buyers should consider the compatibility of the litter type, as some sifting boxes only work with specific clumping litters. Additionally, these units may require a more substantial upfront investment but can lead to long-term savings in labor costs.

How Do Self-Cleaning Boxes Enhance Hygiene?

Self-cleaning litter boxes utilize sensors to detect when a cat has used the box, automatically cleaning the litter afterward. This feature is particularly appealing to e-commerce platforms and grooming services, as it promotes a cleaner environment and minimizes odors. However, B2B buyers should be aware of potential noise issues that could deter cats from using the box, especially in sensitive environments. The investment in these boxes can be justified by the significant reduction in time spent on litter maintenance.

What Are the Benefits of Health Monitoring Boxes?

Health monitoring litter boxes are equipped with advanced sensors that track various health metrics related to a cat’s waste. This type of product is particularly valuable for veterinary practices and pet care providers, offering insights that can lead to early detection of health issues. While the initial purchase price may be higher, the potential for improved cat health and reduced veterinary costs can make this a worthwhile investment for B2B buyers. However, the technology may face reliability issues that should be considered.

Why Choose Disposable Litter Boxes for Temporary Use?

Disposable litter boxes are ideal for temporary situations, such as in shelters or during travel. They are designed for single or short-term use, offering a convenient solution with no maintenance required. However, B2B buyers should consider the environmental impact and recurring costs associated with these products. While they provide immediate convenience, the long-term costs can add up, making them less sustainable for regular use.

How Do Multi-Cat Systems Address Space and Conflict?

Multi-cat systems are designed to accommodate several cats, featuring larger units with separate areas to minimize conflict. These systems are especially suitable for pet boarding facilities and multi-pet households. B2B buyers should evaluate the space requirements and initial investment needed for these larger units. Although they can effectively reduce territorial disputes among cats, the size and cost may pose challenges for smaller operations.

Key Industrial Applications of how do automatic litter boxes work

| Industry/Sector | Specific Application of how do automatic litter boxes work | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Automated waste management in cat boarding facilities | Reduces labor costs and improves hygiene, enhancing client satisfaction | Compatibility with various litter types and ease of maintenance |

| Pet Supply Retail | Retail display for self-cleaning litter boxes | Attracts tech-savvy customers and increases sales of premium products | Product reliability and customer support from manufacturers |

| Animal Shelters | Efficient litter management for multiple cats | Streamlines operations, allowing staff to focus on animal care | Durability and ease of use for different cat sizes and behaviors |

| Pet Grooming Services | Integration of self-cleaning boxes in grooming salons | Enhances cleanliness and client experience, increasing repeat business | Space requirements and noise levels to avoid scaring pets |

| Research Institutions | Use in behavioral studies involving feline subjects | Provides consistent and clean environments for accurate data collection | Precision in monitoring and data reporting capabilities |

How Can Automatic Litter Boxes Enhance Veterinary Clinics’ Operations?

In veterinary clinics, particularly those with boarding facilities for cats, automatic litter boxes streamline waste management. By reducing the need for manual scooping, clinics can lower labor costs and maintain a higher standard of hygiene. This not only improves the environment for the animals but also enhances client satisfaction, making the facility more appealing to pet owners. When sourcing, clinics should consider compatibility with various litter types and ease of maintenance to ensure seamless integration into their existing workflows.

Illustrative image related to how do automatic litter boxes work

Why Are Automatic Litter Boxes Beneficial for Pet Supply Retailers?

For pet supply retailers, showcasing automatic litter boxes can attract tech-savvy customers looking for innovative solutions. These products can significantly increase sales, especially in premium segments. Retailers should prioritize sourcing from manufacturers known for product reliability and robust customer support, as this can enhance the shopping experience and foster customer loyalty. Displaying these products effectively can also position the retailer as a leader in pet care technology.

How Do Automatic Litter Boxes Improve Efficiency in Animal Shelters?

Animal shelters, often housing multiple cats, benefit greatly from automatic litter boxes. These systems help streamline operations, allowing staff to focus more on animal care rather than waste management. By maintaining a cleaner environment, shelters can improve the overall health and well-being of the animals, increasing the likelihood of adoptions. When sourcing, shelters should look for durable models that cater to various cat sizes and behaviors, ensuring they meet the needs of all residents.

In What Ways Can Grooming Services Leverage Automatic Litter Boxes?

Pet grooming services can integrate automatic litter boxes to enhance cleanliness and improve the overall client experience. A clean environment is essential for attracting repeat business, as pet owners seek facilities that prioritize hygiene. Groomers should consider the space requirements of these boxes and their noise levels, as excessive noise could scare pets. Effective sourcing strategies include evaluating models that minimize disturbances while providing efficient waste management.

How Can Research Institutions Utilize Automatic Litter Boxes for Behavioral Studies?

Research institutions conducting studies on feline behavior can utilize automatic litter boxes to provide consistent and clean environments for their subjects. This technology allows for accurate data collection on litter box habits, which is crucial for understanding various behavioral patterns. When sourcing these products, institutions should focus on models that offer precise monitoring and data reporting capabilities, ensuring that they can gather comprehensive insights while maintaining animal welfare standards.

3 Common User Pain Points for ‘how do automatic litter boxes work’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with Litter Types

The Problem: B2B buyers often encounter difficulties when it comes to sourcing automatic litter boxes that accommodate various litter types. Many self-cleaning litter boxes require specific clumping litters, which can limit options for pet owners who have established preferences or those operating in markets where particular litter types are not readily available. This incompatibility can lead to frustration, as it may cause pets to refuse using the box, ultimately resulting in lost sales and customer dissatisfaction.

Illustrative image related to how do automatic litter boxes work

The Solution: To address this compatibility challenge, B2B buyers should prioritize sourcing automatic litter boxes that boast versatility in litter use. When evaluating products, consider those that explicitly state compatibility with a broad range of clumping litters, including popular options that might be locally sourced in target markets like Brazil or Nigeria. Additionally, work with suppliers who can provide insights into local litter preferences and trends. This not only ensures customer satisfaction but also enhances the likelihood of repeat business as pet owners find the right products that suit their pets’ needs.

Scenario 2: Addressing Concerns Over Pet Safety and Comfort

The Problem: Another significant concern for B2B buyers is the safety and comfort of pets using automatic litter boxes. Buyers may face backlash from customers if their pets experience anxiety or discomfort due to the mechanisms of the boxes, such as noise during the cleaning cycle or difficulty accessing the litter box. This is particularly pertinent in markets where consumers are increasingly aware of pet welfare, leading to potential reputational damage for brands that overlook these aspects.

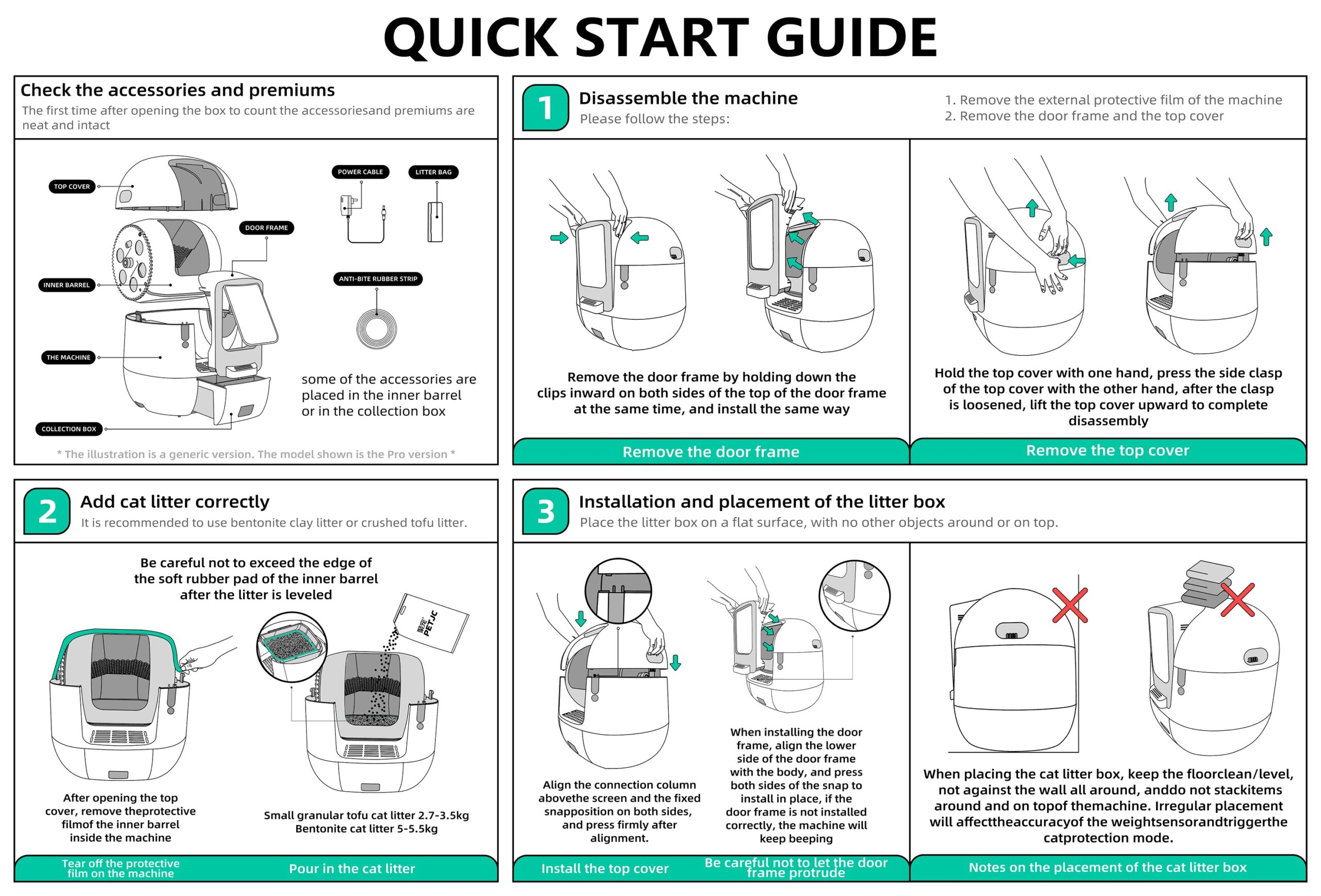

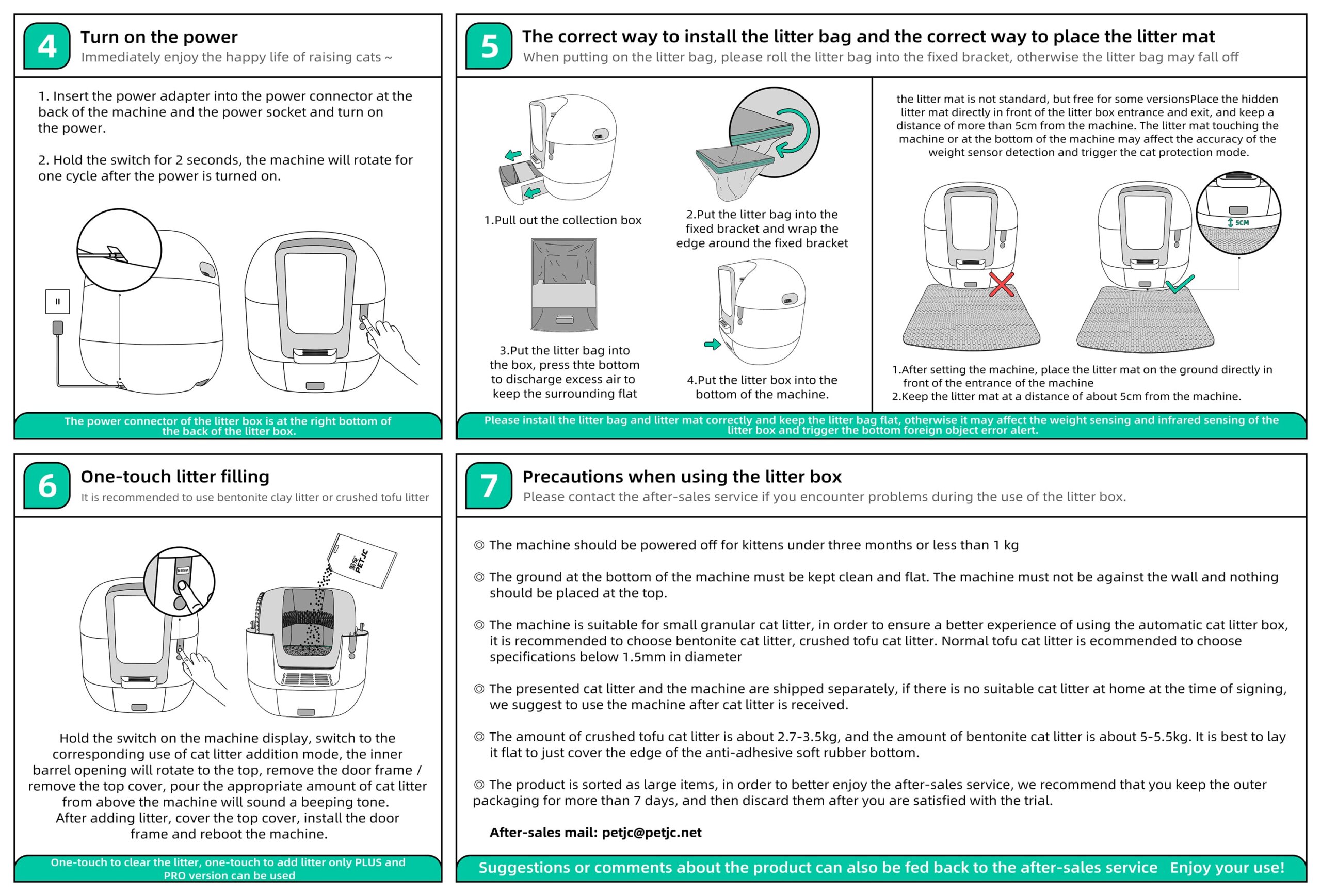

The Solution: To alleviate these concerns, buyers should focus on selecting automatic litter boxes designed with advanced safety features, such as weight-sensitive sensors that prevent operation while a pet is inside. Additionally, consider models that are quiet during operation, minimizing disruption to pets. Provide thorough product education to end-users about how these features enhance pet safety and comfort. Highlighting these aspects in marketing materials can help build trust and assure customers of the product’s reliability, ultimately fostering a positive brand image.

Scenario 3: Overcoming Maintenance and Cleaning Challenges

The Problem: Automatic litter boxes, while designed to reduce the frequency of manual cleaning, can still present maintenance challenges that deter potential buyers. B2B customers may be concerned about the ease of cleaning the internal components, emptying waste drawers, and the overall upkeep required to keep the system functioning optimally. If customers perceive the maintenance as cumbersome, they may opt for traditional solutions, leading to lost sales for retailers.

Illustrative image related to how do automatic litter boxes work

The Solution: Buyers should seek out automatic litter boxes that are designed with user-friendly maintenance in mind. Look for products with modular designs that allow for easy disassembly and access to internal components for cleaning. Additionally, consider offering educational resources or guides on proper maintenance techniques, emphasizing the minimal effort required compared to traditional litter boxes. Providing detailed instructions or video tutorials can empower customers to feel confident in their purchase, reinforcing the value of the automatic litter box as a low-maintenance solution.

Strategic Material Selection Guide for how do automatic litter boxes work

What Materials Are Commonly Used in Automatic Litter Boxes?

When considering the production of automatic litter boxes, selecting the right materials is critical for performance, durability, and user satisfaction. Here, we analyze three common materials used in these products: plastic, stainless steel, and silicone. Each material has unique properties, advantages, and disadvantages that can significantly impact the final product’s effectiveness and marketability.

How Does Plastic Perform in Automatic Litter Boxes?

Plastic is one of the most widely used materials in the manufacturing of automatic litter boxes. Its key properties include lightweight, corrosion resistance, and ease of molding into complex shapes. Common types of plastics used include polyethylene and polypropylene, which can withstand typical temperature variations encountered in household environments.

Pros and Cons: The primary advantage of plastic is its cost-effectiveness, making it an attractive option for manufacturers. However, while plastic is durable, it can become brittle over time, especially when exposed to UV light or extreme temperatures. Additionally, certain plastics may retain odors, which can be a drawback in litter box applications.

Impact on Application: Plastic’s compatibility with various types of litter is generally favorable, but some litters may cause staining or degradation of the plastic over time. This could affect the longevity of the product.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local regulations regarding plastic materials, particularly concerning environmental impact. Compliance with standards such as ASTM or DIN may also be necessary depending on the target market.

What Role Does Stainless Steel Play in Automatic Litter Boxes?

Stainless steel is often favored for its strength, durability, and aesthetic appeal. It is highly resistant to corrosion and can withstand a wide range of temperatures, making it suitable for various environmental conditions.

Pros and Cons: The key advantage of stainless steel is its longevity; it does not absorb odors and is easy to clean. However, the higher cost of stainless steel compared to plastic can be a significant disadvantage for manufacturers aiming to keep production costs low. Additionally, stainless steel can be heavier, which may affect portability.

Impact on Application: Stainless steel is compatible with most litter types and does not degrade over time, ensuring consistent performance. Its non-porous surface helps maintain hygiene, which is vital for pet products.

Illustrative image related to how do automatic litter boxes work

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer stainless steel for its premium feel and durability. Compliance with health and safety standards is crucial, and manufacturers should ensure that their products meet local regulations.

How Does Silicone Enhance Automatic Litter Box Functionality?

Silicone is increasingly used in automatic litter boxes, particularly for components like seals and mats. It offers excellent flexibility, temperature resistance, and is non-toxic, making it safe for pets.

Pros and Cons: The primary advantage of silicone is its ability to create airtight seals, which can help in odor control. However, silicone can be more expensive than traditional plastics and may not be as durable under heavy mechanical stress.

Illustrative image related to how do automatic litter boxes work

Impact on Application: Silicone’s compatibility with various litter types is generally positive, and its flexibility allows for innovative designs that can enhance user experience. However, its performance can be affected by extreme temperatures, which may be a consideration in hotter climates.

Considerations for International Buyers: Buyers from regions with stringent health regulations, such as Europe, will appreciate silicone’s non-toxic properties. Manufacturers should ensure that their silicone components comply with relevant standards.

Summary Table of Material Selection

| Material | Typical Use Case for how do automatic litter boxes work | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Main body and components of automatic litter boxes | Cost-effective and lightweight | Can become brittle over time | Low |

| Stainless Steel | Waste drawer and structural components | Durable and easy to clean | Higher cost and weight | High |

| Silicone | Seals and mats for odor control | Excellent flexibility and safety | More expensive and less durable under stress | Medium |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their market needs and regulatory requirements.

Illustrative image related to how do automatic litter boxes work

In-depth Look: Manufacturing Processes and Quality Assurance for how do automatic litter boxes work

What Are the Key Stages in Manufacturing Automatic Litter Boxes?

The manufacturing of automatic litter boxes involves several critical stages that ensure the final product meets the necessary standards for functionality, safety, and user satisfaction. Understanding these stages can help B2B buyers assess potential suppliers effectively.

-

Material Preparation

The process begins with sourcing high-quality materials, which typically include durable plastics, electronic components, and metal parts. Suppliers often utilize thermoplastics for the main body due to their resilience and ease of molding. Materials are inspected for quality and compliance with international standards, ensuring they are free from defects and suitable for the intended use. -

Forming

Forming techniques play a crucial role in shaping the components of the litter box. Injection molding is a prevalent method used for creating the plastic parts. This technique allows for precise control over dimensions and surface finish. For metal components, stamping and machining processes are often employed to achieve the required specifications. Quality checks at this stage ensure that the formed parts meet design tolerances. -

Assembly

The assembly stage involves integrating various components, including sensors, motors, and electronic circuits, into the litter box. Automated assembly lines are commonly used to enhance efficiency and reduce labor costs. Each assembly line is equipped with specialized tools to facilitate the attachment of components, ensuring consistency across products. This phase is critical for maintaining the functionality of the automatic litter box, as improper assembly can lead to malfunctions. -

Finishing

The finishing stage includes surface treatments such as polishing, painting, or applying coatings to enhance aesthetics and protect against wear and tear. This stage also involves the installation of user interfaces and safety features, such as weight sensors that prevent operation when a cat is inside the box. Final inspections are conducted to ensure that all components are securely attached and that the product meets the specified quality standards.

What Quality Assurance Measures Are Essential for Automatic Litter Boxes?

Quality assurance (QA) is paramount in the manufacturing of automatic litter boxes, as it directly impacts safety, functionality, and customer satisfaction. Buyers should be aware of the key quality standards and checkpoints that suppliers adhere to.

-

International Standards and Certifications

Compliance with international standards, such as ISO 9001, is crucial for manufacturers. This standard outlines requirements for a quality management system (QMS) that ensures consistent product quality and continual improvement. Additionally, certifications like CE mark (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) may apply, particularly for components that interact with other systems. -

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process, including checks after forming and assembly stages, helps identify defects early.

– Final Quality Control (FQC): A comprehensive inspection of the finished product ensures that it meets all performance and safety criteria before shipping. -

Common Testing Methods

Various testing methods are employed to validate the functionality and safety of automatic litter boxes. These may include:

– Functional Testing: Verifying that all electronic components, such as sensors and motors, operate correctly.

– Stress Testing: Assessing the durability of materials under different conditions to ensure long-term reliability.

– Safety Testing: Ensuring compliance with safety standards, particularly concerning electrical components and moving parts.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks associated with procurement.

Illustrative image related to how do automatic litter boxes work

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance measures. During an audit, buyers can assess compliance with international standards and evaluate the effectiveness of QC checkpoints. -

Quality Reports

Requesting detailed quality reports from suppliers can help buyers gauge the consistency of product quality. These reports should include data from IQC, IPQC, and FQC stages, along with any corrective actions taken in response to identified issues. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and quality control systems. These inspections can be particularly useful for buyers unfamiliar with local practices or those sourcing from new suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in different markets is vital for B2B buyers looking to import automatic litter boxes. Buyers should consider the following:

-

Regulatory Compliance

Different regions have varying regulatory requirements for pet products. It is essential for buyers to familiarize themselves with local regulations in their target markets to ensure compliance and avoid potential legal issues. -

Cultural Considerations

Preferences for product features may vary across different markets. For example, buyers from Europe may prioritize eco-friendly materials, while those from Africa might emphasize durability and ease of maintenance. Understanding these preferences can guide procurement strategies. -

Language and Communication Barriers

Clear communication is crucial when discussing quality standards and expectations with suppliers. Buyers should ensure that language barriers are addressed, possibly by employing local intermediaries or translators who can facilitate effective communication.

By thoroughly understanding the manufacturing processes and quality assurance measures associated with automatic litter boxes, B2B buyers can make informed decisions that align with their business needs and customer expectations. Engaging with reputable suppliers who adhere to international standards will ultimately contribute to the success of their product offerings in the marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do automatic litter boxes work’

Introduction

In the evolving pet care market, automatic litter boxes are gaining traction due to their convenience and efficiency. This guide is designed for B2B buyers looking to understand how these devices operate and what to consider when sourcing them for retail or distribution. By following this step-by-step checklist, you can ensure that you select the best automatic litter boxes that meet your market’s needs.

Step 1: Understand the Mechanism of Operation

Before sourcing automatic litter boxes, it’s essential to grasp how they function. Most models utilize a sifting mechanism that separates waste from clean litter after a designated period. This understanding will help in evaluating product features and ensuring they meet customer expectations.

- Key Mechanisms to Consider:

- Clumping Technology: Ensure the litter box effectively clumps waste to facilitate easy removal.

- Rotation Timing: Look for models with adjustable timers for optimal operation based on usage frequency.

Step 2: Define Your Target Market Needs

Identify the specific needs of your target market, as preferences can vary significantly across regions. Different cultures may have unique expectations regarding pet hygiene and care.

Illustrative image related to how do automatic litter boxes work

- Considerations:

- Space Availability: In urban areas, compact models may be preferred.

- User Demographics: Assess whether your customers are likely to have multiple pets or senior cats that may require easier access.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. This step is crucial for ensuring product quality and reliability.

- What to Look For:

- Company Profiles: Request detailed information about their manufacturing processes and product history.

- References and Case Studies: Seek feedback from other businesses in similar markets to gauge satisfaction.

Step 4: Check for Safety Features

Safety is paramount, especially with products designed for pets. Verify that the automatic litter boxes have features that prevent accidents.

- Key Safety Features:

- Cat Sensors: Look for models that halt operation if a cat re-enters during the cleaning cycle.

- Stability and Design: Ensure the design minimizes the risk of tipping or injury to pets.

Step 5: Assess Maintenance and Cleaning Requirements

Consider the ease of maintenance when evaluating automatic litter boxes. A model that is difficult to clean may deter customers.

- Maintenance Factors:

- Modular Design: Opt for boxes that allow easy access for cleaning.

- Waste Drawer Capacity: Ensure the waste drawer can accommodate multiple uses before needing to be emptied.

Step 6: Investigate Compatibility with Different Litters

Not all automatic litter boxes work with every type of litter. Understanding compatibility is vital for customer satisfaction.

- Litter Types to Consider:

- Clumping vs. Non-Clumping: Ensure the product supports widely used clumping litters.

- User Preferences: Investigate if your target market has specific preferences for natural or synthetic litter.

Step 7: Review Warranty and Customer Support Options

A strong warranty and reliable customer support can enhance your brand’s reputation and customer loyalty.

- What to Confirm:

- Warranty Length: Look for products with a comprehensive warranty to protect against defects.

- Support Availability: Ensure the supplier offers robust customer support for troubleshooting and maintenance inquiries.

By following this checklist, B2B buyers can make informed decisions when sourcing automatic litter boxes, ensuring they meet market demands and customer satisfaction.

Comprehensive Cost and Pricing Analysis for how do automatic litter boxes work Sourcing

What Are the Key Cost Components for Sourcing Automatic Litter Boxes?

When evaluating the cost structure of automatic litter boxes, several key components come into play. The primary cost components include:

Illustrative image related to how do automatic litter boxes work

-

Materials: The choice of materials significantly impacts the cost. High-quality plastics, electronics for sensors, and durable motors are essential for performance and longevity. The use of eco-friendly or biodegradable materials may also increase costs but could appeal to environmentally conscious consumers.

-

Labor: Labor costs encompass not only assembly but also design and engineering efforts. Skilled labor is often necessary for the integration of technology and quality assurance, particularly in regions with higher labor costs.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can reduce these costs, allowing for more competitive pricing.

-

Tooling: Initial tooling costs for molds and machinery can be substantial. However, these costs can be amortized over larger production runs, making them less of a concern for high-volume orders.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet safety and performance standards, which can incur additional costs. However, these costs are critical to reduce returns and maintain brand reputation.

-

Logistics: Shipping costs, tariffs, and warehousing play a crucial role in the overall pricing strategy. These costs can vary widely depending on the destination and supplier location.

-

Margin: The desired profit margin will vary based on market positioning and competition. It is essential to balance margin expectations with competitive pricing to capture market share.

How Do Price Influencers Affect the Cost of Automatic Litter Boxes?

Various factors influence the pricing of automatic litter boxes, including:

-

Volume/MOQ: Suppliers often offer better pricing for larger order quantities (Minimum Order Quantity – MOQ). Buyers should negotiate to achieve favorable terms that align with their needs.

-

Specifications and Customization: Custom features or designs can significantly affect pricing. Buyers should clearly define their requirements to avoid unexpected costs during production.

-

Materials: The choice between standard and premium materials can alter the cost structure. Understanding the trade-offs between cost and quality is crucial for buyers.

-

Quality Certifications: Products that meet international quality standards may attract a premium price. However, these certifications can also enhance marketability, especially in regions with strict regulatory environments.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may charge more but often provide better quality assurance and after-sales support.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in shipping and delivery, which can affect overall costs.

What Buyer Tips Can Help in Sourcing Automatic Litter Boxes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Establishing a strong relationship with suppliers can lead to better deals over time.

-

Consider Total Cost of Ownership: Look beyond initial purchase prices. Evaluate long-term costs, including maintenance, warranty, and potential returns, to understand the true cost of ownership.

-

Research Market Trends: Stay informed about trends in the pet care industry and consumer preferences. This knowledge can inform negotiation strategies and product offerings.

-

Evaluate Supplier Capabilities: Assess the supplier’s ability to scale production, manage quality, and comply with regional regulations. A reliable supplier can mitigate risks associated with product quality and delivery.

-

Understand Regional Regulations: Different regions may have specific regulations regarding pet products. Being aware of these can prevent costly compliance issues down the line.

-

Seek Feedback from Peers: Engaging with other buyers in similar markets can provide valuable insights into supplier performance and product quality.

In conclusion, while sourcing automatic litter boxes involves various cost components and price influencers, strategic negotiation and informed decision-making can lead to more favorable outcomes for B2B buyers in the global marketplace.

Alternatives Analysis: Comparing how do automatic litter boxes work With Other Solutions

Understanding Alternatives to Automatic Litter Boxes: A Comparative Analysis

In the quest for cleaner and more efficient pet care solutions, automatic litter boxes have garnered considerable attention for their innovative technology. However, they are not the only option available. This analysis explores several viable alternatives to automatic litter boxes, providing B2B buyers with insights into their functionalities, costs, and suitability for various environments.

| Comparison Aspect | How Do Automatic Litter Boxes Work | Traditional Manual Litter Boxes | Litter Disposal Systems (e.g., Litter Genie) |

|---|---|---|---|

| Performance | Automatically sifts waste after each use, reducing odors. | Requires manual scooping, leading to potential odors. | Collects waste in a sealed bag, reducing odors. |

| Cost | Higher initial investment; ongoing maintenance costs. | Low initial cost; minimal ongoing costs. | Moderate initial cost; recurring bag purchases. |

| Ease of Implementation | Requires setup and power source; may need adjustments. | Simple to set up; no technical knowledge needed. | Requires setup but easy to use once established. |

| Maintenance | Needs occasional cleaning of components and waste drawer. | Regular scooping and cleaning are necessary. | Requires bag replacement; minimal maintenance needed. |

| Best Use Case | Ideal for busy pet owners seeking convenience. | Suitable for budget-conscious consumers. | Best for those prioritizing odor control and convenience. |

In-Depth Analysis of Alternatives to Automatic Litter Boxes

Traditional Manual Litter Boxes: A Cost-Effective Solution

Traditional manual litter boxes are the most straightforward option for cat owners. They require minimal initial investment and are easy to set up without any technical expertise. However, they demand regular maintenance, including daily scooping and cleaning to prevent odors and maintain hygiene. This method is suitable for budget-conscious consumers or those who prefer a hands-on approach to pet care. The downside is the time commitment and potential for unpleasant odors if not managed properly.

Illustrative image related to how do automatic litter boxes work

Litter Disposal Systems: Enhanced Odor Control

Litter disposal systems, such as the Litter Genie, offer a middle ground between manual litter boxes and automatic solutions. These systems allow users to scoop waste into a sealed bag, which helps contain odors and keeps the litter area cleaner. They typically require an initial investment and ongoing purchase of replacement bags, but they simplify waste management considerably. While they don’t eliminate the need for manual scooping, they make the process less odorous and more efficient. However, they may not be suitable for all cat owners, especially those who prefer a more traditional approach.

Conclusion: Making an Informed Decision for Your Pet Care Needs

When evaluating the best litter management solution, B2B buyers should consider factors such as budget, maintenance capabilities, and the specific needs of their clientele. Automatic litter boxes may be ideal for busy professionals seeking convenience, while traditional litter boxes cater to those looking for a cost-effective solution. Litter disposal systems serve as a great compromise, offering odor control with a manageable level of maintenance. By understanding the advantages and disadvantages of each option, businesses can better align their offerings with the preferences and requirements of their target market.

Essential Technical Properties and Trade Terminology for how do automatic litter boxes work

What Are the Key Technical Properties of Automatic Litter Boxes?

Understanding the technical specifications of automatic litter boxes is essential for B2B buyers, especially when considering the performance, durability, and compatibility of these products. Here are some critical specifications:

-

Material Grade

– Automatic litter boxes are typically made from high-grade plastics or polymers that are resistant to wear, moisture, and odors. The choice of material impacts longevity and ease of cleaning, which are vital for maintaining hygiene in pet care products. Buyers should prioritize products with durable materials to minimize replacement costs. -

Weight Capacity

– Many automatic litter boxes come equipped with weight sensors to detect when a cat enters or exits the box. Understanding the weight capacity is crucial, especially for multi-cat households or larger breeds. A higher weight threshold ensures that the product can accommodate a broader range of cat sizes, thereby appealing to a larger customer base. -

Noise Level

– The operational noise level is an important property, as cats have sensitive hearing. Many automatic litter boxes operate with minimal sound, which is beneficial for fearful or skittish cats. B2B buyers should consider this specification to ensure customer satisfaction and reduce the likelihood of returns. -

Cycle Time

– This refers to the time it takes for the litter box to complete its cleaning cycle after a cat has used it. A shorter cycle time enhances user convenience and promotes cleanliness, which is a selling point for consumers. Understanding cycle times allows buyers to compare the efficiency of different models. -

Waste Drawer Capacity

– The size of the waste drawer directly affects how often it needs to be emptied. Larger capacities are advantageous for households with multiple cats, reducing the frequency of maintenance. B2B buyers should assess the waste capacity to align with customer needs for convenience and usability. -

Power Source

– Automatic litter boxes may operate on batteries or be plugged into an electrical outlet. Understanding the power source is essential for assessing the reliability and operational costs of the product. Buyers should look for energy-efficient options that align with sustainability goals.

What Are Common Trade Terms in the Automatic Litter Box Industry?

Familiarizing yourself with industry-specific terminology is crucial for effective communication and negotiation in the B2B space. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of automatic litter boxes, OEMs often create components that brands assemble into finished products. Understanding OEM relationships can help buyers negotiate better pricing and terms. -

MOQ (Minimum Order Quantity)

– This is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. Buyers should aim to negotiate favorable MOQs to avoid overstocking or understocking. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers. It outlines the specifications and quantities needed. Crafting a clear RFQ can lead to more accurate quotes and better pricing, helping buyers make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is vital for managing logistics and shipping costs effectively, ensuring that both parties are clear on delivery responsibilities. -

SKU (Stock Keeping Unit)

– An SKU is a unique identifier for each distinct product and service that can be purchased. SKUs help in inventory management and tracking sales performance. B2B buyers should ensure that suppliers provide detailed SKU information for better order accuracy. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is critical for inventory planning and ensuring that products are available when needed, especially in competitive markets.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing automatic litter boxes, ensuring they meet market demands and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the how do automatic litter boxes work Sector

What Are the Key Market Dynamics and Trends in the Automatic Litter Box Sector?

The automatic litter box sector is experiencing notable growth driven by increasing pet ownership globally, particularly in emerging markets such as Brazil, Nigeria, and other regions in Africa and the Middle East. As urbanization rises, pet owners seek convenient solutions that align with their busy lifestyles. Moreover, technological advancements in sensor technology, app connectivity, and waste management systems are enhancing product offerings, making them more appealing to consumers.

B2B buyers should be aware of current trends such as the integration of health monitoring features in automatic litter boxes. These advancements allow pet owners to track their cats’ health metrics, providing valuable insights that can lead to early disease detection. Additionally, the rise of subscription models for litter supplies and accessories is reshaping sourcing strategies, offering businesses a recurring revenue stream while simplifying inventory management.

Another emerging trend is the demand for customizable and modular designs. International buyers are increasingly looking for products that can be tailored to meet specific needs, such as accommodating multiple cats or varying litter preferences. Understanding these dynamics can help B2B buyers identify potential partners and products that align with market demands.

How Can Sustainability and Ethical Sourcing Impact the Automatic Litter Box Market?

Sustainability is becoming a critical factor for B2B buyers in the automatic litter box sector. As consumers become more environmentally conscious, they are increasingly drawn to products that minimize ecological impact. This includes the use of biodegradable materials for litter and recyclable components in the litter box design.

Ethical sourcing practices are also gaining traction. Buyers should prioritize suppliers that maintain transparent supply chains and adhere to fair labor practices. Certifications such as Forest Stewardship Council (FSC) for wooden components or ISO 14001 for environmental management systems can help identify responsible manufacturers.

Illustrative image related to how do automatic litter boxes work

Moreover, incorporating sustainable practices can enhance brand reputation and appeal to a broader customer base. By aligning with eco-friendly initiatives, businesses can differentiate themselves in a competitive market while contributing to a more sustainable future.

What Is the Historical Context of Automatic Litter Boxes?

The evolution of automatic litter boxes can be traced back to the late 20th century, when the first prototypes aimed to alleviate the tedious task of manual litter box cleaning. Early models were simplistic, relying on basic mechanical designs that often fell short of user expectations. However, advancements in technology over the years have transformed these products into sophisticated devices equipped with sensors, self-cleaning mechanisms, and health monitoring features.

The introduction of smart technology has further revolutionized the market, allowing for remote monitoring and control via smartphone applications. This progression reflects broader trends in pet care, where convenience and technological integration are increasingly valued by consumers. As the sector continues to innovate, understanding its historical context can inform B2B buyers about potential future developments and opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of how do automatic litter boxes work

-

How do automatic litter boxes work?

Automatic litter boxes utilize a combination of sensors and mechanical systems to manage cat waste without manual scooping. When a cat exits the box, a timer activates a sifting mechanism that rotates the litter, separating clumps from clean litter. The waste is then deposited into a drawer for easy disposal. This technology not only simplifies litter management but also promotes a cleaner environment for both pets and their owners. -

What are the advantages of using automatic litter boxes for businesses?

For businesses in the pet care industry, automatic litter boxes can enhance customer satisfaction by offering a convenient solution for cat owners. These products reduce the frequency of cleaning, thereby saving time and effort for pet owners. Additionally, they can attract a tech-savvy demographic looking for innovative pet care solutions, potentially increasing sales and brand loyalty. -

How do I choose the best automatic litter box for my market?

Selecting the right automatic litter box involves considering factors such as target audience preferences, price points, and product features. Research local market trends to identify popular features, such as health monitoring or quiet operation. Ensure the product is compatible with various types of litter to accommodate different customer needs. Conducting surveys or focus groups can provide valuable insights into customer preferences in your region. -

What types of litter are compatible with automatic litter boxes?

Most automatic litter boxes work best with clumping litter, which forms solid clumps for easy removal. However, some models may accept alternative types such as crystal or plant-based litters. It’s essential to communicate the specific litter requirements to customers, as using incompatible litter can hinder the functionality of the box and lead to customer dissatisfaction. -

What are the typical minimum order quantities (MOQs) for automatic litter boxes?

Minimum order quantities for automatic litter boxes can vary significantly by manufacturer and model. Generally, MOQs can range from 50 to several hundred units, depending on the supplier’s production capabilities and the complexity of the product. It’s crucial to negotiate MOQs that align with your business strategy while ensuring you have enough inventory to meet market demand. -

How can I vet suppliers for automatic litter boxes?

To vet suppliers, start by checking their credentials, such as certifications and industry experience. Request samples to evaluate product quality and functionality. Additionally, consider visiting their manufacturing facilities if possible, or seek references from other businesses that have worked with them. It’s also beneficial to assess their responsiveness and support services, as these factors can impact your ongoing relationship. -

What payment terms should I negotiate with suppliers?

When negotiating payment terms, consider options like 30% upfront and 70% upon delivery, which is common in international trade. Ensure that the terms are manageable for your cash flow while also protecting your investment. It’s advisable to discuss potential discounts for early payments or bulk orders, and to clarify any currency exchange implications if dealing with international suppliers. -

What logistics considerations should I keep in mind when importing automatic litter boxes?

Logistics play a crucial role in the successful importation of automatic litter boxes. Consider factors such as shipping costs, customs duties, and delivery timelines. It’s essential to work with a reliable freight forwarder familiar with the regulations of your target market. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance, and factor in storage solutions upon arrival to prevent delays in distribution.

Top 4 How Do Automatic Litter Boxes Work Manufacturers & Suppliers List

1. Litter-Robot – Automatic Self-Cleaning Litter Box

Domain: litter-robot.com

Registered: 1999 (26 years)

Introduction: Litter-Robot uses patented sifting technology to automatically clean your cat’s litter box. When a cat finishes using the box, a timer allows litter to clump before the globe rotates to separate dirty clumps from clean litter. Clumps are deposited into a waste drawer below, leaving a clean bed of litter. The product features a cat sensor that detects when a cat enters or exits, ensuring safety by …

2. Litter Robot – Automatic Litter Box

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Litter Robot is the only automatic litter box mentioned that is considered effective by users. It uses clumping litter and provides a clean bed of litter for cats, which they adjust to easily. However, it is expensive and has potential failure points. Users noted that it does not reduce litter kicking and tracking, and there are concerns about cats getting stuck or startled. The new version of…

3. Neakasa – M1 Cat Litter Box

Domain: neakasa.com

Registered: 2020 (5 years)

Introduction: Neakasa M1 Cat Litter Box features a large and open top design, quiet operation, and effective litter management. It utilizes a gradual self-cleaning mode that rotates the outer shell to ensure thorough cleanliness, efficiently cleaning even soft or unburied waste. The box includes sensors that detect when a cat enters and exits, triggering a cleaning cycle. It employs raking and rotating mechanis…

4. PetSafe – ScoopFree® Ultra Self-Cleaning Litter Box

Domain: support.petsafe.net

Registered: 1998 (27 years)

Introduction: ScoopFree® Ultra Self-Cleaning Litter Box features automatic waste scooping 5, 10, or 20 minutes after use, crystal litter for moisture absorption and odor control, a disposable litter tray for easy cleanup, and a privacy hood to block odors. Key components include a rake sensor for initiating scoop cycles, a control panel for settings, a power jack for connection, a waste cover for odor reduction…

Strategic Sourcing Conclusion and Outlook for how do automatic litter boxes work

In summary, automatic litter boxes present a unique opportunity for B2B buyers to enhance pet care solutions while addressing consumer demands for convenience and hygiene. The core functionality of these devices revolves around efficient waste management through clumping and sifting technologies, which minimize manual cleaning and improve the overall user experience. However, it is essential to consider factors such as compatibility with various litter types, safety features for pets, and the potential challenges associated with noise and accessibility for different cat breeds.

Strategic sourcing plays a crucial role in navigating the competitive landscape of this market. By aligning with manufacturers who prioritize quality, safety, and user-friendliness, B2B buyers can differentiate their offerings and capture a growing segment of pet owners looking for innovative solutions.

As the global pet care market continues to expand, particularly in regions like Africa, South America, the Middle East, and Europe, now is the time to invest in automatic litter box technologies. Embrace the potential for growth by partnering with reliable suppliers and tapping into the increasing demand for advanced pet care products. Your next step could redefine the pet care experience—let’s make it happen.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.