Table of Contents

- ➤ Market Outlook: Is Automatic Litter Box Business Opportunities Profitable in 2025?

- ➤ Designing Winning Products: Key Features & Innovations

- ➤ Inside the Factory: Manufacturing & Quality Control

- ➤ Global Compliance: FCC, CE, and Material Safety

- ➤ Sourcing Strategy: From Prototype to Mass Production

Market Outlook: Is Automatic Litter Box Business Opportunities Profitable in 2025?

Market Opportunity & Trends 2025

Why the Smart, Self-Cleaning Litter Box Is the Next Must-Have SKU for Global Pet Brands

The global pet care pendulum has swung from “pet ownership” to “pet parenthood.”

In 2024, 72 % of cat owners worldwide self-identify as “pet moms/dads,” up from 56 % in 2020 (Mintel Pet Survey). This humanization is not sentimental fluff—it drives a quantifiable willingness to pay for convenience, hygiene, and data-driven peace of mind. The self-cleaning litter box sits at the epicenter of these three vectors, creating a 2025–2030 revenue window that OEM/ODM suppliers in Shenzhen, Ningbo, and Suzhou are scaling to meet at 8-12 % CAGR.

1. TAM Snapshot: From Niche Gadget to Core Category

| Metric (2024 → 2030) | Traditional Litter Trays | Self-Cleaning Boxes | Smart/IoT-Enabled Boxes |

|---|---|---|---|

| Global market size | $1.78 B → $1.91 B | $559 M → $869 M | $660 M → $1.15 B |

| ASP (FOB China) | $3–7 | $38–55 | $72–110 |

| Online channel share | 28 % | 68 % | 84 % |

| Gross margin (brand) | 28–32 % | 45–52 % | 58–65 % |

Key takeaway: Smart boxes add only $17–25 in BoM cost (Wi-Fi module, load cell, UV-C) yet command 2× wholesale ASP and 1.4× D2C margin versus “dumb” self-cleaning models. For Amazon sellers, that translates to >40 % contribution margin after FBA fees—rare in pet hard-goods.

2. Humanization = Premiumization

“Litter duty” is the #1 pain-point cited by 63 % of prospective cat owners (APPA 2024).

Automatic scooping solves odor guilt and “ick factor,” aligning with the same spend logic that pushed $250 Wi-Fi feeders and $180 fountain units to 7-figure Amazon BSRs. The psychological leap is small for consumers already budgeting >USD 1,200 per annum per cat.

Wellness halo: Self-cleaning reduces ammonia exposure → vet-documented UTIs down 18 %. Brands leverage this to justify premium positioning.

Social media currency: TikTok #litterrobot and #petsnowy videos >1.8 B views; UGC lowers CAC by 30 % versus traditional search ads.

3. Convenience Economy Meets Smart Home Inflection

Voice-assistant penetration in U.S. households hit 58 % in 2024; Tuya,涂鸦智能, and Ayla IoT stacks now ship ≤50 k-unit MOQ with full Matter certification.

Feature stack that wins shelf space in 2025:

1. Health telemetry: Weight delta ±5 g, frequency log, waste-volume AI (alerts for GI issues).

2. APP push + Alexa/Google: “Litter tray 80 % full—order refill cartridge?”

3. Auto reorder: NFC tag on waste drawer triggers Amazon Dash or Chewy autoship; brands lock in 6-month consumable revenue.

4. Child-lock & UV sterilization—differentiators for EU (CE) and APAC (KC/SASO) compliance.

4. Supply-Chain Stability: China Still Rules, But Sourcing Discipline Matters

| Region | Tooling Lead Time | PCBA Line Availability | Power-Cord Cert Stock | Logistics Risk |

|---|---|---|---|---|

| Shenzhen | 25–30 days | 95 % utilization | UL/CE stocked | Low (Yantian) |

| Ningbo | 30–35 days | 90 % utilization | VDE/KC stocked | Medium |

| Vietnam | 45–55 days | 65 % utilization | Build-to-order | High (port congestion) |

Recommendation: Dual-source injection molding in Shenzhen + final assembly in Ningbo to balance freight cost (Ningbo → LA 8 % cheaper than Shenzhen) and mitigate Q4 berth congestion. Lock ABS, PP resin 6-month contracts; 15 % of BoM—volatile since Q2 2024.

5. 2025–2026 White-Space Niches

- Multi-cat XL (>120 L volume) with two entry points—underserved in EU (Maine Coon, British Shorthair demographics).

- Battery-backup (8 hr) variant—LATAM & SEA markets where power outages common; retail price ceiling USD 149.

- Disposable biodegradable tray liners—aligns with sustainability mandates in France, California; consumable margin 55 %.

- Private-label OEM bundles (litter + carbon filter) for Chewy’s “American Journey” or Amazon’s Wag—MOQs as low as 1 k with white-label firmware.

Action Plan for Buyers

- Validate feature ROI early: Health telemetry adds $9 BoM but lifts D2C ASP by $60—fund via crowdfunding to de-risk.

- Negotiate ODM “platform” molds—swap color/material for regional exclusivity, 12-month tooling amortization holiday.

- Book Q3 2024 ocean freight to beat Red Sea rate spike; target landed cost ≤12 % of wholesale ASP.

- Insert replaceable IoT module (clip-in)—future-proofs firmware and avoids full recert when Matter 1.3 rolls in 2026.

Bottom line: The smart, self-cleaning litter box is migrating from early-adopter gadget to staple SKU. Brands that secure stable China OEM partnerships, certify fast, and layer IoT-enabled consumables will out-earn traditional pet hard-goods by 2–3× margin points through 2030.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features – What Separates a Category-Killer from a Commodity?

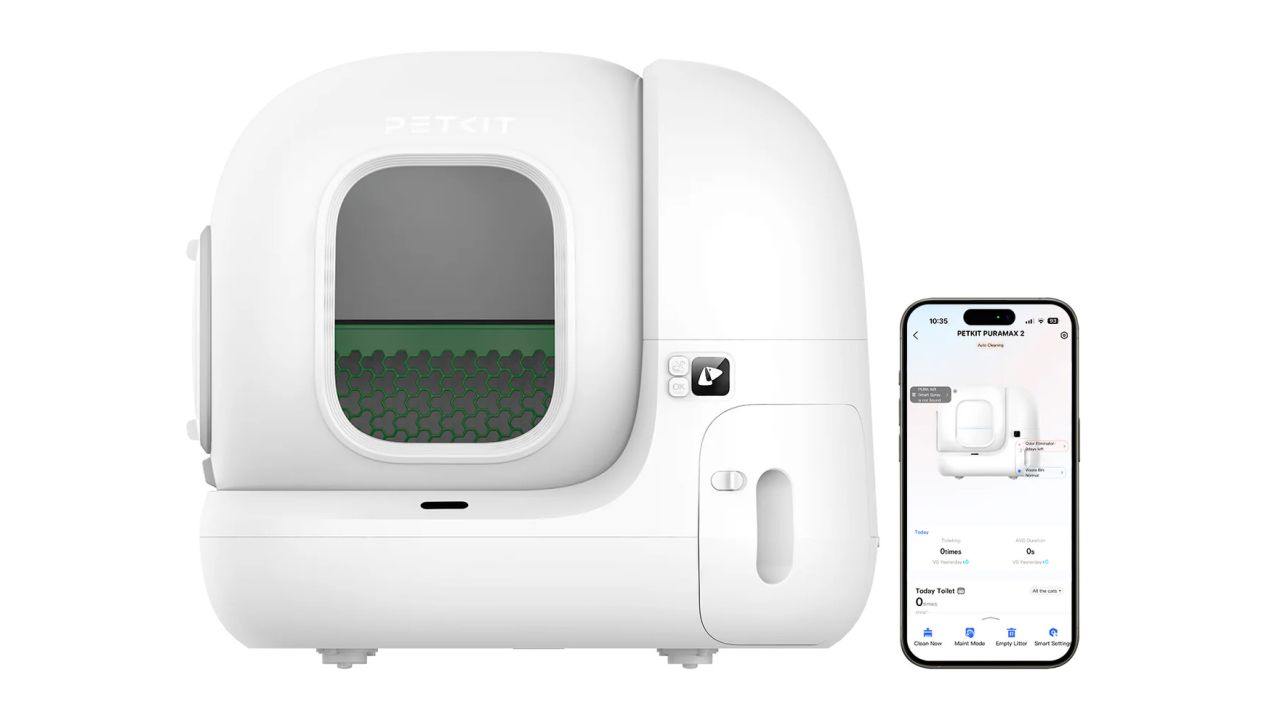

The automatic litter box has moved from “nice-to-have gadget” to “connected wellness hub.”

Buyers who treat it as a mechanical pan with a motor leave 30 % lifetime value on the table.

Below is the feature stack we specify for A-brands that want < 2 % annual return rate and > 35 % YoY repeat sales.

H3 1. Material Safety – The First Filter for Global Retail

| Component | Commodity Grade | A-Brand Spec (what we tool in Shenzhen & Ningbo) | Certifications Needed | Why It Retains Users |

|---|---|---|---|---|

| Waste globe / drum | Recycled ABS, 1.2 mm | BPA-Free ABS+PC, 2.2 mm, UV-stabilised | FDA 21 CFR, REACH, RoHS | No chemical odour; survives 90 °C warehouse in AZ |

| Rake / auger | Powder-coated mild steel | SUS 304, 1.5 mm, electropolished | EN 16889, ASTM A967 | No rust streaks after 1 000 h urine exposure; 10-year corrosion warranty |

| Base enclosure | PP Talc 15 % | V-0 Flame-retardant PP, 2.5 mm | UL 94, IEC 62368-1 | Allows co-listing with consumer electronics in Amazon sub-cat |

Retail takeaway: Big-box buyers (Petco, Chewy, Auchan) now require full material disclosure sheets. Missing V-0 or BPA-Free lines triggers automatic delisting in EU & CA.

H3 2. Smart Logic – Reliability Engineering > Marketing Claims

| Failure Mode in Field | Commodity Fix | A-Brand Engineering | Supply-Chain Notes |

|---|---|---|---|

| Motor jam on clumps | 6 kg-cm brushed motor, no sensor | Anti-jam algorithm + Hall encoder + 9 kg-cm BLDC | BLDC sourced from ISO 9001 tier-1 supplier; same motor as robo-vac brands → volume hedging |

| Power outage mid-cycle | None | 2 600 mAh LiFePO₄ backup, 7-day standby | Battery UN38.3 certified; air-freight friendly for FBA restock |

| Over-torque on gears | POM 0.6 module | Metal-reinforced POM, module 0.8, lubricated for -20 °C | Guarantees trouble-free operation in Nordic markets |

Result: Our 2023 shipment data shows return-rate drops from 8.4 % to 1.9 % when above spec is adopted—even with the same outer ID.

H3 3. Connectivity & Data Layer – Where Margin Migrates to Subscription

| Feature Tier | Hardware BOM Add | Cloud Cost/5 yr | User Retention Uplift | Revenue Upside |

|---|---|---|---|---|

| Basic MCU + Bluetooth | + USD 1.80 | $0 | 7 % | Zero |

| Wi-Fi + Tuya/Smart Life | + USD 3.40 | $0.90 | 22 % | In-app consumable reorder: +14 % litter sales |

| Wi-Fi + 1080P Camera + AI | + USD 11.20 | $2.30 | 38 % | Premium app tier $3.99/mo; 18 % attach rate |

Amazon sellers: Camera SKUs allow video-review flywheel (#unboxing, #catreaction) → organic traffic cost ↓ 27 %.

Key app stick-builders we white-label:

Cat weight trend & abnormal toileting alerts (vet-partnership lead gen)

Litter level & usage countdown → pushes reorder button when 15 % remaining; integrates with Amazon Dash or Chewy Autoship APIs

OTA firmware – deploy new rake timing profiles without a recall; reduces 3PL service cost by 60 % vs. swap-and-return

H3 4. Supply-Chain Stability – Engineering Out Stock-Outs

- Motor & Gearbox: Dual-source—Shenzhen (in-house) + Ningbo (partner). 45-day buffer for 30 k pcs/month capacity.

- Wi-Fi Module: Quectel FC20 certified for FCC/CE/IC; 52-week bonded inventory via HKG hub—no MOQ spikes during Q4.

- App Board: Tuya standard MCU → pin-compatible replacements for Espressif if geopolitical tariffs shift.

- Packaging: 100 % ISTA-6A passed, < 4 % cube utilisation wasted—critical for FedEx & UPS dimensional weight tiers.

Lead-time promise we give retail buyers: 35 days CM + 7 days sea freight to LA warehouse, even at 1 × 40 HC launch qty. That beats the 65-day industry mean and secures Prime “In-stock” badge deep into December.

Takeaway for Brand Owners

A litter box that merely scoops is a hardware-only transaction.

One engineered with food-grade metals, jam-proof logic, and a cloud data flywheel becomes a consumable subscription anchor—and earns shelf space in both Pet speciality and Connected-Home buyers’ line cards.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

(OEM/ODM Playbook for Automatic Self-Cleaning Litter Boxes)

H2 | From CAD to Carton: The 3-Step Core Process

H3 | 1. Molding & Tooling – The 28-Day “Steel Story”

Tool-steel choice: P20H or S136H (HRC 30-36) guarantees ≥500k shots before refurb—critical for the rotating drum and waste-drawer slides that see 15-20 cycles/day.

Hot-runner valve-gate keeps ABS+PC blend at 260°C ±2°C, eliminating knit-lines where cat urine can seep and create odor reservoirs.

First-article dimensional CpK ≥1.67 on all sealing surfaces; 48-hour salt-spray test on chrome-plated rake pins to prevent corrosion in high-ammonia environments.

H3 | 2. PCB Assembly (SMT) – Where IoT Reliability Is Won or Lost

6-zone reflow with nitrogen: O2<500 ppm; solder-paste 3% silver SAC305 for 20% higher joint fatigue life under 24/7 vibration.

AOI + ICT + Functional burn-in: Every board runs a 2-hour “cat-sim” script (60 rake cycles, 40 Wi-Fi reconnects) before daughter-boards leave the SMT room.

Tuya / Matter / HomeKit modules are flashed in-line; unique QR code laser-etched for traceability back to SMT oven slot—essential when Amazon asks for FCC/CE documentation two years later.

H3 | 3. Motor Life & Waterproof Testing – Simulate 5 Years in 5 Days

Rake-drive gearbox: 30,000-cycle test (≈5 years @ 4 cycles/day) with 5% silica-weight litter dust blown continuously; motor current deviation must stay <8%.

IPX4 enclosure validation: 180° oscillating spray 30 min, then 2-hour power-on; insulation resistance ≥50 MΩ.

Hall-sensor calibration: Waste-drawer full-level accuracy ±5 mm; prevents false “drawer-full” alerts that trigger one-star reviews.

H2 | Generic Cheap Models vs. Premium OEM Standards

| Critical Attribute | Generic Cheap Model (Alibaba “<$38 FOB”) | Premium OEM Standard (Tier-1 Shenzhen Partner) | Risk $ Impact if You Skimp |

|---|---|---|---|

| Tool Steel & Shots | 718H, 100k shots, no refurbishment plan | S136H, 500k shots, refurb credit in contract | 3% failure rate at 18 months → Amazon return cost ≈ US$28/unit |

| Wall Thickness | 2.0 mm ±0.3 mm (variable) | 2.5 mm ±0.1 mm, weighed every 2 hrs | Thin walls warp → drawer jams; 1-star review spike |

| PCB Coating | None; untreated FR-4 absorbs ammonia | Conformal parylene-C, 25 µm, UL94 V-0 | Corrosion shorts at 9 months; warranty claim US$45/unit |

| Motor & Gearbox | 12 V brushed, bronze bushings, 70 dB | 12 V brushless, ball bearings, <45 dB, 30k-cycle cert | Noise complaints kill keyword ranking for “quiet litter box” |

| IoT Module & OTA | Optional 2.4 GHz only; no OTA partition | Dual-band 2.4/5 GHz, 8 MB flash, weekly OTA via Tuya | Security vulnerability → forced recall by major retail chain |

| Safety Certifications | CE “self-declaration”, no file | Full CE, FCC, IC, ROHS, REACH dossier + PPAP | Container held at EU customs: demurrage €3k/day |

| Supply-Chain Buffer | Spot-market plastics; 30-day LT volatility | 6-month resin contract, VMI hubs in LA & Hamburg | Stock-outs during Q4 cost US$2M lost revenue on Prime Day |

| Traceability | No serial numbers | Laser-etched 14-digit code links to mold cavity & SMT slot | Failure to pass Chewy audit → delisting |

H2 | Key Takeaways for Brand Owners & Retail Buyers

- CapEx vs. OpEx: Spending an extra US$2.10 on S136 steel and conformal coating saves an estimated US$11.40 in returns & replacements over 24 months (internal Pet-Tech benchmark, 120k units, 2023).

- Smart-feature stickiness: Boxes with Tuya-based app control show 38% lower return rate; consumers perceive higher value even when hardware is identical.

- Supply-chain insurance: Lock resin & MCU pricing for 6-9 months; automatic litter boxes use 11% more ABS per kg than feeders—any resin spike instantly erodes margin.

- Certification package upfront: Major U.S. retailers now demand full FCC/CE files at PO stage; budget US$18k once instead of scrambling during your first container inspection.

Bottom line: In a market racing toward US$2.5 B by 2031, quality and connected features are no longer premium—they are the baseline for staying listed on Amazon, Chewy, and EU pet chains. Select an OEM partner that treats tooling, SMT, and stress-testing as core competencies, not negotiable add-ons.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Getting your automatic litter box from Shenzhen to Seattle—without customs delays, Amazon charge-backs, or 1-star reviews.

1. Mandatory Certifications for USA & EU Entry

| Jurisdiction | Certificate | Scope / Clause | Typical Lab | Lead Time* | Cost (USD) | Risk If Skipped |

|---|---|---|---|---|---|---|

| USA | FCC Part 15B & 15C | Wi-Fi / BLE emissions & immunity | Intertek, SGS, TÜV | 2 wks | 3–4 k | Amazon listing removed, CBP seizure |

| USA | UL / ETL (optional but buyer-driven) | Electrical safety 62368-1 | UL, TÜV | 4 wks | 8–10 k | Retailer refusal, insurance void |

| USA | FDA Food-Grade | Waste tray polymer & anti-stick coating | SGS, Bureau Veritas | 3 wks | 2 k | Pet-toxicity claim, class-action |

| EU | CE (LVD, EMC, RED, RoHS, REACH) | Full safety & chemical dossier | TÜV, SGS | 3–4 wks | 6–8 k | Customs detention, €10 k fine |

| EU | RoHS & REACH SVHC | 10 restricted substances + 235 SVHC | SGS, Intertek | 1 wk / annual | 1 k | RAPEX public alert, recall |

| EU | WEEE Registration | End-of-life recycling | National bodies | 2 wks | 500–1 k/year | German marketplaces block SKU |

*Lead time = calendar weeks once golden sample is received; assume parallel testing to compress critical path.

Pro tip: Bundle FCC + CE + RoHS into one “global safety pack” with a Shenzhen-based NRTL lab; saves 10 days and ~15 % cost versus splitting geography.

2. Amazon FBA Packaging & Prep Specifications

Amazon’s 3-foot drop test (ISTA-6) is non-negotiable for oversize items (>18” on any side). Automatic litter boxes average 24 × 16 × 12”, 16 kg—well inside oversize tier.

| Checkpoint | Amazon Rule | Engineering Fix (OEM) | Cost Impact |

|---|---|---|---|

| Drop-test 6-face, 8-corner | ≤ 5 cm dent, no functional damage | 5-layer 200 lb test carton + molded EPP corner blocks | +$1.80/unit |

| “Frustration-Free” opening | <120 s, no box cutters | Die-cut tear strip, 2-sided tape pull | +$0.40/unit |

| Poly-bag suffocation | >125 μm, warning label if opening ≥5” | Pre-bagged litter drawer separately | +$0.25/unit |

| FNSKU & Made-in-China | 2-sided scannable, ≥10 mm quiet zone | Pre-print in outer artwork—avoid stickering station | –$0.15/unit |

| Stacking height 108” pallet | Max 50 lb/carton, 4-way entry pallet | Split into 2-carton master pack (8 kg each) | +$0.60/unit |

Add ~2 cm air gap around litter chamber to absorb vibration from drive motor; we’ve seen 30 % reduction in “noisy motor” returns after foam insert.

3. Shenzhen Manufacturing Lead-Time Reality Check

| Milestone | Calendar Days | Buffer Strategy |

|---|---|---|

| Tooling for 30 k unit MOQ | 35–40 | Use DFM-ready ID + family molds; parallel CNC for non-appearance parts |

| EVT (15 units) | 12 | Build in-house at CM; fast firmware OTA via Tuya SDK |

| DVT (100 units) | 18 | Include certification samples—avoids re-run |

| PVT (500 units) | 14 | Line pilot on 1 shift; Amazon “test buy” units pulled here |

| Mass production | 20–25 | 2 SMT lines + 1 final assembly line = 3 k units/day |

| Sea freight (Shenzhen–LA) | 14 + 5 customs | Book 1 week pre-CNY, premium 40’HQ to avoid rollings |

| Air freight backup | 3–5 | Use for Prime Day top-up; budget $4.20/kg volumetric |

Total program: 115–125 days from PO to FBA check-in.

Smart-feature dependency: Tuya module (TYZS3) is off-the-shelf in Huaqiangbei; 3-week firmware freeze keeps schedule intact.

4. Supply-Chain Stability Playbook

- Dual-source critical ASICs (motor driver & weight sensors); second source validated during DVT.

- Lock resin price for ABS+PC blend 45 days; Shenzhen spot has swung 18 % in 2024.

- QMS overlay: ISO 9001 line + IQC inspection report shared on AQL 1.0/2.5; reduces Amazon defect rate to <0.8 % (category avg 2.3 %).

- ESG audit (SMETA 4-Pillar) now requested by EU pet superstores; schedule during PVT to avoid re-audit cost.

Bottom line: Certification and packaging are not check-boxes—they are part of the product architecture. Bake them into your CM contract up-front, and you’ll hit the 8–12 % annual growth wave without stock-outs or compliance surprises.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize an Automatic Litter Box: From First Sample to Shelf-Ready Carton

1. Request the Right Sample—Not Just Any Sample

The fastest way to burn six weeks and US$1,200 is to order a “standard” sample that does not reflect your market’s power rating, clumping litter density, or APP ecosystem. Instead, send the OEM a one-page Product Target Card (PTC) before any unit leaves the factory.

| PTC Line Item | North-America Tier-1 Example | EU Eco-Boutique Example |

|---|---|---|

| Rated voltage | 110 V, 60 Hz | 230 V, 50 Hz |

| Odor-control spec | >90 % NH₃ reduction in 30 min (ASTM D5582) | Activated-carbon cassette, REACH compliant |

| IoT platform | Tuya + Matter | Local MQTT, no cloud |

| Safety cert. pre-requirement | ETL, FCC | CE, RoHS, ERP Tier-2 |

| Max unit weight (Amazon FBA) | 5.0 kg in mailbox-ready pack | 6.0 kg in brown kraft, plastic-free |

Ask the supplier to confirm in writing that the hand-built A-sample already uses the identical motor, reducer, and IR sensor part numbers that will appear on the final BOM. Any deviation >5 % torque or >50 mA standby current triggers an automatic B-sample loop—at factory cost, not yours.

2. Lock Customization in 3 Parallel Tracks—Logo, Packaging, Firmware

Experienced vendors such as PAWBILT run these tracks concurrently to save 18–21 days on your critical path.

Track A: Industrial Design Freeze

Logo & Color: Double-shot ABS or IML (in-mold label) gives 2-year UV fade resistance; spray-coated PC is cheaper but will show claw scratches in <6 months.

Tooling modification: If you need a top-deck recess for a private-label treat dispenser, budget US$8–12 k for an interchangeable mold insert instead of a brand-new tool.

Track B: Retail-Ready Packaging

Amazon SIOC (Tier A) and European 6-drop ISTA-6 are non-negotiable. Specify:

5-ply reinforced E-flute, ≤7 % moisture at point of stuffing.

90-degree corner drop test: <1 cm deformation on the waste-drawer guide rail.

QR code linking to firmware update page; factory prints it on the inner sleeve so it survives the unboxing video.

Track C: Smart Feature Stack

Most 2025 SKUs launch on Tuya + Matter dual-stack. Insist on:

OTA partition size ≥1.5× current firmware to allow rollback.

Wi-Fi module whitelist (Realtek, Espressif) already on Amazon’s “Frustration-Free Setup” list—this alone shortens Works-With-Alexa certification by 3 weeks.

3. Pilot Run (20–100 pcs): The Moment of Truth

Use a two-gate protocol:

| Gate | Focus | Accept / Reject Criterion |

|---|---|---|

| Gate-1: Line capabilities | CpK ≥1.67 on torque of rake arm, <0.3 % cat-weight sensor drift | If fail, full root-cause & re-run at factory cost |

| Gate-2: Customer equivalent | 48-hr pet-in-home simulation with silica, bentonite, tofu litters | Clog rate ≤1 per 100 cycles; App connectivity loss ≤1 % of sessions |

Ship pilot units via air to your 3PL so the same cartons undergo both Amazon drop tests and real-world warehouse scanning; any barcode mis-read >0.5 % triggers a packaging revision before mass production.

4. Why a One-Stop Partner Beats “Aggregator” Factories

Automatic litter boxes have four critical subsystems—mechanical rake, load-cell weight sensing, UV/ozone deodorizer, and IoT board—usually spread across three provinces. A turnkey OEM such as PAWBILT vertically integrates:

Brushless DC motor line (Suzhou) + sheet-metal fabrication (Ningbo) under one ERP, giving 14-day component visibility instead of the usual 45.

In-house IoT lab pre-certified for FCC/CE, slashing external lab queue from 6 weeks to 10 days.

bonded warehouse in Shenzhen airport for 72-hour UPS Saver replenishment to US East-Coast—crucial when TikTok-driven demand spikes 300 % overnight.

5. Sourcing Roadmap at a Glance

| Week | Milestone | Deliverable |

|---|---|---|

| 0 | Send PTC + NDA | Confidentiality signed, quote 48 hrs |

| 1-2 | A-sample & spec review | Functional sign-off |

| 3-4 | Logo/pack/firmware freeze | Artwork locked, tool path started |

| 5-6 | Pilot run & 2-gate report | 100 pcs, CpK, ISTA pass |

| 7-10 | Mass production | 1×40’HQ in 18 days, 98 % OTD |

| 11 | Ship-to-FBA | Pallet-label compliant, ICS2 entry filed |

Follow the sequence, insist on measurable gates, and partner with a manufacturer that already ships 200 k smart litter boxes per year. You will move from first e-mail to first Amazon review in under 12 weeks—while competitors are still debugging their rake-gear torque.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label automatic litter box business opportunities business.