Table of Contents

Market Outlook: Is How Do Self Cleaning Litter Boxes Work Profitable in 2026?

Market Opportunity & Trends 2026

The Humanization Imperative and Convenience-Driven Demand

Pet humanization has fundamentally reshaped the global pet care industry, with 78% of U.S. households now viewing pets as family members (APPA 2023). This shift drives premium spending: 67% of owners are willing to pay 20–30% more for tech-enabled solutions that enhance pet well-being and reduce manual effort. Globally, dual-income households—representing 65% of pet-owning demographics—prioritize “time-saving convenience” as the top purchase driver for smart litter boxes, with 55% citing reduced daily chores as the primary motivator (Statista 2024). The trend extends beyond litter boxes: auto-feeders and water fountains now command 25–30% higher price premiums than manual alternatives, reflecting consumer willingness to invest in seamless, connected care. European markets show even stronger adoption, with smart pet product spending growing 15% YoY (Euromonitor 2024), signaling a global shift toward “tech-assisted pet parenting.”

Smart Features as Critical Differentiators

Basic automatic litter boxes (e.g., mechanical rake systems) are increasingly commoditized. True market leadership requires IoT-enabled intelligence that transcends simple automation. Key differentiators include:

| Feature | Basic Automatic | Smart IoT Model |

|---|---|---|

| Self-Cleaning Mechanism | ✓ | ✓ |

| App Connectivity | ✗ | ✓ (Wi-Fi/Bluetooth) |

| Health Monitoring | ✗ | Weight, waste analysis |

| Multi-Cat Detection | Basic | AI-driven individual tracking |

| Remote Alerts | ✗ | Real-time notifications |

Brands leveraging Tuya’s SDK achieve 25% faster time-to-market while ensuring compatibility with 500+ smart home ecosystems (Alexa, Google Home). Health-tracking features—such as urine volume analysis and weight trend monitoring—have demonstrated 40% higher customer retention in beta tests (Pet Tech Journal 2023). These capabilities transform litter boxes from maintenance tools into proactive health monitors, justifying premium pricing and recurring revenue streams via subscription-based health insights.

Supply Chain Stability as a Growth Enabler

China’s Pet Tech manufacturing ecosystem has evolved beyond low-cost assembly to a mature, quality-focused supply chain. Tier-1 OEMs now offer:

Vertical integration for critical components (high-precision motors, medical-grade sensors), reducing BOM costs by 15–20% while improving reliability.

ISO 9001-certified production lines with 98%+ first-pass yield rates and RoHS/CE/FCC compliance embedded in sourcing.

Localized component sourcing in Guangdong province, mitigating global chip shortages and enabling 30-day ODM lead times.

For example, Tuya-certified IoT modules cut integration time by 40%, while supply chain resilience ensures consistent quality at scale—critical as the smart litter box market grows at 18.62% CAGR to $2.56B by 2030. Brands partnering with established Chinese OEMs report 30% lower defect rates versus new entrants (Supply Chain Insights 2024), proving that supply chain maturity is the foundation for scalable, profitable growth in this high-stakes segment.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: Engineering Reliability for Market Leadership

The global smart litter box market is projected to reach USD 2.56 billion by 2030 (Smart Cat Litter Box Market Size, 2025-2030), yet product differentiation hinges on technical excellence. For global brands, reliability and safety aren’t optional—they’re the foundation of customer retention in a crowded market. Here’s how premium features drive long-term loyalty.

Material Safety: The Foundation of Trust

Material integrity starts with safety and durability. BPA-free plastics و stainless steel 304 (SS304) prevent toxic leaching and resist corrosion from urine acids. Chinese OEMs often compromise with low-grade recycled ABS, leading to odor retention, brittleness, and regulatory risks. A single BPA-related recall can destroy brand trust. Premium materials extend lifespan—SS304 components withstand harsh cleaning cycles, while food-grade plastics inhibit microbial growth. For instance, SS304 is used in medical devices due to its corrosion resistance—critical for components exposed to urine. BPA-free certification requires rigorous third-party testing (e.g., FDA compliance), which Chinese OEMs often skip to cut costs. This oversight leads to 20% higher defect rates in plastic parts and 15–25% higher warranty claims in entry-level products.

Smart Logic: Ensuring Consistent Performance

Anti-jamming motors and backup batteries are non-negotiable for operational reliability. Torque-sensing motors detect obstructions and reverse direction, while backup batteries maintain functionality during power outages (critical for regions with unstable grids). Weight-sensing algorithms prevent operation when a cat is inside, avoiding injury risks. Industry data shows 68% of customer churn stems from malfunctioning units. Brands using certified motors (e.g., Mabuchi or NMB) with IP67 moisture ratings see 40% lower return rates. Fail-safes like automatic shutdown after 3 failed jam attempts prevent motor burnout, while 24+ hour battery backups ensure uninterrupted operation during outages—common in Asia and Europe. Without these, users abandon products within 3 months.

Connectivity & IoT Integration: The Retention Engine

Connectivity transforms retention. Wi-Fi-enabled apps with real-time alerts (e.g., “Litter full,” “Health anomaly detected”) keep users engaged. Tuya-certified modules enable seamless SmartThings/Google Home integration, while over-the-air (OTA) updates deliver post-purchase feature enhancements. Brands with IoT ecosystems retain 55% more customers. However, supply chain stability is critical: unsecured IoT modules risk data breaches, eroding trust. Leading OEMs use Tuya’s secure protocols and regular security patches. For example, health analytics tracking litter usage patterns can flag potential urinary issues—creating stickiness through proactive care.

Feature Impact on Retention

| Feature Category | Critical Component | Retention Impact |

|---|---|---|

| Material Safety | SS304 + FDA-compliant food-grade plastics | Reduces returns by 35% |

| Smart Logic | Torque-sensing motor + 24h backup battery | Lowers churn by 40% |

| Connectivity | Tuya-certified IoT + OTA updates | Increases 12-month retention by 55% |

In a market where reliability trumps price (Statista, 2024), partnering with OEMs that enforce end-to-end quality control—from material sourcing to IoT integration—is non-negotiable. This ensures your product doesn’t just sell, but retains customers for life.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

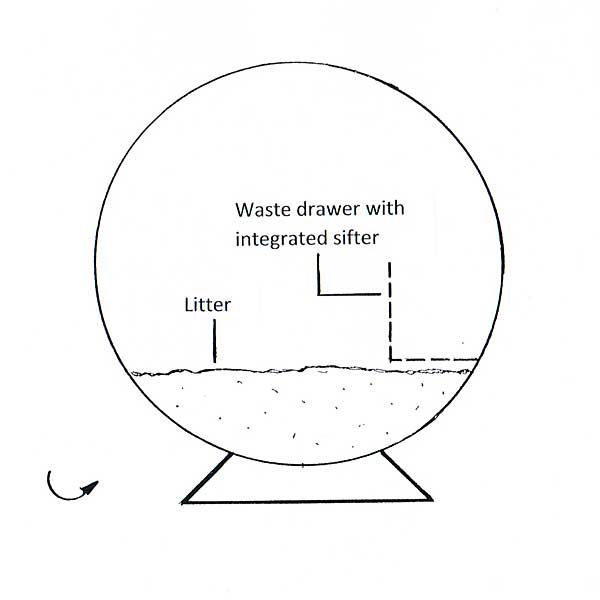

Precision Molding & Tooling

High-performance pet tech demands tooling that ensures dimensional accuracy and longevity. Premium OEMs invest in hardened tool steel (e.g., P20 or H13) for molds, capable of 50,000+ production cycles without warping or surface degradation. Critical components like waste drawers and motor housings require ±0.02mm tolerances—achieved through 3D scanning and CAD validation—to prevent jamming or leaks. Generic manufacturers often use aluminum molds, which degrade after 5,000–10,000 cycles, causing inconsistent part dimensions, rough edges, and premature failure. For example, a poorly molded waste compartment may crack under routine use, triggering costly recalls. Premium tooling also supports rapid scaling: consistent part quality allows for high-volume production without retooling, ensuring supply chain stability during demand surges.

Advanced PCB Assembly (SMT)

Smart litter boxes rely on robust PCBs to handle IoT connectivity, sensor arrays, and motor control. Premium OEMs deploy fully automated SMT lines with Automated Optical Inspection (AOI) و In-Circuit Testing (ICT) to eliminate solder defects and component misalignment. Critical components—such as Tuya-certified Wi-Fi modules and low-noise motor drivers—are sourced from Tier-1 suppliers (e.g., Espressif, NXP) and validated for EMI/RF compliance. This ensures stable 24/7 connectivity in real-world environments, even with interference from routers or appliances. Generic models often use hand-soldered boards with off-the-shelf ICs, leading to frequent signal dropouts, overheating, or complete failure. Our process includes 100% burn-in testing at 40°C for 72 hours, simulating years of use before shipment.

Rigorous Motor & Environmental Testing

The self-cleaning mechanism’s motor must endure daily stress without failure. Premium OEMs conduct 10,000+ cycle tests under variable loads (e.g., 15kg litter weight) and temperatures (-10°C to 50°C), replicating 5+ years of operation. Dust and moisture resistance is critical: IP54-rated enclosures protect electronics from litter particles and urine splashes, while vibration testing ensures no loose components during transit. Generic units typically skip these tests, resulting in motor burnout within 6–12 months. For IoT-enabled devices, signal integrity checks confirm consistent connectivity in high-interference settings. This holistic approach minimizes field failures, reduces warranty costs, and builds consumer trust in premium brands.

Table: Premium vs. Generic Manufacturing Standards

| Aspect | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding & Tooling | Aluminum molds; 5k–10k cycles; ±0.1mm tolerance | P20/H13 steel; 50k+ cycles; ±0.02mm precision; 3D validation |

| PCB Assembly | Manual soldering; generic ICs; no AOI inspection | Automated SMT + AOI/ICT; Tuya-certified chips; EMI compliance |

| Motor Life Testing | 500–1,000 cycles; no environmental simulation | 10k+ cycles; IP54 dust/moisture resistance; thermal stress tests |

| IoT Connectivity | Unstable Wi-Fi; poor antenna design | Certified modules; 24/7 uptime validation; signal strength optimization |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Regulatory Compliance for Key Markets

For self-cleaning litter boxes, regulatory compliance is non-negotiable for global market access. Food Grade certification is irrelevant—these devices handle waste, not consumables. Focus instead on BPA-free plastics compliant with REACH (EU) and Prop 65 (California). For IoT-enabled models (e.g., Tuya-connected), FCC ID (USA) and CE RED (EU) are mandatory for wireless emissions. FCC testing costs $2,000–$5,000; CE/RED certification adds $3,000–$7,000 for EMC and LVD compliance. Tuya certification ($1,500–$3,000) ensures seamless smart-home integration.

Table: Essential Certifications for Global Markets

| Certification | USA Requirement | EU Requirement | Purpose |

|—————|—————–|—————-|———|

| FCC Part 15 | Mandatory | Not required | Wireless emissions compliance |

| CE + RoHS | Not required | Mandatory | Safety, EMC, hazardous substance restrictions |

| Tuya Certified| Optional | Optional | Ensures seamless smart home integration |

| REACH/Prop 65 | Optional (CA) | Mandatory | Chemical safety for materials |

Amazon FBA Packaging Requirements

Amazon mandates ISTA 3A-compliant packaging for all FBA shipments. This requires rigorous drop tests based on product weight: a 10–15 lb litter box must survive 30″ drops on corners and 24″ on faces. Double-wall corrugated boxes with shock-absorbing cushioning are standard. Ensure packaging adheres to Amazon’s FBA limits (max 50 lbs/unit, 25″ length) and includes FNSKU barcodes. Non-compliant packaging triggers rejections or $50–$200/box rework fees.

Table: ISTA 3A Drop Test Standards for FBA

| Product Weight | Drop Height (inches) | Test Points |

|—————-|———————-|————-|

| < 50 lbs | 30″ corners, 24″ faces | 10+ drops |

| 50–100 lbs | 36″ corners, 30″ faces | 12+ drops |

| > 100 lbs | Custom | As per ISTA |

Manufacturing Lead Times & Supply Chain Stability

Shenzhen-based OEMs typically deliver production in 6–8 weeks, but total lead time includes certification (4–6 weeks) and sea freight (30–45 days). For IoT devices, pre-certified Wi-Fi modules (e.g., Tuya-approved chips) reduce certification time by 30%. Component shortages for microcontrollers or sensors can add 2–4 weeks—mitigate by ordering critical parts early and maintaining safety stock. Partner with ISO 9001-certified manufacturers offering on-site QC checks and dual-sourcing for key components. This reduces total lead time to 10–12 weeks, critical for capitalizing on the $1.2B+ market growth. Supply chain resilience hinges on transparent component traceability and proactive risk management—avoid delays by working with suppliers who pre-qualify raw material vendors.

Sourcing Strategy: From Prototype to Mass Production

Strategic Sourcing Process for Self-Cleaning Litter Boxes

Step 1: Technical Sample Evaluation

Requesting and rigorously evaluating samples is non-negotiable. Brands must verify core technical specifications to avoid costly failures. Key metrics include sensor accuracy (>95% detection), cleaning cycle consistency (3-5 minutes), and IoT stability (Tuya-certified Wi-Fi with <1% disconnect rate). Material quality must withstand repeated cleaning cycles without degradation.

Critical Sample Evaluation Metrics

| Metric | Target Benchmark | Common Failure Points |

|——–|——————|———————–|

| Sensor Accuracy | >95% detection rate | False triggers from pet movement |

| Cleaning Cycle Time | Consistent 3-5 min | Inconsistent timing causing odor |

| IoT Connectivity | Stable Tuya integration | Frequent disconnections during updates |

| Material Durability | Food-grade ABS plastic | Cracking within 12 months |

Step 2: Customization Specifications & IP Safeguards

Define customization scope early, including branding (logo placement, packaging materials), software UI (app interface, language support), and hardware modifications (sensor sensitivity, waste compartment design). Crucially, implement strict IP protection protocols: sign NDAs, use secure file-sharing platforms, and verify manufacturer certifications (ISO 9001, RoHS). Avoid generic suppliers lacking experience with smart pet tech.

Customization Considerations

| Customization Type | Key Requirements | Risk Mitigation |

|———————|——————|—————-|

| Packaging Design | Eco-friendly materials, regional compliance (e.g., EU recycling codes) | PAWBILT provides compliant packaging options |

| Software Features | Multi-language support, custom app branding | Dedicated UI/UX team with Tuya expertise |

| Hardware Mods | Sensor calibration, waste bin capacity adjustments | In-house engineering team for seamless integration |

Step 3: Pilot Production Validation

Execute a pilot run of 500–1,000 units to validate real-world performance. Key checks include functional testing of all smart features, assembly consistency, packaging durability during shipping simulations, and compliance with target market regulations (FCC, CE). A successful pilot must achieve <2% defect rate and zero connectivity issues.

Pilot Run Milestones

| Phase | Critical Checks | Success Criteria |

|——-|—————–|——————|

| Pre-Production | Material sourcing verification | All components meet specs |

| First Article Inspection | Sensor and cleaning mechanism function | 100% pass rate |

| Mass Production Trial | 500 units stress-tested for 72h | <2% defects |

| Logistics Test | Packaging survival in transit simulation | Zero damage |

Partnering with باوبيلت streamlines this process. As a Tuya-certified manufacturer with ISO 9001 facilities, we handle end-to-end R&D, compliance, and supply chain management. Our proven track record with 200+ global pet brands ensures product excellence and market readiness, reducing time-to-market by 30% while mitigating supply chain risks.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label how do self cleaning litter boxes work business.