Introduction: Navigating the Global Market for fountain plastic

In today’s competitive landscape, sourcing high-quality fountain plastic can be a daunting task for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable suppliers but also in understanding the various types, applications, and costs associated with fountain plastics. This guide is designed to equip buyers with the knowledge necessary to navigate this complex market effectively.

Throughout this comprehensive guide, we will explore the different types of fountain plastics available, including tiered, wall-mounted, and decorative designs, as well as their practical applications in residential and commercial settings. We’ll delve into critical factors such as supplier vetting processes, ensuring that buyers can identify trustworthy partners who meet their quality and ethical standards. Additionally, we will provide insights into pricing strategies, helping buyers understand the cost implications and how to optimize their purchasing decisions.

By leveraging the information presented in this guide, B2B buyers from regions like Brazil and Nigeria can make informed choices that align with their business needs and sustainability goals. Whether you are enhancing outdoor spaces with aesthetic features or seeking durable materials for large-scale installations, this guide serves as a valuable resource to help you succeed in the fountain plastic market.

Table Of Contents

- Top 5 Fountain Plastic Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fountain plastic

- Understanding fountain plastic Types and Variations

- Key Industrial Applications of fountain plastic

- 3 Common User Pain Points for ‘fountain plastic’ & Their Solutions

- Strategic Material Selection Guide for fountain plastic

- In-depth Look: Manufacturing Processes and Quality Assurance for fountain plastic

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fountain plastic’

- Comprehensive Cost and Pricing Analysis for fountain plastic Sourcing

- Alternatives Analysis: Comparing fountain plastic With Other Solutions

- Essential Technical Properties and Trade Terminology for fountain plastic

- Navigating Market Dynamics and Sourcing Trends in the fountain plastic Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fountain plastic

- Strategic Sourcing Conclusion and Outlook for fountain plastic

- Important Disclaimer & Terms of Use

Understanding fountain plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tiered Fountains | Multiple levels, cascading water flow | Landscaping, public parks, commercial spaces | Pros: Aesthetic appeal, enhances ambiance. Cons: Requires regular maintenance to prevent clogging. |

| Solar-Powered Fountains | Operates on solar energy, eco-friendly | Outdoor settings, eco-conscious businesses | Pros: Low operating cost, sustainable. Cons: Performance can be affected by weather conditions. |

| Wall Fountains | Mounted on walls, space-efficient | Urban settings, small gardens | Pros: Space-saving, unique design options. Cons: Limited water capacity and flow. |

| Birdbath Fountains | Combines birdbath with fountain functionality | Gardens, wildlife-friendly businesses | Pros: Attracts wildlife, dual functionality. Cons: May require additional cleaning and maintenance. |

| Tabletop Fountains | Small, portable designs, often decorative | Indoor settings, offices, retail displays | Pros: Easy to install and relocate. Cons: Limited water capacity and impact. |

What Are the Characteristics of Tiered Fountains?

Tiered fountains are characterized by their multiple levels that create a cascading water effect. They are often used in landscaping projects, public parks, and commercial spaces to enhance aesthetic appeal. These fountains can serve as focal points in outdoor designs, adding elegance and tranquility. However, B2B buyers should consider the maintenance requirements, as debris can clog the pumps and hinder functionality.

How Do Solar-Powered Fountains Benefit Businesses?

Solar-powered fountains utilize renewable energy, making them an eco-friendly choice for outdoor settings. Ideal for businesses that prioritize sustainability, these fountains can significantly reduce operating costs. They are particularly suited for gardens and parks in sunny regions. However, potential buyers should be aware that their performance can fluctuate based on weather conditions, which may limit water flow during cloudy days.

Why Choose Wall Fountains for Urban Settings?

Wall fountains are designed to be mounted on vertical surfaces, making them a perfect solution for urban environments where space is limited. They add a unique visual element to small gardens or patios and can be used in commercial settings such as restaurants or hotels. While they offer a distinct aesthetic, buyers should note that their water capacity and flow may be less than larger freestanding models, which could affect their impact.

Illustrative image related to fountain plastic

What Makes Birdbath Fountains a Unique Option?

Birdbath fountains combine the functionality of a birdbath with that of a traditional fountain, making them an attractive option for businesses focused on wildlife-friendly landscaping. These fountains not only enhance the beauty of gardens but also provide a habitat for birds and other wildlife. While they offer dual functionality, maintenance is crucial to keep the water clean and attract birds effectively.

How Do Tabletop Fountains Fit into Business Environments?

Tabletop fountains are compact, portable, and often used as decorative pieces in indoor settings such as offices and retail displays. Their small size allows for easy installation and relocation, making them a versatile option for businesses looking to enhance their interiors. However, potential buyers should consider their limited water capacity and the subtle impact they have compared to larger outdoor fountains.

Key Industrial Applications of fountain plastic

| Industry/Sector | Specific Application of Fountain Plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Landscaping and Garden Design | Outdoor decorative fountains | Enhances aesthetic appeal and property value | Durability, UV resistance, and ease of installation |

| Hospitality and Tourism | Water features in hotels and resorts | Creates a relaxing atmosphere for guests | Design variety, maintenance requirements, and cost-effectiveness |

| Retail and Commercial Spaces | Indoor and outdoor fountains for shopping centers | Attracts customers and enhances shopping experience | Size, style compatibility, and water circulation efficiency |

| Pet Care and Veterinary Services | Pet drinking fountains made of fountain plastic | Promotes pet hydration and health | Safety standards, ease of cleaning, and filter options |

| Event Planning and Design | Temporary water features for events | Adds visual interest and ambiance | Portability, ease of setup, and rental options |

How is Fountain Plastic Used in Landscaping and Garden Design?

In landscaping, fountain plastic is primarily utilized for creating outdoor decorative fountains that enhance the aesthetic appeal of gardens and parks. These fountains come in various designs, such as tiered or wall-mounted options, which can complement the natural surroundings. For international buyers, particularly in regions like Africa and South America, sourcing durable and UV-resistant plastics is crucial to withstand varying climates and ensure longevity. Additionally, the ease of installation and maintenance can significantly reduce labor costs, making fountain plastic an attractive option for landscaping businesses.

Illustrative image related to fountain plastic

What Role Does Fountain Plastic Play in Hospitality and Tourism?

In the hospitality sector, particularly in hotels and resorts, fountain plastic is often used for water features that create a serene and inviting atmosphere. These fountains can be installed in lobbies, courtyards, or pool areas, contributing to a tranquil environment that enhances guest experiences. For buyers in the Middle East and Europe, selecting designs that align with cultural aesthetics while ensuring the materials are weather-resistant is essential. The ability to create custom designs can also be a significant selling point for hospitality businesses looking to differentiate themselves.

How Can Retail Spaces Benefit from Fountain Plastic?

Retail and commercial spaces leverage fountain plastic for both indoor and outdoor water features, which serve to attract customers and enhance the shopping experience. Fountains can be strategically placed at entrances or within malls to provide a focal point that encourages foot traffic. For B2B buyers, considerations such as size, style compatibility with existing decor, and water circulation efficiency are vital. Sourcing suppliers that offer a range of customizable options can help retailers create unique environments that resonate with their target audience.

Why is Fountain Plastic Important in Pet Care and Veterinary Services?

Fountain plastic is increasingly popular in the pet care industry, particularly for creating drinking fountains designed to keep pets hydrated. These products are made from safe, non-toxic materials and often include filters to ensure water quality. For veterinary services, sourcing fountains that are easy to clean and maintain is critical for hygiene. Buyers should also consider the durability of the materials, especially for high-traffic environments, ensuring that the fountains can withstand daily use while promoting the health of pets.

How is Fountain Plastic Utilized in Event Planning and Design?

In event planning, temporary water features made from fountain plastic can significantly enhance the visual appeal of gatherings, weddings, or corporate events. These portable fountains can be easily set up and taken down, making them an ideal choice for event organizers looking to create a memorable atmosphere. For B2B buyers, considerations around portability, ease of setup, and rental options are important. Ensuring that the materials used are lightweight yet durable can help event planners manage logistics effectively while delivering impactful experiences.

3 Common User Pain Points for ‘fountain plastic’ & Their Solutions

Scenario 1: The Challenge of Durability in Varied Climates

The Problem: B2B buyers, particularly those in regions with extreme weather conditions such as the Middle East or Southern Africa, often find that plastic fountains are not as durable as expected. These fountains may warp, fade, or crack due to intense heat or UV exposure. This leads to increased replacement costs and dissatisfaction from end-users who expect long-lasting outdoor decor. Additionally, the initial investment may seem appealing, but ongoing maintenance and replacements can significantly impact the total cost of ownership.

Illustrative image related to fountain plastic

The Solution: To mitigate these issues, buyers should prioritize sourcing high-quality, UV-resistant plastics specifically designed for outdoor use. When evaluating suppliers, look for those who offer warranties that cover climate-related damage. Request samples to test under actual environmental conditions before making bulk purchases. Furthermore, incorporating additional protective coatings or treatments can enhance the longevity of the fountains. For instance, sourcing fountains with a dual-layer construction or those treated with UV stabilizers can provide added assurance against the elements. Educating clients on proper installation techniques, such as securing the fountain in a shaded area during peak sunlight hours, can also extend its lifespan.

Scenario 2: Complexity in Sourcing Replacement Parts

The Problem: Another common issue B2B buyers face is the difficulty in sourcing replacement parts for plastic fountains, such as pumps and filters. Many suppliers do not stock spare parts, leading to extended downtime when repairs are needed. This can frustrate businesses that rely on these fountains for aesthetic appeal or functional purposes, such as attracting wildlife or creating a soothing environment. A lack of readily available parts can also result in increased costs, as buyers may need to replace entire units rather than just the faulty component.

The Solution: To address this pain point, B2B buyers should establish relationships with suppliers that not only provide the fountains but also a comprehensive range of compatible replacement parts. When negotiating contracts, include clauses for part availability and support. Additionally, consider implementing a proactive maintenance schedule that includes regular checks on pumps and filters, allowing for early detection of issues. Creating an inventory of essential spare parts on hand can also reduce downtime significantly. Leveraging suppliers that offer warranties on components can further enhance reliability, ensuring that businesses can maintain their fountains without interruption.

Scenario 3: Navigating Aesthetic Versus Functional Needs

The Problem: Many B2B buyers struggle with the balance between aesthetics and functionality when selecting plastic fountains. Clients may desire visually appealing designs that enhance their landscaping but often do not consider the practical implications, such as maintenance and water flow rates. Poorly designed fountains can lead to operational issues, including insufficient water circulation or excessive noise, which can detract from the intended ambiance. This misalignment can result in customer dissatisfaction and impact repeat business.

The Solution: To bridge the gap between aesthetics and functionality, buyers should engage in thorough consultations with their clients to understand their specific needs and expectations. Providing educational resources on the importance of water features’ functionality can help guide clients towards more suitable choices. Offer a selection of fountains that combine attractive designs with proven operational efficiency, such as those equipped with adjustable flow rates or energy-efficient pumps. Additionally, consider creating visual mock-ups or using augmented reality tools to help clients visualize how various options will fit into their landscape. By prioritizing both beauty and practicality, businesses can ensure that their fountain selections will meet customer satisfaction and operational requirements effectively.

Strategic Material Selection Guide for fountain plastic

When selecting materials for fountain plastics, it is crucial for B2B buyers to consider the specific properties, advantages, and limitations of various plastics. Here, we analyze four common materials used in fountain production: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), and Acrylonitrile Butadiene Styrene (ABS). Each material has unique characteristics that can significantly impact performance and suitability for different applications.

What are the Key Properties of Polyethylene (PE) for Fountain Plastics?

Polyethylene is known for its excellent chemical resistance and durability. It can withstand a wide temperature range, typically from -50°C to 80°C, making it suitable for various climates. PE is also lightweight, which simplifies transportation and installation. However, it may not be as UV resistant as other materials, which can lead to degradation when exposed to direct sunlight over time.

Pros: PE is cost-effective, easy to mold, and has good impact resistance. Its flexibility allows for various designs, making it a popular choice for decorative fountains.

Cons: The primary drawback is its susceptibility to UV damage, which may necessitate additional treatments or coatings for outdoor applications.

How Does Polypropylene (PP) Compare in Fountain Applications?

Polypropylene offers a slightly higher temperature resistance than PE, withstanding temperatures up to 100°C. It is also resistant to many chemicals, making it ideal for applications involving water treatments. PP has good tensile strength, which contributes to its durability in outdoor settings.

Pros: Its resistance to fatigue and stress cracking makes PP suitable for moving parts in fountains, such as pumps and nozzles.

Cons: The cost of PP can be higher than PE, and it may require more complex manufacturing processes, which can impact production timelines.

What are the Advantages of Using Polyvinyl Chloride (PVC) in Fountain Design?

PVC is widely used in fountain applications due to its excellent weather resistance and durability. It can handle a temperature range of -15°C to 60°C and is inherently resistant to corrosion, making it suitable for various environmental conditions.

Illustrative image related to fountain plastic

Pros: PVC is affordable and readily available, with a variety of finishes and colors that can enhance aesthetic appeal. Its rigidity provides structural integrity, especially in larger fountain designs.

Cons: PVC can be less flexible than other plastics, which may limit design options. Additionally, its production involves the use of additives that can be harmful to the environment, raising concerns for eco-conscious buyers.

Why Choose Acrylonitrile Butadiene Styrene (ABS) for Fountains?

ABS is recognized for its high impact resistance and toughness, making it an excellent choice for outdoor fountains that may experience physical stress. It can withstand temperatures ranging from -20°C to 80°C and offers good UV resistance, which is essential for outdoor applications.

Pros: The aesthetic qualities of ABS allow for a smooth finish and vibrant colors, enhancing the visual appeal of fountains. Its ease of machining and molding makes it suitable for intricate designs.

Illustrative image related to fountain plastic

Cons: ABS is generally more expensive than PE and PP, which may deter budget-conscious buyers. Additionally, it can be less chemical resistant than PVC, limiting its use in certain water treatment applications.

Summary of Material Selection for Fountain Plastics

| Material | Typical Use Case for fountain plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Decorative outdoor fountains | Cost-effective and lightweight | Susceptible to UV damage | Low |

| Polypropylene (PP) | Functional components like pumps | High temperature and chemical resistance | Higher cost and complex manufacturing | Medium |

| Polyvinyl Chloride (PVC) | Structural elements in larger fountains | Excellent weather resistance | Less flexible and environmental concerns | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Aesthetic outdoor fountains | High impact resistance and vibrant colors | Higher cost and limited chemical resistance | High |

In summary, the choice of material for fountain plastics is critical for performance, durability, and aesthetic appeal. International B2B buyers should consider factors such as local climate, compliance with regional standards, and production capabilities when making their selections. Understanding the properties and implications of each material can lead to more informed purchasing decisions that align with both operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for fountain plastic

The manufacturing processes and quality assurance protocols for fountain plastic are critical components for B2B buyers to understand, especially in regions like Africa, South America, the Middle East, and Europe. Fountain plastics are predominantly made from durable materials such as polyethylene and polyvinyl chloride (PVC), selected for their weather resistance and aesthetic appeal. Below is an in-depth exploration of the manufacturing stages, quality control measures, and actionable insights for buyers in the international market.

What Are the Main Stages of Fountain Plastic Manufacturing?

The production of fountain plastic involves several key stages, each critical to ensuring the final product meets quality and performance standards.

Material Preparation: How Are Raw Materials Processed?

The manufacturing process begins with the preparation of raw materials. This stage includes:

-

Material Sourcing: Selecting high-quality plastics that can withstand outdoor conditions is crucial. Suppliers often source materials from reputable manufacturers who provide certifications for the materials used.

-

Compounding: The raw plastic is compounded with additives that enhance properties such as UV resistance, color stability, and impact resistance. This step ensures that the plastic can endure various environmental stresses.

Forming: What Techniques Are Used to Shape Fountain Plastics?

After material preparation, the forming stage shapes the plastic into the desired fountain components. Common techniques include:

-

Injection Molding: This is the most prevalent method for creating complex shapes and designs. Heated plastic is injected into molds where it cools and solidifies. This technique allows for high precision and repeatability.

-

Rotational Molding: For larger, hollow structures, rotational molding is employed. The plastic is placed in a mold and rotated to evenly distribute the material, resulting in a seamless product.

-

Blow Molding: This method is often used for creating lighter components with hollow interiors, such as decorative accents.

Assembly: How Are Components Integrated?

Once the individual components are formed, they are assembled into the final product. This stage may involve:

-

Joining Techniques: Components are typically joined using adhesives, screws, or welds, depending on the design specifications.

-

Quality Checks: During assembly, quality checks are performed to ensure that parts fit correctly and are aligned as per design requirements.

Finishing: What Steps Are Taken for Surface Treatment?

The finishing stage enhances the aesthetic appeal and durability of the fountain plastic. Processes include:

-

Surface Treatment: Techniques such as painting, coating, or texturing can be applied to improve appearance and protect against environmental damage.

-

Final Inspection: A thorough inspection is conducted to assess the quality of the finish and check for any defects that may have occurred during the manufacturing process.

What Quality Assurance Standards Are Relevant for Fountain Plastics?

Quality assurance is paramount in ensuring that fountain plastics meet both safety and performance criteria. Various international standards and industry-specific certifications guide manufacturers.

Which International Standards Should Buyers Be Aware Of?

-

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to deliver consistent quality products.

-

CE Marking: Particularly relevant for products sold in Europe, the CE mark indicates conformity with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards for certain materials used in water features, ensuring they are safe for water use.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into the manufacturing process through several critical checkpoints:

-

Incoming Quality Control (IQC): This initial inspection verifies that the raw materials meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor processes and ensure compliance with quality standards.

-

Final Quality Control (FQC): After assembly, a final inspection is conducted to ensure the finished product meets all design specifications and quality benchmarks.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial for establishing trust and ensuring product reliability.

Illustrative image related to fountain plastic

What Verification Methods Can Be Utilized?

-

Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insight into their quality control processes and adherence to international standards.

-

Quality Control Reports: Requesting detailed quality control reports, including test results and compliance certificates, can help buyers assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspectors to evaluate products before shipment can provide an unbiased assessment of quality and compliance with specifications.

What Nuances Should International Buyers Consider?

Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality assurance:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding local laws regarding material safety and environmental impact is essential.

-

Cultural Considerations: Communication styles and business practices can vary significantly across cultures. Building strong relationships with suppliers can facilitate better quality assurance processes.

-

Logistics and Shipping: Quality can be affected during shipping. Ensuring that suppliers use appropriate packaging and handling methods is crucial to maintaining product integrity.

Conclusion: How Can Understanding Manufacturing and Quality Assurance Impact Your Business?

For B2B buyers in the fountain plastic market, a deep understanding of manufacturing processes and quality assurance protocols is invaluable. By recognizing the importance of material preparation, forming techniques, assembly practices, and finishing processes, buyers can make informed decisions when selecting suppliers. Additionally, being aware of international quality standards and effective verification methods can help mitigate risks and ensure that products meet the necessary specifications for durability and safety. Ultimately, this knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers in the fountain plastic industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fountain plastic’

In the competitive landscape of fountain plastic procurement, understanding the nuances of sourcing is critical for B2B buyers. This guide provides a structured approach to ensure you select the right products and suppliers, facilitating efficient and effective purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing strategy. Consider factors such as the type of fountain (e.g., tiered, wall-mounted), size, material durability, and power source (solar vs. electric). This clarity helps ensure that the products you source meet your project requirements and customer expectations.

Illustrative image related to fountain plastic

Step 2: Research Market Trends and Consumer Preferences

Understanding current market trends is essential for making informed decisions. Investigate popular designs, features, and materials that resonate with your target audience, particularly in regions like Africa, South America, and Europe. This insight will guide your sourcing strategy, ensuring you stock products that appeal to buyers in these diverse markets.

Step 3: Evaluate Potential Suppliers

Before finalizing any partnerships, thorough evaluation of potential suppliers is vital. Request detailed company profiles, product catalogs, and references from existing clients, especially those within your industry. Look for suppliers who demonstrate reliability, quality assurance processes, and a track record of successful deliveries.

- Key Considerations:

- Check for industry certifications that validate quality and compliance.

- Assess their manufacturing capabilities to ensure they can meet your volume requirements.

Step 4: Request Samples for Quality Assessment

Never underestimate the importance of product samples. Request samples from shortlisted suppliers to evaluate the quality, craftsmanship, and functionality of their fountain plastics. This hands-on approach allows you to assess whether the product aligns with your specifications and market expectations.

Step 5: Verify Supplier Certifications

Ensuring that your suppliers adhere to industry standards is crucial for maintaining product quality and compliance. Verify any relevant certifications, such as ISO or environmental standards, which can indicate a commitment to quality and sustainability. This step is particularly important if you are sourcing for markets with stringent regulations.

Illustrative image related to fountain plastic

Step 6: Negotiate Terms and Pricing

Once you have selected your suppliers, it’s time to negotiate terms. Discuss pricing structures, payment terms, and delivery schedules to establish a mutually beneficial agreement. Ensure that you understand the full cost implications, including shipping and potential tariffs, which can affect your overall budget.

Step 7: Establish a Clear Communication Plan

Effective communication is key to a successful sourcing relationship. Set up a communication plan that outlines regular updates, points of contact, and protocols for addressing issues. This will help in managing expectations and ensuring that both parties are aligned throughout the procurement process.

By following these structured steps, B2B buyers can navigate the complexities of sourcing fountain plastic more effectively, ensuring that they make informed decisions that drive business success.

Comprehensive Cost and Pricing Analysis for fountain plastic Sourcing

What Are the Key Cost Components in Fountain Plastic Sourcing?

When sourcing fountain plastics, several cost components must be considered to effectively calculate pricing. The primary cost elements include:

-

Materials: The type of plastic used (e.g., polyethylene, PVC) significantly impacts the cost. High-quality, UV-resistant plastics typically command a higher price due to their durability and longevity.

-

Labor: Labor costs can vary based on the region of production. In areas with higher wage standards, such as parts of Europe, labor costs may be more significant compared to regions like Southeast Asia or Africa.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Efficient production processes can help lower these costs, impacting the final price.

-

Tooling: Custom molds and tooling for specific fountain designs can be a substantial upfront investment. The complexity of the design influences tooling costs—more intricate designs require more investment.

-

Quality Control (QC): Ensuring that the fountains meet quality standards can incur additional costs. Implementing rigorous QC measures is essential to minimize defects and returns, especially for international shipments.

-

Logistics: Transportation costs, including shipping and handling, can vary widely. Factors such as distance, shipping methods, and local tariffs must be accounted for, particularly for international transactions.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary significantly based on market demand, competition, and the supplier’s reputation.

How Do Price Influencers Affect Fountain Plastic Pricing?

Several factors influence the pricing of fountain plastics, particularly for international B2B buyers:

-

Volume/MOQ: Larger orders often qualify for volume discounts. Establishing a minimum order quantity (MOQ) can also lead to better pricing.

-

Specifications and Customization: Customized fountains, whether in design or functionality, typically incur higher costs. Buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO standards) can increase costs but may also enhance product longevity and reduce maintenance needs, contributing to lower Total Cost of Ownership (TCO).

-

Supplier Factors: Established suppliers with a solid track record may command higher prices due to their reliability and quality assurance. New or lesser-known suppliers might offer lower prices but could involve higher risk.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) affects logistics costs and responsibilities. Understanding these terms is crucial for accurate budgeting and risk management.

What Negotiation and Cost-Efficiency Strategies Can Buyers Implement?

To optimize costs and ensure value in fountain plastic sourcing, buyers can adopt several strategies:

-

Negotiate Terms: Engage in negotiations to secure better prices or payment terms. Highlighting long-term partnership potential can incentivize suppliers to offer favorable conditions.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, energy consumption, and longevity. A higher upfront cost may be justified by lower long-term expenses.

-

Explore Local Suppliers: For buyers in regions like Africa and South America, sourcing from local suppliers can reduce logistics costs and lead times. This approach can also support local economies and sustainability efforts.

-

Understand Pricing Nuances: Be aware of regional market conditions that may affect pricing. Currency fluctuations, local regulations, and competitive dynamics can all play a role in the final cost.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices can provide a rough idea of costs, they can vary significantly based on the factors discussed. Buyers should conduct thorough market research and engage in detailed discussions with suppliers to ensure they are getting the best value for their investment in fountain plastics.

Alternatives Analysis: Comparing fountain plastic With Other Solutions

Exploring Alternative Solutions to Fountain Plastic

When it comes to selecting the right materials for outdoor fountains, B2B buyers have several alternatives to fountain plastic. Understanding these options can help organizations make informed decisions based on performance, cost, and specific use cases. This section will provide a comparative analysis of fountain plastic against stone and metal as alternative solutions.

| Comparison Aspect | Fountain Plastic | Stone Fountain | Metal Fountain |

|---|---|---|---|

| Performance | Lightweight, UV resistant, various designs | Durable, natural aesthetic, can crack in extreme weather | Durable, rust-resistant, modern aesthetic |

| Cost | Generally low-cost | Higher initial investment | Mid-range to high cost |

| Ease of Implementation | Easy to install and transport | Requires professional installation | Moderate difficulty, often needs professional help |

| Maintenance | Low maintenance, can discolor over time | Requires sealing and occasional repairs | Moderate maintenance, may need rust treatment |

| Best Use Case | Residential gardens, temporary displays | Commercial landscapes, permanent installations | Urban settings, decorative features |

What Are the Pros and Cons of Stone Fountains?

Stone fountains are renowned for their durability and natural beauty, making them an appealing choice for commercial landscapes or permanent installations. They often provide a sophisticated aesthetic that can enhance the value of properties. However, their higher cost and the need for professional installation can be a barrier for many buyers. Additionally, stone can crack under extreme weather conditions, necessitating repairs that can be costly and time-consuming.

How Do Metal Fountains Compare?

Metal fountains offer a modern aesthetic and are typically rust-resistant, making them suitable for urban environments where they may face exposure to the elements. Their durability makes them a long-term investment; however, the initial cost can be higher than plastic options. Installation can also be more complex, often requiring professional assistance. Maintenance is moderate, as metal fountains may require rust treatment and periodic cleaning to maintain their appearance.

Illustrative image related to fountain plastic

Conclusion: How to Choose the Right Fountain Solution

Selecting the appropriate fountain solution depends on various factors, including the specific environment, budget constraints, and aesthetic preferences. For buyers seeking a cost-effective, low-maintenance option, fountain plastic may be the best choice, especially for temporary setups or residential applications. However, for those looking for durability and an upscale appearance, investing in stone or metal fountains could provide long-term value. Assessing the unique needs of the project, including installation capabilities and maintenance considerations, will guide B2B buyers to the right fountain solution for their requirements.

Essential Technical Properties and Trade Terminology for fountain plastic

What Are the Key Technical Properties of Fountain Plastic?

Fountain plastic is essential for producing durable, aesthetically pleasing, and functional outdoor water features. Understanding its technical properties is crucial for B2B buyers to make informed decisions.

1. Material Grade

The grade of plastic used in fountain construction, typically high-density polyethylene (HDPE) or polyvinyl chloride (PVC), determines the product’s strength, durability, and resistance to environmental factors. For instance, HDPE is known for its excellent impact resistance and UV stability, making it ideal for outdoor applications. Buyers should prioritize high-grade materials to ensure longevity, especially in regions with extreme weather conditions.

2. Tolerance

Tolerance refers to the allowable variation in dimensions during the manufacturing process. In fountain plastic components, maintaining tight tolerances is crucial for ensuring proper fit and function, particularly for parts like pumps and connectors. Poor tolerance can lead to leaks or mechanical failures, resulting in costly repairs and maintenance. Thus, understanding tolerance specifications helps buyers assess the quality of manufacturing.

3. Weight Capacity

This property indicates the maximum load that a fountain structure can support without compromising its integrity. For example, a fountain designed to incorporate additional features like lighting or decorative elements must have adequate weight capacity. Knowing this specification is vital for buyers to ensure that the fountain meets their design requirements and operational expectations.

4. Weather Resistance

Fountain plastics should exhibit weather-resistant properties, such as UV resistance and freeze resistance, to endure outdoor conditions. UV-resistant plastics prevent color fading and degradation from sunlight, while freeze resistance ensures that the fountain remains functional in colder climates. This characteristic is particularly relevant for buyers in regions with diverse climates, ensuring that their investments withstand the test of time.

5. Finish and Aesthetics

The surface finish of fountain plastic can range from matte to glossy, influencing the overall visual appeal of the fountain. High-quality finishes can enhance the product’s aesthetic value, making it suitable for various design themes. Buyers should consider the intended use and environment of the fountain when selecting the finish, as it can significantly impact customer satisfaction.

What Are Common Trade Terms Used in Fountain Plastic Procurement?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to fountain plastic:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company, often the brand owner. In fountain plastic, OEMs produce various components that may be assembled into finished products. Buyers often work with OEMs to customize designs and specifications to meet their unique market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the fountain plastic industry, understanding MOQ is crucial for buyers looking to manage inventory costs. Suppliers may set MOQs based on production runs or material costs, so buyers must balance their needs with supplier requirements to ensure cost-effective procurement.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the context of fountain plastic, an RFQ allows buyers to compare pricing, quality, and delivery terms across multiple suppliers. Crafting a detailed RFQ can lead to better pricing and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers in fountain plastic, particularly when dealing with international suppliers, as it influences overall costs and logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for planning and inventory management. For fountain plastic buyers, knowing lead times helps to align product availability with market demand, reducing the risk of stockouts or excess inventory.

By comprehending these technical properties and trade terms, international B2B buyers can navigate the fountain plastic market more effectively, ensuring they make informed purchasing decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the fountain plastic Sector

What Are the Current Market Dynamics and Key Trends in the Fountain Plastic Sector?

The fountain plastic market is witnessing dynamic growth driven by several global factors. One significant driver is the increasing demand for outdoor decorative elements, particularly in urban and suburban areas across Africa, South America, the Middle East, and Europe. The rise in disposable incomes and urbanization has led consumers to invest more in enhancing their living spaces, including gardens and outdoor areas. Additionally, the trend towards sustainable living is prompting buyers to seek eco-friendly products, including fountains made from recycled or sustainable plastic materials.

Emerging technologies are also reshaping sourcing trends. Smart fountains equipped with IoT capabilities are gaining traction, allowing for remote control and customization of water features. This tech-savvy approach appeals to a younger demographic that values innovation and convenience. Moreover, the rise of e-commerce platforms has made it easier for international B2B buyers to source fountain plastic products from diverse suppliers, streamlining the procurement process.

For buyers from regions like Brazil and Nigeria, understanding local market preferences is crucial. For instance, while European consumers may favor ornate and intricate designs, African markets might lean towards more functional and durable solutions suited for varying climates. As such, adaptability in product offerings is becoming increasingly important for suppliers looking to penetrate these diverse markets.

How Is Sustainability Influencing Sourcing in the Fountain Plastic Sector?

Sustainability has become a pivotal consideration in the sourcing of fountain plastic products. The environmental impact of plastic production is under scrutiny, prompting businesses to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers who implement ethical sourcing methods, focusing on the use of recycled materials and minimizing waste during production.

Moreover, certifications such as ISO 14001 for environmental management and the Global Recycled Standard (GRS) are becoming essential for companies looking to enhance their credibility and appeal to eco-conscious consumers. By choosing products that carry these certifications, B2B buyers can ensure they are contributing to sustainable practices while also meeting market demand for greener options.

Illustrative image related to fountain plastic

Additionally, many manufacturers are exploring bioplastics and other innovative materials that reduce the carbon footprint associated with traditional plastics. This shift not only helps in addressing environmental concerns but also aligns with the growing consumer expectation for brands to demonstrate corporate responsibility.

What Is the Historical Context of the Fountain Plastic Sector?

The fountain plastic sector has evolved significantly over the past few decades. Initially, outdoor fountains were primarily made of stone or metal, which limited their accessibility and affordability. The introduction of plastic as a material in the 1970s revolutionized the industry, making it possible to produce lightweight, durable, and cost-effective fountain options.

As technology advanced, so did the manufacturing processes, leading to a wider variety of styles, sizes, and functionalities. The growth of the DIY market also played a role, as consumers sought easy-to-install solutions for their outdoor spaces. Today, the fountain plastic market is characterized by innovation, with features like solar power integration and smart technology enhancing user experience and functionality.

Understanding this historical context is essential for B2B buyers, as it highlights the ongoing transformation in consumer preferences and the continuous improvement in product offerings. This evolution reflects broader trends in the home and garden sector, where aesthetics, sustainability, and technology converge to meet the demands of modern consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of fountain plastic

-

How do I choose the right plastic fountain supplier for my business?

Selecting the right supplier involves assessing their reputation, product quality, and customer service. Start by researching potential suppliers online and checking reviews from other businesses. Ensure they have experience in international trade, especially with countries in Africa, South America, the Middle East, and Europe. Request samples to evaluate the quality of their products. Additionally, confirm that they comply with relevant safety and environmental regulations, which is crucial for both market acceptance and legal compliance. -

What are the common materials used in plastic fountains?

Plastic fountains are typically made from high-density polyethylene (HDPE), polypropylene, or acrylic. HDPE is durable, UV-resistant, and suitable for outdoor use, making it a popular choice. Polypropylene is lightweight and affordable, while acrylic offers a clear, glass-like finish that can enhance aesthetic appeal. Understanding the material properties will help you select products that meet your durability and design requirements. -

What are the typical minimum order quantities (MOQs) for fountain plastics?

Minimum order quantities can vary widely based on the supplier and specific product. Generally, MOQs for fountain plastics range from 50 to 500 units. Some suppliers may offer flexibility for smaller orders, particularly for first-time buyers or custom designs. Always confirm MOQs before initiating the order process, as this can significantly impact your inventory management and cash flow. -

What customization options are available for plastic fountains?

Many suppliers offer customization options, including size, color, design, and branding. Customization can enhance product appeal and align with your business’s branding strategy. When discussing customization, provide clear specifications and request prototypes if possible. Be aware that custom orders may have longer lead times and higher costs, so factor these into your planning. -

What payment terms should I expect when purchasing plastic fountains?

Payment terms can vary by supplier but commonly include options such as a 30% deposit upfront with the balance due upon shipment, or net 30/60 days after delivery. It’s essential to clarify payment terms before finalizing your order to avoid any surprises. Additionally, consider using secure payment methods and trade finance options to mitigate risks associated with international transactions. -

How can I ensure quality assurance for my fountain plastic products?

To ensure quality, request certifications and quality control processes from your supplier. Many reputable manufacturers will have ISO certifications or similar quality standards. Conducting factory audits or hiring third-party inspection services can provide additional assurance. It’s also helpful to establish a clear agreement regarding quality expectations and return policies in case products do not meet your standards. -

What are the logistics considerations for importing plastic fountains?

Logistics plays a critical role in importing fountain plastics. Consider shipping methods, customs regulations, and potential tariffs specific to your region. Work with a freight forwarder who understands international shipping and can help navigate documentation requirements. Be proactive about potential delays due to customs clearance and ensure that your supplier provides accurate shipping information. -

How do I handle returns or defective products from suppliers?

Establish a clear return policy with your supplier before placing an order. Most suppliers will have a procedure for handling defective products, which may include returns, replacements, or refunds. Document any issues with photos and detailed descriptions to expedite the process. Understanding the supplier’s policies on defective items can save you time and ensure a smoother resolution.

Top 5 Fountain Plastic Manufacturers & Suppliers List

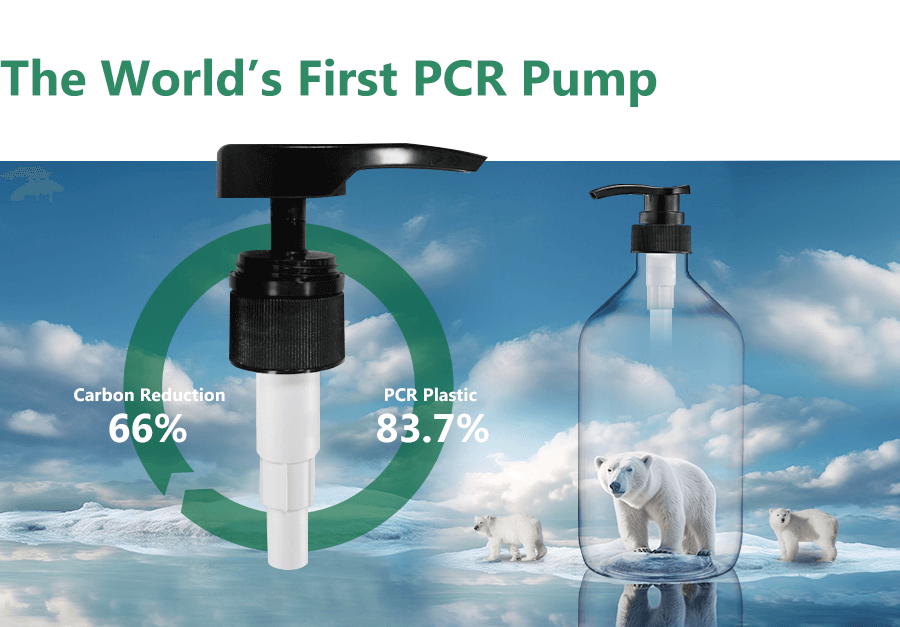

1. Pioneer Pet – Replacement Filters & Drinking Fountain

Domain: pioneerpet.com

Registered: 2006 (19 years)

Introduction: ID:3003 #3003 Pioneer Pet Replacement Filters for Plastic Fountains – $5.79

ID:3004 #3004 Fung Shui™ Premium Plastic Drinking Fountain by Pioneer Pet – 60 oz

ID:3026A #3026A 12V Pump & Transformer – $14.99

ID:3039 #3039 Round Filter 3 Pack for Vortex and Elevated Vortex Only! – $10.99

ID:3040 #3040 Serenity™ Premium Plastic Drinking Fountain by Pioneer Pet – 60 oz

ID:3046 #3046 Vortex Drinking Fou…

2. Target – Outdoor Plastic Fountains

Domain: target.com

Registered: 1997 (28 years)

Introduction: Plastic fountains for outdoor decor available at Target. Trending searches include solar water fountains, solar fountains, indoor water features, and waterfall fountains.

3. Aquascape – Outdoor Fountain Kits

Domain: aquascapeinc.com

Registered: 2005 (20 years)

Introduction: Outdoor Fountain Kits include various styles such as Urn Fountains, Basalt Columns, and Stacked Slate Kits. Key features include:

– Simple installation with all necessary components included.

– Sub-surface basin for water and pump.

– Options for grouping multiple fountains.

– Lightweight, durable fiber-resin composite construction.

– Aesthetic finishes resembling real stone or ceramic.

– Fir…

4. Miller – Dura Flex Rubber Tubs

Domain: cutlersupply.com

Registered: 1998 (27 years)

Introduction: Miller DF01 Dura Flex Rubber Tub 2 Quart HP1 from $5.65, Miller DF02 Dura Flex Rubber Tub 4 Quart HP2 from $6.70, Miller DF03 Dura Flex Rubber Tub 3 Gallon HP3 from $12.05, Miller DF650 Dura Flex Rubber Tub 6-1/2 Gallon HP650 from $20.15, Cutler Supply C 1/2 Pint Feed/Water Cup from $1.50, Cutler Supply C1P 1 Pint Plastic Feed/Water Cup from $1.70, Cutler Supply C1Q 1 Qt. Plastic Feed/Water Cup fr…

5. Cheerble – Cat Fountain Materials: Pros & Cons

Domain: cheerble.com

Registered: 2016 (9 years)

Introduction: Cat Fountain Materials: Pros & Cons

– Popular materials: plastic, stainless steel, ceramic.

– Stainless Steel Cat Drinking Fountains:

– Price: $79.99

– Advantages: Hygiene (non-porous, resists bacteria), Durability (scratch-resistant, rust-proof), Safety (food-grade), Easy cleaning (dishwasher safe).

– Disadvantages: Noise (can be loud), Price (more expensive than plastic).

– Plastic Cat Dri…

Strategic Sourcing Conclusion and Outlook for fountain plastic

In the rapidly evolving market for fountain plastic, strategic sourcing emerges as a cornerstone for international B2B buyers. By understanding the diverse range of products—from tiered fountains to solar-powered options—buyers can make informed decisions that align with regional preferences and environmental considerations. Engaging with reputable suppliers not only ensures quality and sustainability but also fosters long-term partnerships that can lead to enhanced market competitiveness.

Illustrative image related to fountain plastic

As demand for outdoor decor continues to rise in regions such as Africa, South America, the Middle East, and Europe, businesses that prioritize strategic sourcing will be better positioned to capitalize on emerging trends. The integration of innovative technologies, such as energy-efficient pumps and eco-friendly materials, presents a unique opportunity to attract environmentally conscious consumers.

Looking ahead, B2B buyers are encouraged to assess their sourcing strategies, focusing on collaboration with manufacturers that demonstrate a commitment to quality and sustainability. By leveraging insights from the fountain plastic market, businesses can not only meet current demand but also anticipate future opportunities. Now is the time to take action and invest in strategic sourcing to secure a prosperous future in this vibrant industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to fountain plastic

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.