Introduction: Navigating the Global Market for feeder plus

In today’s rapidly evolving global market, sourcing high-quality feeder plus products presents a significant challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With a diverse array of feeder options available—ranging from rodents to insects—the task of selecting the right suppliers can be daunting. This guide aims to equip international buyers with the essential insights needed to navigate this complex landscape effectively.

Throughout this comprehensive resource, we will explore various types of feeder plus products, their applications in different industries, and strategies for vetting suppliers to ensure quality and reliability. Additionally, we will provide an analysis of cost structures, helping you understand the financial implications of your purchasing decisions. By addressing these critical aspects, this guide empowers B2B buyers to make informed choices that align with their operational needs and market demands.

Whether you are a small breeder in Brazil or a large distributor in Germany, understanding the nuances of the feeder plus market is crucial for maintaining competitive advantage. With expert insights and actionable strategies, you will be better positioned to enhance your sourcing processes, ultimately leading to improved product quality and customer satisfaction in your respective markets.

Table Of Contents

- Top 8 Feeder Plus Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for feeder plus

- Understanding feeder plus Types and Variations

- Key Industrial Applications of feeder plus

- 3 Common User Pain Points for ‘feeder plus’ & Their Solutions

- Strategic Material Selection Guide for feeder plus

- In-depth Look: Manufacturing Processes and Quality Assurance for feeder plus

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘feeder plus’

- Comprehensive Cost and Pricing Analysis for feeder plus Sourcing

- Alternatives Analysis: Comparing feeder plus With Other Solutions

- Essential Technical Properties and Trade Terminology for feeder plus

- Navigating Market Dynamics and Sourcing Trends in the feeder plus Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of feeder plus

- Strategic Sourcing Conclusion and Outlook for feeder plus

- Important Disclaimer & Terms of Use

Understanding feeder plus Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Live Feeders | Includes live insects or small animals like crickets and mice. | Zoos, pet shops, and breeders of reptiles and birds. | Pros: High nutritional value; Cons: Requires specific handling and care. |

| Frozen Feeders | Pre-killed and frozen animals, typically vacuum-packed. | Pet stores, veterinary clinics, and breeders. | Pros: Long shelf life; Cons: Thawing required before use. |

| Freeze-Dried Feeders | Dehydrated products that retain nutritional value. | Specialty pet stores and exotic animal care. | Pros: Lightweight, easy to store; Cons: May be less appealing to some animals. |

| Pellet Feeders | Compressed feed in pellet form, often fortified with nutrients. | Commercial animal farms and breeding facilities. | Pros: Easy to measure and store; Cons: May lack variety in diet. |

| Supplement Feeders | Additional nutrient sources like vitamins and minerals. | Veterinary practices and specialty pet shops. | Pros: Enhances health and growth; Cons: Requires knowledge for proper use. |

What Are the Characteristics and Suitability of Live Feeders?

Live feeders include live insects or small animals, such as crickets, mealworms, and mice, which are essential for the diet of many reptiles and birds of prey. These products are particularly suitable for businesses that prioritize high nutritional value and natural feeding behaviors in their animals. When considering a purchase, B2B buyers should evaluate the sourcing and handling practices of suppliers to ensure the health and safety of the live feeders.

Illustrative image related to feeder plus

How Do Frozen Feeders Differ from Live Feeders?

Frozen feeders are pre-killed and vacuum-packed animals that provide a convenient alternative to live feed. They offer a longer shelf life and are easier to manage compared to live options, making them ideal for pet shops and breeders who require consistent supply without the complexities of live animal care. Buyers should consider the thawing requirements and storage solutions when opting for frozen feeders to maintain product quality.

What Benefits Do Freeze-Dried Feeders Offer?

Freeze-dried feeders are dehydrated products that retain essential nutrients while being lightweight and easy to store. They are particularly appealing to specialty pet stores and businesses catering to exotic animal owners. Buyers should assess the palatability of these products, as some animals may prefer live or frozen options. However, their long shelf life and ease of transport can be significant advantages for B2B operations.

Why Choose Pellet Feeders for Animal Nutrition?

Pellet feeders consist of compressed feed that is often fortified with vitamins and minerals, providing a balanced diet for many animals. These are commonly used in commercial animal farms and breeding facilities due to their ease of storage and portion control. Buyers should consider the specific dietary needs of their animals, as well as the quality of ingredients used in pellet formulations.

What Role Do Supplement Feeders Play in Animal Health?

Supplement feeders include various nutrient-rich products designed to enhance the diets of pets and livestock. They are typically used in veterinary practices and specialty pet shops to address specific health concerns or growth requirements. Businesses should be knowledgeable about the appropriate use of supplements to ensure they are providing the correct dosages and combinations for optimal animal health.

Illustrative image related to feeder plus

Key Industrial Applications of feeder plus

| Industry/Sector | Specific Application of feeder plus | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Industry | Supply of live feeders for reptiles and birds | Ensures healthy diet for pets, boosting sales | Consistent supply, quality assurance, competitive pricing |

| Zoological Institutions | Provision of feeder animals for zoo exhibits | Enhances animal health and visitor engagement | Compliance with regulations, ethical sourcing, reliability |

| Veterinary Clinics | Offering feeder animals for pet treatments | Supports pet recovery and health maintenance | Quality control, veterinary approval, year-round availability |

| Educational Institutions | Educational programs involving live animals | Promotes hands-on learning and awareness | Ethical sourcing, educational value, safety standards |

| Research Facilities | Use in biological and ecological research | Facilitates animal studies and ecological insights | Compliance with ethical standards, sourcing reliability, cost |

How is ‘feeder plus’ used in the pet industry?

In the pet industry, ‘feeder plus’ provides a vital supply of live feeder animals such as mice and rats for reptile and bird owners. These feeders are crucial for maintaining the health of pets, as they ensure a balanced diet. For international buyers, particularly in Africa and South America, sourcing live feeders requires careful consideration of local regulations, consistent supply chains, and the assurance of quality to prevent health issues in pets.

What role does ‘feeder plus’ play in zoological institutions?

Zoological institutions utilize ‘feeder plus’ to source live animals for their exhibits, which are essential for the dietary needs of various species. This application not only enhances the health and wellbeing of the animals but also enriches visitor experiences through dynamic animal interactions. Buyers in Europe and the Middle East must focus on ethical sourcing practices and compliance with international wildlife regulations to ensure sustainable operations.

How do veterinary clinics benefit from ‘feeder plus’?

Veterinary clinics use ‘feeder plus’ to provide live feeder animals for treatments and rehabilitation of pets. By offering the right nutrition, clinics can support recovery and overall health, leading to improved outcomes for pet owners. Buyers need to ensure that the feeders are of high quality and vet-approved, with a consistent supply to meet treatment needs throughout the year.

In what ways do educational institutions implement ‘feeder plus’?

Educational institutions incorporate ‘feeder plus’ in their curriculum to facilitate hands-on learning experiences with live animals. This application fosters a deeper understanding of biology and ecology among students, promoting awareness of animal care and conservation. For buyers, sourcing these feeders entails ensuring ethical practices and safety standards, as well as providing educational value to students.

Why are research facilities dependent on ‘feeder plus’?

Research facilities rely on ‘feeder plus’ for sourcing live feeder animals necessary for various biological and ecological studies. These animals play a crucial role in experiments that can lead to significant scientific discoveries. International buyers must consider compliance with ethical standards and the reliability of sourcing to ensure the integrity of their research activities while managing costs effectively.

3 Common User Pain Points for ‘feeder plus’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions for Feeder Plus Products

The Problem: International B2B buyers often face significant challenges in sourcing feeder animals due to unpredictable supply chain disruptions. These disruptions can arise from various factors such as geopolitical issues, natural disasters, or economic fluctuations. For instance, a pet shop in South America may struggle to obtain a consistent supply of quail or mice during peak breeding seasons, leading to potential revenue loss and customer dissatisfaction.

The Solution: To mitigate supply chain risks, B2B buyers should establish relationships with multiple suppliers across different regions. This diversification strategy not only ensures a steady supply of feeder animals but also allows buyers to capitalize on competitive pricing. Additionally, leveraging technology such as inventory management systems can provide real-time data on stock levels and alert buyers when supplies are running low. Implementing a robust logistics plan that accounts for potential delays will also enhance operational efficiency. Buyers should consider negotiating long-term contracts with suppliers to secure better pricing and consistent delivery schedules.

Scenario 2: Ensuring Quality and Compliance with Feeder Plus Products

The Problem: Another common challenge for B2B buyers involves ensuring that the feeder animals they purchase meet stringent health and safety regulations. Buyers, particularly those in Europe, must navigate complex compliance requirements that vary by country. Inadequate quality control can lead to serious health issues for the reptiles or birds of prey that depend on these feeders, potentially resulting in legal repercussions and reputational damage for the businesses involved.

Illustrative image related to feeder plus

The Solution: To address quality assurance, B2B buyers should prioritize sourcing from suppliers that adhere to recognized health and safety standards. This includes obtaining certifications and proof of veterinary-approved feeding practices. Conducting regular audits and inspections of suppliers can also help ensure compliance. Additionally, buyers should establish clear communication channels with suppliers to address any concerns regarding product quality promptly. Implementing a feedback loop with end customers can provide valuable insights into the effectiveness of the feeder products, allowing for continuous improvement and adherence to compliance standards.

Scenario 3: Managing Diverse Customer Needs and Preferences for Feeder Plus

The Problem: B2B buyers often cater to a diverse customer base with varying needs and preferences regarding feeder animals. A small pet store in Africa, for instance, may find it challenging to stock a wide range of feeder options that appeal to different types of reptiles or birds of prey. Failure to meet these diverse preferences can result in lost sales and dissatisfied customers.

The Solution: To effectively manage diverse customer needs, B2B buyers should conduct thorough market research to understand the specific requirements of their target audience. This research can guide inventory decisions, helping businesses stock a variety of feeder animals that cater to different species. Additionally, buyers can implement flexible ordering systems that allow for customized orders based on seasonal trends or customer requests. Engaging with customers through surveys or direct feedback can also provide valuable insights into their preferences, enabling businesses to adjust their offerings accordingly. Building strong relationships with suppliers will facilitate quick adjustments to inventory based on these insights, ensuring that customer needs are consistently met.

Strategic Material Selection Guide for feeder plus

What are the Key Properties of Common Materials Used in Feeder Plus?

When selecting materials for ‘feeder plus’ applications, it’s essential to consider properties that directly influence product performance. Common materials include plastic, stainless steel, silicone, and glass. Each material presents distinct characteristics that cater to various operational needs.

Illustrative image related to feeder plus

1. Plastic

Key Properties: Plastics such as polyethylene and polypropylene are lightweight, resistant to moisture, and can withstand moderate temperatures. They are generally non-reactive, making them suitable for various feeder applications.

Pros & Cons: The durability of plastics is moderate; while they resist breakage, they can be prone to scratches and may degrade under UV exposure. Plastics are cost-effective and easy to mold, allowing for complex shapes. However, they may not withstand high temperatures or harsh chemicals.

Impact on Application: Plastic feeders are compatible with a wide range of media, including dry and moist food. However, their temperature limitations may restrict use in environments with extreme heat.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding food safety and material certifications, such as FDA approval in the U.S. and EU standards in Europe. Understanding local preferences for material safety can also influence purchasing decisions.

2. Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, durability, and ability to withstand high temperatures and pressures. It is also non-reactive, making it ideal for food contact applications.

Illustrative image related to feeder plus

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to wear and tear. However, it is more expensive than plastic and can be heavier, which may increase shipping costs. Manufacturing complexity is higher, requiring specialized equipment.

Impact on Application: Stainless steel feeders can handle a variety of media, including liquids and solids, without risk of contamination. Their durability makes them suitable for both indoor and outdoor environments.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial. Buyers from regions with stringent food safety regulations, such as Germany, should prioritize stainless steel options that meet these standards.

3. Silicone

Key Properties: Silicone is flexible, heat-resistant, and can withstand a broad temperature range. It is also non-toxic and resistant to UV light, making it suitable for outdoor use.

Pros & Cons: The flexibility of silicone allows for easy cleaning and storage. However, it can be more expensive than plastic and may not be as durable under heavy mechanical stress. Manufacturing can also be complex due to the need for specialized molds.

Impact on Application: Silicone feeders are particularly effective for applications requiring flexibility, such as those involving small animals. Their temperature resistance allows for use in various environments.

Considerations for International Buyers: Buyers should verify that silicone products meet local health and safety regulations. In regions like South America, awareness of material certifications can affect buyer confidence.

4. Glass

Key Properties: Glass is non-reactive and provides excellent visibility of contents. It is durable against chemical exposure but can be fragile under impact.

Pros & Cons: Glass feeders are aesthetically pleasing and easy to clean. However, they are heavy and can break easily, making them less suitable for mobile applications. The manufacturing process is also more energy-intensive.

Impact on Application: Glass is ideal for applications where visibility is essential, such as in pet shops or display settings. However, its fragility limits its use in environments where rough handling may occur.

Considerations for International Buyers: Glass products must comply with safety standards to prevent breakage hazards. Buyers should also consider shipping costs due to weight and fragility.

Summary Table of Material Selection for Feeder Plus

| Material | Typical Use Case for feeder plus | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General feeders for small animals | Lightweight and cost-effective | Prone to scratches and UV degradation | Low |

| Stainless Steel | Durable feeders for all media types | High durability and corrosion resistance | Higher cost and weight | High |

| Silicone | Flexible feeders for small animals | Heat-resistant and easy to clean | More expensive and less durable | Medium |

| Glass | Display feeders in retail settings | Non-reactive and aesthetically pleasing | Heavy and fragile | Medium |

This strategic material selection guide provides essential insights for B2B buyers in diverse markets, helping them make informed decisions based on performance, cost, and compliance factors.

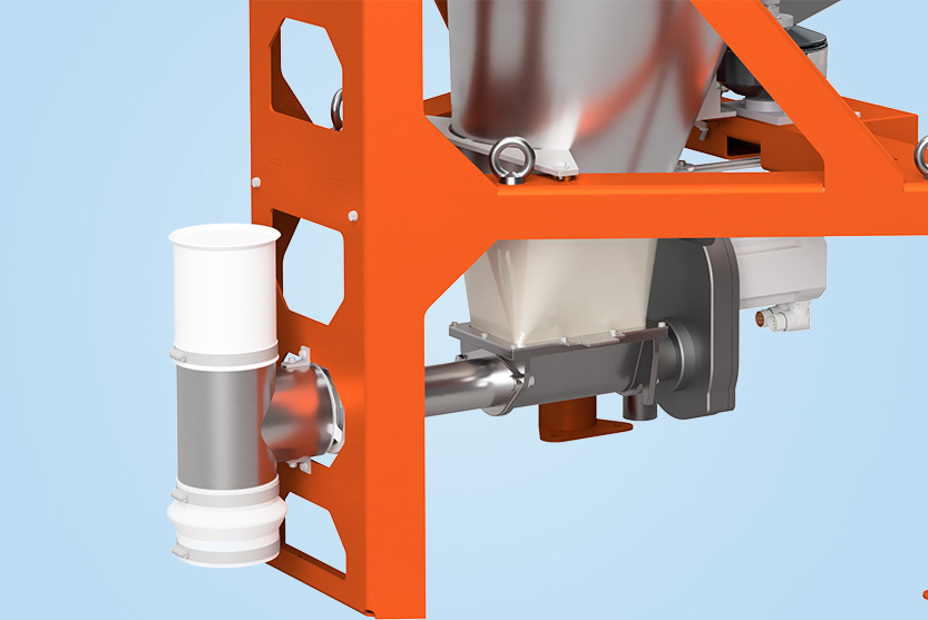

In-depth Look: Manufacturing Processes and Quality Assurance for feeder plus

What Are the Main Stages of Manufacturing Processes for Feeder Plus Products?

The manufacturing of feeder plus products involves several critical stages that ensure quality and consistency in the final output. Each stage is vital for maintaining the integrity of the product, particularly since these feeders cater to the needs of various animals, including reptiles and birds of prey.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting high-quality raw materials that meet industry standards. For feeder plus products, materials typically include safe, non-toxic plastics and silicone for the feeders, ensuring they are durable and safe for animal use. Suppliers should provide certificates of analysis to verify the quality and safety of these materials.

2. Forming Techniques

Once the materials are prepared, they undergo forming processes. Common techniques include injection molding and extrusion, which allow for the creation of complex shapes and designs that are essential for functionality. Injection molding is particularly popular due to its efficiency and ability to produce large volumes with high precision. B2B buyers should inquire about the machinery and technology used in these processes, as advanced equipment can significantly enhance product quality.

Illustrative image related to feeder plus

3. Assembly

After forming, the next stage is assembly. This involves bringing together various components of the feeder plus products, such as attaching silicone sacs to the main body. Automated assembly lines are often used to ensure speed and consistency, but manual assembly may be necessary for more intricate designs. Buyers should assess the assembly process to ensure that it adheres to best practices, which can affect the durability and usability of the products.

4. Finishing Touches

The final stage in the manufacturing process is finishing. This can include surface treatments, quality checks, and packaging. Surface treatments may involve polishing or applying coatings to enhance durability and aesthetic appeal. Packaging is also crucial, particularly for international shipping, as it must protect the products from damage and contamination. Buyers should confirm that the packaging materials comply with international shipping standards.

How is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for feeder plus products. It ensures that the products meet both internal standards and international regulations.

Understanding International Standards for Quality Assurance

B2B buyers should be aware of relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards not only ensures product quality but also enhances the manufacturer’s credibility in the global market. Additionally, industry-specific certifications, such as CE marking for compliance with European health, safety, and environmental protection standards, are essential for exporters targeting markets in Europe.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that products meet specified standards.

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to assess quality. This includes monitoring the forming and assembly stages to catch defects early.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted. This may include functional testing to ensure that the feeders operate as intended.

What Common Testing Methods Are Used for Feeder Plus Products?

Testing is a crucial aspect of the quality assurance process. Common testing methods for feeder plus products include:

- Functional Testing: Ensures that the product performs its intended function effectively.

- Durability Testing: Assesses the product’s ability to withstand repeated use and environmental factors.

- Safety Testing: Checks for any harmful substances and ensures compliance with safety standards.

B2B buyers should request documentation of these tests to verify that the products meet required safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying a supplier’s quality control processes is essential to ensure product reliability.

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control is through onsite audits. Buyers should consider conducting regular audits to evaluate the manufacturing processes, QC checkpoints, and overall compliance with international standards. This direct engagement provides insight into the supplier’s operational integrity.

Reviewing Quality Control Reports

Buyers should also request quality control reports that detail the results of IQC, IPQC, and FQC. These documents should outline any deviations from standards and how they were addressed. Regular reporting fosters transparency and accountability in the supplier relationship.

Illustrative image related to feeder plus

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly beneficial for international transactions, as they help ensure that products meet the buyer’s standards before shipment.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International buyers must navigate various quality control and certification nuances that can differ by region.

Understanding Regional Regulations

Each region may have specific regulations concerning feeder products. For example, European markets may require CE certification, while buyers in the Middle East may look for compliance with local health and safety regulations. It is crucial for buyers to understand these requirements to avoid regulatory issues.

Importance of Traceability

Traceability is another critical factor in quality assurance. Buyers should ensure that suppliers maintain records of materials and processes used in production. This practice not only aids in quality control but also helps in addressing any issues that may arise post-purchase.

Conclusion

Manufacturing processes and quality assurance are integral to the production of feeder plus products. By understanding the key stages of manufacturing, the importance of quality control checkpoints, and the relevant international standards, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only enhances product reliability but also fosters strong partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘feeder plus’

When sourcing “feeder plus” products for your business, having a clear and actionable checklist can significantly streamline the process. This guide aims to provide you with essential steps to ensure you make informed decisions that align with your operational needs and objectives.

Step 1: Identify Your Specific Requirements

Understanding your specific needs is the foundation of a successful sourcing strategy. This includes defining the types and quantities of feeder products you require—be it mice, rats, or other feeder animals. Consider factors such as the species of reptiles or birds of prey you cater to and their dietary needs to ensure the feeders will support their health and growth.

Step 2: Research Potential Suppliers

Begin by compiling a list of potential suppliers who specialize in “feeder plus” products. Look for suppliers with a solid reputation, ideally those who have experience servicing clients in your target regions such as Africa, South America, the Middle East, and Europe. Pay attention to their product range, pricing, and delivery capabilities to ensure they can meet your demands.

Step 3: Evaluate Supplier Certifications

Before finalizing any contracts, verify that potential suppliers hold the necessary certifications. This can include health and safety certifications, quality control processes, and compliance with local regulations. Suppliers that prioritize these certifications demonstrate a commitment to product quality and safety, which is crucial for maintaining your business’s reputation.

Step 4: Request Samples

Always request samples of the feeder products before making a bulk purchase. This allows you to assess the quality, freshness, and packaging of the products firsthand. Additionally, evaluate the shelf life and storage requirements of the samples to ensure they align with your operational capabilities.

Step 5: Compare Pricing and Terms

Once you have narrowed down your list of suppliers, compare their pricing structures and payment terms. Look beyond just the base price; consider shipping costs, bulk discounts, and payment flexibility. Understanding the total cost of acquisition will help you make an informed decision that aligns with your budget constraints.

Step 6: Check References and Reviews

Reach out to other businesses that have sourced from your potential suppliers. Ask for references and look for online reviews or testimonials. This step is crucial to gain insights into the supplier’s reliability, customer service, and product quality, providing a clearer picture of what to expect.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan. Define points of contact, preferred communication channels, and frequency of updates regarding orders and shipments. Effective communication is key to resolving any potential issues swiftly and ensuring a smooth procurement process.

Illustrative image related to feeder plus

By following this checklist, B2B buyers can confidently navigate the sourcing of “feeder plus” products, ensuring they choose the right suppliers to meet their operational needs while maintaining product quality and safety.

Comprehensive Cost and Pricing Analysis for feeder plus Sourcing

What Are the Key Cost Components in Feeder Plus Sourcing?

When sourcing ‘feeder plus’ products, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of feeder materials (e.g., silicone, plastics) significantly impact costs. Higher-quality, certified materials often come with a premium but can ensure better durability and safety.

-

Labor: Labor costs vary based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs may offer competitive pricing, but it’s essential to assess the quality of workmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead and, consequently, the final price.

-

Tooling: Custom tooling for unique designs or specifications can lead to higher initial costs. However, these costs can be amortized over larger production runs, making it essential to consider long-term needs.

-

Quality Control (QC): Implementing rigorous QC processes adds to costs but is vital for ensuring product safety and compliance with regulations, particularly in international markets.

-

Logistics: Shipping and handling costs can vary significantly based on distance, shipping methods, and Incoterms. Buyers should factor in logistics when evaluating total costs.

-

Margin: The supplier’s profit margin also influences pricing. Understanding a supplier’s margin expectations can aid in negotiation.

How Do Pricing Influencers Affect Feeder Plus Costs?

Several factors can influence the pricing of feeder plus products:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract volume discounts. Buyers should assess their needs and negotiate MOQs to optimize pricing.

-

Specifications/Customization: Custom designs or features may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality/Certifications: Higher-quality materials and certifications (e.g., ISO, safety standards) generally lead to higher costs but can enhance product value and consumer trust.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Researching suppliers and establishing long-term relationships may yield better terms.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical, as these affect cost responsibility and risk management in international trade.

What Buyer Tips Can Enhance Cost-Efficiency in Feeder Plus Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiation: Always negotiate pricing, especially for larger orders. Leverage competition among suppliers to secure better deals.

-

Total Cost of Ownership (TCO): Look beyond the purchase price. Consider maintenance, logistics, and disposal costs to assess the true value of the product.

-

Pricing Nuances: Be aware of currency fluctuations and import duties that can affect final costs. Negotiating prices in your local currency may mitigate risks.

-

Supplier Diversity: Engage with multiple suppliers to diversify risks and compare pricing structures. This can also create leverage in negotiations.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to preferential pricing, early access to new products, and better service.

Disclaimer on Indicative Prices

Pricing for feeder plus products can fluctuate based on market conditions, raw material availability, and changes in labor costs. Therefore, the prices discussed here are indicative and should be confirmed with suppliers to ensure accuracy. Buyers are encouraged to conduct thorough market research and supplier evaluations to make informed purchasing decisions.

Illustrative image related to feeder plus

Alternatives Analysis: Comparing feeder plus With Other Solutions

Understanding Alternatives in the B2B Landscape

When evaluating solutions for specific business needs, understanding the alternatives available is crucial. For businesses considering ‘Feeder Plus’, a product designed for feeding various animal species, it’s beneficial to compare it against other viable solutions in the market. This analysis will help buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | ‘Feeder Plus’ | Alternative 1: Custom Animal Feed Solutions | Alternative 2: Automated Feeding Systems |

|---|---|---|---|

| Performance | High-quality, vet-approved feed | Variable quality based on supplier | High efficiency with programmable settings |

| Cost | Affordable pricing with bulk options | Potentially higher costs for bespoke feed | Initial investment is high, but savings on labor |

| Ease of Implementation | Easy to order and integrate | Requires sourcing and vetting suppliers | Setup complexity varies by system |

| Maintenance | Minimal, regular supply chain checks | Regular supplier evaluation needed | Periodic maintenance required |

| Best Use Case | Small to medium breeders and pet shops | Specialized needs for unique species | Large-scale operations with high feeding demands |

In-Depth Analysis of Alternatives

Custom Animal Feed Solutions

Custom animal feed solutions involve sourcing feed tailored to specific dietary requirements of various animal species. The main advantage is the ability to meet unique nutritional needs, which is crucial for breeding or health-specific diets. However, the cost can be significantly higher due to the bespoke nature of the product. Additionally, sourcing involves evaluating multiple suppliers, which can complicate the procurement process. This solution is best suited for businesses with specialized feeding requirements that cannot be met with standard products.

Automated Feeding Systems

Automated feeding systems represent a technological advancement in animal feeding, allowing for programmable feeding schedules and portion control. These systems excel in large-scale operations, where efficiency and consistency are paramount. While they reduce labor costs and ensure timely feed distribution, the initial setup can be expensive and complex, requiring technical expertise for installation. Regular maintenance is also necessary to ensure optimal operation. This solution is ideal for enterprises with high feeding demands, where automation can lead to significant operational efficiencies.

Making the Right Choice for Your Business Needs

Choosing the right feeding solution depends on specific business requirements, including the scale of operations, budget constraints, and the unique nutritional needs of the animals being fed. For small to medium-sized operations, ‘Feeder Plus’ offers a reliable, cost-effective solution with minimal maintenance needs. In contrast, larger enterprises with specific dietary requirements might benefit from custom animal feed solutions or automated systems that enhance efficiency and meet specialized needs. By assessing the various alternatives available, B2B buyers can strategically select the solution that aligns best with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for feeder plus

What Are the Key Technical Properties of Feeder Plus Products?

When considering feeder plus products, understanding their technical specifications is vital for making informed purchasing decisions. Here are some critical specifications that B2B buyers should be aware of:

-

Material Grade

The materials used in feeder plus products, such as plastics or silicone, should meet industry standards for safety and durability. High-grade materials ensure that the feeders can withstand various environmental conditions while maintaining their integrity. For instance, food-grade silicone is essential for ensuring that the feeder is safe for use with live animals and does not leach harmful substances. -

Capacity and Size

The capacity of a feeder plus product, whether it pertains to the volume of feed it can hold or the size of the opening for animal access, directly impacts its usability. A larger capacity is often preferable for businesses that deal with high volumes of feed, reducing the frequency of refills and improving operational efficiency. Understanding size specifications also helps in ensuring compatibility with existing equipment. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in feeder plus products. High tolerance levels ensure precise manufacturing, which is crucial for components that must fit together seamlessly. For B2B buyers, this means fewer issues during installation and operation, leading to reduced downtime and maintenance costs. -

Vacuum Packing Technology

For products like frozen feeder animals, vacuum packing is a critical property. This technology enhances shelf life by preventing air exposure, thus reducing spoilage. B2B buyers should look for suppliers that utilize advanced vacuum packing techniques, as this can greatly affect inventory management and cost efficiency. -

Hygienic Design Features

The design of feeder plus products should incorporate features that promote cleanliness and ease of maintenance. This includes smooth surfaces and easy-to-disassemble components, making it simpler to clean and sanitize. Such features are especially important in the feeding of live animals, where hygiene is paramount. -

Durability and Lifespan

The expected lifespan of feeder plus products is another critical consideration. Buyers should evaluate durability ratings, which indicate how long the product will last under typical operating conditions. Investing in high-quality, durable products can lead to significant long-term cost savings.

What Are Common Trade Terms in the Feeder Plus Industry?

Familiarizing oneself with industry jargon can significantly ease the procurement process. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For feeder plus products, understanding OEM relationships can help buyers identify reputable suppliers who meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can affect inventory management and purchasing strategies. Knowing the MOQ helps in budgeting and planning for future needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products. For B2B buyers, issuing an RFQ can facilitate better negotiations and help secure competitive pricing for feeder plus products. -

Incoterms (International Commercial Terms)

These are predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms is essential for B2B transactions, as they dictate who is responsible for shipping costs, insurance, and customs clearance. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. This is a critical factor in inventory management and can impact a business’s operational efficiency. Buyers should inquire about lead times when negotiating contracts to ensure timely delivery. -

BOM (Bill of Materials)

A BOM is a comprehensive list of raw materials, components, and sub-assemblies required to manufacture a product. For feeder plus products, a clear BOM can aid in understanding the full scope of materials needed, thus facilitating better planning and procurement.

By grasping these technical properties and trade terms, international B2B buyers can enhance their purchasing strategies, ensuring they select the right feeder plus products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the feeder plus Sector

What Are the Key Trends Shaping the Feeder Plus Market for International B2B Buyers?

The feeder plus market is currently experiencing dynamic shifts driven by several global factors. With the rise of the pet industry and an increasing number of reptile and bird enthusiasts, demand for high-quality feeder animals is on the rise. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where the pet ownership culture is expanding. B2B buyers are increasingly seeking suppliers who can offer a diverse range of feeder options, including mice, rats, quail, and insects, to meet the varied dietary needs of their customers.

Emerging technologies are also influencing sourcing trends. The integration of e-commerce platforms and supply chain management software is allowing international buyers to streamline their procurement processes. This shift enables easier access to suppliers and enhances the ability to monitor inventory levels in real-time. As a result, suppliers who leverage technology to enhance transparency and efficiency are likely to stand out in the competitive landscape.

Additionally, the focus on sustainability is reshaping market dynamics. Buyers are becoming more conscious of sourcing practices and are looking for suppliers who prioritize ethical standards and sustainable methods. This has led to an increase in demand for suppliers who can demonstrate their commitment to responsible sourcing and environmental stewardship.

How Is Sustainability Influencing Sourcing Decisions in the Feeder Plus Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the feeder plus market. The environmental impact of animal farming and feed production is under scrutiny, prompting buyers to seek suppliers who implement sustainable practices. This includes sourcing feeder animals that are raised in humane conditions and using feed that is free from harmful additives.

Moreover, certifications such as organic, humane, and environmentally friendly labels are increasingly important in the purchasing decision. Suppliers who can provide evidence of their sustainability practices and certifications are more likely to gain trust and loyalty from international buyers. Additionally, buyers are exploring alternative feeder options, such as insect-based feeds, which have a lower environmental footprint compared to traditional livestock.

The importance of ethical supply chains cannot be overstated. Buyers are not only concerned about the quality of the feeder products but also about the integrity of the supply chain. Suppliers who can assure traceability and ethical treatment of animals will have a competitive advantage, particularly in regions where consumers are increasingly demanding transparency regarding their purchases.

Illustrative image related to feeder plus

What Is the Historical Context Behind the Growth of the Feeder Plus Sector?

The feeder plus sector has evolved significantly over the past few decades, primarily driven by the expansion of the pet industry and the growing popularity of exotic pets. Initially, feeder animals were primarily sourced locally, but as the global pet market expanded, so did the need for a more diverse and readily available supply.

In the early 2000s, the rise of online marketplaces revolutionized the way feeder animals were sourced. Suppliers began to leverage digital platforms to reach a broader audience, enabling them to cater to both small breeders and larger institutions such as zoos. This shift not only increased accessibility but also allowed for the establishment of standardized quality controls, ensuring that buyers received high-quality products consistently.

Today, the feeder plus market continues to adapt, with an emphasis on technology, sustainability, and ethical practices shaping its future. As international B2B buyers navigate these changes, understanding the historical context can provide valuable insights into the current trends and future directions of the sector.

Illustrative image related to feeder plus

Frequently Asked Questions (FAQs) for B2B Buyers of feeder plus

-

How do I ensure the quality of feeder animals from suppliers?

To ensure the quality of feeder animals, start by vetting potential suppliers thoroughly. Look for certifications that indicate adherence to health and safety standards, such as veterinary approvals and compliance with local regulations. Request samples to evaluate the physical condition and overall health of the animals before making a bulk purchase. Establish clear quality assurance protocols with your suppliers, including regular inspections and documentation of feeding practices and breeding conditions. Additionally, consider reviewing customer feedback and testimonials for insights into the supplier’s reliability. -

What are the common payment terms for international B2B transactions?

Payment terms can vary significantly across suppliers and regions, but common practices include net 30, 60, or 90 days after invoice receipt. Many suppliers may require upfront deposits, especially for large orders or new customers. Explore options like letters of credit or escrow services to mitigate risks. It’s crucial to clarify these terms before finalizing any agreement to avoid misunderstandings. Ensure that payment methods are secure and suitable for international transactions, considering currency exchange rates and transaction fees. -

What is the minimum order quantity (MOQ) for feeder animals?

Minimum order quantities (MOQs) for feeder animals can vary based on the supplier and the type of animal. Typically, MOQs are set to ensure that suppliers can cover their costs effectively while maintaining stock levels. For smaller businesses, it’s advisable to negotiate MOQs upfront to suit your operational capacity. Some suppliers may offer flexibility for first-time buyers or provide tiered pricing based on the volume of the order, which can be beneficial for scaling your purchases over time. -

How can I customize my order of feeder animals?

Customizing orders for feeder animals often involves discussing specific needs directly with the supplier. Options may include selecting particular sizes, species, or packaging methods. Some suppliers might also offer tailored feeding programs to ensure the animals meet the dietary requirements of your target reptiles or birds of prey. Clear communication about your requirements is essential, so provide detailed specifications and be open to the supplier’s recommendations based on their expertise. -

What logistics should I consider when sourcing feeder animals internationally?

When sourcing feeder animals internationally, consider logistics such as shipping methods, transit times, and customs regulations. Ensure the supplier has experience handling live animal shipments and can provide the necessary documentation for customs clearance. Evaluate the shipping conditions to maintain the health and safety of the animals during transit. Additionally, factor in delivery schedules to align with your inventory needs and ensure timely replenishment. -

What are the best practices for supplier vetting in the feeder animal industry?

Best practices for supplier vetting include conducting thorough background checks, assessing the supplier’s reputation in the market, and reviewing their compliance with local and international regulations. Request references from existing clients and verify their satisfaction with the supplier’s products and services. Visit the supplier’s facilities if possible to observe their breeding and feeding practices firsthand. Utilizing industry networks and trade shows can also provide valuable insights into potential suppliers’ reliability and quality. -

How can I handle potential risks in international trade for feeder animals?

To manage risks in international trade for feeder animals, implement a comprehensive risk assessment strategy. This should include evaluating suppliers for reliability, understanding the political and economic stability of their region, and ensuring compliance with health regulations. Consider using insurance for shipments and establishing clear contracts that outline responsibilities and liabilities. Diversifying your supplier base can also mitigate risks, allowing you to adapt to any disruptions in supply chains. -

What are the key factors to consider for year-round availability of feeder animals?

For year-round availability of feeder animals, consider the supplier’s production capacity and breeding cycles. Suppliers should have robust inventory management practices to ensure consistent supply, even during peak demand seasons. Discuss seasonal fluctuations with your suppliers and plan ahead for any anticipated shortages. Establishing long-term partnerships can also enhance reliability, as suppliers are more likely to prioritize orders from trusted clients who maintain regular business relationships.

Top 8 Feeder Plus Manufacturers & Suppliers List

1. Feeders Plus – Feeder Animals for Reptiles and Birds of Prey

Domain: feedersplus.com

Registered: 2003 (22 years)

Introduction: Feeders Plus produces mice, rats, and quail, and distributes rabbits, chicks, crickets, and worms as feeder animals for reptiles and birds of prey. They cater to small breeders, local pet shops, leading breeders, and zoos. Their products are available year-round at affordable prices. All animals are fed a scientifically formulated, vet-approved rodent diet, and mice and rats are vacuum packed for …

2. Feeder – RSS Feed Reader Pricing Plans

Domain: feeder.co

Registered: 2010 (15 years)

Introduction: Feeder offers several pricing plans for its RSS feed reader: 1. Free Plan: $0 – 200 feeds, 30-minute updates, ad-free. 2. Plus Plan: $7.99/month – 2500 feeds, 5-minute updates, premium sources, dashboard, rules & filters, email summaries. 3. Professional Plan: $14.99/user/month – Everything in Plus, 10,000 feeds, 1-minute updates, collaboration tools, software integrations, create RSS feeds, publi…

3. Feeders Plus – Original Hay Saver

Domain: feedersplusllc.com

Registered: 2015 (10 years)

Introduction: This company, Feeders Plus – Original Hay Saver, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Really Simple AB – RSS Feed Reader

Domain: chromewebstore.google.com

Registered: 1997 (28 years)

Introduction: {“name”: “RSS Feed Reader”, “developer”: “Really Simple AB”, “version”: “8.0.23”, “last_updated”: “May 9, 2025”, “size”: “3.84MiB”, “average_rating”: “4.4”, “total_ratings”: “7.2K”, “users”: “500,000”, “features”: [“Instant notifications for new posts”, “Easy subscription to RSS/Atom feeds”, “Intuitive feed management”, “Right-click context menus for shortcuts”, “Feed export/import functionality”,…

5. Rainier Seeds – Deer & Elk Feeder Plus

Domain: rainierseeds.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Deer & Elk Feeder Plus”, “category”: “Wildlife Habitat & Reclamation”, “regular_price”: “$60.55 USD”, “sizes_available”: [{“size”: “5 LB”, “price”: “$60.55”}, {“size”: “25 LB”, “price”: “$175.50”}], “seed_composition”: [{“component”: “Mountain Bromegrass”, “percentage”: “25%”}, {“component”: “Intermediate Wheatgrass”, “percentage”: “25%”}, {“component”: “Tetraploid Annual Ryegras…

6. PetSmart – Vittles Vault® Elevated Pet Feeder Plus Pet Food Storage

Domain: petsmart.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Vittles Vault® Elevated Pet Feeder Plus Pet Food Storage”, “item_number”: “5322744”, “price”: “$69.99”, “original_price”: “$72.99”, “size”: “50 lb”, “features”: [“Airtight Engineering”, “Controlled Moisture Balance”, “Pest Proof”, “Food Safe”, “BPA-Free”], “intended_pet”: “Medium to large-sized dogs”, “material”: “Plastic”, “color”: “White”, “product_dimensions”: “25.5 in x 14 in…

7. Kidsme – Food Feeder Plus

Domain: specialneedsessentials.com

Registered: 2014 (11 years)

Introduction: Kidsme Food Feeder Plus features a larger, flexible silicone sac for babies’ growing appetites. It promotes self-feeding and muscle development, allowing children to safely explore solid foods. The cap keeps the sac clean and doubles as a training cup. Suitable for ages 6 months and up, it is BPA free and top-rack dishwasher safe. Price: $13.99.

8. Kidsme – Food Feeder Plus LIME

Domain: kidsmephilippines.com

Registered: 2016 (9 years)

Introduction: Food Feeder Plus LIME – Regular price ₱980.00. Award-winning product featuring a larger, flexible silicone sac designed for babies’ growing appetites. Enhanced ergonomic design allows safe and independent exploration of new tastes and textures. Enables babies to enjoy finger foods without concern. Made of silicone, the pouch allows babies to chew solid foods like fruits, vegetables, and meat safel…

Strategic Sourcing Conclusion and Outlook for feeder plus

How Can Strategic Sourcing Enhance Your Feeder Plus Procurement?

In conclusion, strategic sourcing remains pivotal for international B2B buyers looking to optimize their procurement of feeder plus products. By focusing on quality suppliers, such as those that provide scientifically formulated diets and vacuum-packed options, businesses can ensure the health and longevity of their feeder animals. This approach not only guarantees a reliable supply chain but also enhances the overall quality of the products offered to end customers.

Furthermore, buyers in regions like Africa, South America, the Middle East, and Europe should leverage local partnerships and global networks to negotiate better pricing and terms. Understanding market dynamics, such as seasonal availability and regional demand, can significantly improve sourcing strategies.

Looking ahead, the feeder plus market is poised for growth, driven by increasing interest in exotic pets and sustainable animal husbandry practices. By embracing a forward-thinking approach to sourcing, businesses can capitalize on emerging trends and stay ahead of the competition. We encourage you to explore diverse supplier options and invest in strategic sourcing initiatives that align with your business goals. Your proactive steps today will pave the way for long-term success in the feeder plus market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to feeder plus

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.