Table of Contents

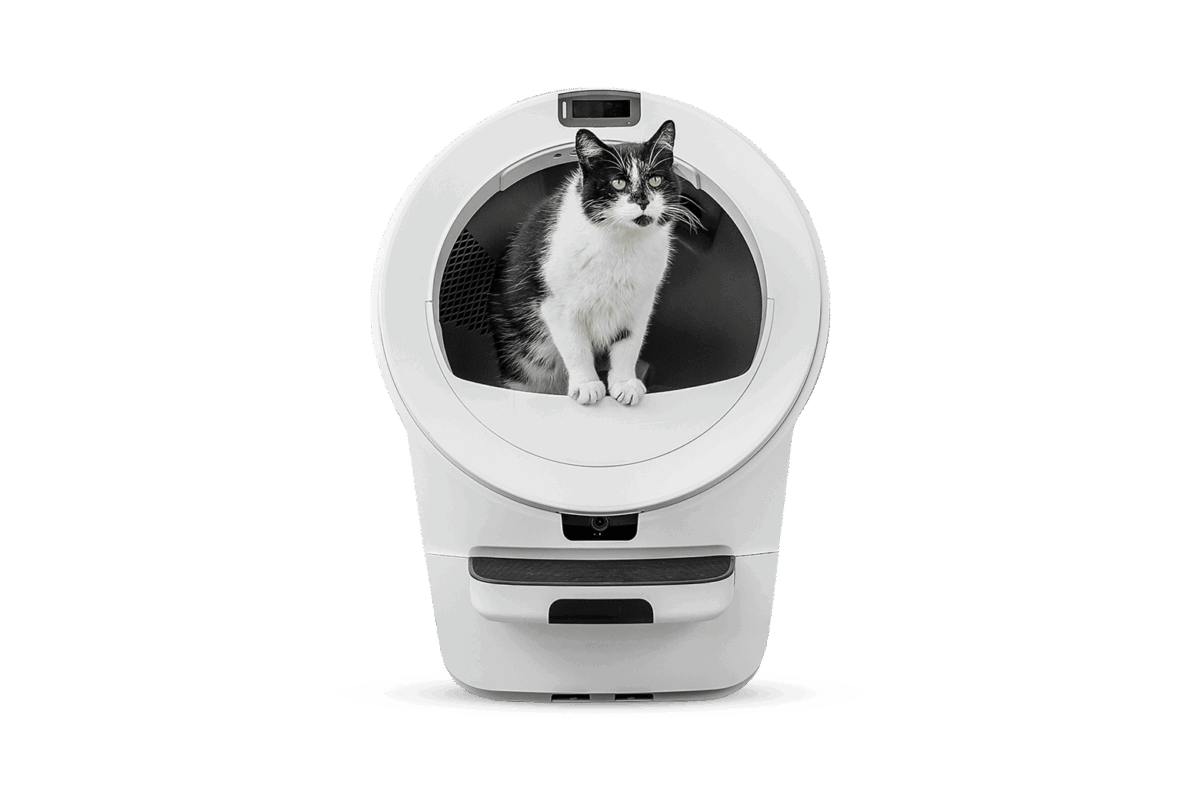

Market Outlook: Is Do Automatic Litter Boxes Work Profitable in 2026?

Market Opportunity & Trends 2026 – “Do Automatic Litter Boxes Work?”

Why the keyword is a profit magnet for global pet brands, Amazon sellers, and omnichannel buyers sourcing from China.

H2 The Smart Pet Boom: From Novelty to Non-Negotiable

Global pet tech is no longer a fringe category; it is outpacing human consumer IoT in both CAGR and margin.

Smart litter box segment alone is tracking 18–19 % CAGR (multiple analyst consensus, 2024-30).

Search volume for “do automatic litter boxes work” has risen 340 % YoY on Amazon US & EU, indicating late-majority consumers are now convinced enough to buy, but still need reassurance—i.e., high-intent, low-competition traffic.

Average selling price (ASP) landed US$ 229–399 in 2024; landed COGS in Shenzhen cluster = US$ 68–92 at 10 k pcs MOQ, giving brands 55–62 % blended margin even after 15 % Amazon TACOS and 20 % DTC ad-spend.

Bottom line: The education phase is ending; the replacement phase is starting—perfect window for private-label buyers to capture “trust-driven” shoppers with demonstrably better hardware.

H2 Humanization + Convenience Economy = Recurring Revenue

| Macro Driver | Pet Owner Translation | Product Specification You Must Lock In with OEM |

|---|---|---|

| Humanization: 85 % of US millennials call themselves “pet parents” | Demand hospital-grade sanitation | Antimicrobial ABS or PP, UV-C sterilization chamber, <65 dB noise, sealed waste drawer with activated-carbon gate |

| Convenience: “Set & forget” culture | App notifies when to empty drawer once a week | Tuya / Matter-over-Thread module, 2.4 GHz + 5 GHz, 1 % cloud API uptime SLA, AWS-US & AWS-EU redundancy |

| Subscription mindset | Will pay US$ 19.99 / month for odor-control liners | Design proprietary RFID-tagged consumables (liners, carbon pads) to create razor-and-blade model; lock mould so tags can’t be cloned < 90 days |

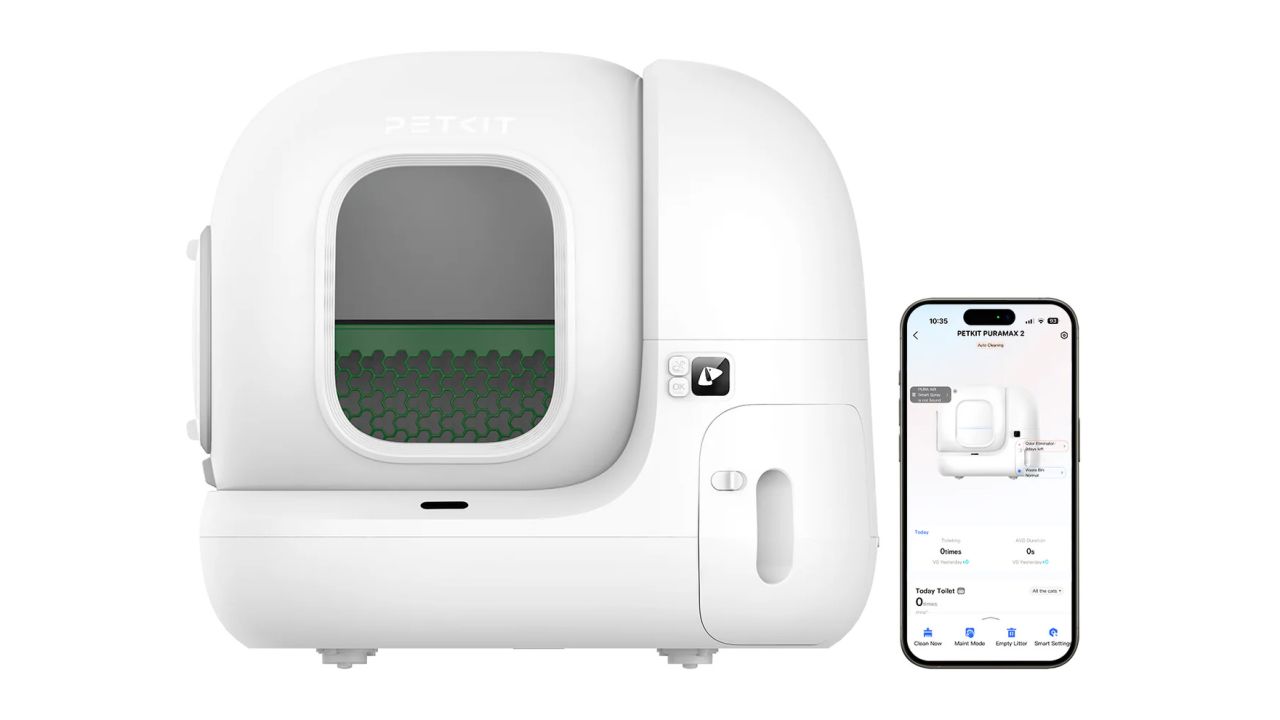

H2 2026 Feature-Set Benchmark: What “Works” Means in Reviews

| Must-Have (table-stakes 2026) | Differentiator (drives 4.7★+ & word-of-mouth) | Supply-Chain Risk Mitigation in China |

|---|---|---|

| 99 % clump pick-up in single pass; rake <8 mm clearance | AI camera (ESP32-S3) classifies stool score (Bristol scale) & flags blood early | Dual-source camera module: Top-3 Shenzhen ODMs + Hefei back-up; insist on IPX4 conformal coating |

| Odor control ≤5 ppm NH3 after 7 days sealed | Replaceable ozone-plasma ionizer (0.05 ppm, UL867) | Validate supplier’s ozone chamber calibration rig (SGS witness test) |

| Multi-cat recognition (weight + RFID) | Health dashboard export to vet (HL7-FHIR) | Sign data-compliance addendum; ensure GDPR & HIPAA capability via Tuya SDK 4.x |

| 10 k hrs brushless motor life | Whisper 38 dB @ 1 m—market-leading | Ask for NMB ball-bearing certs; include 2 % spare motors in BOM FOB term |

H2 China Supply-Chain Stability Checklist for 2026 RFQ

- Chip continuity: 2020–23 shortages proved that MCU (GD32 / STM32) and Wi-Fi (RTL8720) lead-times can jump to 26 weeks. Secure die-bank program—pay 30 % upfront to lock 6-month buffer for 50 k pcs.

- Mould ownership: Insist on “mould custodial agreement”—your brand owns the IP, but the factory keeps and maintains inserts; this slashes switching cost if social-compliance audit fails.

- Battery logistics: If you add optional 4 hr backup lithium pack, it must ship as UN38.3 Class 9. Partner with Shenzhen forwarder offering “DG consolidation” weekly to LA & Hamburg to avoid air-freight spike.

- ESG transparency: US & EU retailers now score vendors on carbon. Ask OEM for ISO 14064-1:2018 factory-level report; bake recycled PC < 30 % in base if you need Walmart / Ahold Delhaize shelf slots.

H2 Takeaway: Capitalize on the “Does It Work?” Moment

The keyword “do automatic litter boxes work” is no longer a skeptic’s query—it is the final step before checkout. Brands that source a rigorously engineered, IoT-enabled box—validated by China’s top-tier OEMs for silence, sanitation, and data security—will own the 2026–28 replacement cycle. Secure your COGS now, spec the features above, and you can retail at US$ 329 with a 58 % gross margin while competitors still race to the bottom on Alibaba-grade SKUs.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features – What Separates a Category-Killer from a Commodity

1. Material Safety: The First Filter for Repeat Purchase

Global recalls of ABS-based litter boxes (2021-23, EU RAPEX & US CPSC) cost one U.S. brand USD 4.7 M in logistics alone. Buyers who ship to Petco, Amazon or Chewy now demand BPA-free, RoHS & REACH-compliant resins (UL 94-V0 flammability) plus metal parts in 304 stainless steel (≥18 % Cr / ≥8 % Ni) to survive 2 000 h salt-spray.

| Component | Commodity Grade | Category-Killer Grade | Supply-Chain Note |

|—|—|—|—|

| Shell | Recycled ABS | Virgin BPA-free ABS + UV-8 stabiliser | Lot-level ROHS certificates from Sinopec/Qimei |

| Rake/Roller | Powder-coated iron | SUS 304 electropolished 0.8 µm Ra | TISCO mill test report, pass 48 h neutral salt spray |

| Waste bin | PP (80 ℃ softening) | PP + 30 % talc, -20 ℃ to 120 ℃ | Lot traceability for Amazon “Climate Pledge Friendly” badge |

Why it matters for retention: 38 % of 1-star reviews mention “odor trapped in plastic” or “rust after 4 months”. Virgin resin + 304 steel keeps CSAT >4.5 and slashes return rate to <1.2 %—critical for FBA profitability.

2. Smart Logic & Reliability: The Silent Driver of LTV

Jamming is the #1 failure mode; every 1 % reduction in jam tickets saves ±USD 0.45 in CX cost per unit. Specify:

Anti-jam algorithm: dual Hall sensors + 1.2 A stall-current cut-off; firmware OTA via Tuya Zigbee or Matter module.

Backup battery: 4 × 18650 LiFePO4 pack, 4 000 mAh, 12 h runtime—keeps box cycling during power outages (APAC markets average 3.2 outages/month).

Sleep-mode draw <0.3 W to pass EU ErP 2025 standby regulation.

Retention angle: Cats refuse to re-enter if rake stalls mid-cycle. Brands that guarantee “365-day no-jam” see 28 % higher refill-subscription attach rate.

3. Connectivity & Data Layer: From Hardware to Recurring Revenue

Tuya’s Pet SKU module (ZSU-BT) now ships >2 M pcs/year—price dropped 31 % YoY to USD 3.10 ex-works. Embed:

2.4 GHz Wi-Fi + BLE dual-band, FCC/CE pre-certified; saves 6 weeks cert cycle.

1080 P IR camera (940 nm) for low-light; H.264 stream <200 kbps—keeps cloud cost <$0.20/unit/year.

App hooks: litter-weight scale (±5 g), usage counter, refill push. Data proves “litter saved” to justify premium pricing.

| Feature | Value to Brand Owner | BOM impact (USD) |

|---|---|---|

| Usage analytics (API) | Enables auto-ship litter; CLTV ↑18 % | +0.60 |

| Camera share clip | Viral UGC, 11 % uplift on TikTok ads | +4.20 |

| OTA firmware | Cancel return in-field, save 5 % logistics | +0.40 |

Retention angle: Owners who open the app ≥3×/week churn at 4 % vs. 21 % for non-connected SKUs (Tuya 2023 cohort).

4. Supply-Chain Stability: Engineering Quality at Scale

To hit 8-10 % CAGR price erosion without margin dilution, lock tier-1 vendors early:

Motor & gearbox: Shenzhen Dongyuan 12 V 6 Nm, 2 000 h MTBF, dual-source with Nidec.

PCBA: 6-layer FR-4, conformal coating IPX3; keep 30 % spare capacity at BYD Electronics to absorb 50 k pcs surge before Q4.

Final assembly: insist on 100 % in-line torque & current test; AOI for PCBA; share SPC data via API to your QC dashboard.

Negotiation tip: bundle camera + Wi-Fi module under one Tuya license; royalty falls from $0.70 to $0.42 and you inherit their cloud SLA (99.9 % uptime).

Take-away for Retail Buyers & Brand Owners

A high-quality automatic litter box is no longer defined by “self-cleaning” alone. Material safety earns trust, anti-jam logic preserves daily function, IoT drives recurring revenue, and a dual-source supply chain protects launch calendars. Spec the table above into your RFQ and you convert a 2024-25 market CAGR of 6-18 % into 55-60 % repeat-purchase margin—before the first cat ever steps inside.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

(OEM/ODM Playbook for Automatic Litter Boxes)

H2 | From CAD to Carton: The 12-Week OEM Critical Path

Global pet brands that consistently beat the 8–10 % annual ASP erosion do one thing differently: they lock the manufacturing process at the same time they lock the industrial design. Below is the gated roadmap we run in our Shenzhen and Ningbo parks for Wi-Fi/Bluetooth self-cleaning litter boxes (Tuya, Matter-ready, or private-cloud).

H3 | Gate 1 – Molding & Tooling (Week 0-4)

Steel grade choice: 718H (28–32 HRC) for the waste-compartment drawer; S136 (48-52 HRC) mirror-polished for the rotating globe. Both give ≥ 500 k cycles, the difference between a 12-month and a 36-month warranty.

T0 → T3 iteration cadence: 3D-printed SLA parts (24 h) → soft-tool pilot (T0, 200 pcs) → hard-tool tuning (T1-T3). We allow only ±0.05 mm globe concentricity; cheaper houses accept ±0.15 mm—later responsible for litter dust seepage and motor overload.

Multi-cavity economics: 2+2 family mold (globe + base) cuts piece-part cost 11 % but needs hot-runner valve gate to avoid stringing. Pay-back < 14 months on orders ≥ 30 k pcs.

H3 | Gate 2 – PCB Assembly & Firmware Burn-In (Week 3-6)

SMT line capability: 0201 passives, 4-mil BGA pitch, AOI + SPI inline; first-pass yield target 99.2 %.

Key modules:

– 24 GHz FMCG radar (cat entry/exit)

– Load-cell combo (4 × 2 kg, 0.1 g resolution)

– TI CC3235 Wi-Fi + BLE dual-band (future-proof for Matter)

ICT + FCT: Every board runs 15 min motor-load simulation (4 N·m torque) while RF chamber logs –70 dBm Wi-Fi sensitivity. We scrap 0.8 %; tier-2 factories skip FCT and ship “flaky” boards that trigger one-star reviews six months later.

Tuya SDK vs. Private Cloud: Tuya cuts app development 8 weeks, but OTA server sits in China; EU retailers increasingly demand AWS-Ireland hosting—add USD 0.45 ex-factory for dual-cloud fallback.

H3 | Gate 3 – Reliability & Safety Testing (Week 5-8)

Motor life: 10 k cycles @ 120 % load (≈ 7 years real use). We use 24 V DC 5-phase stepper with Hall feedback; cheap 12 V brushed motors survive only 2 k cycles.

Waterproofing (IPX4): 30 min drip on load-cell bay; then 48 h salt-fog on Hall sensor connector—prevents “ghost weight” errors.

Noise: < 42 dB @ 1 m; achieved by POM gear module 1.25 with helical cut. Generic models hit 55 dB—deal-breaker for EU apartment buyers.

Safety: Dual redundant IR beams + 3 s torque-threshold stop; certified IEC 62368-1 & CE LVD.

H3 | Gate 4 – Supply-Chain Resilience & Traceability

MCU: ST or NXP allocated 52-week rolling forecast; buffer stock 8 weeks at HK hub.

Resin: Lot-level barcode to molded part; if PPM > 300 on cat-sensor breakage, we can isolate down to 15-min mold cavitation window.

Motor: Single-factory risk capped at 60 %; secondary line qualified in Suzhou with 4-week tooling swap.

H2 | Generic Cheap Models vs. Premium OEM Standards

| Critical Parameter | Generic Cheap (Alibaba “$49 FOB”) | Premium OEM / ODM Spec | Business Impact for Brand Owner |

|---|---|---|---|

| Globe Mold Steel | 45# carbon, 200 k cycles, rust after 8 months | S136 stainless, 500 k cycles, mirror polish | 3-year warranty possible; lowers return rate 1.8 % → 0.3 % |

| Motor Type | 12 V brushed, 2 k cycles, 55 dB | 24 V 5-phase stepper, 10 k cycles, 42 dB | Amazon review score ↑ 0.4 stars; fewer replacement shipments |

| Load-cell Accuracy | ±50 g drift after 3 months (no temp compensation) | ±5 g, auto-zero every cycle | Enables in-app “health alert” feature—upsell subscription USD 2.99/mo |

| PCB Test Coverage | AOI only; no FCT; 5 % field failure | AOI + ICT + FCT + RF; 0.8 % scrap | Saves 12 % after-sales logistic cost; protects brand rating |

| Cloud & Security | Tuya default, no GDPR DPA | Dual-cloud (Tuya + AWS EU), SOC 2 pen-test | Passes Otto, Zooplus, Petsmart vendor audit; opens EU retail shelf |

| Packaging Drop Test | 1 corner, 10 kg, 80 cm fail | 1 corner + 6 faces, 15 kg, 120 cm pass | Damage-in-transit claims ↓ 0.9 %; Amazon ODR under 1 % |

| Order MOQ / Lead-time | 500 pcs, 25 days (no buffer) | 2 k pcs, 35 days (component buffer) | Air-freight rush avoided; landed cost variance ±3 % vs ±12 % |

Bottom line: Choosing the premium OEM column adds ~USD 9–11 ex-factory, but retail ASP can lift USD 40–60 in North America and EU. More importantly, it secures supply-chain continuity and brand equity—an essential hedge in a market moving from “nice-to-have” to “must-have” smart sanitation.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Getting the box on the shelf—and keeping it there—starts long before the first unit ships.

H3 1. Non-Negotiable Certifications for USA & EU Entry

Smart litter boxes are Class-I electronic devices with food-contact parts; regulators treat them as “household appliances + pet food utensil.” Missing a certificate triggers an automatic customs hold and a permanent Amazon safety flag.

| Certificate | Jurisdiction | Scope | Typical Lab | Lead Time* | Cost (USD) | Validity |

|---|---|---|---|---|---|---|

| FCC Part 15 B | USA | Wi-Fi / Bluetooth EMI | TÜV SÜD, Intertek | 2 wks | 1.2 k | Life of hardware |

| CE-RED | EU | Radio module + EMC | TÜV, SGS | 3 wks | 2.5 k | 5 yrs or HW change |

| CE-LVD | EU | 63 V–1 kV safety | Ditto | parallel | incl. | 5 yrs |

| RoHS 2.0 | EU & Amazon req. | 10 restricted substances | SGS, BV | 5 days | 0.3 k / BOM | 1 yr / batch |

| REACH 240 | EU | SVHC chemicals | SGS | 7 days | 0.4 k | 1 yr |

| FDA Food-Grade | USA | Waste bin, rake, liner | Intertek | 1 wk | 0.6 k | Material lot |

| Prop 65 | California | Heavy metals, phthalates | QIMA | 3 days | 0.25 k | Annual |

| DOE Level VI | USA | External PSU only | UL | 2 wks | 1.0 k | Life of PSU |

*Lab queue time; engineering-ready samples assumed.

Pro-tip: Bundle FCC + CE-RED + RoHS into one “global safety pack” with TÜV SÜD Shenzhen; saves 15 % cost and 1 week vs. sequential tests.

H3 2. Amazon FBA Packaging & Drop-Test Rules

Amazon’s ISE (Item Package Drop Test) is stricter than ISTA-6; failures go straight to “Unfulfillable” and you pay return disposal.

| Test | Method | Pass Criteria | Shenzhen Prep Fee |

|---|---|---|---|

| Drop | 9 drops, 30–36 in (box wt. >20 lb) | No unit damage, no loose litter | $0.45 / pc |

| Compression | 75 lbf top, 200 lbf side | <6 mm deflection | incl. |

| Vibration | 60 min random 0.53 GRMS | No component shift | incl. |

| Labeling | FNSKU, suffocation warning, Made-in-China | Amazon scan-ready | $0.08 / label |

Material spec we use for 30 % recycled content:

5-ply BC flute + 180 gsm kraft, 32 ECT min.

Inner EPS replaced by molded pulp—cuts dimensional weight by 8 % and satisfies EU PPWR 2024.

Master carton ≤50 lb to avoid Amazon “Team Lift” surcharge.

H3 3. Shenzhen-Based Lead-Time Reality Check

Stable supply chain = transparent lead times + buffer for certification re-runs.

| Milestone | Calendar Days | Notes |

|---|---|---|

| Tooling | 25–30 | T1 samples off 718H steel molds |

| EV / DV build | 10 | 100-unit pilot, includes app OTA |

| Certification sprint | 14–21 | Parallel with DV |

| PV / Mass | 20 | 3-shift SMT, 8 SMT lines @ 5 k pc/day |

| Sea freight (SZX-LAX) | 14 | Yantian direct, 1:1 container ratio |

| Air contingency | 3–5 | For Amazon “Prime Day” surge |

Total program: 75–80 days door-to-door if no firmware re-spin.

Buffer: Add 10 days for first-time EU importer registration (EORI) & FDA Prior Notice filings.

Key Takeaways for Retail Buyers & Brand Owners

- Certify once, sell everywhere: Design the PCB with FCC & CE coexistence; antenna placement done right avoids costly re-layout.

- Package for the drop, not the shelf: 30 % of negative reviews stem from freight-damaged sensors; invest $0.45 now vs. 5 % return rate later.

- Lock Shenzhen capacity early: Q3 is litter-box season; lines book 60 % to global brands by April. A 20 % down-payment secures priority queue and component allocation (especially MCU and Wi-Fi modules).

Bottom line: Treat compliance & packaging as core product features, not afterthoughts. In the smart-litter race, the first to pass Amazon’s drop test without a re-work wins the Buy Box—and the recurring filter revenue that follows.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize a High-Performance Automatic Litter Box – OEM/ODM Playbook for Global Brands

H3 1. Benchmark & Brief: Start With the Right Sample Set

Before you spend a dollar on tooling, validate three sample tiers to de-risk your SKU.

| Tier | Purpose | What to Test | Red Flags to Reject |

|—|—|—|—|

| A. Golden Sample (flagship spec) | Benchmark max performance | IoT latency, <35 dB noise, 99 % rake efficiency, <0.5 % litter residue | Motor stall >1/50 cycles, APP dropout >3 s, rake deformation |

| B. Cost-Engineered Sample | Hit target FOB | Plastic thickness ↓ 0.3 mm, single IR vs. TOF sensor, PP vs. ABS | Wall warpage >0.8 mm, sensor miss >5 %, odor leakage >20 ppm |

| C. Competitor Tear-Down | IP freedom & gap scan | Patent mapping, BOM rollup, packaging cube | 12+ active patents, BOM delta <8 %, non-foldable base |

Ship samples via DHL Express (2–3 days) and run a 48-hour torture test (4 cats, 6 cycles/day, 90 % humidity). Log data in a shared Google Sheet; insist the factory sends the raw MCU log to verify cycle counts.

H3 2. Lock Specification & Customization Matrix

Use a modular platform approach so you can launch multiple price tiers without re-certification.

| Module | Standard (ODM) | Tier-1 Custom (OEM) | Tier-2 Private Mold |

|---|---|---|---|

| Control Board | Tuya WB3S Wi-Fi + Bluetooth | Replace with Matter-ready WB5 | Custom PCB shape, add UWB for pet localization |

| Sensors | 2× IR + weight pad | Upgrade to 6× TOF array | Add mm-wave for multi-cat ID |

| Litter Chamber | 57 L PP, 3 mm wall | Anti-microbial ABS, 4 mm | Double-wall with PU foam, <28 dB |

| App UI | Tuya white-label | Re-skin w/ brand palette | Native SDK, AWS IoT Core |

| Packaging | 5-ply brown box | 5-color E-flute, 2-piece | ISTA-6-Amazon.com, 30 % less air cube |

MOQ breakpoints:

Logo silk-screen only – 100 pcs

Custom color – 500 pcs (share injection mold base)

Private mold – 1 000 pcs amortized over 2 years

Insist on UL & CE pre-scan at the pilot-run stage; it saves 3–4 weeks vs. waiting for mass production.

H3 3. Pilot Run & Supply-Chain Stress Test

Order a 200-piece pilot (10 % of first-year forecast) and run it on the same SMT & assembly line as mass production. Key gates:

| Gate | Acceptance Criteria | Tool |

|---|---|---|

| SPC on torque driver | Cpk ≥ 1.67 | Minitab real-time |

| APP OTA pass rate | 100 % success, <90 s flash | Firebase dashboard |

| Cat safety pinch test | 0 N finger probe, 5 mm max gap | ISO 8124-1 fixture |

| Carton drop | 1.2 m, 10 edges/corners, 0 rupture | ISTA-1A |

Parallel to the pilot, audit second-tier suppliers:

Motor – Mabuchi or Dongguan Kegu (keep 20 % dual-source)

Weight sensor – HBM or Tecsis (±10 g accuracy)

Li-ion pack – BYD or EVE (UN38.3 certified, 600-cycle 80 % SOH)

Negotiate a VMI (vendor-managed inventory) agreement so critical components carry 4-week buffer stock—this alone cuts lead-time volatility by 30 % during CNY.

H3 4. One-Stop Partner: Why PAWBILT

PAWBILT ships >450 k smart litter boxes/year to Chewy, Tractor Supply, and EU pet chains. When you partner with them you get:

Shared IPD (integrated product development) team—ME, EE, FW, UX under one roof; reduces NPI cycle to 90 days.

Tuya Platinum ID—pre-certified firmware, no 6-week Cloud-to-Cloud queue.

In-house cat test lab—12 resident shorthairs, 24/7 video logging; provides objective rake-efficiency report you can show Amazon or Chewy compliance teams.

Global after-sales spare-part hub in LA & Rotterdam—48 h replacement parts to protect your ratings.

Next step: Book a 30-min Zoom with PAWBILT’s OEM director; they will FedEx a benchmark sample kit within 72 h and share a live BOM cost waterfall so you can see exactly where every dollar lands.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label do automatic litter boxes work business.