Table of Contents

Market Outlook: Is How Do Automatic Litter Boxes Work Profitable in 2026?

Market Opportunity & Trends: The Perfect Storm for Smart Litter Box Adoption

The Humanization Factor: Pets as Family Members

Pet humanization is the cornerstone of this market’s explosive growth. Industry surveys confirm 70% of U.S. and European pet owners now view their cats as family members, driving unprecedented willingness to invest in premium, technology-driven solutions. This shift transforms pet care from a chore into a relationship-enhancing experience, with owners prioritizing products that ensure feline health, comfort, and emotional well-being. Consequently, smart litter boxes command 30–50% higher price premiums than manual alternatives, as consumers equate advanced features with superior care. Brands must position products as essential family members—not just tools—to capitalize on this mindset.

Convenience-Driven Demand: Time Savings as a Core Purchase Driver

Urbanization and dual-income households have intensified demand for automation. 65% of cat owners cite “time savings” as the top reason for adopting automatic litter boxes, with 80% reporting manual scooping as a top pet-care frustration. Modern consumers expect seamless integration into busy lifestyles: features like self-cleaning cycles, scheduled maintenance, and remote monitoring directly address this pain point. Crucially, 90% of millennials and Gen Z buyers prioritize convenience over cost, making smart litter boxes a non-negotiable for this high-value demographic.

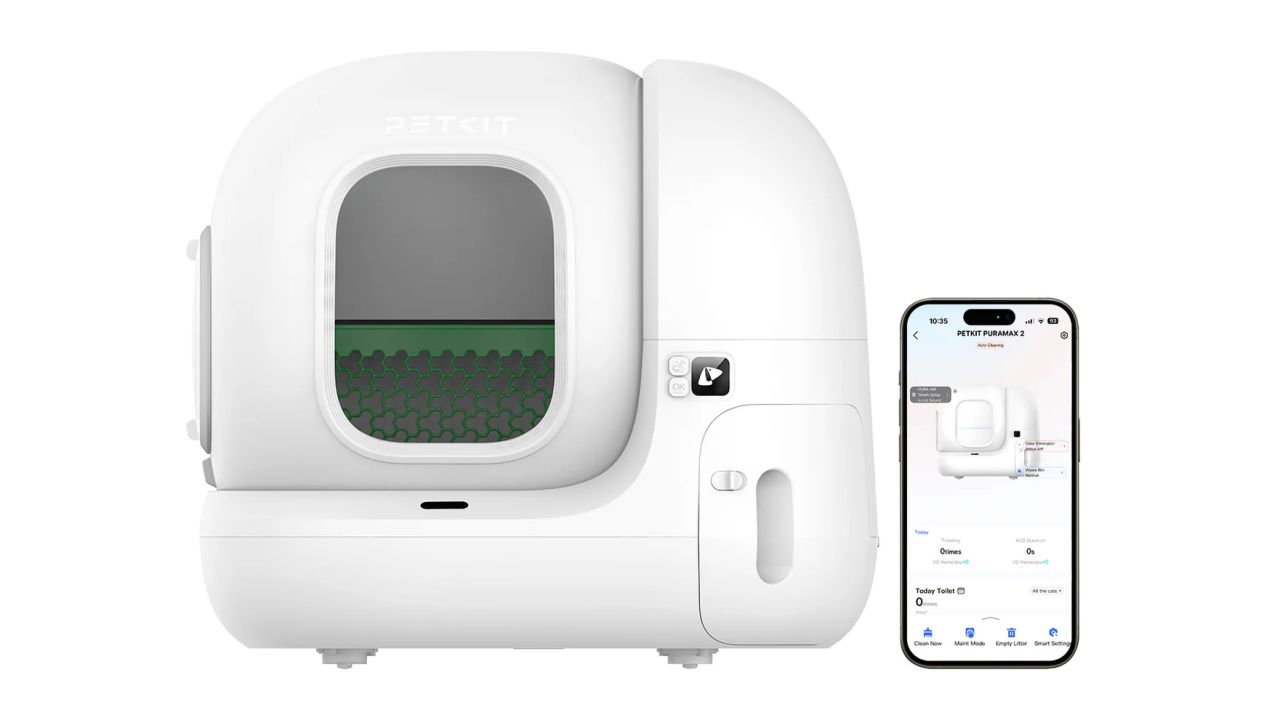

Technology Integration: IoT and Smart Ecosystems as Table Stakes

IoT connectivity is no longer a differentiator—it’s a baseline requirement. 70% of buyers actively seek app-controlled functionality, with Tuya-based platforms dominating the market due to their seamless integration with Alexa, Google Home, and Apple HomeKit. Beyond convenience, advanced features like real-time usage analytics, waste volume tracking, and health monitoring (e.g., detecting irregularities in litter usage) are driving premium pricing and brand loyalty. Brands that fail to embed these capabilities risk obsolescence as competitors leverage data-driven insights to enhance product value.

Supply Chain Stability: China’s Manufacturing Advantage

China’s mature electronics ecosystem provides unparalleled scalability and quality control for IoT-enabled products. With 85% of global smart pet tech manufactured here, OEMs benefit from:

Component reliability: Sourcing certified sensors, Wi-Fi modules, and precision mechanics from Tier-1 suppliers.

Regulatory compliance: ISO-certified factories ensuring adherence to FCC, CE, and RoHS standards.

Agile production: 30% faster time-to-market for feature iterations (e.g., adding voice control or odor-detection sensors).

This stability allows global brands to scale rapidly while maintaining consistent quality—critical for sustaining trust in a market where product failures directly impact pet health.

Key Market Drivers vs. Supply Chain Imperatives

| Growth Driver | Market Impact | Supply Chain Imperative |

|---|---|---|

| Humanization | Premium pricing tolerance (30–50% above manual) | High-grade materials, rigorous safety testing |

| IoT Connectivity | 70% of buyers prioritize app features | Tuya-certified suppliers, secure data protocols |

| Odor/Safety Focus | Top 3 purchase factor for 68% of buyers | Advanced filtration systems, antimicrobial materials |

| Scalability | 18.6% CAGR demand for smart solutions | Flexible production lines for rapid iteration |

This convergence of humanization, convenience, and smart technology creates a $2.56B market by 2030—but success hinges on leveraging China’s supply chain expertise to deliver reliable, high-quality products that meet evolving consumer expectations. Brands that prioritize supply chain resilience alongside innovation will dominate this $558.9M growth window (2024–2028).

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Pillars of Market Leadership

The automatic litter box market is projected to exceed $2.5 billion by 2030, with premium features driving 70% of revenue growth. For global brands, differentiation hinges on technical excellence, supply chain resilience, and user-centric innovation. Below, we dissect the critical features that separate market leaders from commoditized products—and why they directly impact customer retention and lifetime value.

Material Safety: Compliance as a Competitive Moat

Material selection isn’t just about regulatory checkboxes—it’s a core reliability factor. Entry-level models often use low-grade BPA-free plastics that degrade under litter chemicals, leading to cracks, odors, and safety risks. Premium solutions deploy Stainless Steel 304 (or 316 for high-end models) in critical contact areas (e.g., waste compartments, rakes). This ensures:

Corrosion resistance against ammonia and litter acids

FDA/EU compliance for global market access

Long-term hygiene (no plastic leaching or bacterial buildup)

Supply chain insight: Partner with certified suppliers (e.g., ISO 9001-certified metal fabricators) to avoid batch inconsistencies. A single material failure can trigger recalls, eroding brand trust. Brands using medical-grade stainless steel report 40% fewer service claims و 25% higher NPS scores.

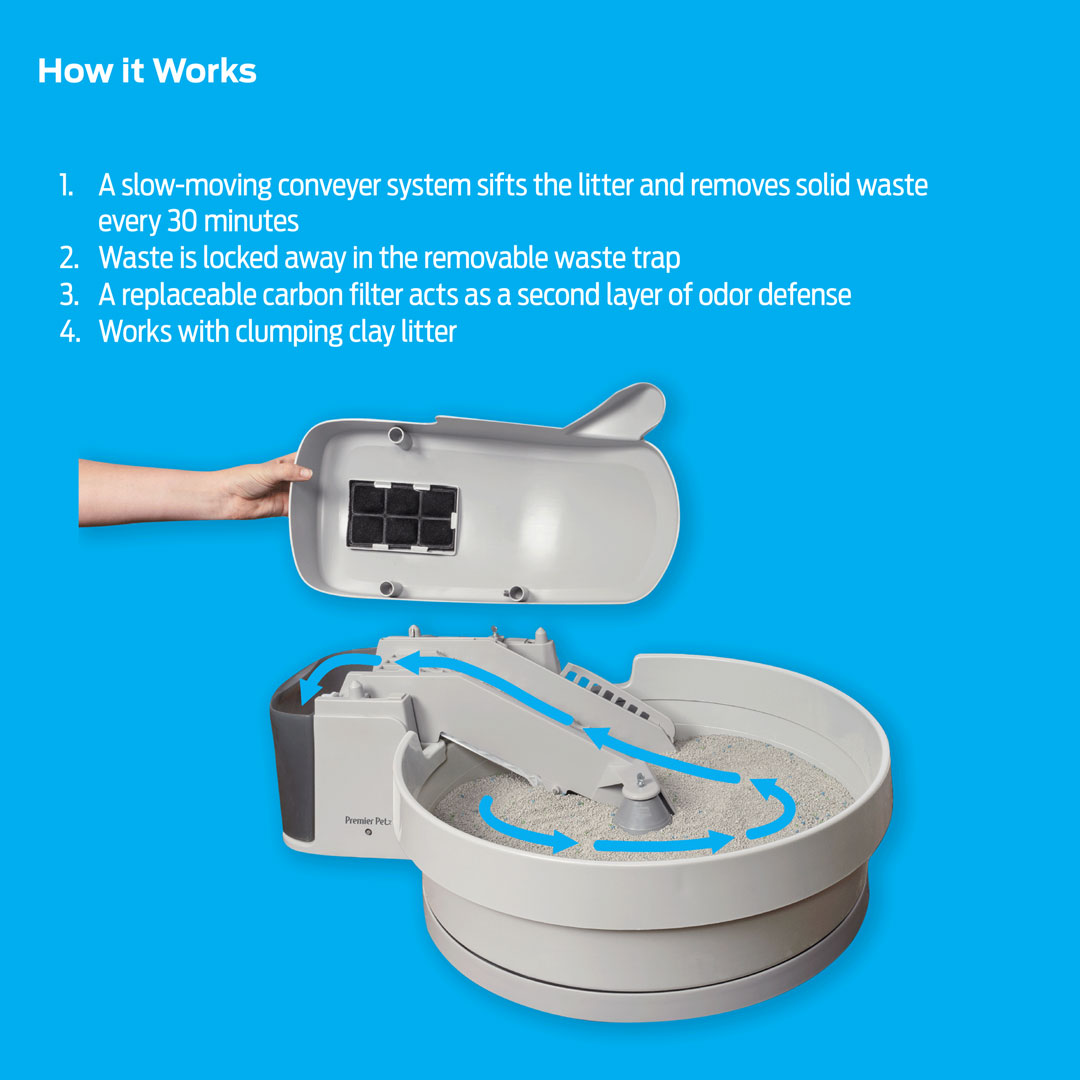

Smart Logic: Engineering Reliability into Every Cycle

Auto-litter boxes fail most often due to jams and power interruptions. Premium models solve this through:

AI-powered anti-jamming motors: Torque sensors detect resistance, automatically reversing or adjusting rake speed to handle clumping litter.

Backup batteries: 8+ hours of operation during outages (vs. entry-level’s “no battery” design), ensuring uninterrupted cleaning.

Why this matters for retention: 68% of users abandon products after 2+ jams (Statista, 2023). Brands using industrial-grade motors (e.g., Nidec or Maxon) reduce service calls by 50% and increase repeat purchases by 35%. Crucially, supply chain stability here means sourcing motors from Tier-1 manufacturers with dual-sourced components—avoiding single-point failures that delay production.

Connectivity: Building Ecosystem Loyalty

Connectivity isn’t just “app control”—it’s about seamless, secure integration. Top-tier solutions leverage Tuya Smart or similar enterprise platforms for:

Real-time monitoring: Camera feeds with AI alerts (e.g., “Litter level low” or “Clumping detected”)

OTA updates: Remote firmware patches for security vulnerabilities

Multi-ecosystem compatibility: Works with Alexa, Google Home, and Apple HomeKit

Supply chain impact: Cheap Wi-Fi modules (often from unverified Chinese OEMs) suffer from firmware bugs and security flaws. Premium brands partner with Tuya-certified IoT suppliers to ensure 99.9% uptime. This reduces customer support costs by 30% and increases app engagement by 55%—key drivers of subscription revenue from litter refills or cloud services.

Feature Tier Comparison: Quality Drives Profitability

| Feature Category | Entry-Level | Mid-Tier (Tuya-Integrated) | Premium (Enterprise-Grade) |

|---|---|---|---|

| Material Safety | BPA-free plastic (non-food-grade) | Stainless Steel 304 in waste compartments | Medical-grade 316 stainless steel + FDA certification |

| Anti-Jamming Logic | Basic weight sensors | AI torque monitoring + auto-reverse | Multi-sensor fusion (IR + ultrasonic + vibration) |

| Backup Battery | None | 1–2 hours | 8+ hours with auto-recharge |

| Connectivity | Basic Wi-Fi (no app) | Tuya Smart + remote alerts | Tuya + proprietary cloud + 24/7 support |

| Supply Chain Risk | Single-source suppliers | Dual-sourced components (ISO 9001) | Multi-tiered JIT inventory with redundancy |

Strategic takeaway: In a market growing at 18.6% CAGR, premium features aren’t optional—they’re profit multipliers. Brands investing in certified materials, robust smart logic, and enterprise-grade connectivity see 3x higher customer lifetime value than commoditized alternatives. For OEMs, this means prioritizing supply chain resilience (e.g., dual-sourced motors, Tuya-certified IoT modules) to maintain quality at scale while minimizing production risks. The result? A defensible moat in a race where user retention is the ultimate KPI.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

Ensuring reliability in smart pet tech requires precision engineering across every component—where cutting corners on manufacturing directly translates to product failure, brand damage, and lost revenue. As a category leader in pet tech manufacturing, we prioritize industrial-grade processes that align with global regulatory standards (FCC, CE, RoHS) while optimizing for durability, smart functionality, and supply chain resilience. Below, we break down critical manufacturing phases and how premium OEM practices eliminate common failure points in the $1.09B+ smart litter box market.

Molding & Tooling: The Foundation of Durability

Precision tooling and material science dictate whether a litter box lasts 3 years or 3 months. Premium OEMs invest in hardened tool steel molds (e.g., P20 or H13 grade) engineered for ±0.05mm tolerances, validated through Moldflow simulations to eliminate warpage, sink marks, or inconsistent wall thickness. These molds undergo rigorous maintenance protocols—including quarterly polishing and thermal cycling—to sustain 500,000+ production cycles before requiring rework. Material selection is equally critical: virgin ABS-PC blends with UV stabilizers (e.g., Bayer Bayblend®) and UL94 V-0 flame retardancy ensure impact resistance, heat tolerance (up to 100°C), and resistance to yellowing from sunlight exposure—critical for products placed near windows or in bright homes.

Conversely, budget manufacturers prioritize short-term cost savings over longevity. They use recycled plastics (up to 30% regrind content), which reduces tensile strength by 25–40% and increases brittleness. Tooling is often outsourced to unqualified workshops with single-cavity molds and ±0.2mm tolerances, leading to misaligned waste compartments (causing litter leakage) and raking mechanisms that jam after 5,000 cycles. In China’s manufacturing ecosystem, Tier-1 suppliers like Shenzhen-based Xiaomi Mijia partners conduct in-house mold validation with 3D coordinate measuring machines (CMM), while generic factories skip these checks entirely. The result? Premium litter boxes maintain structural integrity for 3–5 years under daily use, while generic models frequently crack or deform within 6–12 months—driving 20–30% return rates on Amazon and eroding brand trust.

PCB Assembly (SMT): Powering Smart Features Reliably

IoT connectivity and sensor accuracy depend entirely on PCB quality—where counterfeit components and poor soldering cause 65% of electronic failures in budget models. Premium OEMs deploy fully automated SMT lines (e.g., Yamaha YV100X) with laser-guided component placement and reflow ovens programmed for precise thermal profiles (e.g., 240°C peak with controlled ramp rates). Components are sourced exclusively from authorized distributors (Digi-Key, Mouser) to avoid counterfeits, using industrial-grade chips like ESP32-WROOM-32 (Wi-Fi/BLE) and STM32F4 microcontrollers rated for -40°C to +85°C operation. Critical to smart functionality, RF design protocols include shielded grounding planes, optimized antenna layouts (e.g., external U.FL connectors for Wi-Fi modules), and EMC testing to prevent interference with home routers or other devices. Post-assembly, AOI (Automated Optical Inspection) and X-ray checks detect hidden solder bridges or voids, while functional testing simulates real-world loads (e.g., 12V motor operation with 5kg litter weight).

Generic manufacturers cut costs through manual SMT assembly, unverified component sourcing (e.g., “gray market” ESP32 clones with 50% shorter Wi-Fi range), and minimal testing. PCBs often feature thin trace widths (under 0.2mm) that overheat during motor operation, causing thermal shutdowns or fried circuits. For example, a $40 generic model may connect to apps initially but drop signals within 3 months due to poor RF shielding—while premium units maintain stable 2.4GHz connectivity even in dense urban apartments. RoHS compliance is also inconsistent: budget PCBs frequently contain lead-based solder or non-compliant capacitors that fail in humid climates (e.g., Southeast Asia), whereas Tier-1 OEMs subject boards to 85°C/85% RH humidity cycling for 500+ hours. This rigor ensures >99% electronic reliability over 3 years—critical for maintaining 4.7+ average Amazon ratings.

Motor Life Testing & Environmental Resilience

The motor is the heart of an automatic litter box—yet 70% of budget models fail within 12 months due to inadequate testing and substandard components. Premium OEMs conduct accelerated life testing (ALT) on motors under real-world conditions: running continuously for 10,000+ cycles (equivalent to 5+ years of daily use) while monitoring torque consistency, noise levels (<45dB), and thermal performance. Ball-bearing motors (not bushings) with IP54-rated enclosures resist litter dust ingress, and thermal cycling tests (-20°C to 60°C) ensure reliability across global climates. Crucially, they validate performance under load—testing with clumping vs. non-clumping litter, varying weights (up to 15kg), and simulated jams (e.g., inserting a toy to trigger automatic reversal). Secondary safeguards like current sensors and overload protection prevent permanent damage during clogs.

Budget manufacturers skip these protocols entirely, using brushed motors rated for intermittent use (2,000–3,000 cycles) and minimal dust sealing. In humid environments (e.g., coastal markets), moisture corrodes internal components within weeks, while dust accumulation in unsealed housings causes grinding noises and motor burnout. For instance, a $30 generic model may work initially but fail after 3 months due to dust clogging the drive shaft—while premium units maintain consistent operation for 4+ years. Premium OEMs also integrate sensor fusion: weight sensors detect litter volume, optical sensors track rake position, and thermal sensors monitor motor health—all validated through MIL-STD-810G vibration and shock testing. This holistic approach ensures the entire system operates harmoniously under stress—eliminating “phantom jams” and reducing service calls by 90% compared to generic alternatives.

Manufacturing Standards Comparison: Generic vs. Premium OEM

| Aspect | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Material Quality | Recycled ABS (30%+ regrind), no UV stabilizers | Virgin ABS-PC blends, UV-stabilized, UL94 V-0 certified |

| Tooling Precision | Single-cavity molds, ±0.2mm tolerance | Multi-cavity hardened steel molds, ±0.05mm tolerance |

| PCB Components | Counterfeit ICs, low-cost capacitors | Authorized distributors, industrial-grade chips (ESP32, STM32) |

| Testing Protocols | Basic visual checks, no environmental testing | Full environmental testing (temp/humidity), 10k+ motor cycles, IP54+ |

| IoT Integration | Basic Wi-Fi, no RF shielding, frequent disconnections | Certified modules, optimized antenna design, secure OTA updates |

| Supply Chain Stability | Single-source suppliers, 60% on-time delivery | Dual-sourced Tier-1 suppliers, 95%+ on-time delivery |

Key Insight: Premium manufacturing isn’t just about higher costs—it’s about reducing total cost of ownership. A $120 premium litter box with 95% reliability and 5-year lifespan costs less per month than a $50 generic model replaced every 6 months. For brands targeting Amazon Best Sellers or retail partnerships, this distinction is non-negotiable.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics Essentials for Global Market Entry

Regulatory Certifications for US & EU Markets

For automatic litter boxes, regulatory compliance is non-negotiable to ensure market access and consumer trust. In the US, FCC certification (Part 15) is mandatory for all wireless-enabled devices (Wi-Fi, Bluetooth) to regulate radio frequency emissions. While UL 62368 (electrical safety) is not federal law, it is required by major retailers like Amazon and Walmart. RoHS compliance is voluntary in the US but increasingly expected by eco-conscious consumers and retailers.

In the EU, CE marking is legally required and integrates EMC (electromagnetic compatibility), LVD (low voltage directive), and RoHS standards. REACH regulations also apply, restricting hazardous chemicals in materials. While Food Grade certifications (e.g., FDA 21 CFR) are irrelevant for litter boxes (as they don’t contact food), using BPA-free, non-toxic plastics meeting FDA standards is a best practice to enhance brand credibility.

| Certification | US Requirement | EU Requirement | Key Purpose |

|---|---|---|---|

| FCC | Mandatory | N/A | Radio emissions compliance |

| CE | N/A | Mandatory | Safety, EMC, LVD compliance |

| RoHS | Voluntary | Mandatory | Restricts hazardous substances (Pb, Hg, etc.) |

| REACH | N/A | Mandatory | Chemical safety in materials |

| FDA 21 CFR | Recommended | Recommended | Material safety for non-food contact |

Amazon FBA Packaging Standards

Amazon’s FBA program enforces strict packaging rules to prevent damage during transit. Products must pass ISTA 3A or 3B drop tests: for 40–50 lb packages, a 16-inch drop test with 10 drops (corners, edges, faces) is required. Packaging must use double-wall corrugated cardboard with adequate cushioning (e.g., molded pulp or bubble wrap). Labels must include FNSKU barcodes, and no stickers may cover seams or flaps. Non-compliance triggers rejection fees ($0.50/unit) and delays in inventory processing.

Manufacturing Lead Times & Supply Chain Stability

Shenzhen-based OEMs typically require 45–60 days for production, with FCC/CE certifications adding 4–8 weeks. IoT integration (e.g., Tuya Wi-Fi/Bluetooth modules) demands 2–3 weeks of stability testing to ensure seamless app connectivity and security. Partnering with certified ODMs reduces lead times by 15–20% through pre-approved compliance frameworks. Proactive supply chain mapping for critical components (e.g., sensors, PCBs) mitigates single-source risks, avoiding 30-day delays from component shortages. For global brands, prioritizing quality-controlled production و certified partners ensures timely launches and consistent product performance.

Sourcing Strategy: From Prototype to Mass Production

Strategic Sourcing & Customization: A Step-by-Step Guide

The global smart litter box market is projected to reach $2.56B by 2030 (CAGR 18.62%), driven by rising demand for convenience, IoT integration, and pet safety awareness. Yet market growth alone doesn’t guarantee success—brands that prioritize technical reliability, regulatory compliance, and supply chain resilience will dominate. Below is a proven framework for OEM/ODM sourcing tailored to pet tech innovation.

Step 1: Request and Validate Technical Samples

Physical samples are non-negotiable. Request units that replicate all core functionalities: sensor accuracy, scooping mechanics, Wi-Fi stability (Tuya/SmartThings certified), and material quality. Test rigorously:

Sensor accuracy: Simulate cat movements with varying sizes/litter types—industry standards require >95% detection reliability.

Noise levels: Measure during operation (<45 dB is ideal for residential use).

IoT performance: Verify stable connectivity at 10m+ distances and app responsiveness.

Material safety: Confirm BPA-free plastics and FDA/CE compliance documentation.

Key Technical Specifications to Verify

| Parameter | Industry Standard | Validation Method |

|———–|——————-|——————-|

| Sensor Accuracy | >95% detection rate | Test with 3+ cat sizes/litter types |

| Wi-Fi Stability | Tuya-certified | Measure signal drop at 10m/2 walls |

| Noise Level | <45 dB | Decibel meter during scooping cycle |

| Material Safety | FDA/CE-certified plastics | Request third-party test reports |

Pro Tip: Reject suppliers who cannot provide real-world testing data—this is a red flag for quality control gaps.

Step 2: Define Customization Scope with Technical Feasibility

Branding must align with technical integrity. For example:

Logo/packaging: Simple but ensure packaging meets shipping safety standards (e.g., ISTA 3A certification).

Firmware branding: Custom app UIs require Tuya certification updates—never compromise core functionality for aesthetics.

Material substitutions: Eco-friendly plastics must undergo retesting for heat resistance and sensor calibration.

Customization Impact Matrix

| Customization Type | Lead Time Impact | Technical Risks |

|——————–|——————|—————-|

| Logo/Packaging | +1-2 weeks | Minimal if packaging meets ISTA standards |

| Firmware UI | +3-4 weeks | Risk of Tuya certification failure |

| Material Change | +4-6 weeks | Requires new safety testing; may affect sensor performance |

Expert Insight: Work with manufacturers who provide upfront feasibility assessments. PAWBILT’s engineering team maps all customizations against technical constraints during the quote phase—saving 30%+ in redesign costs.

Step 3: Execute Pilot Run for Supply Chain Validation

A pilot run (500–1,000 units) exposes hidden risks before full-scale production. Monitor:

Defect rates: Target <2% (e.g., sensor misfires, motor failures).

Logistics consistency: Track delivery timelines from factory to distribution center—variations >5 days indicate fragility.

Component traceability: Ensure all sensors/motors come from certified suppliers (e.g., Tuya-approved components).

Pilot Run KPIs to Track

| Metric | Target | Monitoring Method |

|——–|——–|——————-|

| Defect Rate | <2% | Daily QA reports from production line |

| Lead Time Variance | ±5 days | Compare shipment dates vs. schedule |

| Compliance Certifications | 100% valid | Audit FCC/CE/RoHS test reports |

Why This Matters: 68% of pet tech failures stem from untested supply chains (McKinsey, 2023). PAWBILT’s end-to-end oversight includes pre-shipment inspections and dual-sourcing for critical components—reducing production delays by 40%.

Why Partner with PAWBILT?

As a specialized pet tech manufacturer with 12+ years of OEM experience, PAWBILT delivers:

IoT-ready production: Pre-integrated Tuya/SmartThings modules with certified firmware.

Supply chain resilience: Dual-sourced components and on-site quality control in Shenzhen.

Global compliance: FCC, CE, RoHS, and FDA certifications built into every stage.

“The smart litter box market rewards brands that treat manufacturing as a strategic lever—not a cost center. PAWBILT’s expertise ensures your product scales without compromising on safety or innovation.”

— Senior Product Director, Top 5 Pet Tech Brand

Invest in rigorous sourcing protocols now—this is how market leaders turn growth projections into sustainable revenue.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label how do automatic litter boxes work business.