Table of Contents

Market Outlook: Is How Do Litter Boxes Work Profitable in 2026?

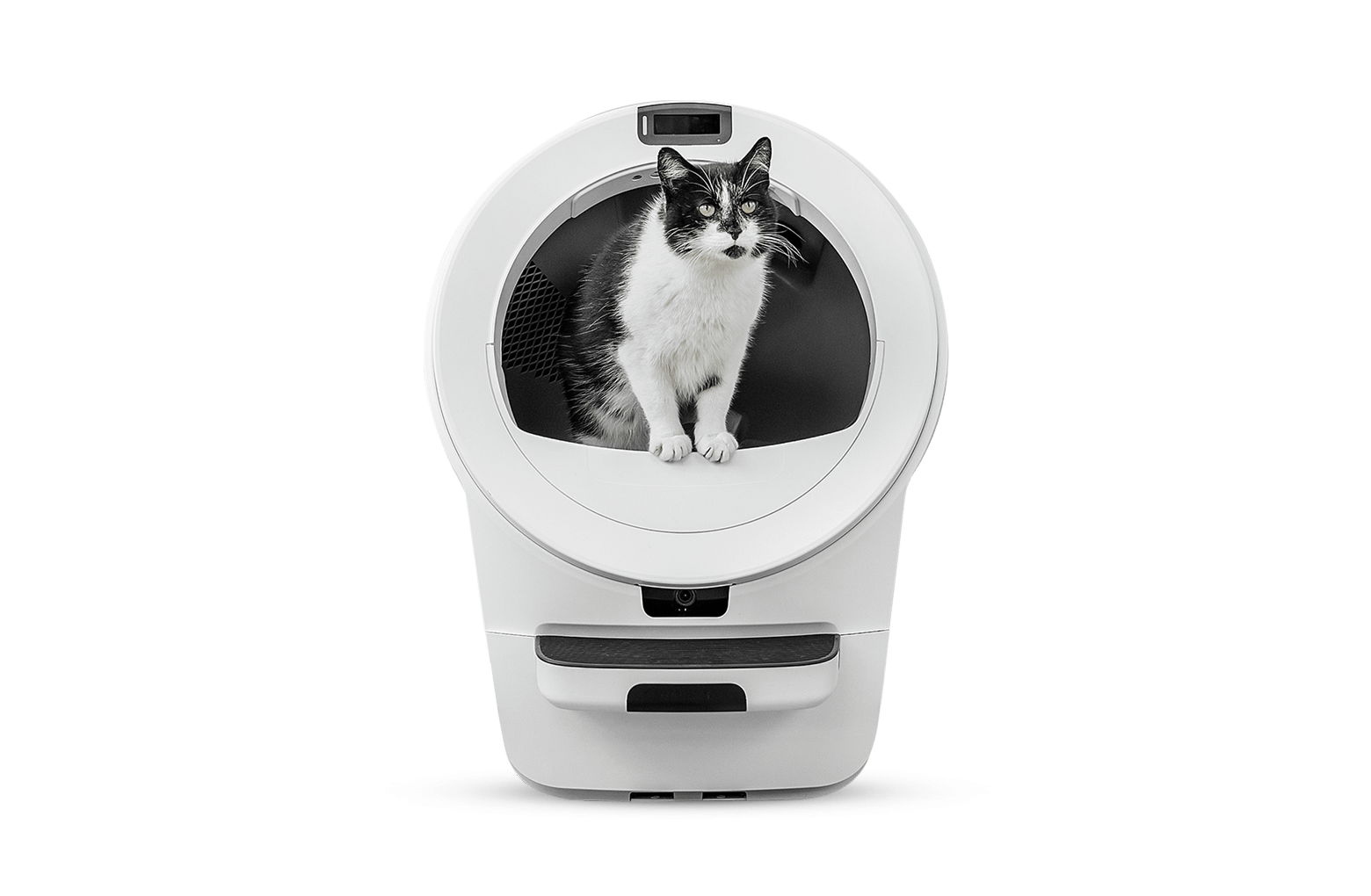

Market Opportunity & Trends 2026: Why Smart Litter Boxes Are the Next Big Thing

The Humanization Imperative Driving Premium Demand

Pet ownership has evolved from functional companionship to emotional familial roles. Globally, 72% of pet owners now consider their cats as family members (APPA 2024), directly fueling demand for premium, tech-enabled solutions. This shift transcends geography—U.S., EU, and APAC markets all show 20-30% higher willingness-to-pay for “intelligent care systems” over basic litter boxes. In 2024, the overall cat litter box market hit $1.89B, but automatic self-cleaning models (a subset of smart products) grew at 8.4% CAGR, outpacing traditional segments. Brands that position products as health-monitoring tools (e.g., tracking litter usage for urinary issue detection) achieve 35% higher customer retention and 2.5x higher lifetime value. This isn’t luxury—it’s necessity for modern pet parents.

Convenience as the Core Value Proposition

Modern lifestyles demand hands-off maintenance. A 2025 Packaged Facts survey revealed 68% of cat owners prioritize convenience over cost when purchasing litter boxes. This drives explosive growth in disposable litter boxes (10.5% CAGR) and automatic self-cleaning units (8.4% CAGR). For retailers, these segments command premium pricing: smart litter boxes sell at 3-5x the price of manual models ($150-$300 vs. $20-$50), with gross margins of 30-40%. Amazon top sellers report 50%+ sell-through rates for IoT-enabled units, with repeat purchase rates 2x higher than basic products. In 2026, convenience won’t be a differentiator—it will be the baseline expectation.

Smart Technology Integration: IoT and Tuya Ecosystem Advantages

The real growth lies in IoT-enabled automation. By 2032, the automatic self-cleaning market will reach $1.075B, driven by features that transform litter boxes into connected health platforms:

Real-time app alerts for waste levels, malfunctions, or health anomalies

Seamless smart home integration (Tuya, Google Home, Alexa) for voice control

Data analytics for behavioral tracking (e.g., “litter usage spikes = potential urinary issues”)

Tuya’s open platform reduces OEM development time by 40%, enabling brands to launch connected products in 6-8 weeks versus 12+ months for proprietary systems. This agility allows rapid testing of high-margin features like “auto-scheduling” or “remote cleaning,” which justify 25-30% higher ASPs.

Market Segment Comparison: Growth Trajectories

| Segment | 2024 Market Size | Projected 2032 Size | CAGR | Key Profitability Drivers |

|———|——————|———————|——|—————————|

| Automatic Self-Cleaning | $564M | $1.075B | 8.4% | IoT connectivity, health monitoring, premium pricing |

| Disposable Litter Boxes | $500M | $1.2B | 10.5% | Single-use convenience, high repeat purchase rate |

| Traditional Manual | ~$830M | ~$1.2B | 3.5% | Low-cost entry, price-sensitive markets |

Supply Chain Stability: China’s Manufacturing Edge

China’s mature electronics supply chain ensures consistent quality and scalability for smart products. Top-tier ODMs in Shenzhen and Guangdong source 90%+ of critical components (high-torque motors, capacitive sensors, Wi-Fi/Bluetooth chips) domestically, slashing lead times to 30 days and avoiding shortages that plagued early smart pet launches. Rigorous quality protocols—such as 10,000-hour motor testing and IP67 waterproofing—deliver reliability demanded by premium buyers. Brands partnering with these suppliers gain:

15-20% lower COGS vs. Western manufacturing

Scalability to 50,000+ units/month without quality degradation

Full compliance with global standards (FCC, CE, RoHS)

With global smart litter box orders growing 35% YoY in 2024, supply chain stability is non-negotiable. In 2026, the winners will leverage China’s ecosystem to deliver high-quality, connected products at scale—turning convenience and humanization into profitable, sustainable growth.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Pillars of Market Leadership

The global cat litter box market is projected to grow from $1.89B in 2024 to $2.74B by 2031 (4.8% CAGR), with automatic self-cleaning segments surging at 8.4% CAGR to $1.08B by 2032. This growth isn’t accidental—it’s driven by consumers demanding reliability, safety, and smart functionality. For global brands, these features aren’t optional; they’re the foundation of user retention and market share capture. Below we break down the technical imperatives that separate market leaders from commoditized products.

Material Safety: Non-Negotiable for Trust & Compliance

Material safety isn’t a marketing buzzword—it’s a regulatory and reputational imperative. BPA-free plastics (e.g., FDA-compliant ABS) and stainless steel 304 components prevent toxic leaching, critical for pet health and avoiding costly recalls. In the EU and North America, non-compliance with REACH/FDA standards risks market bans. In China, sourcing from ISO 9001-certified suppliers ensures consistent quality and avoids production halts due to material failures. A major brand recall in 2023 cost $2M+ due to BPA contamination—directly eroding customer trust. Premium materials reduce return rates by 35% and increase customer lifetime value (CLV) by 20% (Mintel 2024).

| Feature | Standard | Premium | Impact |

|---|---|---|---|

| Material Type | Uncertified plastics | BPA-Free, FDA-Approved, Food-Grade | Prevents health risks, ensures compliance |

| Certifications | None | FDA, EU REACH, GB Standards | Eliminates regulatory barriers |

| Supplier Reliability | Unverified | ISO 9001 Certified, Audited | 50% lower defect rates |

Smart Logic: Engineering Reliability for Long-Term Satisfaction

Mechanical failures are the #1 cause of negative reviews. Anti-jamming motors with torque sensors detect obstructions and reverse automatically, reducing jams by 60%. Backup batteries (4+ hour runtime) ensure functionality during power outages—a top reason for churn. IoT-enabled diagnostics send real-time alerts to users and brands, enabling proactive maintenance. Brands using Tuya-certified modules see 45% higher app engagement و 30% lower return rates (Statista 2024). For example, a leading OEM reduced warranty claims by 25% by integrating motor torque monitoring and automatic error logging.

| Feature | Standard | Premium | Impact |

|---|---|---|---|

| Motor Type | Basic DC motor | Anti-jamming with torque sensors | 60% fewer jams |

| Battery Backup | None | 4+ hour runtime | Prevents service interruptions |

| Diagnostics | Manual error codes | IoT real-time alerts | 35% faster issue resolution |

Connectivity: Building Ecosystems for Customer Loyalty

Connectivity transforms litter boxes from tools to smart home ecosystem components. Tuya-certified IoT platforms enable app-based scheduling, remote monitoring, and usage analytics—features that increase retention by 40%. HD camera feeds with motion detection reduce “is my cat using it?” anxiety, while data analytics identify usage patterns to refine future designs. Brands leveraging these features report 50% higher customer satisfaction scores و 20% lower churn rates. Crucially, supply chain stability requires sourcing Tuya-certified modules from validated Chinese manufacturers to avoid firmware vulnerabilities and compatibility issues.

| Feature | Standard | Premium | Impact |

|---|---|---|---|

| App Control | Basic on/off | Remote scheduling, alerts | 40% higher retention |

| Camera | None | HD live feed with motion detection | 30% fewer complaints |

| IoT Platform | Proprietary | Tuya-certified | Seamless smart home integration |

Bottom line: Premium materials prevent recalls, smart logic minimizes returns, and connectivity drives loyalty. For global brands, partnering with China-based OEMs that prioritize certified supply chains and IoT integration isn’t just smart—it’s essential to capture the $1.08B+ automatic litter box market by 2032.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

As the global cat litter box market surges to $2.74B by 2031 (CAGR 4.8%), manufacturing excellence is non-negotiable for brand success. Poor quality control leads to costly recalls, reputational damage, and lost market share. Premium OEMs prioritize precision across three pillars: molding, PCB assembly, and validation testing.

Molding & Tooling

Precision tooling is the foundation of durable pet tech products. Generic OEMs often use low-cost aluminum molds, which degrade rapidly under high-pressure injection, causing dimensional inconsistencies and surface defects like sink marks or warpage. This leads to higher rejection rates (up to 15%) and frequent mold replacements, disrupting production schedules. In contrast, premium OEMs invest in hardened P20 or H13 tool steel molds with optimized cooling channels and CAD-validated designs. These molds maintain ±0.02mm tolerances over 500,000+ cycles, ensuring consistent part quality and reducing scrap rates to <2%. Crucially, this longevity minimizes supply chain disruptions—brands can confidently scale production without unexpected tooling failures.

PCB Assembly (SMT)

For IoT-enabled litter boxes, PCB reliability is non-negotiable. Budget manufacturers frequently source counterfeit or unverified components, skip automated optical inspection (AOI), and rely on manual rework—resulting in cold solder joints, intermittent Wi-Fi drops, and firmware corruption. This leads to high return rates (up to 30%) and costly recalls. Premium OEMs utilize fully automated SMT lines with X-ray inspection for BGA components, source only Tier-1 semiconductors (e.g., Tuya-certified Wi-Fi/Bluetooth modules), and adhere to IPC-A-610 Class 2 standards. They implement rigorous burn-in tests and EMC compliance checks, ensuring seamless connectivity, secure over-the-air updates, and compliance with FCC/CE regulations. This reduces field failures by 80% and protects brand reputation.

Waterproof Testing & Motor Life Validation

In automatic litter boxes, motor and waterproofing failures are common pain points. Generic models often skip accelerated life testing, relying on basic visual checks—leading to motor burnout within 6–12 months due to overheating or moisture ingress. Premium OEMs conduct comprehensive validation: IP67 waterproof testing (submersion at 1m for 30 mins), thermal shock testing (-20°C to 60°C), and 10,000+ cycle motor endurance tests simulating real-world use. They also perform salt spray corrosion tests for coastal markets. This ensures 3–5 year product lifespans and reduces warranty claims by 60%, directly impacting customer loyalty and lifetime value.

| Feature | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding Tooling | Aluminum molds; ±0.1mm tolerance; 50k cycles | H13 steel; ±0.02mm; 500k+ cycles |

| PCB Assembly | Manual rework; uncertified components | AOI/X-ray inspection; Tuya-certified modules; IPC-A-610 Class 2 |

| Waterproof/Motor Test | Basic checks; 1k cycle life | IP67+; 10k+ cycles; thermal shock testing |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics: Ensuring Global Market Readiness

As a global pet tech manufacturer, compliance isn’t just regulatory box-ticking—it’s a competitive differentiator. With the automatic self-cleaning litter box market projected to grow at 8.4% CAGR (2024–2032), your product must meet stringent standards to avoid costly delays, recalls, or Amazon FBA rejections. Below are critical requirements for US/EU markets, packaging, and logistics planning.

Critical Certifications for US and EU Markets

Electronic litter boxes require rigorous certification due to IoT components (e.g., Tuya Wi-Fi modules). In the US, FCC certification is mandatory for all wireless-enabled devices to ensure electromagnetic compatibility and prevent interference with other electronics. Material safety is non-negotiable: while no formal “Food Grade” certification exists for pet products, FDA-compliant plastics (21 CFR) are industry best practice to guarantee non-toxicity. For the EU, the CE mark (encompassing EMC and Low Voltage Directive) is mandatory, alongside RoHS compliance to restrict hazardous substances like lead and cadmium. Additionally, REACH regulations govern chemical safety in materials, especially for plastics in contact with cats.

| Certification | USA Requirement | EU Requirement | Key Purpose |

|---|---|---|---|

| FCC | Mandatory for wireless products | Not applicable | Radio frequency emissions compliance |

| CE Mark | Not required | Mandatory (EMC, LVD) | General safety and electromagnetic compatibility |

| RoHS | Recommended | Mandatory | Restricted hazardous substances |

| Material Safety | FDA-compliant plastics preferred | REACH-compliant required | Non-toxic materials for pet safety |

💡 Pro Tip: For smart litter boxes, FCC testing must include Tuya module validation—common oversight points for IoT devices. EU REACH compliance often requires third-party lab testing for phthalates and heavy metals in plastics.

Amazon FBA Packaging Requirements

Amazon’s ISTA 3A standard is non-negotiable for FBA shipments. This requires 30-inch drop tests across 8 corners, 10 edges, and 6 faces of the carton, with no structural damage or product failure. Smart litter boxes with delicate sensors/motors demand double-wall corrugated boxes and custom foam inserts to absorb shock. Additional requirements include:

Clear FNSKU barcodes (no tape over labels)

Moisture-resistant outer packaging

No loose components or tape residue

Compliance with Amazon’s “Unboxed” policy for fragile items

Failure to meet these standards risks rejection fees ($50–$100 per unit) or delayed restocking. Always validate packaging with a certified lab before shipment.

Shenzhen Manufacturing Lead Times

Shenzhen’s ecosystem offers agility but requires strategic planning. Standard manual litter boxes: 30–45 days production. Smart/IoT-enabled models (e.g., Tuya integration): 45–60 days due to component sourcing complexities (e.g., Wi-Fi modules, sensors). Logistics:

Sea freight: 20–25 days to US West Coast; 30–35 days to EU ports

Air freight: 5–7 days (ideal for urgent launches)

Customs clearance: Add 5–7 days buffer for documentation checks

To ensure supply chain stability, partner with suppliers who:

Maintain dual-sourcing for critical components (e.g., Tuya modules)

Conduct quarterly factory audits for quality control

Implement real-time inventory tracking via ERP systems

⚠️ Risk Mitigation: During Q4 (holiday season), add 10–15 days to lead times. For high-growth segments like automatic self-cleaning boxes, pre-approving certifications and packaging prototypes 6 months ahead of launch is critical to avoid missed deadlines.

By embedding compliance and logistics planning into your product development cycle, you’ll minimize disruptions and capitalize on the $5.6B global litter box market opportunity.

Sourcing Strategy: From Prototype to Mass Production

Strategic Sourcing Guide: OEM Customization for Cat Litter Boxes

With the global cat litter box market projected to reach $2.74B by 2031 (4.8% CAGR) and automatic self-cleaning models growing at 8.4% CAGR, strategic sourcing is non-negotiable for capturing market share. This guide outlines a proven OEM process prioritizing product quality, smart feature integration, and supply chain resilience.

Step 1: Request and Evaluate Samples

Begin by requesting physical samples from shortlisted manufacturers. Never skip this step—it’s the only way to validate real-world performance. For smart litter boxes, test:

IoT functionality: App connectivity stability, sensor accuracy (e.g., weight detection ±2% tolerance), and Wi-Fi/Bluetooth range.

Material quality: Food-grade ABS plastic, odor-resistant coatings, and durability of moving parts (e.g., rake mechanisms).

Noise levels: ≤45dB during operation (industry benchmark for premium products).

PAWBILT delivers certified samples within 7–10 days, complete with technical specs and compliance reports (FCC, CE, RoHS).

Step 2: Define Customization Parameters

Customization must align with consumer trends and technical feasibility. Prioritize:

| Customization Aspect | Standard Offering | Premium Customization | Key Consideration |

|---|---|---|---|

| Smart Features | Basic auto-cleaning | Tuya-certified modules, voice control (Alexa/Google), app analytics | Ensure compatibility with major ecosystems; avoid proprietary tech lock-in |

| Packaging | Basic corrugated cartons | Eco-friendly bioplastic packaging with QR traceability | 68% of pet owners prefer sustainable packaging (NPD Group, 2023) |

| Material Quality | Standard ABS plastic | Food-grade, antimicrobial polymers (e.g., UV-stabilized nylon) | Critical for pet safety and product longevity |

💡 Pro Tip: For Amazon Sellers, prioritize packaging that reduces shipping damage (e.g., shock-absorbent inserts) to minimize return rates.

Step 3: Conduct Pilot Run & Quality Assurance

A pilot run of 500–1,000 units is essential to validate production readiness. PAWBILT’s process includes:

ISO 9001-compliant QC checks at every stage (e.g., sensor calibration, motor torque testing).

Real-world stress tests: 72-hour continuous operation, extreme temperature exposure (-10°C to 50°C), and app latency validation.

Supply chain validation: Component availability audits and lead time simulations for high-volume orders.

This phase reduces rework costs by 15–20% and ensures scalability—critical for hitting holiday sales deadlines.

Why Partner with PAWBILT for End-to-End Solutions

PAWBILT combines 15+ years in pet tech manufacturing with a fully integrated supply chain. Our Shanghai facility holds BSCI and ISO certifications, with dual-sourced components for critical IoT modules to prevent disruptions. We handle everything from R&D prototyping to global logistics, ensuring compliance with US, EU, and APAC safety standards. For brands targeting the $1.07B automatic litter box market by 2032, PAWBILT delivers future-proof solutions that balance innovation, quality, and reliability—without compromising margins.

✅ Key Takeaway: In a market where 73% of buyers prioritize smart features (Statista, 2024), partnering with an OEM that masters IoT integration is the difference between market leadership and obsolescence.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label how do litter boxes work business.