Introduction: Navigating the Global Market for tap water temperature cold

In today’s global market, sourcing cold tap water solutions presents a unique challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for efficiently chilled water is growing, yet many buyers struggle with understanding the various factors influencing water temperature, quality, and supplier reliability. This comprehensive guide to cold tap water temperature aims to equip international buyers with the essential insights needed to navigate this complex landscape.

We will explore the different types of cold water systems available, their applications across various sectors, and the importance of vetting suppliers to ensure quality and compliance with regional standards. Additionally, we will provide a detailed analysis of cost structures associated with sourcing cold tap water solutions, empowering buyers to make informed financial decisions.

By addressing these critical areas, this guide will help B2B buyers, especially those from emerging markets like Brazil and Nigeria, to enhance their procurement strategies. With actionable insights and a thorough understanding of cold tap water dynamics, you will be better positioned to secure reliable, high-quality solutions that meet your organization’s needs. Whether you’re looking to improve hydration solutions for your workforce or seeking sustainable water delivery methods, this guide serves as a vital resource for informed purchasing decisions in the evolving global market.

Table Of Contents

- Top 4 Tap Water Temperature Cold Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tap water temperature cold

- Understanding tap water temperature cold Types and Variations

- Key Industrial Applications of tap water temperature cold

- 3 Common User Pain Points for ‘tap water temperature cold’ & Their Solutions

- Strategic Material Selection Guide for tap water temperature cold

- In-depth Look: Manufacturing Processes and Quality Assurance for tap water temperature cold

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tap water temperature cold’

- Comprehensive Cost and Pricing Analysis for tap water temperature cold Sourcing

- Alternatives Analysis: Comparing tap water temperature cold With Other Solutions

- Essential Technical Properties and Trade Terminology for tap water temperature cold

- Navigating Market Dynamics and Sourcing Trends in the tap water temperature cold Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tap water temperature cold

- Strategic Sourcing Conclusion and Outlook for tap water temperature cold

- Important Disclaimer & Terms of Use

Understanding tap water temperature cold Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chilled Tap Water | Typically around 5-10°C; offers immediate refreshment | Restaurants, cafes, gyms | Pros: Refreshing, enhances customer experience. Cons: Requires proper cooling systems. |

| Ambient Cold Water | Generally around 15°C; not artificially cooled | Offices, schools, residential buildings | Pros: Cost-effective, easier to maintain. Cons: May not satisfy those seeking very cold water. |

| Ice-Cold Water | Usually below 5°C; achieved by adding ice or advanced cooling | Events, catering, outdoor venues | Pros: Highly refreshing, attracts customers. Cons: Potentially wasteful, requires ice management. |

| Thermally Regulated Water | Maintains a consistent cold temperature through insulation | Industrial applications, laboratories | Pros: Reliable temperature control, energy efficient. Cons: Higher upfront costs for installation. |

| Seasonal Cold Water | Temperature fluctuates with seasons; varies widely | Agriculture, outdoor facilities | Pros: Utilizes natural temperature variations. Cons: Inconsistent availability, may require backup systems. |

What Are the Characteristics of Chilled Tap Water?

Chilled tap water is commonly served at temperatures between 5-10°C, making it an attractive option for businesses such as restaurants and gyms where customer satisfaction is paramount. This type of water is typically produced using specialized cooling systems that ensure a constant supply of refreshing water. When considering this option, B2B buyers should evaluate the initial investment in cooling equipment and ongoing energy costs, as well as the potential for enhanced customer engagement and satisfaction.

How Does Ambient Cold Water Differ from Other Types?

Ambient cold water, typically around 15°C, is not artificially cooled but rather reflects the ambient temperature of the environment. This type is widely used in office settings, schools, and residential buildings due to its cost-effectiveness and ease of maintenance. Buyers should consider that while it provides a satisfactory drinking experience, it may not meet the expectations of those seeking extremely cold water, particularly in warmer climates.

What Are the Benefits of Ice-Cold Water in B2B Settings?

Ice-cold water, often served below 5°C, is particularly appealing for events, catering services, and outdoor venues. The cooling effect is achieved either through ice addition or advanced cooling technologies. While this type of water can significantly enhance the customer experience, it also comes with challenges, such as the need for ice management and potential waste. B2B buyers should assess their capacity to manage these logistical considerations effectively.

Why Choose Thermally Regulated Water for Industrial Applications?

Thermally regulated water systems are designed to maintain a consistent cold temperature through insulation and controlled environments. This type is particularly beneficial for industrial applications and laboratories where precise temperature control is crucial. Although the upfront installation costs may be higher, the long-term energy efficiency and reliability can provide significant value. Buyers should consider their specific needs for temperature stability against the investment costs.

What Are the Implications of Seasonal Cold Water Variations?

Seasonal cold water varies significantly in temperature depending on the time of year, which can be advantageous for agricultural businesses and outdoor facilities that rely on natural resources. While this type of water can be cost-effective, it presents challenges related to consistency and availability, necessitating backup systems to ensure a reliable supply. B2B buyers in these sectors should weigh the benefits of natural resource utilization against the risks of temperature fluctuations impacting operations.

Key Industrial Applications of tap water temperature cold

| Industry/Sector | Specific Application of tap water temperature cold | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cooling systems in beverage production | Enhances product quality and taste; ensures safety | Quality of water, compliance with health regulations |

| Hospitality and Catering | Chilled water dispensers for guests | Improves guest experience and satisfaction | Reliability, maintenance support, and energy efficiency |

| Agriculture | Irrigation systems for crops | Optimizes water use, ensuring healthy crop growth | Water quality testing, local regulations, and sustainability |

| Healthcare | Cold water systems in hospitals | Supports patient hydration and comfort | Sterility, supply chain reliability, and emergency readiness |

| Manufacturing | Cooling processes in production lines | Prevents overheating of machinery and improves efficiency | Equipment compatibility, water purity standards, and local sourcing |

How is Tap Water Temperature Cold Used in the Food and Beverage Industry?

In the food and beverage industry, cold tap water is essential for cooling systems in beverage production. It ensures that products like soft drinks and juices maintain their intended taste and quality. Cold water also plays a crucial role in sanitization processes, preventing bacterial growth during production. For international buyers, particularly in regions like Africa and South America, understanding local water quality standards and sourcing reliable suppliers is critical to ensuring compliance with health regulations.

What Role Does Tap Water Temperature Cold Play in Hospitality and Catering?

In the hospitality sector, chilled water dispensers are a staple for enhancing guest experience. Providing cold water, especially in hot climates, not only satisfies customer preferences but also encourages hydration, which is vital for overall health. Businesses must consider the reliability of their water supply, the ease of maintenance for dispensers, and energy efficiency to manage operational costs effectively.

How is Cold Tap Water Beneficial in Agriculture?

Cold tap water is utilized in irrigation systems to optimize water use in agriculture. It ensures that crops receive the right temperature of water, which can enhance nutrient absorption and promote healthy growth. For buyers in agricultural sectors across the Middle East and Africa, sourcing water with minimal contaminants is crucial, as it directly impacts crop yields and marketability. Understanding local regulations regarding water use in irrigation can also be a determining factor in sourcing decisions.

Why is Cold Tap Water Important in Healthcare Settings?

In healthcare facilities, cold water systems are vital for patient hydration, especially in environments where patients may be confined to beds. Cold water can help alleviate discomfort and promote recovery. For B2B buyers in this sector, ensuring that the water supply is sterile and meets health standards is paramount. Additionally, having a reliable supply chain for emergency situations must be prioritized to maintain consistent patient care.

How is Cold Tap Water Used in Manufacturing Processes?

In manufacturing, cold tap water is integral to cooling processes, preventing machinery from overheating during production runs. This helps maintain efficiency and prolongs equipment lifespan. Buyers in this sector should focus on sourcing water that meets purity standards to avoid contamination in their products. Understanding local sourcing options can also help mitigate risks associated with supply chain disruptions, especially in regions with varying infrastructure capabilities.

3 Common User Pain Points for ‘tap water temperature cold’ & Their Solutions

Scenario 1: Struggling with Inconsistent Cold Water Supply

The Problem: Many businesses, particularly those in hotter climates such as Nigeria or Brazil, face the challenge of inconsistent cold water supply from their taps. When employees fill their glasses expecting refreshing cold water, they are often met with lukewarm temperatures. This inconsistency can lead to dissatisfaction among staff and affect productivity, especially in environments where hydration is critical for performance. Additionally, the issue may arise from poorly insulated plumbing systems or water lines that traverse unconditioned spaces, causing the water to warm before reaching the tap.

The Solution: To combat this issue, B2B buyers should prioritize the installation of insulated piping systems. Investing in high-quality insulation for cold water pipes can significantly reduce the temperature fluctuations caused by ambient heat. Additionally, organizations can implement a routine maintenance schedule to flush the water lines regularly, ensuring that any stagnant water, which may become warm, is cleared. For businesses that require immediate access to cold water, consider installing point-of-use water coolers or dispensers that can chill the water before it is consumed. This not only enhances employee satisfaction but also promotes hydration, leading to improved health and productivity.

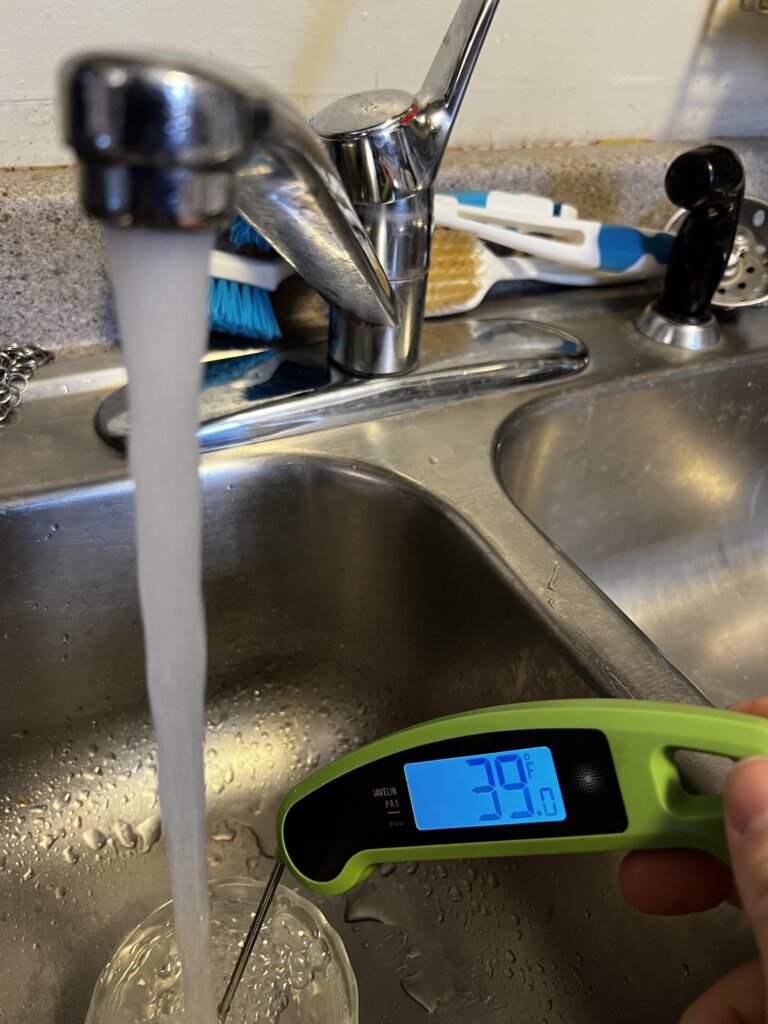

Illustrative image related to tap water temperature cold

Scenario 2: Cold Water Not Chilled Enough for Customer Satisfaction

The Problem: In hospitality sectors, such as restaurants or hotels in the Middle East and Europe, the temperature of tap water served to customers can significantly impact their experience. A common complaint is that the cold tap water served is not sufficiently chilled, especially during peak summer months. This can lead to negative reviews and decreased customer satisfaction, ultimately affecting the bottom line.

The Solution: B2B buyers in the hospitality industry should consider investing in advanced water cooling systems that can provide consistently chilled water on demand. Options include under-sink water chillers or countertop water dispensers that deliver water at the ideal temperature. Additionally, businesses can establish a protocol for serving chilled water, such as pre-chilling water in large pitchers or offering ice alongside water service. Training staff to understand the importance of serving appropriately chilled beverages can further enhance customer experience and promote positive feedback.

Scenario 3: Health Concerns Over Cold Water Temperature

The Problem: In certain regions, there are health concerns associated with the consumption of cold water, especially in environments where the water supply may not be consistently safe. B2B buyers, particularly in healthcare or food service industries in areas like South America, may find that customers or employees are reluctant to drink tap water due to fears about contamination or temperature-related discomfort.

The Solution: To address these concerns, organizations should invest in comprehensive water filtration and purification systems that ensure the safety of the tap water. Alongside this, providing options for both cold and room temperature water can cater to different preferences and health concerns. For instance, offering water that is slightly cooler than room temperature can be a compromise for those hesitant about cold water. Additionally, communicating the benefits of hydration and safe drinking practices through signage or employee training can encourage more individuals to consume water confidently, thereby promoting overall health and wellness within the organization.

Illustrative image related to tap water temperature cold

Strategic Material Selection Guide for tap water temperature cold

What Materials Are Best for Cold Tap Water Applications?

When selecting materials for systems designed to deliver cold tap water, it is essential to consider factors such as temperature resistance, corrosion resistance, and overall durability. Here, we analyze four common materials used in these applications: PVC, PEX, Copper, and Stainless Steel.

How Does PVC Perform for Cold Water Applications?

Key Properties: PVC (Polyvinyl Chloride) is known for its excellent chemical resistance and low thermal conductivity. It can typically handle temperatures up to 60°C (140°F) without significant deformation.

Pros & Cons: PVC is lightweight, cost-effective, and easy to install, making it a popular choice for plumbing systems. However, its rigidity can be a drawback in applications requiring flexibility. Additionally, while PVC is resistant to corrosion, it can become brittle over time when exposed to UV light.

Illustrative image related to tap water temperature cold

Impact on Application: PVC is compatible with cold water and is often used in residential and commercial plumbing. However, it is not suitable for hot water applications, which limits its versatility.

Considerations for International Buyers: PVC pipes must comply with local standards, such as ASTM in the U.S. and DIN in Europe. Buyers in regions like Africa and South America should ensure that the material meets local regulations regarding drinking water safety.

What About PEX for Cold Water Systems?

Key Properties: PEX (Cross-linked Polyethylene) is highly flexible and can withstand temperatures up to 95°C (203°F). It has excellent resistance to scale and chlorine, which makes it suitable for various water qualities.

Illustrative image related to tap water temperature cold

Pros & Cons: The flexibility of PEX allows for easier installation, especially in complex layouts. It is also resistant to freezing, reducing the risk of pipe bursts in colder climates. However, PEX can be more expensive than PVC and may require special fittings for installation.

Impact on Application: PEX is ideal for both cold and hot water applications, making it a versatile choice. Its resistance to corrosion and scaling enhances its longevity in cold water systems.

Considerations for International Buyers: PEX must comply with local plumbing codes, which may vary significantly between regions. In countries like Brazil and Nigeria, buyers should verify that the material meets local health and safety standards.

Is Copper Still a Viable Option for Cold Water?

Key Properties: Copper has a high thermal conductivity and can handle temperatures exceeding 100°C (212°F). It is also naturally resistant to bacteria and corrosion.

Pros & Cons: Copper pipes are durable and have a long lifespan, making them a reliable choice for cold water systems. However, they are more expensive than plastic alternatives and require skilled labor for installation, which can increase overall project costs.

Impact on Application: Copper is suitable for both cold and hot water applications and is often used in commercial settings. Its antimicrobial properties make it a preferred choice for drinking water systems.

Considerations for International Buyers: Buyers must consider the price volatility of copper and ensure compliance with international standards, such as JIS in Japan or ASTM in the U.S. In regions like the Middle East, where copper theft is a concern, alternative materials may be preferred.

How Does Stainless Steel Compare for Cold Water Use?

Key Properties: Stainless steel is highly resistant to corrosion and can handle extreme temperatures, making it suitable for various applications. It is also strong and durable, with a long service life.

Pros & Cons: While stainless steel is one of the most durable materials available, it is also among the most expensive. Its resistance to corrosion makes it an excellent choice for areas with aggressive water quality. However, its weight can complicate installation.

Impact on Application: Stainless steel is ideal for cold water systems in both residential and commercial applications, particularly where hygiene is a priority, such as in food processing.

Illustrative image related to tap water temperature cold

Considerations for International Buyers: Compliance with standards like ISO or ASTM is crucial for international buyers. In regions with less stringent regulations, the quality of stainless steel can vary, so sourcing from reputable suppliers is essential.

Summary Table of Material Selection for Cold Tap Water

| Material | Typical Use Case for tap water temperature cold | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential plumbing systems | Cost-effective and easy to install | Brittle over time, UV sensitivity | Low |

| PEX | Complex plumbing layouts | Flexible and resistant to freezing | More expensive, requires special fittings | Med |

| Copper | Commercial plumbing systems | Durable and antimicrobial | High cost, installation complexity | High |

| Stainless Steel | Food processing and hygiene-sensitive areas | Corrosion-resistant and durable | High cost, heavy weight | High |

This analysis provides B2B buyers with a comprehensive understanding of material options for cold tap water applications, enabling informed decisions that align with regional standards and project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tap water temperature cold

What Are the Main Stages in the Manufacturing Process for Cold Tap Water Systems?

The manufacturing process for cold tap water systems involves several critical stages, each designed to ensure the delivery of high-quality, safe drinking water. Understanding these stages is essential for B2B buyers who need reliable products for their operations.

Material Preparation: What Raw Materials Are Used?

The first stage involves the selection and preparation of materials. Common materials include food-grade plastics for pipes, stainless steel for fixtures, and specialized materials for water filtration systems. Quality is paramount; thus, suppliers should use materials that comply with international safety standards, such as NSF/ANSI standards for drinking water system components.

Forming: How Are Components Created?

During the forming stage, raw materials are shaped into the necessary components using techniques such as injection molding for plastic parts and casting for metal fixtures. Advanced manufacturing technologies, like CNC machining and 3D printing, are also employed to produce complex shapes and ensure precise dimensions. This precision is crucial for maintaining water quality and flow rates.

Assembly: What Are the Key Steps in Assembling the System?

The assembly process involves integrating various components, including pipes, valves, and filtration units. This stage typically requires skilled labor and adherence to strict assembly protocols to ensure that all parts fit correctly and function as intended. Automated assembly lines are increasingly used to enhance efficiency and reduce human error.

Finishing: How Is the Final Product Prepared for Delivery?

Finishing processes may include surface treatments, cleaning, and quality inspections. Before products are packaged for shipment, they undergo rigorous testing to verify that they meet established performance and safety standards. This may involve checking for leaks, pressure testing, and ensuring that water quality parameters are within acceptable ranges.

What Quality Control Measures Are Essential for Cold Tap Water Systems?

Quality control (QC) is critical in the manufacturing process of cold tap water systems. It ensures that products are safe, reliable, and compliant with international standards.

What International Standards Should B2B Buyers Consider?

International standards, such as ISO 9001, serve as a foundation for quality management systems across various industries. These standards focus on consistent quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking in Europe and NSF certification in North America, can provide assurance of product safety and effectiveness.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During production, ongoing checks ensure that each component meets specifications.

- Final Quality Control (FQC): The final inspection occurs before products leave the facility, verifying that they comply with all relevant standards and specifications.

What Testing Methods Are Commonly Used in Quality Control?

Various testing methods are employed to ensure the quality of cold tap water systems. These may include:

- Pressure Testing: Verifying that pipes and fittings can withstand specified pressure levels without leaking.

- Water Quality Testing: Analyzing samples for contaminants, pH levels, and other quality indicators.

- Durability Testing: Assessing the lifespan of materials under simulated environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying supplier quality control is essential for ensuring product reliability. Here are several strategies to consider:

Illustrative image related to tap water temperature cold

What Role Do Audits Play in Supplier Verification?

Conducting regular audits of suppliers can provide insight into their manufacturing processes and QC measures. Buyers should request access to audit reports and assess whether suppliers adhere to international quality standards.

Why Are Certification Reports Important?

Certification reports from recognized bodies, such as NSF or ISO, can serve as proof of compliance with safety and quality standards. Buyers should always request these documents to ensure that suppliers have met the necessary criteria.

How Can Third-Party Inspections Enhance Supplier Reliability?

Engaging third-party inspectors can offer an unbiased assessment of a supplier’s manufacturing practices and product quality. This is particularly valuable for international buyers who may not be able to conduct on-site inspections themselves.

What Are the QC and Certification Nuances for International B2B Buyers?

For buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is crucial.

How Do Regional Regulations Impact Quality Standards?

Different regions may have specific regulations and standards governing drinking water quality. For instance, the European Union has stringent regulations that suppliers must meet to sell products in member states. Buyers should familiarize themselves with these regional standards to ensure compliance.

What Should Buyers Consider About Supply Chain Transparency?

Transparency in the supply chain is vital for maintaining quality. Buyers should work with suppliers who are willing to share information about their sourcing, manufacturing processes, and quality control measures. This openness can help establish trust and ensure that products meet the expected standards.

Conclusion: Why Quality Assurance Is Essential for Cold Tap Water Systems

In summary, the manufacturing processes and quality assurance measures for cold tap water systems are integral to ensuring product safety and reliability. By understanding these processes and implementing robust verification strategies, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements. Investing time in evaluating suppliers based on their manufacturing and QC capabilities will ultimately lead to better outcomes and safer products for end-users.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tap water temperature cold’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure cold tap water solutions. Understanding the specific requirements for cold water temperature can significantly enhance your operational efficiency and meet customer needs. This checklist will help you navigate the essential steps for sourcing quality cold tap water products and services.

Illustrative image related to tap water temperature cold

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for cold tap water is crucial for ensuring that the products meet your operational needs. Consider factors such as the desired temperature range, flow rate, and intended applications.

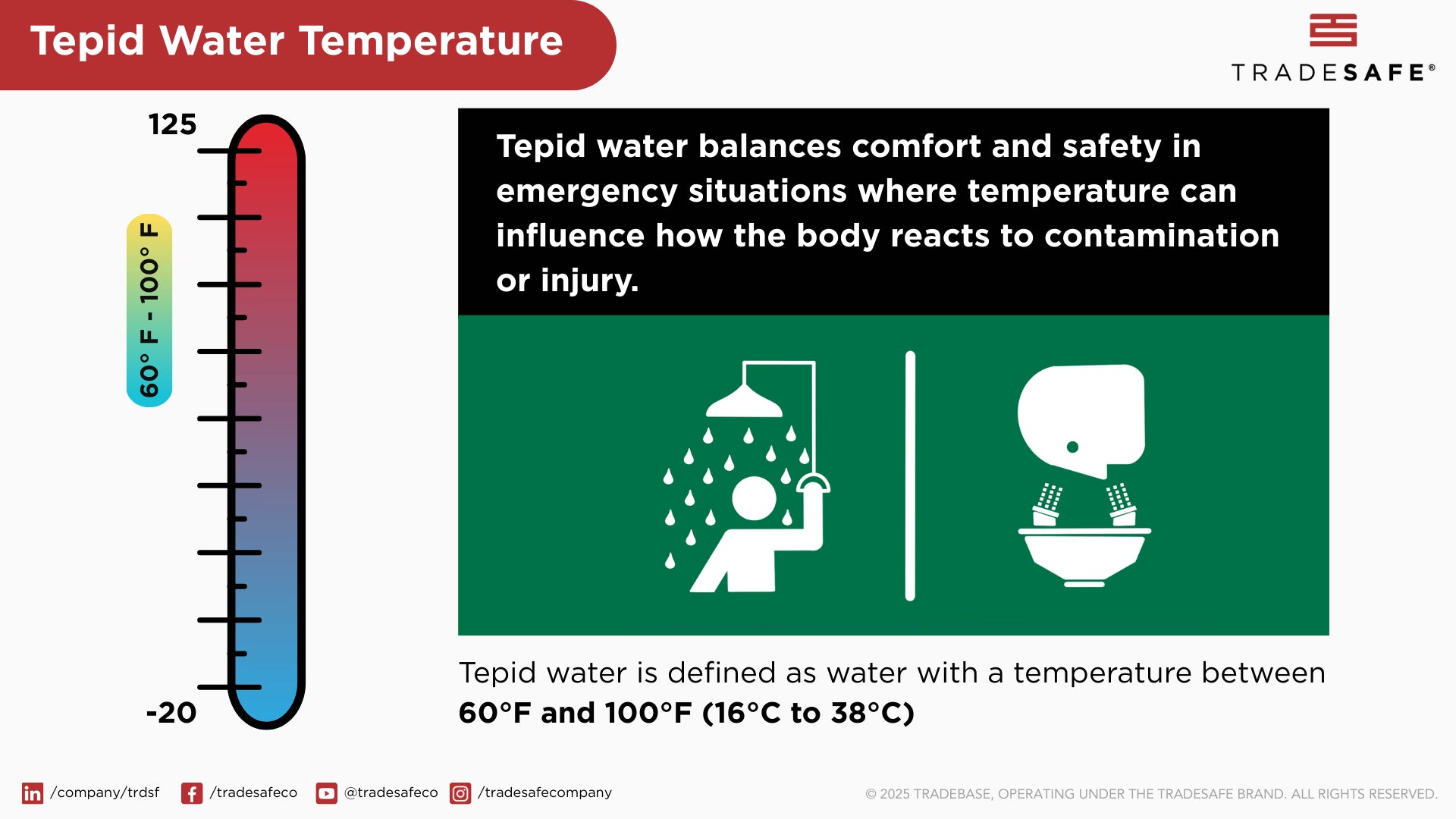

– Temperature Requirements: Specify the ideal cold water temperature, typically around 15 degrees Celsius (60 degrees Fahrenheit).

– Usage Context: Determine whether the water will be used for drinking, food preparation, or industrial processes.

Step 2: Identify Regulatory Compliance

Ensuring that your cold water supply meets local and international regulations is non-negotiable. Compliance with health and safety standards protects both your business and consumers.

– Health Standards: Verify that the supplier adheres to drinking water quality standards established by relevant health authorities in your region.

– Environmental Regulations: Check for compliance with local environmental laws regarding water sourcing and usage.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation to ensure reliability and quality. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Reputation: Look for reviews and testimonials from previous clients to gauge their reliability and service quality.

– Experience in Your Region: Suppliers familiar with the specific challenges and regulations in your target markets (e.g., Africa, South America, Middle East, Europe) can provide tailored solutions.

Step 4: Assess Water Quality Testing Procedures

Understanding how suppliers test their water quality is essential for ensuring safety and compliance. Inquire about their testing protocols and frequency.

– Testing Standards: Ensure that the supplier employs recognized testing methods to monitor contaminants and ensure water quality.

– Documentation: Request certificates and reports from recent water quality tests to verify compliance with your specifications.

Step 5: Consider Logistics and Distribution Capabilities

Efficient logistics are crucial for maintaining the integrity of cold tap water during transport. Evaluate the supplier’s logistics capabilities to ensure timely and safe delivery.

– Temperature Control: Inquire about temperature-controlled transportation methods to maintain water quality.

– Delivery Timelines: Discuss lead times and delivery schedules to ensure they align with your operational needs.

Step 6: Negotiate Pricing and Contract Terms

Engaging in a thorough negotiation process can help you secure the best pricing and favorable contract terms. Transparency during this phase is key to building a long-term partnership.

– Bulk Purchase Discounts: Inquire about pricing structures for larger orders to optimize your budget.

– Contract Flexibility: Look for terms that allow for adjustments based on changing demand or unforeseen circumstances.

Step 7: Plan for Ongoing Quality Assurance

Establish a plan for ongoing quality assurance to maintain high standards over time. Regular evaluations can prevent issues before they arise.

– Periodic Reviews: Schedule regular assessments of the water quality and supplier performance.

– Feedback Mechanisms: Implement systems to collect feedback from end-users to continuously improve the supply process.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing cold tap water, ensuring quality and compliance while meeting their operational needs effectively.

Comprehensive Cost and Pricing Analysis for tap water temperature cold Sourcing

What Are the Key Cost Components for Sourcing Cold Tap Water?

When analyzing the cost structure for sourcing cold tap water, it is essential to consider multiple components that contribute to the overall expense. The primary cost components include:

-

Materials: The cost of sourcing water can vary based on location, water quality, and treatment processes. In regions where water scarcity is an issue, prices may be higher due to increased treatment and distribution efforts.

-

Labor: Labor costs include the wages of workers involved in water treatment, quality control, and distribution. In regions with higher labor costs, such as parts of Europe, the overall cost may increase.

-

Manufacturing Overhead: This encompasses the indirect costs associated with operating water treatment facilities, including utilities, facility maintenance, and administrative expenses.

-

Tooling: This refers to the costs associated with the machinery and equipment used in water purification and bottling processes. Advanced technologies may require higher initial investments but can improve efficiency and reduce long-term costs.

-

Quality Control (QC): Ensuring that the water meets health and safety standards is critical. QC processes incur costs related to testing, certifications, and compliance with local regulations.

-

Logistics: Distribution costs can vary significantly depending on the distance from the source to the end consumer. Factors such as fuel prices, vehicle maintenance, and transportation regulations play a role in logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing to sustain operations and invest in future improvements.

How Do Price Influencers Impact Cold Tap Water Sourcing?

Several factors can influence the pricing structure of cold tap water, particularly for B2B buyers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to maximize cost efficiency.

-

Specifications/Customization: Custom requirements, such as specific water quality standards or packaging, can increase costs. It’s essential to define specifications clearly to avoid unexpected price hikes.

-

Materials: The quality of water sources (e.g., groundwater vs. surface water) can affect pricing. Higher-quality sources may incur higher treatment costs.

-

Quality/Certifications: Compliance with international quality standards (such as ISO certifications) can influence prices. Suppliers with recognized certifications may charge a premium.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may command higher prices due to perceived value.

-

Incoterms: Understanding the Incoterms used in contracts can help buyers anticipate additional costs related to shipping, insurance, and customs duties.

What Are Effective Buyer Tips for Sourcing Cold Tap Water?

B2B buyers should consider several strategies when sourcing cold tap water to ensure cost-efficiency:

-

Negotiation: Engage in negotiations to secure favorable terms. Highlight potential long-term partnerships to encourage suppliers to offer competitive pricing.

-

Cost-Efficiency: Conduct a thorough analysis of total costs, including hidden expenses like shipping and handling. This ensures a comprehensive understanding of the pricing structure.

-

Total Cost of Ownership (TCO): Assess the TCO by considering not just the purchase price but also maintenance, compliance, and potential risks associated with sourcing water.

-

Pricing Nuances for International Buyers: International buyers, especially from regions like Africa, South America, and the Middle East, should be mindful of currency fluctuations and geopolitical factors that could impact pricing.

-

Local Partnerships: Establishing relationships with local suppliers can reduce logistics costs and enhance supply chain reliability. Local suppliers may also have better knowledge of regional regulations and standards.

Disclaimer for Indicative Prices

Prices can vary significantly based on numerous factors, including location, supplier practices, and market conditions. It is advisable for buyers to conduct their own market research and obtain multiple quotes to arrive at a fair pricing structure tailored to their specific needs.

Illustrative image related to tap water temperature cold

Alternatives Analysis: Comparing tap water temperature cold With Other Solutions

Introduction: Exploring Alternatives to Cold Tap Water

In the quest for optimal hydration solutions, particularly in regions with varying climates and consumer preferences, it’s essential to consider alternatives to cold tap water. These alternatives can range from bottled water to advanced water cooling systems. Each option has its unique benefits and drawbacks that can significantly impact operational efficiency, cost-effectiveness, and overall user satisfaction. For B2B buyers, understanding these differences is crucial in making informed purchasing decisions.

Comparison Table

| Comparison Aspect | Tap Water Temperature Cold | Bottled Water | Water Cooler Systems |

|---|---|---|---|

| Performance | Refreshing, hydration-focused | Portable, convenient | Instant cold and hot water |

| Cost | Low ongoing costs | Higher long-term costs | Moderate to high initial costs |

| Ease of Implementation | Simple to access | Requires logistics for delivery | Requires installation and maintenance |

| Maintenance | Minimal, city-regulated | Disposal of plastic bottles | Regular cleaning and filter changes |

| Best Use Case | Everyday hydration in homes and offices | On-the-go consumption, events | Offices and public spaces needing consistent supply |

Detailed Breakdown of Alternatives

Bottled Water

Bottled water is a widely recognized alternative that provides convenience and portability. It is ideal for businesses that require immediate access to drinking water in various locations, such as events or outdoor activities. However, the long-term costs associated with purchasing bottled water can be significant, and it raises environmental concerns regarding plastic waste. Additionally, the need for proper storage and handling can complicate logistics.

Water Cooler Systems

Water cooler systems offer a versatile solution that can dispense both hot and cold water, making them suitable for various applications. They are especially beneficial in office environments where employees may require different water temperatures throughout the day. While the initial investment in water cooler systems may be higher, their ability to provide a consistent and reliable water supply can justify the costs. Regular maintenance, including filter changes and cleaning, is essential to ensure optimal performance and hygiene.

Illustrative image related to tap water temperature cold

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate hydration solution, B2B buyers should carefully evaluate their specific requirements, including budget constraints, space availability, and user preferences. Cold tap water remains a cost-effective and straightforward option for everyday hydration, but alternatives like bottled water and water cooler systems can offer added convenience and flexibility. Ultimately, the right choice will depend on balancing performance, cost, and maintenance considerations to meet the unique demands of your organization or clientele.

Essential Technical Properties and Trade Terminology for tap water temperature cold

What Are the Key Technical Properties of Cold Tap Water Temperature?

1. Temperature Range:

Cold tap water is typically maintained at around 15 degrees Celsius (60 degrees Fahrenheit). This temperature is essential for various applications, from drinking to industrial processes. For B2B buyers, ensuring that the cold water supply meets this standard is crucial for both health and operational efficiency.

2. Thermal Conductivity:

Thermal conductivity refers to the ability of water to conduct heat. Cold tap water should ideally have low thermal conductivity to maintain its temperature during transport from the source to the end-user. For businesses, understanding thermal conductivity helps in designing efficient plumbing systems that minimize temperature loss, ensuring that the water remains cold upon delivery.

3. Flow Rate:

The flow rate of cold tap water is measured in liters per minute (L/min). A standard residential tap may deliver about 6-10 L/min, while commercial systems require higher rates for efficiency. For B2B transactions, knowing the required flow rate is critical for meeting production schedules, especially in sectors like food and beverage, where water temperature can affect product quality.

4. Pressure Rating:

Pressure ratings indicate the maximum pressure that the plumbing system can withstand without failure. Cold water systems typically operate under lower pressure than hot water systems, but maintaining the correct pressure is essential to avoid leaks and ensure consistent delivery. For B2B buyers, selecting the right pressure rating can prevent costly downtime and repairs.

Illustrative image related to tap water temperature cold

5. Water Quality Standards:

Cold tap water must meet specific quality standards, including parameters for temperature, pH, turbidity, and microbial content. Compliance with these standards is vital for health regulations, especially in food and beverage industries. Buyers should verify that their suppliers adhere to local and international water quality standards to avoid legal issues and ensure consumer safety.

What Are Common Trade Terminology Related to Cold Tap Water?

1. OEM (Original Equipment Manufacturer):

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of cold water systems, OEM components must meet specific temperature and pressure specifications to ensure compatibility and efficiency. Understanding OEM relationships can help buyers source quality parts for their systems.

2. MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for cold water systems or components can influence purchasing decisions, especially for smaller businesses that may not need large volumes. Negotiating MOQs can lead to better pricing and inventory management.

Illustrative image related to tap water temperature cold

3. RFQ (Request for Quotation):

An RFQ is a formal document that solicits price quotes from suppliers. When sourcing cold water systems, issuing an RFQ allows buyers to compare pricing, terms, and specifications across multiple suppliers. This process is essential for ensuring competitive pricing and value for money.

4. Incoterms (International Commercial Terms):

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. They define the responsibilities of buyers and sellers regarding shipping, risk, and insurance. For international B2B transactions involving cold tap water systems, understanding Incoterms is crucial for clarifying responsibilities and reducing the risk of disputes.

5. TDS (Total Dissolved Solids):

TDS measures the combined content of all inorganic and organic substances contained in a liquid. For cold tap water, TDS levels can affect taste and health. B2B buyers should be aware of TDS levels when selecting suppliers to ensure that the water meets quality standards for their specific applications.

By understanding these essential properties and terms, B2B buyers can make informed decisions regarding cold tap water systems, ensuring efficiency and compliance in their operations.

Illustrative image related to tap water temperature cold

Navigating Market Dynamics and Sourcing Trends in the tap water temperature cold Sector

What Are the Current Market Dynamics for Cold Tap Water Sourcing?

The cold tap water sector is experiencing significant growth driven by increasing health consciousness and changing consumer preferences towards hydration. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are tapping into this trend as they seek reliable sources of cold water solutions. In regions like Brazil and Nigeria, where hot climates prevail, the demand for cold water options is particularly pronounced. Emerging technologies in water purification and cooling systems are making it easier for businesses to provide cold water efficiently and sustainably.

Moreover, innovations such as smart water dispensers that monitor usage and optimize water temperature are gaining traction. These systems not only enhance user experience but also contribute to water conservation efforts by reducing wastage. The integration of IoT technologies allows businesses to track consumption patterns, making it easier to tailor offerings to specific market needs. As urbanization continues to rise, especially in developing regions, the need for efficient cold water solutions will only intensify.

In addition, regulatory frameworks are evolving, pushing companies to comply with stricter health and safety standards. This creates opportunities for B2B buyers to engage with suppliers who can guarantee quality and safety certifications, thus ensuring they meet local regulations while providing optimal hydration solutions.

Illustrative image related to tap water temperature cold

How Are Sustainability and Ethical Sourcing Influencing the Cold Water Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the cold tap water market. As environmental concerns rise globally, businesses are increasingly prioritizing ethical sourcing practices. This includes selecting suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials in their production processes.

For international buyers, especially those in regions like Africa and South America, aligning with suppliers that hold ‘green’ certifications—such as ISO 14001—can enhance brand reputation and appeal to environmentally conscious consumers. This trend is particularly relevant as consumers are more likely to choose products from companies that prioritize sustainability in their operations.

Additionally, the environmental impact of bottled water has prompted a shift towards tap water solutions. By investing in infrastructure that supports the efficient delivery of cold tap water, companies can significantly reduce plastic waste and promote a more sustainable model of consumption. Businesses that actively participate in water conservation efforts not only help the planet but can also benefit financially by reducing operational costs associated with waste management.

Illustrative image related to tap water temperature cold

What Historical Context is Relevant for B2B Buyers in the Cold Water Sector?

The evolution of cold tap water solutions dates back to the introduction of modern plumbing systems in the 19th century, which revolutionized access to clean water. As urban centers expanded, the demand for efficient cold water distribution systems grew, leading to innovations in water cooling technology.

In the late 20th century, the focus shifted towards enhancing the quality and safety of drinking water, resulting in the establishment of various health regulations and standards. This historical context is crucial for B2B buyers today as they navigate a landscape that values both quality and sustainability. Understanding the advancements that have shaped the industry can help buyers make informed decisions when selecting suppliers and technologies that align with current market demands.

In summary, the cold tap water sector is poised for continued growth, influenced by health trends, sustainability initiatives, and technological advancements. For international B2B buyers, these factors present numerous opportunities to enhance their offerings while remaining compliant with evolving standards and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of tap water temperature cold

-

How do I ensure the cold tap water I receive meets quality standards?

To ensure the cold tap water you source meets quality standards, it’s crucial to partner with suppliers who adhere to international water quality regulations, such as WHO guidelines. Conduct comprehensive supplier audits that assess their water treatment processes, testing methodologies, and certifications. Request documentation that demonstrates their compliance with health and safety standards. Additionally, consider implementing regular quality assurance checks and third-party testing to maintain consistent quality throughout your supply chain. -

What is the best temperature range for cold tap water?

The ideal temperature for cold tap water typically ranges from 10°C to 15°C (50°F to 60°F). This range is considered refreshing and palatable for consumers, especially in warmer climates. Cold water at this temperature can enhance hydration, especially after physical activities or during hot weather. When sourcing cold tap water, ensure that your suppliers can consistently deliver within this temperature range, as variations can affect consumer satisfaction and health benefits. -

How can I customize the cold tap water supply for my business needs?

Customization options for cold tap water supply may include temperature specifications, mineral content adjustments, and packaging preferences. Communicate your specific needs to potential suppliers during the sourcing process. Many suppliers can offer tailored solutions, such as enhanced mineralization for taste or adjusted temperature controls. Ensure you discuss any customization capabilities early in negotiations to align with your business requirements and consumer preferences. -

What are the minimum order quantities (MOQs) for sourcing cold tap water?

Minimum order quantities for cold tap water can vary significantly depending on the supplier, region, and your specific requirements. Typically, MOQs may range from a few hundred liters for smaller businesses to several thousand liters for larger enterprises. When negotiating with suppliers, clarify their MOQ policies to ensure they align with your operational needs. If your demand fluctuates, inquire about flexible purchasing options or tiered pricing to optimize your procurement strategy. -

What payment terms should I expect when sourcing cold tap water internationally?

Payment terms for sourcing cold tap water can vary widely among suppliers. Common arrangements include payment in advance, net 30, or net 60 terms, depending on the supplier’s policies and your business relationship. It’s important to negotiate favorable terms that accommodate your cash flow needs while ensuring the supplier’s security. Additionally, consider utilizing escrow services or letters of credit for large orders to mitigate financial risks in international transactions. -

How can I vet suppliers for cold tap water sourcing?

To effectively vet suppliers for cold tap water sourcing, start by researching their reputation in the market through reviews and references. Request detailed information about their water sourcing, treatment processes, and compliance with local and international regulations. Conduct site visits if possible, or utilize third-party auditing services to verify their operations. Building a strong relationship with suppliers who prioritize transparency and quality will enhance your supply chain reliability. -

What logistics considerations are important when sourcing cold tap water?

Logistics for sourcing cold tap water involve several key considerations, including transportation methods, temperature control, and delivery schedules. Choose suppliers who can ensure proper insulation and refrigeration during transit to maintain the desired water temperature. Additionally, factor in local regulations regarding the transportation of potable water, which may vary by region. Collaborate with logistics providers experienced in handling liquid commodities to streamline your supply chain operations. -

How does climate affect the temperature of cold tap water?

Climate can significantly impact the temperature of cold tap water, especially in regions with extreme heat. In hot environments, water sitting in uninsulated pipes may warm up before reaching the tap, leading to inconsistent temperatures. Consider sourcing from suppliers who utilize insulated pipelines or advanced cooling technologies to maintain cold water temperatures. Additionally, understanding local climate conditions can help you plan for seasonal variations in water temperature and adapt your sourcing strategy accordingly.

Top 4 Tap Water Temperature Cold Manufacturers & Suppliers List

1. Brita – Optimal Drinking Water Temperature

Domain: brita.co.uk

Registered: 1996 (29 years)

Introduction: The best temperature range for drinking water is between 10-22 degrees Celsius (50 – 72 degrees Fahrenheit). Room temperature water is around 25 degrees Celsius (78 degrees Fahrenheit), while cold tap water is about 15 degrees Celsius (60 degrees Fahrenheit). Room temperature water is easier on the digestive system and can aid hydration, while cold water is refreshing and can help cool the body. D…

2. Augustine Plumbing – Seasonal Water Temperature Insights

Domain: augustineplumbing.com

Registered: 2004 (21 years)

Introduction: This company, Augustine Plumbing – Seasonal Water Temperature Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Urban Ice Tribe – Cold Water Therapy

Domain: urbanicetribe.com

Registered: 2022 (3 years)

Introduction: Cold water is defined as being below 15°C (59°F). Exposure to cold water can offer health benefits such as muscle recovery, pain relief, and improved circulation, but also poses risks like cold shock and hypothermia. Safety measures include gradual acclimatization, protective gear like wetsuits, and monitoring exposure duration. Typical water temperatures vary: coastal waters range from low single…

4. Facebook – Water Temperature Insights

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Water Temperature Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tap water temperature cold

In conclusion, understanding the implications of cold tap water temperature is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Cold water, typically around 15 degrees Celsius, not only quenches thirst but also enhances hydration, particularly in hot climates or after physical exertion. Companies should consider the varying needs of their workforce and clientele when sourcing water solutions, as preferences for water temperature can significantly influence consumer satisfaction and health outcomes.

Strategic sourcing in this context involves evaluating suppliers who can provide consistent quality and temperature control, ensuring that the water delivered meets the desired standards. By investing in effective water management solutions, businesses can enhance employee wellness and productivity, fostering a healthier workplace environment.

Looking ahead, the demand for tailored water solutions is set to rise. B2B buyers are encouraged to partner with suppliers who prioritize innovation and sustainability in their offerings. By aligning sourcing strategies with market trends, companies can position themselves as leaders in delivering quality hydration solutions. Engage with your suppliers today to explore how you can optimize your water sourcing strategy for a healthier tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.