Introduction: Navigating the Global Market for how often to replace hummingbird nectar

As the demand for hummingbird feeders continues to rise globally, understanding how often to replace hummingbird nectar becomes a crucial aspect for B2B buyers in the agricultural and wildlife sectors. One key challenge faced by suppliers is ensuring that the nectar remains fresh and appealing to these delicate birds, especially in diverse climates from the warm tropics of Brazil to the arid landscapes of Saudi Arabia. This comprehensive guide addresses essential considerations, including the types of nectar, optimal replacement schedules, and the impact of environmental conditions on nectar longevity.

By equipping international B2B buyers with actionable insights on sourcing high-quality nectar and maintaining optimal feeder conditions, this guide empowers informed purchasing decisions that cater to specific regional needs. It delves into supplier vetting processes, cost analysis, and market trends, enabling businesses to align their offerings with best practices in hummingbird care.

Whether you are a retailer, distributor, or manufacturer, understanding the nuances of nectar replacement will enhance your product offerings and ensure customer satisfaction. This guide serves as a vital resource for navigating the complexities of the hummingbird nectar market, ultimately leading to a more sustainable and profitable operation.

Table Of Contents

- Top 3 How Often To Replace Hummingbird Nectar Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often to replace hummingbird nectar

- Understanding how often to replace hummingbird nectar Types and Variations

- Key Industrial Applications of how often to replace hummingbird nectar

- 3 Common User Pain Points for ‘how often to replace hummingbird nectar’ & Their Solutions

- Strategic Material Selection Guide for how often to replace hummingbird nectar

- In-depth Look: Manufacturing Processes and Quality Assurance for how often to replace hummingbird nectar

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to replace hummingbird nectar’

- Comprehensive Cost and Pricing Analysis for how often to replace hummingbird nectar Sourcing

- Alternatives Analysis: Comparing how often to replace hummingbird nectar With Other Solutions

- Essential Technical Properties and Trade Terminology for how often to replace hummingbird nectar

- Navigating Market Dynamics and Sourcing Trends in the how often to replace hummingbird nectar Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often to replace hummingbird nectar

- Strategic Sourcing Conclusion and Outlook for how often to replace hummingbird nectar

- Important Disclaimer & Terms of Use

Understanding how often to replace hummingbird nectar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Replacement | Nectar replaced based on seasonal temperature variations | Bird feeder supply companies, seasonal retailers | Pros: Aligns with natural feeding patterns; reduces waste. Cons: Requires monitoring of local climate conditions. |

| Temperature-Based Replacement | Nectar change frequency varies with temperature | Retail suppliers in warm climates | Pros: Prevents spoilage in warmer conditions. Cons: Increased labor for frequent checks in hot weather. |

| Weekly Maintenance | Regular weekly replacement regardless of conditions | Commercial birdwatching tours, parks | Pros: Simplifies logistics; ensures freshness. Cons: May lead to unnecessary waste in cooler months. |

| Customizable Nectar Solutions | Tailored replacement schedules based on local species | Specialty feeders for diverse ecosystems | Pros: Optimizes bird attraction; enhances sales of custom products. Cons: Requires detailed knowledge of local species behavior. |

| Emergency Replacement Protocol | Immediate replacement protocol for spoiled nectar | Urban wildlife management, conservation efforts | Pros: Protects bird health; maintains feeder reputation. Cons: Requires prompt action and monitoring. |

What Are the Characteristics of Seasonal Replacement for Hummingbird Nectar?

Seasonal replacement involves adjusting the nectar replacement frequency based on local climate and seasonal changes. This method is particularly effective in regions where temperature fluctuations are significant. For B2B buyers, this approach aligns with natural feeding patterns of hummingbirds, minimizing waste during cooler months when nectar spoilage is less likely. Companies that provide bird feeders can market this as an environmentally friendly practice, appealing to eco-conscious consumers.

How Does Temperature-Based Replacement Work?

Temperature-based replacement focuses on changing the nectar more frequently during hot weather to prevent spoilage. In regions with consistently high temperatures, such as parts of Africa and South America, this method is crucial for maintaining nectar quality. B2B suppliers in warmer climates can educate customers about the importance of this practice, potentially increasing sales of cleaning supplies and replacement nectar products. However, it requires diligent monitoring and may lead to increased labor costs.

Why Choose Weekly Maintenance for Hummingbird Nectar?

Weekly maintenance entails changing the nectar every seven days, irrespective of environmental factors. This approach is beneficial for businesses like birdwatching tours and parks, where maintaining a consistent feeder experience is essential for attracting visitors. While this method simplifies logistics and ensures fresh nectar, it may result in unnecessary waste during cooler periods. B2B buyers should weigh the benefits of convenience against potential cost implications.

What Are Customizable Nectar Solutions?

Customizable nectar solutions allow businesses to tailor replacement schedules based on specific local hummingbird species and their behaviors. This method is particularly relevant for specialty feeders in diverse ecosystems, where different species may have varying nectar preferences. B2B companies can leverage this knowledge to enhance their product offerings and attract niche markets. However, it requires a deeper understanding of local wildlife, which may necessitate additional training for staff.

How Important Is an Emergency Replacement Protocol?

An emergency replacement protocol ensures that feeders are promptly serviced if nectar shows signs of spoilage. This practice is vital for urban wildlife management and conservation efforts, as it protects the health of visiting birds and maintains the feeder’s reputation. For B2B buyers, implementing such protocols can enhance customer satisfaction and loyalty. However, it demands quick action and consistent monitoring, which can increase operational costs.

Key Industrial Applications of how often to replace hummingbird nectar

| Industry/Sector | Specific Application of how often to replace hummingbird nectar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Wildlife Conservation | Regular monitoring and replacement of nectar in feeders | Ensures healthy bird populations, promoting biodiversity and ecotourism | Quality and consistency of nectar; adherence to local environmental regulations |

| Agricultural Services | Use of hummingbird feeders to pollinate crops | Enhances crop yields through improved pollination | Availability of feeders and nectar; compatibility with local flora |

| Eco-Tourism | Hummingbird feeders in tourist attractions | Attracts visitors, boosting revenue and promoting conservation awareness | Feeder design and maintenance; ease of nectar replacement for staff |

| Retail and Distribution | Selling hummingbird feeders and nectar supplies | Expands product offerings to nature enthusiasts and bird watchers | Supplier reliability; product differentiation and pricing strategy |

| Research Institutions | Studying hummingbird feeding behaviors and nectar preferences | Generates valuable data for ecological studies and conservation efforts | Access to diverse nectar types; compliance with research protocols |

How is Regular Nectar Replacement Critical for Wildlife Conservation?

In wildlife conservation, maintaining healthy ecosystems is paramount. Regularly replacing hummingbird nectar in feeders helps to ensure that these birds receive fresh, uncontaminated food sources. This practice not only supports the birds’ health but also fosters biodiversity by encouraging their presence in local habitats. Buyers in this sector need to consider sourcing high-quality nectar that meets local environmental standards and ensures the longevity of the feeding stations.

How Can Agricultural Services Benefit from Hummingbird Feeders?

Agricultural services can leverage hummingbird feeders to enhance pollination, particularly for crops that rely on these birds for fertilization. By ensuring that nectar is replaced frequently, farmers can attract hummingbirds, thereby increasing crop yields and promoting sustainable farming practices. Buyers in this sector should focus on the compatibility of feeders with local flora and the availability of nectar supplies that are easy to manage.

What Role Do Hummingbird Feeders Play in Eco-Tourism?

In eco-tourism, hummingbird feeders serve as attractions that draw visitors interested in bird watching and nature. Regular nectar replacement is essential to maintain the appeal of these feeding stations, ensuring that birds are consistently present for observation. This not only enhances the visitor experience but also raises awareness about conservation efforts. Businesses in this industry should prioritize feeder design and ease of nectar replacement to maximize operational efficiency.

How Does Retail and Distribution Benefit from Hummingbird Products?

Retailers and distributors can expand their product offerings by including hummingbird feeders and nectar supplies. Regular replacement of nectar is crucial to maintain product quality and customer satisfaction. Businesses should seek reliable suppliers who provide consistent product availability and innovative solutions that differentiate their offerings in a competitive market.

Why is Nectar Replacement Important for Research Institutions?

Research institutions studying hummingbird behavior and ecology require fresh nectar for accurate data collection. Regular replacement of nectar in feeders ensures that the birds have access to nutritious food, which is vital for behavioral studies. Institutions must consider sourcing diverse nectar types that align with their research objectives while adhering to ethical guidelines for wildlife studies.

3 Common User Pain Points for ‘how often to replace hummingbird nectar’ & Their Solutions

Scenario 1: Inconsistent Hummingbird Visits Due to Spoiled Nectar

The Problem: B2B buyers, particularly retailers or distributors of bird feeding products, often face the challenge of inconsistent hummingbird visits to feeders. This inconsistency can be attributed to improperly managed nectar that has spoiled due to inadequate replacement practices. In warmer climates or during peak summer months, nectar can ferment and spoil within a single day, leading to reduced hummingbird activity. Customers may become frustrated, believing that the feeders are ineffective, which can affect sales and customer loyalty.

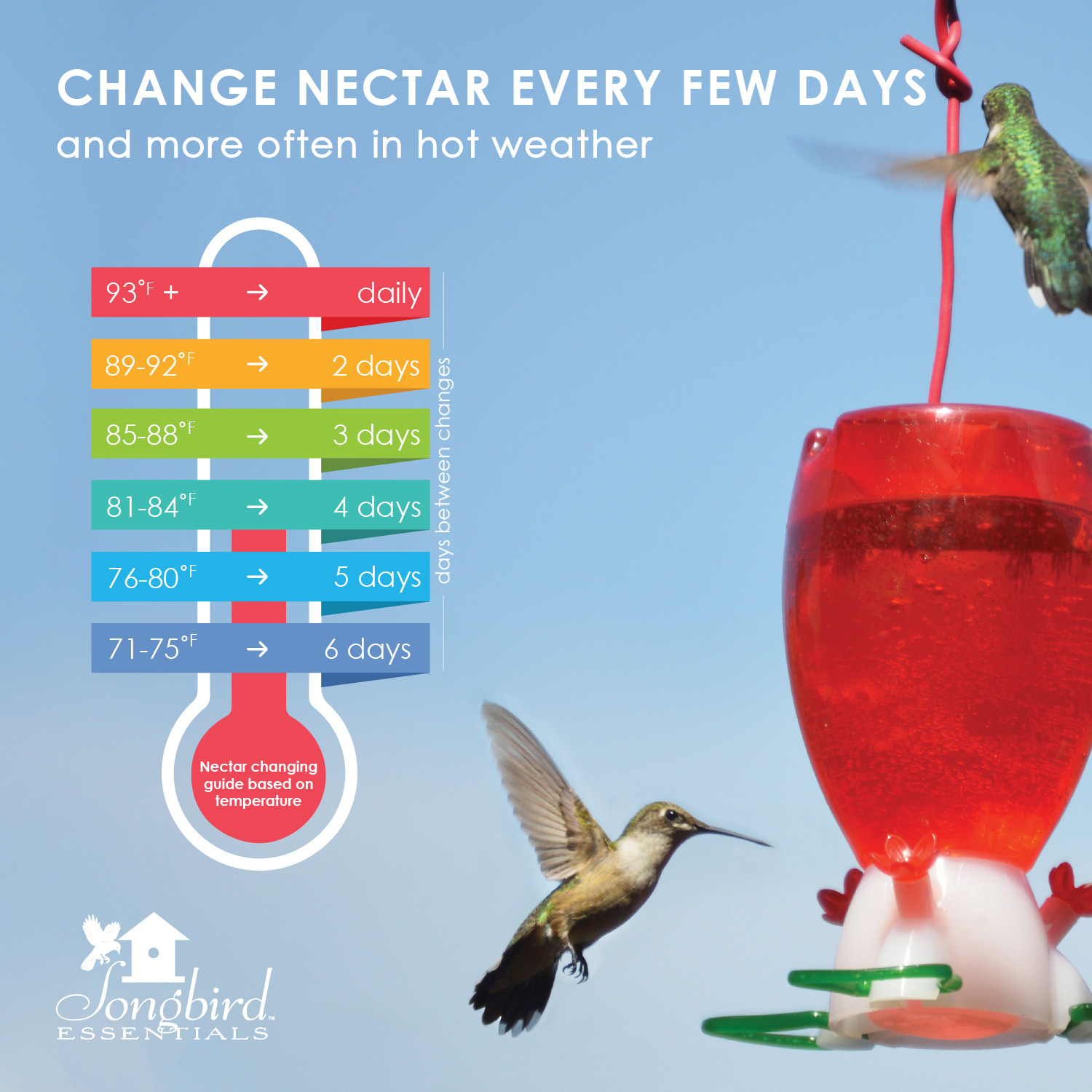

The Solution: To address this issue, it is crucial to establish clear guidelines for nectar replacement based on environmental conditions. Retailers should educate their customers on the importance of changing the nectar daily during hot weather, and every two to three days during cooler weather. Providing a simple chart or guide with specific recommendations based on temperature ranges can enhance customer experience. Additionally, retailers can offer high-quality, easy-to-clean feeders that allow for quick nectar changes, thus encouraging regular maintenance. By incorporating these practices, businesses can improve customer satisfaction and ensure a consistent hummingbird presence at feeders.

Scenario 2: Misunderstanding Nectar Ratios Leading to Poor Bird Health

The Problem: Another common issue for B2B buyers is the misunderstanding of how to properly mix hummingbird nectar. This can lead to incorrect sugar-to-water ratios, negatively impacting the health of the birds. For example, a ratio that is too weak may not provide sufficient energy for the birds, while one that is too strong can cause osmotic stress. Retailers may find that their customers are frustrated by the lack of hummingbirds visiting their feeders, resulting in returns and poor reviews.

The Solution: To combat this problem, suppliers should provide educational resources that clearly explain the correct nectar mixing ratios—specifically, a standard ratio of 1 part sugar to 4 parts water. Offering pre-measured nectar mixes can also simplify the process for customers, ensuring that they achieve the right concentration without the risk of error. Consider hosting workshops or creating online content that demonstrates the mixing process, emphasizing the importance of using pure cane sugar and avoiding additives like dyes or honey. By empowering customers with knowledge and easy-to-use products, businesses can foster trust and build lasting relationships.

Scenario 3: Difficulty in Cleaning Feeders Leading to Mold Issues

The Problem: Mold and bacteria growth in feeders is a significant concern for B2B buyers who sell hummingbird feeders and nectar. Buyers may receive complaints from customers about moldy feeders, which can deter birds from visiting and ultimately damage the reputation of the product. This situation is especially prevalent in humid climates where nectar can spoil more quickly, creating a breeding ground for harmful fungi.

The Solution: To mitigate this issue, B2B businesses should emphasize the importance of regular feeder cleaning as part of their customer education initiatives. Recommend that customers clean their feeders thoroughly with hot water and a brush at least once a week, and more frequently in humid conditions. Providing specialized cleaning kits or brushes designed for hummingbird feeders can also encourage proper maintenance. Additionally, incorporating a reminder system through email or social media to prompt customers about cleaning schedules can further enhance product performance and customer satisfaction. By prioritizing feeder hygiene, businesses can ensure healthier environments for hummingbirds and boost customer loyalty.

Strategic Material Selection Guide for how often to replace hummingbird nectar

What Materials Are Commonly Used for Hummingbird Nectar Feeders?

When considering the frequency of nectar replacement in hummingbird feeders, the materials used in their construction play a crucial role. The following analysis highlights four common materials—glass, plastic, metal, and silicone—examining their properties, advantages, disadvantages, and implications for international B2B buyers.

Glass: The Classic Choice for Hummingbird Feeders

Key Properties: Glass feeders are often favored for their aesthetic appeal and durability. They are non-reactive, meaning they won’t leach harmful substances into the nectar. Glass can withstand a wide range of temperatures, making it suitable for various climates.

Pros & Cons: The primary advantage of glass is its resistance to UV degradation, which helps maintain nectar quality. However, glass feeders can be heavy and fragile, making them less suitable for outdoor environments where they might be dropped or knocked over. They are generally more expensive than plastic options.

Impact on Application: Glass feeders are ideal for regions with stable weather conditions, but they may require more careful handling in areas prone to extreme weather or high winds.

Considerations for International Buyers: In regions like Europe and South America, glass feeders may comply with strict environmental regulations, but their weight could increase shipping costs. Buyers should consider local preferences for aesthetics and durability.

Plastic: A Lightweight Alternative

Key Properties: Plastic feeders are lightweight and often designed for easy cleaning. They are typically made from high-density polyethylene (HDPE) or polycarbonate, which are resistant to impact and UV light.

Pros & Cons: The main advantage of plastic is its affordability and ease of handling. However, lower-quality plastics may degrade over time, especially in high UV exposure areas. They can also absorb odors and flavors, potentially affecting nectar quality.

Impact on Application: Plastic feeders can be a practical choice in regions with fluctuating temperatures, as they are less likely to shatter. However, they may require more frequent replacement due to wear and tear.

Considerations for International Buyers: In regions like Africa and the Middle East, where cost-effectiveness is crucial, plastic feeders may be more appealing. Buyers should ensure compliance with local safety standards regarding food-grade materials.

Metal: Durability Meets Functionality

Key Properties: Metal feeders, often made from aluminum or stainless steel, offer excellent durability and resistance to corrosion. They can withstand harsh weather conditions and are less prone to damage than glass or plastic.

Pros & Cons: The durability of metal feeders is a significant advantage, especially in outdoor settings. However, they can be more expensive and may conduct heat, potentially affecting nectar temperature.

Impact on Application: Metal feeders are suitable for regions with extreme weather, as they are less likely to break or degrade. However, they require careful design to avoid overheating the nectar.

Considerations for International Buyers: In regions with high humidity, such as parts of South America, stainless steel options may be preferable due to their corrosion resistance. Compliance with local manufacturing standards is essential for ensuring product safety.

Silicone: The Flexible Choice

Key Properties: Silicone is increasingly used in feeder designs, particularly for gaskets and seals. It is flexible, resistant to extreme temperatures, and easy to clean.

Pros & Cons: The flexibility of silicone allows for innovative designs and easy assembly. However, it may not be as durable as glass or metal and can degrade over time with exposure to UV light.

Impact on Application: Silicone components can enhance the functionality of feeders, ensuring a tight seal to prevent leaks. However, the overall lifespan of silicone-based products may be shorter.

Considerations for International Buyers: In regions with stringent environmental regulations, silicone may meet safety standards for food contact. Buyers should assess the longevity of silicone products in their specific climate conditions.

Summary Table of Material Selection for Hummingbird Nectar Feeders

| Material | Typical Use Case for how often to replace hummingbird nectar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Ideal for stable climates with aesthetic appeal | Non-reactive and UV-resistant | Heavy and fragile | High |

| Plastic | Cost-effective and lightweight for frequent use | Affordable and easy to clean | Can degrade and absorb odors | Low |

| Metal | Durable option for extreme weather conditions | Excellent durability and corrosion resistance | Can conduct heat and be expensive | Medium |

| Silicone | Flexible design elements and seals | Innovative and easy to clean | Less durable and UV-sensitive | Medium |

This analysis provides insight into the materials commonly used in hummingbird feeders, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how often to replace hummingbird nectar

What Are the Main Stages of the Manufacturing Process for Hummingbird Nectar?

The manufacturing of hummingbird nectar involves several critical stages, each essential for ensuring a high-quality product that meets both consumer expectations and regulatory standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Quality of Ingredients

The process begins with sourcing high-quality ingredients, primarily granulated sugar, which must be free from contaminants. Manufacturers often opt for refined sucrose as it closely resembles natural flower nectar, which is essential for attracting hummingbirds. This ingredient should be tested for purity and compliance with international standards such as ISO 9001, which outlines quality management systems. In regions like Africa and South America, local suppliers may offer alternatives, but it is crucial to ensure they meet safety and quality guidelines to prevent any negative impact on the product.

Forming: Mixing and Concentration

In the forming stage, the prepared sugar is mixed with purified water, typically in a ratio of four parts water to one part sugar. This mixture is heated to ensure complete dissolution of the sugar and to eliminate any chlorination that could affect the nectar’s taste and quality. Manufacturers may employ techniques such as reverse osmosis to ensure water purity. This step is critical, as the concentration directly impacts the nectar’s effectiveness in attracting hummingbirds.

Assembly: Packaging and Distribution

Once the nectar is mixed, it is cooled and packaged in appropriate containers that prevent contamination. The packaging must comply with relevant industry standards, such as CE marking in Europe, which indicates conformity with health and safety standards. During this phase, manufacturers often conduct inline quality checks to ensure that packaging is intact and free from defects. Proper labeling, including ingredient transparency and usage instructions, is also vital for consumer trust and regulatory compliance.

Finishing: Final Quality Assurance and Shelf Life Considerations

The finishing stage involves additional quality checks and testing for shelf life. Manufacturers should conduct tests to determine the nectar’s stability under various conditions, particularly in warmer climates, where spoilage can occur rapidly. This is particularly relevant for B2B buyers in regions like Brazil and Saudi Arabia, where high temperatures can affect product longevity. The use of preservatives is generally discouraged in hummingbird nectar, so understanding natural shelf life is essential.

What Quality Control Measures Are Essential for Hummingbird Nectar Production?

Quality control (QC) is crucial in the production of hummingbird nectar to ensure that the final product is safe and effective. Adhering to international standards, such as ISO 9001, provides a framework for quality management that can help suppliers maintain consistent quality.

What Are the Key QC Checkpoints in Nectar Production?

-

Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials upon arrival. Suppliers should verify that sugar and water meet specified quality standards and are free from contaminants.

-

In-Process Quality Control (IPQC): During the mixing and packaging phases, manufacturers should implement IPQC checks to monitor the process and detect any deviations from standard operating procedures. This can include temperature checks during mixing and visual inspections of packaging.

-

Final Quality Control (FQC): Before distribution, FQC ensures that the finished product meets all specifications. This may involve taste testing, checking for consistency in color and viscosity, and conducting microbiological tests to confirm that no harmful bacteria are present.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions with varying regulations, verifying a supplier’s quality control processes is essential. Here are key steps to ensure you are partnering with a reliable manufacturer:

Conducting Audits and Assessing Compliance

B2B buyers should conduct regular audits of suppliers to assess their adherence to quality standards. This includes reviewing their quality management systems, production processes, and documentation of past QC results.

Requesting Quality Reports and Certifications

Buyers should request quality reports that detail the results of IQC, IPQC, and FQC checks. Certifications such as ISO 9001 or local food safety certifications can provide reassurance regarding the supplier’s commitment to quality.

Illustrative image related to how often to replace hummingbird nectar

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspectors can verify compliance with international standards and ensure that the manufacturing process meets the buyer’s specifications.

What Are the Quality Assurance Nuances for International B2B Buyers?

When sourcing hummingbird nectar from international suppliers, buyers should be aware of several nuances that can affect quality assurance:

-

Regulatory Differences: Different regions may have varying regulations regarding food safety and quality. Buyers should familiarize themselves with the specific requirements in their region and ensure that suppliers can meet these standards.

-

Cultural Variations in Quality Perception: Quality expectations can vary based on regional preferences and cultural perceptions of food safety. B2B buyers should communicate their quality requirements clearly to suppliers to avoid misunderstandings.

-

Logistical Challenges: The transportation of nectar, especially in warmer climates, requires careful handling to prevent spoilage. Buyers should inquire about the supplier’s logistics processes to ensure that products are shipped and stored under conditions that maintain quality.

Conclusion

Understanding the manufacturing processes and quality assurance measures for hummingbird nectar is essential for B2B buyers looking to source high-quality products. By focusing on each stage of production—from material preparation to final quality checks—and implementing rigorous QC measures, suppliers can ensure that their nectar meets the highest standards. This not only enhances product effectiveness but also builds trust with buyers across diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to replace hummingbird nectar’

Introduction

In the competitive landscape of bird care products, understanding the optimal frequency for replacing hummingbird nectar is essential for maintaining a healthy feeding environment. This guide provides a structured checklist for B2B buyers to ensure the highest standards of nectar management. By adhering to these steps, suppliers can enhance their product offerings and cater to the needs of both retailers and end-users, leading to improved customer satisfaction and loyalty.

Step 1: Understand Seasonal Demand Fluctuations

Recognizing the seasonal patterns of hummingbird activity is crucial for inventory management. Hummingbirds typically migrate and are most active during warmer months, which means nectar replacement needs will peak in spring and summer. Ensure your procurement plan aligns with these seasonal demands to avoid stock shortages or excess inventory.

Illustrative image related to how often to replace hummingbird nectar

- Research regional migration patterns to anticipate peak times.

- Adjust orders based on local climate, as warmer areas may require more frequent replacements.

Step 2: Establish Quality Standards for Nectar

Quality is paramount when sourcing hummingbird nectar. Buyers should prioritize products that meet industry standards for purity and composition, ensuring they are free from harmful additives like dyes or preservatives.

- Request samples to evaluate the nectar’s consistency and sweetness.

- Verify ingredient sourcing to ensure compliance with health and safety regulations.

Step 3: Monitor Temperature and Weather Conditions

Weather significantly impacts nectar spoilage rates. Nectar should be replaced more frequently during hot weather, as high temperatures accelerate fermentation and mold growth. Establish guidelines for your suppliers to follow based on typical temperature ranges.

- Define clear replacement intervals (e.g., daily during heat waves, every 2-3 days during cooler weather).

- Educate customers on the importance of monitoring conditions to maintain nectar quality.

Step 4: Implement Cleaning Protocols for Feeders

Regular cleaning of feeders is critical to prevent mold and bacterial growth, which can deter hummingbirds from feeding. Include recommendations for feeder cleaning frequency alongside nectar replacement guidelines in your product offerings.

- Encourage the use of specialized cleaning tools to reach hard-to-clean areas.

- Provide detailed cleaning instructions to ensure customers maintain feeder hygiene effectively.

Step 5: Educate on the Signs of Spoilage

Training your sales team and customers to recognize signs of nectar spoilage can significantly enhance user experience. Spoiled nectar may appear cloudy or develop a foul smell, making it unappealing to hummingbirds.

- Create informative materials that outline spoilage indicators.

- Promote the importance of regular checks to encourage proactive nectar management.

Step 6: Offer Customizable Nectar Solutions

Different regions and climates may require customized nectar solutions. Offering products that allow for adjustments in sugar concentration can cater to diverse hummingbird species and their dietary needs.

- Highlight the benefits of customizable nectar in your marketing materials.

- Collaborate with suppliers to develop region-specific formulations that meet local demands.

Step 7: Establish Strong Supplier Relationships

Building lasting relationships with suppliers can lead to better pricing, priority access to products, and improved collaboration on product development. Engage regularly with suppliers to discuss trends and gather feedback.

- Schedule regular check-ins to align on inventory needs and product quality.

- Negotiate terms that allow for flexibility during peak seasons, ensuring a reliable supply chain.

By following these steps, B2B buyers can ensure a consistent and high-quality nectar supply, ultimately enhancing the hummingbird feeding experience for their customers.

Comprehensive Cost and Pricing Analysis for how often to replace hummingbird nectar Sourcing

What Are the Key Cost Components in Hummingbird Nectar Replacement?

When analyzing the cost structure for sourcing hummingbird nectar, several components come into play. The primary cost elements include:

-

Materials: The main ingredient is sucrose, which can be sourced either as a raw ingredient or in pre-mixed solutions. The cost of sugar fluctuates based on global commodity prices and regional availability. Additional ingredients, if any, such as preservatives or vitamins, also affect material costs.

-

Labor: This encompasses the workforce involved in the production and packaging of the nectar. Labor costs can vary significantly depending on the region, with higher wages generally found in developed markets compared to emerging economies.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. In regions with higher operational costs, such as Europe, overhead can be a significant factor in the pricing structure.

-

Tooling: Specialized equipment for mixing and bottling nectar can require significant investment. The initial tooling cost can be amortized over production volumes, affecting the unit price.

-

Quality Control (QC): Ensuring that nectar meets safety and quality standards incurs additional costs. Regular testing for spoilage and contaminants is critical, particularly in international markets where regulations may differ.

-

Logistics: Transportation costs vary based on the distance from manufacturing facilities to distribution points. Factors such as shipping mode, customs duties, and local taxes can significantly impact the final price.

-

Margin: Suppliers typically add a markup to cover overhead and generate profit. Understanding the standard margins in your region can aid in negotiating better deals.

How Do Price Influencers Affect Hummingbird Nectar Sourcing?

Several price influencers can impact the cost of hummingbird nectar:

-

Volume/MOQ: Bulk purchasing can lead to significant savings, as suppliers often provide discounts for higher volumes. Buyers should consider their consumption patterns and negotiate minimum order quantities (MOQ) to optimize costs.

-

Specifications/Customization: Custom formulations or packaging can lead to higher costs. Buyers should clearly define their needs to avoid unnecessary expenses while ensuring product specifications are met.

-

Materials: The quality of sugar used (e.g., organic vs. conventional) can significantly affect pricing. Buyers must weigh the benefits of premium ingredients against their budget constraints.

-

Supplier Factors: Supplier reliability and reputation can influence pricing. Established suppliers may charge more but provide guarantees on quality and delivery, reducing risks associated with supply chain disruptions.

-

Incoterms: Understanding the terms of trade (e.g., FOB, CIF) can help buyers manage logistics costs effectively. This knowledge is crucial for international buyers to avoid unexpected charges during the shipping process.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Total Cost of Ownership (TCO): Evaluate not only the purchase price but also ongoing costs such as storage, spoilage, and transportation. A lower initial price may not always equate to the best value.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better negotiation outcomes. Long-term partnerships often yield favorable terms and reliability.

-

Market Research: Staying informed about market trends and competitor pricing can provide leverage during negotiations. Understanding regional dynamics can help identify the best sourcing opportunities.

-

Diverse Sourcing: Consider multiple suppliers to mitigate risks associated with single-source dependency. This strategy can also foster competitive pricing.

-

Flexibility in Specifications: Being open to alternatives in product specifications can lead to cost savings. For example, if a specific sugar type is too expensive, exploring local alternatives may yield better pricing.

Conclusion

In summary, understanding the various cost components and price influencers involved in sourcing hummingbird nectar is crucial for B2B buyers. By employing effective negotiation strategies and considering the Total Cost of Ownership, companies can optimize their procurement processes while ensuring quality and reliability in their supply chain. Always remember that prices may vary based on local market conditions, and conducting thorough research is key to making informed purchasing decisions.

Alternatives Analysis: Comparing how often to replace hummingbird nectar With Other Solutions

Exploring Alternatives to Hummingbird Nectar Replacement Frequency

In the realm of bird feeding, particularly for hummingbirds, the regular replacement of nectar is crucial for maintaining a healthy feeding environment. However, there are various methods and technologies that can serve as alternatives or enhancements to the traditional approach of replacing hummingbird nectar. This analysis aims to provide B2B buyers with insights into these alternatives, highlighting their performance, cost, and practicality.

| Comparison Aspect | How Often To Replace Hummingbird Nectar | Automated Nectar Dispenser | Nectar Reservoir System |

|---|---|---|---|

| Performance | High, requires daily or bi-daily changes in hot weather | Moderate, consistent flow but can malfunction | High, maintains freshness for extended periods |

| Cost | Low, primarily sugar and water costs | Medium, initial investment for the device | High, costs associated with installation and maintenance |

| Ease of Implementation | Simple, requires minimal setup | Moderate, requires setup and occasional adjustments | Complex, requires installation and may need professional assistance |

| Maintenance | Regular cleaning needed every few days | Requires battery changes and occasional cleaning | Low maintenance, but filters must be checked periodically |

| Best Use Case | Ideal for casual bird enthusiasts | Suitable for businesses or educational institutions | Best for nature reserves or commercial settings with high bird traffic |

What are the Advantages and Disadvantages of Automated Nectar Dispensers?

Automated nectar dispensers offer a modern solution for hummingbird feeding by providing a consistent flow of nectar without the need for frequent manual replacement. This method can be particularly beneficial for businesses or educational institutions that seek to maintain bird activity without constant oversight. However, these devices may require an initial investment and can malfunction if not properly maintained, which could lead to periods of no available nectar for the birds.

How Does a Nectar Reservoir System Enhance Hummingbird Feeding?

Nectar reservoir systems are designed to store larger quantities of nectar, maintaining freshness over longer periods. This technology is ideal for nature reserves or commercial settings that experience high bird traffic. The system reduces the frequency of nectar changes, which can save time and labor costs. However, the complexity of installation and potential higher upfront costs may deter casual users or smaller operations from adopting this solution.

Conclusion: How Should B2B Buyers Choose the Right Solution for Hummingbird Feeding?

When selecting the most suitable nectar feeding solution, B2B buyers should consider their specific operational needs, budget constraints, and the local environment. Traditional nectar replacement is effective for smaller setups or casual bird feeding, while automated dispensers and reservoir systems can significantly enhance efficiency in commercial applications. Ultimately, the choice will hinge on balancing initial investment with long-term operational efficiency and the desired level of bird engagement. Understanding these alternatives empowers buyers to make informed decisions that align with their business objectives and environmental considerations.

Essential Technical Properties and Trade Terminology for how often to replace hummingbird nectar

What Are the Essential Technical Properties for Hummingbird Nectar Replacement?

When managing hummingbird feeders, understanding the technical properties related to nectar replacement is crucial for maintaining a healthy environment for these birds. Here are some key specifications that B2B buyers should consider:

-

Nectar Composition: Hummingbird nectar is typically made from a 4:1 ratio of water to sugar (sucrose). This ratio mimics the natural nectar found in flowers, which is vital for hummingbirds’ energy needs. Buyers should ensure that the nectar they supply is free from additives like dyes, as these can be harmful to birds. This knowledge aids in product selection and ensures adherence to health standards.

-

Shelf Life: The shelf life of prepared nectar is influenced by environmental conditions. In cooler temperatures (below 60°F), nectar can last up to three days; however, in warmer conditions (above 90°F), it should be replaced daily to prevent fermentation and mold growth. Understanding shelf life helps businesses manage inventory effectively, reducing waste and ensuring product quality.

-

Feeder Material: The materials used in hummingbird feeders can affect how often nectar needs to be replaced. Plastic feeders may degrade faster in sunlight compared to glass feeders, which can maintain nectar quality longer. Buyers should consider the durability and UV resistance of materials when selecting feeders for their markets.

-

Cleaning Protocols: Regular cleaning is essential to prevent mold and bacteria growth in feeders. The recommended cleaning frequency is at least once a week, or more often in hot weather. Understanding effective cleaning protocols ensures that businesses can provide guidance to customers, enhancing user experience and promoting bird health.

-

Temperature Tolerance: The nectar’s ability to withstand temperature fluctuations is important. Nectar should be stored in cool conditions and should not be exposed to direct sunlight for prolonged periods. This property ensures that the nectar remains palatable and safe for hummingbirds, which is essential for maintaining customer satisfaction.

What Are the Common Trade Terms Related to Hummingbird Nectar?

Navigating the hummingbird nectar market involves familiarizing oneself with specific jargon that can facilitate better business transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products that are marketed by another company. For hummingbird nectar suppliers, understanding OEM relationships can help in sourcing feeders or nectar solutions that meet specific branding requirements.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage their budgets and inventory efficiently, especially when dealing with seasonal products like hummingbird feeders and nectar.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Understanding how to prepare and respond to RFQs can streamline procurement processes for hummingbird nectar and associated products.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps businesses clarify shipping arrangements and costs associated with hummingbird nectar delivery, which is particularly useful for international buyers.

-

Lead Time: This refers to the amount of time it takes from placing an order to delivery. Understanding lead times for hummingbird nectar and feeders can help businesses plan their inventory and ensure that they meet customer demand without delays.

-

Sustainability Certifications: These certifications indicate that a product meets certain environmental standards. Buyers should look for sustainability certifications for nectar products and feeders to appeal to eco-conscious customers and align with global sustainability trends.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance product quality, optimize inventory management, and improve customer satisfaction in the hummingbird nectar market.

Navigating Market Dynamics and Sourcing Trends in the how often to replace hummingbird nectar Sector

Market Overview & Key Trends in Hummingbird Nectar Replacement

The global market for hummingbird nectar is influenced by several factors, including the increasing interest in backyard birdwatching and wildlife conservation. As urbanization continues to encroach on natural habitats, many consumers are seeking ways to support local wildlife, particularly hummingbirds, which play a crucial role in pollination. This trend has led to a surge in demand for hummingbird feeders and nectar products, particularly in regions like Africa, South America, the Middle East, and Europe, where biodiversity is often under threat.

Emerging B2B technologies are reshaping how businesses source and distribute hummingbird nectar. The rise of e-commerce platforms has made it easier for suppliers to reach international buyers, while advancements in logistics and supply chain management enhance efficiency. In addition, the adoption of data analytics helps suppliers understand regional preferences, enabling them to tailor products to specific markets, such as offering nectar formulated for local species.

Current market dynamics indicate a growing emphasis on quality and freshness, leading to more frequent nectar replacement. On hot days, for instance, suppliers recommend changing nectar daily to prevent spoilage, which aligns with consumer demands for high-quality products. B2B buyers must remain vigilant about these trends to ensure their offerings meet the expectations of environmentally conscious consumers who prioritize freshness and quality.

How is Sustainability & Ethical Sourcing Addressed in the Hummingbird Nectar Market?

Sustainability is becoming a cornerstone of sourcing strategies for hummingbird nectar. Environmental impacts, particularly the carbon footprint associated with production and distribution, are under scrutiny. B2B buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using locally sourced ingredients and eco-friendly packaging.

Ethical supply chains are essential, especially in regions where environmental degradation can severely impact local ecosystems. Buyers should look for suppliers that adhere to sustainability certifications, which not only assure product quality but also demonstrate a commitment to responsible sourcing. For example, certifications like the Rainforest Alliance or Fair Trade can add value to products, appealing to eco-conscious consumers and businesses alike.

Moreover, businesses are encouraged to adopt green practices, such as reducing waste in production and utilizing renewable energy sources. By prioritizing sustainability, companies not only contribute to environmental preservation but also enhance their brand reputation, attracting a broader customer base that values ethical consumption.

What is the Brief Evolution of Hummingbird Nectar Products?

The evolution of hummingbird nectar products can be traced back to the increasing popularity of backyard bird feeding in the 20th century. Initially, homemade nectar solutions were common, but as demand grew, manufacturers began offering pre-mixed, commercial options that promised convenience and consistency. This shift enabled wider access to high-quality nectar, fostering greater awareness of hummingbirds and their needs.

In recent years, the market has seen a diversification of nectar products, including organic options and those formulated to attract specific hummingbird species. Innovations such as easy-to-clean feeder designs and eco-friendly packaging have also emerged, reflecting changing consumer preferences. This evolution highlights the industry’s adaptability and commitment to meeting the evolving needs of both B2B buyers and end consumers, ensuring that hummingbird nectar remains a popular product in the global market.

Illustrative image related to how often to replace hummingbird nectar

Frequently Asked Questions (FAQs) for B2B Buyers of how often to replace hummingbird nectar

-

1. How often should I replace hummingbird nectar to ensure freshness?

Nectar should be replaced based on environmental conditions. In cooler weather (around 60°F or 15°C), it can last for 2-3 days. However, during hot weather (90°F or above), it should be replaced daily to prevent spoilage. Regularly cleaning the feeder and monitoring the nectar’s clarity can help maintain a healthy feeding environment for hummingbirds, which is crucial for attracting these birds to your feeders. -

2. What is the ideal nectar-to-water ratio for making hummingbird nectar?

The recommended ratio for homemade hummingbird nectar is 4 parts water to 1 part sugar. For example, mix 1 cup of water with ¼ cup of granulated sugar. Boiling the water before mixing helps dissolve the sugar and eliminates chlorine. This simple recipe mimics the natural nectar found in flowers, providing the energy hummingbirds need while avoiding harmful additives like dyes. -

3. How can I ensure the quality of nectar from suppliers?

When sourcing nectar from suppliers, prioritize those who offer high-quality, dye-free products. Request samples to assess the nectar’s consistency and sweetness. Check for certifications that indicate adherence to food safety standards. Building relationships with suppliers who have a solid reputation in the industry can also ensure consistent quality and reliability. -

4. What are the minimum order quantities (MOQs) for hummingbird nectar?

MOQs can vary significantly between suppliers. Some may offer small batches for trial orders, while others might require larger quantities. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that suit your business model, especially if you are targeting different international markets like Brazil or Saudi Arabia, where demand may fluctuate. -

5. What payment terms should I consider when sourcing hummingbird nectar?

Payment terms often depend on the supplier’s policies and your business relationship. Common options include upfront payment, net 30, or net 60 days. Ensure you clarify these terms before finalizing orders, especially for international transactions, to avoid cash flow issues. Consider using secure payment methods that protect both parties in the transaction. -

6. How do I vet suppliers for international trade in hummingbird nectar?

Vetting suppliers involves researching their business history, customer reviews, and certifications. Utilize platforms like Alibaba or trade shows to find reputable suppliers. Request references and samples to assess product quality. Additionally, understanding their logistics capabilities and compliance with international trade regulations can help mitigate risks associated with sourcing from different regions. -

7. What logistics considerations should I keep in mind for importing hummingbird nectar?

When importing nectar, consider shipping methods, customs regulations, and potential tariffs. Ensure that your supplier is familiar with international shipping procedures and can provide necessary documentation, such as health certificates. Planning for potential delays and ensuring proper storage conditions during transit is essential to maintain product quality upon arrival. -

8. How can I customize hummingbird nectar products for my market?

Customization options may include varying nectar concentrations or packaging sizes to meet local preferences. Engage with your supplier to discuss available customization options, such as incorporating specific branding or labels. Understanding regional demands will help you tailor your offerings, making them more appealing to your target audience in diverse markets like Africa, South America, and Europe.

Top 3 How Often To Replace Hummingbird Nectar Manufacturers & Suppliers List

1. Reddit – Bird Feeder Care Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Change sugar-water in feeders every day when temperatures exceed 80 degrees to prevent mold and bacteria growth. In cooler weather, change every two days. Use a small amount of nectar if only a few birds are visiting.

2. Facebook – Hummingbird Feeder

3. BirdForum – Hummingbird Food Guide

Domain: birdforum.net

Registered: 2002 (23 years)

Introduction: Hummingbird food should be changed every 2 to 3 days under normal conditions, and can be extended to 5 to 6 days in cooler temperatures. The recommended recipe for homemade hummingbird food is 1 part white table sugar to 4 parts water, without any artificial coloring or substitutes like honey or brown sugar. Commercial nectar products are discouraged due to potential harmful chemicals. Clean feede…

Strategic Sourcing Conclusion and Outlook for how often to replace hummingbird nectar

As the demand for hummingbird feeders grows globally, especially in regions like Africa, South America, the Middle East, and Europe, understanding the optimal frequency for replacing hummingbird nectar becomes crucial for businesses in the avian products sector. Regularly replacing nectar not only enhances the health and vitality of hummingbirds but also ensures repeat visits, fostering customer satisfaction and loyalty.

For optimal nectar management, consider local climatic conditions: in cooler temperatures, nectar can remain for two to three days, while in hotter climates, a daily change is necessary. This knowledge enables suppliers to craft targeted strategies for different markets, tailoring their product offerings to meet local needs effectively.

Investing in high-quality nectar and feeders can also streamline maintenance processes, reducing waste and improving the overall experience for end-users. As the market evolves, businesses should leverage this insight to establish themselves as trusted providers of hummingbird solutions.

Looking ahead, companies are encouraged to explore innovative nectar formulations and feeder designs that cater to the unique preferences of hummingbirds in diverse environments. By doing so, they can capitalize on emerging opportunities and drive sustainable growth within the global hummingbird feeder market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how often to replace hummingbird nectar

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.