Introduction: Navigating the Global Market for water depleted

In today’s rapidly evolving global market, the challenge of sourcing sustainable solutions for water-depleted regions is becoming increasingly urgent. With rising demand for reliable water resources, international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Saudi Arabia and Nigeria—must navigate complex landscapes to secure effective water management strategies. This comprehensive guide delves into the multifaceted world of water depletion, providing insights into various types of water resources, innovative applications, and best practices for supplier vetting.

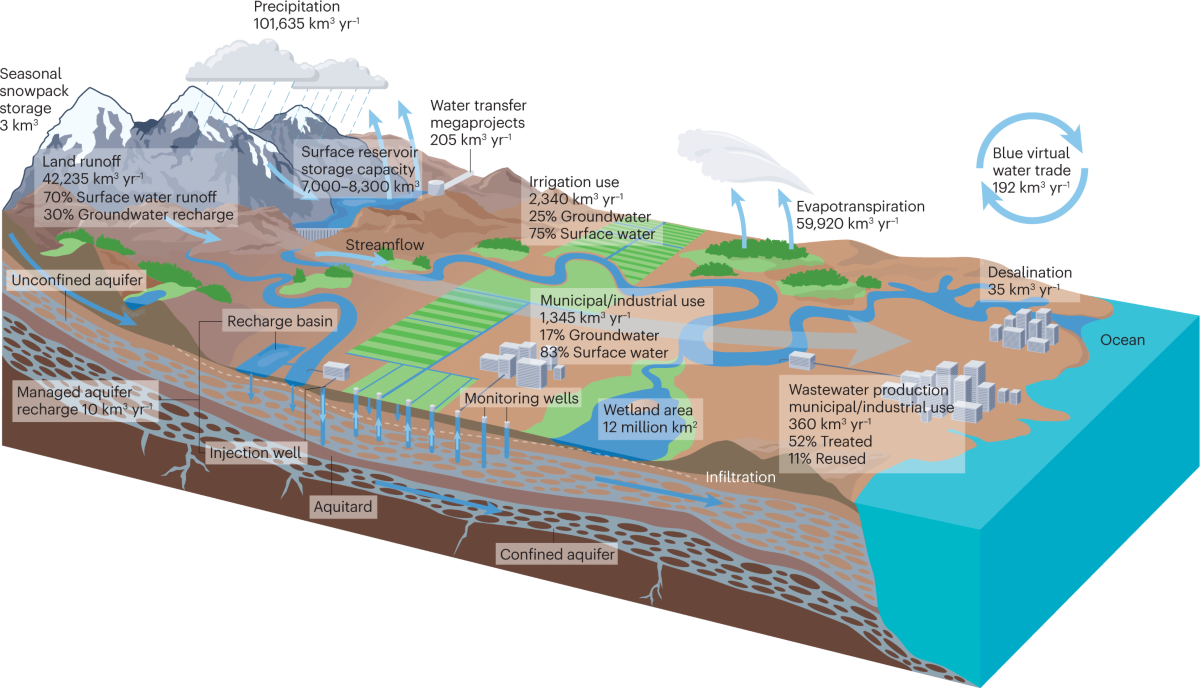

Buyers will find actionable information on cost structures and financing options, enabling informed purchasing decisions that align with sustainability goals. By addressing critical aspects such as the interconnectedness of groundwater and surface water, as well as emerging technologies for water recharge, this guide empowers businesses to make strategic investments. Moreover, it highlights collaborative approaches that leverage nature-based solutions to enhance water resilience. With a focus on actionable insights and real-world applications, this resource serves as a vital tool for international B2B buyers seeking to make a positive impact while securing their water needs in an increasingly resource-constrained environment.

Table Of Contents

- Top 1 Water Depleted Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water depleted

- Understanding water depleted Types and Variations

- Key Industrial Applications of water depleted

- 3 Common User Pain Points for ‘water depleted’ & Their Solutions

- Strategic Material Selection Guide for water depleted

- In-depth Look: Manufacturing Processes and Quality Assurance for water depleted

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water depleted’

- Comprehensive Cost and Pricing Analysis for water depleted Sourcing

- Alternatives Analysis: Comparing water depleted With Other Solutions

- Essential Technical Properties and Trade Terminology for water depleted

- Navigating Market Dynamics and Sourcing Trends in the water depleted Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water depleted

- Strategic Sourcing Conclusion and Outlook for water depleted

- Important Disclaimer & Terms of Use

Understanding water depleted Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Groundwater Depletion | Reduction in aquifer levels due to excessive extraction | Agriculture, Mining, Water Supply | Pros: Essential for long-term sustainability. Cons: High costs for replenishment. |

| Surface Water Depletion | Reduction in lakes, rivers, and reservoirs due to evaporation and usage | Hydropower, Irrigation, Recreation | Pros: Immediate resource availability. Cons: Vulnerable to climate change impacts. |

| Soil Moisture Depletion | Reduced moisture in soil affecting crop growth and land productivity | Agriculture, Landscaping | Pros: Increases efficiency in irrigation. Cons: Requires ongoing management and monitoring. |

| Aquifer Contamination | Pollution in groundwater affecting quality and availability | Drinking Water, Agriculture | Pros: Drives innovation in water treatment solutions. Cons: Expensive remediation processes. |

| Seasonal Water Depletion | Fluctuations in water availability based on seasonal cycles | Agriculture, Water Management | Pros: Predictable patterns for planning. Cons: Uncertainty during extreme weather events. |

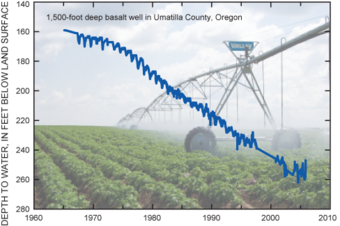

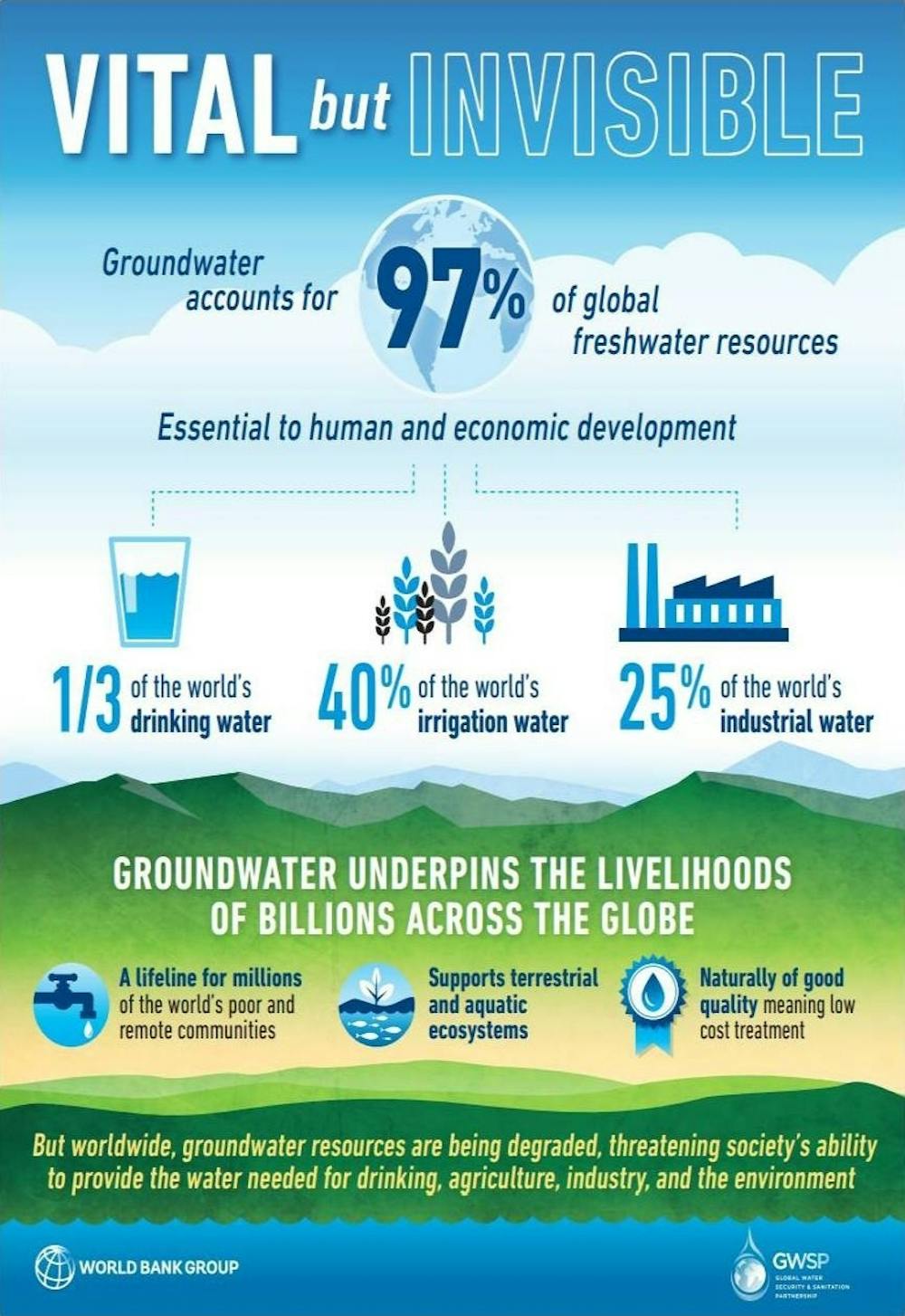

What Are the Characteristics of Groundwater Depletion?

Groundwater depletion occurs when the rate of water extraction from aquifers exceeds the rate of natural replenishment. This phenomenon is particularly critical in arid regions where groundwater serves as a primary water source for agriculture, industry, and domestic use. B2B buyers in sectors like agriculture and mining must consider the sustainability of their water sourcing strategies, as reliance on depleted aquifers can lead to increased operational costs and regulatory challenges.

How Does Surface Water Depletion Affect Businesses?

Surface water depletion refers to the reduction of water levels in lakes, rivers, and reservoirs, primarily driven by evaporation, overuse, and climate change. This type of depletion poses significant risks for industries reliant on hydropower, irrigation, and recreational activities. Companies must assess their water usage patterns and explore alternative sources or conservation strategies to mitigate the impact of surface water shortages.

Why Is Soil Moisture Depletion Important for Agriculture?

Soil moisture depletion directly affects agricultural productivity, as reduced moisture levels hinder crop growth and soil health. This condition is often exacerbated by inefficient irrigation practices and climate variability. B2B buyers in agriculture should prioritize investments in advanced irrigation technologies and soil management practices to enhance water retention and optimize yield, ensuring food security and sustainability.

What Are the Implications of Aquifer Contamination?

Aquifer contamination occurs when pollutants infiltrate groundwater, compromising water quality and availability. This issue is particularly relevant for industries that depend on clean water for drinking and agricultural purposes. B2B buyers must be proactive in implementing water treatment solutions and conducting regular quality assessments to prevent costly remediation efforts and ensure compliance with health regulations.

How Does Seasonal Water Depletion Influence Water Management?

Seasonal water depletion refers to the predictable fluctuations in water availability based on seasonal cycles, often influenced by climate conditions. This variability is crucial for businesses in agriculture and water management sectors, as it necessitates strategic planning for irrigation and resource allocation. Understanding seasonal patterns allows companies to optimize their operations while minimizing risks associated with water shortages during dry periods.

Key Industrial Applications of water depleted

| Industry/Sector | Specific Application of water depleted | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Groundwater recharge strategies | Enhanced crop yields and sustainability | Knowledge of local aquifer conditions and regulations |

| Construction | Water management in building projects | Reduced costs from water scarcity | Availability of sustainable water sourcing solutions |

| Mining | Water recycling and management systems | Compliance with environmental regulations | Technology for efficient water reuse and treatment |

| Energy | Cooling systems using depleted water | Lower operational costs and improved efficiency | Sourcing reliable technologies for cooling solutions |

| Food Processing | Water-efficient processing techniques | Reduced water usage and costs | Compliance with health and safety standards |

How Can Agriculture Benefit from Groundwater Recharge Strategies?

In agriculture, implementing groundwater recharge strategies is crucial in regions facing water depletion. By enhancing aquifer replenishment through managed floodplain restoration, farmers can secure a more reliable water supply for irrigation. This approach not only boosts crop yields but also promotes sustainable farming practices. For international buyers, understanding local aquifer conditions and complying with regional water management regulations are essential to ensure the effectiveness of these strategies.

What Are the Water Management Needs in Construction?

In the construction industry, managing water resources effectively is vital, especially in arid regions. Utilizing water-efficient systems during building projects can significantly reduce costs associated with water scarcity. By sourcing sustainable water management technologies, construction firms can minimize their environmental footprint while adhering to local regulations. Buyers must consider the availability of innovative solutions that align with their project requirements and regional water policies.

How Does Mining Utilize Water Recycling and Management Systems?

The mining sector faces stringent environmental regulations regarding water use and waste. Implementing advanced water recycling and management systems allows mining operations to minimize their freshwater consumption and comply with legal standards. By sourcing technologies that enable efficient water reuse, companies can enhance their operational sustainability and reduce costs. Buyers should prioritize suppliers with proven technologies that can meet the specific regulatory requirements of their operational regions.

What Are the Advantages of Using Depleted Water in Energy Cooling Systems?

In the energy sector, particularly in power generation, using water-depleted resources for cooling systems can lead to lower operational costs and improved efficiency. By leveraging innovative cooling technologies, energy companies can mitigate the impacts of water scarcity while maintaining performance standards. Buyers should seek reliable suppliers of cooling technologies that can effectively utilize depleted water, ensuring compliance with environmental regulations and operational requirements.

How Can Food Processing Improve Water Efficiency?

Food processing industries are increasingly adopting water-efficient techniques to address the challenges of water depletion. By implementing systems that minimize water usage during production, companies can significantly reduce their operational costs while enhancing product sustainability. Buyers in this sector must ensure that their water sourcing aligns with health and safety standards, and they should look for suppliers that offer innovative solutions tailored to the specific needs of food processing operations.

3 Common User Pain Points for ‘water depleted’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Amid Water Scarcity

The Problem: B2B buyers, particularly in sectors reliant on agriculture and manufacturing, often face the challenge of navigating complex regulations surrounding water use. In regions experiencing severe water depletion, compliance with stringent water management laws is crucial. Non-compliance can lead to hefty fines, operational shutdowns, and damage to reputation. Buyers need to ensure that their water usage not only meets current regulations but also anticipates future restrictions.

The Solution: To effectively manage compliance, buyers should invest in comprehensive water management systems that include real-time monitoring and reporting tools. Implementing smart water meters and data analytics can provide insights into water usage patterns and help identify areas for conservation. Additionally, collaborating with local water authorities to stay informed about upcoming regulations is essential. By actively participating in water management discussions, companies can advocate for fair policies while aligning their practices with sustainability goals.

Illustrative image related to water depleted

Scenario 2: Balancing Operational Efficiency with Water Conservation

The Problem: For many B2B companies, especially in manufacturing, water depletion directly impacts operational efficiency. Businesses struggle to maintain productivity levels while adhering to water conservation measures. This balancing act often leads to increased operational costs and potential delays in production, affecting the bottom line.

The Solution: Implementing water-efficient technologies is a critical step towards achieving operational efficiency in a water-scarce environment. Companies should evaluate and invest in water recycling systems that treat and reuse wastewater within their operations. Additionally, adopting water-efficient equipment, such as low-flow fixtures and process modifications, can significantly reduce water consumption. Training employees on best practices for water use can foster a culture of conservation, further enhancing efficiency while reducing costs.

Scenario 3: Ensuring Sustainable Supply Chains in Water-Scarce Regions

The Problem: B2B buyers often source materials from regions facing significant water depletion, which can jeopardize the sustainability of their supply chains. As water becomes increasingly scarce, suppliers may struggle to meet production demands, leading to delays and higher costs. This situation poses a risk to the reliability and ethical standards of the entire supply chain.

The Solution: To mitigate these risks, buyers should prioritize partnerships with suppliers committed to sustainable water management practices. Conducting thorough assessments of suppliers’ water usage and conservation strategies can identify potential vulnerabilities in the supply chain. Buyers can also collaborate with suppliers to develop water stewardship programs that promote efficient water use and investment in local water infrastructure. By fostering relationships with water-conscious suppliers, companies can enhance their supply chain resilience while contributing to broader sustainability efforts in water-depleted regions.

Strategic Material Selection Guide for water depleted

What Are the Key Properties of Common Materials for Water Depletion Applications?

When addressing the challenges associated with water depletion, selecting the right materials for infrastructure and technology is crucial. Below, we analyze four common materials used in applications related to water depletion, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Steel and Stainless Steel Perform in Water Depletion Applications?

Steel is a widely used material in water management systems due to its strength and durability. It has excellent pressure ratings, making it suitable for pipelines and tanks. However, it is prone to corrosion, especially in environments with high moisture or saline content. Stainless steel, on the other hand, offers superior corrosion resistance, making it ideal for applications where water quality is critical. Its higher cost and manufacturing complexity can be a drawback, but its longevity often justifies the investment.

For international buyers, compliance with standards such as ASTM A240 for stainless steel is essential, particularly in regions like Europe and the Middle East, where quality regulations are stringent. Buyers should also consider the availability of local suppliers to mitigate logistics costs.

What Are the Benefits of Using High-Density Polyethylene (HDPE) in Water Depletion Systems?

High-Density Polyethylene (HDPE) is increasingly favored for water-related applications due to its flexibility, chemical resistance, and lightweight nature. HDPE pipes can withstand a range of temperatures and pressures, making them suitable for various water management systems. They are also resistant to corrosion and do not leach harmful chemicals into the water, which is vital for maintaining water quality.

However, HDPE’s lower durability compared to metals can be a limitation in high-stress environments. International buyers should be aware of compliance with standards like ASTM D3350, which governs the quality of HDPE materials. In regions like Africa and South America, where infrastructure may be less developed, sourcing HDPE from reliable manufacturers is crucial to ensure quality and longevity.

What Role Does Concrete Play in Water Management Solutions?

Concrete is a traditional material used in water management, particularly for reservoirs and canals. Its high compressive strength and durability make it suitable for large-scale applications. However, concrete is heavy, which can complicate transportation and installation. Additionally, it is susceptible to cracking under extreme temperature changes, which can lead to water loss.

For international buyers, understanding local regulations regarding concrete quality is important. Standards like ASTM C150 for cement and ASTM C33 for aggregates are commonly referenced. Buyers in regions like the Middle East should also consider the impact of high temperatures on concrete performance and seek materials designed to withstand such conditions.

How Does Fiberglass Reinforced Plastic (FRP) Compare in Water Depletion Applications?

Fiberglass Reinforced Plastic (FRP) is gaining traction in water depletion applications due to its lightweight, corrosion-resistant properties. FRP can handle a variety of chemical exposures, making it ideal for water treatment facilities. Its flexibility allows for easy installation and maintenance, which can reduce overall project costs.

Illustrative image related to water depleted

However, FRP can be more expensive than traditional materials like steel and concrete, which may deter some buyers. Compliance with standards such as ASTM D2563 for FRP is essential for ensuring quality. Buyers from regions with emerging markets, like Nigeria, should evaluate the long-term benefits of FRP against initial costs, especially in environments where corrosion could lead to significant maintenance expenses.

Summary of Material Selection for Water Depletion Applications

| Material | Typical Use Case for Water Depleted | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Pipelines, tanks | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Water quality-sensitive applications | Excellent corrosion resistance | Higher cost and complexity | High |

| HDPE | Water pipes and tanks | Lightweight and chemical resistant | Lower durability under stress | Medium |

| Concrete | Reservoirs, canals | High compressive strength | Heavy and temperature sensitive | Low |

| FRP | Water treatment facilities | Lightweight and corrosion resistant | Higher initial cost | High |

This strategic material selection guide provides insights that can help B2B buyers make informed decisions regarding materials for water depletion applications, ensuring they choose the best options for their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for water depleted

What Are the Key Stages in the Manufacturing Process for Water Depleted Solutions?

The manufacturing process for products related to water depletion involves several critical stages, each designed to ensure the end product meets stringent quality and performance standards. Understanding these stages is vital for B2B buyers who are investing in solutions aimed at combating water scarcity.

1. Material Preparation

Material preparation is the foundational step where raw materials are sourced and treated to ensure they meet specific quality requirements. In the context of water management products, this could include aggregates for construction, membranes for filtration systems, or chemical agents for soil moisture retention. Key techniques during this stage include:

- Sourcing Quality Materials: Establishing relationships with reliable suppliers who provide materials that comply with international standards.

- Pre-Treatment Processes: This may involve washing, drying, or chemically treating materials to enhance their properties, ensuring they are suitable for subsequent processing.

2. Forming

The forming stage involves shaping the prepared materials into the desired product forms. Depending on the product, techniques can vary widely:

Illustrative image related to water depleted

- Molding: For products like water retention gels or filtration membranes, molding processes are commonly used to achieve precise shapes and sizes.

- Extrusion: Used for producing continuous profiles such as pipes or membranes, where material is forced through a die to create specific cross-sectional shapes.

- Casting: Employed for creating complex shapes that might be difficult to achieve through other methods, this technique is often used for concrete solutions in water management.

3. Assembly

Once individual components are formed, they must be assembled into final products. This may involve:

- Joining Techniques: Methods such as welding, adhesive bonding, or mechanical fastening are utilized depending on the materials involved and the end product requirements.

- Integration of Systems: For systems like water filtration units, integrating various components (filters, pumps, and sensors) must be done carefully to ensure optimal functionality.

4. Finishing

The finishing stage is crucial for enhancing the product’s durability and performance. Techniques in this stage can include:

- Surface Treatment: Processes such as coating or sealing are applied to improve resistance to environmental factors and enhance longevity.

- Quality Checks: Final inspections and testing to ensure that the product meets all specifications before shipment.

How Is Quality Assurance Implemented in the Manufacturing of Water Depleted Solutions?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for products related to water management, where reliability and performance are paramount. B2B buyers must understand how QA is integrated into the manufacturing workflow.

What International Standards Should Buyers Consider?

International quality standards, such as ISO 9001, play a crucial role in ensuring that manufacturers maintain a consistent level of quality. ISO 9001 focuses on a quality management system (QMS) that emphasizes continuous improvement and customer satisfaction. Other relevant standards may include:

- CE Marking: This indicates compliance with European safety standards for products sold in the EU.

- API Standards: Pertinent for products related to the oil and gas industry, ensuring that materials and methods meet industry-specific requirements.

What Are the Key QC Checkpoints in Manufacturing?

Quality control (QC) involves systematic checks at various stages of the manufacturing process to ensure that products meet quality standards. The main checkpoints include:

- Incoming Quality Control (IQC): Assessing raw materials upon receipt to ensure they meet specified requirements before being used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify issues in real-time.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure compliance with all specifications before shipment.

What Common Testing Methods Are Used to Ensure Product Quality?

A variety of testing methods can be employed to evaluate the quality and performance of products related to water depletion:

- Physical Testing: This includes tensile strength tests, compressive strength tests, and permeability tests to assess the physical properties of materials.

- Chemical Analysis: Essential for products like soil conditioners, where the chemical composition must be verified to ensure efficacy.

- Field Testing: In-situ testing for products like filtration systems to validate performance under actual operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks associated with product reliability. Here are several strategies:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Reviewing Quality Reports: Request comprehensive quality reports that detail testing results, compliance with standards, and any corrective actions taken.

- Third-Party Inspections: Engage third-party inspection services to provide an unbiased evaluation of the supplier’s manufacturing and quality assurance processes.

What Nuances Should International Buyers Be Aware Of Regarding QC and Certification?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of several nuances in quality control and certification:

Illustrative image related to water depleted

- Regional Standards: Different regions may have specific standards and regulations that must be adhered to, which can affect the certification process.

- Cultural Differences in Quality Perception: Understanding how quality is perceived in different cultures can impact negotiations and expectations.

- Logistical Considerations: Shipping and transportation can affect product quality; thus, ensuring that suppliers have robust logistics and storage practices is vital.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for water depletion solutions is essential for B2B buyers. By focusing on key stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that enhance their procurement strategies and ensure reliable outcomes in addressing water scarcity challenges.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water depleted’

Introduction

This practical sourcing guide aims to assist international B2B buyers in effectively procuring solutions for addressing water depletion. As water scarcity becomes increasingly critical across regions like Africa, South America, the Middle East, and Europe, understanding the steps involved in sourcing appropriate water management solutions is essential. This checklist will provide actionable insights to ensure that your procurement process is thorough and effective.

Step 1: Assess Your Water Needs

Identifying the specific water needs of your operation is the first step in the sourcing process. Consider the volume of water required, the intended use (agricultural, industrial, or municipal), and the local climate conditions. Understanding these parameters will help you determine the most suitable solutions and technologies for your situation.

Step 2: Research Sustainable Water Solutions

Explore various sustainable water management solutions that can mitigate depletion. This includes technologies for groundwater recharge, rainwater harvesting, and water-efficient irrigation systems. Look for innovative practices like floodplain restoration, which can enhance aquifer replenishment and improve water quality.

Step 3: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This could include the desired capacity of water systems, the technology to be used, and any regulatory compliance that must be met. Having well-defined specifications will streamline communication with potential suppliers and ensure that their offerings align with your needs.

Step 4: Evaluate Potential Suppliers

Conduct a thorough evaluation of suppliers to ensure they have the expertise and reliability to meet your needs. Request detailed company profiles, case studies, and references from previous clients, particularly those in similar industries or geographical areas. Pay attention to their track record in delivering successful water management projects.

Step 5: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and licenses relevant to water management solutions. This may include environmental compliance certificates, quality assurance standards, and industry-specific credentials. Verified certifications not only indicate professionalism but also assure you of adherence to local and international regulations.

Illustrative image related to water depleted

Step 6: Request Proposals and Conduct Site Visits

Once you’ve narrowed down your list of suppliers, request detailed proposals that outline their approach to your specific water management challenges. Where possible, conduct site visits to their completed projects to assess the quality and effectiveness of their solutions firsthand. This can provide valuable insights into their operational practices and customer service.

Step 7: Negotiate Terms and Finalize Contracts

Engage in negotiations to agree on pricing, delivery timelines, and maintenance support. Ensure that all terms are clearly documented in the contract to avoid misunderstandings later. Discuss the possibility of ongoing support and training, which can be crucial for the successful implementation of water management solutions.

By following these steps, B2B buyers can ensure a comprehensive approach to sourcing effective solutions for water depletion, ultimately contributing to sustainable water management practices in their regions.

Comprehensive Cost and Pricing Analysis for water depleted Sourcing

What Are the Key Cost Components in Water Depleted Sourcing?

Understanding the cost structure of sourcing for water-depleted initiatives is crucial for B2B buyers, especially in regions facing significant water scarcity. The primary cost components include:

Illustrative image related to water depleted

-

Materials: The choice of materials significantly impacts costs. For instance, sourcing eco-friendly materials for water conservation infrastructure may lead to higher upfront expenses but lower long-term costs through increased efficiency.

-

Labor: Labor costs vary depending on the region and skill level required. In developing regions like Africa and South America, labor may be less expensive, but the availability of skilled workers for specialized tasks can be limited, leading to potential delays and increased costs.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities and facilities. Efficient manufacturing processes can reduce overhead, translating to lower prices for buyers.

-

Tooling: Investment in specialized tooling for customized solutions can be significant. Buyers should assess whether the tooling costs are justified by the expected benefits of customized water-depleted solutions.

-

Quality Control (QC): Ensuring quality in water sourcing solutions is paramount. Robust QC processes can add to costs but are essential for compliance with international standards and certifications, which can enhance marketability.

-

Logistics: The logistics of transporting materials and finished products can be a major cost factor, especially in regions with inadequate infrastructure. Understanding local logistics challenges is vital for accurate cost estimation.

-

Margin: Supplier margins can vary widely based on market conditions and competition. Buyers should consider negotiating margins to ensure they are getting a fair price while maintaining supplier viability.

How Do Price Influencers Affect Water Depleted Sourcing Costs?

Several factors influence the pricing of water-depleted sourcing, including:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to reduced unit prices. Buyers should evaluate their needs against MOQ requirements to optimize costs.

-

Specifications and Customization: Custom solutions tailored to specific environmental conditions or regulatory requirements may incur additional costs. Buyers should weigh the benefits of customization against standard solutions.

-

Material Quality and Certifications: High-quality materials or those that meet specific certifications (e.g., ISO, environmental certifications) may demand higher prices. Buyers should assess the long-term value of investing in certified products that ensure durability and compliance.

-

Supplier Factors: Supplier reputation, reliability, and financial stability can influence pricing. Established suppliers may charge a premium but often provide better service and support.

-

Incoterms: Understanding Incoterms is essential for pricing negotiations. The chosen Incoterm affects responsibility for shipping costs, insurance, and risk, which can impact overall pricing.

What Are the Best Buyer Tips for Cost-Efficient Water Depleted Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for cost-efficient sourcing:

-

Negotiation: Always engage in negotiations with suppliers. Understanding market rates and being clear about your budget can help secure better pricing.

-

Total Cost of Ownership (TCO): Look beyond initial purchase prices. Evaluate the TCO, which includes maintenance, operational efficiency, and potential savings from water conservation measures. This holistic approach often reveals more cost-effective options.

-

Understand Pricing Nuances for International Transactions: Be aware of fluctuations in currency exchange rates, tariffs, and import duties that can affect final pricing. Additionally, cultural differences in negotiation styles should be acknowledged to foster better relationships with suppliers.

-

Evaluate Local Suppliers: In regions with high logistics costs, local suppliers may offer more competitive pricing due to reduced shipping expenses. However, ensure they meet quality and compliance standards.

Conclusion

Navigating the cost and pricing landscape for water-depleted sourcing requires a comprehensive understanding of various cost components and price influencers. By employing strategic negotiation tactics and considering the total cost of ownership, B2B buyers can make informed decisions that align with their operational goals and sustainability objectives. Always remember, prices can vary significantly based on regional factors and market conditions, so maintaining flexibility and openness in negotiations is key.

Alternatives Analysis: Comparing water depleted With Other Solutions

Exploring Alternative Solutions for Water Management

As global water scarcity continues to challenge industries, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential for B2B buyers to explore alternatives to traditional water management solutions. This section compares ‘water depleted’—a method or product aimed at addressing groundwater depletion—against other viable solutions. Understanding the strengths and weaknesses of these alternatives will help buyers make informed decisions that align with their operational needs and sustainability goals.

| Comparison Aspect | Water Depleted | Nature-Based Solutions | Desalination |

|---|---|---|---|

| Performance | Effective in recharging aquifers but requires extensive land and resources | High effectiveness in restoring ecosystems and groundwater levels, but results may vary based on environmental conditions | Provides a consistent water supply, but energy-intensive and costly |

| Cost | Moderate initial investment; long-term savings through sustainable water supply | Generally lower costs, with potential for government funding and community support | High capital and operational costs, often requiring subsidies |

| Ease of Implementation | Complex; requires collaboration with multiple stakeholders and land acquisition | Relatively easier to implement with community involvement; may require less technical expertise | Technically complex; requires significant infrastructure and maintenance |

| Maintenance | Low maintenance once established; ongoing monitoring needed for effectiveness | Moderate; depends on ecological health and community management | High; requires constant monitoring and maintenance of equipment |

| Best Use Case | Ideal for regions with existing aquifers needing replenishment | Suitable for areas with degraded landscapes and a need for ecosystem restoration | Best for coastal regions with access to seawater and high water demand |

Understanding Nature-Based Solutions as an Alternative

Nature-based solutions (NbS) leverage the power of ecosystems to address water scarcity issues. By restoring floodplains and wetlands, these solutions not only enhance groundwater recharge but also provide ecological benefits such as improved water quality and biodiversity. The pros of NbS include lower operational costs and the potential for community engagement, which can foster local support. However, they may require more time to yield measurable results, and their effectiveness can be influenced by environmental factors.

Evaluating Desalination as an Alternative Solution

Desalination is a technological approach that transforms seawater into potable water. It offers a reliable water supply, especially for arid coastal regions where freshwater sources are limited. The primary advantage of desalination is its ability to provide a consistent volume of water, meeting high demand in urban areas. However, the process is energy-intensive and costly, both in terms of initial infrastructure and ongoing operational expenses. This makes it less feasible for regions with limited financial resources.

Illustrative image related to water depleted

Conclusion: Choosing the Right Water Management Solution

When selecting a water management solution, B2B buyers must consider factors such as performance, cost, ease of implementation, and maintenance requirements. Each alternative—be it ‘water depleted’, nature-based solutions, or desalination—has its unique advantages and challenges. By evaluating these aspects against the specific needs of their operations and the environmental context, buyers can make informed decisions that not only address immediate water needs but also contribute to long-term sustainability. Engaging with local experts and stakeholders can further enhance the selection process, ensuring the chosen solution aligns with both business objectives and community priorities.

Essential Technical Properties and Trade Terminology for water depleted

What Are the Key Technical Properties of Water Depleted Resources?

Understanding the technical properties of water-depleted resources is crucial for B2B buyers involved in sustainable water management, especially in regions facing severe water scarcity. Here are several essential specifications:

-

Aquifer Recharge Capacity

This refers to the ability of a specific area to replenish groundwater supplies through natural processes, such as percolation from surface water. Knowledge of aquifer recharge capacity is vital for businesses aiming to invest in land for restoration projects, as it directly impacts long-term water sustainability and operational costs. -

Hydraulic Conductivity

This property measures how easily water can move through soil or rock. High hydraulic conductivity indicates that water can infiltrate quickly, which is essential for effective groundwater recharge. For buyers, understanding this metric can aid in selecting suitable sites for projects, ensuring that investments yield maximum water retention and recharge. -

Soil Permeability

Closely related to hydraulic conductivity, permeability assesses the ability of soil materials to transmit water. Different soil types (sandy, clayey, loamy) offer varying permeability levels. Businesses must consider this property to evaluate the feasibility of floodplain restoration projects, influencing design and implementation strategies. -

Water Table Depth

The depth of the water table is a critical measurement that affects groundwater accessibility. For companies involved in water extraction or conservation efforts, knowing the water table depth can inform operational planning and resource allocation, ensuring that projects are viable and cost-effective. -

Subsurface Composition

This property involves understanding the layers of materials (sand, gravel, clay) beneath the surface, which influence both water movement and storage. For B2B buyers, geological surveys revealing subsurface composition can guide investment decisions, as areas with favorable conditions are more likely to support effective groundwater recharge initiatives.

What Are Common Trade Terms Related to Water Depletion?

Familiarity with industry jargon can streamline communication and negotiations for B2B buyers. Here are several key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In water management, OEMs often provide specialized technology for groundwater monitoring or irrigation systems, making it essential for buyers to assess quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For businesses involved in large-scale water projects, understanding MOQ is crucial for budgeting and ensuring that procurement meets project timelines without excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that businesses use to invite suppliers to bid on a project or provide pricing for specific services or products. Issuing an RFQ is an essential step for buyers seeking competitive pricing and service options in the water management sector. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that delineate responsibilities between buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping responsibilities, costs, and risk management in cross-border water resource procurement. -

Sustainability Metrics

This term encompasses various indicators used to measure the environmental impact and long-term viability of water management practices. For B2B buyers, understanding these metrics is essential to ensure that their investments align with sustainability goals and regulatory requirements. -

Water Rights

Water rights refer to the legal entitlement to use a specific amount of water from a source. For businesses operating in water-scarce regions, understanding local water rights is critical to secure necessary resources and avoid legal disputes, ensuring the sustainability of their operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that promote sustainable water management practices while optimizing resource allocation in their projects.

Navigating Market Dynamics and Sourcing Trends in the water depleted Sector

What Are the Key Market Dynamics and Trends Affecting Water-Depleted Regions?

The global landscape for water-depleted sectors is increasingly shaped by climate change, population growth, and industrial demands. In regions such as Africa, South America, the Middle East, and Europe, the urgency for innovative water management solutions is paramount. International B2B buyers are witnessing a surge in technologies that facilitate sustainable water sourcing. Notably, advancements in water recycling, desalination, and rainwater harvesting are gaining traction. The integration of IoT and AI in water management systems is also emerging, providing real-time monitoring and efficient resource allocation.

Illustrative image related to water depleted

As companies seek to address water scarcity, collaboration is becoming a key trend. Partnerships between governments, NGOs, and private sectors are fostering research-driven initiatives to restore groundwater levels. For instance, in California, collaborative projects focus on leveraging natural processes for groundwater recharge, which can serve as a model for international markets. The demand for such innovative solutions is likely to increase, particularly in water-stressed regions, as businesses recognize the economic and operational benefits of sustainable water practices.

How Can Sustainability and Ethical Sourcing Impact B2B Operations in Water-Depleted Areas?

Environmental impact is a critical consideration in the water-depleted sector. Ethical sourcing is not just a trend; it is a necessity for businesses aiming to align with global sustainability goals. Companies are increasingly pressured to demonstrate their commitment to responsible water usage and to invest in technologies that reduce their ecological footprint. This includes seeking certifications for ‘green’ practices, such as ISO 14001 for environmental management, which can enhance brand reputation and open up new markets.

Moreover, the sourcing of materials and technologies that promote water conservation is becoming essential. For example, companies focusing on eco-friendly irrigation systems or biodegradable materials for water filtration are more likely to attract environmentally-conscious buyers. The importance of transparency in supply chains cannot be overstated; businesses that provide clear documentation of their sourcing practices and sustainability efforts will stand out in a competitive marketplace.

How Has the Water-Depleted Sector Evolved Over Time to Meet B2B Needs?

Historically, the water-depleted sector has faced challenges that stem from over-extraction and mismanagement of water resources. In response, significant advancements have been made in water management practices over the last few decades. Initially focused on concrete solutions, such as dams and reservoirs, the industry is now shifting towards more holistic approaches that integrate natural systems for water replenishment.

The evolution of groundwater management strategies, particularly in regions experiencing severe drought, has led to innovative practices like floodplain restoration and managed aquifer recharge. These methods highlight the interconnectedness of surface water and groundwater, paving the way for more sustainable and effective water resource management. As the sector continues to adapt, the emphasis on collaborative, technology-driven, and sustainable practices will be crucial for meeting the needs of international B2B buyers in a rapidly changing environment.

Illustrative image related to water depleted

Frequently Asked Questions (FAQs) for B2B Buyers of water depleted

-

1. How do I solve groundwater depletion issues in my region?

To address groundwater depletion, consider implementing sustainable water management practices such as investing in rainwater harvesting, promoting efficient irrigation systems, and restoring natural landscapes. Collaborating with local research institutions can provide insights into the best practices tailored to your specific region. Engaging in community awareness programs can also help in promoting water conservation. Additionally, exploring partnerships with organizations focused on ecological restoration can leverage nature-based solutions for groundwater recharge. -

2. What is the best technology for monitoring groundwater levels?

The optimal technology for monitoring groundwater levels includes remote sensing, piezometers, and groundwater modeling software. Remote sensing provides real-time data on surface and subsurface water, while piezometers offer precise measurements of groundwater levels at various depths. Groundwater modeling software can simulate water flow and predict future levels based on current usage patterns. Selecting the right technology should align with your specific needs and budget, considering factors like data accuracy, installation ease, and maintenance requirements. -

3. What are the key factors to consider when sourcing water conservation technologies?

When sourcing water conservation technologies, evaluate the technology’s efficiency, scalability, and compatibility with existing systems. Research the supplier’s reputation and track record in the industry, as well as their commitment to sustainability. Additionally, consider the technology’s adaptability to local conditions and regulations, and assess the availability of after-sales support and training services. Engaging in pilot projects can also help in determining the efficacy of the technology before full-scale implementation. -

4. How can I vet suppliers for water management solutions?

To vet suppliers for water management solutions, start by reviewing their certifications, industry experience, and client testimonials. Conduct background checks to verify their financial stability and operational capabilities. Request case studies or references from similar projects to gauge their effectiveness. Additionally, consider visiting their facilities or previous project sites to assess their processes and technologies firsthand. Establishing clear communication and conducting interviews can further ensure that their values align with your organization’s goals. -

5. What are the typical minimum order quantities (MOQ) for water management products?

Minimum order quantities (MOQ) for water management products can vary significantly based on the supplier and product type. Generally, MOQs range from a few units for specialized equipment to larger quantities for bulk materials like filtration systems or irrigation components. It’s crucial to discuss your specific needs with suppliers to negotiate MOQs that align with your budget and project requirements. Some suppliers may offer flexibility for first-time orders or pilot projects, making it easier for you to trial their products. -

6. What payment terms should I expect when purchasing water management solutions?

Payment terms for purchasing water management solutions typically range from upfront payments to net 30 or net 60 days after delivery. Some suppliers may offer financing options or installment payments for larger projects. It is essential to clarify payment terms during negotiations to ensure they align with your cash flow capabilities. Additionally, inquire about any early payment discounts or penalties for late payments to avoid unforeseen costs. -

7. How can I ensure quality assurance (QA) in my water management solutions?

To ensure quality assurance (QA) in your water management solutions, establish clear specifications and standards before placing orders. Request certifications and compliance documentation from suppliers to verify that their products meet industry regulations. Conduct regular inspections and testing of the products upon delivery to identify any defects or discrepancies. Building a strong relationship with your supplier can facilitate better communication regarding quality expectations and encourage them to prioritize QA in their operations. -

8. What logistics considerations should I keep in mind when sourcing water management products internationally?

When sourcing water management products internationally, consider the logistics involved in shipping, customs clearance, and delivery timelines. Evaluate the supplier’s ability to handle international shipping and their experience with customs regulations in your country. Factor in potential delays due to transportation issues or border regulations. Additionally, assess the costs associated with shipping and insurance to ensure that they fit within your budget. Establishing a reliable logistics partner can streamline the process and mitigate risks.

Top 1 Water Depleted Manufacturers & Suppliers List

1. LATimes – Groundwater Depletion Study

Domain: latimes.com

Registered: 1990 (35 years)

Introduction: New research based on 22 years of satellite data shows vast areas of the world are losing fresh water and getting drier, with groundwater depletion accounting for an estimated 68% of the water loss. The study indicates that nearly 6 billion people live in 101 countries experiencing water loss, with drying areas expanding significantly. The primary causes are rising temperatures from fossil fuel us…

Strategic Sourcing Conclusion and Outlook for water depleted

What Are the Key Takeaways for B2B Buyers in Water-Depleted Regions?

As global water scarcity intensifies, strategic sourcing of water management solutions becomes imperative for businesses across Africa, South America, the Middle East, and Europe. By investing in innovative approaches, such as floodplain restoration and nature-based solutions, companies can not only mitigate risks associated with water depletion but also enhance their sustainability profiles. Collaborating with local experts and leveraging advanced technologies can lead to more effective groundwater recharge strategies that benefit both communities and ecosystems.

How Can International Buyers Engage in Sustainable Water Solutions?

International B2B buyers should prioritize partnerships with organizations committed to sustainable practices and research-driven solutions. Understanding the interconnectedness of groundwater and surface water is crucial for developing comprehensive water management strategies. By embracing these insights, businesses can secure reliable water sources, improve operational resilience, and fulfill corporate social responsibility goals.

What Is the Future of Water Resource Management?

Looking ahead, there is an urgent need for collaborative efforts to address the challenges of water depletion. The future lies in harnessing innovative technologies and sustainable practices to ensure water availability for all. We encourage international buyers to take proactive steps in their sourcing strategies, engaging with solutions that not only address immediate needs but also contribute to the long-term health of our planet’s water resources. Together, we can create a sustainable future in water management.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.