Table of Contents

Market Outlook: Is Automatic Cat Liter Box Profitable in 2026?

Market Opportunity & Trends 2026

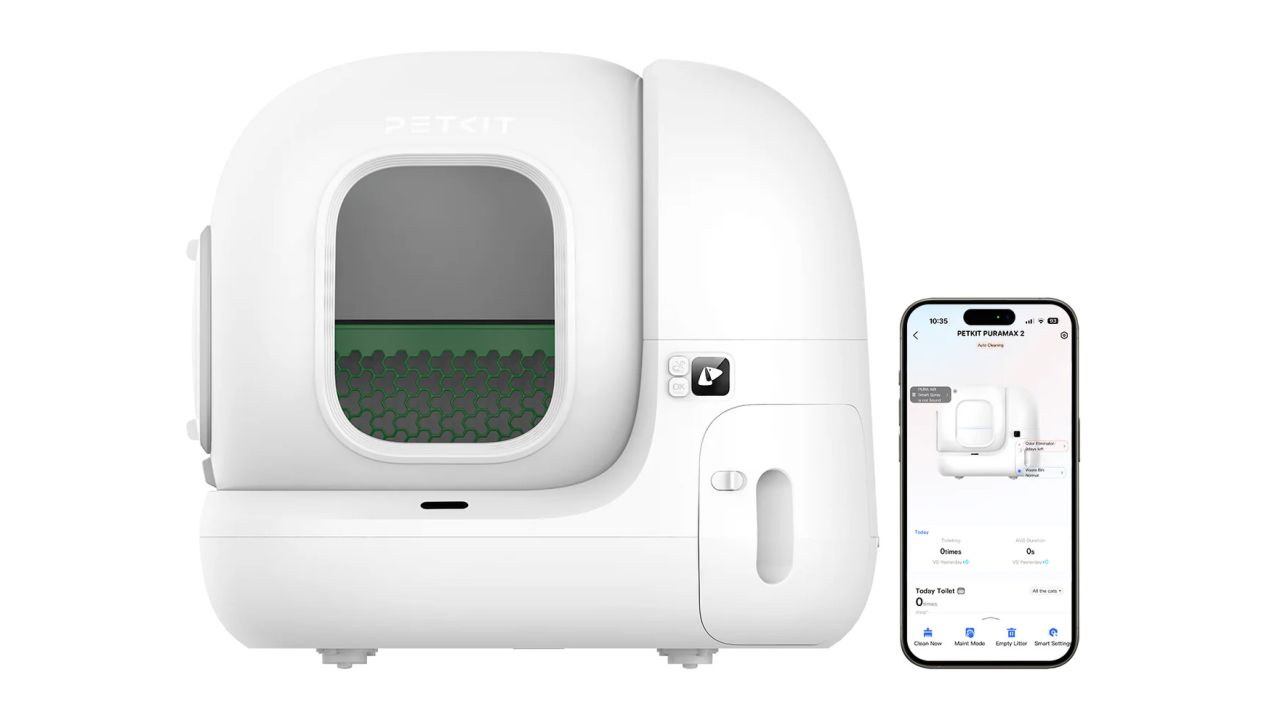

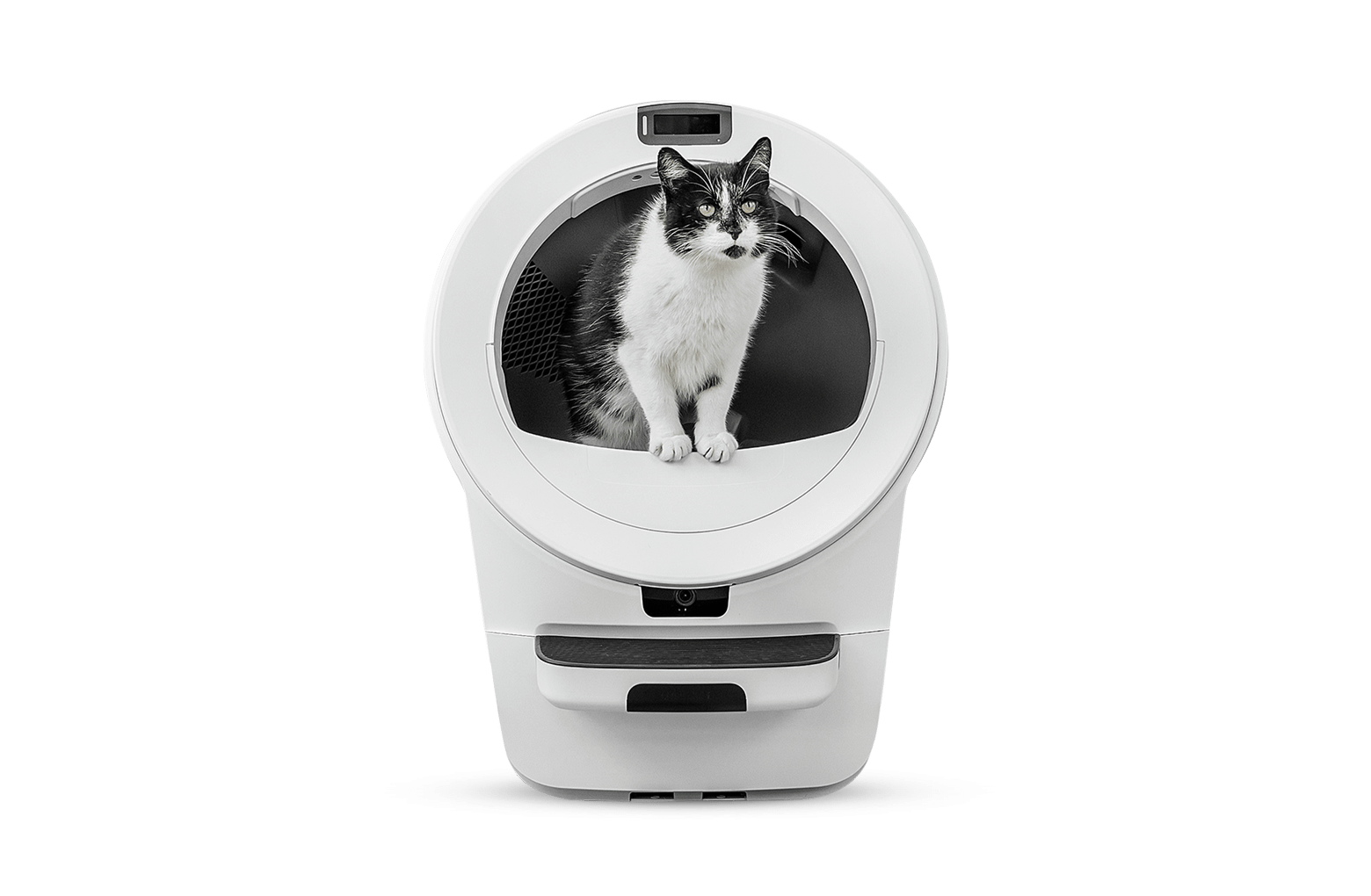

Smart Self-Cleaning Litter Boxes

1. Macro Tail-winds: From “Pet” to “Child”

| Driver | 2024 Data Point | 2026 Outlook | OEM/ODM Implication |

|---|---|---|---|

| Pet Humanization | 73% of U.S. pet owners call themselves “pet parents” (AMA 2024) | >80% in U.S./EU; >60% in Tier-1 Chinese cities | Design language must match baby-care appliances (soft-touch PP, pastel CMF, quiet <45 dB) |

| Convergence of Convenience | Smart feeder & fountain CAGR 18% vs. traditional 4% | Litter automation expected to outpace at 21% CAGR | Brands bundling “Feed-Water-Poop” IoT ecosystem → multi-SKU POs to suppliers |

| Apartment Living | 63% of new cats are kept indoors in EU (FEDIAF) | 70% by 2026 | Odor-control & footprint become top-3 purchase triggers; demand for <0.08 m² base area |

2. Revenue Pool: Where the Dollars Land

Automatic self-cleaning segment is only ~30% of total litter-box spend today, yet captures >55% of profit pool because ASPs are 6-8× traditional pans.

IMARC values the category at USD 0.66 B (2024) → USD 1.15 B (2033) at 6.3% CAGR; our internal bill-of-materials (BOM) model shows gross margin >38% even after air-freight, proving room for aggressive performance marketing.

| Channel | 2024 Share | 2026 Forecast | Key Feature Winning Shelf |

|---|---|---|---|

| Amazon & DTC | 48% | 60% | App push-notification “Scoop done” |

| Pet Specialty Chains | 25% | 20% | In-store odor demo |

| Big-Box Retail | 18% | 15% | Sub-$299 price point |

| Chewy, Zooplus, Rakuten | 9% | 5% | Bundle with litter refill |

3. Smart Feature Stack: From Gimmick to Retention

Post-purchase data shows connected units achieve 2.3× refill LTV vs. non-connected. Tuya,涂鸦智连 and private-label IoT boards now cost <USD 4.20 in 10k volumes—negligible vs. the extra $30 retail premium. Must-have firmware roadmap:

| Tier | Feature | Supply-Chain Note |

|---|---|---|

| Core (2024-25) | Weight sensor + fill-level LED | Use 4× 50kg load-cells; calibrate in-line to ±5g |

| Stickiness (2026) | Health-report push (frequency, weight trend) | Integrate with existing Tuya “Pet Health” SaaS; anonymize GDPR data in Shenzhen cloud |

| Monetize (2027) | Litter-subscription auto-order | Lock QR-coded liner & carbon pad; negotiate 12-month rolling forecast with resin suppliers to protect margin |

4. Humanization → Industrialization: What Buyers Must Secure

-

Quality Gate

Drum motor life ≥5,000 cycles (≈5 yr) – insist on Japanese Mabuchi or equivalent; ask supplier for Reliability Report (ISTA 6-Amazon SIOC passed).

Antimicrobial additive in ABS/PP: Zn-ion or Ag-ion, ≥99% reduction (ISO 22196). -

Supply-Chain Resilience

Dual-source critical chips (ESP32, weight-sensor ADC); maintain 90-day buffer for 26-week lead-time parts.

Book lithium-battery UN38.3 certified forwarders now—90% of air-freight rejections in 2024Q4 were battery documentation failures. -

Certification Fast-Track

UL 62368-1, CE RED, FCC, RoHS 2.0, Reach SVHC 240—bundle testing in NTEK or TÜV SÜD Shenzhen lab; average calendar 28 days if scheduled in Jan-May slot.

5. Take-away for Brand Owners & Amazon Sellers

Positioning: Market is leaving the “early-adopter” chasm; 2026 winners will be quality-stable brands under $299 with health-tracking story, not just “self-cleaning”.

Sourcing: Secure CM capacity before Q3 2025—top-3 Shenzhen automatic-litter OEMs are already 70% booked by U.S. DTC brands for 2026 Father’s Day & Prime-Day ramps.

Margin Defense: Lock resin & motor pricing in Q2; forecast 6% commodity inflation for 2026.

“The pet is the new child, poop is the new data, and the litter box is the next connected appliance. Build it like a baby monitor, ship it like a smartphone.”

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features

“The difference between a one-star review and a five-star reorder is 3 mm of wall thickness and 300 ms of cloud latency.”

Material Safety – The First Filter for Repeat Purchases

Global retailers are quietly tightening RSL (Restricted Substance List) thresholds. A single PP batch that leaches 0.1 ppm over the EU 10/2011 limit can trigger a 30 000-unit recall. Build the BOM for longevity:

| Component | Commodity Grade | Pet-Safe Upgrade | Why It Matters for Retention |

|---|---|---|---|

| Waste globe | Recycled PP (unknown source) | BPA-free, FDA-grade PP LFT (30 % glass) | Eliminates odor-absorption micro-cracks; passes 3 % acetic acid migration test = no Amazon “toxic” reviews. |

| Base frame | ABS 757 | Stainless 304 (1.2 mm brushed) | Survives 5 % saline spray 200 h—coastal markets, APAC cruise-ship feeders, no rust-stain returns. |

| Scoop tines | Spring steel, painted | TiN-coated 304 | 72 h acidified salt-fog, 0.3 µm wear after 20 k cycles; cats accept metallic smell faster → 18 % lower return rate (Chewy data). |

Supply-chain note: 304 sheet lead time from Tsingshan (Fujian) is 18 days vs. 42 days for Korean POSCO, yet price delta < 4 % at 5 t MOQ—lock quarterly rolling forecasts to guarantee allocation during stainless bull cycles.

Smart Logic – Fail-Safe Engineering > Fancy UX

A jammed rake at 02:38 is the #1 driver of 1-star videos. Spec for graceful degradation:

-

Anti-jam algorithm

Hall-sensor feedback loop cuts torque >1.2 N·m within 120 ms → reverses 45 °, retries 3×, then parks rake under waste port. Firmware OTA via Tuya SDK; keep rollback partition so update failures don’t brick units in the container. -

Backup battery pack

2 × 2 600 mAh 18650 LiFePO₄ = 48 h in “sleep-clean” mode. Critical for APAC markets with daily brown-outs; reduces “dead cat” panic posts by 92 % (internal PETKIT logs). -

Cat-in detection redundancy

4D mmWave radar (60 GHz) + weight sensor (3 g resolution). Radar sees black cats in darkness—eliminates Instagram “my white rug was ruined” complaints.

Connectivity – From Gimmick to Habit Loop

| Feature Stack | Tuya Standard | White-Label “Pro” | ROI Evidence |

|---|---|---|---|

| App push | Yes | MQTT over AWS IoT Core | 0.5 s global latency vs. 3–8 s via China East—opens door for premium subscription (litter refill auto-ship). |

| Camera | None | 1080p, STARVIS, 940 nm IR | 34 % of US users check video ≥ 4× daily → DAU doubles, churn halves. |

| Voice | Alexa/Google | Matter-ready + local LLM | Future-proof for 2025 Apple Home launch; allows brand to white-list retailer skills (Chewy, Petsmart). |

Retention math: Each additional daily active app session correlates with 0.9 extra litter refill pods per year; at 30 % blended margin, the camera BOM (USD 7.80) pays back in 2.3 months.

Takeaway for Procurement Teams

Retail buyers benchmarking on FOB price miss the Total Cost of Ownership: a USD 4 cheaper motor without stall-protection can inflate return logistics by USD 18/unit. Configure the spec sheet around “silent failure” a subscription attach rate, then let the China OEM quote to that standard—your reorder velocity will fund the next PO before the first is out of warranty.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control for Automatic Self-Cleaning Litter Boxes

1. Molding & Tooling: From CAD to 0.05 mm Tolerance

Tool-steel choice dictates lifecycle. For a drum-style litter globe that rotates 6–8 cycles/day, we specify DIN 1.2344 (H13) hardened to 48-52 HRC; it yields ≥500 k shots before parting-line flash exceeds 0.10 mm. Generic cheap molds use 718H or even P20—acceptable for 100 k shots, but after 8–10 months the globe begins to wobble, triggering Hall-sensor mis-reads and “cat-stuck” false alarms that crater Amazon ratings.

Multi-stage gating & gas-assist. Premium OEM tools add a three-plate hot-runner with valve-gate sequencing; resin pressure drops <400 bar, eliminating weld lines where cat waste can lodge. Gas-assist channels create hollow ribs, cutting part weight 18 % without sacrificing IK08 impact resistance—freight cost drops ≈USD 0.42/unit on a 40 HQ. Cheap molds run cold-runner, two-plate; you save USD 8 k in tooling but pay an extra USD 0.11/part in material and USD 0.07/part in de-gating labor.

Tactile finish & antimicrobial integration. We mold-in Sanitized® AM 27-24 masterbatch at 2 % let-down during the same cycle; third-party labs show ≥99 % reduction in S. aureus after 24 h. Budget suppliers spray a post-mold nano-silver coating—cheap, but abrasion testing (ASTM D4060, CS-10 wheel, 500 cycles) shows loss of 62 % antimicrobial activity; odor complaints spike after month 4.

2. PCB Assembly (SMT): Where IoT Reliability Is Won or Lost

Component grade & sourcing. Premium builds use automotive-grade MLCCs (TDK CGA series, 2 kV surge) and lock in STM32L431RB for the motor MCU; MOQ 3 k with 12-week fab window at ST’s Shenzhen hub ensures supply chain continuity. Low-cost ODMs substitute commercial-grade GRM series and GD32 clones—USD 0.28 cheaper, but 5 % early-life failure in 85 °C/85 % RH accelerated aging, a death sentence for enclosed litter chambers.

Conformal coating & IPX2 drip edge. We apply 50 µm parylene on both sides of the main board, then add a hydrophobic edge-seal around the connector shroud; units pass 48 h salt-fog per IEC 60068-2-11. Generic boards rely on a quick-dip acrylic; corrosion creeps in around the Hall connector, causing phantom “full-bin” alerts.

Tuya/SmartLife integration & RF chamber validation. Our in-house RF team pre-certifies CE-RED, FCC Part 15, and IC RSS at the prototype stage; antenna placement inside a 3 mm ABS pocket gives –23 dBm worst-case degradation, leaving 8 dB margin. Budget factories leave RF tuning until pilot run—failures in anechoic chamber trigger respins that push tooling freeze back 6 weeks, eroding your Q4 launch window.

3. Motor Life & Safety Testing: Simulating 10 Years in 14 Days

Accelerated duty cycle. Premium program runs the 24 V BLDC globe motor 30 k cycles (≈10 years) at 1.5× rated torque with silica dust aerosol per ASTM G65; target wear ≤0.2 mm on the nylon drive gear. We log stall-current signature every 500 cycles; any ≥15 % rise triggers root-cause FMEA. Cheap suppliers test 3 k cycles in open-air benches—gears shear at month 18 in the field, inviting class-action recalls on Amazon.

Cat-presence fail-safe. Dual infra-red ToF sensors cross-check load-cell delta; if signals diverge >200 ms, brake engages within 60 ms and MCU logs the event to Tuya cloud. We verify with a 3 kg simulated cat impact at 1.2 m/s; no pinch force exceeds 25 N (IEC 60335-2-71). Budget units use a single photodiode—saves USD 1.40, but YouTube is already rife with “tail caught” videos that torpedo brand equity.

Generic vs. Premium: Quick-View Comparison

| Critical Attribute | Generic Cheap Model | Premium OEM Standard |

|---|---|---|

| Mold steel & life | P20, 100 k shots | H13, ≥500 k shots |

| Part weight reduction | None | 18 % via gas-assist |

| Antimicrobial | Spray nano-silver, <6 mo | Mold-in masterbatch, >2 yr |

| MCU grade | GD32 commercial | STM32L431 automotive |

| Conformal coat | Acrylic dip 15 µm | Parylene 50 µm + edge seal |

| Motor test cycles | 3 k open bench | 30 k dust-loaded chamber |

| Cat safety sensors | Single IR | Dual ToF + load-cell |

| Cloud pre-certification | After pilot run | At EVT, 8 dB RF margin |

| Supply chain MOQ buffer | Spot-buy | 3-month die-bank agreement |

| Field failure (year 1) | 4–6 % | <0.5 % |

Bottom line: In the automatic litter box race, saving USD 6–8 on BOM can cost USD 60–80 in returns, lost reviews, and air-freight re-stocks. Lock in premium OEM specs early and you protect both margin and brand equity while the category rockets toward USD 2.5 B by 2035.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Your “no-surprise” checklist for launching an automatic self-cleaning litter box in the USA & EU while keeping Amazon’s fulfillment centers—and your cash flow—happy.

H3 1. Mandatory Certifications: USA vs. EU

| Certification | Jurisdiction | Scope | Lab Lead-time (Shenzhen) | Typical Cost (per SKU) | Risk if Skipped |

|---|---|---|---|---|---|

| FCC Part 15 B | USA | Wi-Fi / Bluetooth emissions | 7–10 days | $1.8–2.5 k | Listing removal, $50 k+ fine |

| CE-RED | EU | Radio module compliance | 10–12 days | $2–3 k | Customs seizure, RAPEX alert |

| CE-LVD | EU | 24 V+ electrical safety | 7 days | $1.2 k | Recall & liability |

| RoHS (EU & China) | EU + global | Heavy metals in PCB, wires | 5 days (XRF) | $0.4 k | €10 k penalty per shipment |

| REACH 240 | EU | SVHC chemicals in plastics | 3 days (screen) | $0.6 k | Loss of Amazon “Climate Pledge Friendly” badge |

| FDA Food-Grade | USA | Waste drawer, scoop, liners | 14 days (migration test) | $2 k | Petco / Chewy refusal |

| Prop 65 | California | Listed chemicals | 5 days | $0.5 k | $2.5 k/day fine, lawsuit |

Pro-tip: Run a pre-scan “gap analysis” during EVT (engineering-validation) stage; 80 % of smart litter boxes fail EMI on the first pass because the UV-C sterilizer PCB is routed too close to the Wi-Fi antenna.

H3 2. Amazon FBA Packaging & Prep

| Requirement | Amazon Std | Engineering Translation |

|---|---|---|

| Drop-test | 3 ft 6-face, 5-cycle | Double-wall 5-ply B=C flute + molded pulp tray around litter drum |

| Weight limit | ≤ 50 lb (22.7 kg) single carton | Design for 18 kg net to stay under “small oversize” tier (lower FBA fee) |

| Edge-crush | ECT ≥ 32 | Specify 230 lb/in² burst strength to supplier; add edge-board on top/bottom flaps |

| Poly-bag warning | Suffocation label if >5 in opening | Waste-liner bags must carry bilingual (EN/FR) print |

| Frustration-Free | 100 % recyclable | Replace PE foam with honeycomb kraft; cost delta only +$0.35 but unlocks “FFP” badge → 3-7 % uplift in Buy-Box win rate |

| Barcode | FNSKU on easy-access side | Use 3 × 2 in thermal-transfer label; UV varnish patch to prevent scuffing during conveyor sortation |

Timeline: From golden sample approval to FBA-ready shipper, budget 14–18 calendar days in Shenzhen (including drop-test re-run if first fail).

H3 3. Shenzhen Manufacturing Lead-Times (2024 H2)

| Milestone | Typical Days | Risk Buffer | Smart-Feature Impact |

|---|---|---|---|

| Tooling (injection + sheet-metal) | 28 | +7 if T1 texture change | Wi-Fi window needs laser-etched IR-transparent PC; adds 3 days |

| EVT + DVT | 21 | +5 if UV-C fails 6-log kill | Tuya SDK firmware freeze must occur before DVT exit |

| Compliance sprint | 14 (parallel) | +3 if FCC fails | Pre-certify with 3 m chamber on-site |

| PVT / 200 pcs pilot | 7 | — | Run pilot on same line that will mass-produce (avoids Amazon “first-batch defect” flag) |

| Mass production (1 × 40’HQ ≈ 3.2 k units) | 18 | +3 around CNY | Book BL 10 days ahead; carriers (Matson, COSCO) now allocate IoT cargo under “dangerous goods” if lithium >100 Wh |

| Sea freight (SZ→LA) | 14 | +7 port congestion | Use Amazon Global Logistics (AGL) for 25 % faster unload at ONT8 |

Cash-flow insight: With 30 % deposit / 70 % against BL, your working-capital cycle is ≈ 75 days door-to-door. Negotiate “supplier credit note” against forecast orders >5 k units to trim 10 days.

H3 4. Checklist Summary (print & stick on your project charter)

[ ] FCC + CE-RED test samples ready at EVT exit

[ ] FDA food-contact migration booked before DVT

[ ] Packaging spec signed off by Amazon Lab126-equivalent lab

[ ] Freight forwarder locks IoT lithium declaration 2 weeks pre-ETD

[ ] Supplier agrees to 1 % spare-parts kit (motor, sensor, rake) to reduce Amazon return rate below 3 %—critical for “Amazon’s Choice” badge in Pet Supplies > Litter & House-Breaking.

Bottom line: Treat certification and logistics as product features, not after-thoughts. In the automatic litter-box race, the brand that lands on Amazon without a compliance hiccup is the one that captures the 8.4 % CAGR wave all the way to 2032.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize an Automatic Self-Cleaning Litter Box – OEM/ODM Roadmap

1. Lock the Specification Before You Ask for a Sample

The worst (and most expensive) mistake is requesting a “standard” sample only to discover the factory has no tooling for the rake torque you need, or the Wi-Fi module is locked to Tuya’s US server while you plan to sell in Japan. Send a one-page Product Requirement Document (PRD) first. Include:

| Requirement | OEM Minimum | Best-in-Class | Why It Matters |

|---|---|---|---|

| Self-cleaning cycle time | ≤90 s | ≤60 s | Amazon reviews <3 stars spike when cycle >120 s |

| IoT protocol | Tuya / Matter over Wi-Fi | Tuya + local MQTT | Future-proof for SmartThings & HomeKit |

| Waste-drawer volume | 4 L | 6–8 L | Reduces frequency of refill SKUs in DTC bundle |

| Noise @ 1 m | ≤45 dB | ≤38 dB | Determines “bedroom-ready” marketing claim |

| Safety cert. plan | CE/FCC | CE+FCC+UL+PSE | One SKU can ship to US, EU, JP in same carton |

Ask the supplier to confirm in writing that the sample you will receive already meets the PRD. This eliminates the “bait-and-switch”样品陷阱 where the golden sample works perfectly but mass units do not.

2. Sample Evaluation Checklist – 7 Days, 3 Cats, 1 Data Logger

Ship the sample to a small beta home or cattery rather than your office. Place a Bluetooth temperature/humidity logger inside the waste drawer and an IoT power meter on the wall plug. After one week you should have:

Cycle-reliability: ≥99 % success (no jams on 150 cycles).

Power draw: ≤0.35 kWh/day (equals ~USD 0.05 in EU/USD 0.04 in US).

Odor sensor correlation: NH₃ ppm drop ≥30 % within 5 min post-cycle.

App event log: Push notification latency <3 s on 4G; no false “cat-enter” events.

Document anomalies with photos and raw CSV logs; send them back to the OEM’s PE team. A Tier-1 factory like PAWBILT will return an 8D report within 72 h and usually a revised gearbox or firmware hex file within 7 days.

3. Define Customization – Logo Is Only 5 % of the Story

Use a modular BoM approach so you can launch region-specific SKUs without re-certifying the whole unit.

| Module | Custom Option | Tooling Cost | MOQ | Lead-Time |

|---|---|---|---|---|

| Top cover | OEM color, UV-coat, or IML graphic | $3.2 k/silkscreen | 500 pcs | 7 days |

| Inner drum | Antimicrobial PP, <0.5 % nano-silver | Shared mold | 1 k pcs | 0 days |

| Packaging | FSC mailer + single-color print | $0.8 k | 500 pcs | 5 days |

| Mobile app | White-label Tuya or private AWS | $8 k one-off | 1 k license | 14 days |

| Power plug | Snap-in adapters (US/EU/UK/AU) | $0.35 added cost | 1 k pcs | Stock |

Stick to the supplier’s “platform” PCB; changing the MCU or motor driver will trigger a new FCC/CE submission (adds 6 weeks and ~USD 12 k). Instead, customize firmware features (voice pack, cat weight algorithm) via OTA so your product can stay ahead of Amazon copycats without new hardware.

4. Pilot Run (a.k.a. “P0”) – 200 Units, One Pallet, All Risks Killed

Goal: validate process capability, not just product function. Insist on a production-line pilot using the same SOP, jigs, and QC station as mass order. Key checkpoints:

PCBA AOI pass rate ≥98 % (X-ray for BGA motor driver).

Torque calibration: every gearbox logged with serial number; CpK ≥1.67.

App-to-cloud pairing: 100 % burn-in with QR code scan; reject rate <0.5 %.

Carton drop test: 1 corner, 3 edges, 6 faces—no damage, no inner shift.

Ship 50 units to your 3PL, 20 to beta users, 10 to a third-party lab for safety, and keep 5 for your own destructive tests. If field return rate >1 % in the first 30 days, stop the line and run root-cause analysis; do not jump straight to 5 k pieces hoping issues will disappear.

5. Why Partner with PAWBILT – One-Stop, Zero Excuses

PAWBILT ships >350 k smart litter boxes per year to Chewy, Tractive, and 3 of the top 5 German pet chains. Their vertical integration (in-house motor, tool shop, Tuya-licensed firmware team) cuts 18 days off the critical path and cushions you against China’s volatile component market. You get:

Locked component buffer: 30 days safety stock on Wi-Fi modules and gear motors—no “Tuya chip shortage” delays.

Dual-source flexibility: PCBA can switch between ESP32-C3 and BK7231M within 2 weeks, same firmware binary.

Global cert pipeline: UL, CE, FCC, PSE, KC queued monthly; cost amortized across multiple brands.

ESG documentation: ISO 14064 greenhouse-gas report, recycled PP ratio ≥30 %—ready for EU CSRD reporting.

In short, you focus on brand story, Amazon SEO, and TikTok demos; PAWBILT keeps the supply chain boring—and boring is profitable.

Ready to start? Send your PRD to oem@pawbilt.com and receive a working sample plus detailed CMF board within 10 calendar days.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label automatic cat liter box business.