Introduction: Navigating the Global Market for automatic pet

The rapid growth of the automatic pet market presents both opportunities and challenges for international B2B buyers looking to source innovative solutions for pet care. As demand for automatic pet feeders and related products surges, buyers face the critical task of identifying reliable suppliers that meet their specific needs. This guide serves as a comprehensive resource, detailing various types of automatic pet feeders, their applications, and essential factors to consider when vetting suppliers. From understanding the nuances of smart feeding technology to assessing cost structures and shipment logistics, this guide equips businesses with the insights necessary for informed purchasing decisions.

Navigating the complexities of the global market requires a strategic approach, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Each market presents unique challenges, including regulatory requirements, cultural preferences, and economic conditions that can influence product selection and supplier relationships. By leveraging the information provided in this guide, businesses can streamline their sourcing processes, mitigate risks, and ensure they invest in high-quality products that resonate with their target customers. Ultimately, this resource empowers buyers to make strategic decisions that enhance their competitive edge in the burgeoning automatic pet sector.

Table Of Contents

- Top 5 Automatic Pet Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automatic pet

- Understanding automatic pet Types and Variations

- Key Industrial Applications of automatic pet

- 3 Common User Pain Points for ‘automatic pet’ & Their Solutions

- Strategic Material Selection Guide for automatic pet

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic pet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic pet’

- Comprehensive Cost and Pricing Analysis for automatic pet Sourcing

- Alternatives Analysis: Comparing automatic pet With Other Solutions

- Essential Technical Properties and Trade Terminology for automatic pet

- Navigating Market Dynamics and Sourcing Trends in the automatic pet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic pet

- Strategic Sourcing Conclusion and Outlook for automatic pet

- Important Disclaimer & Terms of Use

Understanding automatic pet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smart Automatic Feeders | Wi-Fi connectivity, mobile app control, and meal tracking | Pet care retailers, online marketplaces | Pros: Enhanced monitoring, customizable feeding. Cons: Higher initial investment. |

| RFID Pet Feeders | RFID recognition for individual pet feeding | Pet supply chains, veterinary clinics | Pros: Personalized feeding, reduces food waste. Cons: Requires compatible RFID technology. |

| Multi-Pet Feeders | Designed for feeding multiple pets simultaneously | Pet hotels, shelters, multi-pet households | Pros: Efficient for multi-pet families, time-saving. Cons: Bulkier design, potential for food competition. |

| Wet Food Feeders | Features refrigeration or vacuum sealing for wet food freshness | Pet specialty stores, grooming services | Pros: Maintains food quality, appeals to picky eaters. Cons: Higher maintenance, limited to specific food types. |

| Portion Control Feeders | Integrated scales for precise meal portions | Veterinary practices, pet nutritionists | Pros: Helps manage pet weight, reduces overfeeding. Cons: Limited to dry food, may require calibration. |

What are Smart Automatic Feeders and Their B2B Benefits?

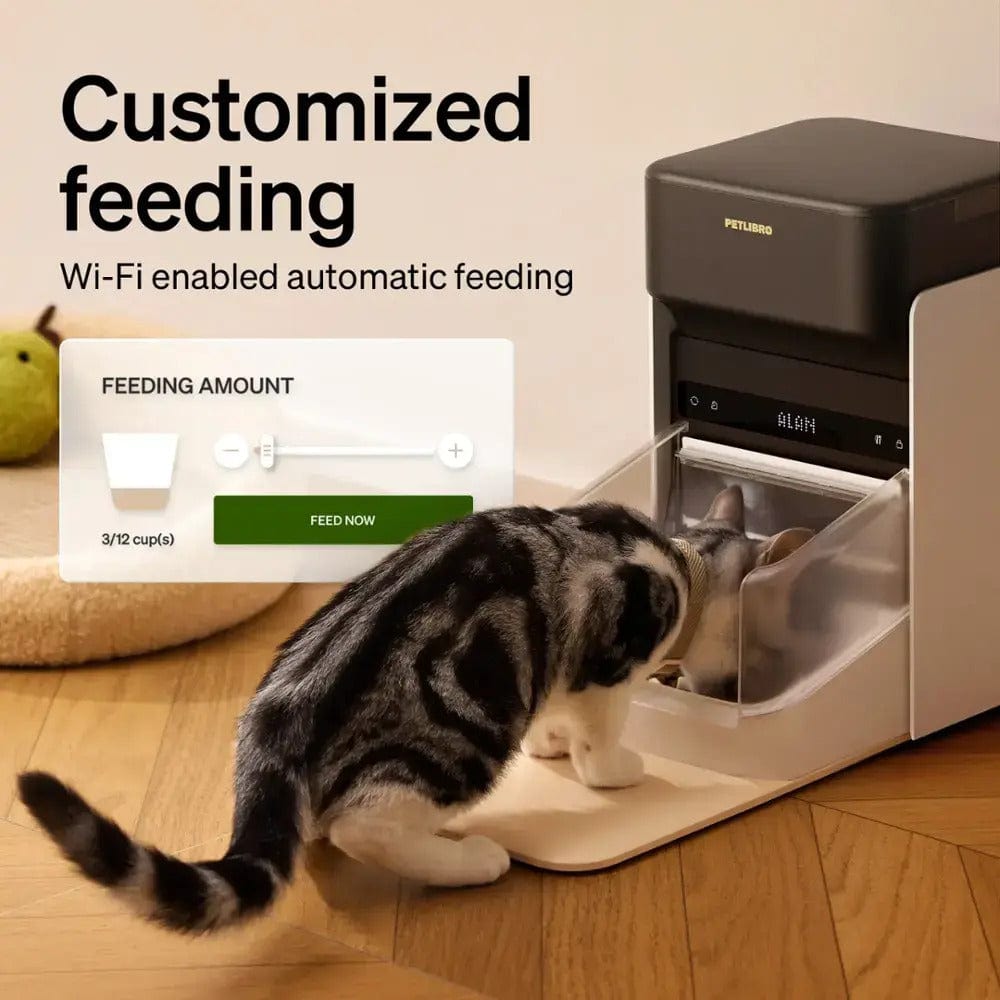

Smart automatic feeders utilize advanced technology, including Wi-Fi connectivity and mobile app control, allowing pet owners to manage feeding schedules and monitor their pets remotely. These feeders are particularly beneficial for retailers and distributors targeting tech-savvy pet owners. Key B2B purchasing considerations include the integration of user-friendly apps and the ability to offer ongoing support and updates, which can enhance customer satisfaction and loyalty.

How Do RFID Pet Feeders Work and Why Are They Important?

RFID pet feeders recognize individual pets through RFID tags, ensuring that each pet receives the correct portion of food. This technology is ideal for businesses catering to multi-pet households or facilities like veterinary clinics and pet boarding services. B2B buyers should consider the compatibility of RFID technology with their existing systems and the potential for reduced food waste, which can result in cost savings over time.

What Are the Advantages of Multi-Pet Feeders?

Multi-pet feeders are designed to serve several pets at once, making them ideal for pet hotels, shelters, and households with multiple animals. These feeders can save time for pet owners and caretakers, streamlining the feeding process. B2B buyers should evaluate the feeder’s capacity and design to ensure it meets the needs of their target market, particularly in terms of space and ease of use.

Why Choose Wet Food Feeders for Pet Care?

Wet food feeders often include features like refrigeration or vacuum sealing to maintain food freshness, making them attractive to pet owners who feed their pets wet food. Pet specialty stores and grooming services can benefit from offering these feeders as they cater to the needs of picky eaters. Buyers should consider the maintenance requirements and the types of wet food that can be used, as these factors impact customer satisfaction.

How Do Portion Control Feeders Enhance Pet Nutrition?

Portion control feeders come equipped with integrated scales to provide precise meal portions, helping to manage pet weight effectively. This type of feeder is particularly relevant for veterinary practices and pet nutritionists who prioritize pet health. B2B buyers should focus on the feeder’s compatibility with different types of food and its ease of calibration, as these features can significantly influence purchase decisions and customer trust.

Key Industrial Applications of automatic pet

| Industry/Sector | Specific Application of automatic pet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Retail | Smart Pet Feeders | Enhances customer experience and retention | Product quality, technology integration, and support |

| Veterinary Clinics | Automated Pet Feeding Solutions | Streamlines feeding for boarders and patients | Compliance with health regulations, ease of use, and reliability |

| Pet Services & Boarding | Remote Monitoring Feeders | Allows for real-time monitoring of pet health | Connectivity features, app compatibility, and security |

| Animal Shelters | RFID-enabled Feeding Stations | Efficient feeding management for multiple animals | Cost-effectiveness, ease of maintenance, and scalability |

| E-commerce Platforms | Subscription-based Automatic Feeders | Recurring revenue model and customer loyalty | Supply chain logistics, product availability, and pricing |

How Are Smart Pet Feeders Transforming the Pet Retail Industry?

In the pet retail sector, smart pet feeders are revolutionizing customer engagement. Retailers can offer high-tech feeding solutions that attract tech-savvy pet owners. These feeders often come with features such as app integration and personalized feeding schedules, providing a unique selling proposition. For international buyers, especially in emerging markets like Nigeria and Vietnam, sourcing products that comply with local regulations and consumer preferences is crucial. Retailers should also consider the durability and warranty of these devices to ensure customer satisfaction.

What Are the Benefits of Automated Feeding Solutions in Veterinary Clinics?

Veterinary clinics can leverage automated pet feeding solutions to enhance their boarding services. These feeders allow for precise meal portions and can be programmed to accommodate specific dietary needs, ensuring that pets receive the right nutrition while away from home. This not only improves pet care but also frees up staff time for other critical tasks. For clinics in regions such as South America and the Middle East, sourcing compliant and reliable equipment is essential to maintain high standards of pet care.

How Do Remote Monitoring Feeders Benefit Pet Services and Boarding Facilities?

Pet services and boarding facilities utilize remote monitoring feeders to ensure the well-being of animals in their care. These devices enable pet owners to monitor feeding times and portions via mobile apps, providing peace of mind. This technology can significantly enhance the service offering, making facilities more attractive to potential clients. When sourcing these products, buyers should prioritize features like Wi-Fi connectivity and data security, particularly in regions where tech adoption is rapidly evolving.

What Role Do RFID-enabled Feeding Stations Play in Animal Shelters?

Animal shelters can benefit from RFID-enabled feeding stations that streamline the feeding process for multiple animals. These systems can automatically recognize pets and dispense the appropriate amount of food, reducing waste and ensuring each animal receives its required nutrition. For shelters in Africa and Europe, considerations such as cost-effectiveness and ease of maintenance are vital when sourcing these technologies, as budgets are often constrained.

Illustrative image related to automatic pet

How Can E-commerce Platforms Capitalize on Subscription-based Automatic Feeders?

E-commerce platforms can tap into the growing trend of subscription-based automatic feeders, offering convenience to pet owners who prefer scheduled deliveries of pet food. This model not only ensures consistent revenue but also fosters customer loyalty. For international B2B buyers, especially those in developing markets, it’s important to assess supply chain logistics and product availability to meet customer demands effectively. Competitive pricing and robust customer support can further enhance the attractiveness of these offerings.

3 Common User Pain Points for ‘automatic pet’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions for Automatic Pet Feeders

The Problem: B2B buyers in the pet supply industry often face significant challenges related to supply chain disruptions, particularly when sourcing automatic pet feeders. These disruptions can lead to delays in product availability, affecting inventory management and ultimately customer satisfaction. For instance, a retailer in Nigeria may find that their usual supplier cannot meet the demand for smart feeders due to logistical issues, resulting in empty shelves and lost sales opportunities. Additionally, fluctuating prices and inconsistent product quality can further complicate procurement efforts.

The Solution: To mitigate these issues, B2B buyers should establish relationships with multiple suppliers across different regions to diversify their sourcing options. Consider utilizing local suppliers within Africa or South America, which can reduce shipping times and costs. It’s also advisable to engage in advance purchasing agreements during off-peak seasons to secure products at stable prices. Implementing a robust inventory management system that tracks stock levels and sales trends can help anticipate demand and avoid stockouts. Moreover, leveraging technology like predictive analytics can provide insights into future demand, enabling buyers to make informed purchasing decisions.

Scenario 2: Ensuring Compatibility with Diverse Pet Feeding Needs

The Problem: Automatic pet feeders vary significantly in features and functionality, making it challenging for B2B buyers to select products that meet the diverse needs of their customers. For example, a pet store in Europe may cater to both dog and cat owners, each requiring different feeding mechanisms (e.g., wet vs. dry food). Additionally, multi-pet households complicate the situation as these customers may seek feeders that can accommodate various feeding schedules and portion sizes, leading to potential dissatisfaction if the wrong product is offered.

The Solution: To address this challenge, B2B buyers should prioritize suppliers that offer a comprehensive range of automatic pet feeders with customizable features. This includes options for wet food, dry food, and multi-pet functionalities. Conducting market research to understand local pet ownership trends and preferences will help buyers make informed decisions. Additionally, providing educational materials and training for staff on product features can enhance customer service and ensure that buyers can effectively recommend the right solutions. Consider creating bundled offerings that include feeders, accessories, and replacement parts to cater to diverse needs and encourage upselling.

Scenario 3: Managing Customer Expectations for Smart Features

The Problem: As the demand for smart technology in pet care grows, B2B buyers must navigate customer expectations regarding the features of automatic pet feeders. Many consumers now expect advanced functionalities such as app connectivity, RFID recognition, and real-time monitoring. A retailer in the Middle East, for instance, may receive feedback from customers who are disappointed with feeders lacking these capabilities, leading to negative reviews and decreased sales.

The Solution: To meet and exceed customer expectations, B2B buyers should focus on sourcing automatic pet feeders that integrate smart technology effectively. Prioritize products that offer user-friendly app interfaces, ensuring that they can be easily set up and operated by pet owners of varying tech-savviness. Conducting product demonstrations and providing clear information on how these features benefit pet care can enhance customer engagement. Additionally, establishing a feedback loop with customers can help buyers understand which features are most valued, allowing them to tailor their product offerings accordingly. Investing in smart feeders that offer real-time analytics can also provide pet owners with valuable insights into their pets’ feeding habits, further enhancing customer satisfaction and loyalty.

Strategic Material Selection Guide for automatic pet

What Are the Key Materials Used in Automatic Pet Feeders?

In the manufacturing of automatic pet feeders, the selection of materials plays a crucial role in product performance, durability, and user satisfaction. Below, we analyze four common materials used in the industry: plastic, stainless steel, glass, and silicone. Each material has unique properties, advantages, and limitations that should be considered by international B2B buyers.

How Does Plastic Benefit Automatic Pet Feeders?

Plastic is one of the most widely used materials in automatic pet feeders due to its versatility and cost-effectiveness. Key properties include lightweight construction, resistance to moisture, and the ability to mold into various shapes. Plastics like polypropylene and polyethylene are commonly used for their durability and resistance to impact.

Pros: Plastic feeders are generally less expensive to produce, making them attractive for budget-conscious buyers. They are also easy to clean and maintain, which is essential for pet owners.

Cons: However, plastics may not withstand extreme temperatures and can degrade over time with exposure to UV light. Additionally, certain plastics may leach chemicals if not properly formulated, raising safety concerns.

Impact on Application: Plastic feeders are suitable for dry food but may not be ideal for wet food unless specifically designed with moisture barriers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the plastics used comply with local safety standards, such as ASTM or ISO certifications.

What Advantages Does Stainless Steel Offer for Automatic Pet Feeders?

Stainless steel is another popular choice for automatic pet feeders, particularly for premium products. Its key properties include high corrosion resistance, durability, and the ability to withstand high temperatures.

Pros: Stainless steel feeders are robust and can last for years, making them a worthwhile investment. They are also easy to clean and are less likely to harbor bacteria compared to plastic.

Illustrative image related to automatic pet

Cons: The primary drawback is the higher cost associated with stainless steel, which may not appeal to all market segments. Additionally, they can be heavier and more cumbersome to handle.

Impact on Application: Stainless steel is suitable for both dry and wet food applications, making it versatile for different pet feeding needs.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards for food safety, such as those set by the FDA or EU regulations.

Why Is Glass Considered for Automatic Pet Feeders?

Glass is often used for feeders that require a high level of aesthetic appeal and hygiene. Its key properties include non-reactivity, ease of cleaning, and resistance to staining.

Pros: Glass feeders do not retain odors or flavors, making them ideal for wet food. They also provide a premium look that can enhance the product’s marketability.

Cons: The main disadvantage of glass is its fragility; it can break easily if dropped. Additionally, glass feeders tend to be heavier, which may not be suitable for all consumers.

Impact on Application: Glass is particularly effective for wet food applications, as it prevents contamination and maintains food quality.

Considerations for International Buyers: Buyers should ensure that glass products comply with safety regulations to prevent breakage during shipping and handling, especially in regions with less robust logistics.

What Role Does Silicone Play in Automatic Pet Feeders?

Silicone is increasingly being used in automatic pet feeders, particularly for parts like seals and mats. Its key properties include flexibility, resistance to heat, and non-toxicity.

Pros: Silicone is durable and can withstand temperature variations, making it suitable for various feeding applications. It is also easy to clean and can be safely used with both dry and wet food.

Illustrative image related to automatic pet

Cons: The primary limitation of silicone is its cost, which can be higher than traditional plastics. Additionally, it may not be as rigid as other materials, potentially affecting the feeder’s structural integrity.

Impact on Application: Silicone is ideal for creating airtight seals that keep food fresh and prevent spills.

Considerations for International Buyers: Buyers should look for silicone that meets food-grade standards and is free from harmful chemicals, especially in regions with strict regulations.

Summary Table of Material Selection for Automatic Pet Feeders

| Material | Typical Use Case for automatic pet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Dry food feeders | Cost-effective and lightweight | May degrade and leach chemicals | Low |

| Stainless Steel | Premium feeders for wet/dry food | Durable and easy to clean | Higher cost and heavier | High |

| Glass | Wet food feeders | Non-reactive and hygienic | Fragile and heavier | Med |

| Silicone | Seals and mats for feeders | Flexible and heat-resistant | Higher cost and less rigid | Med |

This analysis provides a comprehensive overview of the materials used in automatic pet feeders, allowing B2B buyers to make informed decisions based on performance, cost, and compliance with international standards.

Illustrative image related to automatic pet

In-depth Look: Manufacturing Processes and Quality Assurance for automatic pet

What Are the Key Stages in the Manufacturing Process of Automatic Pet Feeders?

The manufacturing process for automatic pet feeders involves several critical stages, each aimed at ensuring the final product is reliable, user-friendly, and meets the needs of both pets and their owners. Here’s a breakdown of the main stages:

-

Material Preparation: This initial stage involves sourcing high-quality materials such as BPA-free plastics, stainless steel, and electronic components. Suppliers must provide certification to guarantee that these materials meet safety and environmental standards. For instance, using food-grade materials is essential to ensure the health and safety of pets.

-

Forming: The next phase includes the shaping of components through methods such as injection molding or extrusion for plastics, and stamping or machining for metals. Advanced technologies like 3D printing may also be employed for prototyping and small batch production. This stage is critical for achieving precise dimensions and ensuring that parts fit together seamlessly.

-

Assembly: After forming, the various components are assembled. This process can be manual or automated, depending on the complexity of the feeder. Automated assembly lines may use robotics for high precision and speed, which can significantly reduce labor costs and time. During assembly, electronic components such as timers, sensors, and Wi-Fi modules are integrated.

-

Finishing: The finishing stage involves surface treatments, painting, or coating to enhance durability and aesthetics. This may include applying non-slip bases or moisture-resistant coatings to protect electronic components. Quality checks during this stage ensure that the product not only looks good but also performs reliably under different conditions.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that automatic pet feeders meet both international standards and customer expectations. Here’s how QA is typically structured:

-

International and Industry-Specific Standards: Adhering to international standards such as ISO 9001 is crucial. This standard outlines the criteria for a quality management system and emphasizes customer satisfaction, continuous improvement, and the involvement of top management. Additionally, compliance with industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market ensures that the feeders meet safety, health, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards. Any non-compliant materials are rejected or returned to the supplier.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production quality. This can include checking dimensions, assembly accuracy, and functionality of electronic components.

– Final Quality Control (FQC): Before products are shipped, a final inspection is performed. This includes functional testing of the feeders, checking for user-friendly operation, and verifying that all features, such as timers and sensors, work as intended. -

Common Testing Methods: Various testing methods are employed to assess product quality:

– Functional Testing: Ensures that all electronic features, such as timers and sensors, operate correctly.

– Stress Testing: Simulates real-world conditions to assess durability and reliability over time.

– Safety Testing: Verifies that materials used are safe for pets, particularly in terms of toxicity and durability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are effective strategies:

-

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing and quality assurance processes. This may include reviewing their quality management systems, inspection records, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help assess their performance. These reports should include data on defect rates, corrective actions taken, and results from quality checks throughout the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices. These agencies can conduct inspections at various stages of production and provide certification to confirm compliance with relevant standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of specific nuances related to quality control when sourcing automatic pet feeders:

-

Understanding Regional Regulations: Different regions may have varying regulations regarding pet product safety. Buyers should familiarize themselves with local standards, such as the Food and Drug Administration (FDA) regulations in the U.S. or REACH compliance in Europe.

-

Cultural Expectations: Quality expectations may vary by region, influenced by local consumer preferences and cultural norms. For instance, buyers in Europe may prioritize eco-friendliness and sustainability more than those in other regions.

-

Logistical Challenges: International shipping can pose risks to product integrity. B2B buyers should ensure that suppliers have robust packaging and shipping processes to minimize damage during transit.

Conclusion

In the competitive landscape of automatic pet feeders, understanding the manufacturing processes and quality assurance practices is essential for B2B buyers. By focusing on material quality, rigorous manufacturing techniques, and effective quality control measures, suppliers can ensure they deliver reliable and safe products. For buyers, thoroughly vetting suppliers through audits, quality reports, and third-party inspections is vital to establishing trustworthy partnerships that can meet the demands of the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic pet’

Introduction

Sourcing automatic pet feeders requires a strategic approach to ensure quality, functionality, and cost-effectiveness. This guide provides B2B buyers with a detailed checklist to streamline the procurement process. By following these steps, you can confidently select the best suppliers and products that meet your business needs.

Step 1: Identify Your Market Needs

Understanding your target market is essential for sourcing the right automatic pet feeders. Research regional preferences, such as popular pet types and feeding habits, to tailor your offerings effectively. This insight will help you choose products that resonate with your customer base, enhancing your competitive edge.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the feeders you wish to procure. Consider aspects such as capacity (e.g., liters), type of food (dry or wet), and additional features like RFID recognition or camera monitoring. Defining these specifications upfront will streamline discussions with suppliers and ensure you receive products that fit your criteria.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a thorough evaluation. Request company profiles, product samples, and references from previous clients, particularly those in similar markets. Look for suppliers with a proven track record in quality and reliability, as this will minimize risks associated with product defects or service delays.

- Check for Certifications: Ensure that suppliers comply with relevant industry standards, which can vary by region. Certifications can indicate adherence to safety and quality benchmarks.

- Assess Production Capabilities: Understand the supplier’s manufacturing capabilities to ensure they can meet your volume requirements and timelines.

Step 4: Review Product Features and Innovations

When comparing products, focus on innovative features that can add value to your offerings. For instance, smart feeders with app connectivity allow pet owners to monitor feeding schedules remotely. These added functionalities can differentiate your products in a competitive market.

- Consider User-Friendly Designs: Look for feeders that are easy to clean and refill, as convenience is a significant selling point for pet owners.

- Evaluate Energy Efficiency: Automatic feeders that consume less power or operate on batteries can be attractive to environmentally-conscious consumers.

Step 5: Analyze Pricing and Payment Terms

Pricing plays a crucial role in your sourcing decision. Compare quotes from multiple suppliers while considering the total cost of ownership, which includes shipping, duties, and potential after-sales support. Negotiate payment terms that align with your cash flow needs, and inquire about bulk purchase discounts.

- Assess Warranty and Support: Ensure that the products come with a warranty and that the supplier offers adequate after-sales support, as this can impact customer satisfaction.

Step 6: Conduct Quality Assurance Checks

Implement quality control measures to ensure that the products meet your specifications upon delivery. Consider setting up a system for inspecting samples before full orders are placed. This step is crucial to avoid costly returns and maintain your brand’s reputation.

Step 7: Establish a Long-Term Relationship with Suppliers

Building a strong relationship with your suppliers can lead to better pricing, priority service, and access to new products. Regular communication and feedback can foster collaboration, helping both parties adapt to market changes and customer demands effectively.

Following this checklist will guide you through the sourcing process of automatic pet feeders, ensuring you make informed decisions that benefit your business and your customers.

Comprehensive Cost and Pricing Analysis for automatic pet Sourcing

Understanding the cost structure and pricing strategies for automatic pet feeders is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various cost components, price influencers, and strategic tips for negotiation and purchasing.

What Are the Key Cost Components in Automatic Pet Feeders?

When sourcing automatic pet feeders, several cost components must be considered:

-

Materials: The primary materials used in the production of automatic pet feeders include plastics, stainless steel, and electronic components. Quality and type of materials can significantly affect the overall cost.

-

Labor: Labor costs vary by region, influenced by local wage standards and the complexity of assembly. Higher-skilled labor, particularly for devices with advanced technology (e.g., RFID recognition), will incur higher costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Factories in regions with lower overhead costs can provide more competitive pricing.

-

Tooling: Initial tooling costs for molds and specialized equipment can be substantial, particularly for custom designs. These costs are often amortized over large production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. These processes can increase costs but are essential for maintaining brand reputation.

-

Logistics: Shipping costs, which include freight and customs duties, can be significant, especially for international buyers. Factors such as the Incoterms used (e.g., FOB, CIF) will influence the total logistics cost.

-

Margin: Suppliers typically mark up their costs to achieve a profit margin. Understanding the expected margins in different markets can assist buyers in negotiating better prices.

How Do Price Influencers Impact Automatic Pet Feeder Costs?

Several factors can influence the pricing of automatic pet feeders:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can significantly reduce per-unit costs. Suppliers often provide discounts for larger orders, making it advantageous for businesses planning to resell.

-

Specifications and Customization: Custom designs or additional features (like app connectivity or camera monitoring) can lead to higher costs. Standard models usually offer better pricing.

-

Material Quality and Certifications: Higher quality materials and compliance with safety certifications (e.g., CE, ISO) can increase the price but are often necessary for market acceptance and legal compliance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their brand value but often provide better service and quality assurance.

-

Incoterms: The choice of Incoterms will affect the total cost of ownership, impacting logistics, insurance, and liability costs.

What Are Some Effective Buyer Tips for Negotiating Costs?

For B2B buyers, especially those from diverse markets like Nigeria and Vietnam, effective negotiation and strategic sourcing can lead to significant savings:

-

Negotiate: Always negotiate prices, especially for bulk orders. Suppliers may have room for discounts, particularly if you demonstrate long-term purchasing potential.

-

Consider Total Cost of Ownership (TCO): Factor in not just the purchase price but also logistics, customs duties, and potential maintenance costs when evaluating suppliers.

-

Explore Local Suppliers: In certain markets, local manufacturers may offer competitive pricing and lower shipping costs, alongside quicker turnaround times.

-

Stay Informed on Pricing Nuances: Be aware of regional pricing trends and currency fluctuations, which can impact costs when sourcing internationally.

-

Request Samples: Before committing to large orders, request samples to assess quality, ensuring that the products meet your specifications and market standards.

Conclusion

Navigating the cost structure and pricing landscape for automatic pet feeders requires a comprehensive understanding of various components and influencing factors. By leveraging strategic negotiation techniques and being mindful of the total cost of ownership, B2B buyers can secure favorable deals that enhance their product offerings in competitive markets. Always remember that prices can fluctuate based on market conditions, so staying informed and adaptable is key.

Illustrative image related to automatic pet

Alternatives Analysis: Comparing automatic pet With Other Solutions

Exploring Alternatives to Automatic Pet Solutions

In the rapidly evolving landscape of pet care technology, automatic pet feeders have gained popularity for their convenience and efficiency. However, various alternatives can also meet the needs of pet owners. This section compares automatic pet feeders with traditional feeding methods and smart feeding bowls, providing insights for B2B buyers considering their options.

| Comparison Aspect | Automatic Pet | Traditional Feeding Method | Smart Feeding Bowl |

|---|---|---|---|

| Performance | Consistent portion control, programmable schedules | Inconsistent, manual oversight | Portion control, some smart features |

| Cost | Moderate to high (varies by features) | Low initial investment, but may incur costs for multiple feedings | Moderate, depending on technology |

| Ease of Implementation | Requires setup and sometimes app integration | Simple, no technology needed | Requires initial setup and possibly app usage |

| Maintenance | Periodic cleaning, battery or power maintenance | Minimal, just food refills | Regular cleaning, battery replacements for smart features |

| Best Use Case | Ideal for busy owners, multiple pets, and specific dietary needs | Suitable for hands-on pet owners or those with single pets | Great for tech-savvy owners wanting to monitor feeding |

What Are the Benefits and Drawbacks of Traditional Feeding Methods?

Traditional feeding methods involve manually filling bowls with pet food at designated times. This approach is cost-effective and straightforward, requiring no technology or setup. However, it lacks the convenience of automated systems, leading to potential inconsistencies in feeding schedules, especially for busy pet owners or those with multiple pets. Additionally, it may not be suitable for pets with specific dietary needs or those that require portion control, as it relies heavily on the owner’s memory and attention.

How Do Smart Feeding Bowls Compare to Automatic Pet Feeders?

Smart feeding bowls offer a blend of traditional feeding and technology, often featuring portion control and connectivity options to track feeding habits. They are typically more affordable than high-end automatic feeders and provide some level of smart functionality. However, they may not be as robust in terms of scheduling and remote access. These bowls require regular maintenance and cleaning to ensure optimal performance, which can deter some users. Smart feeding bowls are ideal for pet owners who are comfortable with technology but may not require the full range of features offered by automatic feeders.

Conclusion: How Should B2B Buyers Choose the Right Pet Feeding Solution?

When selecting a pet feeding solution, B2B buyers should evaluate their specific needs and circumstances. Automatic pet feeders provide advanced features suitable for busy households and multi-pet environments, while traditional feeding methods offer simplicity and low cost. Smart feeding bowls serve as a middle ground, integrating technology with classic feeding practices. Buyers must consider performance, cost, ease of implementation, maintenance requirements, and the best use case for their target market. Ultimately, the right choice will depend on the balance between convenience, functionality, and the unique needs of their customers.

Essential Technical Properties and Trade Terminology for automatic pet

What Are the Key Technical Properties of Automatic Pet Feeders?

When considering automatic pet feeders, understanding their technical properties is crucial for making informed purchasing decisions. Here are several key specifications that B2B buyers should prioritize:

-

Material Grade

– Definition: The quality and type of materials used in the construction of the feeder, often including plastics, stainless steel, and BPA-free components.

– Importance: High-quality materials ensure durability, safety, and ease of cleaning. For international markets, compliance with local health and safety standards is also essential. -

Capacity

– Definition: The volume of food the feeder can hold, typically measured in liters (L).

– Importance: Capacity affects how often the feeder needs to be refilled, which is particularly important for businesses that cater to pet owners with multiple animals. A larger capacity can also mean fewer operational interruptions, thus enhancing customer satisfaction. -

Power Supply

– Definition: The type of power source the feeder uses, such as battery-operated, AC power, or a combination of both.

– Importance: Understanding the power supply is vital for reliability, especially in regions with inconsistent electricity. Battery-operated models may provide backup in case of power outages, making them more appealing for various markets. -

Programming Options

– Definition: The settings that allow users to schedule feeding times, portion sizes, and feeding frequencies.

– Importance: Advanced programming features can attract tech-savvy consumers and enhance pet health management. This is particularly relevant in markets where pet care is increasingly viewed as a priority. -

Smart Features

– Definition: Technologies integrated into the feeder, such as Wi-Fi connectivity, app control, and real-time notifications.

– Importance: Smart features offer convenience and control for pet owners, making the products more marketable. In competitive environments, these features can differentiate a brand, especially among younger consumers. -

Safety Features

– Definition: Elements designed to prevent accidents, such as low food detection sensors and moisture control systems.

– Importance: Ensuring the safety of pets is paramount for any B2B buyer. Products with robust safety features can reduce liability concerns and enhance brand reputation.

What Are Common Trade Terms in the Automatic Pet Feeder Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing whether a supplier operates as an OEM can influence sourcing decisions, particularly regarding customization and branding. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Understanding MOQ helps businesses manage inventory and cash flow. This is especially significant for companies entering new markets where initial demand may be uncertain. -

RFQ (Request for Quotation)

– Definition: A document that solicits price proposals from suppliers.

– Importance: An RFQ is a critical step in the procurement process, allowing buyers to compare costs and services from different suppliers effectively. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is crucial for B2B transactions, as they dictate shipping responsibilities, risk management, and cost allocation, which vary significantly across regions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Understanding lead times is vital for inventory planning and customer satisfaction. Longer lead times can impact market responsiveness, especially in competitive markets. -

Warranty and Return Policy

– Definition: Terms under which a product can be returned or repaired.

– Importance: A solid warranty and return policy can enhance buyer confidence, particularly for high-value items like automatic pet feeders. This is especially important in markets where customer service expectations are high.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the automatic pet feeder market more effectively, ensuring they make choices that align with their operational needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the automatic pet Sector

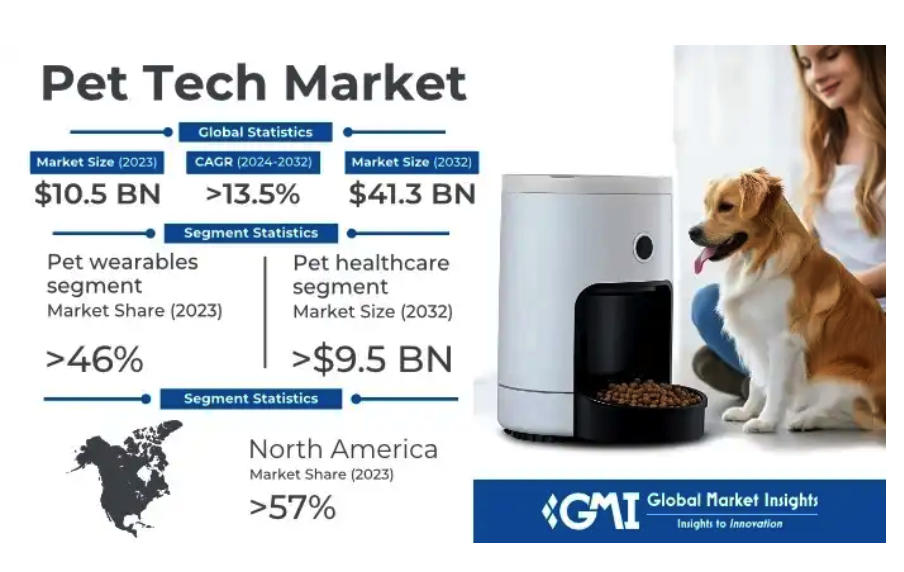

What Are the Key Market Dynamics and Trends Shaping the Automatic Pet Sector?

The global automatic pet sector is witnessing significant growth driven by a surge in pet ownership and a shift towards convenience-oriented products. As urbanization increases, especially in regions like Africa, South America, the Middle East, and Europe, busy lifestyles are prompting pet owners to seek automated solutions for pet care. This trend is further fueled by technological advancements, including smart feeders with app integration, RFID recognition, and real-time monitoring capabilities. International B2B buyers are increasingly drawn to products that offer not only ease of use but also enhanced pet health features, such as portion control and food freshness.

Emerging technologies are transforming the sourcing landscape for automatic pet products. IoT integration is a key trend, allowing pet owners to manage feeding schedules remotely, which is particularly appealing in regions where access to pet care services may be limited. Additionally, the demand for multi-functional products, such as feeders that also provide hydration or integrate with pet cameras, is rising. This creates opportunities for suppliers to innovate and differentiate their offerings. Buyers should focus on establishing partnerships with manufacturers that prioritize tech-driven solutions to meet the evolving needs of the market.

Illustrative image related to automatic pet

How Can Sustainability and Ethical Sourcing Influence Your B2B Decisions in the Automatic Pet Sector?

Sustainability is becoming a pivotal factor in the automatic pet sector, as consumers increasingly demand products that minimize environmental impact. B2B buyers should prioritize suppliers who utilize eco-friendly materials and practices in their manufacturing processes. This includes sourcing biodegradable plastics, recycled materials, and energy-efficient production methods. Moreover, certifications such as ISO 14001 for environmental management can help buyers identify responsible suppliers.

Ethical sourcing is also crucial, particularly as consumers become more aware of the origins of their products. Ensuring that the supply chain adheres to fair labor practices and responsible sourcing can enhance brand reputation and customer loyalty. Buyers should seek manufacturers that are transparent about their sourcing practices and can demonstrate commitment to ethical standards. By aligning with suppliers that prioritize sustainability and ethics, B2B buyers can contribute positively to the environment while also responding to consumer demand for responsible products.

What Is the Evolution of the Automatic Pet Sector Relevant to B2B Buyers?

The automatic pet sector has evolved significantly over the past few decades, transitioning from basic mechanical feeders to sophisticated smart devices equipped with advanced technology. Initially, automatic feeders were simple devices that provided timed meals, but the introduction of smart technology has revolutionized this market. Today’s products feature app controls, camera monitoring, and RFID technology, enabling pet owners to customize feeding schedules and monitor their pets’ eating habits remotely.

Illustrative image related to automatic pet

This evolution presents B2B buyers with a unique opportunity to engage with a market that is not only growing but also becoming increasingly tech-oriented. Understanding the historical context of these products can help buyers identify trends and anticipate future developments, allowing them to make informed sourcing decisions that align with market demands. As the automatic pet sector continues to innovate, staying abreast of these changes will be essential for B2B buyers looking to capitalize on emerging opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic pet

-

How do I select the right automatic pet feeder for my business needs?

Choosing the right automatic pet feeder involves assessing your target market and understanding their preferences. Consider factors such as the type of pet (cats, dogs, or multi-pet households), the capacity required, and any special features like RFID recognition, app control, or camera monitoring. Additionally, investigate the price range that aligns with your customer demographics. Sampling products before placing a bulk order can also help ensure quality and functionality meet your expectations. -

What features should I look for in an automatic pet feeder?

When sourcing automatic pet feeders, prioritize features that enhance usability and pet care. Look for programmable feeding schedules, portion control capabilities, and compatibility with wet and dry food. Advanced options like real-time monitoring through mobile apps, built-in cameras, and moisture control systems can add significant value. Ensure the feeders are easy to clean and have durable materials to withstand daily use, especially in a commercial setting. -

What is the minimum order quantity (MOQ) for automatic pet feeders?

The MOQ for automatic pet feeders can vary significantly based on the manufacturer and the complexity of the product. Typically, you can expect MOQs to range from 50 to 500 units. It’s advisable to communicate directly with suppliers to negotiate terms that suit your business model. Some suppliers may offer lower MOQs for first-time buyers or allow for mixed orders of different models to help you test various products in your market. -

How can I ensure the quality of automatic pet feeders from international suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request samples to evaluate the product firsthand, and check for certifications that meet international standards. It’s also beneficial to ask for references or reviews from other businesses that have worked with the supplier. Consider conducting factory visits if feasible, or utilize third-party quality assurance services to verify production processes and materials. -

What are the typical payment terms when sourcing automatic pet feeders internationally?

Payment terms can vary widely based on the supplier and the relationship established. Common practices include a 30% deposit upfront with the balance due before shipping, or payment upon delivery. Some suppliers may offer credit terms for repeat customers. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and ensure that terms are documented in your purchase agreement to avoid misunderstandings. -

What logistics should I consider when importing automatic pet feeders?

Logistics play a crucial role in international trade. Consider shipping methods (air vs. sea), estimated delivery times, and customs clearance procedures in your country. Work with a reputable freight forwarder who can assist with documentation, tariffs, and duties. Factor in warehousing solutions if necessary, and ensure that you have a plan for inventory management upon arrival to meet customer demand efficiently. -

Can I customize automatic pet feeders to meet my brand requirements?

Many manufacturers offer customization options for automatic pet feeders, including branding, color variations, and specific features tailored to your market. Discuss your requirements with suppliers to explore available customization options. Keep in mind that customized products may have higher MOQs and longer lead times, so plan accordingly to ensure timely market entry. -

What are the common challenges in sourcing automatic pet feeders from international suppliers?

Challenges can include language barriers, cultural differences, and varying quality standards. Delays in shipping or customs can also pose issues. To mitigate these risks, establish clear communication with suppliers, set realistic timelines, and consider using contracts that outline expectations. Building a strong relationship with your supplier can lead to more reliable service and better problem resolution in the future.

Top 5 Automatic Pet Manufacturers & Suppliers List

1. Petlibro – Polar Smart Wet Food Feeder

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro

Key Products:

1. Polar Smart Wet Food Feeder – $149.99

– Refrigerated wet food storage

– RFID pet recognition

– Pre-order available

2. Granary Smart Camera Feeder – $139.99

– Dual bowl design for surveillance

– App-controlled feeding

– Pre-order available

3. Granary Smart Feeder – $89.99

– Automatic feeding with app control…

2. Closer Pets – MiBowl Automatic Microchip Pet Feeder

Domain: closerpets.com

Registered: 2020 (5 years)

Introduction: Pet Feeders Collection includes 19 products. Automatic pet feeders designed for cats and small dogs with timer-operated compartments and integrated ice packs. Featured products include: 1. MiBowl Automatic Microchip Pet Feeder (CP500) – Sale price: $129.99, Regular price: $199.99, 127 reviews. 2. Closer Pets Five-Meal Automatic Pet Feeder with Stainless Steel Bowl Inserts and Ice Packs (C500) – Sa…

3. PetSafe – Smart Feed Automatic Dog and Cat Feeder

Domain: petsafe.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘Smart Feed Automatic Dog and Cat Feeder, 2nd Generation’, ‘capacity’: ’24 cups of food’, ‘price’: ‘$134.99’}, {‘name’: ‘Drinkwell® Seascape Pet Fountain Drinking Bowl’, ‘capacity’: ’70 oz.’, ‘features’: ‘Dual Filtration’, ‘price’: ‘$95.99’}, {‘name’: ‘Healthy Pet Simply Feed™’, ‘meals’: ‘Schedule 12 meals daily’, ‘capacity’: ’24 cups of food’, ‘price’: ‘$95.99’}, {‘name’: ‘Drinkwell® Ou…

4. Arf Pets – Memory Training Puzzle Toy

Domain: arfpets.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”Memory Training Puzzle Toy”,”regular_price”:”$74.99″,”sale_price”:”$59.99″},{“name”:”Automatic Pet Feeder”,”regular_price”:”$129.99″,”sale_price”:”$89.99″}]}

5. Petlibro – Bundle, Catit – Wet Food Feeder, VEKEN – Water Fountain, PETLIBRO – Dry Food Feeder

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Petlibro Bundle: Price $300+, mixed reviews.

2. Catit Brand: Wet food feeder with 6 compartments.

3. VEKEN Water Fountain: Easy to clean, used for about a year.

4. PETLIBRO Dry Food Feeder: Used for almost 3 years, consistent performance, records feeding, dispenses varying amounts of dry food 4 times per day, newer models available at lower prices.

Strategic Sourcing Conclusion and Outlook for automatic pet

As the demand for automatic pet products continues to rise globally, strategic sourcing becomes increasingly critical for B2B buyers in diverse markets, including Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of selecting suppliers that offer innovative solutions, such as RFID pet recognition and app-controlled feeding systems, which enhance pet care while ensuring convenience for pet owners. Additionally, exploring bundled offerings can lead to significant cost savings and provide comprehensive care options for multi-pet households.

Investing in automatic pet feeders not only addresses the growing consumer trend towards convenience but also positions businesses to capitalize on the emerging pet technology market. By establishing partnerships with reliable manufacturers, buyers can secure quality products that resonate with local consumer needs and preferences.

Looking ahead, the future of the automatic pet market is bright, with continuous advancements in technology and consumer expectations. International B2B buyers are encouraged to act now—research potential suppliers, evaluate product offerings, and consider how these innovations can enrich their business portfolios. By embracing strategic sourcing, you can ensure your company remains competitive and responsive to the evolving demands of pet owners worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to automatic pet

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.