Introduction: Navigating the Global Market for best wet food feeder for cats

In the ever-evolving landscape of pet care, sourcing the best wet food feeder for cats presents both opportunities and challenges for international B2B buyers. With the growing demand for innovative pet products across markets in Africa, South America, the Middle East, and Europe, suppliers must navigate a myriad of options that meet diverse consumer needs. This guide offers a thorough exploration of various types of wet food feeders, including programmable, gravity-based, and dish-style models, each tailored to different feeding habits and lifestyles of cats.

Moreover, it delves into essential applications, such as how these feeders enhance pet well-being, support busy lifestyles, and maintain food freshness. Understanding the nuances of supplier vetting is critical; this guide outlines key factors to consider, from product reliability to compliance with international safety standards. Additionally, we provide insights into cost considerations, helping buyers balance quality with budget constraints.

By equipping B2B buyers with comprehensive knowledge and actionable insights, this guide empowers informed purchasing decisions that can lead to successful partnerships and increased market competitiveness. The insights shared herein are tailored to meet the specific challenges faced by buyers in diverse regions, ensuring that they can confidently source the best wet food feeders that cater to the needs of pet owners globally.

Table Of Contents

- Top 1 Best Wet Food Feeder For Cats Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best wet food feeder for cats

- Understanding best wet food feeder for cats Types and Variations

- Key Industrial Applications of best wet food feeder for cats

- 3 Common User Pain Points for ‘best wet food feeder for cats’ & Their Solutions

- Strategic Material Selection Guide for best wet food feeder for cats

- In-depth Look: Manufacturing Processes and Quality Assurance for best wet food feeder for cats

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best wet food feeder for cats’

- Comprehensive Cost and Pricing Analysis for best wet food feeder for cats Sourcing

- Alternatives Analysis: Comparing best wet food feeder for cats With Other Solutions

- Essential Technical Properties and Trade Terminology for best wet food feeder for cats

- Navigating Market Dynamics and Sourcing Trends in the best wet food feeder for cats Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best wet food feeder for cats

- Strategic Sourcing Conclusion and Outlook for best wet food feeder for cats

- Important Disclaimer & Terms of Use

Understanding best wet food feeder for cats Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Programmable Dish-Style Feeder | Features multiple compartments; can dispense wet food at scheduled intervals. | Veterinary clinics, pet care businesses | Pros: Versatile for different food types; Cons: Limited to short-term use. |

| Automatic Ice Pack Feeder | Incorporates ice packs to keep wet food fresh for extended periods. | Pet retailers, online pet supply stores | Pros: Maintains food freshness; Cons: Requires power source and maintenance. |

| Microchip-Controlled Feeder | Uses RFID technology to limit access to specific pets, ideal for multi-cat households. | Animal shelters, multi-pet households | Pros: Prevents food theft; Cons: Higher initial cost. |

| Gravity-Based Wet Food Feeder | Simple design that relies on gravity to dispense food without programming. | Budget-conscious retailers, casual pet owners | Pros: Low cost; Cons: Not suitable for controlled feeding. |

| WiFi-Enabled Smart Feeder | Connects to apps for remote feeding control and meal scheduling. | Tech-savvy pet stores, e-commerce platforms | Pros: Remote management; Cons: Higher price point. |

What are the Characteristics of Programmable Dish-Style Feeders?

Programmable dish-style feeders are designed with multiple compartments that release wet food at predetermined intervals. This feature allows for a controlled feeding schedule, making it suitable for both cats that prefer routine and those with specific dietary needs. B2B buyers in veterinary clinics and pet care businesses may find these feeders particularly valuable, as they can help manage feeding regimens for cats with health concerns. However, they are best suited for short-term usage due to their limited food capacity.

How Do Automatic Ice Pack Feeders Maintain Freshness?

Automatic ice pack feeders are equipped with built-in ice packs that keep wet food fresh for longer periods, making them ideal for pet owners who travel or are away from home for extended hours. These feeders are particularly appealing to pet retailers and online supply stores, as they address concerns about food spoilage. While they effectively maintain food quality, buyers should consider the need for a power source and potential maintenance issues to ensure consistent performance.

Illustrative image related to best wet food feeder for cats

What Benefits Do Microchip-Controlled Feeders Offer?

Microchip-controlled feeders utilize RFID technology to ensure that only designated pets can access the food, making them ideal for multi-cat households or animal shelters. This feature can prevent food stealing and ensure that each cat receives the appropriate diet, thus appealing to B2B buyers in animal welfare and veterinary sectors. Despite their advantages, these feeders typically come with a higher initial cost, which may be a consideration for budget-conscious buyers.

Why Choose Gravity-Based Wet Food Feeders?

Gravity-based wet food feeders are the simplest type of feeder, relying on gravity to dispense food without any programming or timers. This makes them an attractive option for budget-conscious retailers and casual pet owners who require a straightforward feeding solution. However, these feeders may not be suitable for managing precise feeding schedules, which can be a drawback for buyers looking to control their pets’ diets effectively.

What Features Do WiFi-Enabled Smart Feeders Provide?

WiFi-enabled smart feeders allow pet owners to manage feeding schedules and portion sizes remotely through smartphone applications. This technology appeals to tech-savvy pet stores and e-commerce platforms looking to cater to modern pet owners. While these feeders offer convenience and flexibility, they typically come at a higher price point, which may limit their market to more affluent consumers or businesses focused on premium pet products.

Key Industrial Applications of best wet food feeder for cats

| Industry/Sector | Specific Application of best wet food feeder for cats | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Providing scheduled feeding for cats in care | Ensures consistent nutrition for recovering or stressed cats | Reliability, ease of use, and cleaning features |

| Pet Boarding Facilities | Automated feeding for multiple cats | Reduces labor costs and ensures timely feeding schedules | Capacity, programmability, and hygiene standards |

| Pet Retail & E-commerce | Selling automatic feeders to consumers | Expands product offerings and meets growing demand | Product diversity, pricing strategy, and supplier reliability |

| Animal Shelters | Feeding multiple cats efficiently | Improves operational efficiency and reduces food waste | Durability, ease of programming, and maintenance support |

| Pet Training Centers | Use in behavioral training for feeding routines | Supports training by establishing feeding schedules | Programmability, portion control, and compatibility with various foods |

How Can Veterinary Clinics Benefit from Best Wet Food Feeders for Cats?

Veterinary clinics often care for cats that require special diets or consistent feeding schedules. Utilizing automatic wet food feeders allows clinics to ensure that each cat receives the appropriate amount of food at regular intervals, even when staff are busy or away from the feeding area. This is crucial for the recovery of stressed or ill cats. Buyers from clinics should prioritize reliability and ease of cleaning, as well as features that prevent food spoilage.

What Advantages Do Pet Boarding Facilities Gain from Automated Feeders?

Pet boarding facilities can significantly benefit from the use of automatic wet food feeders, which streamline the feeding process for multiple cats. These feeders reduce the labor costs associated with manual feeding and ensure that all cats receive their meals on time, regardless of the staff’s availability. Key considerations for procurement include the feeder’s capacity to hold multiple meals and programmability to cater to various dietary needs, ensuring compliance with pet owners’ instructions.

Why Are Pet Retailers and E-commerce Platforms Interested in Automatic Feeders?

Pet retailers and e-commerce platforms are increasingly offering automatic wet food feeders to meet the growing consumer demand for convenient pet care solutions. By stocking a variety of feeders, these businesses can expand their product offerings and attract a wider customer base. When sourcing these feeders, businesses should focus on product diversity, competitive pricing, and supplier reliability to ensure they can meet customer expectations and maintain inventory levels.

How Do Animal Shelters Improve Efficiency with Wet Food Feeders?

Animal shelters often face the challenge of feeding a large number of cats simultaneously, which can lead to food waste and inefficiencies. Best wet food feeders allow shelters to automate the feeding process, ensuring that each cat receives the right portion size while minimizing labor costs. Buyers should look for feeders that are durable, easy to program, and simple to maintain, as these features will enhance operational efficiency and ensure the well-being of the animals.

In What Ways Do Pet Training Centers Utilize Automatic Feeders?

Pet training centers can incorporate automatic wet food feeders into their training routines by establishing consistent feeding schedules that reinforce positive behaviors. These feeders help trainers manage portion control and can be programmed to dispense food at specific times, aiding in behavioral conditioning. Buyers in this sector should prioritize feeders that are versatile in their programmability and compatible with various types of wet food, as this will enhance the training experience for both pets and trainers.

3 Common User Pain Points for ‘best wet food feeder for cats’ & Their Solutions

Scenario 1: Difficulty in Maintaining Freshness of Wet Food

The Problem: B2B buyers frequently encounter challenges with wet food feeders that fail to keep food fresh for extended periods. This is particularly crucial for pet stores or veterinary clinics that want to ensure the quality of the food they provide. If a feeder does not maintain an optimal temperature, wet food can spoil quickly, leading to wasted inventory and dissatisfied customers. The challenge is compounded by the need for feeders that are not only efficient but also easy to clean, as stale food residue can lead to hygiene issues.

Illustrative image related to best wet food feeder for cats

The Solution: To tackle this issue, B2B buyers should prioritize wet food feeders equipped with advanced cooling features, such as built-in ice packs or refrigeration systems. When sourcing products, look for automatic feeders that explicitly state their ability to maintain food freshness for a specified duration, ideally up to three days. Additionally, consider feeders that allow for easy disassembly and cleaning to prevent bacterial growth. Suppliers should also provide clear guidelines on the optimal temperatures for storage and usage, helping businesses educate their customers on best practices for feeding their pets.

Scenario 2: Programming Complexities and User Experience

The Problem: Many automatic wet food feeders come with complex programming options that can be daunting for users, particularly those in retail environments where staff turnover may be high. B2B buyers often find that customers struggle to set feeding schedules correctly, leading to frustration and potential misuse of the product. A feeder that is difficult to operate can result in negative customer experiences and increased return rates, ultimately impacting the bottom line.

The Solution: When selecting wet food feeders, B2B buyers should look for models that feature user-friendly interfaces and straightforward programming options. Products with single-button programming or intuitive smartphone app integration can significantly enhance the user experience. Additionally, providing comprehensive training materials, such as video tutorials or easy-to-follow manuals, can empower staff and customers to utilize the feeders effectively. Retailers can also offer hands-on demonstrations in-store to familiarize customers with the product’s features, thus reducing the likelihood of errors in operation.

Scenario 3: Compatibility with Various Wet Food Types

The Problem: Another common pain point for B2B buyers is the compatibility of wet food feeders with different types of wet food. Many feeders are designed for specific food brands or consistencies, limiting their versatility. This can lead to inventory challenges, as businesses may need to stock multiple feeders to cater to various customer preferences, resulting in increased costs and complexity.

The Solution: To address compatibility issues, B2B buyers should prioritize feeders that are designed to accommodate a wide range of wet food types, including pouches, cans, and homemade blends. It is crucial to source products that explicitly state their versatility in food compatibility. Additionally, buyers should engage with suppliers who can provide detailed specifications on the feeder’s design, including bowl sizes and material compatibility, to ensure they meet customer needs. Offering a selection of feeders that can handle various food types not only simplifies inventory management but also enhances customer satisfaction by allowing pet owners to use their preferred brands without limitation.

Strategic Material Selection Guide for best wet food feeder for cats

What Materials Are Commonly Used in Wet Food Feeders for Cats?

When selecting materials for wet food feeders for cats, it is essential to consider their properties, suitability, and compliance with international standards. Here, we analyze four common materials: plastic, stainless steel, ceramic, and silicone.

How Does Plastic Perform in Wet Food Feeders?

Plastic is widely used in the manufacturing of wet food feeders due to its lightweight nature and cost-effectiveness. Common types include high-density polyethylene (HDPE) and polypropylene (PP).

Key Properties: Plastic is resistant to moisture and can withstand a range of temperatures, making it suitable for wet food. However, it may not endure extreme heat or cold as effectively as other materials.

Pros & Cons: The primary advantages of plastic include its low cost and ease of manufacturing, allowing for diverse shapes and designs. However, it can be less durable than metals or ceramics, potentially leading to cracking or fading over time. Additionally, some plastics may retain odors or stains from food.

Impact on Application: Plastic feeders are generally compatible with various wet food types but may require careful selection to avoid leaching harmful chemicals into the food.

Illustrative image related to best wet food feeder for cats

Considerations for International Buyers: Compliance with food safety standards like FDA regulations is crucial. In regions like Africa and South America, buyers should ensure that the plastics used are BPA-free and meet local health regulations.

What Are the Benefits of Using Stainless Steel in Cat Feeders?

Stainless steel is another popular choice for wet food feeders, known for its durability and resistance to corrosion.

Key Properties: Stainless steel can withstand high temperatures and is non-reactive, meaning it won’t impart any flavors to the food. It is also resistant to rust and staining, making it ideal for wet environments.

Illustrative image related to best wet food feeder for cats

Pros & Cons: The durability of stainless steel is a significant advantage, as it can last for years without degrading. However, it tends to be more expensive than plastic and may be heavier, which can be a consideration for shipping costs.

Impact on Application: Stainless steel feeders are suitable for all types of wet food and are easy to clean, making them a hygienic option. They are particularly beneficial in regions with high humidity, as they resist mold and bacteria growth.

Considerations for International Buyers: Buyers should look for compliance with international standards such as ASTM and ISO for food-grade materials. In Europe, adherence to EU regulations regarding food safety is essential.

Illustrative image related to best wet food feeder for cats

Why Choose Ceramic for Wet Food Feeders?

Ceramic feeders provide a stylish and functional option for pet owners who prioritize aesthetics and durability.

Key Properties: Ceramic is non-porous, which helps prevent bacterial growth and makes cleaning easy. It can also maintain temperature well, keeping food fresh for longer.

Pros & Cons: The visual appeal of ceramic feeders can attract buyers looking for attractive pet products. However, they are generally more fragile than plastic or stainless steel, making them susceptible to chipping or breaking.

Impact on Application: Ceramic is compatible with all types of wet food, but its weight can be a disadvantage if the feeder is tipped over by an enthusiastic cat.

Considerations for International Buyers: Buyers should ensure that the ceramic used is lead-free and complies with safety standards in their respective regions. In the Middle East and Africa, awareness of local regulations regarding ceramic materials is crucial.

How Does Silicone Enhance Wet Food Feeders?

Silicone is increasingly being used in feeder designs, particularly for mats or lids that enhance usability.

Key Properties: Silicone is flexible, durable, and resistant to extreme temperatures, making it an excellent material for various applications in wet food feeders.

Pros & Cons: The flexibility of silicone allows for unique designs and easy cleaning. However, it may not be suitable as a primary material for the feeder body due to its softness and potential for wear over time.

Illustrative image related to best wet food feeder for cats

Impact on Application: Silicone can be used effectively in conjunction with other materials to provide a non-slip surface or seal for wet food feeders.

Considerations for International Buyers: Buyers should ensure that silicone products are food-grade and meet relevant safety standards. Compliance with regulations in regions like Europe and South America is essential for market acceptance.

Summary Table of Material Selection for Wet Food Feeders

| Material | Typical Use Case for best wet food feeder for cats | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Budget-friendly feeders for wet food | Lightweight and cost-effective | Less durable; may retain odors | Low |

| Stainless Steel | Durable, hygienic feeders for all wet food types | High durability; resistant to corrosion | Higher cost; heavier | High |

| Ceramic | Aesthetic feeders for wet food | Non-porous; easy to clean | Fragile; can chip or break | Med |

| Silicone | Non-slip mats or lids for wet food feeders | Flexible; easy to clean | Not suitable for primary feeder body | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for best wet food feeder for cats

What Are the Main Stages in the Manufacturing Process of Wet Food Feeders for Cats?

The production of high-quality wet food feeders for cats involves several critical stages, each designed to ensure that the final product meets the functional and safety requirements of both pets and their owners. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Wet Food Feeders?

Material preparation is the foundational step in the manufacturing process. This includes sourcing high-quality, food-safe materials such as plastics (like ABS or polypropylene), stainless steel, and silicone. Suppliers must comply with international regulations regarding pet products, which often require materials to be non-toxic and resistant to wear and tear.

Once the materials are sourced, they undergo testing for compliance with relevant safety standards. This may include checking for harmful substances, verifying food safety certifications, and ensuring durability under various environmental conditions.

What Techniques Are Used in Forming Wet Food Feeders?

The forming stage typically involves molding processes such as injection molding or blow molding. Injection molding is commonly used for plastic components, where molten plastic is injected into a mold to create specific shapes. This method allows for high precision and repeatability, essential for components like food bowls and lids that must fit securely.

Illustrative image related to best wet food feeder for cats

For metal parts, processes like stamping or CNC machining are employed to create durable and accurately shaped components. These techniques ensure that parts can withstand repeated use and provide a reliable feeding mechanism.

How Is Assembly Conducted for Wet Food Feeders?

Assembly is a critical phase where individual components are brought together to create the final product. This process often involves automated assembly lines but may also include manual labor for more intricate parts. Quality control checkpoints are typically integrated throughout the assembly line to catch defects early.

During assembly, components such as timers, motors, and sensors are installed. It is crucial that these electronic components are assembled correctly to ensure functionality, particularly for feeders that rely on programmable features.

Illustrative image related to best wet food feeder for cats

What Finishing Processes Are Implemented for Wet Food Feeders?

Finishing processes enhance the aesthetic and functional properties of the feeders. This may include surface treatments like polishing, coating, or painting to improve durability and appeal. Additionally, any electronic components undergo final testing to ensure they operate correctly before the product is packaged for distribution.

What Quality Assurance Measures Are Essential for Wet Food Feeders?

Quality assurance (QA) is critical in the manufacturing of wet food feeders to ensure safety, reliability, and customer satisfaction. International standards such as ISO 9001 are often employed, alongside industry-specific certifications like CE marking or API (American Petroleum Institute) standards for products that might have electronic components.

How Are International Standards Incorporated into Quality Control?

ISO 9001 establishes a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Adopting this standard can significantly enhance a manufacturer’s credibility in international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

CE marking indicates that a product complies with EU safety, health, and environmental protection standards, which is particularly relevant for B2B buyers in Europe. Additionally, products may need to comply with local regulations in specific countries, requiring manufacturers to stay informed about various international standards.

What Are the Key Quality Control Checkpoints in Manufacturing Wet Food Feeders?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that every stage meets the required standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified quality standards before they enter the production process.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early. This may include checking dimensions, functionality of electronic components, and overall assembly integrity.

-

Final Quality Control (FQC): Once the product is assembled, a final inspection verifies that it meets all functional and aesthetic standards before packaging. This includes testing for durability, safety, and performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can be achieved through:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control practices, including results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes and product compliance with international standards.

What QC and Certification Nuances Should International B2B Buyers Be Aware Of?

When dealing with international suppliers, B2B buyers must navigate various certification and quality assurance nuances. This includes understanding the specific requirements of each region. For example, products sold in the EU may require CE marking, while those entering markets in Africa or South America may need to comply with local safety regulations.

Additionally, cultural differences in business practices can affect quality expectations and communication. Buyers should ensure that suppliers are not only compliant with international standards but also understand the specific needs of their target markets.

Conclusion

The manufacturing processes and quality assurance measures for wet food feeders for cats are critical to ensuring that products are safe, reliable, and appealing to consumers. B2B buyers should take an active role in understanding these processes and verifying supplier practices to ensure they are sourcing high-quality products that meet international standards. By focusing on these aspects, buyers can enhance their purchasing decisions and contribute to the success of their business in the competitive pet product market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best wet food feeder for cats’

To assist B2B buyers in sourcing the best wet food feeder for cats, this practical guide outlines essential steps to ensure a successful procurement process. Understanding the nuances of product selection and supplier evaluation is critical for making informed decisions that align with market demands and customer expectations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the wet food feeders you procure meet the unique needs of your target market. Consider factors such as capacity, material quality, and functionality. For instance, look for feeders that maintain food freshness, have programmable feeding schedules, and are easy to clean.

Step 2: Research Market Trends and Customer Preferences

Understanding market trends and customer preferences can significantly influence your purchasing decisions. Analyze sales data, customer reviews, and competitor offerings to identify popular features and designs. This will help you select products that resonate with consumers, such as smart feeders with app connectivity or feeders that accommodate multiple pets.

Step 3: Evaluate Potential Suppliers

Before finalizing any supplier, conduct thorough evaluations to gauge their reliability and product quality. Request comprehensive company profiles, including years in business, production capabilities, and client testimonials. It’s also beneficial to seek references from buyers within your region to assess their experiences with the supplier.

Step 4: Verify Supplier Certifications and Compliance

Ensuring that suppliers adhere to industry standards and regulations is crucial for maintaining product quality and safety. Check for certifications such as ISO 9001 for quality management systems or relevant safety standards for pet products. Compliance not only mitigates risks but also enhances your brand’s credibility in the market.

Step 5: Assess Pricing and Payment Terms

A competitive pricing structure is essential for maximizing profitability while remaining attractive to buyers. Request detailed quotes from multiple suppliers, considering factors such as bulk order discounts and shipping costs. Additionally, negotiate payment terms that align with your cash flow management strategies to facilitate smoother transactions.

Step 6: Request Samples for Testing

Before making a large order, request samples of the wet food feeders to evaluate their performance and quality firsthand. Assess key features such as ease of use, durability, and how well they maintain food freshness. Testing samples allows you to make informed decisions and ensure that the products meet your specifications.

Step 7: Plan for After-Sales Support and Warranty

After securing a supplier, ensure that they offer robust after-sales support and warranty options. This is crucial for addressing any potential issues that may arise post-purchase. Understand the terms of the warranty, including coverage duration and conditions, as this will enhance customer satisfaction and reinforce your brand reputation.

By following these steps, B2B buyers can effectively navigate the sourcing process for wet food feeders for cats, ensuring they select high-quality products that meet market demands and foster long-term business success.

Comprehensive Cost and Pricing Analysis for best wet food feeder for cats Sourcing

What Are the Key Cost Components in Sourcing Wet Food Feeders for Cats?

When considering the sourcing of wet food feeders for cats, it’s crucial to understand the cost structure involved. The primary components include:

Illustrative image related to best wet food feeder for cats

-

Materials: The choice of materials significantly impacts the overall cost. Feeders made from high-quality plastics, stainless steel, or food-grade silicone may incur higher upfront costs but offer greater durability and hygiene, which can appeal to health-conscious consumers.

-

Labor: Labor costs can vary based on the location of manufacturing. Regions with lower labor costs can offer competitive pricing, but it’s essential to ensure that quality isn’t compromised. Skilled labor in assembly or programming for advanced feeders can also influence costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient factories that optimize production processes can keep these costs lower, ultimately affecting pricing for buyers.

-

Tooling: Custom designs or specific features, like programmable timers or microchip compatibility, require specialized tooling. This initial investment can raise prices but may be necessary for differentiation in the market.

-

Quality Control (QC): Implementing strict QC measures ensures that products meet safety and performance standards. While this adds to costs, it enhances brand reputation and customer satisfaction, which can lead to repeat orders.

-

Logistics: Shipping and handling costs are significant, especially for international buyers. Factors such as distance, shipping method, and customs duties can add substantial amounts to the final price.

-

Margin: Suppliers typically add a markup to cover their expenses and profit. Understanding the expected margin can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Wet Food Feeders?

Several factors influence the pricing of wet food feeders:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often results in lower unit prices. Establishing a strong relationship with suppliers can provide leverage for negotiating better terms.

-

Specifications/Customization: Custom features, such as unique designs or specific functionalities, can increase costs. Buyers should assess whether these features provide sufficient value to justify the added expense.

-

Materials: Premium materials may enhance product longevity and safety but at a higher cost. Buyers must balance quality with budget constraints.

-

Quality and Certifications: Certifications (e.g., ISO, CE) can assure buyers of product safety and reliability, impacting pricing. Suppliers that invest in certifications may charge higher prices.

-

Supplier Factors: The reputation and reliability of suppliers can influence costs. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect overall pricing.

What Are the Best Practices for International B2B Buyers to Negotiate Costs?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing and quality levels. This knowledge equips buyers to negotiate confidently.

-

Leverage Total Cost of Ownership (TCO): Consider long-term costs, including maintenance, shipping, and potential returns, rather than focusing solely on initial purchase price. This approach can justify higher upfront costs for more durable products.

-

Flexibility in Specifications: Being open to slight modifications in product specifications can provide room for cost reductions. Suppliers may have excess inventory or different production capabilities that can be leveraged.

-

Build Relationships: Establishing a strong relationship with suppliers can facilitate better pricing and terms. Regular communication and mutual understanding can lead to long-term partnerships.

-

Negotiate Payment Terms: Favorable payment terms can help manage cash flow. Propose installment payments or extended payment periods to ease financial pressure.

Disclaimer on Indicative Prices

Prices for wet food feeders can fluctuate based on market conditions, supplier negotiations, and changes in material costs. It is essential for buyers to obtain updated quotes from suppliers to ensure accuracy and relevance to current market conditions.

Alternatives Analysis: Comparing best wet food feeder for cats With Other Solutions

Exploring Alternative Solutions for Cat Feeding

In the realm of pet care, particularly for cat owners, ensuring proper feeding practices is crucial. While the best wet food feeder for cats offers a reliable and convenient solution, it’s valuable to explore alternative methods that can also meet the needs of both cats and their owners. This comparison analyzes the wet food feeder against two viable alternatives: traditional feeding methods and automated dry food dispensers.

Illustrative image related to best wet food feeder for cats

Comparison Table

| Comparison Aspect | Best Wet Food Feeder For Cats | Traditional Feeding Methods | Automated Dry Food Dispensers |

|---|---|---|---|

| Performance | Provides scheduled, fresh meals; keeps wet food from spoiling | Dependent on owner’s presence; risk of spoilage if left unattended | Dispenses dry food at set intervals; less spoilage risk |

| Cost | Typically ranges from $30 to $150 | Low initial cost (food bowls) | Ranges from $50 to $150 |

| Ease of Implementation | Requires setup and occasional maintenance | Simple and straightforward; no technology needed | Requires initial setup and programming |

| Maintenance | Needs regular cleaning and ice pack management | Minimal maintenance; just need to refill food and water | Needs occasional cleaning; requires battery changes or power source |

| Best Use Case | Ideal for owners who work long hours or travel frequently | Best for those at home who prefer direct feeding | Suitable for owners wanting to control portion sizes without human intervention |

Detailed Breakdown of Alternatives

Traditional Feeding Methods

Traditional feeding methods involve using standard bowls to provide food and water for cats. This method is cost-effective and simple, making it accessible for all cat owners. However, it requires the owner to be present to refill food and water, which can lead to spoilage of wet food if left out too long. This approach is best for owners who are home frequently and can manage feeding times directly.

Automated Dry Food Dispensers

Automated dry food dispensers offer a modern solution for feeding cats. These devices allow for scheduled feeding and portion control, making them ideal for pet owners who want to ensure their cat receives the right amount of food without needing to be present. However, they can only dispense dry food, which may not meet the dietary needs of all cats. Additionally, initial setup can be slightly more complicated compared to traditional feeding methods, and they require regular maintenance to keep clean and functional.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate feeding solution for cats, B2B buyers must consider several factors, including the specific needs of their clientele, the dietary requirements of the cats, and the lifestyle of the cat owners. The best wet food feeder is particularly advantageous for those who need to manage feeding schedules while ensuring food freshness. In contrast, traditional methods may appeal to budget-conscious owners who prefer simplicity, while automated dry food dispensers can attract tech-savvy customers looking for convenience. Ultimately, the choice should align with the target market’s preferences and the specific use cases each solution addresses.

Essential Technical Properties and Trade Terminology for best wet food feeder for cats

What are the Critical Technical Properties of the Best Wet Food Feeder for Cats?

When selecting the best wet food feeders for cats, several technical specifications are crucial for ensuring product quality, reliability, and suitability for various market needs.

Illustrative image related to best wet food feeder for cats

-

Material Grade

The materials used in wet food feeders must be durable, non-toxic, and easy to clean. Common materials include food-grade plastic, stainless steel, and silicone. Each material has its benefits: stainless steel is resistant to odors and bacteria, while silicone offers flexibility and ease of cleaning. B2B buyers should prioritize feeders made from high-quality materials to ensure safety and longevity. -

Capacity

The capacity of the feeder refers to how much wet food it can hold, typically measured in cups or liters. A larger capacity is advantageous for buyers catering to multi-cat households or for those who want to reduce the frequency of refills. Understanding capacity helps businesses assess if the product meets the demands of their target market, especially in regions where consumers may prefer bulk feeding solutions. -

Dispensing Mechanism

The mechanism by which the feeder dispenses food can vary. Options include gravity-fed, timed dispensers, and those with sensors to detect when a cat is present. Each mechanism has different implications for ease of use and maintenance. B2B buyers should consider the target consumer’s lifestyle, as some may prefer advanced technology for convenience while others may value simplicity. -

Programmability and Scheduling

Advanced feeders often come with programmable settings that allow users to schedule feeding times and portions. This feature is particularly important for busy pet owners who want to ensure their cats are fed at regular intervals. Buyers should evaluate the ease of programming and the flexibility of the scheduling options to cater to diverse consumer needs. -

Power Source

Most automatic feeders are powered either by batteries or electrical outlets. Battery-operated models offer portability, while electric models often come with more advanced features. Understanding the power source is essential for B2B buyers to recommend products that fit their customers’ preferences and situations.

What are the Common Trade Terminology and Jargon in the Wet Food Feeder Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products based on another company’s specifications. In the context of wet food feeders, OEMs may create feeders for brands that wish to sell them under their own name. B2B buyers should understand OEM relationships to ensure product quality and branding alignment. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is vital for B2B transactions, as it impacts inventory management and initial investment costs. Buyers must negotiate MOQs that align with their business plans and market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. B2B buyers should use RFQs to gather detailed information on costs, lead times, and payment terms, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) specify who bears the costs and risks during shipping. Understanding Incoterms is crucial for B2B buyers to negotiate shipping terms effectively and manage logistics. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. It includes manufacturing and shipping durations. For B2B buyers, understanding lead times is essential for planning inventory and ensuring timely product availability.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing wet food feeders for cats, ensuring they meet market demands and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the best wet food feeder for cats Sector

What Are the Current Market Dynamics and Key Trends in the Best Wet Food Feeder for Cats Sector?

The global market for wet food feeders for cats is experiencing significant growth, driven by several factors, including increasing pet ownership, a rising focus on pet health, and advancements in pet technology. In regions such as Africa, South America, the Middle East, and Europe, demand for innovative pet products is on the rise, fueled by changing consumer lifestyles and the growing trend of pet humanization. International B2B buyers are particularly interested in automatic feeders that can dispense wet food, as they offer convenience and ensure a controlled feeding schedule for pets, which is essential for pet owners who travel or work long hours.

Illustrative image related to best wet food feeder for cats

Emerging technologies in this sector include smart feeders equipped with app connectivity, allowing pet owners to manage feeding times and portion sizes remotely. Such innovations are appealing to tech-savvy consumers who prioritize convenience and efficiency. Furthermore, the integration of sustainability into product design is becoming a key trend, with manufacturers increasingly focusing on eco-friendly materials and energy-efficient technologies. The market is also seeing a shift toward customizable feeding options, accommodating diverse dietary needs and preferences among cats, which is particularly relevant for B2B buyers catering to niche markets.

How Important Is Sustainability and Ethical Sourcing for B2B Buyers in the Wet Food Feeder Market?

As environmental concerns gain traction globally, sustainability and ethical sourcing have become paramount for B2B buyers in the wet food feeder sector. Manufacturers are increasingly held accountable for their environmental impact, prompting a focus on sustainable production practices. This includes utilizing recyclable or biodegradable materials for feeder construction and packaging, which appeals to environmentally conscious consumers.

Ethical supply chains are also critical, as buyers seek transparency in sourcing materials and production processes. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems can enhance a product’s appeal in the marketplace. B2B buyers are encouraged to partner with suppliers who prioritize ethical practices, as this not only mitigates risks associated with environmental regulations but also aligns with consumer demand for socially responsible products.

In addition, incorporating ‘green’ certifications into product offerings can provide a competitive edge. As pet owners become more discerning about their purchases, offering sustainable options can enhance brand loyalty and drive sales in a crowded marketplace.

How Has the Wet Food Feeder Market Evolved Over Time?

The evolution of the wet food feeder market reflects broader trends in pet care and technology. Initially, feeders were simple manual devices, primarily designed for dry food. However, as consumer preferences shifted toward wet food, particularly for its nutritional benefits, the market adapted by introducing automatic feeders that accommodate wet options.

The introduction of programmable and app-controlled feeders marks a significant advancement, allowing for precise feeding schedules and portion control, which cater to modern pet owners’ needs. The growth of e-commerce has also transformed how these products are marketed and sold, enabling international buyers to access a wider range of options.

Overall, the wet food feeder market continues to evolve, driven by innovation, consumer demand for convenience, and a growing emphasis on sustainability. This dynamic landscape presents numerous opportunities for B2B buyers to engage with suppliers who align with these trends, ensuring they remain competitive in a fast-changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of best wet food feeder for cats

-

How do I select the best wet food feeder for my business needs?

When choosing a wet food feeder, consider factors such as the feeder’s capacity, compatibility with various wet food types, and ease of cleaning. Evaluate the features that align with your target market’s preferences, such as programmable settings, portion control, and durability. Additionally, assess supplier reliability and product reviews to ensure the feeder meets quality standards. It’s also crucial to consider logistics and shipping costs, particularly if sourcing from international suppliers. -

What types of automatic wet food feeders are available in the market?

There are several types of automatic wet food feeders, including dish-style feeders, programmable feeders, and gravity-based options. Dish-style feeders are ideal for wet food as they can accommodate multiple compartments for different meals. Programmable feeders offer flexibility in meal timing and portion sizes, while gravity feeders are more straightforward and budget-friendly but less suitable for wet food. Understanding these types will help you match products to the specific needs of your customers. -

What are the key features to look for in a wet food feeder?

Essential features to consider include programmable meal schedules, portion control, built-in ice packs for food freshness, and compatibility with various wet food types. Additionally, look for feeders with stainless steel or easy-to-clean materials to ensure hygiene and durability. User-friendly interfaces and reliable customer support from suppliers are also critical factors, as they can significantly impact the end-user experience. -

How can I ensure the quality of wet food feeders from suppliers?

To ensure quality, vet suppliers by checking their certifications, product samples, and customer reviews. Request information about their manufacturing processes, quality assurance protocols, and any relevant safety standards they adhere to. Consider visiting their facilities if feasible or using third-party inspection services to validate product quality before placing bulk orders. -

What is the typical minimum order quantity (MOQ) for wet food feeders?

MOQs for wet food feeders can vary widely depending on the manufacturer and product type. Generally, you might encounter MOQs ranging from 50 to 500 units. It’s essential to communicate your requirements clearly with potential suppliers, as some may offer flexibility based on your specific needs or the potential for future orders. Always negotiate terms that align with your business strategy. -

What payment terms are commonly offered by suppliers?

Payment terms can differ significantly among suppliers. Common arrangements include full payment upfront, a deposit with the balance due before shipment, or net payment terms allowing payment after delivery. It’s advisable to establish clear payment terms during negotiations to ensure cash flow management. Additionally, consider using secure payment methods that offer buyer protection, especially for international transactions. -

How should I approach logistics and shipping for wet food feeders?

When planning logistics, evaluate shipping costs, delivery times, and the reliability of shipping partners. For international trade, consider customs regulations and import duties that may affect your overall costs. Working with a freight forwarder can simplify the process, ensuring compliance with local laws. Additionally, explore options for bulk shipping to minimize costs and maximize efficiency. -

What are the typical lead times for ordering wet food feeders?

Lead times for wet food feeders can vary based on factors such as supplier location, manufacturing capacity, and order size. Typically, you can expect lead times ranging from 4 to 12 weeks for international orders. Always confirm lead times with your supplier before placing an order, and consider building in extra time for potential delays in shipping or customs clearance, especially when sourcing from overseas.

Top 1 Best Wet Food Feeder For Cats Manufacturers & Suppliers List

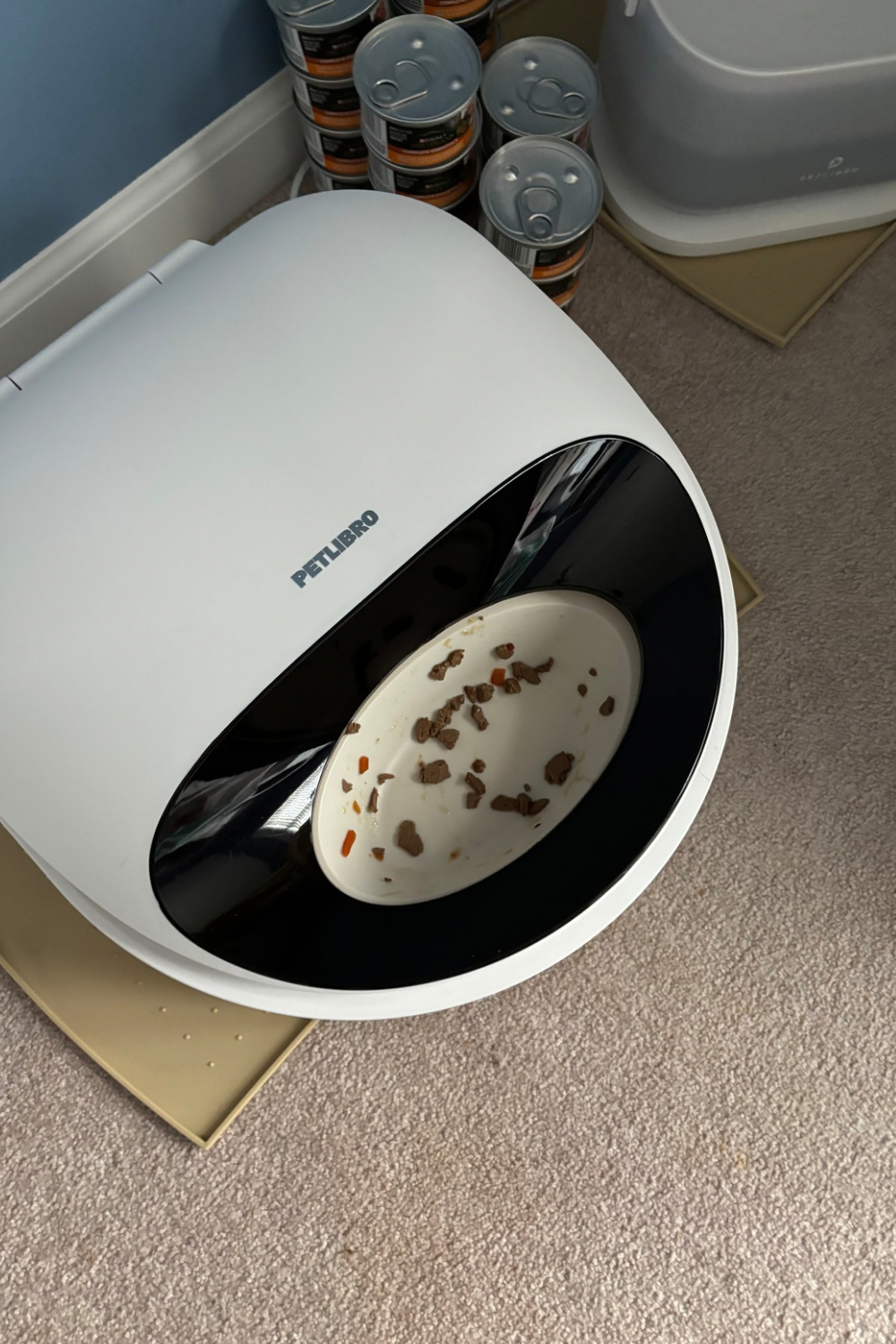

1. Petlibro – Automatic Pet Feeders

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro includes various models such as Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Air Smart Feeder. Key features include RFID pet recognition, app control, vacuum sealing technology, and camera monitoring. Capacities range from 2L to 8L. Prices vary from under $50 to over $100, with options for bundles and discounts. Free shippin…

Strategic Sourcing Conclusion and Outlook for best wet food feeder for cats

In the evolving landscape of pet care, the strategic sourcing of automatic wet food feeders for cats represents a vital opportunity for international B2B buyers. Key takeaways highlight the importance of selecting feeders that not only accommodate various types of wet food but also maintain freshness and portion control. Buyers should prioritize models that offer programmable features, versatility, and reliable performance, ensuring they meet the diverse needs of pet owners across different regions.

Illustrative image related to best wet food feeder for cats

The value of strategic sourcing in this sector cannot be overstated. By choosing high-quality products from reputable suppliers, businesses can enhance customer satisfaction and foster loyalty, which is essential in a competitive market. Furthermore, understanding regional preferences and market trends will enable suppliers to tailor their offerings effectively, maximizing both reach and profitability.

Looking ahead, the demand for innovative and efficient pet feeding solutions is set to grow. B2B buyers are encouraged to explore partnerships with manufacturers that prioritize quality and technology. By doing so, they can stay ahead of market trends and better serve the pet-owning community, particularly in fast-growing markets across Africa, South America, the Middle East, and Europe. Embrace this opportunity to lead in the pet care industry by sourcing the best solutions for your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to best wet food feeder for cats

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.