Introduction: Navigating the Global Market for biofilm dog bowl

In the ever-evolving landscape of pet care, sourcing biofilm dog bowls presents a significant challenge for international B2B buyers. Biofilm—a complex microbial community that thrives in pet food and water bowls—poses health risks not only to our furry companions but also to humans, particularly in regions where hygiene standards may vary. This comprehensive guide addresses the critical aspects of biofilm dog bowls, including types, applications, supplier vetting processes, and cost considerations.

By delving into the nuances of biofilm formation and its implications, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—to make informed purchasing decisions. It equips businesses with the knowledge to identify high-quality products that mitigate biofilm risks and enhance pet health.

Moreover, our insights on supplier selection and market trends will facilitate effective sourcing strategies, ensuring that buyers can secure reliable, hygienic solutions for their customers. As the global market for pet products continues to expand, understanding the challenges posed by biofilm will be essential for maintaining a competitive edge and fostering customer trust in the pet care industry.

Table Of Contents

- Top 1 Biofilm Dog Bowl Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for biofilm dog bowl

- Understanding biofilm dog bowl Types and Variations

- Key Industrial Applications of biofilm dog bowl

- 3 Common User Pain Points for ‘biofilm dog bowl’ & Their Solutions

- Strategic Material Selection Guide for biofilm dog bowl

- In-depth Look: Manufacturing Processes and Quality Assurance for biofilm dog bowl

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘biofilm dog bowl’

- Comprehensive Cost and Pricing Analysis for biofilm dog bowl Sourcing

- Alternatives Analysis: Comparing biofilm dog bowl With Other Solutions

- Essential Technical Properties and Trade Terminology for biofilm dog bowl

- Navigating Market Dynamics and Sourcing Trends in the biofilm dog bowl Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of biofilm dog bowl

- Strategic Sourcing Conclusion and Outlook for biofilm dog bowl

- Important Disclaimer & Terms of Use

Understanding biofilm dog bowl Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Biofilm Bowls | Lightweight, cost-effective, often colorful | Pet supply retailers, budget-conscious buyers | Pros: Affordable, easy to handle; Cons: Prone to scratches, absorb odors and bacteria. |

| Stainless Steel Bowls | Durable, dishwasher-safe, resistant to bacteria | Veterinary clinics, high-end pet stores | Pros: Long-lasting, easy to clean; Cons: Higher initial cost compared to plastic. |

| Ceramic Pet Bowls | Aesthetic appeal, heavy, non-porous surface | Boutique pet shops, premium pet brands | Pros: Attractive designs, resistant to bacteria; Cons: Fragile, can chip or break. |

| Automated Pet Feeders | Incorporates technology for portion control and hygiene | E-commerce platforms, pet technology vendors | Pros: Reduces food waste, minimizes biofilm; Cons: Higher price point, requires power source. |

| Pet Water Fountains | Continuous water flow, often with filtration systems | Pet specialty stores, online retailers | Pros: Keeps water fresh, reduces biofilm growth; Cons: Requires regular maintenance and cleaning. |

What Are the Characteristics of Plastic Biofilm Bowls?

Plastic biofilm bowls are often the most affordable option on the market, making them attractive for budget-conscious buyers. They come in a variety of colors and designs, appealing to a wide range of pet owners. However, their lightweight nature makes them prone to scratches, which can harbor bacteria and odors over time. For B2B buyers, these bowls are suitable for retailers targeting cost-sensitive customers but should be paired with education on proper cleaning practices to mitigate biofilm risks.

Why Choose Stainless Steel Bowls for Dogs?

Stainless steel bowls are favored for their durability and resistance to biofilm formation. They can withstand high temperatures in dishwashers, making them easy to sanitize, which is crucial for maintaining pet health. These bowls are ideal for veterinary clinics and high-end pet stores where quality and hygiene are paramount. While they come at a higher price, the long-term benefits of durability and ease of cleaning make them a worthwhile investment for B2B buyers.

What Benefits Do Ceramic Pet Bowls Offer?

Ceramic pet bowls are known for their aesthetic appeal, often featuring unique designs that attract pet owners looking for stylish options. The non-porous surface of ceramic helps in resisting bacterial growth, making them a safer choice for pets. They are suitable for boutique pet shops and premium brands. However, their fragility is a concern, as they can chip or break easily, which may deter some buyers from stocking them.

How Do Automated Pet Feeders Reduce Biofilm?

Automated pet feeders are designed to dispense precise portions of food, which not only minimizes food waste but also helps in reducing the buildup of biofilm. These feeders are increasingly popular among tech-savvy pet owners and can be marketed through e-commerce platforms. While they come with a higher price point, their convenience and hygiene benefits make them appealing for B2B buyers who cater to modern pet owners.

Why Are Pet Water Fountains Essential for Pet Health?

Pet water fountains provide a continuous flow of fresh water, which is essential for reducing biofilm accumulation. Many models come equipped with filtration systems that further enhance water quality. These products are ideal for pet specialty stores and online retailers focusing on pet health. However, they require regular maintenance and cleaning, which should be communicated to buyers to ensure they understand the long-term care needed for optimal performance.

Key Industrial Applications of biofilm dog bowl

| Industry/Sector | Specific Application of biofilm dog bowl | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Use in patient recovery areas for feeding and hydration | Reduces risk of infection post-surgery; enhances pet recovery | Ensure bowls are easy to clean and made from non-porous materials |

| Pet Supply Retail | Retailing biofilm-resistant dog bowls | Appeals to health-conscious pet owners; differentiates product offerings | Source from manufacturers with proven biofilm prevention technology |

| Animal Shelters | Feeding bowls for rescued animals | Promotes animal health and hygiene; reduces veterinary costs | Consider bulk purchasing options and sustainability of materials |

| Pet Grooming Services | Bowls used during grooming sessions | Enhances customer experience; promotes hygiene and safety | Look for bowls that are durable and easy to sanitize |

| Pet Boarding Facilities | Water and food bowls for boarding pets | Ensures cleanliness and reduces health risks; boosts customer trust | Evaluate supplier reliability and product certifications |

How Can Veterinary Clinics Benefit from Biofilm Dog Bowls?

Veterinary clinics can utilize biofilm dog bowls in recovery areas, ensuring pets receive clean food and water post-surgery. This application helps mitigate the risk of post-operative infections, which is crucial for patient recovery. Clinics should prioritize sourcing bowls that are easy to clean and made from non-porous materials to prevent biofilm accumulation. International buyers, particularly in regions with varying access to veterinary supplies, must consider suppliers who provide reliable, high-quality products that meet health standards.

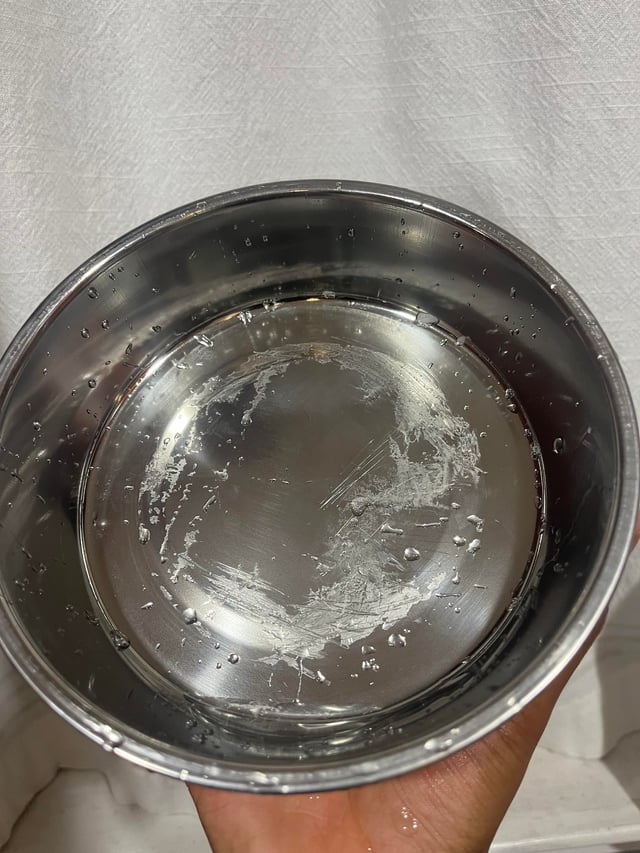

Illustrative image related to biofilm dog bowl

What Advantages Do Pet Supply Retailers Gain from Selling Biofilm-Resistant Bowls?

Pet supply retailers can enhance their offerings by stocking biofilm-resistant dog bowls, appealing to health-conscious pet owners. These products not only provide a unique selling point but also help in building customer loyalty by promoting pet health and safety. Retailers should seek manufacturers that have demonstrated effectiveness in biofilm prevention technologies. This is especially important for international buyers who need to ensure compliance with local health regulations.

Why Are Animal Shelters Prioritizing Biofilm Dog Bowls?

Animal shelters increasingly recognize the importance of using biofilm dog bowls to promote the health and hygiene of rescued animals. Clean feeding bowls reduce the risk of infections and veterinary costs, ultimately improving the welfare of the animals. Shelters should consider bulk purchasing options to manage costs effectively and look for environmentally sustainable materials in their sourcing decisions. International buyers should also evaluate the logistics of sourcing to ensure timely delivery and compliance with local regulations.

How Do Pet Grooming Services Enhance Client Experience with Biofilm Dog Bowls?

Pet grooming services can use biofilm dog bowls during grooming sessions to enhance the overall customer experience. Providing clean, hygienic feeding options helps to ensure the safety of pets while they are in care. Groomers should look for durable bowls that are easy to sanitize, allowing for quick transitions between clients. International buyers must consider the availability of these products in their regions and the reliability of suppliers to maintain consistent service quality.

What Role Do Biofilm Dog Bowls Play in Pet Boarding Facilities?

In pet boarding facilities, biofilm dog bowls are essential for providing clean water and food to pets during their stay. This application helps ensure a hygienic environment, reducing health risks and enhancing customer trust in the facility’s operations. Boarding facilities should evaluate suppliers based on product durability and ease of sanitation, as well as the ability to meet specific local health and safety standards. International buyers must also consider logistical aspects to ensure a steady supply of these essential products.

3 Common User Pain Points for ‘biofilm dog bowl’ & Their Solutions

Scenario 1: Concerns About Health Risks from Biofilm in Dog Bowls

The Problem: B2B buyers, particularly those in the pet care industry, face significant challenges regarding the health risks associated with biofilm buildup in dog bowls. Biofilm can harbor harmful bacteria such as E. coli and Salmonella, posing threats not only to pets but also to humans, especially in environments like veterinary clinics, pet hotels, and grooming facilities. The presence of these pathogens can lead to severe health issues, resulting in costly liabilities and damage to a business’s reputation.

The Solution: To mitigate these health risks, B2B buyers should prioritize sourcing biofilm-resistant dog bowls made from materials such as stainless steel or ceramic, which are less prone to harboring bacteria compared to plastic. Additionally, implementing a strict cleaning protocol that involves regular sanitization of dog bowls with pet-safe disinfectants is crucial. Buyers can establish a routine where bowls are washed daily, and disinfected using specialized cleaning solutions designed to break down biofilm, thus ensuring a safe feeding environment for dogs. Investing in automated pet feeders that dispense fresh food can further minimize the risk of biofilm formation, creating a healthier experience for pets and peace of mind for business owners.

Scenario 2: Difficulty in Educating Staff on Proper Bowl Hygiene

The Problem: Many businesses struggle with ensuring that staff are adequately trained on the importance of maintaining proper hygiene for dog bowls. Without a consistent approach to cleaning and sanitizing these bowls, biofilm can quickly accumulate, leading to potential health hazards. This lack of knowledge can result in increased turnover rates and dissatisfaction among pet owners who expect high standards of cleanliness in pet care facilities.

The Solution: To address this training gap, B2B buyers should develop comprehensive training programs focused on the importance of biofilm prevention in dog bowls. This can include workshops, written guidelines, and visual aids that demonstrate proper cleaning techniques and the frequency of sanitization required. Providing staff with high-quality cleaning tools and pet-safe disinfectants will empower them to maintain hygiene effectively. Additionally, implementing a checklist system for daily cleaning tasks can foster accountability and ensure that no steps are overlooked, thereby enhancing the overall health standards of the facility.

Scenario 3: Managing Inventory of Pet Bowls to Prevent Biofilm Build-Up

The Problem: B2B buyers often face inventory management issues related to pet bowls, particularly in ensuring that there is a sufficient supply of clean, biofilm-resistant options readily available. Inconsistent inventory can lead to the use of older or less hygienic bowls, increasing the risk of biofilm accumulation and jeopardizing pet health. This situation can also lead to financial losses due to increased vet bills or reputational damage from unsatisfied customers.

The Solution: To effectively manage inventory, businesses should implement a systematic approach to track the usage and condition of dog bowls. Utilizing inventory management software can help monitor the quantity and quality of bowls, ensuring that biofilm-resistant options are always in stock. Establishing a rotation system where bowls are cycled out regularly for deep cleaning will also help maintain hygiene standards. Additionally, forming partnerships with suppliers who offer bulk discounts on high-quality, biofilm-resistant bowls can ensure that businesses are never caught short, allowing them to provide a consistently safe environment for pets. Regular assessments of bowl condition and timely replacement of older bowls will further bolster pet health and customer satisfaction.

Strategic Material Selection Guide for biofilm dog bowl

What Are the Key Properties of Common Materials for Biofilm Dog Bowls?

When selecting materials for biofilm dog bowls, it is essential to consider properties such as temperature resistance, corrosion resistance, and overall durability. The right material can significantly impact the bowl’s performance, longevity, and hygiene.

How Do Different Materials Compare for Biofilm Dog Bowls?

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it suitable for both hot and cold food. It is also non-porous, which helps prevent bacterial growth.

Pros & Cons: Stainless steel bowls are highly durable and resistant to scratches, which is crucial for preventing biofilm accumulation. However, they can be more expensive than plastic options and may not be as aesthetically pleasing to some consumers.

Illustrative image related to biofilm dog bowl

Impact on Application: Stainless steel is compatible with a variety of media, including wet and dry foods. Its non-porous nature minimizes the risk of biofilm formation, thus promoting better pet health.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe may prioritize stainless steel bowls due to their hygienic properties, while those in Africa and South America might consider cost-effectiveness.

2. Ceramic

Key Properties: Ceramic bowls are typically heavy and stable, offering good resistance to chipping and scratching. They can withstand moderate temperature changes but may crack under extreme conditions.

Pros & Cons: Ceramic bowls are visually appealing and come in various designs, making them popular among pet owners. However, they can be fragile and may require more careful handling during manufacturing and shipping.

Impact on Application: Ceramic bowls are suitable for both food and water but may require more frequent cleaning to prevent biofilm buildup due to their porous nature.

Considerations for International Buyers: In regions like the Middle East and Europe, ceramic bowls may be favored for their aesthetic appeal. Buyers should ensure that the ceramics meet local safety standards to avoid lead contamination.

3. Plastic

Key Properties: Plastic bowls are lightweight and inexpensive, making them a popular choice for many pet owners. However, they can absorb odors and stains, which can lead to biofilm formation.

Pros & Cons: While plastic bowls are cost-effective and available in various colors and designs, they are less durable than stainless steel or ceramic options. Over time, they may warp or scratch, making them more susceptible to bacterial growth.

Impact on Application: Plastic bowls are generally suitable for dry food but may not be ideal for wet food due to their propensity to harbor bacteria.

Considerations for International Buyers: Buyers in developing regions may prefer plastic for its affordability, but they should be cautious about the quality and safety of the materials used, ensuring compliance with relevant standards.

4. Glass

Key Properties: Glass bowls are non-porous and easy to clean, offering excellent resistance to staining and odors. They can handle a wide range of temperatures without degrading.

Illustrative image related to biofilm dog bowl

Pros & Cons: Glass is highly durable and aesthetically pleasing, but it can be heavy and prone to breaking. Additionally, the manufacturing process can be more complex compared to plastic.

Impact on Application: Glass bowls are suitable for both food and water and are less likely to harbor biofilm due to their smooth surface.

Considerations for International Buyers: European buyers may favor glass for its hygienic properties, while buyers from regions with high transportation risks should consider the fragility of glass during shipping.

Summary Table of Material Selection for Biofilm Dog Bowls

| Material | Typical Use Case for biofilm dog bowl | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and water bowls | Excellent durability and hygiene | Higher cost than plastic | High |

| Ceramic | Aesthetic food and water bowls | Attractive designs | Fragile, can crack | Medium |

| Plastic | Budget-friendly food and water bowls | Lightweight and inexpensive | Prone to scratches and odors | Low |

| Glass | Premium food and water bowls | Non-porous, easy to clean | Heavy and breakable | Medium |

This guide provides B2B buyers with a comprehensive overview of the materials available for biofilm dog bowls, enabling informed decisions that align with their market needs and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for biofilm dog bowl

What Are the Main Stages of Manufacturing a Biofilm Dog Bowl?

Manufacturing biofilm dog bowls involves several critical stages to ensure that the final product is effective, durable, and safe for pets. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for Biofilm Dog Bowls?

The first step in the manufacturing process is selecting the right materials. Biofilm dog bowls are typically made from a variety of materials, including stainless steel, glass, ceramics, and high-quality plastics. Each material has its advantages in terms of biofilm resistance, durability, and ease of cleaning.

-

Stainless Steel: Known for its resistance to bacteria, stainless steel bowls are durable and can withstand high temperatures during cleaning. They are less likely to harbor biofilm compared to plastic.

-

Ceramics: These bowls offer aesthetic appeal and are easy to clean. However, they must be glazed properly to prevent the absorption of odors and bacteria.

-

Plastics: While lightweight and cost-effective, plastic bowls can absorb odors and are more prone to biofilm accumulation. Manufacturers often use high-density polyethylene (HDPE) or polypropylene, which are less susceptible to microbial growth.

Forming: How Are Biofilm Dog Bowls Shaped?

Once the materials are prepared, they undergo the forming process. This can involve techniques such as injection molding for plastics, casting for ceramics, or stamping for metals.

-

Injection Molding: Common for plastic bowls, this technique allows for high precision and the production of complex shapes. It also ensures uniform thickness, which is crucial for maintaining the structural integrity of the bowl.

-

Casting: For ceramics, the material is poured into molds and fired in kilns. This process can enhance the bowl’s resistance to biofilm if done correctly.

-

Stamping: Stainless steel bowls are often stamped out of sheets of metal, followed by processes like welding or seam sealing to ensure there are no gaps where biofilm can develop.

Assembly: How Are the Components Joined?

In the assembly stage, various components may be joined together. For instance, some bowls may come with detachable bases or non-slip rings. Quality assembly is crucial as any gaps or poor joins can lead to accumulation points for biofilm.

-

Welding and Sealing: For metal bowls, welding techniques ensure that seams are tight and secure, minimizing the risk of biofilm formation.

-

Adhesives: For plastic or ceramic bowls, high-quality adhesives may be used to bond different parts. These adhesives should be non-toxic and safe for pets.

Finishing: What Final Touches Are Applied?

The final stage of manufacturing involves finishing processes such as polishing, glazing, or coating. These steps enhance the aesthetic appeal and functionality of the bowls.

-

Polishing: Stainless steel bowls are polished to a smooth finish, reducing the likelihood of bacterial adherence.

-

Glazing: Ceramic bowls receive a glaze that not only provides color but also seals the surface, making it less porous and easier to clean.

-

Coatings: Some manufacturers may apply antimicrobial coatings to plastic bowls to further inhibit biofilm growth.

What Are the Quality Assurance Protocols for Biofilm Dog Bowls?

Quality assurance is critical in the production of biofilm dog bowls, particularly given the health risks associated with biofilm. Adhering to international standards ensures product safety and effectiveness.

Which International Standards Are Relevant?

Manufacturers of biofilm dog bowls should comply with various international standards such as:

-

ISO 9001: This standard outlines quality management principles that ensure consistent product quality and customer satisfaction. Certification can be a key indicator of a manufacturer’s commitment to quality.

-

CE Marking: In Europe, products must meet specific safety and health requirements. The CE mark indicates compliance with EU regulations, which is especially important for pet products.

-

API Standards: Although primarily for petroleum and natural gas, some API standards may apply to materials used in bowl production, ensuring that they are safe and non-toxic.

What Are the Key Quality Control Checkpoints?

Quality control (QC) should be integrated into every stage of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process. This includes checks for dimensional accuracy and adherence to design specifications.

-

Final Quality Control (FQC): Before products are packaged and shipped, a thorough inspection ensures that each bowl meets quality standards. This may involve testing for durability, resistance to biofilm, and overall safety.

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the quality of biofilm dog bowls:

-

Microbial Testing: Samples of the bowls may be tested for bacterial presence to ensure that they meet hygiene standards.

-

Material Testing: Tests for material durability and resistance to wear and tear are conducted, particularly for plastics and ceramics.

-

Safety Testing: This includes checks for harmful chemicals or toxins that could leach from the material into food or water.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of suppliers is essential. Here are several strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices.

-

Request Reports: Suppliers should be able to provide documentation on their quality control measures, including any certifications, test results, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices and the integrity of their products.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations. Understanding local compliance requirements is vital for market entry.

-

Cultural Considerations: Communication and collaboration may differ across regions. Building strong relationships with suppliers can aid in navigating these differences.

-

Logistical Challenges: International shipping can introduce risks such as damage during transport. Ensuring that packaging meets international standards is crucial for product integrity.

In summary, understanding the manufacturing processes and quality assurance protocols for biofilm dog bowls is essential for B2B buyers. By focusing on material selection, production techniques, and rigorous quality control, buyers can ensure they are sourcing products that meet both safety and performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘biofilm dog bowl’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure biofilm-resistant dog bowls. As awareness of the health risks associated with biofilm grows, ensuring that your products meet high hygiene standards is paramount. This checklist will help you navigate the sourcing process effectively, ensuring that the bowls you choose not only meet quality standards but also contribute to the well-being of pets and their owners.

Illustrative image related to biofilm dog bowl

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing biofilm dog bowls. Consider factors such as material composition, size, and ease of cleaning. Look for bowls made from non-porous materials like stainless steel or ceramic, which are less likely to harbor biofilm compared to plastic options.

- Material Durability: Ensure the material can withstand regular cleaning without degrading.

- Size Variability: Specify sizes that accommodate different dog breeds to cater to a broader market.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in pet products. Create a shortlist based on their reputation, product offerings, and customer reviews. A reliable supplier should demonstrate a commitment to quality and hygiene standards.

- Industry Experience: Prefer suppliers with a proven track record in the pet product sector.

- Customer Feedback: Look for testimonials or case studies from other businesses in your region to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your suppliers have relevant certifications. Certifications like ISO 9001 for quality management and pet safety standards ensure that the products are produced under stringent conditions.

- Health and Safety Compliance: Check if the products meet local and international regulations regarding pet health.

- Sustainability Certifications: Consider suppliers who are environmentally conscious, as this can enhance your brand’s reputation.

Step 4: Request Samples for Testing

Always request samples of the biofilm dog bowls before making a bulk purchase. This allows you to assess the quality, durability, and ease of cleaning firsthand. Testing samples will help you ensure they meet your standards and expectations.

- Cleaning Tests: Evaluate how easily the bowls can be cleaned and if they resist biofilm accumulation.

- Durability Assessments: Examine the physical integrity of the bowls after exposure to typical wear and tear.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures offered by your shortlisted suppliers. Ensure that the costs align with your budget while considering the quality of the products. Negotiate payment terms that suit your financial capabilities, such as payment upon delivery or staggered payments.

- Bulk Discounts: Inquire about discounts for larger orders to maximize your profit margins.

- Hidden Fees: Clarify shipping and handling costs to avoid unexpected expenses.

Step 6: Plan for Ongoing Support and Communication

Establish a communication plan with your chosen supplier for ongoing support. Regular communication is essential for addressing any issues that may arise, such as product recalls or supply chain disruptions.

- Dedicated Account Manager: Request a point of contact for streamlined communication.

- Feedback Mechanism: Implement a system to provide feedback on product performance and customer satisfaction.

Step 7: Monitor Market Trends and Innovations

Stay updated on emerging trends and innovations in pet hygiene and biofilm prevention technologies. This awareness will help you make informed decisions about future purchases and adapt your product offerings accordingly.

- Industry Publications: Subscribe to relevant pet industry journals and newsletters.

- Trade Shows and Conferences: Attend events to network with suppliers and discover new products.

By following this checklist, B2B buyers can confidently navigate the procurement process for biofilm dog bowls, ensuring they select products that prioritize both pet health and customer satisfaction.

Comprehensive Cost and Pricing Analysis for biofilm dog bowl Sourcing

When sourcing biofilm-resistant dog bowls, it is essential to understand the cost structure and pricing dynamics involved. This analysis focuses on key cost components, price influencers, and strategic buyer tips to facilitate informed decision-making.

What Are the Key Cost Components for Biofilm Dog Bowls?

The total cost of manufacturing biofilm dog bowls can be broken down into several critical components:

-

Materials: The choice of materials significantly impacts pricing. Durable options like stainless steel or ceramic are typically more expensive than plastic but offer better resistance to biofilm formation. High-quality raw materials may also require certifications, which can add to costs.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs may offer competitive pricing, but quality control should not be compromised.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, thus lowering the overall cost.

-

Tooling: Custom designs or specific shapes for biofilm-resistant bowls may necessitate specialized tooling, which can be a significant upfront investment. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that the bowls meet health and safety standards is crucial, especially given the health risks associated with biofilm. Investing in robust QC processes can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping and handling costs can fluctuate based on the distance to the buyer, shipping method, and volume. Buyers should consider these costs in their total procurement budget.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. Understanding the market norms for margins can help in negotiations.

What Influences Pricing for Biofilm Dog Bowls?

Several factors can influence the pricing structure for biofilm dog bowls:

-

Volume/MOQ: Higher order quantities often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQs) that align with their purchasing strategies.

-

Specifications and Customization: Customization, such as personalized designs or additional features like built-in filtration systems, can increase costs. Clear communication about specifications can help manage expectations and budget.

-

Material Quality and Certifications: Premium materials that are certified as safe for pets and humans may come at a higher price. Buyers should weigh the long-term benefits of investing in quality against initial costs.

-

Supplier Factors: The reputation, reliability, and production capabilities of suppliers can impact pricing. Established suppliers may charge more for their services due to proven quality and reliability.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can affect the overall cost. Understanding these terms is crucial for budgeting and risk management in international transactions.

How Can Buyers Effectively Negotiate Prices?

To optimize costs when sourcing biofilm dog bowls, buyers can employ several strategies:

-

Leverage Volume Discounts: Negotiating based on larger orders can lead to substantial savings. Consider consolidating orders across multiple products to achieve better pricing.

-

Assess Total Cost of Ownership (TCO): While upfront costs are important, evaluating TCO—including durability, maintenance, and potential health-related costs associated with poor-quality bowls—can guide better purchasing decisions.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that can affect pricing. Collaborating with local agents can help navigate these complexities.

-

Build Relationships with Suppliers: Long-term relationships can foster better pricing and service. Regular communication can lead to more favorable terms and prioritized service during production peaks.

Conclusion

In summary, understanding the cost structure and pricing dynamics of biofilm dog bowls is essential for international B2B buyers. By focusing on key cost components, being aware of price influencers, and employing effective negotiation strategies, buyers can make informed decisions that enhance their purchasing efficiency and ensure the health and safety of pets. Always remember to obtain indicative prices and seek multiple quotes to ensure competitive sourcing.

Alternatives Analysis: Comparing biofilm dog bowl With Other Solutions

Understanding Alternatives for Biofilm Dog Bowls

When addressing the issue of biofilm in pet feeding solutions, it’s essential to explore various alternatives that can effectively mitigate the risks associated with bacterial build-up. The right choice can significantly impact the health of pets and, by extension, the satisfaction of pet owners. Below, we compare biofilm dog bowls against other viable solutions to provide B2B buyers with actionable insights.

| Comparison Aspect | Biofilm Dog Bowl | Automated Pet Feeder | Pet Fountain with Filters |

|---|---|---|---|

| Performance | Reduces biofilm accumulation effectively | Provides fresh food at every serving, minimizing residue | Continuously circulates water, reducing stagnation |

| Cost | Moderate initial investment | Higher initial investment; ongoing costs for food | Moderate to high initial investment; ongoing costs for filters |

| Ease of Implementation | Simple setup; requires regular cleaning | Requires initial setup and programming | Requires setup; may need additional plumbing |

| Maintenance | Requires regular cleaning to maintain efficacy | Minimal maintenance; refill food as needed | Filter replacement every few weeks; regular cleaning |

| Best Use Case | Ideal for pet owners prioritizing hygiene | Best for busy pet owners needing convenience | Ideal for pets prone to urinary issues or dehydration |

In-Depth Analysis of Alternatives

Automated Pet Feeder

Automated pet feeders offer a modern solution to maintaining pet hygiene by ensuring that food is served fresh and in controlled portions. This significantly reduces the chances of biofilm formation since old food is less likely to remain in the bowl. However, the initial cost can be a barrier for some buyers, and the technology requires a bit of setup. Regular refilling of food is necessary, but overall maintenance is low, making it a convenient option for busy pet owners.

Illustrative image related to biofilm dog bowl

Pet Fountain with Filters

Pet fountains provide a continuous supply of fresh water, which is essential for preventing stagnation—a common cause of biofilm growth. The filtration system helps keep the water clean and free from contaminants. While the upfront investment can be higher, the benefits include improved hydration for pets, particularly those prone to urinary tract issues. Maintenance involves changing filters regularly, which can add to the overall cost, but the health benefits for pets can outweigh these concerns.

Choosing the Right Solution for Your Needs

When selecting a solution for combating biofilm in pet bowls, B2B buyers should consider their specific needs, such as the type of pets they cater to, their budget, and the level of convenience they desire. Biofilm dog bowls offer a straightforward, effective method for reducing bacterial build-up, while automated feeders and pet fountains present advanced options that can enhance pet health and convenience. Ultimately, the decision should align with the target customer base’s preferences and the business’s operational capabilities.

Essential Technical Properties and Trade Terminology for biofilm dog bowl

What Are the Key Technical Properties of Biofilm Dog Bowls?

When sourcing biofilm-resistant dog bowls, understanding the technical properties is crucial for ensuring product quality and longevity. Here are some essential specifications that buyers should consider:

Material Grade

Biofilm dog bowls are typically made from materials such as stainless steel, glass, or high-quality ceramics. Each material has distinct properties that affect durability and resistance to biofilm formation. Stainless steel is particularly favored for its non-porous surface, which resists scratches and is easy to clean. Glass offers visibility for cleanliness but can be more fragile. Choosing the right material grade influences the bowl’s lifespan and maintenance requirements.

Surface Finish

The surface finish of the bowl plays a significant role in biofilm prevention. A smooth, high-gloss finish minimizes the likelihood of bacteria adhering to the surface, making it easier to clean. In contrast, rough or matte finishes can harbor biofilm, making maintenance more challenging. Opting for bowls with a polished finish can reduce cleaning times and enhance hygiene.

Illustrative image related to biofilm dog bowl

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For dog bowls, tight tolerances ensure that lids fit properly on automated feeders and that bowls sit securely on surfaces. This is important for preventing spills and maintaining a clean feeding area. High tolerance levels also reflect manufacturing quality, which can be a selling point for B2B buyers.

Weight and Stability

The weight of the dog bowl affects its stability, particularly for larger breeds. Heavier bowls are less likely to be tipped over, reducing mess and the potential for biofilm accumulation from spilled food or water. This property is vital for buyers considering the practical applications of the bowls in various environments, such as homes or kennels.

Dishwasher-Safe Features

Being dishwasher-safe is a critical specification for biofilm dog bowls. This feature allows for thorough cleaning at high temperatures, which is essential for eliminating biofilm and bacteria. Buyers should look for bowls that can withstand repeated dishwasher cycles without degrading, ensuring both hygiene and product longevity.

What Are Common Trade Terms Related to Biofilm Dog Bowls?

Understanding trade terminology is essential for effective communication and negotiations in the B2B marketplace. Here are several key terms relevant to the biofilm dog bowl industry:

Illustrative image related to biofilm dog bowl

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of biofilm dog bowls, an OEM may supply bowls to a brand that sells them under its name. Understanding OEM relationships can help buyers identify reliable suppliers and assess product quality.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For biofilm dog bowls, MOQs can vary based on material, design, and supplier capabilities. Knowing the MOQ helps buyers plan their inventory and manage costs effectively, especially when entering new markets.

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price and terms for specific quantities of products. In the biofilm dog bowl sector, an RFQ can help buyers compare pricing and conditions from multiple suppliers, facilitating informed purchasing decisions.

Illustrative image related to biofilm dog bowl

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery of goods. Familiarity with these terms is crucial for international buyers of biofilm dog bowls, as they govern aspects like shipping costs, risk transfer, and customs clearance, which can significantly impact overall procurement costs.

Lead Time

Lead time is the period between placing an order and receiving the goods. In the biofilm dog bowl market, understanding lead times helps buyers plan their inventory levels and avoid stockouts. Suppliers with shorter lead times may provide a competitive advantage in fast-paced markets.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions when sourcing biofilm dog bowls, ultimately enhancing product quality and customer satisfaction.

Illustrative image related to biofilm dog bowl

Navigating Market Dynamics and Sourcing Trends in the biofilm dog bowl Sector

What Are the Key Market Drivers Influencing the Biofilm Dog Bowl Sector?

The biofilm dog bowl market is experiencing significant growth driven by increasing awareness of pet health and hygiene. As pet ownership rises, particularly in emerging markets across Africa and South America, so does the demand for products that enhance pet well-being. Global health crises, such as the COVID-19 pandemic, have further underscored the importance of hygiene, leading to a heightened focus on cleaning and sanitization in households.

Technological advancements are also shaping the landscape, with innovations in materials that inhibit biofilm formation. For instance, manufacturers are exploring the use of antimicrobial plastics and coatings that reduce bacterial growth, appealing to health-conscious consumers. Additionally, automation in production processes is improving efficiency and product quality, allowing suppliers to meet increasing demand while maintaining competitive pricing.

International B2B buyers, especially those from Europe and the Middle East, are increasingly looking for suppliers that can provide not just quality products but also transparency in sourcing and manufacturing processes. The ongoing trend toward direct sourcing from manufacturers is allowing buyers to negotiate better prices while ensuring product integrity.

How Are Sustainability and Ethical Sourcing Impacting the Biofilm Dog Bowl Market?

Sustainability and ethical sourcing are becoming central themes in the biofilm dog bowl market. As consumers demand environmentally friendly products, manufacturers are responding by adopting sustainable practices. This includes utilizing biodegradable materials and reducing waste in the production process.

Ethical supply chains are critical for B2B buyers, as they increasingly prefer suppliers who demonstrate corporate social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade can significantly enhance a product’s appeal in the global marketplace. Moreover, using recycled materials not only reduces environmental impact but also appeals to eco-conscious consumers.

The importance of proper disposal methods for biofilm dog bowls cannot be overlooked. Suppliers who provide clear guidelines on recycling or disposing of their products responsibly can differentiate themselves in a crowded market. This trend is particularly relevant in regions with strict environmental regulations, such as Germany, where consumers are more likely to invest in brands that align with their values.

What Is the Brief Evolution of the Biofilm Dog Bowl Market?

The biofilm dog bowl market has evolved significantly over the past two decades. Initially, traditional materials like plastic dominated the sector, but concerns over hygiene and the health risks associated with biofilm led to a shift towards more durable and easily sanitized materials such as stainless steel and ceramics.

As awareness of the dangers posed by biofilm grew, manufacturers began to innovate, incorporating antimicrobial properties into their products to combat bacterial growth effectively. This evolution reflects a broader trend in the pet industry, where health and hygiene are now paramount considerations for consumers. The market continues to adapt to changing consumer preferences, with an increasing emphasis on sustainability and ethical sourcing shaping future developments.

Overall, understanding these market dynamics, sourcing trends, and the importance of sustainability can empower B2B buyers to make informed decisions when procuring biofilm dog bowls, ensuring they meet both consumer demand and regulatory standards.

Frequently Asked Questions (FAQs) for B2B Buyers of biofilm dog bowl

-

How do I solve the biofilm problem in dog bowls?

To effectively address the biofilm issue in dog bowls, choose materials that resist biofilm formation, such as stainless steel or ceramic. Regularly clean and disinfect bowls after each use, ensuring they are free from food residue and moisture. Consider implementing automated pet feeders and water fountains with filtration systems to provide clean food and water consistently, which can significantly reduce biofilm buildup. Educating pet owners about the risks of biofilm and the importance of hygiene can also promote better practices and sales for your products. -

What is the best material for dog bowls to prevent biofilm buildup?

The best materials for dog bowls to prevent biofilm formation are stainless steel and ceramic. Stainless steel is durable, dishwasher-safe, and resistant to scratches that harbor bacteria. Ceramic bowls, while less durable, are easy to clean and do not absorb odors or residues. Avoid plastic bowls, as they can retain bacteria and are often harder to sanitize effectively. Highlighting these materials in your product offerings can attract health-conscious buyers and differentiate your brand in the market. -

What customization options should I consider when sourcing biofilm dog bowls?

When sourcing biofilm dog bowls, consider customization options such as size, color, and branding. Offering bowls in various sizes caters to different dog breeds and preferences. Custom colors or designs can appeal to specific markets or trends. Additionally, consider adding features like anti-slip bases or unique shapes that enhance usability. Discussing these options with suppliers can help you create a product line that stands out and meets diverse consumer needs. -

What minimum order quantities (MOQ) are typical for biofilm dog bowls?

MOQs for biofilm dog bowls can vary widely depending on the supplier and the complexity of the customization. Generally, you might encounter MOQs ranging from 500 to 2,000 units for standard designs. However, for highly customized products, the MOQ may increase significantly. It’s essential to communicate your needs clearly with potential suppliers to negotiate favorable terms that align with your business model and market demand. -

What payment terms should I expect when sourcing internationally?

When engaging in international trade for biofilm dog bowls, payment terms can vary based on the supplier’s policies and your negotiating power. Common terms include 30% upfront deposit with the balance due before shipment or upon delivery. Some suppliers may offer letter of credit options for larger orders. Always confirm the terms in writing and ensure you understand any additional fees related to currency exchange or international transactions to avoid unexpected costs. -

How can I ensure quality assurance (QA) for biofilm dog bowls?

To ensure quality assurance for biofilm dog bowls, establish clear specifications and standards with your supplier before production begins. Request samples to evaluate the materials and construction quality. Implement regular quality checks during production and before shipment, and consider third-party inspections if necessary. Discussing QA processes with your supplier can help build trust and ensure that your products meet health and safety standards. -

What logistics considerations should I be aware of when importing dog bowls?

When importing biofilm dog bowls, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost savings, depending on your urgency. Familiarize yourself with import duties and taxes in your destination country to avoid unexpected expenses. Collaborating with a reliable logistics partner can streamline the shipping process and ensure timely delivery to your customers. -

What marketing strategies can I use to promote biofilm dog bowls in international markets?

To effectively market biofilm dog bowls internationally, leverage digital marketing strategies such as targeted social media campaigns and search engine optimization (SEO) to reach pet owners. Highlight the health benefits of using biofilm-resistant materials and educate consumers about the risks of biofilm in pet bowls. Collaborate with local influencers or veterinarians to build credibility and trust within specific markets. Participating in pet trade shows and exhibitions can also increase brand visibility and generate leads.

Top 1 Biofilm Dog Bowl Manufacturers & Suppliers List

1. Boil & Broth – Dehydrated Broths for Pets

Domain: boilandbroth.com

Registered: 2018 (7 years)

Introduction: Dehydrated Beef Broth for Dogs & Cats – $28.00

Dehydrated Venison Bone Broth for Dogs & Cats – $28.00

Dehydrated Chicken Broth for Dogs & Cats – $28.00

Dehydrated Lamb Broth for Dogs & Cats – $28.00

Strategic Sourcing Conclusion and Outlook for biofilm dog bowl

The importance of strategic sourcing in the biofilm dog bowl market cannot be overstated. As awareness of biofilm’s health risks grows among pet owners globally, the demand for high-quality, easy-to-clean dog bowls is on the rise. B2B buyers should prioritize sourcing durable materials such as stainless steel and ceramic, which not only reduce biofilm accumulation but also enhance product longevity. Furthermore, investing in automated feeding solutions and water fountains can significantly mitigate biofilm risks, thereby improving pet health and owner satisfaction.

International buyers from Africa, South America, the Middle East, and Europe must remain vigilant in identifying suppliers who prioritize hygiene and product innovation. Consider collaborating with manufacturers that offer comprehensive cleaning solutions tailored for pet care. This proactive approach ensures that your offerings meet emerging market demands while promoting the health of pets and their owners alike.

Illustrative image related to biofilm dog bowl

Looking ahead, the biofilm dog bowl segment presents a unique opportunity for B2B buyers to lead the charge in creating safer pet environments. By prioritizing strategic sourcing and innovation, you can position your business at the forefront of this evolving market. Engage with trusted suppliers today to secure a competitive advantage and contribute to a healthier future for pets worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to biofilm dog bowl

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.