Introduction: Navigating the Global Market for how often do i change hummingbird feeder

The delicate balance of attracting and nurturing hummingbirds hinges significantly on one crucial aspect: how often to change hummingbird feeders. For B2B buyers sourcing bird feeding solutions, understanding this frequency is vital for ensuring product efficacy and customer satisfaction. This comprehensive guide delves into the nuances of hummingbird feeder maintenance, addressing critical factors such as seasonal variations, regional climate impacts, and the specific needs of different hummingbird species.

By exploring various types of feeders, applications in diverse environments, and effective supplier vetting processes, this guide equips international buyers—particularly those from Africa, South America, the Middle East, and Europe—with the knowledge necessary to make informed purchasing decisions. The content emphasizes the importance of maintaining nectar freshness to prevent spoilage and avoid deterring these essential pollinators, thereby maximizing the effectiveness of feeder usage.

Furthermore, we provide insights into cost considerations and innovative solutions that cater to the unique challenges faced by businesses operating in different markets. With this guide, B2B buyers can confidently navigate the global market for hummingbird feeders, ensuring they select products that not only meet their needs but also enhance the experience for their customers.

Table Of Contents

- Top 3 How Often Do I Change Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often do i change hummingbird feeder

- Understanding how often do i change hummingbird feeder Types and Variations

- Key Industrial Applications of how often do i change hummingbird feeder

- 3 Common User Pain Points for ‘how often do i change hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often do i change hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often do i change hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often do i change hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often do i change hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often do i change hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often do i change hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often do i change hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often do i change hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often do i change hummingbird feeder

- Important Disclaimer & Terms of Use

Understanding how often do i change hummingbird feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Frequency | Changes based on seasonal temperature variations. | Retailers in temperate climates. | Pros: Adjusts to bird activity; enhances feeder usage. Cons: Requires monitoring and adjustment. |

| Climate-Based Adjustment | Nectar change frequency tailored to local humidity and heat. | Suppliers in tropical or humid regions. | Pros: Prevents spoilage; attracts more birds. Cons: Needs constant attention in hot climates. |

| Standardized Routine | Fixed schedule regardless of conditions (e.g., every 3 days). | Mass retailers or large-scale operations. | Pros: Simplifies inventory management; predictable. Cons: May lead to waste if conditions vary. |

| Event-Driven Changes | Adjustments based on specific events (e.g., migratory patterns). | Conservation organizations or birdwatching tours. | Pros: Maximizes bird attraction during key times. Cons: Requires knowledge of bird migration. |

| Product-Specific Guidelines | Manufacturer recommendations for specific feeder types. | Retailers and distributors of specific brands. | Pros: Ensures optimal feeder performance; adheres to warranties. Cons: Limits flexibility in management. |

What Are the Key Characteristics of Seasonal Frequency Changes?

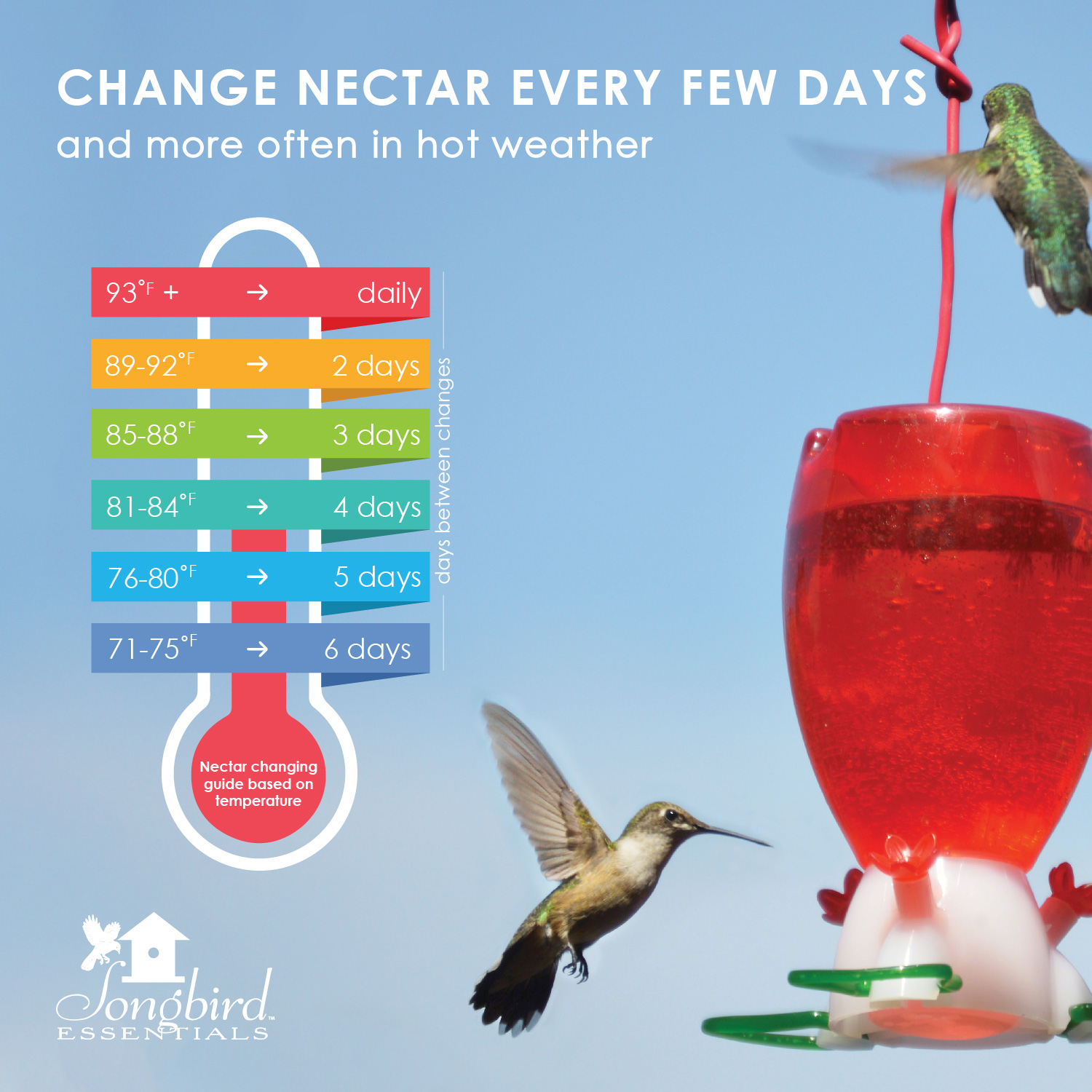

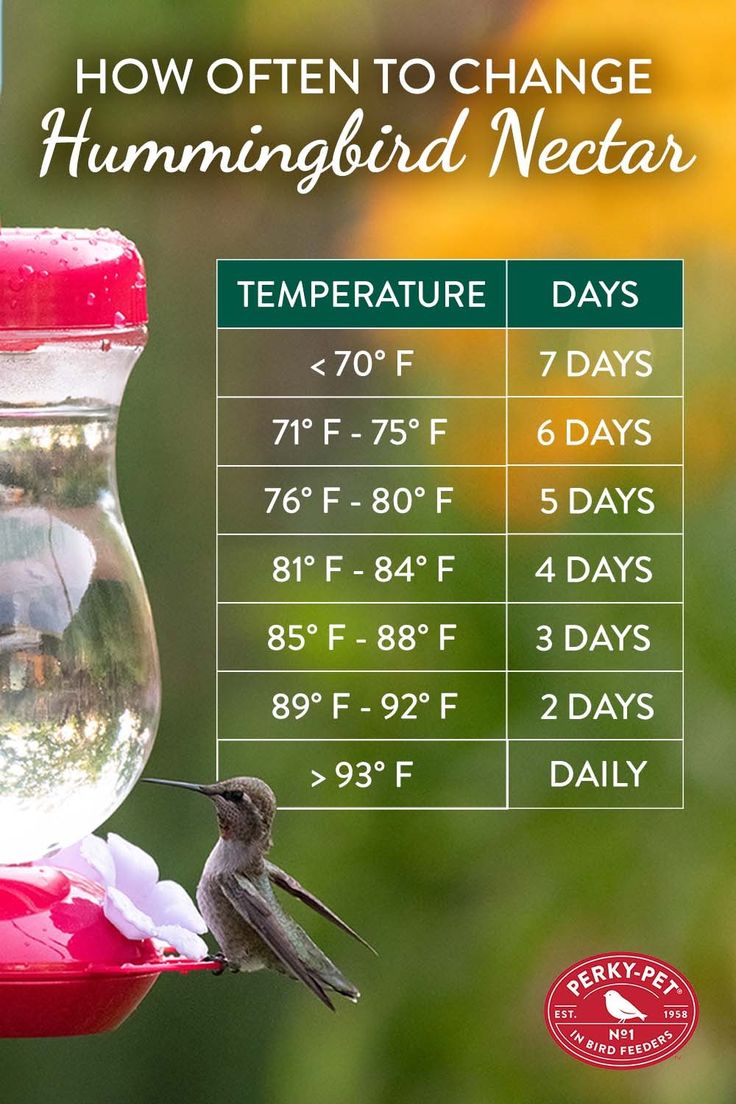

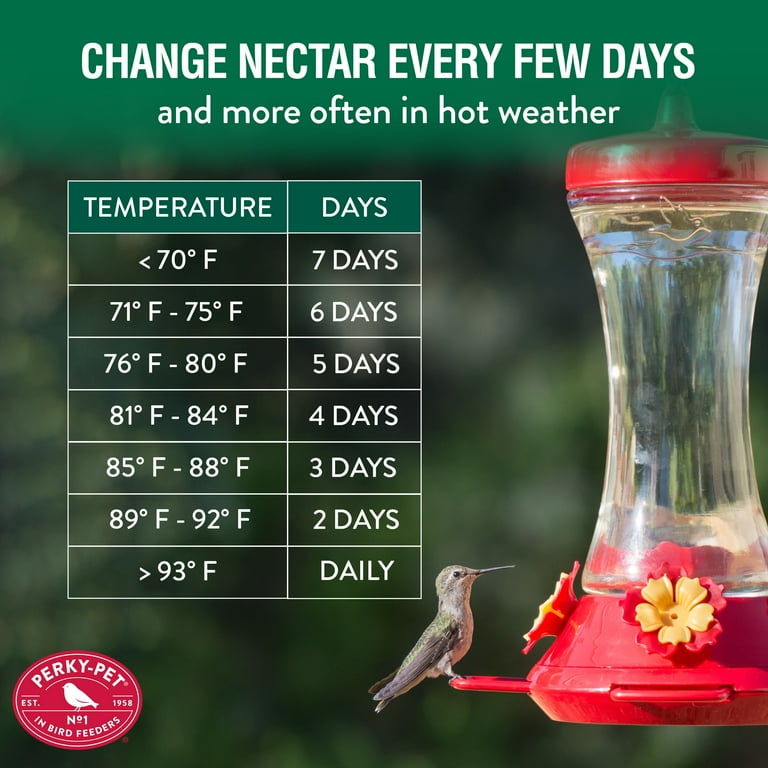

Seasonal frequency changes are tailored to the temperature and behavior of hummingbirds during different times of the year. In cooler months, nectar can last longer, requiring changes every 2-4 days, while in warmer months, especially above 90°F, it should be changed daily. This approach is particularly beneficial for B2B buyers in temperate regions, as it aligns with natural feeding patterns, enhancing customer satisfaction and bird attraction.

How Does Climate-Based Adjustment Influence Nectar Management?

Climate-based adjustment focuses on the local environmental conditions affecting nectar spoilage. In humid or tropical regions, nectar may ferment quickly, necessitating changes every 1-2 days. B2B buyers in these areas should consider this type of management to ensure product freshness and maintain high bird visitation rates. This proactive approach can significantly impact sales and customer loyalty, especially in regions where birdwatching is popular.

Why Opt for a Standardized Routine for Nectar Changes?

A standardized routine involves setting a fixed schedule for changing nectar, such as every three days, regardless of environmental conditions. This method simplifies operations for mass retailers and large-scale operations. While it provides predictability and eases inventory management, it may lead to waste if conditions change unexpectedly. B2B buyers should weigh the benefits of operational efficiency against potential losses from spoiled nectar.

What Are the Benefits of Event-Driven Nectar Changes?

Event-driven changes are based on specific occurrences, such as migratory patterns or breeding seasons, when hummingbird activity peaks. This strategy is especially relevant for conservation organizations and birdwatching tours, as it maximizes bird attraction during critical times. B2B buyers can leverage this knowledge to create targeted marketing campaigns, enhancing customer engagement and boosting sales during peak bird activity.

How Do Product-Specific Guidelines Impact Nectar Change Frequency?

Product-specific guidelines provided by manufacturers recommend nectar change frequencies tailored to their feeders. This is crucial for retailers and distributors who want to ensure optimal performance and adherence to warranties. While following these guidelines can enhance customer trust and product effectiveness, it may limit flexibility in management strategies. B2B buyers should consider these recommendations as part of their overall product offering to ensure customer satisfaction.

Key Industrial Applications of how often do i change hummingbird feeder

| Industry/Sector | Specific Application of how often do i change hummingbird feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Implementing regular nectar changes in hummingbird feeders to support pollination | Enhanced crop yield through improved pollination | Availability of durable feeders, local climate conditions, and ease of cleaning. |

| Eco-tourism | Regular maintenance schedules for hummingbird feeders in eco-lodges | Increased visitor engagement and satisfaction | High-quality, aesthetically pleasing feeders that are easy to maintain. |

| Wildlife Conservation | Establishing guidelines for nectar replacement in conservation areas | Promoting healthy bird populations and biodiversity | Compliance with local wildlife regulations and sourcing sustainable materials. |

| Retail (Garden & Pet Supplies) | Stocking and selling hummingbird feeders with clear maintenance instructions | Increased customer loyalty through education | Partnerships with manufacturers for quality assurance and supply chain reliability. |

| Landscaping Services | Providing hummingbird feeder maintenance as part of landscaping services | Differentiation in service offerings | Knowledge of local fauna and flora needs, as well as seasonal changes. |

How Does Changing Hummingbird Feeders Benefit Agriculture?

In agriculture, hummingbirds play a crucial role as pollinators. Regularly changing the nectar in feeders can significantly enhance pollination rates, leading to improved crop yields. Businesses in this sector must consider local climate conditions, as warmer regions may require more frequent nectar changes to prevent spoilage. Additionally, sourcing durable feeders that are easy to clean can streamline maintenance efforts, ensuring that pollinators remain attracted to the area.

Why is Eco-Tourism Enhanced by Hummingbird Feeder Maintenance?

Eco-tourism businesses can leverage hummingbird feeders to create immersive experiences for visitors. By maintaining feeders and ensuring that nectar is changed regularly, lodges can attract more hummingbirds, enriching the natural environment for guests. This not only boosts visitor engagement but also fosters a deeper appreciation for local wildlife. Suppliers should focus on providing aesthetically pleasing feeders that are easy to maintain, aligning with the eco-friendly ethos of these businesses.

How Does Wildlife Conservation Benefit from Regular Nectar Changes?

In wildlife conservation areas, the health of bird populations is paramount. Establishing guidelines for changing nectar in hummingbird feeders can help maintain healthy hummingbird populations, which in turn supports biodiversity. Organizations must navigate local wildlife regulations and ensure that the materials used in feeders are sustainable. This approach not only aids in conservation efforts but also raises awareness among visitors about the importance of bird health.

What Role Does Retail Play in Educating Customers About Hummingbird Feeders?

Retail businesses specializing in garden and pet supplies can enhance customer loyalty by providing clear maintenance instructions for hummingbird feeders. By educating customers on the importance of changing nectar regularly, these retailers can encourage repeat purchases and foster a community of bird enthusiasts. Establishing partnerships with manufacturers ensures that high-quality feeders are available, which can lead to better customer satisfaction and retention.

How Can Landscaping Services Differentiate Themselves with Hummingbird Feeders?

Landscaping services can offer hummingbird feeder maintenance as a unique value-added service. By incorporating feeder maintenance into their offerings, they can attract clients interested in enhancing their gardens’ biodiversity. Knowledge of local flora and fauna needs, along with an understanding of seasonal changes, is essential for these businesses. This differentiation can lead to increased customer satisfaction and a stronger market presence in the landscaping industry.

3 Common User Pain Points for ‘how often do i change hummingbird feeder’ & Their Solutions

Scenario 1: Inconsistent Nectar Freshness in Tropical Climates

The Problem: B2B buyers in tropical regions face the challenge of maintaining nectar freshness due to high temperatures and humidity. This environment accelerates spoilage, leading to potential health risks for hummingbirds and discouraging their return to feeders. Businesses that supply bird feeders or related products must ensure that their customers understand the importance of frequent nectar changes to avoid losing clientele.

The Solution: To mitigate this issue, establish clear guidelines for your customers on nectar maintenance in warmer climates. Recommend changing the nectar every 1 to 2 days during hot and humid conditions. Provide educational materials, such as infographics or videos, that illustrate the ideal nectar preparation process and the signs of spoilage (e.g., cloudiness or mold). Additionally, consider offering products like insulated feeders or nectar solutions specifically designed for hotter climates to support your customers in keeping their feeders effective and safe for hummingbirds.

Scenario 2: Confusion Over Nectar Ratios and Preparation

The Problem: Many B2B buyers struggle with the correct nectar-to-water ratios and preparation methods, leading to inconsistent sweetness levels that may deter hummingbirds. This confusion can result in wasted product and dissatisfaction among end-users, which reflects poorly on suppliers and their brands.

The Solution: To address this pain point, provide comprehensive training for your sales team that includes detailed information on how to create hummingbird nectar. Offer clear guidelines on the standard 4:1 water-to-sugar ratio, along with step-by-step instructions for boiling water, dissolving sugar, and cooling the mixture. Create printable recipe cards that can be included with feeder purchases, ensuring your customers have easy access to the right information. Additionally, consider hosting webinars or workshops that educate buyers about proper nectar preparation, enhancing their confidence in using your products.

Scenario 3: Pest Attraction Due to Nectar Spoilage

The Problem: B2B buyers frequently encounter the problem of pests, such as bees and wasps, which are attracted to spoiled nectar. This not only affects the feeding experience for hummingbirds but can also deter these birds from visiting altogether. Suppliers may receive complaints from customers who find that their feeders are not attracting hummingbirds due to pest interference, which can harm sales and brand reputation.

The Solution: Offer solutions that help customers minimize pest attraction while maintaining feeder cleanliness. Recommend regular cleaning of feeders every 2 to 4 days, depending on local weather conditions, to prevent nectar spoilage. Provide your customers with pest deterrent tips, such as moving feeders away from yellow flowers or using feeders with bee guards. Additionally, consider developing and marketing specialized feeders that are designed to reduce pest access, ensuring that your customers can enjoy a hummingbird-friendly environment without the nuisance of unwanted insects. By equipping your clients with practical advice and effective products, you enhance their overall experience and foster loyalty to your brand.

Illustrative image related to how often do i change hummingbird feeder

Strategic Material Selection Guide for how often do i change hummingbird feeder

When considering the optimal materials for hummingbird feeders, especially in the context of how often to change the nectar, it’s essential to analyze the properties, advantages, and limitations of various materials. This analysis will aid international B2B buyers in making informed decisions that align with their regional market requirements and standards.

What are the Key Properties of Glass in Hummingbird Feeders?

Glass is a common material for hummingbird feeders due to its aesthetic appeal and durability. It is non-reactive, ensuring that the nectar remains uncontaminated. Glass can withstand a range of temperatures, making it suitable for various climates, although it can be prone to breakage if dropped. Additionally, glass is resistant to corrosion, which is critical for maintaining the integrity of the feeder in humid environments.

Pros:

– Non-reactive and easy to clean.

– Durable and resistant to UV light, preventing degradation of nectar.

– Provides a classic look that appeals to consumers.

Cons:

– Heavier than plastic, which may affect shipping costs.

– Can break easily if not handled properly.

– Generally more expensive than plastic options.

How Does Plastic Compare for Hummingbird Feeders?

Plastic is often chosen for its lightweight nature and cost-effectiveness. It is available in various colors and designs, making it versatile for different markets. However, the quality of plastic can vary significantly; lower-grade plastics may leach chemicals into the nectar or degrade under UV exposure.

Pros:

– Lightweight and easy to transport.

– Generally less expensive than glass or metal.

– Available in a wide range of colors and designs.

Cons:

– May not be as durable as glass; prone to scratching and fading.

– Potential for chemical leaching if not made from food-grade materials.

– UV degradation can shorten the lifespan of the feeder.

What Role Does Metal Play in Hummingbird Feeders?

Metal, such as aluminum or stainless steel, is another option for hummingbird feeders. Metal feeders are often designed for durability and can withstand various weather conditions. They can also be treated to resist corrosion, making them suitable for humid climates.

Pros:

– Highly durable and resistant to breakage.

– Corrosion-resistant options available, enhancing longevity.

– Can be designed to be aesthetically pleasing while maintaining functionality.

Cons:

– Can be heavier and more expensive than plastic.

– May conduct heat, potentially warming the nectar in hot climates.

– Requires careful design to prevent sharp edges that could harm birds.

What are the Considerations for International B2B Buyers?

When selecting materials for hummingbird feeders, international buyers must consider regional preferences and compliance with local standards. For instance, in Europe, adherence to DIN standards is crucial, while ASTM standards may be more relevant in the U.S. and parts of Africa. Buyers should also evaluate the environmental impact of the materials, as sustainability is becoming increasingly important in markets across South America and the Middle East.

Summary Table of Material Selection for Hummingbird Feeders

| Material | Typical Use Case for how often do i change hummingbird feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Premium feeders that require frequent cleaning and nectar changes | Non-reactive and UV resistant | Prone to breakage and heavier | High |

| Plastic | Economical feeders for mass production and varied designs | Lightweight and cost-effective | Potential chemical leaching and UV degradation | Low |

| Metal | Durable feeders for long-term use in various climates | Highly durable and corrosion-resistant | Heavier and can conduct heat | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, helping them choose the right materials for hummingbird feeders that align with their business needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for how often do i change hummingbird feeder

What Are the Key Stages in the Manufacturing Process for Hummingbird Feeders?

The manufacturing process for hummingbird feeders involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and reliability of the products they are sourcing.

-

Material Preparation: The first step involves sourcing high-quality materials, typically plastic, glass, or metal. These materials must be durable, weather-resistant, and non-toxic to ensure the safety of the birds. Suppliers often conduct tests on raw materials to confirm they meet industry standards for safety and durability.

-

Forming: In this stage, materials are shaped into the desired components of the feeder. This may involve injection molding for plastics or glass-blowing techniques for glass feeders. Precision is vital here to ensure that each part fits together seamlessly, which directly impacts the feeder’s functionality and ease of cleaning.

-

Assembly: After the components are formed, they are assembled. This may be done manually or through automated processes. Quality control measures during assembly include checking for correct fitting of parts and ensuring that any seals are effective to prevent leaks.

-

Finishing: The final stage involves surface treatments and coatings. These treatments enhance the aesthetic appeal of the feeders and add protective layers to withstand outdoor conditions. For instance, UV-resistant coatings may be applied to prevent fading from sunlight exposure.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is a crucial aspect of the manufacturing process, especially when it comes to products designed for wildlife. Various international and industry-specific standards guide these processes.

-

Relevant International Standards: ISO 9001 is a widely recognized quality management standard that outlines requirements for a quality management system. Manufacturers aiming for ISO certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, CE marking may be required in Europe, indicating compliance with health, safety, and environmental protection standards.

-

Industry-Specific Standards: In regions with specific wildlife protection regulations, manufacturers may also adhere to standards set by organizations such as the American National Standards Institute (ANSI) or the American Bird Conservancy. This ensures that the materials and designs are safe for birds.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This checkpoint verifies that raw materials meet specified standards before they enter the manufacturing process.

– In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed to monitor the production process and identify any deviations from established standards.

– Final Quality Control (FQC): After assembly and finishing, FQC involves thorough inspections of the completed feeders to ensure they function as intended and are free from defects.

What Testing Methods Are Commonly Used to Ensure Product Quality?

To ensure that hummingbird feeders meet safety and quality standards, various testing methods are employed throughout the manufacturing process:

Illustrative image related to how often do i change hummingbird feeder

- Visual Inspection: This basic but essential method involves checking for any visible defects or inconsistencies in the product.

- Leak Testing: For feeders that hold liquid, manufacturers often conduct leak tests to ensure that there are no leaks in the seals or joints.

- Durability Testing: Products may undergo stress tests to assess their ability to withstand environmental factors such as UV exposure, temperature fluctuations, and physical impacts.

- Chemical Testing: This ensures that materials used are safe and non-toxic to birds, which is crucial for maintaining consumer trust and regulatory compliance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is vital for ensuring product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should look for evidence of adherence to international standards and best practices.

-

Quality Reports: Requesting detailed quality reports can help buyers assess the consistency and reliability of a supplier’s products. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality assurance processes. This is particularly important for international buyers who may not have direct access to the supplier’s facilities.

-

Certifications: Verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking. These certifications indicate a commitment to maintaining high quality and safety standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control and certification when sourcing hummingbird feeders:

-

Regulatory Compliance: Different regions may have varying regulations regarding the materials and safety of wildlife feeders. Understanding local laws in target markets is essential for compliance.

-

Cultural Considerations: Preferences for feeder designs and materials may vary by region. B2B buyers should consider cultural factors when selecting suppliers to ensure the products meet local expectations.

-

Logistics and Supply Chain: Quality assurance processes can be affected by logistics and supply chain factors. Buyers should ensure that suppliers have robust systems in place for managing supply chain risks that could impact product quality.

By understanding these aspects of the manufacturing and quality assurance processes for hummingbird feeders, B2B buyers can make more informed decisions, ensuring they source high-quality products that meet both safety and performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often do i change hummingbird feeder’

In the hummingbird feeder market, understanding the optimal frequency for changing nectar is crucial for maintaining a healthy feeding environment. This guide offers actionable steps for B2B buyers seeking to establish best practices in their operations, ensuring they meet the needs of their customers while promoting responsible bird feeding.

Illustrative image related to how often do i change hummingbird feeder

Step 1: Understand Climate Impacts on Nectar Freshness

Different climates affect how quickly nectar can spoil. In warmer or humid areas, nectar should be changed every 1-2 days, while cooler climates may allow for changes every 2-4 days. Understanding these nuances can help you better serve customers in various regions, ensuring they have the right guidelines for their specific environments.

Step 2: Educate Your Team on Nectar Preparation

Proper nectar preparation is essential for attracting hummingbirds. The standard ratio is four parts water to one part sugar, and boiling the water before mixing eliminates any chlorine. Training your team to prepare nectar correctly can enhance customer satisfaction and ensure the health of the birds.

Step 3: Evaluate the Quality of Feeders

The type and quality of feeders can influence how often nectar needs to be changed. Look for feeders made from materials that are easy to clean and maintain, as well as those with designs that minimize spoilage. Prioritizing high-quality feeders can lead to better customer retention and positive feedback.

Step 4: Implement a Maintenance Schedule

Develop a routine schedule for changing nectar based on the local climate and feeder location. Regular maintenance not only keeps the nectar fresh but also reduces the risk of mold growth, which can deter hummingbirds. Providing a clear schedule to customers can enhance their experience and encourage them to keep their feeders clean.

Step 5: Communicate Best Practices to Customers

Providing guidance on when and how to change nectar is essential for customer education. Consider creating informational materials, such as brochures or online resources, that detail best practices. Educating your customers can improve their engagement and increase the likelihood of repeat purchases.

Step 6: Monitor Customer Feedback and Adapt

Regularly solicit feedback from customers regarding their experiences with nectar changing and feeder maintenance. Understanding their challenges can inform your product offerings and customer support strategies. Adaptability is key in ensuring that your solutions remain relevant and effective.

Step 7: Promote Sustainable Practices

Encourage customers to use natural ingredients in their nectar and to avoid dyes or preservatives. This not only aligns with eco-friendly practices but also promotes the health of the hummingbirds. Positioning your brand as a sustainable choice can attract environmentally conscious buyers, enhancing your market presence.

By following these steps, B2B buyers can effectively source and manage hummingbird feeders while ensuring they provide a healthy and appealing experience for both customers and birds.

Comprehensive Cost and Pricing Analysis for how often do i change hummingbird feeder Sourcing

What Are the Key Cost Components for Hummingbird Feeder Nectar?

When sourcing hummingbird feeder nectar, various cost components must be considered to build an accurate pricing model. The primary costs include:

-

Materials: The primary ingredients for hummingbird nectar are sugar and water. High-quality, non-dyed sugar is essential for producing safe nectar. The cost of sugar can fluctuate based on global market rates, impacting the overall cost structure.

-

Labor: This involves the workforce needed for production, packaging, and quality control. Labor costs can vary significantly depending on the region and local wage standards, particularly when sourcing from different countries.

-

Manufacturing Overhead: This encompasses utilities, rent, equipment depreciation, and other indirect costs associated with production facilities. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Equipment for bottling and packaging nectar can require significant investment. High-quality tooling can ensure consistent product quality and reduce waste, but it also adds to the initial costs.

-

Quality Control (QC): Ensuring the nectar is safe for birds involves rigorous testing and quality assurance processes. This adds additional costs but is crucial for maintaining brand reputation and compliance with safety standards.

-

Logistics: Transportation costs for delivering the product to various markets can vary widely. Factors include distance, shipping method, and regional tariffs. Understanding these logistics is essential for international buyers.

-

Margin: The profit margin is the final component, which can be influenced by all the aforementioned factors. Buyers should be aware of the typical industry margins to assess fair pricing.

How Do Price Influencers Affect Hummingbird Feeder Nectar Sourcing?

Several factors can influence the pricing of hummingbird feeder nectar, particularly for international B2B buyers:

Illustrative image related to how often do i change hummingbird feeder

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to economies of scale, reducing the per-unit cost. Buyers should negotiate for bulk pricing to maximize cost efficiency.

-

Specifications and Customization: Custom formulations or packaging can increase costs. Buyers need to define their requirements clearly to avoid unexpected expenses.

-

Material Quality and Certifications: High-quality ingredients and certifications (like organic or non-GMO) can raise prices. Buyers must balance quality with budget constraints when sourcing.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can impact pricing. A well-established supplier may charge a premium for their proven quality and service.

-

Incoterms: Understanding the international commercial terms governing shipping responsibilities can affect total costs. Buyers should clarify who bears the shipping risks and costs to avoid surprises.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate for Better Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Establishing a good relationship can lead to better deals and flexibility.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with sourcing nectar, including quality issues, shipping delays, and potential waste from spoilage. A slightly higher upfront price may lead to lower TCO.

-

Leverage Local Suppliers: Whenever possible, source from local suppliers to reduce logistics costs and support local economies. This can also streamline the supply chain, reducing lead times.

-

Stay Informed About Market Trends: Regularly monitor sugar prices and global supply chain issues that could affect costs. Being proactive can help in making timely sourcing decisions.

-

Understand Pricing Nuances: Be aware of the impact of currency fluctuations, tariffs, and import regulations on pricing, especially when dealing with international suppliers.

Disclaimer on Pricing

The prices discussed are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and supplier evaluation before making purchasing decisions.

Alternatives Analysis: Comparing how often do i change hummingbird feeder With Other Solutions

Exploring Alternatives to Changing Hummingbird Feeders

In the world of bird feeding, maintaining the health and safety of hummingbirds is paramount. While regularly changing hummingbird feeders is essential, there are alternative solutions that can help achieve similar results in a more efficient or convenient manner. This section evaluates the frequency of changing hummingbird nectar against two viable alternatives: automatic hummingbird feeders and nectar guard technology.

Comparison Table

| Comparison Aspect | How Often Do I Change Hummingbird Feeder | Automatic Hummingbird Feeder | Nectar Guard Technology |

|---|---|---|---|

| Performance | Requires changing nectar every 1-4 days depending on weather | Provides consistent nectar flow; reduces spoilage risk | Minimizes insect interference; keeps nectar fresh longer |

| Cost | Low initial cost; ongoing sugar/water expenses | Higher initial investment; minimal ongoing costs | Moderate investment; minimal ongoing costs |

| Ease of Implementation | Simple to use, but requires regular attention | Installation may require tools; automated operation | Easy to install; requires occasional cleaning |

| Maintenance | Regular cleaning needed; labor-intensive | Low maintenance once installed | Requires occasional replacement and cleaning |

| Best Use Case | Ideal for casual bird watchers | Suitable for busy environments or professional setups | Great for areas with high insect activity |

Analyzing Automatic Hummingbird Feeders

Automatic hummingbird feeders are designed to dispense nectar at a controlled rate, minimizing the frequency of manual refilling. These feeders often come with built-in mechanisms that allow for easy cleaning and maintenance, making them a convenient choice for busy professionals or organizations managing multiple feeders. However, the initial investment can be significantly higher than traditional feeders, which may deter some buyers. Additionally, while they reduce the need for frequent nectar changes, they still require occasional monitoring to ensure optimal performance.

Illustrative image related to how often do i change hummingbird feeder

Evaluating Nectar Guard Technology

Nectar guard technology is a novel solution that prevents insects from accessing the nectar while allowing hummingbirds to feed freely. This technology typically involves specialized feeding ports that deter bees and wasps, thus preserving the quality of the nectar for longer periods. The primary advantage of this method is that it reduces the frequency of nectar changes, as the nectar remains uncontaminated by insects. However, the installation of nectar guard systems can involve additional costs, and they may require occasional cleaning to maintain effectiveness.

Conclusion: Selecting the Right Solution for Your Needs

Choosing the right solution for maintaining hummingbird feeders hinges on understanding your specific requirements and operational context. For organizations with limited time for maintenance, automatic feeders may offer the best balance of convenience and performance. Conversely, if insect interference is a significant concern, nectar guard technology could be the most effective choice. Ultimately, evaluating the cost, maintenance, and performance of each option will empower B2B buyers to select a solution that aligns with their needs while promoting the health and well-being of hummingbirds.

Essential Technical Properties and Trade Terminology for how often do i change hummingbird feeder

What Are the Key Technical Properties to Consider When Changing Hummingbird Feeders?

When it comes to maintaining hummingbird feeders, understanding the technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties that B2B buyers should consider:

Illustrative image related to how often do i change hummingbird feeder

1. Material Composition

The material of the feeder—often plastic, glass, or metal—affects both durability and ease of cleaning. High-grade plastics, such as polyethylene or polycarbonate, resist weathering and UV degradation, which is vital for outdoor use in various climates. Glass feeders offer aesthetic appeal and ease of monitoring nectar levels, but they can be prone to breakage.

2. Capacity

The capacity of the feeder directly influences how often nectar needs to be changed. Feeders with larger capacities can hold more nectar, which is beneficial for businesses focusing on high-volume bird feeding. However, in warmer climates, even larger feeders may require more frequent changes due to quicker spoilage.

3. Feeding Port Design

The design of the feeding ports plays a critical role in preventing leaks and ensuring that nectar remains accessible to hummingbirds. Port size and shape can also influence the feeder’s attractiveness to bees and other insects, which is a common concern. A well-designed port minimizes the risk of contamination and spoilage.

4. Ease of Cleaning

Feeders that are easy to disassemble and clean are essential for maintaining hygiene and ensuring the nectar remains fresh. Look for feeders with removable parts and smooth surfaces that prevent mold growth. This property is especially important for businesses that operate on a large scale and require efficient maintenance.

5. Color and Attractiveness

The color of the feeder can influence its effectiveness in attracting hummingbirds. Bright red is often used, as it mimics natural flower colors. However, the material used should be UV-resistant to maintain vibrancy over time. This characteristic is important for marketing purposes, as an attractive feeder can enhance sales.

Illustrative image related to how often do i change hummingbird feeder

6. Weather Resistance

The ability of a feeder to withstand various weather conditions is vital for longevity. Feeders should be designed to resist temperature fluctuations, rain, and UV exposure. This is particularly relevant for international buyers in diverse climates, ensuring that their investments remain viable throughout the year.

What Are Common Trade Terms Related to Hummingbird Feeders?

Understanding industry jargon is essential for effective communication and successful transactions. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of hummingbird feeders, an OEM might produce feeders that are branded and marketed by another business. Recognizing OEMs can be crucial for sourcing high-quality products at competitive prices.

Illustrative image related to how often do i change hummingbird feeder

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of products that a supplier is willing to sell. This is important for B2B buyers to understand as it affects inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases effectively, especially when entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and other details for a specific product or service. For hummingbird feeders, issuing an RFQ can help buyers compare costs, materials, and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs, risk, and logistics. For instance, terms like FOB (Free on Board) indicate that the seller is responsible for transportation costs until the goods reach the shipping point.

Illustrative image related to how often do i change hummingbird feeder

5. Lead Time

This refers to the time it takes from placing an order to receiving the product. In the hummingbird feeder market, knowing the lead time can help businesses plan their inventory and marketing strategies effectively, especially during peak seasons.

6. Warranty

A warranty provides assurance regarding the quality and durability of a product. Understanding the warranty terms for hummingbird feeders can help buyers evaluate the reliability of their investment and facilitate easier returns or replacements if issues arise.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and ensure the satisfaction of their customers.

Navigating Market Dynamics and Sourcing Trends in the how often do i change hummingbird feeder Sector

What Are the Key Trends Impacting the Hummingbird Feeder Market?

The hummingbird feeder market is experiencing dynamic changes driven by several global factors. With increasing interest in birdwatching and wildlife conservation, particularly in regions such as Africa, South America, the Middle East, and Europe, there is a growing demand for high-quality feeders that cater to the needs of hummingbirds. Technological advancements are also influencing the market; smart feeders equipped with sensors that monitor nectar levels and cleanliness are emerging, appealing to tech-savvy consumers and businesses alike.

Moreover, climate change is altering migratory patterns and feeding behaviors of hummingbirds, prompting manufacturers to develop feeders that are more adaptable to varying weather conditions. For international B2B buyers, understanding these trends is crucial, as they dictate consumer preferences and product specifications. The rising awareness about the importance of maintaining fresh nectar—ideally changed every 1-4 days depending on climate conditions—has further emphasized the need for easy-to-clean and efficient feeder designs.

Illustrative image related to how often do i change hummingbird feeder

Additionally, as e-commerce continues to grow, B2B buyers are increasingly sourcing products online, leading to heightened competition among suppliers. This shift necessitates a robust online presence and strategic marketing to reach targeted demographics effectively.

How Is Sustainability and Ethical Sourcing Reshaping the Hummingbird Feeder Industry?

Sustainability is becoming a cornerstone in the hummingbird feeder market, with businesses increasingly focusing on ethical sourcing and environmentally friendly materials. The environmental impact of plastic waste is prompting manufacturers to explore biodegradable alternatives and recycled materials for feeder production. This shift not only aligns with global sustainability goals but also caters to a growing segment of environmentally conscious consumers.

B2B buyers should prioritize suppliers that adhere to sustainability certifications, such as FSC (Forest Stewardship Council) for wood products or certifications related to the use of recycled materials. By fostering ethical supply chains, businesses can enhance their brand reputation and appeal to a broader audience that values corporate responsibility.

Moreover, the introduction of “green” product lines—such as feeders made from sustainable materials that promote biodiversity—can create competitive advantages in the marketplace. As consumers become more educated about the environmental impacts of their purchases, B2B buyers who prioritize sustainable sourcing will likely see improved customer loyalty and increased sales.

What Is the Historical Context of Hummingbird Feeders in B2B Markets?

The evolution of hummingbird feeders has been shaped significantly by advancements in material science and design. Initially, feeders were simple glass or plastic containers designed to hold sugar-water solutions. However, as consumer preferences evolved, so did the technology and aesthetics of hummingbird feeders.

In the late 20th century, manufacturers began to incorporate features such as bee guards, easy-clean designs, and decorative elements to attract both birds and buyers. The rise of the internet in the early 2000s opened new channels for B2B buyers, allowing them to source innovative products from global suppliers.

Today, the market reflects a blend of tradition and innovation, with an emphasis on quality, ease of maintenance, and sustainability. This historical context is essential for B2B buyers who seek to understand the product lifecycle and anticipate future trends in the hummingbird feeder market.

Illustrative image related to how often do i change hummingbird feeder

By recognizing these dynamics, businesses can make informed sourcing decisions that align with both current market demands and long-term sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of how often do i change hummingbird feeder

-

1. How often should I change the nectar in a hummingbird feeder?

The frequency of changing nectar in hummingbird feeders depends largely on environmental conditions. In warmer climates, it’s advisable to change the nectar every 1-2 days to prevent spoilage, while in cooler regions, every 2-4 days is acceptable. Regular changes not only ensure the health of the birds but also enhance their visitation rates. For suppliers, emphasizing the importance of quality nectar and the need for frequent changes can help position your products as vital for hummingbird care. -

2. What are the signs that hummingbird nectar has spoiled?

Spoiled nectar can appear cloudy, contain sediment, or develop mold. A change in color, particularly if it darkens, is also a red flag. Suppliers should educate buyers on these signs to ensure they maintain high standards for bird health. Providing clear guidelines on nectar freshness can enhance customer satisfaction and loyalty, as buyers will appreciate the proactive measures taken to safeguard wildlife. -

3. How can I source high-quality hummingbird feeders for my business?

When sourcing hummingbird feeders, consider partnering with manufacturers that prioritize durability, ease of cleaning, and effectiveness in attracting birds. Look for suppliers that offer customizable options to meet your market’s preferences. Additionally, vet suppliers through reviews, certifications, and samples to ensure the products align with your quality standards. Establishing strong relationships with reliable suppliers will facilitate smoother logistics and consistent product availability. -

4. What customization options should I consider for hummingbird feeders?

Customization options can include size, color, feeding port design, and materials used. Offering unique designs that cater to local aesthetics can enhance market appeal. For B2B buyers, discussing customization with suppliers can lead to competitive advantages in specific markets. Ensure that your suppliers can accommodate your desired specifications while maintaining quality to foster brand loyalty among your customers. -

5. What are the minimum order quantities (MOQs) for hummingbird feeders?

MOQs can vary significantly among suppliers. It’s essential to discuss your needs with potential partners to find a supplier that can accommodate smaller or larger orders based on your business model. Understanding the MOQ is crucial for managing inventory and cash flow effectively. Suppliers that offer flexible MOQ options can be beneficial for new businesses or those looking to test the market with various products. -

6. How should I handle payment terms with international suppliers?

When dealing with international suppliers, establish clear payment terms upfront. Common practices include partial payments upfront, with the balance due upon delivery or after a specified period. Consider using secure payment methods that offer buyer protection. Additionally, discussing currency exchange rates and potential fees can help avoid surprises during transactions. Transparent payment terms foster trust and facilitate smoother business operations. -

7. What quality assurance measures should I implement for hummingbird feeders?

To ensure product quality, implement a thorough quality assurance (QA) process that includes pre-shipment inspections, testing for durability, and compliance with safety standards. Collaborate with suppliers who are willing to provide documentation of their quality control processes. Regular feedback from customers can also guide improvements. Establishing a robust QA system is crucial for maintaining your brand’s reputation and customer satisfaction. -

8. How can I ensure efficient logistics for importing hummingbird feeders?

Efficient logistics are vital for timely product delivery. Work with suppliers who have reliable shipping partners and can provide accurate shipping timelines. Familiarize yourself with import regulations in your target market to avoid delays. Additionally, consider warehousing solutions to manage inventory more effectively. Building strong logistical partnerships will enhance your overall supply chain management and customer satisfaction.

Top 3 How Often Do I Change Hummingbird Feeder Manufacturers & Suppliers List

1. Reddit – Hummingbird Feeder Care Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Change sugar-water in feeders every day when temperatures exceed 80 degrees Fahrenheit to prevent mold and bacteria growth. In cooler weather, change every two days. Use a small amount of nectar if only a few hummingbirds are visiting.

2. Facebook – Hummingbird Feeder

3. Perky-Pet® – Clear Hummingbird Nectar Concentrate

Domain: perkypet.com

Introduction: Perky-Pet® offers a variety of instant hummingbird nectars made with 100% sucrose, containing no artificial flavors or sweeteners. The products include:

1. Perky-Pet® Clear Hummingbird Nectar Concentrate – 64 oz bottle, makes up to 256 oz of hummingbird food, mimics natural flower nectar.

2. Perky-Pet® Instant Clear Hummingbird Nectar – 2 lb bag, makes up to 192 oz of nectar, easy to mix with wate…

Strategic Sourcing Conclusion and Outlook for how often do i change hummingbird feeder

In the realm of hummingbird feeder management, understanding the frequency of nectar changes is pivotal for ensuring the well-being of these delicate birds. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize sourcing high-quality feeders that facilitate easy maintenance. The consensus from industry experts highlights the necessity of changing nectar every 2 to 4 days, with more frequent changes in warmer climates. This not only prevents spoilage but also enhances the attractiveness of your feeder to hummingbirds, ultimately driving customer satisfaction.

Strategic sourcing of feeders that are easy to clean and maintain can elevate the user experience and foster long-term customer loyalty. Additionally, investing in feeders that are designed to deter unwanted pests can significantly reduce maintenance challenges, creating a more appealing environment for hummingbirds.

As you navigate the global market, consider the ecological impact and customer preferences in your sourcing strategies. By aligning your product offerings with the best practices for hummingbird care, you position your business as a leader in the avian supply industry. Embrace this opportunity to enhance your product portfolio and make a positive impact on both nature and your bottom line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.