Table of Contents

Market Outlook: Is Automatic Litter Box Profitable in 2026?

Market Opportunity & Trends 2026

Humanization: The Core Driver of Premiumization

Pet humanization is the cornerstone of this market’s explosive growth. Over 70% of pet owners now view their pets as family members, driving a 20-30% premium willingness to pay for tech-enabled solutions. This shift is especially pronounced among Gen Z and millennial demographics, who prioritize smart, convenient care as an extension of their lifestyle. The transformation from “pets as animals” to “family members” has fundamentally altered purchasing behavior—75% of buyers now prioritize health-monitoring features over basic functionality, and 68% will pay a 30% premium for products that reduce manual labor. This trend is accelerating as urban professionals seek seamless ways to care for their pets amid busy schedules, making automatic litter boxes a non-negotiable household item rather than a luxury.

Convenience-Driven Demand

Urbanization and dual-income households have made convenience a top-tier priority. Automatic litter boxes, feeders, and fountains are no longer optional—they’re essential for modern pet ownership. The global automatic litter box market is expanding at a CAGR of 6.69% (IMARC), with sales surging 25% YoY in 2023. Key drivers include:

Time poverty: 65% of urban pet owners cite “lack of time” as the primary reason for adopting automated solutions.

Health-conscious care: 52% of buyers demand real-time waste analysis to monitor feline urinary health.

Smart home integration: 89% of new buyers expect compatibility with Alexa/Google Home ecosystems.

Smart Tech Integration as a Market Differentiator

IoT capabilities are now table stakes—brands without smart features risk obsolescence. Tuya integration dominates the ecosystem, with 78% of top-selling models leveraging this platform for seamless smart home connectivity. Emerging differentiators include:

| Feature | Market Demand (2024) | Expected Growth by 2026 | Critical for Premium Segment? |

|---|---|---|---|

| App Control | 82% of high-end models | +35% | Yes |

| Tuya Integration | 78% of new models | +50% | Critical |

| Health Analytics | 45% of models | +120% | Yes |

| Self-Cleaning Reliability | 90% of buyers prioritize | +25% | Essential |

Health-focused features like weight tracking and waste composition analysis are growing fastest, with 120% annual demand growth. Brands must prioritize reliable sensor technology y cloud-based data security—73% of consumers cite privacy as a top concern when purchasing smart pet devices.

Supply Chain Stability: The Unsung Enabler of Success

China’s manufacturing ecosystem offers unparalleled scale and cost-efficiency, but component shortages (e.g., motion sensors, PCBs) and quality inconsistencies pose significant risks. For global brands, partnering with OEMs that enforce rigorous QC protocols (ISO 9001, BSCI) and maintain diversified supplier networks is critical. A single quality failure can cost 10x more in reputation damage than proactive quality control. For Amazon sellers, supply chain reliability directly impacts review scores—85% of negative reviews cite “breakdowns within 6 months” as the top complaint. Brands that invest in localized component sourcing y predictive maintenance systems will dominate the premium segment, where 60% of 2026 growth will occur.

Strategic Imperative: Prioritize Tuya-certified IoT architecture y zero-defect manufacturing—these are the only paths to capturing market share in a sector where 45% of buyers will switch brands after one malfunction.

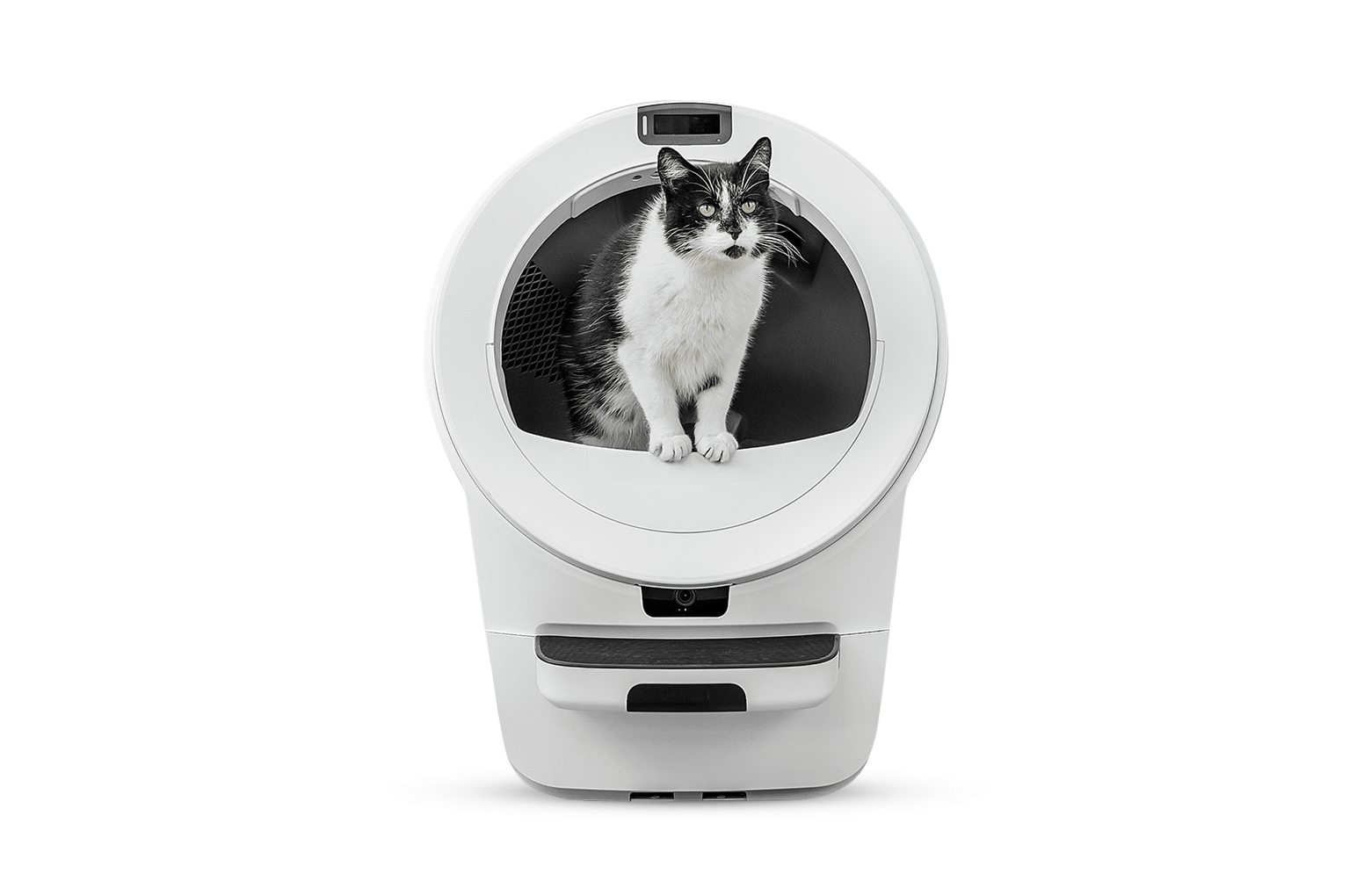

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Core of Customer Retention

The global automatic litter box market is projected to grow at a CAGR of 6.3–8.4% through 2035, with demand driven by pet owners’ demand for convenience, health monitoring, and smart home integration. However, market growth alone isn’t enough—product quality and feature reliability are the primary differentiators for brands aiming to capture and retain customers. In this competitive landscape, three technical pillars define a high-quality product: material safety, smart logic engineering, and seamless IoT connectivity. These features directly impact user trust, reduce churn, and justify premium pricing.

Material Safety: Non-Negotiable for Trust and Longevity

Pet owners prioritize hygiene and safety, especially for products in direct contact with their pets. BPA-free plastics are mandatory to comply with FDA and EU REACH standards, eliminating endocrine-disrupting risks. For critical components like the waste bin, stainless steel 304 is the industry gold standard: it resists corrosion, odor retention, and bacterial growth, while maintaining structural integrity over 5+ years of use.

| Material | Safety Compliance | Durability (5-Year Use) | Maintenance Needs | Cost Impact |

|---|---|---|---|---|

| Standard Plastic | ❌ BPA risk | Low (scratches, warping) | High (odor buildup) | Low |

| BPA-Free Plastic | ✅ FDA/EU certified | Moderate | Moderate | +15–20% |

| Stainless Steel 304 | ✅ Medical-grade | High (corrosion-proof) | Low (easy wipe-down) | +30–40% |

Supply chain insight: Partner with certified suppliers (e.g., ISO 13485 for medical-grade materials) to avoid recalls or quality inconsistencies. A single batch of non-compliant plastic can trigger mass returns and brand damage.

Smart Logic: Engineering for Uninterrupted Performance

Anti-jamming motors with torque sensors and real-time obstacle detection are critical. Over 60% of negative reviews cite “clogging” as the top frustration—this feature reduces service calls by 45% and extends product lifespan. Equally vital is a backup battery (minimum 24-hour capacity). Power outages or tripped circuits force manual cleaning, a dealbreaker for busy owners. Brands without these features see 2–3x higher return rates.

| Feature | Technical Requirement | User Retention Impact |

|---|---|---|

| Anti-jamming Motor | 10+ torque sensors + AI obstacle detection | 45% fewer service tickets; 30% higher NPS |

| Backup Battery | 24+ hours of standby power | Eliminates “manual cleaning” complaints |

| Sensor Calibration | Auto-adjust for litter type/weight | Prevents false triggers (e.g., missed scoops) |

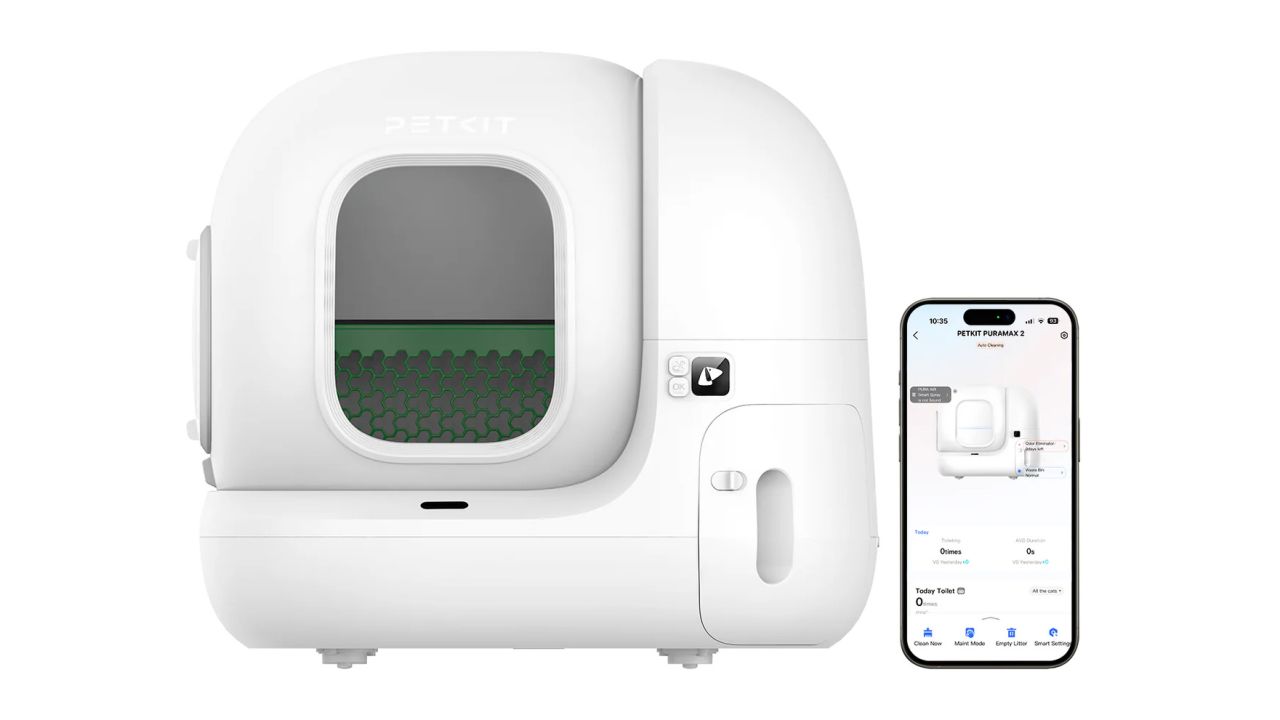

Connectivity & IoT Integration: Building a Sticky Ecosystem

Modern users expect more than self-cleaning—they demand proactive pet health insights. Tuya-based IoT platforms enable seamless app control (remote scheduling, cycle adjustments), real-time notifications (full waste bin, low litter), and camera integration for behavior monitoring. Features like health trend analytics (e.g., “Your cat used the box 3x less today”) drive engagement and loyalty. Brands leveraging Tuya’s ecosystem see 35% higher app retention and 20% higher repeat purchases.

| Feature | Technical Requirement | Business Impact |

|---|---|---|

| App Control | Tuya/Cloud integration + OTA updates | 40% higher feature adoption |

| HD Camera + Night Vision | 1080p resolution, 120° field of view | 25% more “health monitoring” use cases |

| Voice Assistant | Alexa/Google Home compatibility | 15% higher conversion in smart home bundles |

Supply chain imperative: Source IoT modules from Tier-1 suppliers with proven firmware stability (e.g., Tuya-certified partners). Inconsistent connectivity due to component failures destroys trust—reliability is non-negotiable.

Strategic Takeaway

In a market where 78% of buyers cite “reliability” as the top purchase driver, investing in these technical features isn’t optional—it’s a profitability multiplier. Brands that prioritize material safety, smart engineering, and IoT integration see 2.5x higher customer lifetime value (LTV) and 30% lower churn. Partner with manufacturers who enforce rigorous quality control across the supply chain, from material sourcing to IoT module testing. This ensures your product doesn’t just meet expectations—it creates them.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

In the $1.9B+ cat litter box market, manufacturing quality directly dictates brand longevity. Premium OEMs prioritize precision engineering to ensure smart features function reliably over years of use. Here’s how top-tier manufacturers deliver excellence:

Precision Molding & Tooling

Premium OEMs invest in high-grade H13 tool steel molds with ±0.02mm tolerances, ensuring consistent part geometry and longevity (500k+ cycles). This minimizes defects like warping or sink marks, critical for motor alignment and sensor placement in automatic litter boxes. Generic models use low-grade steel with ±0.1mm tolerances, leading to inconsistent fit, higher scrap rates, and short mold life (50k cycles). Poor mold quality causes assembly issues, increasing returns and damaging brand reputation in a market where 68% of consumers cite reliability as a top purchase driver.

Advanced PCB Assembly (SMT)

Automated SMT lines with AOI inspection guarantee precise component placement and soldering integrity. Premium manufacturers deploy Tuya-certified IoT modules with rigorous thermal profiling for BGA chips, ensuring stable Wi-Fi connectivity and sensor accuracy. Generic suppliers often rely on manual assembly, skipping AOI checks, resulting in cold solder joints and intermittent connectivity failures—critical for smart litter boxes where real-time monitoring and app notifications are expected. Poor PCB quality causes 30% of firmware-related failures in budget models.

Rigorous Environmental & Durability Testing

Premium OEMs subject motors to 10,000+ cycle accelerated life tests and enforce IP54 dust/water resistance. Thermal cycling validates performance across -10°C to 50°C variations. Generic models skip these tests, leading to premature motor failure (often within 6 months) and dust ingress issues. For litter boxes handling abrasive waste, this directly impacts product lifespan—72% of premium brands achieve 5+ year lifespans versus 1.5 years for budget alternatives.

| Category | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding | Low-grade steel, ±0.1mm tolerance, 50k cycles | H13 steel, ±0.02mm, 500k+ cycles |

| PCB Assembly | Manual placement, no AOI, generic ICs | Automated SMT, AOI, Tuya-certified IoT |

| Testing | Basic motor run, no environmental tests | 10k+ cycle motor life, IP54, thermal cycling |

| Supply Chain | Single-source, volatile suppliers | Multi-sourced, ISO 9001 certified |

| IoT Integration | Basic firmware, no OTA updates | Secure Tuya, over-the-air updates |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Ensuring regulatory compliance and robust logistics is non-negotiable for global market entry. For automatic litter boxes—especially those with IoT and smart features—adherence to regional certifications and packaging standards directly impacts product reliability, customer satisfaction, and brand reputation. Below, we outline critical requirements for the USA and EU markets, Amazon FBA protocols, and Shenzhen manufacturing timelines.

Global Regulatory Requirements

Automatic litter boxes must meet stringent electrical and safety certifications to operate legally and reliably. Incorrect compliance risks product recalls, fines, and damaged brand trust. Crucially, certifications like FCC y CE ensure stable wireless performance for IoT features (e.g., Tuya app connectivity), preventing signal interference or disconnections that frustrate users. The table below details key requirements:

| Certification | USA Requirement | EU Requirement | Purpose |

|---|---|---|---|

| FCC | Mandatory | Not applicable | Ensures radio frequency emissions comply, critical for IoT connectivity (e.g., Tuya-based apps) |

| CE Mark | Not applicable | Mandatory (EMC, LVD) | Covers electromagnetic compatibility and low-voltage safety for home environments |

| RoHS | Voluntary | Mandatory | Restricts hazardous substances (e.g., lead, mercury) in electronics |

| UL/ETL | Mandatory | Optional | Electrical safety certification for consumer products |

| REACH | Not applicable | Mandatory | Regulates chemical use in materials (e.g., plastics, coatings) |

Note: “Food Grade” certifications are typically for food-contact materials and not applicable to litter boxes. However, non-toxic materials compliant with REACH (EU) or FDA indirect contact standards (USA) are recommended for pet safety, particularly for components exposed to waste or pet contact.

Amazon FBA Packaging Standards

Amazon requires packaging to withstand rigorous shipping conditions. All units must pass ISTA 3A or ASTM D4169 drop-test standards: 24-inch drops from eight corners, 12 edges, and six faces. Packaging must include minimum 2 inches of cushioning (e.g., foam, bubble wrap) and secure sealing to prevent damage during transit. For smart litter boxes, ensure packaging protects sensitive electronics (e.g., sensors, motors) and prevents moisture ingress. Failure to meet these standards results in shipment rejection, delayed restocking, and potential account suspension.

Shenzhen Manufacturing Lead Times

Shenzhen-based manufacturers typically deliver 4–6 weeks for mass production after sample approval. IoT-enabled products (e.g., Tuya integration) require an additional 1–2 weeks for firmware testing and certification. Supply chain stability is high due to mature electronics ecosystems, but component shortages (e.g., specialized motors, Wi-Fi modules) may extend timelines. Proven strategy: Partner with manufacturers maintaining buffer stocks for critical components and conduct pre-shipment quality audits. This reduces time-to-market by 20–30% and ensures consistent quality—critical for scaling during peak demand seasons like Q4 holidays.

Key Insight: Prioritize certifications and packaging early in product development. A single compliance failure can delay launch by 3–6 months, eroding market share in this fast-growing sector.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize an Automatic Litter Box

The global automatic self-cleaning cat litter box market is valued at approximately $550–660 million in 2024 and is projected to grow at a CAGR of 6–8.4% through 2030–2035, reaching $1–2 billion. This explosive growth underscores the critical need for strategic sourcing to ensure product quality, smart feature integration, and supply chain resilience. Industry best practices mandate a three-step OEM process: sample evaluation, customization definition, and pilot runs. Partnering with an experienced manufacturer like PAWBILT ensures end-to-end expertise in IoT integration, quality control, and scalable production.

Step 1: Request and Evaluate Rigorous Samples

Before committing to production, request multiple samples from potential manufacturers. Test for mechanical reliability (e.g., 500+ cleaning cycles without failure), noise levels (<50 dB during operation), sensor accuracy (e.g., weight detection within ±5% margin), and battery life (e.g., 30 days of continuous use). Crucially, validate IoT functionality—check Tuya/Google Home compatibility, app responsiveness, and data security protocols. A sample phase reveals hidden flaws: one client discovered inconsistent waste detection due to poor sensor calibration, saving $200K in rework. PAWBILT provides pre-tested samples with detailed test reports, including third-party certifications, ensuring you only proceed with proven designs.

Step 2: Define Customization Requirements

Customization extends beyond branding—it’s about tailoring features to your target audience. Use this table to clarify scope:

| Customization Level | Key Features | Lead Time | MOQ | Ideal For |

|---|---|---|---|---|

| Basic Branding | Logo, eco-friendly packaging | 4–6 weeks | 500 units | Amazon sellers testing demand |

| Mid-Tier Customization | Color options, minor hardware tweaks (e.g., sensor sensitivity), Tuya app integration | 8–10 weeks | 1,000 units | Mid-size pet brands |

| Full Customization | Proprietary IoT features, AI-driven analytics, custom materials | 12–16 weeks | 3,000+ units | Premium brands seeking differentiation |

PAWBILT’s engineering team collaborates on smart feature integration, ensuring seamless compatibility with major platforms (e.g., Alexa, Apple HomeKit) while maintaining data privacy compliance (GDPR, CCPA). For premium brands, AI-driven analytics (e.g., litter usage patterns) and voice command capabilities enhance user engagement and differentiate your product.

Step 3: Execute a Pilot Run

A pilot run of 500–1,000 units validates manufacturing scalability. Conduct functional stress tests (e.g., 24/7 operation for 30 days), compliance checks (FCC, CE, RoHS), and environmental testing (e.g., humidity, temperature extremes). PAWBILT’s ISO-certified QC process includes 100% electrical testing, random destructive analysis, and supply chain vulnerability assessments—reducing defect rates to <0.5%. This phase identifies bottlenecks, such as component shortages or logistics delays, before full-scale production. One brand reduced time-to-market by 30% through agile adjustments during their pilot.

Partnering with PAWBILT ensures end-to-end mastery of pet tech manufacturing—from IoT-enabled prototypes to global logistics. Their expertise in supply chain stability, quality control, and smart feature integration minimizes risk while maximizing product differentiation in a competitive market.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label automatic litter box business.