Introduction: Navigating the Global Market for how often should hummingbird feeders be changed

In the competitive landscape of avian products, understanding how often hummingbird feeders should be changed is essential for B2B buyers looking to meet the demands of discerning customers. The freshness of nectar plays a pivotal role in attracting hummingbirds, which can directly impact sales for suppliers in regions like Africa, South America, the Middle East, and Europe. However, the challenge lies in navigating varying climatic conditions and consumer expectations, which can significantly influence nectar spoilage rates and feeder maintenance.

This comprehensive guide addresses the critical aspects of hummingbird feeder management, including the types of feeders available, their specific applications, supplier vetting processes, and cost considerations. We delve into the recommended frequency for changing nectar based on environmental factors, ensuring that buyers can make informed decisions that align with best practices in the industry. Additionally, this resource provides insights into the preferences of different markets, enabling suppliers to tailor their offerings accordingly.

By leveraging the information in this guide, international B2B buyers will be empowered to enhance their product lines and marketing strategies, thereby increasing customer satisfaction and driving sales growth. With an authoritative, solution-oriented approach, this guide serves as a vital tool for those aiming to succeed in the hummingbird feeder market.

Table Of Contents

- Top 2 How Often Should Hummingbird Feeders Be Changed Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often should hummingbird feeders be changed

- Understanding how often should hummingbird feeders be changed Types and Variations

- Key Industrial Applications of how often should hummingbird feeders be changed

- 3 Common User Pain Points for ‘how often should hummingbird feeders be changed’ & Their Solutions

- Strategic Material Selection Guide for how often should hummingbird feeders be changed

- In-depth Look: Manufacturing Processes and Quality Assurance for how often should hummingbird feeders be changed

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should hummingbird feeders be changed’

- Comprehensive Cost and Pricing Analysis for how often should hummingbird feeders be changed Sourcing

- Alternatives Analysis: Comparing how often should hummingbird feeders be changed With Other Solutions

- Essential Technical Properties and Trade Terminology for how often should hummingbird feeders be changed

- Navigating Market Dynamics and Sourcing Trends in the how often should hummingbird feeders be changed Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often should hummingbird feeders be changed

- Strategic Sourcing Conclusion and Outlook for how often should hummingbird feeders be changed

- Important Disclaimer & Terms of Use

Understanding how often should hummingbird feeders be changed Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Change Frequency | Change nectar every 2-4 days under normal conditions. | Retailers and distributors of hummingbird feeders and nectar. | Pros: Easy maintenance; aligns with typical consumer behavior. Cons: May not account for varying climates. |

| Climate-Sensitive Frequency | Adjusts nectar change based on local climate conditions (1-2 days in heat). | Businesses operating in diverse climatic regions. | Pros: Ensures optimal nectar quality; improves bird visitation. Cons: Requires knowledge of local climate patterns. |

| Seasonal Variation | Changes frequency based on seasonal changes (more frequent in summer). | Suppliers targeting specific seasonal markets. | Pros: Maximizes hummingbird attraction during peak seasons. Cons: Seasonal variability can complicate inventory management. |

| Long-Term Maintenance Plan | Establishes a routine for regular cleaning and nectar change every 1-2 weeks. | Organizations focused on long-term bird care solutions. | Pros: Reduces maintenance frequency; encourages bird health. Cons: Risk of nectar spoilage if not monitored closely. |

| Event-Based Frequency | Nectar change aligned with specific events (e.g., birdwatching festivals). | Event organizers and promotional businesses. | Pros: Maximizes bird activity during events; enhances visitor experience. Cons: Requires careful planning and coordination. |

What is the Standard Change Frequency for Hummingbird Feeders?

The standard recommendation for changing hummingbird nectar is every 2 to 4 days, depending on environmental conditions. This approach is ideal for retailers and distributors who want to provide customers with straightforward guidance. While it simplifies maintenance for users, it may not adequately address the nuances of varying climates, potentially leading to nectar spoilage in hotter regions.

How Does Climate Influence Hummingbird Feeder Maintenance?

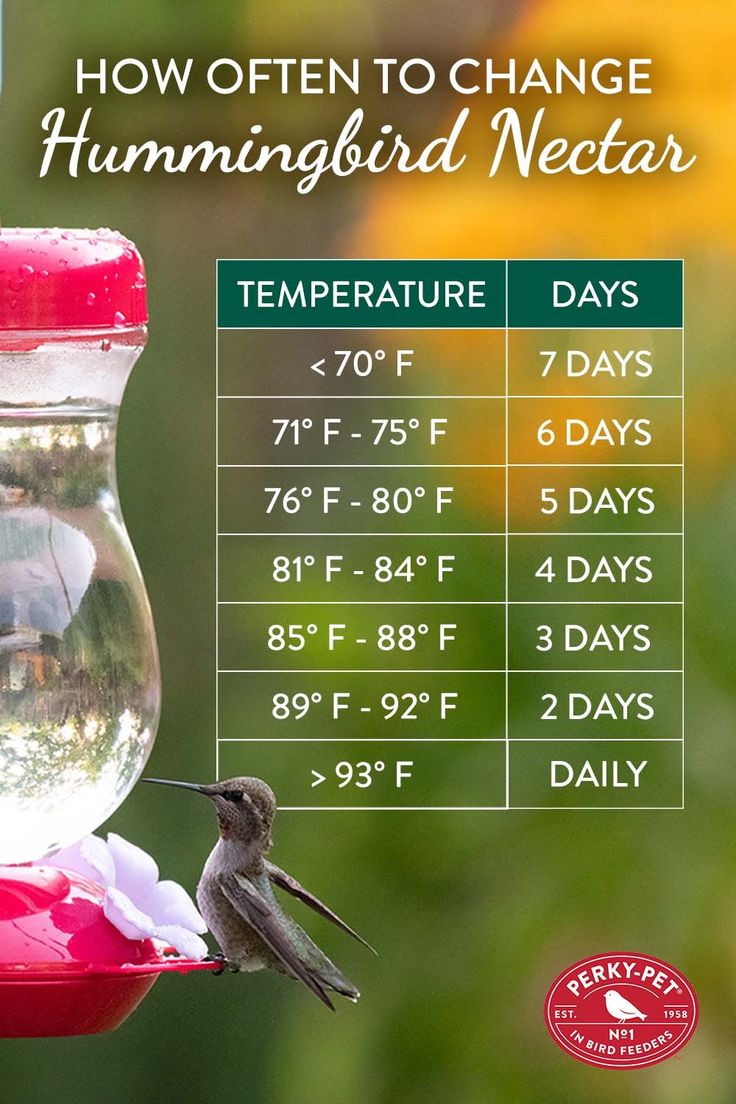

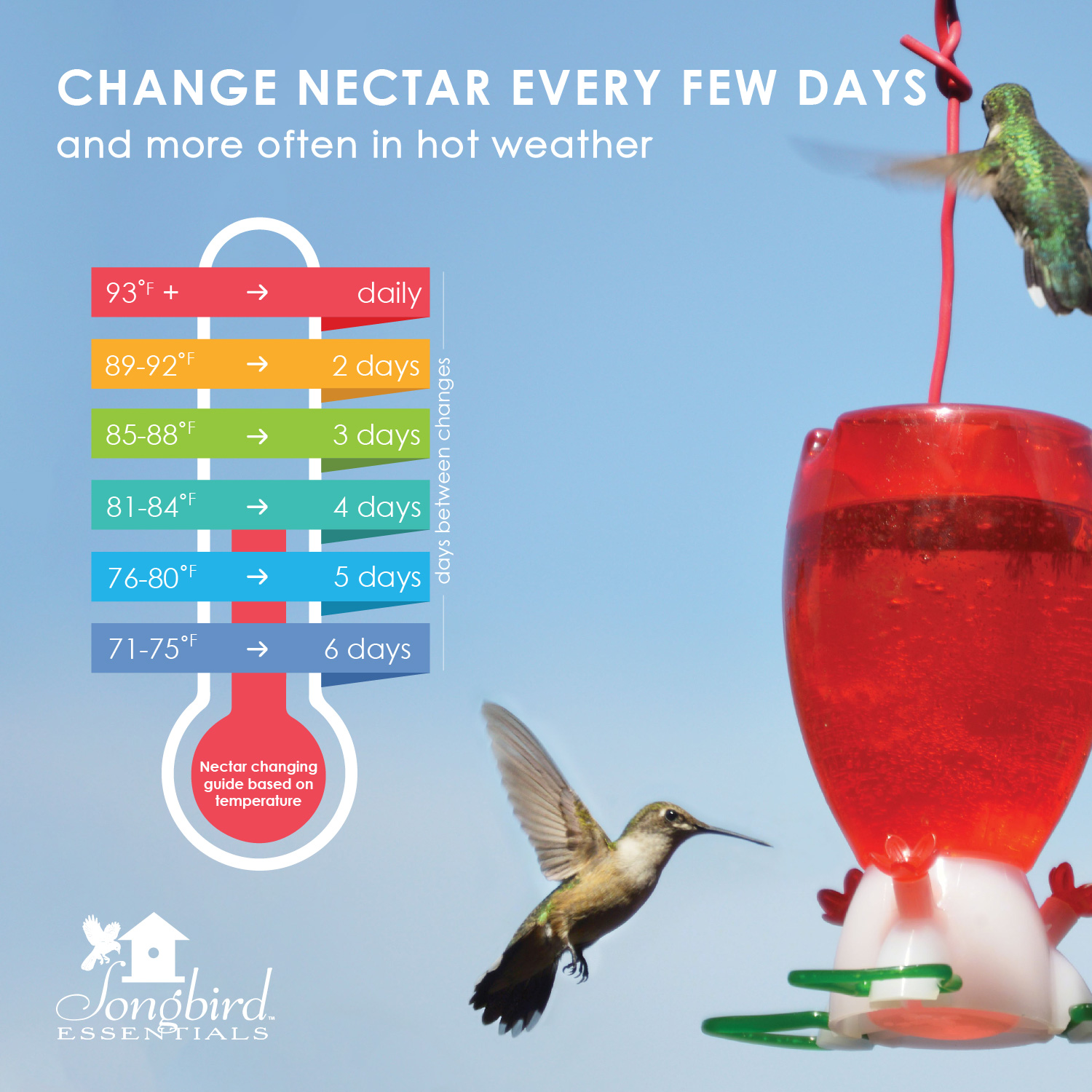

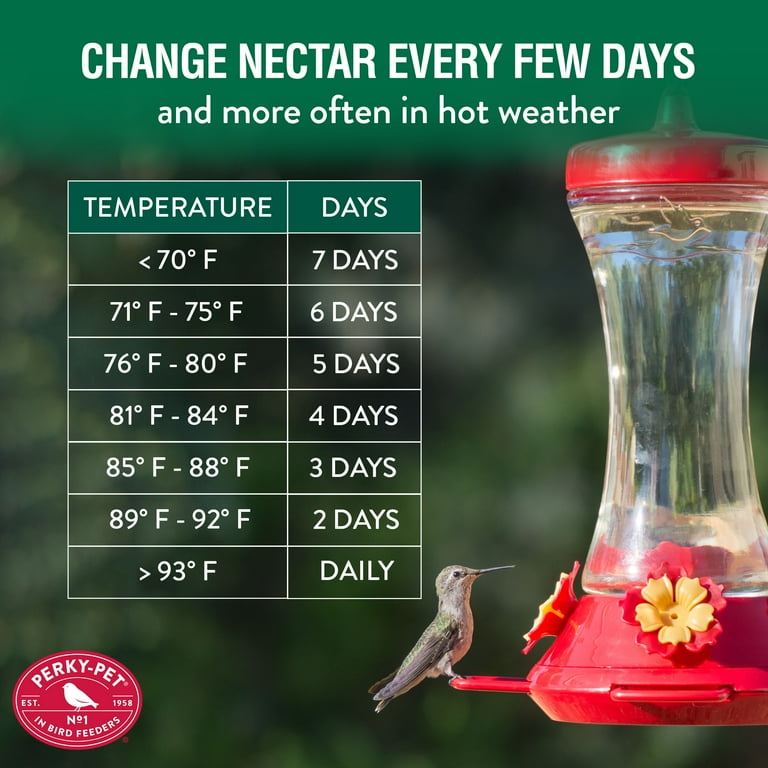

Climate-sensitive frequency adjustments are crucial for businesses operating in diverse environments. In hotter regions, nectar may need to be changed every 1-2 days to prevent spoilage. This awareness can help companies tailor their products and advice to local conditions, ensuring better bird visitation and customer satisfaction. Understanding regional climate patterns becomes essential for effective inventory management.

Why Consider Seasonal Variation in Nectar Change?

Adopting a seasonal variation strategy allows suppliers to adapt nectar change frequencies based on seasonal activity. For instance, during the peak summer months, more frequent changes can attract more hummingbirds. This strategy not only maximizes customer engagement but also aligns with the natural behaviors of hummingbirds, making it an attractive option for businesses targeting specific seasonal markets.

What is a Long-Term Maintenance Plan for Hummingbird Feeders?

A long-term maintenance plan involves establishing a routine for nectar changes and cleaning every 1-2 weeks. This approach is particularly appealing to organizations focused on sustainable bird care solutions. While it reduces the frequency of maintenance, companies must ensure that users are educated about monitoring nectar freshness to prevent spoilage.

How Can Event-Based Frequency Enhance Hummingbird Engagement?

Event-based frequency changes align nectar maintenance with specific birdwatching events or festivals. This strategy is beneficial for event organizers and promotional businesses looking to enhance visitor experiences. However, it requires careful planning and coordination to ensure that feeders are adequately maintained, maximizing bird activity during peak times.

Key Industrial Applications of how often should hummingbird feeders be changed

| Industry/Sector | Specific Application of how often should hummingbird feeders be changed | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Ecotourism and Wildlife Parks | Regular maintenance of feeders to attract hummingbirds for visitors | Enhances visitor experience and promotes wildlife conservation | Quality of feeders, ease of cleaning, and durability in various climates |

| Agriculture | Use of hummingbird feeders for pollination in fruit and flower farms | Improves crop yield through effective pollination | Nectar formulation, feeder design to prevent insect interference |

| Education and Research | Hummingbird feeder maintenance in educational programs | Provides hands-on learning experiences about ecosystems and conservation | Compliance with safety regulations, educational materials, and feeder accessibility |

| Retail and E-commerce | Selling hummingbird feeders and nectar solutions | Increases product offerings and customer engagement | Supplier reliability, product variety, and pricing strategies |

| Landscaping and Gardening | Incorporation of feeders in landscape designs for aesthetic appeal | Enhances property value and attracts diverse bird species | Design compatibility, feeder placement strategies, and maintenance ease |

How is Regular Hummingbird Feeder Maintenance Applied in Ecotourism and Wildlife Parks?

In ecotourism and wildlife parks, regular maintenance of hummingbird feeders is crucial to attract these birds and enhance visitor experiences. By ensuring that the nectar is fresh and the feeders are clean, parks can create a vibrant atmosphere that encourages wildlife observation. This not only promotes conservation efforts but also drives higher visitor engagement and satisfaction. Buyers in this sector need to consider feeders that are durable and easy to clean, as well as nectar formulations that can withstand varying weather conditions.

What Role Do Hummingbird Feeders Play in Agriculture?

Hummingbird feeders are increasingly used in agricultural settings, particularly in fruit and flower farms, where these birds serve as essential pollinators. Regularly changing the nectar helps to maintain a consistent feeding source, thereby attracting hummingbirds and improving pollination rates. This can lead to increased crop yields and better quality produce. B2B buyers in agriculture should focus on feeders that minimize insect interference and are designed for easy maintenance, ensuring that they can provide a reliable food source for these beneficial birds.

How Can Educational Institutions Utilize Hummingbird Feeders?

Educational institutions often incorporate hummingbird feeders into their curriculum to provide students with hands-on learning experiences about ecosystems and wildlife conservation. By maintaining fresh nectar and clean feeders, schools can create an inviting environment for these birds, fostering interest in biology and environmental science. Buyers in this sector must ensure that the feeders comply with safety regulations and are accessible for students of all ages, while also providing educational materials that enhance the learning experience.

Why Should Retailers Focus on Hummingbird Feeders?

For retailers and e-commerce platforms, offering hummingbird feeders and nectar solutions can significantly enhance product offerings and customer engagement. Regularly changing the nectar is a key selling point, as it ensures that customers can attract and retain hummingbirds effectively. Retailers should consider supplier reliability and product variety to meet diverse customer needs. Additionally, pricing strategies that reflect the quality and uniqueness of the products can help in building a loyal customer base.

How Do Hummingbird Feeders Enhance Landscaping Projects?

In landscaping and gardening, incorporating hummingbird feeders can add aesthetic value while attracting a variety of bird species. Regular maintenance of these feeders ensures that they remain functional and visually appealing. This not only enhances property values but also contributes to biodiversity in urban and suburban areas. Buyers in landscaping should focus on the design compatibility of feeders with different garden styles and ensure that they are easy to maintain, thus providing a long-term solution for attracting wildlife.

3 Common User Pain Points for ‘how often should hummingbird feeders be changed’ & Their Solutions

Scenario 1: Inconsistent Nectar Quality Affects Bird Visits

The Problem: B2B buyers managing birdwatching parks or eco-tourism businesses often face the challenge of ensuring a consistent influx of hummingbirds to their feeders. When nectar is not changed frequently enough, it can spoil, leading to mold or fermentation, which deters birds. This not only affects the visitors’ experience but can also harm the birds, resulting in negative feedback from customers who expect vibrant bird activity.

The Solution: To maintain nectar quality and attract hummingbirds, establish a rigorous schedule for changing the nectar based on local climate conditions. In warmer or humid areas, nectar should be replaced every 1-2 days, while in cooler climates, every 3-4 days may suffice. Implement a tracking system using calendars or reminders to ensure that the nectar is changed on time. Additionally, consider investing in durable, easy-to-clean feeders that allow for quick maintenance. Educate staff on the importance of this routine to enhance the overall birdwatching experience, ensuring that visitors see healthy and active hummingbirds.

Scenario 2: Seasonal Changes Impact Nectar Requirements

The Problem: Buyers often encounter issues during transitional seasons when the feeding habits of hummingbirds change. For instance, as temperatures drop in autumn or rise in spring, the frequency with which nectar needs to be changed may shift. Failure to adapt to these changes can lead to either wasted resources or neglected feeders that do not meet the birds’ needs, potentially leading to lower customer satisfaction and reduced bird activity.

The Solution: Develop a seasonal management plan that includes guidelines for nectar preparation and feeder maintenance. For instance, during peak migration seasons, such as spring and fall, increase the frequency of nectar changes to accommodate higher bird traffic. Use a mix of local weather forecasts and historical data to anticipate these changes. It’s also beneficial to communicate these adjustments to clients or visitors, perhaps through newsletters or social media, to keep them engaged and informed about the hummingbird activity. This proactive approach not only enhances the experience but also positions your business as a knowledgeable leader in bird care.

Scenario 3: Attracting Hummingbirds While Managing Pests

The Problem: Many B2B buyers face the dual challenge of attracting hummingbirds while managing pests, particularly bees and wasps that can invade nectar feeders. These pests not only compete with hummingbirds for food but can also deter them from visiting altogether. This creates a frustrating situation for businesses that rely on birdwatching as a key attraction, as visitors may leave disappointed if they do not see the desired birds.

The Solution: To effectively manage this issue, incorporate strategic feeder placement and design modifications. Position feeders away from flowering plants that attract bees and consider using feeders with bee guards or ports designed specifically for hummingbirds. Regularly changing the nectar will also help; fresh nectar is less likely to attract pests compared to spoiled solutions. Furthermore, educate your staff on pest management techniques, such as using natural repellents or adjusting feeder heights, to minimize bee interactions. By implementing these strategies, businesses can create a welcoming environment for hummingbirds while reducing pest-related issues, thereby enhancing the overall visitor experience.

Strategic Material Selection Guide for how often should hummingbird feeders be changed

What Materials Are Best for Hummingbird Feeders?

When selecting materials for hummingbird feeders, it’s essential to consider properties that affect their performance, durability, and suitability for various climates. Below, we analyze four common materials used in the construction of hummingbird feeders, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

Glass: A Timeless Choice for Hummingbird Feeders

Key Properties:

Glass is non-porous, making it resistant to mold and easy to clean. It can withstand a wide range of temperatures, which is beneficial in varying climates.

Illustrative image related to how often should hummingbird feeders be changed

Pros & Cons:

The durability of glass is a significant advantage; it does not degrade over time like some plastics. However, glass feeders can be heavier and more fragile, leading to potential breakage during shipping or use. The manufacturing complexity is moderate, as glass requires specialized processes.

Impact on Application:

Glass feeders maintain nectar freshness longer than plastic due to their non-reactive nature. However, they can become too hot in direct sunlight, potentially affecting the nectar’s quality.

International Considerations:

For buyers in regions like Africa and South America, where shipping glass can be risky, ensuring proper packaging is crucial. Compliance with local regulations regarding materials and safety is also necessary.

Plastic: A Lightweight Alternative for Hummingbird Feeders

Key Properties:

Plastic is lightweight and can be molded into various shapes, allowing for innovative designs. It often comes with UV protection to resist fading and degradation.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing. However, lower-quality plastics may warp or degrade over time, especially in high temperatures.

Impact on Application:

Plastic feeders can be less effective in maintaining nectar freshness, as they may absorb odors or flavors over time. Regular cleaning is essential to prevent mold growth.

International Considerations:

Buyers in the Middle East may prefer plastic due to its lightweight nature, which reduces shipping costs. Compliance with international standards for food safety and environmental impact is essential.

Metal: A Durable Option for Hummingbird Feeders

Key Properties:

Metal, particularly stainless steel, offers excellent corrosion resistance and durability. It can withstand extreme temperatures without degrading.

Pros & Cons:

Metal feeders are highly durable and less likely to break compared to glass. However, they can be more expensive and may require specialized manufacturing processes. Additionally, they can heat up quickly in direct sunlight, which may affect nectar quality.

Impact on Application:

Metal feeders are often used in commercial applications due to their robustness. However, they may not be suitable for all environments, particularly in humid areas where rust can be an issue.

Illustrative image related to how often should hummingbird feeders be changed

International Considerations:

In Europe, compliance with environmental regulations regarding metal recycling is crucial. Buyers should also consider local preferences for aesthetics, as metal feeders may not appeal to all markets.

Silicone: An Innovative Material for Hummingbird Feeders

Key Properties:

Silicone is flexible, durable, and resistant to extreme temperatures. It is also non-toxic and easy to clean.

Pros & Cons:

The flexibility of silicone allows for unique designs and shapes. However, it may not be as durable as glass or metal, and certain formulations can degrade over time when exposed to UV light.

Impact on Application:

Silicone feeders can be effective in maintaining nectar freshness, but they may require more frequent replacement than other materials.

International Considerations:

For regions like Vietnam, where innovation is valued, silicone feeders may appeal to buyers looking for modern designs. Compliance with safety standards is essential to ensure they are safe for bird consumption.

Summary Table of Material Selection for Hummingbird Feeders

| Material | Typical Use Case for how often should hummingbird feeders be changed | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Ideal for residential use; maintains nectar freshness | Non-porous, easy to clean | Fragile, heavier | Medium |

| Plastic | Suitable for lightweight, portable feeders | Low cost, versatile designs | May degrade in heat, odors | Low |

| Metal | Best for commercial or long-lasting feeders | Highly durable, corrosion-resistant | Higher cost, can heat up quickly | High |

| Silicone | Innovative designs for modern feeders | Flexible, non-toxic | Less durable, UV degradation | Medium |

This analysis provides a comprehensive overview of material options for hummingbird feeders, helping B2B buyers make informed decisions based on their specific market needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how often should hummingbird feeders be changed

What Are the Main Stages in the Manufacturing Process of Hummingbird Feeders?

The manufacturing process of hummingbird feeders typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials that are safe for birds and durable enough to withstand various environmental conditions. Common materials include plastics, glass, and metal. Suppliers often focus on UV-resistant plastics to prevent degradation from sunlight. For glass components, manufacturers ensure that the glass is tempered to resist breakage.

-

Forming: This stage involves shaping the materials into the desired components of the feeder. Techniques such as injection molding are commonly used for plastic parts, while glass blowing or molding is used for glass components. Metal parts may undergo stamping or die-casting. The choice of technique affects the cost, durability, and aesthetics of the final product.

-

Assembly: Once the components are formed, they are assembled into the final product. This may be done manually or through automated assembly lines, depending on the scale of production. Components such as feeding ports, reservoirs, and bases are carefully fitted together, ensuring that they are secure and functional.

-

Finishing: The final stage includes quality checks, painting, or coating to enhance durability and appearance. Finishing processes may also involve applying non-toxic coatings to prevent rust on metal parts or using environmentally friendly paints.

What Key Techniques Are Used in Manufacturing Hummingbird Feeders?

Manufacturers employ various techniques to enhance the quality and functionality of hummingbird feeders. Key techniques include:

-

Injection Molding: This is essential for creating complex shapes and ensuring consistency in plastic parts. It allows for high-volume production while maintaining precision.

-

Tempering Glass: For glass feeders, tempering strengthens the glass, making it less prone to breakage. This is particularly important for outdoor products exposed to elements.

-

Surface Treatment: Applying UV-resistant coatings protects plastic components from sun damage and ensures longevity. Additionally, surfaces are often treated to resist bacterial growth, crucial for maintaining feeder hygiene.

-

Automated Quality Control: Many manufacturers use automated systems to monitor the production process in real-time. This includes sensors that can detect defects or inconsistencies during forming and assembly.

How Are Quality Assurance Processes Implemented in Hummingbird Feeder Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that products meet specific standards and customer expectations. Key elements of QA in hummingbird feeder manufacturing include:

-

International Standards Compliance: Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. This ensures that processes are efficient and consistent.

-

Industry-Specific Certifications: Depending on the market, manufacturers may also seek certifications like CE marking for products sold in Europe or specific environmental certifications that demonstrate compliance with safety and sustainability standards.

-

Quality Control Checkpoints: Quality control is implemented at various stages:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Checks are performed during production to identify defects early.

– Final Quality Control (FQC): The finished products are thoroughly inspected before packaging and shipping.

What Common Testing Methods Are Used for Hummingbird Feeders?

To ensure the safety and functionality of hummingbird feeders, various testing methods are employed:

-

Durability Testing: Products are subjected to environmental testing, including UV exposure, temperature fluctuations, and impact resistance tests, to simulate real-world conditions.

-

Hygiene Testing: This involves testing for bacterial growth in feeders, ensuring that materials used do not promote mold or mildew.

-

Leak Testing: For feeders with liquid components, manufacturers conduct tests to ensure that there are no leaks at joints or seals.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of suppliers:

-

Supplier Audits: Conducting regular audits of the supplier’s facilities can provide insights into their manufacturing processes and quality assurance practices. This includes checking for compliance with international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for quality reports, including details of testing methods, results, and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased evaluations of the supplier’s quality control processes. This is particularly valuable for buyers in international markets who may not be able to visit facilities personally.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions may have distinct regulations regarding product safety and environmental impact. Buyers should ensure that suppliers are compliant with local regulations, which may differ significantly from international standards.

-

Cultural Considerations: Understanding the local market’s expectations regarding quality and sustainability can influence purchasing decisions. Buyers should be aware of how cultural factors affect product design and features.

-

Logistics and Supply Chain Management: International buyers should consider the implications of shipping and handling on product quality. Ensuring that suppliers have robust logistics processes in place can mitigate risks associated with product damage during transit.

In conclusion, the manufacturing processes and quality assurance practices for hummingbird feeders are vital for ensuring product safety, durability, and customer satisfaction. B2B buyers must engage thoroughly with suppliers to verify quality control measures and certifications, especially when navigating international markets. By understanding these processes, buyers can make informed decisions that align with their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should hummingbird feeders be changed’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers interested in understanding how often hummingbird feeders should be changed. Regular maintenance of these feeders is vital for ensuring the health and safety of hummingbirds, which can directly affect customer satisfaction and the success of wildlife-related businesses. This guide will help you establish clear protocols for nectar management and supplier evaluation.

Step 1: Assess Environmental Conditions

Understanding the environmental conditions where the feeders will be used is crucial. Factors such as temperature, humidity, and sunlight exposure can significantly influence how quickly nectar spoils. In warmer, humid climates, nectar may need to be changed every day or two, while cooler climates can allow for a longer duration of 2-4 days.

Step 2: Define Nectar Composition Standards

Establishing standards for nectar composition is essential for attracting hummingbirds effectively. The typical nectar ratio is four parts water to one part sugar, which mimics natural flower nectar. Ensure that suppliers provide nectar without dyes or additives, as these can be harmful to birds and deter them from feeding.

Step 3: Determine Cleaning Protocols

Regular cleaning of hummingbird feeders is critical to prevent mold and bacteria growth. Develop a cleaning schedule that aligns with nectar change intervals—ideally, feeders should be cleaned every time the nectar is refreshed. Look for suppliers who offer easy-to-clean feeder designs, which can simplify maintenance.

Step 4: Verify Supplier Certifications and Standards

Before finalizing any procurement, it’s important to verify that potential suppliers meet industry standards for bird feeding products. Request documentation of certifications such as those from wildlife organizations or quality assurance programs. This ensures that the products are safe for both birds and consumers.

Step 5: Evaluate Supplier Reliability

Assess the reliability of potential suppliers by checking their track record with existing clients. Request references or case studies from similar businesses to gauge their performance in product quality and delivery timelines. A reliable supplier can significantly reduce the risk of stock shortages or product failures.

Step 6: Establish Feedback Mechanisms

Implement a feedback system to gather insights from customers regarding the effectiveness of the feeders and nectar. This can help you adjust your purchasing strategy based on customer preferences and the performance of different products. Regular feedback will enhance customer loyalty and improve product offerings.

Step 7: Monitor Seasonal Changes

Recognize that the frequency of nectar changes may vary with the seasons. During peak migration periods, hummingbird activity may increase, necessitating more frequent nectar changes. Stay informed about seasonal patterns in your region to adjust your procurement and maintenance schedules accordingly.

By following this checklist, B2B buyers can ensure they are effectively managing hummingbird feeders, ultimately leading to healthier birds and satisfied customers. Regular maintenance and supplier evaluation are key to sustaining a successful business in the wildlife feeding sector.

Comprehensive Cost and Pricing Analysis for how often should hummingbird feeders be changed Sourcing

What Are the Key Cost Components in Sourcing Hummingbird Feeders?

When sourcing hummingbird feeders, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality plastics or glass, which are durable and suitable for outdoor use, tend to be more expensive. Eco-friendly materials may also attract a premium price due to their sustainability credentials.

-

Labor: Labor costs can vary based on the region of production. Countries with higher labor costs may lead to increased prices. However, investing in skilled labor can enhance product quality, which is crucial for customer satisfaction.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, thereby lowering the overall cost.

-

Tooling: Initial setup costs for molds and tools used in the production of feeders can be substantial. These costs are typically amortized over the volume of production, so higher orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the feeders meet safety and quality standards. While this incurs additional costs, it can prevent returns and enhance brand reputation.

-

Logistics: Shipping costs, including freight and insurance, can vary widely depending on the destination and Incoterms. For international buyers, understanding these costs is crucial for accurate pricing.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market competition and product demand.

How Do Price Influencers Affect Hummingbird Feeders?

Several factors influence the pricing of hummingbird feeders, particularly in international markets:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically benefit from bulk pricing, reducing the cost per unit. This is particularly advantageous for B2B buyers looking to distribute feeders across multiple locations.

-

Specifications and Customization: Custom designs or specialized features (like bee guards) may increase the cost. Buyers should weigh the benefits of customization against their budget.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., BPA-free, eco-friendly) can elevate costs but may also justify a higher retail price due to enhanced consumer appeal.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role. Established suppliers with proven track records may command higher prices but offer better assurance of quality and service.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Different Incoterms can significantly affect the total landed cost of the product.

What Are the Best Buyer Tips for Cost-Efficiency in Hummingbird Feeders?

To optimize cost-efficiency when sourcing hummingbird feeders, consider the following strategies:

-

Negotiate Pricing: Don’t hesitate to negotiate terms with suppliers. Discuss volume discounts and payment terms to secure a better deal.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider factors like durability, maintenance, and potential returns when assessing the overall cost-effectiveness of a feeder.

-

Understand Pricing Nuances for International Buyers: For B2B buyers from regions like Africa, South America, the Middle East, and Europe, be aware of potential import duties, taxes, and currency fluctuations that can impact total costs. Building relationships with local distributors can also mitigate some of these costs.

-

Stay Informed on Market Trends: Keep abreast of trends in the hummingbird feeder market, such as shifts towards sustainable products, which can influence pricing structures.

Conclusion

Sourcing hummingbird feeders involves a complex interplay of costs and pricing factors. By understanding these elements and applying strategic buying practices, B2B buyers can enhance their procurement processes, ensuring they secure quality products at competitive prices while meeting their operational needs.

Alternatives Analysis: Comparing how often should hummingbird feeders be changed With Other Solutions

Exploring Alternatives to Changing Hummingbird Feeders

In the realm of attracting and feeding hummingbirds, maintaining the freshness of nectar is crucial for the birds’ health and well-being. While the traditional approach involves changing the nectar in feeders every few days, alternative solutions and technologies can streamline this process, offering different benefits and drawbacks. This analysis explores various methods, comparing the standard nectar-changing practice with innovative alternatives.

| Comparison Aspect | How Often Should Hummingbird Feeders Be Changed | Smart Hummingbird Feeder | Automated Nectar Dispenser |

|---|---|---|---|

| Performance | Ensures fresh nectar; requires frequent changes | Maintains optimal nectar levels automatically | Delivers fresh nectar on a schedule |

| Cost | Low initial cost for feeders; ongoing sugar costs | Higher initial investment; minimal ongoing costs | Moderate to high initial investment; low sugar costs |

| Ease of Implementation | Simple manual process; requires regular attention | Easy to set up; minimal maintenance required | Requires installation; user-friendly interface |

| Maintenance | Regular cleaning needed to prevent mold | Low maintenance; occasional cleaning required | Regular cleaning; requires monitoring for clogs |

| Best Use Case | Ideal for casual bird watchers | Perfect for tech-savvy users and busy professionals | Suitable for bird enthusiasts seeking advanced solutions |

What is the Smart Hummingbird Feeder?

Smart hummingbird feeders leverage technology to automate nectar distribution. These feeders are designed with sensors that monitor nectar levels and dispense fresh nectar as needed.

Pros: The primary advantage is convenience; users no longer need to remember to refill feeders frequently. Additionally, these feeders can often be monitored via smartphone applications, providing real-time updates on nectar levels and bird visits.

Illustrative image related to how often should hummingbird feeders be changed

Cons: The initial investment can be substantial, which may deter some users. Furthermore, reliance on technology may lead to complications if the device malfunctions, requiring troubleshooting.

How Does an Automated Nectar Dispenser Work?

Automated nectar dispensers are similar to smart feeders but are generally designed to dispense nectar on a predetermined schedule rather than using sensors. These devices can be programmed to release nectar at specific intervals, ensuring a consistent supply for hummingbirds.

Pros: This method reduces the need for manual intervention, making it ideal for users with busy schedules. Additionally, it can prevent spoilage by managing the amount of nectar dispensed.

Cons: Like smart feeders, the initial cost can be a barrier. Moreover, these devices may require more substantial maintenance to ensure they operate correctly, including regular cleaning to prevent clogs.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a solution for hummingbird feeding, B2B buyers should consider their operational capacity, budget, and the level of interaction they desire with their feeders. For businesses focused on providing a simple, traditional experience, regularly changing nectar may suffice. However, for those looking to enhance efficiency and attract more birds with less manual effort, investing in smart feeders or automated dispensers could yield better long-term results. Understanding the specific needs of your target market—whether they prioritize cost, convenience, or technology—will guide the decision-making process in choosing the most effective hummingbird feeding solution.

Essential Technical Properties and Trade Terminology for how often should hummingbird feeders be changed

What Are the Critical Specifications for Hummingbird Feeders and Their Nectar?

When sourcing hummingbird feeders, several technical properties are crucial to ensure product quality and effectiveness in the field. Understanding these specifications helps businesses make informed purchasing decisions that can enhance customer satisfaction and operational efficiency.

1. Material Composition

Hummingbird feeders are typically made from plastic, glass, or metal. Each material has its benefits and drawbacks. Plastic feeders are lightweight and less likely to break, making them ideal for shipping and outdoor use in various climates. Glass feeders, while heavier and more fragile, offer better visibility of nectar levels and are often more aesthetically pleasing. Metal feeders can provide durability and resistance to pests but may conduct heat, potentially affecting nectar quality. Selecting the right material aligns with market demands for durability and user-friendliness.

2. Nectar Capacity

The nectar capacity of feeders can vary significantly. Standard feeders hold anywhere from 8 ounces to over 32 ounces. A feeder with a larger capacity can reduce the frequency of refills, making it convenient for users in regions with high hummingbird traffic. However, larger feeders may also lead to nectar spoilage if not monitored closely. Understanding capacity is essential for businesses aiming to cater to specific customer preferences or regional requirements.

3. Feeder Port Design

The design of feeding ports affects both accessibility for hummingbirds and the prevention of nectar spoilage. Ports should be sized appropriately to accommodate various hummingbird species while preventing bees and other insects from accessing the nectar. A well-designed port can reduce the need for frequent cleaning and nectar changes, ultimately improving user experience. Companies should prioritize feeders with versatile port designs to attract a broader customer base.

4. Cleaning and Maintenance Features

Ease of cleaning is a critical property of hummingbird feeders. Features such as removable components or dishwasher-safe materials can significantly influence purchasing decisions. Regular maintenance is essential to prevent mold growth and nectar spoilage, which can deter hummingbirds. B2B buyers should look for products that emphasize easy cleaning to enhance customer satisfaction and reduce product returns.

Illustrative image related to how often should hummingbird feeders be changed

5. Temperature Resistance

Nectar quality can be affected by temperature. Feeders must be designed to withstand high temperatures without warping or degrading. This is particularly important in regions with extreme heat, where nectar can spoil rapidly. Understanding the temperature resistance of materials used in feeders helps businesses select products that will perform well in diverse climates.

What Are the Key Trade Terms Related to Hummingbird Feeders?

Navigating the B2B landscape requires familiarity with specific trade terminology. Understanding these terms can streamline procurement processes and enhance communication with suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of hummingbird feeders, businesses may partner with OEMs to produce customized feeders that meet their specifications. This relationship can provide competitive advantages in branding and product differentiation.

Illustrative image related to how often should hummingbird feeders be changed

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs effectively. Suppliers may have different MOQs based on production capabilities or material sourcing, impacting pricing strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. When purchasing hummingbird feeders, businesses can issue RFQs to gauge market rates and negotiate better terms. This process is essential for budgeting and cost management in procurement.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for B2B buyers involved in cross-border transactions, as they clarify who is responsible for shipping, insurance, and tariffs associated with hummingbird feeders.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. Understanding lead times helps businesses manage inventory levels and meet customer demand effectively. Factors influencing lead time include production schedules, shipping routes, and seasonal demand fluctuations.

By grasping these technical specifications and trade terms, businesses can enhance their operational efficiency, ensure product quality, and meet customer expectations in the competitive market of hummingbird feeders.

Illustrative image related to how often should hummingbird feeders be changed

Navigating Market Dynamics and Sourcing Trends in the how often should hummingbird feeders be changed Sector

What Are the Current Market Dynamics Influencing Hummingbird Feeder Nectar Change Frequency?

The global hummingbird feeder market is increasingly shaped by several key drivers. An expanding interest in wildlife conservation and backyard birding, particularly in regions like Africa, South America, the Middle East, and Europe, has led to a surge in demand for high-quality hummingbird feeders and nectar solutions. In these markets, consumers are becoming more aware of the importance of maintaining proper feeding schedules to promote the health of local hummingbird populations.

Emerging technologies, such as smart feeders equipped with sensors, are revolutionizing how users monitor nectar levels and freshness. These innovations allow for more precise control over nectar management, reducing waste and enhancing the feeding experience for birds. Additionally, B2B buyers are increasingly sourcing products that incorporate user-friendly features, such as easy-to-clean designs and materials that deter pests.

The climatic conditions in these regions also play a significant role. For example, in hotter climates, the nectar must be changed more frequently to prevent spoilage, ideally every 1-2 days. This requirement drives the demand for suppliers who can offer reliable and durable products suited for varying environmental conditions. Therefore, understanding local market dynamics and consumer behavior is crucial for B2B buyers looking to optimize their supply chains.

How Is Sustainability Shaping the Sourcing of Hummingbird Feeders and Nectar?

Sustainability is becoming a pivotal consideration in the hummingbird feeder sector. The environmental impact of nectar production and feeder materials is drawing increasing scrutiny from consumers and businesses alike. B2B buyers are prioritizing suppliers who demonstrate a commitment to ethical sourcing practices and environmentally friendly materials. This includes the use of recycled plastics or sustainably sourced glass, reducing the carbon footprint associated with production and distribution.

Moreover, certifications such as the Forest Stewardship Council (FSC) or Global Organic Textile Standard (GOTS) are gaining traction among buyers seeking to ensure that their products align with sustainability goals. Suppliers that can provide transparency in their supply chains and demonstrate adherence to green practices are likely to stand out in a competitive market.

Additionally, the importance of educating consumers on proper nectar management—such as changing nectar every 2-4 days in moderate climates—contributes to reducing waste. By promoting best practices, businesses not only enhance bird welfare but also reinforce their commitment to sustainability, appealing to environmentally conscious consumers.

Illustrative image related to how often should hummingbird feeders be changed

How Has the Hummingbird Feeder Market Evolved Over Time?

Historically, the market for hummingbird feeders has evolved from simple, functional designs to a more diverse array of products that cater to aesthetic preferences and technological advancements. Initially, feeders were primarily utilitarian, designed to hold nectar without much consideration for ease of cleaning or maintenance.

As interest in birdwatching grew, particularly in regions like North America, manufacturers began to innovate, introducing features that enhance user experience and bird attraction. Today, options range from decorative feeders to those equipped with smart technology that monitors nectar levels and freshness. This evolution reflects broader trends in consumer preferences towards products that are not only functional but also visually appealing and environmentally responsible.

In conclusion, the hummingbird feeder market is witnessing transformative changes driven by consumer awareness, technological advancements, and a growing emphasis on sustainability. B2B buyers must stay informed about these trends to effectively navigate the market and align their sourcing strategies with the evolving demands of their customers.

Illustrative image related to how often should hummingbird feeders be changed

Frequently Asked Questions (FAQs) for B2B Buyers of how often should hummingbird feeders be changed

-

How often should hummingbird feeders be changed in hot climates?

In warmer climates, it is essential to change the nectar in hummingbird feeders every 1 to 2 days. High temperatures can cause the sugar solution to spoil quickly, leading to mold and bacteria growth that can harm the birds. Regularly monitoring the feeder and changing the nectar ensures that it remains fresh and safe for the hummingbirds, promoting their health and encouraging frequent visits. -

What factors influence the frequency of changing hummingbird nectar?

Several factors affect how often you should change hummingbird nectar, including temperature, humidity, and feeder location. In cooler weather (around 60°F), nectar can last for up to 2 to 3 days. Conversely, in hotter and humid conditions, it’s best to change the nectar daily. Additionally, if the feeder attracts many birds or insects, it may require more frequent changes to maintain cleanliness and freshness. -

What are the best practices for cleaning hummingbird feeders?

To maintain optimal hygiene, clean hummingbird feeders thoroughly every time you change the nectar. Use hot water and a brush to scrub the feeding ports and ensure there is no mold or residue left behind. Avoid using soap, as residues can be harmful to birds. Rinse the feeder thoroughly with clean water before refilling it with fresh nectar. -

How can I ensure the quality of my hummingbird feeders from suppliers?

When sourcing hummingbird feeders from international suppliers, it’s crucial to vet them thoroughly. Check for certifications that confirm product safety and compliance with local regulations. Request samples to assess quality, and inquire about the materials used, especially if they are non-toxic and durable. Establishing a relationship with reputable suppliers can also enhance trust and quality assurance. -

What are the minimum order quantities (MOQ) for hummingbird feeders?

Minimum order quantities for hummingbird feeders can vary widely between suppliers. Some may offer flexible MOQs for smaller businesses, while others might have strict requirements for bulk orders. It’s advisable to communicate your needs clearly and negotiate MOQs that suit your purchasing capabilities, especially if you are entering a new market or testing product demand. -

What payment terms should I expect when ordering hummingbird feeders?

Payment terms can differ based on supplier policies and the nature of the transaction. Common terms include upfront payments, deposits, or net payment options after delivery. It’s important to clarify payment methods accepted (e.g., wire transfer, credit card, PayPal) and any potential discounts for early payment. Establishing clear payment terms helps avoid misunderstandings and fosters smooth transactions. -

How do logistics impact the supply chain for hummingbird feeders?

Logistics play a vital role in the supply chain of hummingbird feeders, affecting lead times, shipping costs, and inventory management. When sourcing internationally, consider factors such as freight options, customs clearance, and delivery times. Collaborating with logistics providers experienced in international shipping can streamline the process and ensure timely delivery, which is critical for maintaining stock levels. -

What quality assurance measures should I implement for hummingbird feeders?

Implementing quality assurance measures is essential for maintaining the integrity of your hummingbird feeders. Establish clear quality standards with suppliers, conduct regular inspections of incoming shipments, and keep records of any quality issues encountered. Additionally, consider third-party quality checks, especially for large orders, to ensure that the products meet your specifications and are safe for consumer use.

Top 2 How Often Should Hummingbird Feeders Be Changed Manufacturers & Suppliers List

1. Facebook – Nectar Feeder Care

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Nectar Feeder Care, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Perky-Pet® – Instant Clear Hummingbird Nectar

Domain: perkypet.com

Registered: 1996 (29 years)

Introduction: Perky-Pet® offers a variety of instant hummingbird nectars made with 100% sucrose, containing no artificial flavors or sweeteners. The Clear Hummingbird Nectar Concentrate comes in a 64 oz bottle, making up to 256 oz of hummingbird food. The Instant Clear Hummingbird Nectar is available in a 2 lb bag, making up to 192 oz of nectar. Both products provide a high-energy sugar solution vital for hummi…

Strategic Sourcing Conclusion and Outlook for how often should hummingbird feeders be changed

In conclusion, maintaining hummingbird feeders is not just a matter of aesthetics; it is a strategic practice that can significantly enhance your business’s engagement with customers and wildlife enthusiasts. For optimal results, it is recommended to change the nectar every 2 to 4 days, with more frequent changes in warmer or humid climates. This practice ensures that the nectar remains fresh and appealing, thereby attracting more hummingbirds and enhancing customer satisfaction.

By implementing a strategic sourcing approach, businesses can streamline their supply chain for nectar and feeders, ensuring quality and consistency that meets consumer demands. This not only helps in maintaining the health of the hummingbirds but also positions your brand as a leader in responsible and sustainable bird feeding practices.

As we look forward, consider expanding your offerings to include various feeder types and nectar solutions that cater to diverse climates and preferences. Engaging with suppliers from Africa, South America, the Middle East, and Europe will allow you to tap into a growing market of nature enthusiasts eager for quality products. Embrace this opportunity to elevate your brand while contributing positively to local ecosystems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.