Introduction: Navigating the Global Market for how often to change hummingbird food

In the competitive landscape of avian products, understanding how often to change hummingbird food is crucial for businesses looking to satisfy the nutritional needs of these energetic birds while ensuring product quality and customer satisfaction. International B2B buyers face the challenge of sourcing effective hummingbird food solutions that not only meet varying climate conditions but also adhere to regional preferences and standards. This comprehensive guide delves into the intricacies of hummingbird food, including the types of nectar available, their applications, and best practices for supplier vetting.

By exploring vital aspects such as cost considerations and shelf life, this guide equips B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe (notably Germany and Brazil)—with the knowledge necessary to make informed purchasing decisions. As the demand for high-quality hummingbird feeders and nectar continues to rise, understanding the nuances of changing hummingbird food can directly impact product effectiveness and customer loyalty. This resource aims to empower businesses with actionable insights that enhance their product offerings and ultimately contribute to a thriving market for hummingbird enthusiasts worldwide.

Table Of Contents

- Top 4 How Often To Change Hummingbird Food Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often to change hummingbird food

- Understanding how often to change hummingbird food Types and Variations

- Key Industrial Applications of how often to change hummingbird food

- 3 Common User Pain Points for ‘how often to change hummingbird food’ & Their Solutions

- Strategic Material Selection Guide for how often to change hummingbird food

- In-depth Look: Manufacturing Processes and Quality Assurance for how often to change hummingbird food

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change hummingbird food’

- Comprehensive Cost and Pricing Analysis for how often to change hummingbird food Sourcing

- Alternatives Analysis: Comparing how often to change hummingbird food With Other Solutions

- Essential Technical Properties and Trade Terminology for how often to change hummingbird food

- Navigating Market Dynamics and Sourcing Trends in the how often to change hummingbird food Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often to change hummingbird food

- Strategic Sourcing Conclusion and Outlook for how often to change hummingbird food

- Important Disclaimer & Terms of Use

Understanding how often to change hummingbird food Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Frequency | Adjusts nectar replacement based on seasonal temperature and humidity changes. | Bird feeder manufacturing, landscaping services. | Pros: Aligns with natural hummingbird behavior. Cons: Requires close monitoring of weather conditions. |

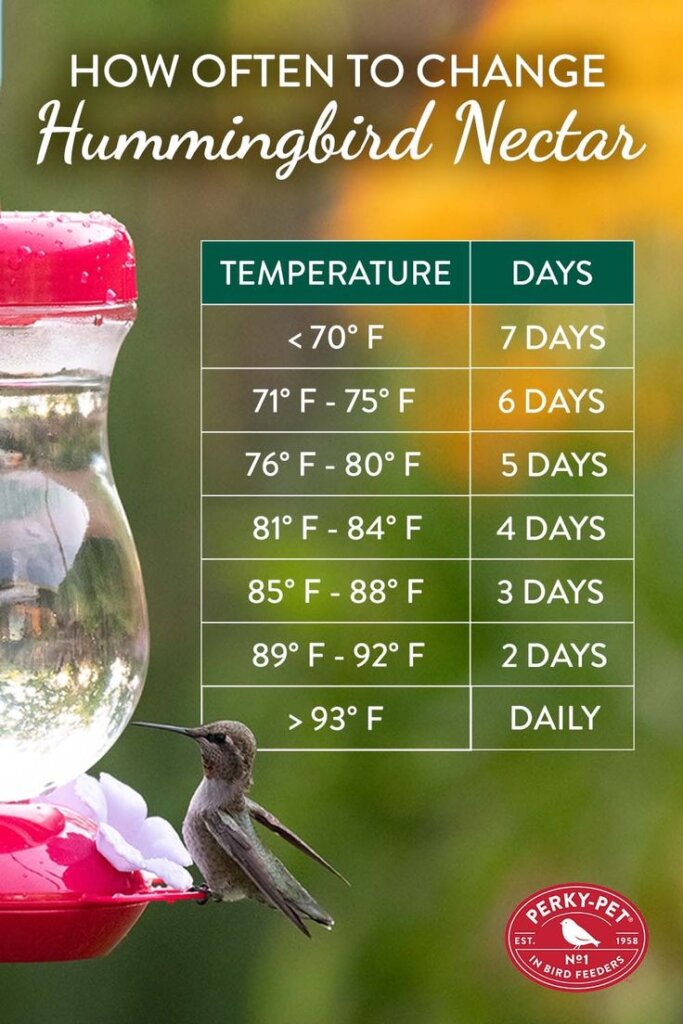

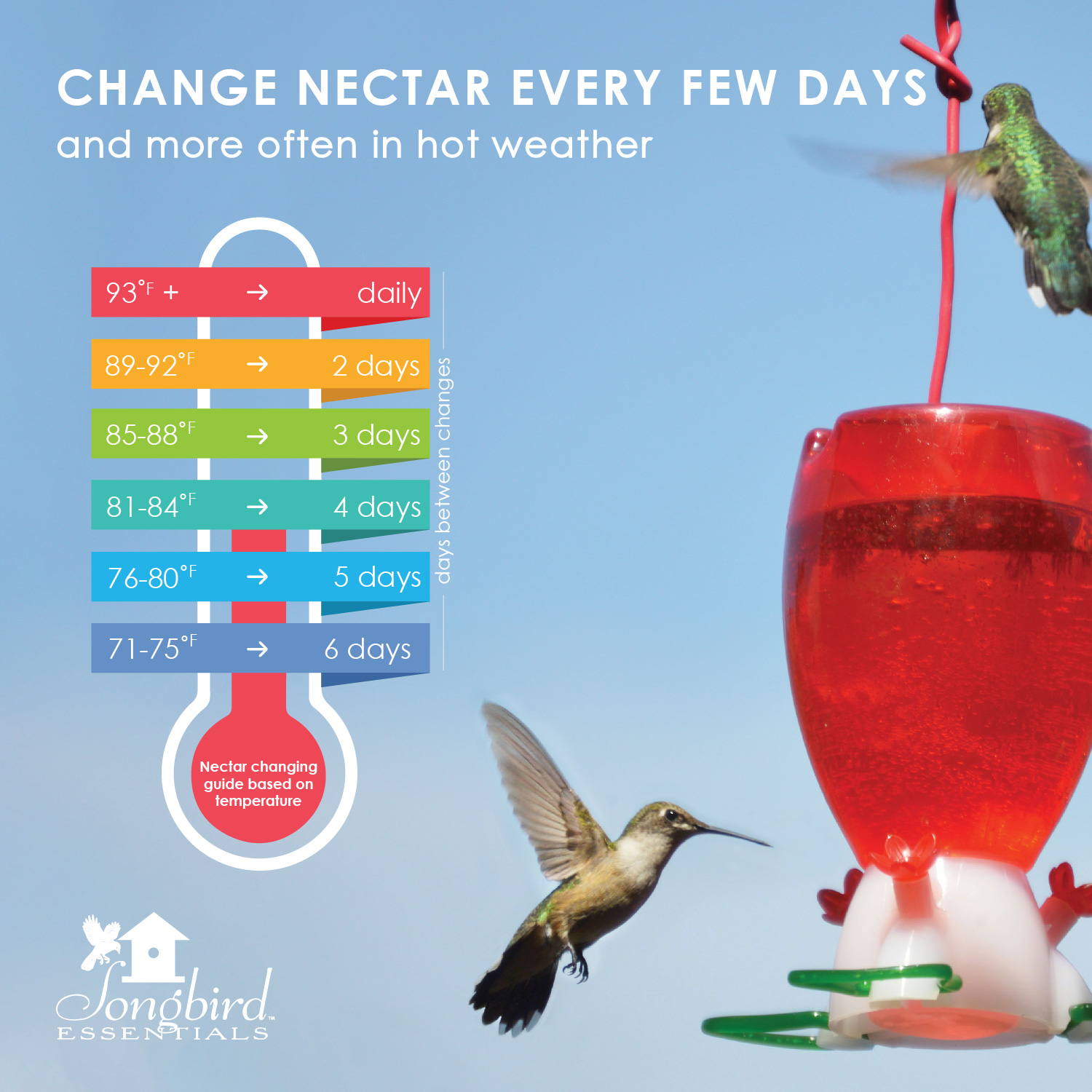

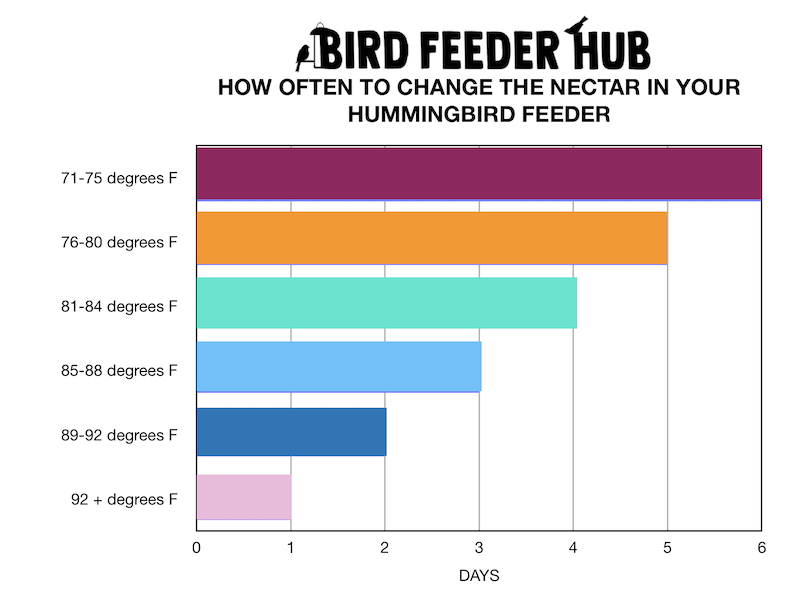

| Temperature-Based Frequency | Changes nectar every day in high temperatures (90°F+) and every 2-3 days in cooler weather. | Retailers and distributors of bird feeding supplies. | Pros: Reduces spoilage risk in hot climates. Cons: Increased labor for frequent changes. |

| Nectar Type Variation | Different nectar types (liquid, powder, or pre-mixed) may have varying shelf lives. | Producers of hummingbird food products. | Pros: Versatile options for diverse markets. Cons: Requires education on proper usage and storage. |

| Cleaning Frequency | Emphasizes the importance of regular cleaning (weekly or bi-weekly) for feeder maintenance. | Bird care service providers, environmental organizations. | Pros: Prevents mold and bacteria growth. Cons: Higher maintenance costs for frequent cleaning. |

| Market-Specific Adaptation | Tailors nectar replacement frequency based on regional bird behavior and climate. | International suppliers and retailers. | Pros: Ensures optimal feeding conditions for local species. Cons: May require extensive market research. |

What are the characteristics of Seasonal Frequency in changing hummingbird food?

Seasonal frequency takes into account the varying temperatures and humidity levels throughout the year. During warmer months, nectar should be replaced more frequently due to faster spoilage, while cooler months allow for longer intervals. This approach is particularly beneficial for businesses involved in bird feeder manufacturing and landscaping, as it aligns product offerings with natural bird behavior. Companies must educate customers on the importance of adjusting nectar frequency seasonally to maintain healthy hummingbird populations.

How does Temperature-Based Frequency impact hummingbird food management?

Temperature-based frequency dictates that nectar should be changed daily in high heat (above 90°F) and can last 2-3 days in cooler conditions (around 60°F). This method is critical for retailers and distributors of bird feeding supplies, as it minimizes spoilage and ensures a reliable food source for hummingbirds. Buyers need to consider their regional climate when stocking products, as temperature fluctuations can significantly affect nectar longevity and bird visitation rates.

What should B2B buyers know about Nectar Type Variation?

Nectar type variation includes liquid, powdered, and pre-mixed options, each with different shelf lives and preparation methods. This diversity allows businesses to cater to various consumer preferences and regional needs. Producers of hummingbird food products must ensure that their offerings are clearly labeled and easy to use. Buyers should consider the storage and preparation requirements of each nectar type to optimize sales and customer satisfaction.

Why is Cleaning Frequency essential for hummingbird feeders?

Regular cleaning of hummingbird feeders is vital to prevent mold and bacterial growth, which can deter birds from visiting. A recommended cleaning frequency is once a week or bi-weekly, depending on the feeder’s usage and local conditions. This practice is crucial for bird care service providers and environmental organizations that prioritize wildlife health. Businesses should emphasize the importance of maintenance in their marketing efforts, as it directly affects feeder performance and bird health.

How can Market-Specific Adaptation influence hummingbird food sales?

Market-specific adaptation involves tailoring nectar replacement frequency and product offerings based on regional bird behavior and climate conditions. This strategy is particularly relevant for international suppliers and retailers, as it allows them to meet local demand effectively. Conducting thorough market research is essential to understand the specific needs of different regions, ensuring that businesses can provide optimal feeding conditions for local hummingbird species and enhance customer loyalty.

Key Industrial Applications of how often to change hummingbird food

| Industry/Sector | Specific Application of how often to change hummingbird food | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Ornithology Research | Monitoring nectar spoilage rates in controlled studies | Ensures accurate data collection on bird feeding habits | Quality of nectar, feeder design, and cleaning protocols |

| Landscaping & Gardening | Providing consistent food sources for local hummingbird populations | Enhances biodiversity and attracts pollinators | Sourcing of organic, dye-free nectar and feeder maintenance tools |

| Eco-Tourism & Wildlife Parks | Maintaining feeders to attract hummingbirds for visitor engagement | Improves visitor experience and educational opportunities | Seasonal changes, visitor traffic, and feeder visibility |

| Bird Feeding Retailers | Educating customers on nectar freshness and feeder maintenance | Builds customer loyalty through expert guidance | Quality of instructional materials and product availability |

| Agricultural Research | Studying the impact of hummingbirds on crop pollination | Informs sustainable farming practices and crop yield improvement | Collaboration with local farmers and access to field research data |

How is ‘how often to change hummingbird food’ applied in Ornithology Research?

In ornithology research, understanding the frequency of nectar changes is crucial for studying hummingbird behavior and health. Researchers monitor nectar spoilage rates to ensure that the data collected reflects accurate feeding habits. This application addresses issues like the impact of spoiled nectar on bird visitation rates. For international buyers, sourcing high-quality nectar and feeders designed for easy maintenance is essential to facilitate research efforts.

What role does ‘how often to change hummingbird food’ play in Landscaping & Gardening?

In landscaping and gardening, the frequency of changing hummingbird food is vital for sustaining local bird populations. By providing fresh nectar, landscapers can enhance biodiversity and attract important pollinators to their gardens. This practice not only supports hummingbirds but also contributes to a healthier ecosystem. Buyers in this sector should prioritize organic, dye-free nectar and invest in feeder maintenance tools to ensure optimal conditions for the birds.

How does ‘how often to change hummingbird food’ enhance Eco-Tourism & Wildlife Parks?

Eco-tourism and wildlife parks benefit from maintaining hummingbird feeders to attract these birds, thereby enhancing the visitor experience. Regularly changing the nectar ensures that the feeders remain appealing to hummingbirds, which in turn draws visitors interested in observing these vibrant creatures. International buyers need to consider seasonal changes and visitor traffic when sourcing feeders and nectar to maximize engagement and education opportunities.

Why is ‘how often to change hummingbird food’ important for Bird Feeding Retailers?

Bird feeding retailers can significantly enhance customer loyalty by educating consumers on the importance of changing nectar regularly. Providing expert guidance on feeder maintenance and nectar freshness not only builds trust but also encourages repeat purchases. Retailers should focus on sourcing high-quality instructional materials and ensuring a steady supply of nectar products to support their customers effectively.

How can ‘how often to change hummingbird food’ inform Agricultural Research?

In agricultural research, the frequency of changing hummingbird food can play a pivotal role in studying the impact of these birds on crop pollination. Researchers can gain insights into how hummingbirds contribute to crop yields and sustainable farming practices. Collaborating with local farmers and accessing field research data are key considerations for buyers in this sector to ensure that their studies reflect real-world conditions.

3 Common User Pain Points for ‘how often to change hummingbird food’ & Their Solutions

Scenario 1: Difficulty in Maintaining Nectar Freshness During Hot Weather

The Problem: B2B buyers in warmer climates, such as parts of Africa and the Middle East, face significant challenges in maintaining the freshness of hummingbird food. High temperatures can cause nectar to spoil quickly, leading to waste and potential harm to the birds. This scenario is particularly concerning for businesses that rely on attracting hummingbirds for ecotourism or wildlife observation, as spoiled nectar can deter these birds from visiting feeders altogether.

The Solution: To ensure nectar freshness in hot climates, it’s essential to implement a rigorous monitoring and maintenance schedule. Buyers should change the nectar every day during heatwaves or when temperatures exceed 90°F (32°C). Additionally, consider using insulated feeders that can help maintain a cooler environment for the nectar. If possible, position feeders in shaded areas to reduce direct sunlight exposure. For businesses, training staff on these protocols can enhance the overall experience for both the birds and customers, ensuring a vibrant and healthy environment.

Scenario 2: Managing Nectar Spoilage in Humid Conditions

The Problem: In regions with high humidity, such as parts of South America and coastal Europe, nectar can ferment more quickly, which poses a risk to hummingbird health. B2B buyers may struggle with frequent nectar spoilage, leading to increased costs associated with constant replenishment and cleaning of feeders. This situation can be particularly detrimental for businesses that operate birdwatching tours or nature parks, where a reliable food source is crucial for attracting birds.

The Solution: To combat nectar spoilage in humid conditions, it’s advisable to prepare smaller batches of nectar that can be consumed within a day or two. Additionally, using a nectar recipe with a higher sugar concentration (1:3 ratio of sugar to water) can slow down fermentation. Implementing a regular cleaning schedule—at least every few days—will also help prevent mold and bacteria growth. Businesses should consider investing in quality, easy-to-clean feeders that minimize the risk of spoilage and are durable enough to withstand challenging weather conditions. This proactive approach not only protects the birds but also enhances the overall customer experience.

Scenario 3: Attracting Hummingbirds with Consistent Food Supply

The Problem: Many B2B buyers, such as those managing wildlife sanctuaries or educational programs in Europe, face the challenge of attracting hummingbirds consistently. Irregular nectar changes can result in birds learning to avoid feeders due to spoiled food, leading to decreased visitor satisfaction and engagement. This inconsistency can harm the reputation of businesses that rely on these birds to draw in visitors.

The Solution: Establishing a standard operating procedure (SOP) for nectar management is critical for maintaining a consistent hummingbird presence. Buyers should schedule nectar changes based on seasonal patterns—typically every 2-3 days in cooler months and daily in warmer months. Utilizing clear signage to inform visitors about the feeding schedule can enhance the educational aspect of the experience. Additionally, implementing a tracking system to monitor bird activity at feeders can provide insights into their feeding habits, allowing for better planning and adaptation of nectar supply. This data-driven approach not only maximizes bird visits but also strengthens the business’s role as a responsible steward of wildlife, enhancing brand reputation and customer loyalty.

Strategic Material Selection Guide for how often to change hummingbird food

What Materials are Best for Hummingbird Food Feeder Components?

When considering how often to change hummingbird food, the choice of materials for feeders and associated components plays a critical role in maintaining product performance and ensuring the health of the birds. Here, we analyze several common materials used in hummingbird feeders, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Glass: A Traditional Material for Hummingbird Feeders

Key Properties: Glass is non-porous and resistant to staining, which makes it an excellent choice for maintaining the purity of hummingbird nectar. It can withstand a range of temperatures, though extreme conditions may lead to breakage.

Pros & Cons: Glass feeders are durable and easy to clean, preventing the buildup of mold and bacteria. However, they can be heavy and fragile, which may lead to shipping costs and breakage during transit. Additionally, glass can be more expensive than plastic options.

Impact on Application: Glass is compatible with various cleaning agents and does not leach harmful chemicals into the nectar, making it suitable for maintaining the quality of the food.

Considerations for International Buyers: Compliance with safety standards is essential, especially in regions with stringent regulations. Buyers in Europe, for instance, may prefer glass feeders that meet EU safety standards, while those in Africa may prioritize cost-effectiveness.

Plastic: A Lightweight and Cost-Effective Option

Key Properties: Plastic is lightweight and resistant to corrosion, making it a popular choice for hummingbird feeders. It can be molded into various shapes and designs, allowing for creative feeder configurations.

Pros & Cons: The primary advantage of plastic is its affordability and ease of manufacturing. However, it may not be as durable as glass and can degrade over time when exposed to UV light, leading to potential leaching of chemicals into the nectar.

Impact on Application: Plastic feeders may require more frequent replacement, particularly in regions with high UV exposure. They are generally easier to transport due to their lightweight nature.

Considerations for International Buyers: Buyers should ensure that the plastic used is food-safe and compliant with local regulations. For instance, European buyers may look for plastics that meet REACH compliance, while those in South America might prioritize cost over compliance.

Metal: A Durable Choice for Hummingbird Feeders

Key Properties: Metal, particularly stainless steel, offers excellent durability and resistance to corrosion. It can withstand harsh weather conditions, making it suitable for long-term outdoor use.

Illustrative image related to how often to change hummingbird food

Pros & Cons: Metal feeders are robust and can last for many years without significant wear. However, they can be heavier and more expensive than plastic options. Additionally, metal can heat up quickly in direct sunlight, potentially harming the nectar.

Impact on Application: Metal feeders may require insulation or design modifications to prevent overheating. They are also compatible with various cleaning methods, ensuring hygiene.

Considerations for International Buyers: Buyers should consider the availability of stainless steel and other metals in their region, as well as compliance with local regulations regarding food safety and material sourcing.

Silicone: An Innovative Material for Seals and Ports

Key Properties: Silicone is flexible and resistant to temperature fluctuations, making it ideal for seals and ports in hummingbird feeders. It is also non-toxic and food-safe.

Pros & Cons: The main advantage of silicone is its ability to create airtight seals, preventing leaks and maintaining nectar quality. However, silicone components may wear out over time and require replacement.

Impact on Application: Silicone is compatible with various feeder designs and can enhance the overall functionality of the feeder by preventing spills and attracting unwanted insects.

Considerations for International Buyers: Buyers should ensure that silicone components meet food safety standards in their regions. In Europe, for instance, silicone must comply with EU regulations regarding food contact materials.

Summary Table

| Material | Typical Use Case for how often to change hummingbird food | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Hummingbird feeders that require frequent cleaning and nectar changes | Non-porous and easy to clean | Fragile and heavier than plastic | High |

| Plastic | Affordable feeders for mass distribution | Lightweight and cost-effective | Less durable and may leach chemicals | Low |

| Metal | Long-lasting feeders for outdoor use | Durable and weather-resistant | Can overheat and is heavier | Medium |

| Silicone | Seals and ports in feeders | Creates airtight seals and prevents leaks | May wear out over time | Medium |

This analysis provides a comprehensive overview of material options for hummingbird feeders, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

Illustrative image related to how often to change hummingbird food

In-depth Look: Manufacturing Processes and Quality Assurance for how often to change hummingbird food

What Are the Key Manufacturing Processes for Hummingbird Food?

The manufacturing of hummingbird food involves several critical stages that ensure the final product is safe, nutritious, and appealing to the birds. Understanding these processes can help B2B buyers make informed decisions when sourcing products for their markets.

Material Preparation: How Are Ingredients Selected and Processed?

The first stage in the manufacturing process is material preparation, where high-quality ingredients are sourced. The primary component of hummingbird food is sugar, typically sucrose, which mimics the natural nectar found in flowers. Suppliers often prefer refined white sugar due to its purity and lack of impurities that could affect the health of hummingbirds.

Once the sugar is sourced, it undergoes a purification process to remove any contaminants. This process may involve granulation, where larger sugar crystals are broken down into finer particles, enhancing solubility. Additionally, water used in the mixture should be dechlorinated, as chlorine can be harmful to birds.

Forming: What Techniques Are Used to Create Nectar?

In the forming stage, the prepared materials are mixed to create the nectar solution. The standard ratio is four parts water to one part sugar, which should be thoroughly dissolved to ensure a consistent product. This solution is typically heated to expedite the dissolution process, and quality control checks are performed to ensure the correct concentration and absence of any foreign substances.

Some manufacturers may also produce concentrated forms of nectar for customers who prefer to dilute it at home. This involves more complex mixing techniques and requires additional quality checks to ensure that the concentration levels are accurate.

Assembly: How Is the Product Packaged for Distribution?

Once the nectar is formed, it is transferred to packaging, which must comply with food safety standards. Packaging materials are selected based on their ability to protect the product from moisture and contaminants while ensuring ease of use for consumers.

Automated bottling and labeling systems are often employed to enhance efficiency. Labels must clearly indicate nutritional content, expiration dates, and proper usage instructions. This is particularly important for international markets, where regulations on labeling can vary significantly.

Finishing: What Final Touches Ensure Product Quality?

The finishing stage involves a series of quality checks and final adjustments. This may include visual inspections for packaging integrity, checking for leaks, and ensuring that labels are correctly applied. Additionally, finished products are often sampled for taste and consistency.

To ensure the product remains fresh during distribution, manufacturers may use nitrogen flushing techniques to displace oxygen in the packaging, thereby extending shelf life. This is crucial for international shipments, where products may be in transit for extended periods.

How Is Quality Assurance Maintained Throughout the Manufacturing Process?

Quality assurance (QA) is vital in the hummingbird food manufacturing process, as it ensures that the final product is safe and meets industry standards. B2B buyers should be aware of the various QA checkpoints and international standards that govern production.

What International Standards Are Relevant to Hummingbird Food Production?

Manufacturers of hummingbird food often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This standard emphasizes customer satisfaction, continual improvement, and regulatory compliance.

In addition to ISO standards, industry-specific certifications, such as CE marking for European markets or API certification for specific ingredients, may be relevant. These certifications provide assurances that products meet safety and quality benchmarks recognized in various regions.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production line. This includes testing sugar purity and verifying the dechlorination of water.

-

In-Process Quality Control (IPQC): During production, samples of the nectar solution are taken to ensure the correct concentration and absence of contaminants. Any deviations from the standard recipe can lead to spoilage or unpalatable products.

-

Final Quality Control (FQC): After packaging, final inspections are conducted to assess the integrity of the packaging and ensure that labeling is accurate. Random samples may be tested for microbial contamination, ensuring that the product is safe for consumption.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying the quality control practices of suppliers is crucial. Here are some actionable steps:

Illustrative image related to how often to change hummingbird food

-

Request Certifications and Audit Reports: Suppliers should be able to provide documentation of their ISO certifications and any other relevant industry-specific certifications. Regular audit reports can also provide insights into their QC processes.

-

Conduct Supplier Audits: Direct audits of manufacturing facilities allow buyers to assess quality control practices firsthand. This can include reviewing SOPs (Standard Operating Procedures), inspecting production areas, and evaluating employee training programs.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and adherence to quality standards. This is particularly important for international transactions, where regulations may differ.

What Unique QC Considerations Exist for International Markets?

B2B buyers from regions like Africa, South America, the Middle East, and Europe must be aware of specific QC nuances:

-

Regulatory Compliance: Different countries have varying regulations regarding food products, including labeling requirements and ingredient restrictions. Buyers should ensure that their suppliers are compliant with local regulations in their target markets.

-

Cultural Preferences: Understanding regional preferences for product formulations can also influence quality assurance. For example, some regions may prefer organic or dye-free products, which should be reflected in the manufacturing process.

-

Logistics and Shelf Life: International shipping can impact product quality, so buyers should confirm that manufacturers utilize appropriate packaging and preservation techniques to maintain freshness throughout transit.

By understanding the manufacturing processes and quality assurance measures in place for hummingbird food, B2B buyers can make well-informed decisions, ensuring they source high-quality products that meet the expectations of their customers while adhering to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change hummingbird food’

Introduction

This guide serves as a practical checklist for B2B buyers in the hummingbird food supply industry, focusing on the critical aspect of changing hummingbird nectar. Understanding how often to change hummingbird food is essential for maintaining the health of the birds and ensuring customer satisfaction. This guide will help you establish best practices for sourcing, managing inventory, and maintaining product quality.

Step 1: Assess Environmental Factors

Consider the climatic conditions of your target market when determining how often to change hummingbird food. For instance, warmer climates can accelerate spoilage, necessitating more frequent changes.

- Regional Climate Variations: Identify whether your market experiences high temperatures or humidity, as these factors directly influence nectar longevity.

- Seasonal Changes: Understand seasonal patterns that may affect bird activity and nectar consumption rates.

Step 2: Establish a Standard Replacement Schedule

Develop a standardized schedule for changing nectar based on average weather conditions in your target regions.

- General Guidelines: In cooler temperatures (around 60°F), nectar can last 2-3 days, while in hotter conditions (above 90°F), it should be replaced daily.

- Custom Schedules: Adjust this schedule based on local climate specifics or customer feedback to optimize service.

Step 3: Implement Quality Control Measures

Quality control is vital for ensuring that the nectar supplied remains fresh and safe for hummingbirds.

- Inspection Protocols: Regularly inspect nectar batches for signs of spoilage, such as cloudiness or sediment.

- Supplier Standards: Ensure your suppliers adhere to strict quality standards and provide fresh nectar formulations that do not contain harmful additives.

Step 4: Educate Customers on Proper Nectar Management

Providing education and resources to your customers is crucial for ensuring they understand the importance of changing hummingbird food.

- Training Materials: Develop guides or workshops that explain the best practices for nectar replacement and feeder maintenance.

- Customer Support: Offer ongoing support to address any questions or concerns regarding nectar management.

Step 5: Monitor Customer Feedback and Adjust Accordingly

Gathering feedback from your customers about their experiences with nectar longevity can help refine your processes.

- Surveys and Reviews: Implement regular surveys to assess customer satisfaction with nectar freshness and quality.

- Adaptation: Use this feedback to adjust product offerings and replacement recommendations, ensuring they meet customer needs effectively.

Step 6: Create a Supplier Evaluation Process

Establish a thorough evaluation process for potential suppliers of hummingbird nectar to ensure they meet your quality and service standards.

- Certifications and Compliance: Verify that suppliers have the necessary certifications and comply with industry regulations regarding food safety.

- Track Record: Look for suppliers with a proven history of reliability and quality in their product offerings.

Step 7: Leverage Technology for Inventory Management

Utilize technology to enhance inventory management and streamline the process of tracking nectar freshness.

- Inventory Systems: Implement systems that alert you when nectar is nearing its expiration or needs replacement based on environmental conditions.

- Data Analysis: Use data analytics to predict demand trends, ensuring you maintain optimal stock levels to meet customer needs without excess waste.

By following these steps, B2B buyers can effectively manage their hummingbird food offerings, ensuring high-quality products that satisfy their customers while promoting the well-being of the hummingbirds they serve.

Comprehensive Cost and Pricing Analysis for how often to change hummingbird food Sourcing

What Are the Key Cost Components for Sourcing Hummingbird Food?

When analyzing the cost structure for sourcing hummingbird food, several critical components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary component is the raw materials used in the nectar, typically sugar (sucrose) and water. The quality of sugar can vary significantly, impacting the final product’s cost. Additionally, any organic or certified ingredients will increase material costs.

-

Labor: Labor costs encompass the workforce involved in production, including mixing, bottling, and packaging. In regions with higher labor costs, such as Western Europe, sourcing may be more expensive compared to countries in Africa or South America.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, allowing for competitive pricing.

-

Tooling: The initial setup for production, including molds and bottling equipment, represents a fixed cost that can be amortized over large production runs. The higher the volume, the lower the per-unit tooling cost.

-

Quality Control (QC): Ensuring the nectar meets health standards and quality specifications requires investment in testing and compliance measures. This is particularly crucial for international buyers who must adhere to stringent import regulations.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and Incoterms. International buyers should account for tariffs, taxes, and shipping insurance, which can significantly affect the final cost.

-

Margin: Manufacturers typically add a markup to cover risks, operational costs, and profit. The margin can vary based on market demand and competition.

How Do Pricing Influencers Affect the Cost of Hummingbird Food?

Several factors can influence the pricing of hummingbird food, which international B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often results in lower per-unit costs. Buyers should negotiate MOQs that align with their consumption rates to optimize savings.

-

Specifications and Customization: Customized formulations or packaging can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials Quality and Certifications: Higher quality or certified ingredients (e.g., organic or non-GMO) will increase costs. Buyers should weigh the benefits of premium products against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with strong track records may charge higher prices but offer better consistency and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect cost responsibilities and overall pricing.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

International B2B buyers should employ several strategies to negotiate better terms and improve cost efficiency:

-

Understand Total Cost of Ownership (TCO): Evaluate not only the purchase price but also logistics, storage, and disposal costs. This comprehensive view can lead to more informed purchasing decisions.

-

Leverage Volume Discounts: If a buyer can commit to higher volumes, they should negotiate for discounts. This approach can significantly reduce unit costs.

-

Build Long-Term Relationships with Suppliers: Establishing trust with suppliers can lead to better pricing, priority service, and favorable terms over time.

-

Stay Informed About Market Trends: Understanding market conditions, such as sugar prices or supply chain disruptions, can empower buyers during negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers may reduce shipping costs and lead times, providing a competitive edge in pricing and availability.

Conclusion

In summary, understanding the cost structure and pricing influencers is essential for international B2B buyers of hummingbird food. By focusing on cost components, leveraging negotiation strategies, and considering the Total Cost of Ownership, businesses can make informed purchasing decisions that enhance profitability and sustainability. Keep in mind that prices can fluctuate based on market conditions, so it’s prudent to regularly review supplier contracts and market data.

Alternatives Analysis: Comparing how often to change hummingbird food With Other Solutions

Exploring Alternatives to Changing Hummingbird Food

In the context of maintaining hummingbird feeders, the frequency with which to change the nectar is crucial for attracting these birds and ensuring their health. However, there are several alternative solutions and methods that can also aid in keeping hummingbird feeding stations effective and appealing. This analysis compares the traditional approach of changing hummingbird food against innovative technologies and practices that serve a similar purpose.

Comparison Table

| Comparison Aspect | How Often To Change Hummingbird Food | Automatic Nectar Dispenser | Nectar Preservation Technology |

|---|---|---|---|

| Performance | High; prevents spoilage and attracts birds | Moderate; relies on technology and may malfunction | High; extends freshness and reduces waste |

| Cost | Low; minimal ongoing costs for sugar and water | Medium; initial investment in device | High; costs associated with advanced technology |

| Ease of Implementation | Simple; requires basic knowledge of nectar preparation | Moderate; setup requires technical understanding | Complex; requires installation and monitoring |

| Maintenance | Low; regular cleaning needed but straightforward | Medium; requires occasional refills and maintenance | High; needs regular checks and potential repairs |

| Best Use Case | Ideal for casual bird watchers and small gardens | Suitable for busy environments or commercial settings | Best for large-scale operations or research facilities |

Detailed Breakdown of Alternatives

1. Automatic Nectar Dispenser

An automatic nectar dispenser is a technology designed to dispense hummingbird food at set intervals. This solution is particularly advantageous for businesses or individuals who may not be able to frequently refill feeders due to time constraints.

Pros: It ensures a consistent supply of nectar, reducing the risk of spoilage and attracting more birds. These devices can also be programmed to dispense nectar based on environmental conditions.

Cons: Initial costs can be higher compared to traditional methods, and they may require technical know-how for setup. Additionally, reliance on technology can lead to malfunctions, which could deter hummingbirds if not addressed promptly.

2. Nectar Preservation Technology

Nectar preservation technology involves specialized containers and materials that extend the freshness of hummingbird food, reducing the frequency of changes. This method is particularly useful in large-scale settings, such as wildlife reserves or research facilities.

Pros: This technology can significantly reduce waste by prolonging the nectar’s shelf life. It is especially beneficial in environments where access to feeders may be limited.

Illustrative image related to how often to change hummingbird food

Cons: The upfront investment can be substantial, and the complexity of the systems may require specialized training for staff. Regular monitoring is essential to ensure the technology is functioning properly.

Conclusion: Choosing the Right Solution for Your Needs

When considering the best approach to hummingbird feeding, B2B buyers should evaluate their specific context and requirements. For smaller operations or casual birdwatchers, the traditional method of changing nectar frequently is often the most cost-effective and straightforward. In contrast, businesses that operate in environments requiring automation or large-scale feeding may find value in investing in automatic dispensers or preservation technologies. By aligning the chosen method with operational needs and available resources, buyers can effectively enhance their hummingbird feeding strategies.

Essential Technical Properties and Trade Terminology for how often to change hummingbird food

What Are the Key Technical Properties Related to Changing Hummingbird Food?

When discussing the frequency of changing hummingbird food, several technical properties play a crucial role in ensuring optimal feeding conditions for these birds. Understanding these specifications can assist B2B buyers in making informed decisions about their products and services.

1. Nectar Freshness Duration

Nectar freshness is critical for attracting hummingbirds. The recommended duration for changing nectar varies with temperature; at cooler temperatures (around 60°F), nectar can last 2-3 days, while at temperatures exceeding 90°F, it should be changed daily. This property is vital for maintaining customer satisfaction, as spoiled nectar can deter birds and impact sales.

2. Sugar Concentration Ratio

The standard sugar-water ratio for homemade nectar is 4:1 (water to sugar). This ratio mimics the natural nectar found in flowers, providing the necessary energy for hummingbirds. B2B buyers should consider this property when sourcing or producing hummingbird food, as maintaining the correct concentration can influence the feeding behavior of the birds and enhance product efficacy.

3. Feeder Material Quality

The quality of materials used in hummingbird feeders, such as glass or high-grade plastic, affects the feeder’s durability and ease of cleaning. High-quality materials resist mold and bacterial growth, which can spoil the nectar. For B2B buyers, understanding material properties ensures that they invest in products that meet both consumer expectations and regulatory standards.

4. Cleaning Frequency Guidelines

Regular cleaning of feeders is essential to prevent mold and bacterial growth. It is recommended to clean feeders every time the nectar is changed, particularly in warmer climates. Establishing clear guidelines on cleaning frequency can enhance product longevity and bird health, thereby increasing customer loyalty.

5. Shelf Life of Prepared Nectar

Prepared nectar, whether homemade or commercially produced, has a limited shelf life, typically lasting about 1-2 weeks when refrigerated. Understanding this property helps businesses manage inventory effectively and reduces waste, ensuring that products remain fresh for consumers.

6. Nectar Composition

Nectar must be free from harmful additives like red dye or honey, which can be detrimental to hummingbirds. Understanding the composition of nectar is essential for B2B buyers to ensure compliance with health standards and consumer preferences.

What Are Common Trade Terms Related to Hummingbird Food?

Familiarity with industry terminology is crucial for B2B buyers as it facilitates smoother transactions and better communication with suppliers and customers.

Illustrative image related to how often to change hummingbird food

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are rebranded by other firms. In the context of hummingbird food, this could involve manufacturers who create custom formulations or specialized feeders that are then sold under different brand names.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory management and budgeting for hummingbird food products.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on the supply of goods or services. B2B buyers should use RFQs to obtain competitive pricing for hummingbird food and feeders, ensuring they receive the best value.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is crucial for B2B transactions, particularly for buyers importing hummingbird food from different regions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for B2B buyers to ensure timely availability of hummingbird food, particularly in peak seasons.

6. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. B2B buyers should utilize SKUs for efficient inventory management of hummingbird food and related products, allowing for better tracking and reordering processes.

By grasping these essential properties and terms, B2B buyers can navigate the hummingbird food market more effectively, ensuring they meet the needs of their customers while maintaining high standards of quality and service.

Navigating Market Dynamics and Sourcing Trends in the how often to change hummingbird food Sector

Market Overview & Key Trends in Hummingbird Food Sourcing

The global market for hummingbird food is witnessing significant growth driven by increasing awareness of wildlife conservation and the rising popularity of backyard bird feeding. This trend is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where urbanization has created a disconnect between nature and communities. Consequently, international B2B buyers are increasingly sourcing hummingbird food products that cater to this growing interest in avian life.

Emerging technologies in the B2B sector are also influencing sourcing trends. For instance, the development of smart feeders equipped with sensors allows for real-time monitoring of nectar levels and freshness, providing valuable data for businesses in maintaining product quality. Additionally, e-commerce platforms are streamlining supply chains, enabling buyers from various regions to access a wider range of products, often at competitive prices.

Market dynamics are shifting as consumers become more discerning about the ingredients in hummingbird food. There is a growing demand for natural, dye-free, and preservative-free options. As more businesses recognize the importance of catering to these preferences, the emphasis on product quality, transparency, and traceability is becoming paramount. This trend is not only about meeting consumer demand but also about building brand loyalty in an increasingly competitive market.

How is Sustainability & Ethical Sourcing Impacting Hummingbird Food Supply Chains?

Sustainability and ethical sourcing have become critical considerations for international B2B buyers in the hummingbird food sector. The environmental impact of production processes and packaging materials is under scrutiny, prompting businesses to adopt more sustainable practices. This includes sourcing raw materials, such as sugar and other ingredients, from suppliers that prioritize eco-friendly farming methods.

Illustrative image related to how often to change hummingbird food

Buyers are increasingly seeking suppliers with certifications that signify adherence to sustainable practices, such as organic or fair-trade certifications. These credentials not only enhance the credibility of the products but also appeal to environmentally conscious consumers who are willing to pay a premium for sustainable options. This shift is particularly relevant in Europe, where stringent environmental regulations often influence purchasing decisions.

Moreover, the push for reducing carbon footprints is leading companies to rethink their logistics strategies. Sourcing ingredients closer to end markets reduces transportation emissions, aligning with both corporate sustainability goals and the expectations of environmentally aware consumers. By focusing on ethical sourcing and sustainability, businesses can differentiate themselves in a crowded market and foster customer loyalty.

What is the Evolution of Hummingbird Food and Its Sourcing Practices?

The evolution of hummingbird food has been influenced by changes in consumer preferences and advancements in production technologies. Initially, hummingbird nectar was primarily homemade, using simple sugar and water mixtures. However, as awareness grew about the nutritional needs of hummingbirds, commercially produced nectar became more prevalent. This shift has led to an expansion of product offerings, including pre-packaged nectars that cater to various regional tastes and needs.

In recent years, the emphasis on quality and sustainability has transformed sourcing practices. The industry has moved towards sourcing ingredients that are not only effective for attracting hummingbirds but are also environmentally friendly. This evolution reflects a broader trend within the pet and wildlife care sectors, where ethical sourcing and sustainable practices are becoming non-negotiable standards for businesses aiming to thrive in the global marketplace.

By adapting to these changes, international B2B buyers can position themselves strategically within this growing market, ensuring they meet the demands of both consumers and the environment.

Frequently Asked Questions (FAQs) for B2B Buyers of how often to change hummingbird food

-

How often should I change hummingbird food in warmer climates?

In warmer climates, it is crucial to change hummingbird food daily or every other day. High temperatures accelerate the spoilage of nectar, leading to mold growth and fermentation, which can harm the birds. Regularly monitoring the feeder and replacing the nectar helps ensure that it remains fresh and appealing to hummingbirds, thereby increasing visitation rates. -

What factors influence the frequency of changing hummingbird food?

Several factors affect how often hummingbird food should be changed, including temperature, humidity, and the level of feeder activity. In hotter and more humid conditions, nectar should be replaced daily. Conversely, in cooler climates, it may last up to three days. Additionally, if the feeder is frequently visited, nectar may spoil faster due to increased consumption and exposure to contaminants. -

What is the best nectar recipe for hummingbirds?

The optimal nectar recipe for hummingbirds is a mixture of four parts water to one part granulated white sugar. Boil the water to eliminate chlorine and dissolve the sugar completely. Avoid using dyes or alternative sweeteners like honey, as they can be harmful to birds. This homemade nectar mimics the natural sugar content found in flowers, ensuring that hummingbirds receive the necessary energy. -

How do I ensure the quality of hummingbird nectar from suppliers?

When sourcing hummingbird nectar, it is essential to vet suppliers for quality assurance. Look for suppliers that provide detailed product specifications, including the sugar composition and absence of artificial additives. Request samples to evaluate freshness and taste. Establishing a strong relationship with suppliers can also facilitate discussions about quality standards and adherence to safe manufacturing practices. -

What minimum order quantity (MOQ) should I expect when sourcing hummingbird food?

Minimum order quantities for hummingbird food can vary widely based on the supplier and production capabilities. Typically, suppliers may require an MOQ ranging from 500 to 5,000 units. It is advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are looking to enter a new market or require customized formulations. -

What payment terms are common when purchasing hummingbird food internationally?

Payment terms can differ based on the supplier’s policies and the buyer’s location. Common terms include 30% upfront payment and 70% upon delivery, or net 30 days after receipt of goods. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks associated with currency fluctuations and supplier reliability. -

How can I customize hummingbird food for specific regional preferences?

Customizing hummingbird food for specific markets involves understanding local flora and hummingbird species. Collaborate with suppliers to create formulations that mimic local nectar sources. Additionally, conducting market research can provide insights into consumer preferences, allowing you to tailor your product offerings effectively. Be prepared to adjust sweetness levels or add natural flavors to meet regional expectations. -

What logistics considerations should I keep in mind when sourcing hummingbird food?

When sourcing hummingbird food internationally, logistics play a critical role in maintaining product quality. Ensure that suppliers have reliable shipping methods that minimize transit times and exposure to temperature extremes. Evaluate their warehousing capabilities to prevent spoilage before distribution. Additionally, familiarize yourself with import regulations and tariffs in your target market to avoid delays and unexpected costs.

Top 4 How Often To Change Hummingbird Food Manufacturers & Suppliers List

1. Reddit – Hummingbird Feeder Care

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Change sugar-water in hummingbird feeders every day when temperatures exceed 80 degrees Fahrenheit to prevent mold and bacteria growth. In cooler weather, change it every two days. It’s recommended to only fill the feeders with a small amount if there are only one or two birds, and to keep the feeders clean for the health of the hummingbirds.

2. Facebook – Hummingbird Whisperer

3. Perky-Pet – Instant Hummingbird Nectar

Domain: perkypet.com

Registered: 1996 (29 years)

Introduction: Perky-Pet® offers a variety of instant hummingbird nectars made with 100% sucrose, containing no artificial flavors or sweeteners. The clear hummingbird nectar concentrate comes in a 64 oz bottle, making up to 256 oz of hummingbird food. The Instant Clear Hummingbird Nectar is available in a 2 lb bag, making up to 192 oz of nectar. Both products are easy to mix with water and are designed to provi…

4. BirdForum – Hummingbird Nectar Guide

Domain: birdforum.net

Registered: 2002 (23 years)

Introduction: Hummingbird food is typically made with a simple formula of 1 part sugar to 4 parts water. It is recommended to change the food every 2 to 3 days under normal conditions, and every day in hot weather. If feeding during cooler temperatures, it can be changed every 5 to 6 days. Homemade nectar is preferred over store-bought options due to the absence of unnatural chemicals and dyes. The standard rec…

Strategic Sourcing Conclusion and Outlook for how often to change hummingbird food

What Are the Key Takeaways for Changing Hummingbird Food?

In summary, the frequency of changing hummingbird food is essential for maintaining healthy feeding practices. For optimal freshness, nectar should be changed every 1-3 days, depending on the weather conditions. In warmer climates, especially above 90°F, daily changes are crucial to prevent spoilage and to attract these vibrant birds consistently. Additionally, keeping feeders clean and free from mold is vital for ensuring a reliable food source for hummingbirds, which, in turn, enhances their visitation rates.

How Does Strategic Sourcing Impact Hummingbird Food Supply?

For international B2B buyers, understanding the nuances of sourcing high-quality hummingbird food can significantly impact your inventory management and sales strategies. Establishing reliable partnerships with suppliers who prioritize quality and freshness can set your business apart in competitive markets across Africa, South America, the Middle East, and Europe.

What’s Next for B2B Buyers in the Hummingbird Food Market?

As the demand for hummingbird products continues to grow, now is the time to evaluate your sourcing strategies. Invest in suppliers that not only meet quality standards but also align with sustainability practices. By doing so, you will not only cater to the needs of your customers but also contribute positively to the environment. Engage with your suppliers today to ensure a steady and high-quality supply of hummingbird food, and position your business for future growth in this niche market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.