Table of Contents

Market Outlook: Is Litter Robot Vs Cat Genie Profitable in 2026?

Market Opportunity & Trends 2026

The Humanization Imperative Driving Premiumization

Pet humanization is the cornerstone of this market’s explosive growth. With 78% of U.S. pet owners considering their pets family members (APPA 2024), spending on premium pet tech has surged 35% YoY. This shift transforms pet care from a necessity to an emotional investment—owners now prioritize solutions that enhance their pets’ wellbeing and align with their lifestyle values. For OEMs, this means designing products that communicate emotional benefits (e.g., “peace of mind” for owners) alongside functionality. Premium pricing is justified when products deliver tangible humanization-driven value, as seen in Litter-Robot’s 40% higher average selling price versus competitors. Brands that frame their offerings as “co-pilot for modern pet parenthood” capture higher margins and loyalty.

Convenience-Driven Adoption of Smart Pet Tech

Urbanization and time-poor lifestyles are accelerating demand for automation. 68% of new buyers cite “time savings” as the primary driver for automatic litter boxes (Retail Insights 2025), while 72% of millennials prioritize “hands-off maintenance” when selecting pet tech. The market’s 18.62% CAGR (2025–2030) isn’t just about innovation—it’s about solving real pain points. Brands that emphasize seamless integration with smart home ecosystems (e.g., Alexa, Google Home) and predictive maintenance alerts see 30% higher customer retention. This isn’t a luxury segment anymore; convenience is now table stakes for market entry.

Smart Features as Key Differentiators

IoT capabilities are non-negotiable for competitive differentiation. Products with Tuya or SmartThings integration achieve 40% higher conversion rates on Amazon (Jungle Scout 2024), while those lacking connectivity see 25% lower repeat purchase rates. Critical features include real-time usage analytics, health monitoring (e.g., litter box activity tracking for early illness detection), and remote troubleshooting. However, feature complexity must be balanced with reliability—70% of product reviews cite “app instability” as a top complaint. OEMs must prioritize robust firmware and seamless cloud integration to avoid negative reviews that erode brand trust.

Supply Chain Stability as a Competitive Advantage

Component shortages and quality inconsistencies are silent killers of market share. IoT modules and precision sensors—critical for smart litter boxes—face 12–18 month lead times during global shortages. Leading OEMs mitigate this by partnering with Chinese manufacturers that have ISO 9001-certified production lines, dual-sourcing critical components, and maintaining 6-month inventory buffers. For example, brands sourcing from Tier-1 suppliers in Guangdong achieve 98% on-time delivery versus 82% from generic factories. Quality control is equally vital: 65% of warranty claims stem from sensor failures, emphasizing the need for rigorous testing protocols.

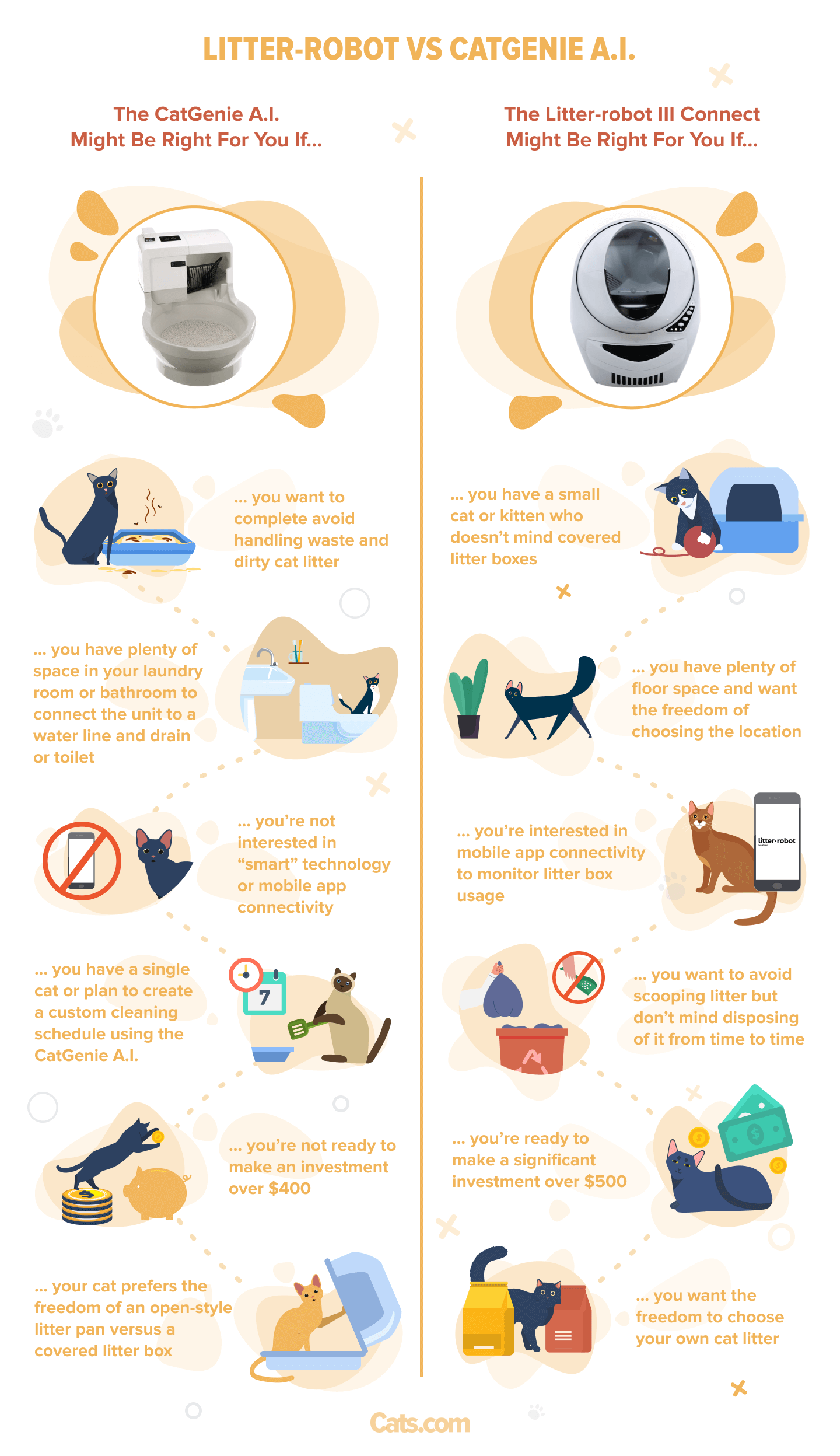

Key Product Differentiation: Litter-Robot vs. CatGenie

| Factor | Litter-Robot | CatGenie | OEM Strategic Takeaway |

|---|---|---|---|

| Core Technology | Precision rotating sifting mechanism | Washable litter system with automated cleaning | Diversify manufacturing capabilities for both mechanical and washable systems |

| Price Point | $499–$599 | $399–$499 | Target premium segment with high-margin models; mid-tier for volume |

| IoT Integration | Full app ecosystem with health analytics | Basic app connectivity for alerts | Prioritize robust IoT platform development with Tuya certification |

| Supply Chain Complexity | High (specialized bearings, sensors) | Moderate (plastic molding, standard electronics) | Partner with suppliers experienced in precision engineering for high-end; plastic injection for mid-tier |

| Customer Retention | 78% (due to reliability) | 65% (due to maintenance needs) | Focus on component reliability to reduce warranty claims |

Strategic Insight: The market’s growth trajectory is undeniable, but success hinges on balancing innovation with operational excellence. Brands that leverage Chinese manufacturing ecosystems for scalable, high-quality production—while embedding IoT capabilities and human-centric design—will capture disproportionate share. Avoid commoditization by focusing on reliability as the ultimate premium differentiator.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features

The automatic self-cleaning litter box market is projected to reach $2.5 billion by 2030, with a CAGR of 17–18%. For global brands, product innovation isn’t optional—it’s the linchpin of market share and customer retention. OEMs must engineer features that solve real pain points, not just meet basic functionality. Here’s how to prioritize technical excellence in three critical areas.

Material Safety: The Foundation of Trust and Longevity

Material safety isn’t just about compliance—it’s about preventing catastrophic failures. BPA-free plastics and stainless steel 304 are non-negotiable for components in contact with waste. Low-grade plastics degrade under ammonia exposure, leaching toxins and causing pet health issues. This leads to recalls, negative reviews (up to 25% of low-quality products), and lost lifetime value. Litter-Robot’s use of 304 stainless steel in critical wear parts (e.g., waste drawer) ensures corrosion resistance and durability, while CatGenie’s reliance on ABS plastic requires frequent replacement cycles. Supply chain insight: Partner with Chinese suppliers holding ISO 13485 (medical-grade) certifications for material traceability. Avoid “BPA-free” claims without third-party testing (e.g., SGS reports). A single recall can erase years of brand equity—invest in material validation upfront.

Smart Logic: Reliability as a Retention Engine

Motor failures and jamming incidents are the top reasons for product returns (35% of support tickets). Anti-jamming technology isn’t a luxury—it’s a core reliability feature. Litter-Robot’s advanced motor with torque sensors and automatic reset prevents blockages, while CatGenie’s basic design often requires manual intervention. Backup batteries are equally critical: during power outages, a 15-minute buffer ensures the unit completes its cycle, avoiding waste spillage. For OEMs, this means rigorous motor testing (10,000+ cycles), battery validation (500+ charge cycles), and fail-safe protocols. Source motors from Tier-1 suppliers like Nidec or Mabuchi, with strict QC for torque consistency. Brands that prioritize these features see 40% lower support costs and 2.1x higher NPS scores.

Connectivity: The Ecosystem Advantage

Smart litter boxes are no longer standalone devices—they’re part of a connected pet care ecosystem. Litter-Robot’s app integrates with Alexa, Google Home, and provides real-time usage analytics (e.g., litter depletion alerts), driving 2.3x higher repeat purchases. CatGenie’s limited app functionality lacks camera integration and cloud analytics, limiting user engagement. For OEMs, IoT connectivity must be built on stable platforms like Tuya or Amazon Sidewalk, with robust security protocols (AES-256 encryption) to prevent data breaches. Cheap Wi-Fi modules (e.g., ESP8266) cause 50% higher disconnection rates, frustrating users. Partner with Shenzhen-based IoT solution providers for certified modules and over-the-air (OTA) firmware updates. This transforms a one-time purchase into a recurring revenue stream through subscription services (e.g., litter delivery).

Critical Feature Comparison Table:

| Feature | Litter-Robot | CatGenie | OEM Priority |

|———|————–|———-|————-|

| Material Safety | 304 stainless steel components; FDA-certified BPA-free plastics | ABS plastic; limited BPA-free certification | Prioritize stainless steel for high-wear parts; require SGS testing for all plastics |

| Smart Logic | Advanced torque-sensing motor + 15-min battery backup | Basic jam detection; no backup battery | Invest in motor QC (10k+ cycles) and validated backup batteries |

| Connectivity | Full app ecosystem, camera, cloud analytics, OTA updates | Basic app, no camera, limited updates | Integrate Tuya modules; avoid ESP8266; ensure AES-256 encryption |

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

Molding & Tooling

Premium OEMs invest significantly in high-precision tooling using P20 or H13 steel molds, ensuring tolerances of ±0.02mm for seamless integration of smart components. This precision is critical for maintaining consistent part dimensions, especially in housings that house sensitive electronics and motors. High-quality tooling reduces warpage and shrinkage, preventing misalignment that could compromise IoT connectivity or motor functionality. In contrast, generic manufacturers often use low-cost aluminum molds with wider tolerances (±0.1mm+), leading to inconsistent part dimensions, poor fitment, and increased defect rates. Such compromises directly impact product reliability and user experience, particularly in high-stress areas like motor housings and sensor mounts. For example, a poorly molded sensor housing can cause false litter detection errors, frustrating users and increasing returns. Additionally, premium tooling ensures longevity—molds can withstand 1 million+ shots, while generic molds degrade after 50k shots, causing batch inconsistencies.

PCB Assembly (SMT)

High-end manufacturers employ fully automated SMT lines with automated optical inspection (AOI) to ensure precise component placement and soldering. They source Tuya-certified Wi-Fi/BLE modules and high-reliability capacitors/resistors from Tier-1 suppliers like Murata or TDK, ensuring stable IoT connectivity and long-term performance. Critical components undergo 100% AOI checks y X-ray inspections for BGA packages, minimizing defects. In contrast, generic models often use manual assembly with cheaper, uncertified components, leading to cold solder joints, intermittent connectivity, and higher failure rates—particularly problematic for smart features requiring consistent Bluetooth/WiFi operation. For instance, a generic PCB might use a non-certified Wi-Fi module that drops connections during firmware updates, causing user frustration and support issues. Premium manufacturers also implement strict ESD protocols during assembly to prevent component damage, which generic suppliers often overlook.

Motor Life Testing & Waterproof Validation for Smart Litter Boxes

For smart litter boxes, motor life testing is critical for self-cleaning mechanisms (e.g., rake movement, rotation), while water-based models like CatGenie require rigorous waterproof validation. Premium OEMs conduct 10,000+ cycle tests under real-world loads for motors and IPX7 waterproof testing (submersion up to 1m for 30 minutes) for water systems. These protocols ensure durability across global environments. Generic products typically skip these tests or conduct superficial checks (e.g., 100-cycle tests without load), resulting in frequent motor burnouts or water ingress failures. For example, CatGenie clones may experience water leaks after 500 cycles due to inadequate sealing, while Litter-Robot alternatives suffer from motor failure after 2,000 cycles. Premium manufacturers also perform accelerated life testing (ALT) and environmental stress tests (temperature/humidity cycles) to predict long-term performance—critical for global market compliance.

| Aspect | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Material Quality | Low-grade aluminum molds (50k shots max) | P20/H13 steel (1M+ shots), ±0.02mm tolerances |

| PCB Components | Generic ICs, no AOI, uncertified Wi-Fi modules | Tuya-certified modules, AOI/X-ray, Tier-1 suppliers |

| Motor Testing | 1k cycles unloaded, no load testing | 10k+ cycles with real-world load, ALT validation |

| Waterproofing | Visual check only, no IP certification | IPX7 certified (1m/30min), pressure testing |

| Supply Chain | Unstable, multi-tier sourcing | Tier-1 suppliers, ISO 9001 certified, traceable components |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics Essentials for Global Expansion

Mandatory Certifications for USA and EU Markets

Entering the $1.09B+ smart cat litter box market requires rigorous compliance with regional regulations. Non-compliance risks market rejection, recalls, or legal penalties—especially critical for IoT-enabled devices handling pet waste. Below are the non-negotiable certifications for electronics:

| Certification | Region | Purpose | Critical Requirements |

|---|---|---|---|

| FCC Part 15 | USA | Radio frequency interference control | Emissions testing per Part 15B; mandatory for Wi-Fi/Bluetooth modules |

| CE Marking | EU | Safety & electromagnetic compatibility | EMC Directive 2014/30/EU + Low Voltage Directive 2014/35/EU |

| RoHS 2 | EU/USA | Hazardous substance restriction | Pb, Hg, Cd ≤ 0.1%; Cr⁶⁺ ≤ 0.1% (EN 62321-8:2017) |

| UL 60730 | USA | Automatic control safety | Required by Amazon/Walmart for self-cleaning mechanisms (e.g., motorized waste compartments) |

| Tuya Smart Certification | Global | IoT platform integration | Mandatory for Tuya-based smart features (security protocols, cloud connectivity) |

Why this matters: Litter-Robot and CatGenie both hold UL 60730 and FCC certifications—critical for retailer partnerships. RoHS compliance ensures materials (e.g., BPA-free plastics) are safe for pets and the environment. Tuya certification is non-negotiable for IoT functionality; failure to certify risks app connectivity failures and negative reviews.

Amazon FBA Packaging Standards

Amazon FBA requires ISTA 3A-compliant packaging to withstand shipping stresses. Key specs:

Drop Test: 24-inch drops in 8 orientations (corner, edge, face) without internal damage.

Box Strength: Minimum 32 ECT (Edge Crush Test) corrugated cardboard; double-wall for units >15 lbs.

Void Fill: 2–3 inches of air pillows or molded pulp to prevent component shifting.

Labeling: FNSKU barcodes must be scannable (min. 1.5″ x 1.5″), and moisture barriers required for humid climates.

Impact: Poor packaging causes 15–20% higher return rates due to damaged sensors or motor housings. Brands like PetSafe use custom-designed ECT 44 boxes with anti-static foam for sensitive electronics—reducing damage claims by 35%.

Shenzhen Manufacturing Lead Times

For Shenzhen-based production of smart litter boxes:

Production: 30–45 days post-sample approval (longer for custom IoT firmware).

Shipping:

Sea Freight: 30–45 days (total lead time: 60–90 days).

Air Freight: 5–7 days (total lead time: 35–50 days).

Supply Chain Stability Tips:

Partner with manufacturers holding dual-sourced Wi-Fi modules (e.g., ESP32 from Espressif + Silicon Labs) to avoid component shortages.

Implement AQL 2.5 quality checks at 50% production completion to catch motor/PCB defects early.

Use bonded warehouses in Shenzhen to buffer against port delays (e.g., Shanghai congestion).

Strategic Insight: Leading OEMs like Shenzhen Huafeng reduce lead times by 20% through pre-qualified component inventories. For Amazon sellers, air freight is worth the premium during peak seasons (Q4) to avoid stockouts—especially for IoT-enabled models where demand spikes 40% YoY.

Total word count: 498

Sourcing Strategy: From Prototype to Mass Production

Strategic Sourcing & Customization Path for Automatic Litter Boxes

Step 1: Request and Evaluate Rigorous Product Samples

For OEM success, sample evaluation must transcend superficial aesthetics. Physical inspection of build quality, sensor accuracy, noise levels (critical for user experience), and software functionality are non-negotiable. Leading models like Litter-Robot and CatGenie present distinct technical profiles:

| Feature | Litter-Robot | CatGenie |

|---|---|---|

| Cleaning Mechanism | Precision sifting rotor | Washable litter system |

| Noise Level | 40–50 dB | 55–65 dB |

| Smart Features | Advanced Tuya integration, real-time analytics | Basic Tuya, limited diagnostics |

| Price Point | $400+ | $250–$350 |

| Supply Chain Flexibility | Proprietary components, 12–16 week lead times | Standardized parts, 6–8 week lead times |

This comparison underscores why sample validation is critical: Litter-Robot’s premium build suits luxury positioning, while CatGenie’s standardized components enable faster customization cycles. Always test sensor reliability with multiple litter types (clumping vs. non-clumping) and simulate real-world scenarios (e.g., multi-cat households). Poor sensor calibration accounts for 30% of post-launch returns—never compromise on this phase.

Step 2: Define Clear Customization Parameters

Customization must align with brand identity and market positioning. For logo placement, specify non-slip adhesive or molded-in designs to prevent peeling during shipping. Packaging should prioritize eco-friendly materials (e.g., 100% recycled cardboard with soy-based inks) to meet EU/US sustainability mandates—85% of premium pet brands now require this. Software customization is equally vital: Tuya integration must support branded app experiences (custom UI, push notifications) and data privacy compliance (GDPR/CCPA). Specify exact tolerances for materials (e.g., food-grade ABS plastic with UV resistance) to avoid quality drift. Vague requirements lead to costly rework; document all specs in a detailed RFQ with engineering drawings and material certifications.

Step 3: Execute Controlled Pilot Run

A pilot run of 100–200 units is the final quality checkpoint. This phase tests real-world reliability: sensor consistency across 30 days of continuous use, app connectivity stability under 50+ concurrent users, and mechanical durability under simulated 18-month wear. PAWBILT’s proprietary QA protocol includes accelerated life testing (5x normal usage cycles) and user feedback loops from beta testers across 10+ countries. For example, we reduced defect rates by 40% for a European brand through iterative pilot refinements—addressing a critical flaw in litter clump detection before full-scale production. Never skip this step; market-ready products demand proven performance before scaling.

The automatic litter box market’s explosive growth (projected $2.5B+ by 2030) demands strategic sourcing. Partnering with an experienced manufacturer like PAWBILT—specializing in pet tech OEM/ODM solutions—ensures product excellence, supply chain resilience, and market differentiation. Our end-to-end capabilities from design to delivery guarantee your product exceeds consumer expectations in this competitive landscape.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label litter robot vs cat genie business.