Introduction: Navigating the Global Market for pet automatic food dispenser

In today’s fast-paced world, sourcing a reliable pet automatic food dispenser presents unique challenges for international B2B buyers. With the increasing demand for pet care solutions across diverse markets, businesses must navigate a landscape filled with varying product types, functionalities, and supplier options. This comprehensive guide is designed to streamline your purchasing journey, providing in-depth insights into the different types of automatic feeders available, their applications, and key features such as smart technology integration and capacity options.

As the pet care industry continues to expand, particularly in regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Saudi Arabia and Vietnam—understanding the nuances of supplier vetting and cost considerations becomes crucial. This guide empowers buyers to make informed decisions by outlining essential criteria for selecting suppliers, evaluating product quality, and optimizing cost-effectiveness.

From RFID-enabled feeders that ensure personalized feeding experiences to models designed for multi-pet households, this resource covers the spectrum of available solutions. By leveraging the insights presented in this guide, B2B buyers can confidently navigate the global market for pet automatic food dispensers, ensuring they meet their clients’ needs while capitalizing on growth opportunities within the pet care sector.

Table Of Contents

- Top 5 Pet Automatic Food Dispenser Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pet automatic food dispenser

- Understanding pet automatic food dispenser Types and Variations

- Key Industrial Applications of pet automatic food dispenser

- 3 Common User Pain Points for ‘pet automatic food dispenser’ & Their Solutions

- Strategic Material Selection Guide for pet automatic food dispenser

- In-depth Look: Manufacturing Processes and Quality Assurance for pet automatic food dispenser

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet automatic food dispenser’

- Comprehensive Cost and Pricing Analysis for pet automatic food dispenser Sourcing

- Alternatives Analysis: Comparing pet automatic food dispenser With Other Solutions

- Essential Technical Properties and Trade Terminology for pet automatic food dispenser

- Navigating Market Dynamics and Sourcing Trends in the pet automatic food dispenser Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pet automatic food dispenser

- Strategic Sourcing Conclusion and Outlook for pet automatic food dispenser

- Important Disclaimer & Terms of Use

Understanding pet automatic food dispenser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smart Feeders | App-controlled, programmable schedules, camera monitoring | Pet stores, veterinary clinics, pet hotels | Pros: Remote access, customizable feeding. Cons: Higher initial cost. |

| Gravity Feeders | Simple design, uses gravity to dispense food | Retail, shelters, homes with multiple pets | Pros: Affordable, low maintenance. Cons: Limited portion control. |

| Wet Food Dispensers | Refrigeration capabilities, vacuum-sealing technology | Pet cafes, restaurants, high-end pet services | Pros: Freshness, enhanced flavor. Cons: More complex to manage. |

| Multi-Pet Feeders | Dual food trays, RFID recognition for individual feeding | Multi-pet households, pet boarding facilities | Pros: Tailored feeding, reduced conflict. Cons: Can be bulky. |

| Automated Portion Control | Programmable portions, timed dispensing | Veterinary clinics, training facilities | Pros: Prevents overeating, consistent nutrition. Cons: May require frequent refills. |

What Are the Key Characteristics of Smart Feeders?

Smart feeders are equipped with advanced technology, allowing pet owners to control feeding schedules and portions via mobile applications. These devices often include features such as camera monitoring, enabling users to visually check on their pets during feeding times. For B2B buyers, the appeal lies in their ability to cater to tech-savvy customers and offer premium products that enhance pet care. When considering smart feeders, businesses should evaluate the ease of use, integration with other smart home devices, and potential for customer support.

How Do Gravity Feeders Function and Where Are They Best Suited?

Gravity feeders operate on a straightforward principle where food is dispensed as pets consume it, ensuring a continuous supply. This type of feeder is particularly suitable for environments such as shelters and homes with multiple pets, where simplicity and cost-effectiveness are paramount. B2B buyers should assess the quality of materials used, as well as the feeder’s capacity to handle varying pet sizes. While gravity feeders are generally low-cost, they may not offer the precise portion control that some pet owners desire.

What Advantages Do Wet Food Dispensers Offer for B2B Buyers?

Wet food dispensers are designed to keep food fresh with features like refrigeration and vacuum sealing. These dispensers are ideal for businesses that serve wet food, such as pet cafes and specialty pet service providers. The key purchasing considerations include the dispenser’s capacity, ease of cleaning, and how well it maintains food quality. While they provide a gourmet experience for pets, they require more management compared to dry food feeders, which could affect operational efficiency.

Why Choose Multi-Pet Feeders for Diverse Pet Households?

Multi-pet feeders are designed to cater to households with several pets, featuring dual food trays and RFID technology to ensure each pet receives their designated portion. This solution is particularly beneficial for boarding facilities and pet hotels. B2B buyers should look for feeders that are durable and easy to clean, as they will see heavy use. While they help reduce competition among pets, their larger size may pose a challenge in smaller spaces.

How Do Automated Portion Control Feeders Improve Pet Nutrition?

Automated portion control feeders allow for precise programming of food amounts and feeding times, addressing concerns about overfeeding and obesity in pets. These feeders are valuable for veterinary clinics and training facilities where maintaining a specific diet is crucial. B2B buyers should consider the feeder’s capacity, reliability, and user interface. Although they may require more frequent refills, the benefits of improved pet health and consistent feeding schedules make them a worthwhile investment.

Key Industrial Applications of pet automatic food dispenser

| Industry/Sector | Specific Application of pet automatic food dispenser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Automated feeding for hospitalized pets | Ensures timely feeding, reduces staff workload, and improves patient care | Reliability, ease of cleaning, and programmable features |

| Pet Boarding Facilities | Scheduled feeding for multiple pets | Streamlines operations, reduces food waste, and ensures all pets are fed on time | Capacity, durability, and remote monitoring capabilities |

| Pet Retail Stores | Display and demo of automatic feeders | Attracts customers, enhances shopping experience, and increases sales | Variety of models, pricing strategies, and promotional support |

| Animal Shelters | Consistent feeding for rescued animals | Helps maintain health standards, reduces labor costs, and improves animal welfare | Sourcing from ethical manufacturers, maintenance support, and warranty options |

| E-commerce Platforms | Online sales of automated feeders | Expands product offerings, caters to a growing market, and provides convenience to customers | Competitive pricing, shipping logistics, and product variety |

How Can Veterinary Clinics Benefit from Pet Automatic Food Dispensers?

In veterinary clinics, pet automatic food dispensers are essential for managing the feeding schedules of hospitalized pets. These devices ensure that pets receive their meals on time, which is critical for recovery and overall health. By automating the feeding process, clinics can alleviate the workload on staff, allowing them to focus on other care needs. Buyers in this sector should prioritize dispensers that are reliable, easy to clean, and programmable to accommodate various dietary requirements.

What Advantages Do Pet Boarding Facilities Gain from Using Automatic Feeders?

Pet boarding facilities can significantly benefit from automatic food dispensers by providing scheduled feeding for multiple animals. This not only streamlines daily operations but also reduces food waste and ensures that all pets receive their meals according to their specific dietary needs. For B2B buyers in this industry, key considerations include the capacity of the dispensers, their durability to withstand frequent use, and features like remote monitoring to oversee feeding from a distance.

How Do Pet Retail Stores Leverage Automatic Feeders to Boost Sales?

Pet retail stores utilize automatic feeders as a way to enhance customer engagement and increase sales. By displaying and demonstrating these products, retailers can attract pet owners looking for convenience and innovative solutions for their pets. B2B buyers in this sector should focus on sourcing a variety of models at competitive prices, as well as seeking promotional support from manufacturers to effectively market these dispensers.

What Role Do Automatic Food Dispensers Play in Animal Shelters?

In animal shelters, pet automatic food dispensers play a crucial role in ensuring consistent feeding for rescued animals. These dispensers help maintain health standards by providing regular meals, which is vital for the well-being of the animals. Moreover, they reduce labor costs associated with manual feeding. Buyers from shelters should consider sourcing from ethical manufacturers that offer maintenance support and warranty options to ensure the longevity and reliability of the dispensers.

How Can E-commerce Platforms Benefit from Selling Pet Automatic Feeders?

E-commerce platforms can expand their product offerings by including a range of automatic pet feeders, catering to the growing market of tech-savvy pet owners. Selling these devices provides convenience to customers who prefer online shopping. B2B buyers in this space should prioritize competitive pricing, effective shipping logistics, and a diverse product variety to meet different customer needs and preferences.

3 Common User Pain Points for ‘pet automatic food dispenser’ & Their Solutions

Scenario 1: Inconsistent Feeding Schedules for Pets in Shelters

The Problem: Many B2B buyers, especially those managing pet shelters or boarding facilities, face the challenge of inconsistent feeding schedules. With multiple pets to care for, it’s difficult to ensure that each animal receives the correct amount of food at the right times. This inconsistency can lead to overfeeding, underfeeding, or feeding at irregular intervals, which can affect the health and behavior of the animals. Additionally, staff turnover and busy environments can exacerbate this issue, making it harder to maintain a stable feeding routine.

The Solution: To tackle this problem, B2B buyers should invest in programmable automatic pet feeders that allow for scheduled meal times and portion control. When selecting a dispenser, look for models that can hold varying quantities of food and have features like digital timers and customizable feeding schedules. For shelters, feeders with a large capacity, such as those that can hold up to 24 cups of food, are ideal for managing multiple pets. Additionally, consider models with smartphone connectivity for remote management. This technology allows staff to monitor and adjust feeding schedules from any location, ensuring that every pet receives their meals on time, even during busy shifts.

Scenario 2: Managing Diverse Dietary Needs Among Multiple Pets

The Problem: In facilities catering to a variety of pets, such as multi-species shelters or pet hotels, managing diverse dietary requirements can be a significant challenge. Different animals may have specific needs, such as weight management, allergies, or special diets. This complexity can lead to confusion, accidental overfeeding, or inappropriate food being given to the wrong pet, which can result in health complications.

The Solution: To address this issue, B2B buyers should consider investing in automatic feeders with RFID technology or multi-pet recognition features. These advanced feeders can be programmed to dispense different types or amounts of food based on each pet’s dietary needs. For example, using RFID collars, the feeder can identify which pet is approaching and release the pre-set portion of food specific to that animal. When sourcing these feeders, look for models that offer customizable feeding options and compatibility with various types of pet food, including dry, wet, and specialized diets. This ensures that each pet receives the appropriate nutrition without human error.

Scenario 3: Difficulty in Maintaining Food Freshness and Hygiene

The Problem: For B2B buyers in the pet care industry, ensuring the freshness and hygiene of pet food can be a daunting task. Automatic feeders, if not designed properly, can lead to stale food, contamination, and even pests if the food is not stored correctly. This issue is particularly critical in regions with varying climates, where humidity and temperature can affect food quality.

The Solution: To combat these concerns, B2B buyers should opt for automatic pet feeders that feature vacuum-sealing technology or airtight containers to preserve food freshness. Look for models that incorporate desiccant packs or built-in moisture control to keep food dry and free from mold. When purchasing, inquire about the materials used in the feeder’s construction, ensuring they are BPA-free and easy to clean. Additionally, regular maintenance and cleaning schedules should be established, emphasizing the importance of keeping the feeding area hygienic. Implementing these practices will help maintain food quality and ensure a safe feeding environment for pets.

Strategic Material Selection Guide for pet automatic food dispenser

What Are the Key Materials Used in Pet Automatic Food Dispensers?

When selecting materials for pet automatic food dispensers, it is essential to consider their properties, advantages, and limitations. The right material can significantly impact the product’s performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of these dispensers.

How Does Plastic Perform in Pet Automatic Food Dispensers?

Key Properties: Plastic, particularly high-density polyethylene (HDPE) and polypropylene (PP), is lightweight, resistant to moisture, and easy to mold into various shapes. These plastics can withstand temperatures up to 120°C, making them suitable for dry and semi-moist food.

Pros & Cons: The primary advantage of plastic is its cost-effectiveness and versatility in design. It can be produced in various colors and shapes, appealing to diverse consumer preferences. However, plastics may not be as durable as metals and can degrade over time, especially under UV exposure. Additionally, some plastics may not be suitable for high-temperature applications.

Impact on Application: Plastic dispensers are often used for dry food and are compatible with various food types. However, they may not be ideal for wet food applications unless specifically designed with moisture barriers.

Considerations for International Buyers: Compliance with food safety standards such as FDA and EU regulations is crucial. Buyers in regions like Africa and South America should ensure that the plastic used is BPA-free and meets local health regulations.

What Role Does Stainless Steel Play in Pet Automatic Food Dispensers?

Key Properties: Stainless steel is known for its corrosion resistance, durability, and ability to withstand high temperatures (up to 500°C). The material is also non-reactive, making it safe for all types of pet food.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to wear and tear. It is easy to clean and maintain, which is essential for hygiene in pet feeding. However, stainless steel is more expensive than plastic and can increase the overall cost of the product. Manufacturing processes can also be more complex due to the need for specialized equipment.

Impact on Application: Stainless steel is suitable for both dry and wet food dispensers, making it a versatile choice. Its robust nature ensures that it can handle various feeding environments, including outdoor settings.

Considerations for International Buyers: Buyers should look for compliance with ASTM and ISO standards for food-grade materials. In regions like the Middle East and Europe, ensuring that the stainless steel is of high quality (e.g., 304 or 316 grade) is essential for durability and safety.

Why Choose Glass for Pet Automatic Food Dispensers?

Key Properties: Glass is non-porous, easy to clean, and resistant to staining and odors. It can withstand high temperatures and is typically safe for both dry and wet food.

Illustrative image related to pet automatic food dispenser

Pros & Cons: The advantage of glass is its aesthetic appeal and the fact that it does not leach chemicals into food. However, glass is fragile and can break easily, which poses a risk in households with active pets. It is also heavier than plastic and stainless steel, which may affect portability.

Impact on Application: Glass dispensers are often used for high-end pet products, particularly in markets that emphasize design and aesthetics. However, their fragility limits their suitability for all environments.

Considerations for International Buyers: Compliance with safety standards is crucial, particularly in regions with stringent regulations. Buyers should ensure that the glass used is tempered or borosilicate to enhance durability.

How Do Silicone Materials Enhance Pet Automatic Food Dispensers?

Key Properties: Silicone is flexible, heat-resistant (up to 230°C), and non-toxic. It provides excellent sealing properties, making it suitable for moisture-sensitive applications.

Pros & Cons: The primary advantage of silicone is its ability to create airtight seals, which helps maintain food freshness. It is also lightweight and easy to clean. However, silicone can be more expensive than traditional plastics and may not be as durable in the long term.

Impact on Application: Silicone is often used in components such as seals and gaskets in dispensers, enhancing their functionality. It is compatible with both dry and wet foods.

Considerations for International Buyers: Buyers should verify that silicone materials meet food safety standards and are free from harmful additives. Compliance with local regulations is essential, particularly in regions with varying standards.

Summary Table of Material Selection for Pet Automatic Food Dispensers

| Material | Typical Use Case for pet automatic food dispenser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Dry food dispensers | Cost-effective and versatile | Less durable than metals | Low |

| Stainless Steel | Wet and dry food dispensers | Durable and easy to clean | Higher cost and complex manufacturing | High |

| Glass | High-end pet food dispensers | Non-reactive and aesthetically pleasing | Fragile and heavy | Med |

| Silicone | Seals and gaskets in dispensers | Excellent sealing properties | More expensive than traditional plastics | Med |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in pet automatic food dispensers, enabling informed decisions that align with product performance and market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for pet automatic food dispenser

What Are the Main Stages of Manufacturing Pet Automatic Food Dispensers?

Manufacturing pet automatic food dispensers involves a structured process that ensures the final product meets quality and functionality standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to pet automatic food dispenser

-

Material Preparation: The first step involves sourcing high-quality materials that are durable and safe for pets. Common materials include BPA-free plastics, stainless steel, and electronic components for smart features. Suppliers must provide material certifications to ensure compliance with safety standards.

-

Forming: In this stage, the prepared materials undergo various forming techniques such as injection molding, blow molding, or thermoforming. These methods shape the plastic components of the dispensers, ensuring they meet design specifications. Advanced technology, such as computer-aided design (CAD), is often employed to optimize the forming process.

-

Assembly: Once the components are formed, the assembly process begins. This includes integrating electronic systems, such as timers and sensors, into the dispensers. Automated assembly lines can enhance efficiency, but manual assembly is also common, especially for complex designs. Workers should be trained to adhere to strict assembly protocols to minimize errors.

-

Finishing: The final stage involves surface treatment and quality checks. This may include polishing, painting, or applying protective coatings. Finishing processes not only enhance the aesthetic appeal but also improve durability. Products are then prepared for packaging, ensuring they are protected during transit.

How Is Quality Assurance Implemented in Pet Automatic Food Dispenser Manufacturing?

Quality assurance (QA) is critical in the manufacturing process to ensure that each pet automatic food dispenser meets international safety and performance standards.

-

International Standards Compliance: Manufacturers often adhere to international standards such as ISO 9001, which outlines quality management systems. Compliance with CE marking regulations is also common in Europe, indicating that products meet safety, health, and environmental protection standards.

-

Industry-Specific Standards: Other relevant certifications may include the American National Standards Institute (ANSI) for safety and performance or the Association of Pet Product Manufacturers (APPM) guidelines. These certifications are crucial for building trust with B2B buyers.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Suppliers must provide documentation, such as certificates of analysis (COA), to prove material compliance.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are tested to ensure adherence to specifications. This includes checking for dimensional accuracy and functional testing of components.

– Final Quality Control (FQC): Before packaging, finished products undergo comprehensive testing, including functionality tests, safety assessments, and visual inspections to ensure they meet the required standards.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods are essential for validating the quality and safety of pet automatic food dispensers. Common testing approaches include:

-

Functional Testing: This verifies that the dispenser operates as intended, including the timing mechanisms, portion control, and connectivity for smart features. Functionality is often tested under various conditions to mimic real-world usage.

-

Safety Testing: Products are subjected to safety tests to ensure they do not pose any risk to pets or humans. This may include electrical safety tests for products with electronic components and material safety tests to check for harmful chemicals.

-

Durability Testing: Manufacturers often simulate long-term use to evaluate how the product holds up over time. This includes testing for wear and tear, resistance to impacts, and exposure to different environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall compliance with international standards. This firsthand experience can provide invaluable insights into a supplier’s capabilities.

-

Documentation Review: Buyers should request comprehensive documentation from suppliers, including quality control reports, certifications, and testing records. This information should detail the QA processes and any relevant certifications that the supplier holds.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of the manufacturing process and final products. These inspections can include random sampling and testing, ensuring that products meet agreed-upon specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of specific nuances related to quality control when sourcing pet automatic food dispensers:

-

Regulatory Compliance: Different regions have varying regulations regarding pet products. For instance, the European Union has stringent requirements for pet safety that might not apply elsewhere. Buyers should ensure that their suppliers comply with the relevant regulations in their target markets.

-

Cultural Considerations: Understanding cultural preferences and expectations regarding pet products can influence quality perceptions. For example, buyers in the Middle East may prioritize specific materials or designs that align with local customs.

-

Language Barriers: Communication can be a challenge when dealing with international suppliers. Ensuring that quality documentation and contracts are available in the buyer’s preferred language can help avoid misunderstandings related to quality expectations.

-

Lead Times and Logistics: Quality control processes can be affected by logistical challenges, such as shipping delays or customs inspections. Buyers should account for these factors when planning their supply chain and ensure that suppliers are equipped to handle potential disruptions.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing pet automatic food dispensers, ensuring that they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet automatic food dispenser’

In today’s pet care market, automatic food dispensers have become essential tools for pet owners seeking convenience and efficiency. This guide provides a step-by-step checklist for B2B buyers looking to procure automatic pet food dispensers, ensuring a streamlined sourcing process that meets both business and customer needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right automatic pet food dispensers for your market. Consider factors such as the types of food the dispensers can handle (dry vs. wet), capacity (measured in liters or cups), and any additional features like Wi-Fi connectivity or RFID recognition. Understanding these specifications will help you target products that align with customer preferences.

Illustrative image related to pet automatic food dispenser

Step 2: Research Market Demand and Trends

Investigate current market trends and customer preferences for automatic pet feeders in your target regions. Analyze sales data, customer reviews, and competitor offerings to identify popular features and price points. This insight will inform your purchasing decisions and help you stock products that meet market demands.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request company profiles, product samples, and references from other B2B clients in similar markets. Pay attention to suppliers’ certifications and compliance with international standards, which can affect product quality and safety.

Step 4: Assess Product Quality and Durability

Quality and durability are vital factors when selecting automatic pet feeders. Examine materials used in the construction of the dispensers, such as BPA-free plastics and stainless steel, to ensure they are pet-safe and long-lasting. Look for features like tamper-proof lids and easy-to-clean designs, which enhance usability and customer satisfaction.

Step 5: Verify Warranty and After-Sales Support

A robust warranty and after-sales support can significantly impact customer satisfaction and brand loyalty. Ensure that your suppliers offer comprehensive warranty options and responsive customer service. This not only protects your investment but also assures your customers of product reliability and support in case of issues.

Step 6: Determine Pricing and Payment Terms

Establish a clear understanding of pricing structures and payment terms with potential suppliers. Consider bulk purchasing discounts, shipping costs, and payment flexibility to optimize your budget. Comparing multiple suppliers will enable you to negotiate better terms that align with your financial strategy.

Step 7: Plan for Logistics and Distribution

Finally, outline your logistics and distribution strategy to ensure timely delivery of products to your customers. Coordinate with suppliers to understand their shipping capabilities and lead times. Efficient logistics management will enhance customer satisfaction by ensuring that products reach the market promptly.

By following this checklist, B2B buyers can effectively navigate the procurement process for automatic pet food dispensers, ensuring they meet both business objectives and customer needs.

Comprehensive Cost and Pricing Analysis for pet automatic food dispenser Sourcing

What Are the Key Cost Components in Sourcing Automatic Pet Food Dispensers?

When sourcing automatic pet food dispensers, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly influences pricing. Common materials include BPA-free plastics, stainless steel, and electronic components for smart feeders. Higher-quality materials may lead to increased durability and customer satisfaction but will also raise costs.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia, can offer competitive pricing, while labor-intensive processes may increase costs in regions like Europe or North America.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can minimize these costs, impacting the final pricing structure.

-

Tooling Costs: Initial setup costs for molds and machinery can be significant, particularly for customized designs. These costs are amortized over the production volume, so larger orders can lead to lower per-unit tooling costs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability, which is critical for pet products. However, these practices can add to the overall cost. Certifications for safety and quality, such as ISO or CE marks, also come with fees.

-

Logistics: Transportation costs, including shipping and customs, are essential in the overall cost structure. Incoterms play a vital role in determining who bears these costs and risks.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market competition and perceived value.

How Do Price Influencers Affect Automatic Pet Food Dispenser Costs?

Several factors can influence the pricing of automatic pet food dispensers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capacity.

-

Specifications and Customization: Customized dispensers with unique features or branding will incur additional costs. Standard models are generally more cost-effective.

-

Material Quality and Certifications: Higher-quality materials and products that meet stringent certifications tend to have higher price points. Buyers should assess whether the additional cost aligns with their target market’s expectations.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices due to perceived quality and service levels.

-

Incoterms: Understanding Incoterms is essential for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and delivery responsibilities.

What Buyer Tips Can Help Navigate Cost and Pricing Nuances?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Always negotiate pricing, especially for bulk orders. Building a good relationship with suppliers can lead to better terms and discounts.

-

Focus on Cost Efficiency: Evaluate the total cost of ownership (TCO), which includes purchase price, shipping, customs duties, and potential return costs. Sometimes a higher upfront cost may lead to lower long-term expenses due to durability or lower maintenance needs.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, products may be priced higher in Europe compared to South America due to varying demand and supply chain costs.

-

Evaluate Quality vs. Price: Opt for suppliers that offer a balance between quality and cost. Cheaper products may lead to higher return rates and customer dissatisfaction.

-

Consider Logistics and Customs: Factor in shipping times and customs clearance when planning orders. Delays can affect inventory and sales.

Disclaimer on Indicative Prices

It is important to note that prices for automatic pet food dispensers can vary significantly based on the factors mentioned above. Prices may fluctuate based on market trends, supplier negotiations, and regional economic conditions. Therefore, buyers should conduct thorough market research and supplier evaluations to obtain accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing pet automatic food dispenser With Other Solutions

In the evolving landscape of pet care technology, businesses must evaluate various feeding solutions to meet the demands of pet owners. While pet automatic food dispensers are increasingly popular, alternative solutions also exist that may better align with specific needs or preferences. This analysis compares pet automatic food dispensers against gravity feeders and manual feeding methods, helping B2B buyers make informed decisions.

| Comparison Aspect | Pet Automatic Food Dispenser | Gravity Feeder | Manual Feeding |

|---|---|---|---|

| Performance | Programmable, precise portions; can handle dry and wet food | Dispenses food as needed; less control over portions | Total control over food amount and timing |

| Cost | Ranges from $50 to $500 depending on features | Generally lower, typically $20 to $100 | Cost of food only; no equipment required |

| Ease of Implementation | Requires initial setup and possibly Wi-Fi connectivity | Simple setup; no power or programming needed | No setup required; can be done anywhere |

| Maintenance | Requires regular cleaning and battery/plug maintenance | Minimal maintenance; occasional cleaning needed | Dependent on owner’s schedule; can be inconsistent |

| Best Use Case | Ideal for busy pet owners or those with multiple pets needing scheduled feeding | Suitable for free-feeders or those with less structured feeding needs | Best for owners who prefer direct interaction during feeding |

What Are the Advantages and Disadvantages of Gravity Feeders?

Gravity feeders are a popular alternative that allows pets to access food as they desire. These feeders work on a simple mechanism where gravity pulls food down into the bowl as it is consumed. The main advantage of gravity feeders is their low cost and ease of use, making them accessible for pet owners on a budget. However, they do not provide portion control, which may lead to overeating in pets that graze throughout the day. This method may not be suitable for pets requiring strict feeding schedules or portion sizes.

How Does Manual Feeding Compare to Automatic Solutions?

Manual feeding is the most straightforward method, where pet owners dispense food themselves at designated times. This approach allows for complete control over the amount and timing of each meal, fostering a strong bond between the pet and owner. The downside is that it requires the owner’s presence and commitment to a consistent schedule, which may not be feasible for busy professionals or those who travel frequently. Moreover, this method can lead to irregular feeding patterns if the owner is unable to maintain the schedule.

Illustrative image related to pet automatic food dispenser

Conclusion: How Can B2B Buyers Choose the Right Feeding Solution?

When selecting the appropriate feeding solution for their clients, B2B buyers should consider the specific needs of the target market. Automatic food dispensers are excellent for modern pet owners who value convenience and technology, while gravity feeders may appeal to those seeking simplicity and cost-effectiveness. Manual feeding remains an option for pet owners who prioritize direct engagement with their pets. Ultimately, understanding the unique preferences and lifestyles of customers will guide buyers in making strategic decisions that enhance their offerings in the pet care industry.

Essential Technical Properties and Trade Terminology for pet automatic food dispenser

What Are the Key Technical Properties of Pet Automatic Food Dispensers?

Understanding the critical technical specifications of pet automatic food dispensers is essential for B2B buyers looking to ensure product quality, reliability, and consumer satisfaction. Below are some of the most important properties to consider:

-

Material Grade

The materials used in pet automatic food dispensers, such as BPA-free plastic or stainless steel, significantly impact product durability and safety. High-quality materials not only withstand wear and tear but also ensure that the feeder is safe for pets. For B2B buyers, sourcing dispensers made from premium materials can enhance brand reputation and reduce returns. -

Capacity

The capacity of the feeder, typically measured in liters or cups, dictates how much food it can hold. Dispensers range from small units for single pets to larger models designed for multi-pet households. Choosing the right capacity is crucial for meeting customer needs, especially in markets with a high demand for multi-pet solutions. -

Programmability and Scheduling Features

Many automatic feeders offer programmable settings for meal times and portion sizes, which can vary from 1 to 12 meals per day. This feature is vital for pet owners who want to regulate their pets’ diets effectively. B2B buyers should prioritize products that offer intuitive programming options to appeal to tech-savvy consumers. -

Power Source

Pet automatic food dispensers may be powered by AC adapters or batteries, and some models even offer cordless options. Understanding the power source is crucial for assessing convenience and reliability. Battery-operated models can be appealing in areas with unstable electricity, making them a good choice for diverse markets. -

Smart Features

Advanced dispensers may include smart technology such as Wi-Fi connectivity or mobile app integration, allowing pet owners to monitor feeding schedules remotely. This feature is increasingly sought after in the modern pet care market. B2B buyers can leverage smart technology to differentiate their offerings and meet the growing demand for connected pet products. -

Cleaning and Maintenance

Ease of cleaning is an essential specification that affects long-term usability. Removable parts and dishwasher-safe components can enhance customer satisfaction and reduce complaints. B2B buyers should ensure that the products they source are designed for easy maintenance to foster repeat business.

What Common Trade Terms Should B2B Buyers Know in the Pet Feeder Industry?

Familiarity with industry-specific jargon is crucial for effective communication and negotiation in the pet automatic food dispenser market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the pet feeder industry, working with OEMs can help businesses expand their product lines without the need for significant investment in manufacturing capabilities. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of product a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they can meet their inventory needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific quantities of products. This term is crucial for procurement processes, as it helps buyers compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms is important for B2B buyers to understand shipping costs, risks, and delivery timelines when sourcing pet feeders from different countries. -

SKU (Stock Keeping Unit)

A SKU is a unique identifier for each product in inventory. Using SKUs helps businesses manage stock levels effectively and simplifies the ordering process. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage inventory effectively and ensure timely delivery to customers.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, improve supplier negotiations, and ultimately enhance their product offerings in the competitive pet care market.

Navigating Market Dynamics and Sourcing Trends in the pet automatic food dispenser Sector

What Are the Current Trends Shaping the Pet Automatic Food Dispenser Market?

The global pet automatic food dispenser market is experiencing significant growth, driven by several factors, including the rising pet ownership rates and the increasing demand for convenience among pet owners. International buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a surge in interest in smart feeding solutions that leverage technology for enhanced pet care. Key trends include the adoption of app-controlled feeders, which allow pet owners to manage their pets’ feeding schedules remotely, and the integration of features such as RFID pet recognition and camera monitoring for personalized feeding experiences.

Emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT) are revolutionizing the way automatic feeders operate. These advancements not only improve functionality but also enhance user experience, making them attractive to B2B buyers looking for innovative products. Additionally, the market is seeing a shift toward eco-friendly materials and designs, reflecting a growing consumer preference for sustainability.

Another significant trend is the focus on multi-pet households. Products that cater to multiple pets, such as dual food trays and customizable feeding options, are gaining traction, making them ideal for international markets where pet ownership is diverse. As a result, businesses should consider diversifying their product lines to meet the evolving demands of pet owners across different regions.

How Is Sustainability Influencing the Sourcing of Pet Automatic Food Dispensers?

Sustainability has become a critical factor in the sourcing of pet automatic food dispensers, as environmental concerns gain prominence among consumers and businesses alike. The impact of plastic waste from traditional pet feeders has led to an increased demand for products made from biodegradable or recyclable materials. B2B buyers are now looking for suppliers who prioritize ethical sourcing and sustainable practices, as this aligns with the broader global trend toward corporate social responsibility.

Certifications such as ISO 14001 (Environmental Management) and the use of recycled materials are becoming essential for businesses aiming to differentiate themselves in the competitive market. Buyers should seek partnerships with manufacturers that are committed to reducing their environmental footprint and can provide transparency regarding their supply chains.

In addition to material sourcing, companies are also focusing on the energy efficiency of their products. Automatic feeders that incorporate energy-saving features or utilize renewable energy sources are particularly appealing to environmentally conscious buyers. By prioritizing sustainability, businesses can not only meet regulatory requirements but also enhance their brand reputation and appeal to a growing segment of eco-aware consumers.

What Historical Developments Have Shaped the Pet Automatic Food Dispenser Sector?

The evolution of pet automatic food dispensers can be traced back to simple gravity feeders, which emerged in the mid-20th century, designed primarily for convenience. However, as pet ownership increased and consumer expectations changed, the industry saw a shift toward more sophisticated feeding solutions. The introduction of programmable timers in the 1990s marked a significant advancement, allowing pet owners to schedule meals for their pets.

The 21st century has brought about a technological revolution, with the integration of smart technology into pet feeders. The rise of IoT has enabled features such as remote feeding control and real-time monitoring, transforming the way pet owners manage their pets’ diets. This evolution reflects broader trends in consumer behavior, where convenience and personalization have become paramount. As the market continues to innovate, B2B buyers must stay informed about these historical shifts to better understand current consumer demands and anticipate future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of pet automatic food dispenser

-

How do I select the right automatic pet food dispenser for my business needs?

Choosing the right automatic pet food dispenser involves understanding your target market’s preferences and requirements. Consider factors such as the type of pets (cats, dogs, or multi-pet households), the feeding capacity, programmable features, and connectivity options (like app control). It’s also essential to assess the quality of materials, energy efficiency, and ease of cleaning. Conduct market research or surveys to gather insights on what features potential customers prioritize to ensure the product aligns with their needs. -

What is the best capacity for an automatic pet food dispenser for retail?

The ideal capacity for an automatic pet food dispenser largely depends on your customer base. For households with one or two pets, dispensers with capacities of 2L to 5L are often sufficient. However, for multi-pet homes or for those who travel frequently, larger capacities of 8L or more may be more appealing. Offering a range of sizes can cater to diverse customer needs, making your product line more attractive and versatile. -

What customization options are available for automatic pet food dispensers?

Many suppliers offer customization options, including branding, color choices, and unique features tailored to specific markets. This can include adding RFID technology for pet recognition or integrating smart technology for app control. Discussing customization with your supplier can lead to differentiated products that stand out in the marketplace, attracting a wider customer base. Ensure to clarify any minimum order quantities (MOQs) that may apply for customized designs. -

What are the minimum order quantities (MOQ) for pet automatic food dispensers?

MOQs can vary significantly between suppliers. Typically, for standard products, MOQs can range from 50 to 500 units, while customized dispensers may require higher quantities. It’s crucial to confirm MOQs with potential suppliers to ensure your initial investment aligns with your business plan. If you are a new business, consider negotiating lower MOQs or exploring suppliers who offer flexible ordering options to help manage your inventory. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely depending on the supplier’s policies and your negotiation skills. Common terms include a 30% deposit upon order confirmation and the remaining 70% before shipping. Some suppliers may offer net 30 or net 60 payment terms, especially for established relationships. It’s advisable to request flexible payment options that suit your cash flow and consider using secure payment methods like letters of credit or escrow services for larger transactions to minimize risk. -

How can I ensure quality assurance (QA) for the automatic pet food dispensers I source?

To ensure quality assurance, request samples from potential suppliers before placing a bulk order. Establish clear quality standards and specifications in your purchasing agreement. Implement a quality control process, which may include third-party inspections, to assess the products before shipment. Regular communication with suppliers and understanding their quality management practices can also help maintain consistent product quality. -

What logistics considerations should I keep in mind when importing pet food dispensers?

Logistics considerations include shipping methods, delivery timelines, and customs regulations in your country. Opt for reputable freight forwarders who understand the complexities of international shipping and can handle necessary documentation. Be aware of import duties and taxes that may apply and factor these into your pricing strategy. Additionally, consider warehousing solutions if you anticipate high demand, allowing for quick fulfillment of customer orders. -

What are the trends in the pet automatic food dispenser market that B2B buyers should be aware of?

Current trends include the increasing demand for smart pet products, such as dispensers with app connectivity and built-in cameras for remote monitoring. Eco-friendly materials and energy-efficient designs are also gaining traction as consumers become more environmentally conscious. Additionally, the rise of subscription models for pet food delivery is influencing dispenser designs to accommodate recurring feeding needs. Staying informed about these trends can help you align your product offerings with market demands, enhancing your competitive edge.

Top 5 Pet Automatic Food Dispenser Manufacturers & Suppliers List

1. Petlibro – Automatic Pet Feeders

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro offers various models including the Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Air Smart Feeders. Key features include RFID pet recognition, vacuum sealing technology, app control, and camera monitoring. The feeders come in different capacities (2L, 3L, 5L, 8L) and are designed for both wet and dry food. Prices range from …

2. PetSafe – Smart Feed Automatic Dog and Cat Feeder

Domain: petsafe.com

Registered: 1996 (29 years)

Introduction: [{“name”:”Smart Feed Automatic Dog and Cat Feeder, 2nd Generation”,”capacity”:”24 cups of food”,”price”:”$134.99″},{“name”:”Healthy Pet Simply Feed™”,”capacity”:”24 cups of food”,”features”:”Schedule 12 meals daily”,”price”:”$95.99″},{“name”:”FlexFeed Automatic Pet Feeder”,”price”:”$59.99″},{“name”:”5 Meal Pet Feeder”,”capacity”:”5 cups of food”,”features”:”Digital timer for scheduling”,”price”:”$…

3. Arf Pets – Memory Training Puzzle Toy

Domain: arfpets.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”Memory Training Puzzle Toy”,”regular_price”:”$74.99″,”sale_price”:”$59.99″},{“name”:”Automatic Pet Feeder”,”regular_price”:”$129.99″,”sale_price”:”$89.99″}]}

4. Closer Pets – MiBowl Automatic Microchip Pet Feeder

Domain: closerpets.com

Registered: 2020 (5 years)

Introduction: Pet Feeders Collection includes 19 products designed for automatic feeding of cats and small dogs. Key products include: 1. MiBowl Automatic Microchip Pet Feeder (CP500) – Sale price: $129.99, Regular price: $199.99, 127 reviews. 2. Closer Pets Five-Meal Automatic Pet Feeder with Stainless Steel Bowl Inserts and Ice Packs (C500) – Sale price: $74.99, Regular price: $94.99, No reviews. 3. Two-meal …

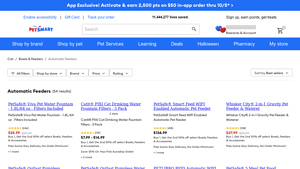

5. PetSmart – Automatic Cat Feeders

Domain: petsmart.com

Registered: 1995 (30 years)

Introduction: Automatic cat feeders available at PetSmart include brands such as PetSafe, PETLIBRO, Whisker City, Catit, and more. Key features include programmable timers, portion control for dry food, and options for gravity-fed systems. Prices range from $16.99 to $299.99, with promotions like ‘Buy 1, Get the 2nd 50% off’ and free same-day delivery on select items. Notable products include the PetSafe Smart …

Strategic Sourcing Conclusion and Outlook for pet automatic food dispenser

As the global demand for pet care products continues to rise, the strategic sourcing of automatic pet food dispensers emerges as a critical component for businesses aiming to capture market share in regions like Africa, South America, the Middle East, and Europe. Key takeaways from this guide highlight the importance of understanding diverse consumer needs, leveraging technology for enhanced product features, and ensuring a reliable supply chain. By incorporating smart technology such as app integration and RFID pet recognition, suppliers can differentiate their offerings and meet the evolving expectations of pet owners.

Moreover, establishing strong partnerships with manufacturers and distributors is essential to navigate the complexities of international trade and logistics. Businesses should also focus on sustainability practices, as eco-conscious consumers increasingly prioritize environmentally friendly products.

Looking ahead, the pet automatic food dispenser market is poised for significant growth. Now is the time for international B2B buyers to engage with suppliers who can deliver innovative solutions that cater to local preferences and enhance pet care experiences. Embrace this opportunity to elevate your product offerings and position your business at the forefront of the pet care industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to pet automatic food dispenser

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.