Introduction: Navigating the Global Market for automatic feeder for guinea pigs

In the evolving landscape of the pet care industry, sourcing automatic feeders for guinea pigs presents a unique challenge for international B2B buyers. With a growing demand for innovative solutions that enhance pet welfare and convenience, understanding the nuances of these products is crucial. Automatic feeders, while convenient, can sometimes lead to dietary issues if not used correctly, making it essential for buyers to navigate the market with a keen eye on quality and functionality.

This comprehensive guide delves into the various types of automatic feeders available, their applications, and the considerations necessary for effective supplier vetting. It will also address cost implications and highlight the importance of aligning product features with the dietary needs of guinea pigs. By leveraging this guide, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will be empowered to make informed purchasing decisions.

Understanding the specific needs of guinea pigs and the potential pitfalls of automatic feeding systems will not only enhance the welfare of these animals but also improve customer satisfaction and retention. With actionable insights and expert recommendations, this guide aims to serve as a valuable resource in successfully sourcing automatic feeders that meet both ethical standards and business objectives.

Table Of Contents

- Top 3 Automatic Feeder For Guinea Pigs Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automatic feeder for guinea pigs

- Understanding automatic feeder for guinea pigs Types and Variations

- Key Industrial Applications of automatic feeder for guinea pigs

- 3 Common User Pain Points for ‘automatic feeder for guinea pigs’ & Their Solutions

- Strategic Material Selection Guide for automatic feeder for guinea pigs

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic feeder for guinea pigs

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic feeder for guinea pigs’

- Comprehensive Cost and Pricing Analysis for automatic feeder for guinea pigs Sourcing

- Alternatives Analysis: Comparing automatic feeder for guinea pigs With Other Solutions

- Essential Technical Properties and Trade Terminology for automatic feeder for guinea pigs

- Navigating Market Dynamics and Sourcing Trends in the automatic feeder for guinea pigs Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic feeder for guinea pigs

- Strategic Sourcing Conclusion and Outlook for automatic feeder for guinea pigs

- Important Disclaimer & Terms of Use

Understanding automatic feeder for guinea pigs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

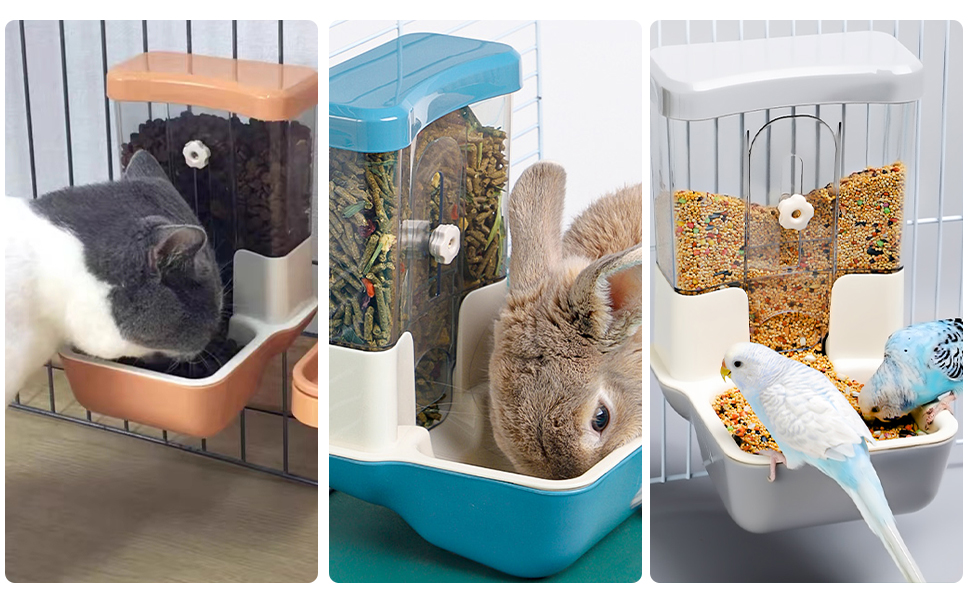

| Gravity Feeders | Simple design, uses gravity to dispense food | Pet stores, breeders, small farms | Pros: Cost-effective, easy to refill. Cons: Food can become stale, limited control over portions. |

| Timed Feeders | Automated feeding at set intervals | Large-scale breeding operations | Pros: Reduces labor, consistent feeding schedule. Cons: Potential for overfeeding if not monitored. |

| Portion Control Feeders | Dispenses specific amounts of food | Veterinary clinics, pet care services | Pros: Helps maintain healthy weight, reduces waste. Cons: More expensive, requires monitoring and maintenance. |

| Combination Feeders | Integrates food and water dispensing | Zoos, shelters, and rescue organizations | Pros: Multi-functional, saves space. Cons: Higher complexity may lead to mechanical failures. |

| Interactive Feeders | Encourages foraging behavior, often with puzzles | Specialty pet shops, enrichment product suppliers | Pros: Promotes mental stimulation, mimics natural behavior. Cons: Can be costly, requires frequent cleaning. |

What Are the Key Features of Gravity Feeders for Guinea Pigs?

Gravity feeders are among the most basic types of automatic feeders available for guinea pigs. They rely on gravity to dispense food, making them easy to use and refill. These feeders are particularly well-suited for pet stores and breeders who need to provide food for multiple animals without frequent intervention. However, a significant drawback is that food can become stale if not consumed promptly, and they do not allow for precise portion control, which is crucial for maintaining the health of guinea pigs.

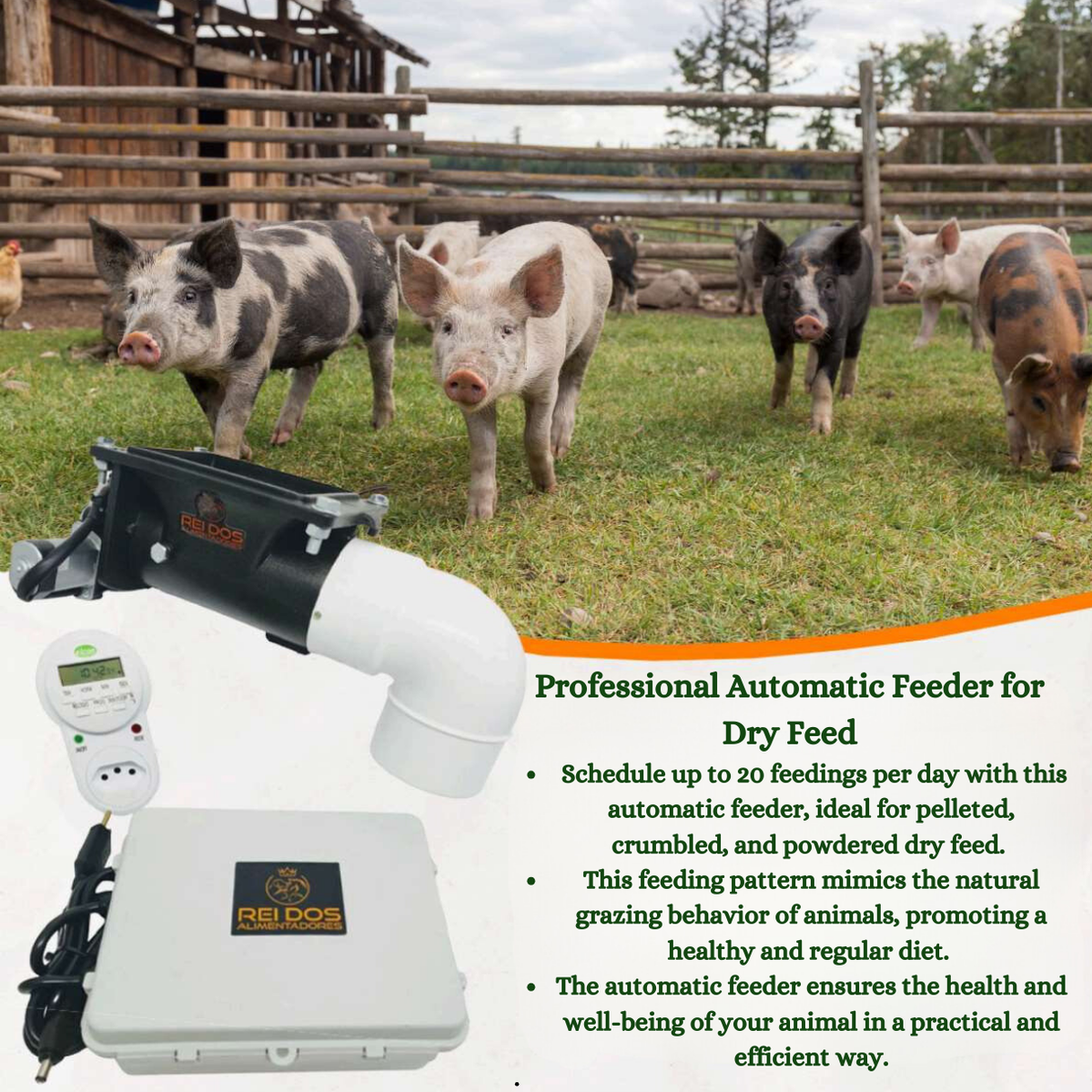

How Do Timed Feeders Benefit Large-Scale Breeding Operations?

Timed feeders automate the feeding process by dispensing food at predetermined intervals. This feature is particularly advantageous for large-scale breeding operations, where consistent feeding schedules are essential. While they reduce labor and ensure that animals are fed regularly, there is a risk of overfeeding if the system is not monitored closely. Buyers should consider the reliability of the timer mechanism and ease of use when selecting this type of feeder.

Why Choose Portion Control Feeders for Veterinary Clinics?

Portion control feeders are designed to dispense specific amounts of food, making them ideal for veterinary clinics and pet care services that prioritize animal health. These feeders help prevent obesity and ensure that guinea pigs receive the correct daily nutrition. Although they may come with a higher price tag compared to simpler models, the long-term health benefits for the animals can justify the investment. Buyers should evaluate the ease of calibration and maintenance when choosing these feeders.

What Are the Advantages of Combination Feeders in Shelters?

Combination feeders that dispense both food and water are particularly useful in environments like shelters and zoos, where space is at a premium. These feeders streamline care routines by providing dual functionality. However, their complexity can lead to mechanical issues, which necessitates regular maintenance. Buyers should assess the durability and ease of cleaning of these feeders to ensure they meet the demands of a busy environment.

How Do Interactive Feeders Enhance the Guinea Pig Experience?

Interactive feeders are designed to stimulate guinea pigs mentally by encouraging foraging behavior through puzzles or mazes. These feeders are ideal for specialty pet shops and enrichment product suppliers looking to enhance animal welfare. While they promote natural behaviors and provide mental stimulation, they can be more expensive and require regular cleaning to maintain hygiene. Buyers should consider the design and durability of these feeders to ensure they withstand daily use.

Key Industrial Applications of automatic feeder for guinea pigs

| Industry/Sector | Specific Application of automatic feeder for guinea pigs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Supply Retailers | In-store product demonstrations and sales | Attracts customers seeking convenience, enhancing sales potential | Quality, reliability, and adaptability to various guinea pig diets |

| Veterinary Clinics | Temporary feeding solutions for boarding animals | Provides peace of mind for pet owners and optimizes clinic resources | Hygiene standards, ease of cleaning, and maintenance requirements |

| Animal Breeding Facilities | Efficient feeding for multiple animals | Reduces labor costs and ensures consistent feeding schedules | Capacity, durability, and the ability to dispense controlled portions |

| Educational Institutions | Learning tools for animal care programs | Enhances educational experiences while teaching responsible pet care | Safety features, user-friendliness, and adaptability for different animal sizes |

| Online E-commerce Platforms | Bundled products for guinea pig care | Increases average order value and customer retention | Shipping logistics, packaging sustainability, and inventory management |

How Can Pet Supply Retailers Benefit from Automatic Feeders for Guinea Pigs?

Pet supply retailers can utilize automatic feeders as part of their in-store product demonstrations. By showcasing these feeders, retailers can attract customers who prioritize convenience in pet care. This not only enhances the shopping experience but also increases sales potential. Retailers should consider sourcing high-quality feeders that are reliable and adaptable to various guinea pig diets to meet diverse customer needs.

What Role Do Automatic Feeders Play in Veterinary Clinics?

Veterinary clinics often require temporary feeding solutions for boarding animals, including guinea pigs. Automatic feeders can provide a reliable and stress-free feeding option, ensuring that pets receive their meals on time. This enhances the overall experience for pet owners and optimizes clinic resources. When sourcing feeders, clinics should focus on hygiene standards, ease of cleaning, and maintenance requirements to maintain a sterile environment.

How Do Animal Breeding Facilities Utilize Automatic Feeders?

In animal breeding facilities, automatic feeders can streamline the feeding process for multiple animals. They help reduce labor costs while ensuring that feeding schedules are consistent, which is crucial for the health and growth of the animals. Buyers in this sector should prioritize feeders that have sufficient capacity, durability, and the ability to dispense controlled portions, ensuring that the dietary needs of the animals are met without overfeeding.

Why Are Automatic Feeders Important for Educational Institutions?

Educational institutions that offer animal care programs can use automatic feeders as learning tools. They provide students with practical experience in responsible pet care while also enhancing the educational experience. These feeders should be designed with safety features and user-friendliness in mind to accommodate various learning environments and animal sizes, ensuring that students can effectively engage with the material.

How Can Online E-commerce Platforms Leverage Automatic Feeders?

Online e-commerce platforms can bundle automatic feeders with other guinea pig care products to increase average order value and customer retention. By offering comprehensive care solutions, these platforms can enhance the shopping experience for pet owners. When sourcing feeders, considerations should include shipping logistics, packaging sustainability, and efficient inventory management to meet the demands of a global customer base.

3 Common User Pain Points for ‘automatic feeder for guinea pigs’ & Their Solutions

Scenario 1: Concerns Over Dietary Management for Guinea Pigs

The Problem: B2B buyers, especially those managing pet stores or animal shelters, often face concerns about the dietary needs of guinea pigs when using automatic feeders. Guinea pigs have specific nutritional requirements, primarily needing hay with a limited portion of pellets. Many automatic feeders can dispense large quantities of pellets, which may lead to overfeeding. This not only compromises the health of the animals—potentially causing obesity and dental issues—but can also lead to dissatisfaction among customers who are increasingly concerned about animal welfare.

The Solution: To address this challenge, buyers should focus on sourcing automatic feeders that allow for controlled portions. When selecting a feeder, look for products that include adjustable settings for portion control, enabling a specific amount of pellets to be dispensed at regular intervals. Additionally, consider incorporating a feeding schedule that aligns with the natural foraging behavior of guinea pigs. This can be done by using a combination of automatic feeders for pellets and manual feeding methods for hay, ensuring a balanced diet. Educating customers on proper usage, such as measuring pellet intake and providing ample hay, can also enhance customer satisfaction and promote healthier guinea pigs.

Scenario 2: Maintenance and Freshness of Food

The Problem: Buyers often struggle with ensuring that the food dispensed by automatic feeders remains fresh. Automatic feeders that store food in bulk can lead to stale pellets, which diminishes the nutritional value and taste that guinea pigs prefer. For pet stores and breeders, this could result in increased returns or negative reviews from customers who expect fresh, high-quality products for their pets.

Illustrative image related to automatic feeder for guinea pigs

The Solution: To mitigate this issue, it’s essential to select feeders that emphasize food freshness. Buyers should seek automatic feeders designed with airtight compartments that protect food from moisture and air exposure. Additionally, they can establish protocols for regular cleaning and food replacement. Implementing a “freshness policy” where food is changed daily can help maintain quality. Educating staff on the importance of freshness and training them to monitor food conditions will also ensure that guinea pigs receive the best possible nutrition, fostering trust with customers and enhancing overall product satisfaction.

Scenario 3: User Experience and Engagement of Guinea Pigs

The Problem: Automatic feeders can reduce the interaction between guinea pigs and their caregivers, leading to a less engaging and fulfilling environment for the animals. Buyers, particularly those in the retail sector, may find that customers are dissatisfied when they notice their pets becoming less active or engaged due to the lack of foraging opportunities, which is critical for guinea pigs’ mental stimulation.

The Solution: To enhance user experience while utilizing automatic feeders, B2B buyers should consider products that encourage foraging behavior. Look for feeders that incorporate puzzle features or dispensing mechanisms that require the guinea pigs to work for their food. This design not only makes feeding time interactive but also promotes exercise, which is crucial for maintaining the health of the animals. Additionally, promoting a hybrid feeding approach—combining automatic feeders with manual foraging methods—can lead to a more satisfying experience for both the guinea pigs and their owners. Providing educational materials or workshops on enriching guinea pigs’ environments can also empower customers to create a more stimulating habitat, ultimately leading to happier pets and satisfied owners.

Strategic Material Selection Guide for automatic feeder for guinea pigs

What Materials Are Best for Automatic Feeders for Guinea Pigs?

When selecting materials for automatic feeders for guinea pigs, it is essential to consider factors such as durability, safety, and ease of maintenance. The following analysis explores four common materials used in the production of these feeders, highlighting their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Plastic Perform in Automatic Feeders?

Plastic is a widely used material for automatic feeders due to its lightweight nature and cost-effectiveness. Key properties include resistance to moisture and ease of cleaning, making it suitable for food applications. However, the type of plastic is crucial; food-grade plastics such as polyethylene or polypropylene are preferred to ensure safety.

Pros: Plastics are generally low-cost, easy to mold into various shapes, and resistant to corrosion. They are also lightweight, which can reduce shipping costs.

Cons: Some plastics may degrade over time, especially when exposed to UV light or extreme temperatures. Additionally, lower-quality plastics can leach chemicals into food, posing health risks to guinea pigs.

Impact on Application: When using plastic, it is vital to ensure that the material is food-safe and can withstand the rigors of daily use.

Considerations for International Buyers: Compliance with food safety regulations such as FDA (U.S.) or EU standards is essential. Buyers should verify that the plastic used meets local safety standards.

What Role Does Stainless Steel Play in Automatic Feeders?

Stainless steel is another popular choice for automatic feeders, known for its durability and resistance to corrosion. With a high resistance to temperature fluctuations and chemicals, stainless steel is an excellent option for environments that may experience wear and tear.

Pros: Stainless steel is highly durable, resistant to rust, and easy to sanitize. It also does not absorb odors or flavors, ensuring that the food remains uncontaminated.

Cons: The initial cost of stainless steel products is generally higher than plastic. Additionally, if not properly maintained, stainless steel can develop scratches that may harbor bacteria.

Illustrative image related to automatic feeder for guinea pigs

Impact on Application: Stainless steel is ideal for feeders that require frequent cleaning and exposure to moisture, as it maintains its structural integrity over time.

Considerations for International Buyers: Buyers should ensure that the stainless steel meets relevant international standards, such as ASTM or DIN, to guarantee quality and safety.

How Effective Are Glass Feeders for Automatic Systems?

Glass is less common but can be used for automatic feeders, particularly in high-end designs. Its key properties include being non-porous and easy to clean, which helps maintain food hygiene.

Pros: Glass does not leach chemicals and is easy to clean, making it a safe option for food storage. It also offers aesthetic appeal, which can be a selling point.

Cons: Glass is fragile and can break easily, posing a risk to both the feeder and the guinea pigs. It is also heavier than plastic or stainless steel, potentially increasing shipping costs.

Impact on Application: While glass feeders can be visually appealing and hygienic, their fragility limits their practicality in environments where durability is a concern.

Considerations for International Buyers: Buyers should be aware of shipping regulations regarding glass products, as they may require special handling or packaging.

What About Wood as a Material for Automatic Feeders?

Wood is sometimes used in automatic feeders, especially in eco-friendly designs. It is biodegradable and can provide a natural look, appealing to certain markets.

Pros: Wood is sustainable and can be treated to enhance durability. It also offers natural insulation properties.

Cons: Wood can absorb moisture and odors, leading to potential hygiene issues. It may also require regular maintenance to prevent decay.

Impact on Application: Wooden feeders can be suitable for indoor use but may not hold up well in humid or outdoor environments.

Considerations for International Buyers: Buyers should check for compliance with environmental standards and ensure that the wood is sourced sustainably.

Summary Table of Material Selection for Automatic Feeders

| Material | Typical Use Case for automatic feeder for guinea pigs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Common for budget-friendly feeders | Lightweight and cost-effective | Can degrade and leach chemicals | Low |

| Stainless Steel | Premium feeders requiring durability | Highly durable and easy to clean | Higher initial cost | High |

| Glass | High-end aesthetic feeders | Non-porous and hygienic | Fragile and heavy | Medium |

| Wood | Eco-friendly designs | Sustainable and natural appearance | Absorbs moisture and odors | Medium |

In conclusion, the choice of material for automatic feeders for guinea pigs greatly influences product performance, safety, and market appeal. International buyers must consider local regulations, material properties, and the specific needs of guinea pigs to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic feeder for guinea pigs

What Are the Main Stages of Manufacturing Automatic Feeders for Guinea Pigs?

The manufacturing process for automatic feeders designed for guinea pigs involves several key stages, each critical to ensuring product quality and functionality. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials that are safe and durable for animal use. Common materials include food-grade plastics and stainless steel, which resist wear and are easy to clean. Suppliers must ensure that all materials comply with international safety standards to prevent harmful chemical leaching.

-

Forming: In this stage, raw materials are shaped into components of the feeder. This can involve injection molding for plastic parts or metal stamping for any metallic components. Advanced techniques such as 3D printing may also be employed for prototyping new designs or creating intricate parts that enhance functionality.

-

Assembly: Following the forming stage, components are assembled into the final product. This may involve manual assembly or the use of automated machines, depending on the scale of production. Precision is key here, as any misalignment can affect the feeder’s performance, such as its ability to dispense food accurately.

-

Finishing: The final stage involves surface treatments and quality checks. This may include polishing, painting, or applying anti-bacterial coatings to enhance durability and hygiene. Aesthetic considerations are also addressed, ensuring the product is visually appealing to consumers.

How Is Quality Assurance Implemented in Automatic Feeders?

Quality assurance (QA) is essential in the manufacturing of automatic feeders for guinea pigs, as it ensures that the products meet both safety standards and consumer expectations. A robust QA process typically follows these guidelines:

-

International Standards Compliance: Manufacturers must adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with CE marking for products sold in Europe is also critical, indicating that the product meets EU safety, health, and environmental protection standards.

-

Industry-Specific Certifications: In addition to general standards, industry-specific certifications may apply. For example, the American Pet Products Association (APPA) may have guidelines that products must meet to ensure they are safe for pet use.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components before they enter the production line. Suppliers must provide documentation proving compliance with relevant standards.

– In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to ensure that each stage meets the specified quality criteria. This may include measuring dimensions, checking for defects, and ensuring that assembly processes are followed correctly.

– Final Quality Control (FQC): Once the feeders are fully assembled, a final inspection is conducted to ensure the product functions as intended. This may involve testing the feeder’s dispensing mechanism and assessing its durability.

What Common Testing Methods Are Used for Quality Assurance?

To ensure the reliability and safety of automatic feeders, several testing methods are commonly employed:

-

Functional Testing: This assesses whether the feeder dispenses food correctly and efficiently. Testing may simulate various scenarios, including different food types and quantities.

-

Durability Testing: Feeders must withstand the rigors of everyday use. Manufacturers often conduct drop tests and stress tests to evaluate how well the feeder holds up under pressure.

-

Safety Testing: This involves checking for sharp edges, toxic materials, and other safety hazards. Products are often tested for compliance with safety standards to ensure they are safe for animals.

-

Hygiene Testing: Given that feeders come into contact with food, manufacturers may also conduct microbiological testing to ensure that the materials used do not harbor bacteria or pathogens.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring a reliable partnership. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing practices and quality control measures. This allows buyers to assess the facility’s cleanliness, employee training, and adherence to safety standards.

-

Requesting Quality Reports: Suppliers should be able to provide detailed reports on their quality control processes, including documentation of tests conducted and results. This transparency builds trust and assures buyers of product quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These inspections can validate compliance with international standards and provide a detailed report of findings.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking, which indicate adherence to recognized quality standards. This can often be done through certification bodies or industry associations.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various certification requirements and quality control nuances when sourcing automatic feeders. Here are some key considerations:

Illustrative image related to automatic feeder for guinea pigs

-

Regional Standards Compliance: Different regions may have varying regulations regarding pet products. For example, European markets may require CE certification, while North American markets might focus on compliance with APPA guidelines. Understanding these differences is critical to ensuring compliance.

-

Cultural Preferences and Regulations: Buyers from different regions may have specific preferences or regulations regarding pet care products. For example, some cultures emphasize natural materials, while others may have stricter safety regulations. Understanding these nuances can help buyers select the right suppliers.

-

Logistics and Import Regulations: International shipping can introduce additional challenges, such as customs regulations and tariffs. B2B buyers should be aware of these factors and work with suppliers who can navigate these complexities effectively.

-

Ongoing Quality Assurance: Establishing a long-term relationship with suppliers includes ongoing quality assurance measures. Regular communication about quality issues, consumer feedback, and potential improvements can help maintain high standards over time.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing automatic feeders for guinea pigs, ensuring that they invest in high-quality products that meet both market demands and animal welfare standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic feeder for guinea pigs’

Introduction

This sourcing guide aims to assist B2B buyers in identifying and procuring automatic feeders for guinea pigs that align with industry standards and animal welfare considerations. Given the varied dietary needs of guinea pigs and the potential pitfalls associated with automatic feeding systems, this checklist provides actionable steps to ensure that buyers make informed decisions.

Step 1: Understand Guinea Pig Dietary Needs

Before exploring automatic feeders, familiarize yourself with the dietary requirements of guinea pigs. These animals primarily need hay, with pellets serving as a supplementary food source. An automatic feeder that allows for unlimited access to pellets can lead to obesity and other health issues. Aim for feeders that dispense limited portions to encourage healthy eating habits.

Step 2: Define Your Technical Specifications

Establish clear technical specifications for the automatic feeders you wish to source. Consider factors such as:

– Capacity: Ensure the feeder can hold an adequate amount of food without compromising freshness.

– Dispensing Mechanism: Opt for a design that dispenses controlled portions rather than free-feeding options.

By defining these specifications, you can streamline your search for suppliers that meet your operational requirements.

Illustrative image related to automatic feeder for guinea pigs

Step 3: Evaluate Potential Suppliers

It’s crucial to thoroughly vet potential suppliers before making a commitment. Request company profiles, product catalogs, and references from previous clients, particularly those in the pet care industry.

– Certifications: Look for suppliers with certifications that comply with animal welfare standards.

– Reputation: Research reviews or case studies to gauge the reliability and quality of their products.

Step 4: Assess Product Quality and Safety

Prioritize the safety and durability of the automatic feeders. Request samples or detailed product descriptions to evaluate:

– Material Quality: Ensure that the materials used are non-toxic and safe for guinea pigs.

– Design Features: Check for features like chew-proof components and easy-to-clean designs to maintain hygiene.

Step 5: Consider Logistics and Supply Chain Factors

Evaluate the logistics involved in sourcing automatic feeders. Consider:

– Shipping Options: Assess the shipping methods and costs to your region, particularly if you are importing from overseas suppliers.

– Lead Times: Understand the typical production and delivery timelines to ensure timely availability of products.

Illustrative image related to automatic feeder for guinea pigs

Step 6: Review Warranty and After-Sales Support

Inquire about warranty terms and after-sales support offered by the supplier. A reliable warranty can protect your investment and ensure you have recourse in case of defects.

– Support Services: Look for suppliers that offer customer support for installation and troubleshooting, as this can enhance your operational efficiency.

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve identified a suitable supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Ensure that you establish clear agreements to avoid misunderstandings later.

– Bulk Discounts: If you plan to purchase in large quantities, inquire about bulk pricing options to maximize your budget.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for automatic feeders for guinea pigs, ensuring that they meet both business and animal welfare standards.

Illustrative image related to automatic feeder for guinea pigs

Comprehensive Cost and Pricing Analysis for automatic feeder for guinea pigs Sourcing

What Are the Key Cost Components in Sourcing Automatic Feeders for Guinea Pigs?

When sourcing automatic feeders for guinea pigs, understanding the cost structure is crucial for B2B buyers. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. Feeders made from durable, non-toxic plastics or stainless steel may have a higher upfront cost but offer longevity and safety. Buyers should evaluate whether cheaper materials might compromise quality or safety, especially in pet products.

-

Labor: Labor costs vary by region, with countries in Europe and North America typically facing higher wages compared to manufacturers in Asia or South America. Labor costs also fluctuate based on the complexity of the feeder design and the skill level required for assembly.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can mitigate these expenses, so it’s wise to assess a supplier’s operational efficiency.

-

Tooling: Custom tooling can be a significant one-time cost for specialized designs. If your order involves custom features, factor in these costs as they may require upfront investment before production begins.

-

Quality Control (QC): Ensuring that products meet safety and quality standards is paramount, especially for items intended for pets. Implementing rigorous QC processes can incur additional costs but helps prevent returns and enhances brand reputation.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the destination market. Consideration of Incoterms is essential to understand who bears the cost and risk during transit.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Margins can differ based on supplier reputation, product uniqueness, and market demand.

What Price Influencers Should Buyers Consider When Sourcing?

Understanding what influences pricing can help buyers negotiate better deals. Key price influencers include:

-

Volume/MOQ: Minimum order quantities (MOQ) often affect pricing. Higher volumes usually lead to lower per-unit costs, making bulk purchases more economical.

-

Specifications/Customization: Custom features or specifications can lead to increased costs. Clear communication of requirements can help suppliers provide accurate quotes.

-

Materials: The choice of materials impacts both cost and quality. Higher-quality materials often lead to higher costs but can result in better long-term value.

-

Quality and Certifications: Certifications such as CE or ISO can add to costs but also assure buyers of product safety and quality. In regions with strict pet product regulations, certified products may be necessary.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding shipping terms can clarify cost responsibilities and risks. Different Incoterms can lead to varying costs and delivery timelines.

What Are Some Buyer Tips for Cost Efficiency in Sourcing Automatic Feeders?

International B2B buyers must navigate various complexities when sourcing automatic feeders. Here are some actionable tips:

-

Negotiate Wisely: Leverage your purchasing power by negotiating prices based on volume. Don’t hesitate to discuss payment terms and discounts for early payment.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, durability, and potential returns. A higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances: Buyers from regions like Africa and South America may face different pricing strategies than those in Europe or the Middle East. Be aware of local market trends and supplier practices.

-

Conduct Market Research: Investigating various suppliers and comparing their offerings can provide insights into competitive pricing and product quality.

-

Request Samples: Before committing to larger orders, request samples to evaluate product quality and functionality.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Always conduct thorough due diligence when sourcing products.

Alternatives Analysis: Comparing automatic feeder for guinea pigs With Other Solutions

Introduction

When considering the best feeding solutions for guinea pigs, it is essential to explore various alternatives to automatic feeders. While automatic feeders offer convenience, they may not always align with the dietary needs and behaviors of guinea pigs. This analysis compares automatic feeders against other viable feeding solutions, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Automatic Feeder For Guinea Pigs | Manual Feeding with Bowls | Scatter Feeding Method |

|---|---|---|---|

| Performance | Provides consistent portion control but may lead to overfeeding. | Allows for precise measurement of food intake, promoting healthier eating habits. | Encourages natural foraging behavior, enhancing mental stimulation. |

| Cost | Moderate initial investment; potential for high maintenance costs. | Low cost; minimal investment required for bowls. | Very low cost; requires no special equipment. |

| Ease of Implementation | Requires setup and programming; may be complex for some users. | Simple to implement; just requires bowls and daily measurements. | Easy to set up; involves scattering food in the cage. |

| Maintenance | Requires regular cleaning and monitoring of mechanical parts. | Low maintenance; bowls need occasional cleaning. | Minimal maintenance; just requires monitoring of food levels. |

| Best Use Case | Suitable for pet owners needing to feed guinea pigs while away for short periods. | Ideal for daily pet owners who can monitor food intake closely. | Best for enriching environments where owners want to encourage natural behaviors. |

Detailed Breakdown

Manual Feeding with Bowls:

Using traditional feeding bowls involves measuring out food portions, typically pellets, and placing them in the cage. This method is cost-effective and straightforward, making it accessible for all guinea pig owners. The main advantage is that it allows for monitoring of dietary intake, preventing overfeeding and ensuring pets receive a balanced diet. However, it requires daily attention and can be less convenient for owners with busy schedules.

Scatter Feeding Method:

Scatter feeding involves distributing pellets throughout the cage, encouraging guinea pigs to forage for their food. This method promotes natural behaviors, providing mental stimulation and physical activity. It is highly economical, as it requires no specialized equipment, just the food itself. However, it may lead to uneven consumption, where some pellets are eaten while others remain uneaten, potentially leading to spoilage if not monitored.

Conclusion

For B2B buyers, selecting the right feeding solution for guinea pigs involves evaluating the specific needs of their operations. Automatic feeders may be appealing for their convenience but can pose risks of overfeeding and require more maintenance. Manual feeding and scatter feeding methods offer cost-effective alternatives that promote healthier eating habits and natural behaviors. Ultimately, the choice should align with the buyer’s operational capabilities, the level of care they can provide, and the specific dietary needs of the guinea pigs in their care. By weighing these factors, businesses can ensure they choose the most appropriate feeding solution for their guinea pig populations.

Essential Technical Properties and Trade Terminology for automatic feeder for guinea pigs

What Are the Essential Technical Properties of Automatic Feeders for Guinea Pigs?

When selecting an automatic feeder for guinea pigs, several technical properties are crucial for ensuring both the feeder’s functionality and the health of the animals. Understanding these properties can help B2B buyers make informed purchasing decisions.

1. Material Composition

The material used in the construction of automatic feeders is critical for durability and safety. Common materials include high-density polyethylene (HDPE) and stainless steel. HDPE is lightweight, easy to clean, and resistant to moisture, while stainless steel offers superior durability and resistance to corrosion. For B2B buyers, selecting feeders made from non-toxic and food-safe materials ensures the health and safety of guinea pigs.

2. Capacity and Size Specifications

Feeders come in various sizes and capacities, which should be matched to the number of guinea pigs being fed. A capacity of 1-5 pounds is typical for small to medium-sized operations. Understanding the size specifications is essential for efficient space utilization within animal housing facilities. Buyers should assess their needs based on the number of animals and their feeding habits.

3. Feed Dispensing Mechanism

The dispensing mechanism is a critical technical property that can significantly influence feeding effectiveness. Options include gravity-fed systems and electronic timers that dispense set portions at specific intervals. For B2B buyers, understanding how these mechanisms work can help prevent overfeeding, which is vital for maintaining the health of guinea pigs.

4. Ease of Cleaning and Maintenance

Automatic feeders must be easy to disassemble and clean to prevent the buildup of bacteria and mold. Features like removable parts and smooth surfaces can enhance cleanliness. For businesses, ease of maintenance translates to lower labor costs and better hygiene practices, which are crucial for animal welfare and operational efficiency.

5. Durability and Warranty

Durability is vital for any equipment used in animal care. Buyers should look for feeders with a robust construction that can withstand wear and tear. Additionally, warranty terms can provide insights into the manufacturer’s confidence in their product’s longevity. A longer warranty may indicate a higher quality product, which can be a significant factor in B2B purchasing decisions.

Which Trade Terminology Should B2B Buyers Know for Automatic Feeders?

Understanding industry jargon is essential for effective communication and negotiation in the procurement process. Here are several key terms relevant to automatic feeders for guinea pigs.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce equipment that may be marketed by another firm. In the context of automatic feeders, buyers may seek OEM suppliers who can provide custom solutions tailored to specific needs. This can lead to improved product offerings and branding opportunities.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management. Higher MOQs might lead to cost savings per unit but could require larger upfront investments.

3. RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests price quotes from suppliers for specific products. In the context of automatic feeders, submitting an RFQ can help buyers compare prices and terms from multiple vendors, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and rights in cross-border transactions involving automatic feeders.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is critical for inventory planning and ensuring that they have the necessary supplies to meet customer demands.

By grasping these technical properties and trade terminology, B2B buyers can navigate the procurement process more effectively, ensuring that they select the best automatic feeders for guinea pigs while optimizing their purchasing strategies.

Navigating Market Dynamics and Sourcing Trends in the automatic feeder for guinea pigs Sector

What Are the Current Market Dynamics and Key Trends for Automatic Feeders for Guinea Pigs?

The market for automatic feeders for guinea pigs is influenced by several global drivers, including the growing trend towards pet ownership, particularly in emerging markets across Africa, South America, and the Middle East. With an increase in disposable income, pet owners in these regions are increasingly looking for convenience solutions that simplify pet care. Additionally, the rise in e-commerce has made it easier for international buyers to access a variety of products, including automatic feeders, from global suppliers.

Emerging B2B tech trends are shaping the sourcing landscape. Smart feeders equipped with sensors and connectivity features are gaining traction, allowing pet owners to monitor feeding habits through mobile applications. This data-driven approach appeals to tech-savvy consumers who seek transparency and control over their pets’ diets. Moreover, sustainability is becoming a significant factor in purchasing decisions, pushing manufacturers to innovate with eco-friendly materials and practices.

For international B2B buyers, understanding regional preferences is crucial. For instance, European markets, particularly Germany, are more inclined towards high-quality, durable products, whereas buyers in the Middle East may prioritize features that enhance convenience and ease of use. Recognizing these regional dynamics can help suppliers tailor their offerings to meet specific market needs.

How Important Is Sustainability and Ethical Sourcing in the Automatic Feeder Market?

Sustainability is a growing concern in the pet product industry, including the automatic feeder sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental stewardship. This includes using recyclable materials, minimizing packaging waste, and ensuring that the production processes have a low carbon footprint.

The demand for ethical supply chains is also on the rise. Buyers want to ensure that the materials used in automatic feeders are sourced responsibly, without compromising the welfare of workers or animals involved in the production process. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, as consumers become more aware of their purchasing decisions’ environmental impact, products labeled as “green” or made from sustainable materials are likely to perform better in the market. B2B buyers who align with these trends can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

What Is the Evolution of Automatic Feeders for Guinea Pigs?

The evolution of automatic feeders for guinea pigs can be traced back to the increasing demand for convenience in pet care. Initially, traditional feeding methods involved simple bowls or gravity feeders, which often led to overfeeding and stale food issues.

As pet ownership grew, particularly in urban settings where time constraints are more pronounced, the need for automated solutions emerged. Early automatic feeders were basic in functionality, mainly designed to dispense food at set intervals. However, technological advancements have transformed these devices into smart feeders that offer customizable feeding schedules and real-time monitoring through mobile apps.

Today, the market features a range of options that cater to diverse consumer preferences, from gravity-fed systems to sophisticated electronic feeders with digital interfaces. As pet owners become more discerning about their pets’ diets, the evolution of automatic feeders is expected to continue, focusing on health, convenience, and sustainability. This ongoing development presents significant opportunities for B2B buyers to source innovative and consumer-friendly products in the competitive pet care market.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic feeder for guinea pigs

-

How do I select the right automatic feeder for guinea pigs?

Choosing the right automatic feeder for guinea pigs involves considering several factors, such as the feeder’s capacity, design, and food dispensing mechanism. It’s crucial to select a model that limits pellet distribution to prevent overfeeding, as guinea pigs require a controlled diet predominantly consisting of hay. Look for feeders that allow for easy cleaning and maintenance, and ensure they are made from safe, durable materials. Additionally, gather feedback from other buyers and check product reviews to assess the feeder’s effectiveness and reliability. -

What is the best feeding solution for guinea pigs?

While automatic feeders can provide convenience, many experts recommend manual feeding methods, such as using a flat, non-tip bowl or scattering pellets in hay to encourage foraging behavior. This approach promotes healthier eating habits by controlling pellet intake and ensuring that guinea pigs consume sufficient hay. For large-scale operations or breeding, consider gravity feeders that dispense limited amounts of food, but always prioritize freshness and monitor consumption closely to detect any health issues. -

What are the common payment terms for sourcing feeders internationally?

When sourcing automatic feeders for guinea pigs internationally, payment terms typically include options such as upfront payment, partial payment before shipping, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow and supplier policies. Consider using secure payment methods like letters of credit or escrow services to protect your investment. Always confirm the supplier’s payment policies and any additional fees that may apply, especially for international transactions. -

How can I vet suppliers of automatic feeders?

Vetting suppliers is crucial to ensure quality and reliability. Start by researching potential suppliers through industry directories and trade shows. Request references and reviews from previous clients to gauge their reputation. Verify certifications, such as ISO or other quality standards, to ensure compliance with safety regulations. Consider conducting a factory visit or using third-party inspection services to evaluate the production process and product quality firsthand. -

What are the minimum order quantities (MOQ) for automatic feeders?

Minimum order quantities (MOQ) for automatic feeders can vary significantly depending on the supplier and the type of feeder. Generally, MOQs can range from a few dozen units for smaller suppliers to several hundred or more for larger manufacturers. It’s advisable to inquire about MOQs upfront and discuss potential flexibility if you are testing the market or are a new buyer. Some suppliers may offer sample units for evaluation before committing to a larger order. -

What are the logistics considerations for importing feeders?

Logistics play a vital role in the importing process of automatic feeders. Consider factors such as shipping methods (air vs. sea), customs clearance, and delivery timelines. Ensure that your supplier can provide necessary documentation, including invoices and packing lists, for smooth customs processing. It’s also important to assess shipping costs, potential tariffs, and insurance options to mitigate risks during transit. Collaborating with a reliable freight forwarder can streamline the logistics process. -

How do I ensure quality assurance for feeders sourced internationally?

Implementing a quality assurance (QA) process is essential when sourcing feeders internationally. Establish clear specifications and quality standards with your supplier before production begins. Request samples to evaluate product quality and functionality. Consider third-party quality inspections at various production stages to ensure compliance with your standards. Lastly, maintain an open line of communication with the supplier throughout the production process to address any concerns promptly. -

What customization options are available for automatic feeders?

Customization options for automatic feeders may include size, color, branding, and functionality modifications. Many suppliers are open to tailoring their products to meet specific buyer needs, particularly for bulk orders. Discuss your requirements with potential suppliers and inquire about their capabilities for customization. Keep in mind that custom orders may affect lead times and pricing, so it’s essential to factor these elements into your planning and negotiations.

Top 3 Automatic Feeder For Guinea Pigs Manufacturers & Suppliers List

1. Guinea Pig Auto Feeder – Smart Food Dispenser

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Auto feeder for guinea pigs purchased from Amazon. It dispenses food twice a day and provides a half portion for a midnight snack. Helps manage feeding schedule when the owner is away.

2. The Guinea Pig Forum – Automatic Feeders

Domain: theguineapigforum.co.uk

Registered: 2006 (19 years)

Introduction: Automatic feeders are not recommended for guinea pigs as they provide nearly unlimited pellets, which can lead to unhealthy weight gain and reduced hay consumption. It is advised to use a measuring spoon to limit pellets to one tablespoon per pig per day and to scatter or sprinkle them in hay for foraging.

3. Guinea Pig Cages – Gravity Feeders

Domain: guineapigcages.com

Registered: 2001 (24 years)

Introduction: Gravity feeders are designed to store a large amount of food for guinea pigs, with some models holding up to 5 lbs. They are convenient for pet owners who may be away for short periods, as they reduce the frequency of feeding. However, concerns were raised about food freshness, as food can become stale if not consumed quickly. Some users reported that their guinea pigs would tip over the feeders, …

Strategic Sourcing Conclusion and Outlook for automatic feeder for guinea pigs

As the market for automatic feeders for guinea pigs continues to evolve, strategic sourcing remains essential for international B2B buyers aiming to meet the nuanced needs of pet owners. Key takeaways highlight the importance of understanding dietary requirements specific to guinea pigs, which favor limited pellet intake and a focus on hay. Buyers should prioritize suppliers that offer feeders designed to promote healthy feeding habits rather than those that risk overfeeding.

Illustrative image related to automatic feeder for guinea pigs

Moreover, sourcing products that facilitate a natural foraging behavior can enhance pet welfare, making it a critical consideration for businesses targeting the growing pet care sector across Africa, South America, the Middle East, and Europe. Engaging with manufacturers who prioritize product quality, fresh food preservation, and ease of use will ensure that buyers can provide optimal solutions to their customers.

Looking ahead, the demand for innovative and health-conscious feeding solutions is likely to increase. By establishing strong relationships with reliable suppliers and staying informed about market trends, B2B buyers can position themselves for success. Embrace this opportunity to enhance your product offerings and contribute positively to the well-being of guinea pigs worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.