Introduction: Navigating the Global Market for feeder dispenser

In the ever-evolving landscape of pet care, sourcing the right feeder dispenser is a critical challenge for B2B buyers looking to meet the growing demand for innovative pet products. As global pet ownership rises, especially in regions such as Africa, South America, the Middle East, and Europe, businesses must navigate a complex market filled with diverse options. This guide offers a comprehensive overview of feeder dispensers, covering various types—automatic, smart, and traditional—along with their applications in both residential and commercial settings. We delve into crucial considerations like supplier vetting processes, pricing strategies, and the latest technological advancements in feeder dispensers.

By equipping international buyers with actionable insights and expert recommendations, this guide empowers them to make informed purchasing decisions that align with their specific market needs. Whether you are a distributor in Brazil seeking to introduce cutting-edge products or a retailer in Saudi Arabia aiming to enhance your inventory, understanding the nuances of feeder dispensers will allow you to capitalize on emerging trends and consumer preferences. Together, we will explore how to effectively source these essential products, ensuring your business remains competitive in the global pet care market.

Table Of Contents

- Top 7 Feeder Dispenser Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for feeder dispenser

- Understanding feeder dispenser Types and Variations

- Key Industrial Applications of feeder dispenser

- 3 Common User Pain Points for ‘feeder dispenser’ & Their Solutions

- Strategic Material Selection Guide for feeder dispenser

- In-depth Look: Manufacturing Processes and Quality Assurance for feeder dispenser

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘feeder dispenser’

- Comprehensive Cost and Pricing Analysis for feeder dispenser Sourcing

- Alternatives Analysis: Comparing feeder dispenser With Other Solutions

- Essential Technical Properties and Trade Terminology for feeder dispenser

- Navigating Market Dynamics and Sourcing Trends in the feeder dispenser Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of feeder dispenser

- Strategic Sourcing Conclusion and Outlook for feeder dispenser

- Important Disclaimer & Terms of Use

Understanding feeder dispenser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Dry Food Feeder | Scheduled dispensing, large capacity (up to 32 cups), remote control via app | Veterinary clinics, pet boarding facilities | Pros: Convenience, portion control; Cons: Limited to dry food, potential for mechanical failure. |

| Smart Wet Food Feeder | Refrigeration for freshness, app integration, portion control | Pet care services, luxury pet hotels | Pros: Ideal for wet food, advanced monitoring; Cons: Higher cost, maintenance required. |

| Gravity Feeder | Simple design, self-dispensing based on gravity, low maintenance | Pet shelters, casual pet owners | Pros: Cost-effective, easy to use; Cons: Less control over portions, may lead to overeating. |

| RFID Smart Feeder | RFID recognition for individual pet feeding, app control, dual food trays | Multi-pet households, specialized pet care | Pros: Personalized feeding, reduces food waste; Cons: Higher upfront investment, requires RFID tags. |

| Multi-Pet Feeder | Dual bowls or multiple compartments, programmable settings | Pet daycare centers, breeders | Pros: Suitable for various pet sizes, customizable; Cons: More complex setup, potential for cross-contamination. |

What are the characteristics of Automatic Dry Food Feeders?

Automatic dry food feeders are designed to dispense pre-measured portions of dry pet food at scheduled intervals. They typically feature large hoppers that can hold up to 32 cups of food, making them suitable for environments like veterinary clinics and pet boarding facilities where consistent feeding is essential. B2B buyers should consider the reliability of the dispensing mechanism and the ease of programming feeding schedules, as these factors directly impact operational efficiency.

How do Smart Wet Food Feeders enhance pet care services?

Smart wet food feeders incorporate advanced technology such as refrigeration to maintain food freshness and app integration for remote monitoring. These feeders are ideal for pet care services and luxury pet hotels that cater to clients looking for premium care for their pets. When considering a purchase, B2B buyers should evaluate the feeder’s capacity, ease of cleaning, and any additional features that enhance user experience and pet safety.

What advantages do Gravity Feeders offer for budget-conscious buyers?

Gravity feeders utilize a simple design that allows food to flow down into the bowl as it is consumed, making them a cost-effective option for pet shelters and casual pet owners. While they require minimal maintenance, B2B buyers should be aware of the potential downsides, such as lack of portion control, which can lead to overeating. Choosing a gravity feeder can be a practical solution for businesses with limited budgets.

Why are RFID Smart Feeders becoming popular in multi-pet households?

RFID smart feeders offer personalized feeding solutions by recognizing individual pets through RFID tags. This feature is particularly beneficial for multi-pet households and specialized pet care facilities that need to manage different dietary requirements and feeding schedules. Buyers should consider the initial investment and the need for RFID tags, as these factors may influence the overall cost-effectiveness and functionality of the feeder.

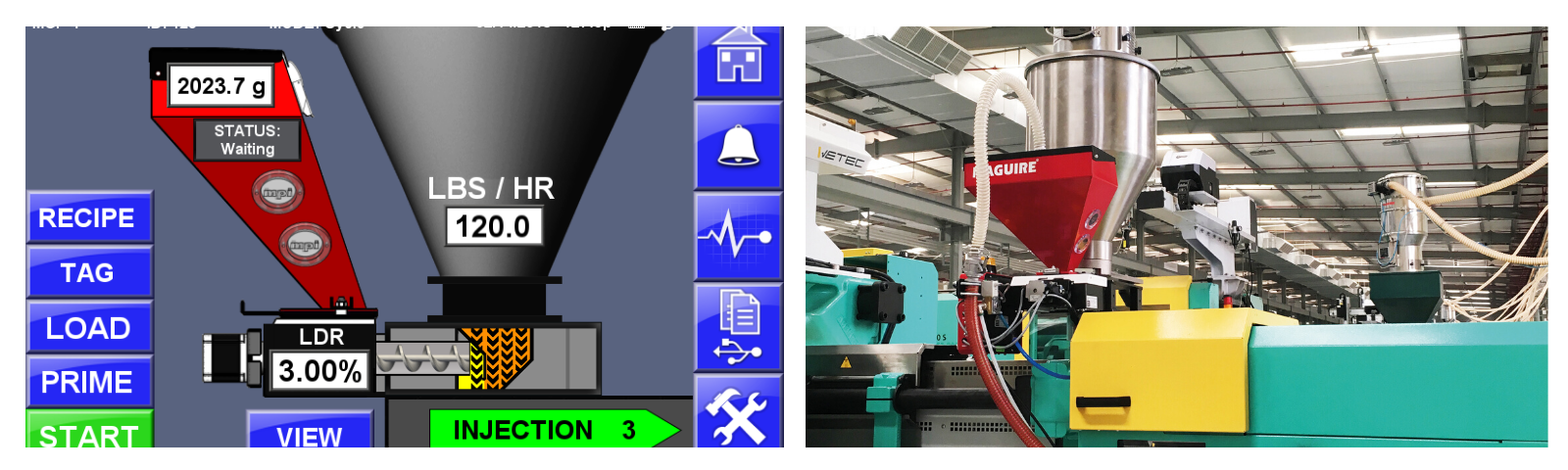

Illustrative image related to feeder dispenser

What should B2B buyers know about Multi-Pet Feeders?

Multi-pet feeders are designed with dual bowls or multiple compartments to cater to various pet sizes and feeding needs. They often come with programmable settings that allow businesses such as pet daycare centers and breeders to customize feeding schedules. When selecting a multi-pet feeder, B2B buyers should assess the feeder’s complexity and potential for cross-contamination, ensuring it meets the hygiene standards required in their operations.

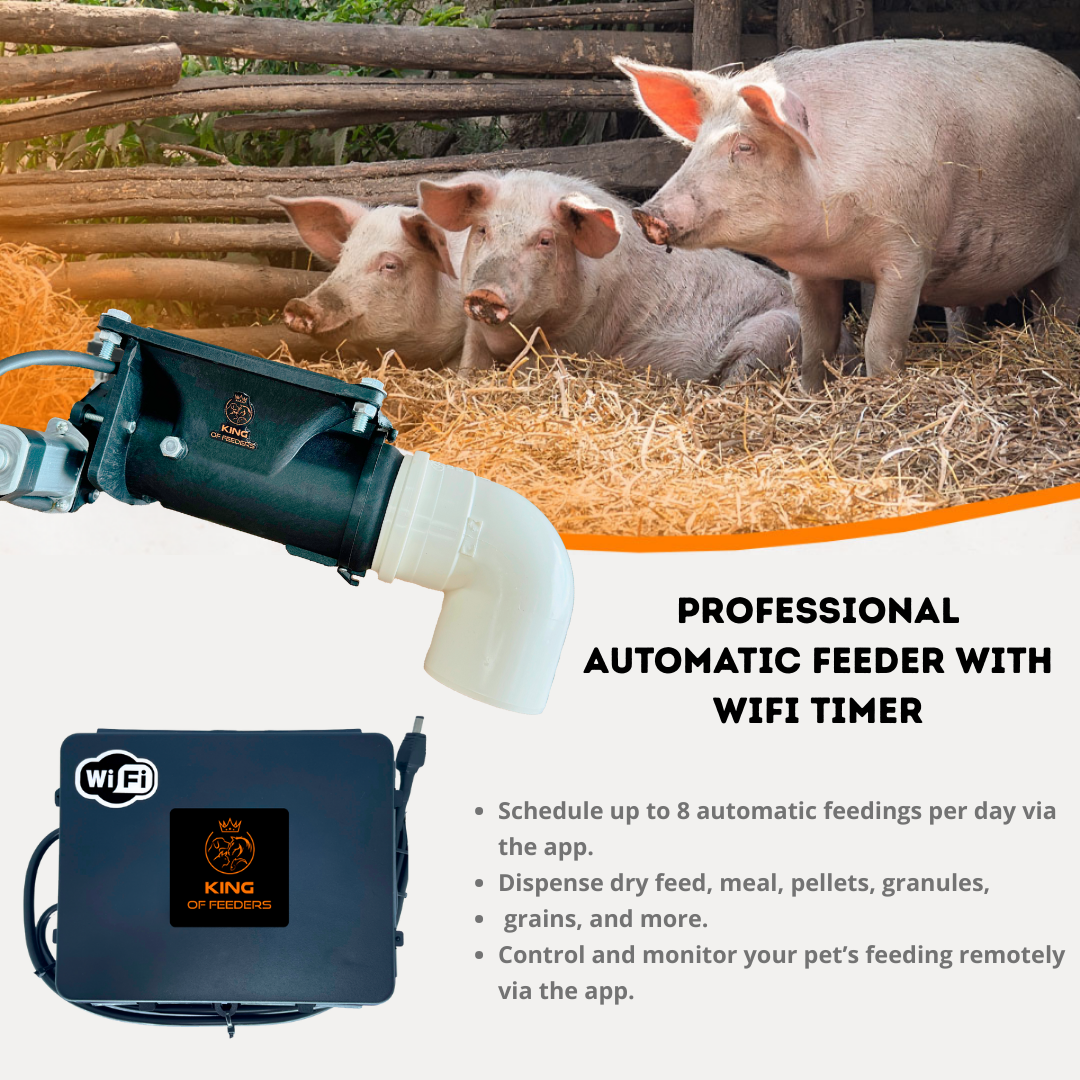

Key Industrial Applications of feeder dispenser

| Industry/Sector | Specific Application of feeder dispenser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care & Veterinary | Automated feeding systems for pet hospitals | Ensures consistent nutrition for animals, reducing human error | Durability, ease of cleaning, food compatibility, and remote monitoring capabilities |

| Agriculture | Livestock feeding systems | Optimizes feed distribution, reducing waste and labor costs | Capacity, material quality, automation level, and adaptability to different feed types |

| Food & Beverage | Ingredient dispensing in food production facilities | Increases efficiency and accuracy in ingredient management | Regulatory compliance, material safety, precision control, and integration with existing systems |

| Manufacturing | Component feeding in assembly lines | Streamlines production processes and enhances productivity | Customizability, reliability, and compatibility with production machinery |

| Aquaculture | Fish feeding systems in aquaculture farms | Improves feeding schedules and reduces overfeeding risks | Water resistance, programmable settings, and ease of maintenance |

How Is the Feeder Dispenser Used in the Pet Care & Veterinary Sector?

In pet care and veterinary settings, feeder dispensers are crucial for automating the feeding process of animals, ensuring that pets receive their meals on time and in the correct portions. This reduces the burden on staff, minimizes human error, and promotes better health for the animals. Buyers in this sector should consider factors such as durability, ease of cleaning, and the ability to monitor feeding remotely, particularly in regions like Africa and the Middle East where resource availability can vary.

What Role Does the Feeder Dispenser Play in Agriculture?

In agriculture, feeder dispensers are employed to efficiently distribute feed to livestock. This technology optimizes feed management, reduces waste, and lowers labor costs, which is essential for farms looking to enhance profitability. For international buyers, particularly in South America, sourcing considerations include the capacity of the feeder, material quality, and adaptability to various feed types, as these factors can significantly impact operational efficiency.

How Can Feeder Dispensers Benefit the Food & Beverage Industry?

In the food and beverage industry, feeder dispensers are used to manage ingredient dispensing in production lines. They enhance accuracy and consistency in ingredient measurements, which is vital for maintaining product quality. Buyers must focus on regulatory compliance, material safety, and precision control when sourcing these dispensers, especially in Europe where food safety standards are stringent.

Why Are Feeder Dispensers Important in Manufacturing?

In manufacturing, feeder dispensers facilitate the feeding of components in assembly lines, thereby streamlining production processes. This automation boosts productivity and reduces the risk of errors during assembly. Buyers should look for customizability, reliability, and compatibility with existing machinery, ensuring that the dispensers can be seamlessly integrated into their operations.

Illustrative image related to feeder dispenser

How Are Feeder Dispensers Used in Aquaculture?

Aquaculture facilities utilize feeder dispensers to optimize feeding schedules for fish, minimizing overfeeding and promoting healthier growth rates. These systems help manage feed distribution effectively, which is crucial for maximizing yield. Buyers in this industry should prioritize water resistance, programmable settings, and ease of maintenance, particularly in regions like Brazil where environmental conditions can vary widely.

3 Common User Pain Points for ‘feeder dispenser’ & Their Solutions

Scenario 1: Inconsistent Feeding Schedules for Multi-Pet Environments

The Problem: B2B buyers managing pet care facilities or multi-pet households often face the challenge of inconsistent feeding schedules. With multiple pets having different dietary needs and feeding times, it becomes increasingly difficult to ensure each animal receives the correct amount of food at the right time. This inconsistency can lead to health issues, such as obesity or malnutrition, and creates additional stress for staff who must juggle various feeding routines.

The Solution: To address this pain point, buyers should consider investing in programmable feeder dispensers equipped with smart technology. Look for models that allow for custom meal scheduling, portion control, and app connectivity. For example, feeders that can be programmed to dispense different amounts of food at specified times ensure that each pet is fed according to its unique dietary requirements. Additionally, choose dispensers that can hold multiple types of food, accommodating both dry and semi-moist options. This flexibility not only simplifies feeding logistics but also enhances overall pet health and wellbeing.

Scenario 2: Difficulty in Monitoring Food Intake and Waste Management

The Problem: Pet care providers and B2B buyers often struggle with tracking food consumption and managing waste effectively. Without proper monitoring, it can be challenging to detect health issues early on, such as changes in appetite or digestive problems. Additionally, insufficient waste management can lead to unpleasant environments, especially in facilities with a high turnover of animals.

The Solution: Investing in feeder dispensers that incorporate monitoring features can be a game-changer. Look for dispensers with built-in sensors that track food levels and dispense specific portions based on set schedules. Many modern feeders come with mobile app integration, allowing users to monitor feeding habits in real-time and receive notifications when food levels are low. Additionally, consider dispensers with anti-jam technology and easy-to-clean designs to facilitate quick waste management and minimize mess. This proactive approach helps maintain a hygienic environment while ensuring pets receive their meals consistently.

Scenario 3: Challenges with Feeding Wet Food in Automatic Dispensers

The Problem: Many B2B buyers encounter difficulties when it comes to feeding wet food using automatic dispensers. Unlike dry food, wet food requires specific handling to prevent spoilage and maintain freshness. Buyers may find that existing dispensers either cannot accommodate wet food or struggle to keep it fresh, leading to waste and dissatisfied pets.

The Solution: To overcome this challenge, buyers should seek feeder dispensers specifically designed for wet food applications. Opt for models that include features like vacuum-sealing to preserve freshness and built-in refrigeration to keep wet food cool until mealtime. Additionally, consider dispensers with dual food trays that can separately store dry and wet food, allowing for a balanced diet. When sourcing these dispensers, verify that they are easy to clean and maintain, as wet food can create buildup and odors if not properly managed. By choosing the right technology, B2B buyers can enhance the feeding experience for pets while minimizing waste and ensuring food safety.

Strategic Material Selection Guide for feeder dispenser

What Are the Common Materials Used in Feeder Dispensers?

When selecting materials for feeder dispensers, understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers. This guide analyzes four common materials: plastic, stainless steel, aluminum, and glass, focusing on their suitability for feeder dispensers in diverse markets.

How Does Plastic Perform in Feeder Dispensers?

Plastic is one of the most widely used materials in feeder dispensers due to its versatility and cost-effectiveness. Key properties include lightweight construction, resistance to corrosion, and ease of molding into various shapes. However, plastics may not withstand extreme temperatures and can degrade over time when exposed to UV light.

Pros:

– Low manufacturing cost and complexity.

– Good resistance to moisture and chemicals.

– Variety of colors and designs available.

Cons:

– Less durable than metals, prone to cracking or warping.

– Environmental concerns regarding recyclability.

Impact on Application: Plastic is suitable for dry food dispensers but may not be ideal for wet food applications due to potential leaching of chemicals.

Considerations for International Buyers: Compliance with food safety standards such as FDA or EU regulations is essential. Buyers should also consider local recycling capabilities and preferences for sustainable materials.

Illustrative image related to feeder dispenser

What Are the Benefits of Using Stainless Steel in Feeder Dispensers?

Stainless steel is favored for its strength, durability, and resistance to corrosion and staining. It can withstand high temperatures and is easy to clean, making it suitable for both dry and wet food applications.

Pros:

– Long lifespan and robust performance.

– Non-reactive, ensuring food safety.

– Aesthetic appeal with a modern finish.

Cons:

– Higher cost compared to plastic.

– Heavier, which may affect portability.

Impact on Application: Stainless steel is ideal for environments where hygiene is paramount, such as veterinary clinics or high-end pet care facilities.

Considerations for International Buyers: Compliance with international standards like ASTM or DIN for food-grade materials is critical. Additionally, buyers should consider the availability of stainless steel in their region and any associated tariffs.

Why Choose Aluminum for Feeder Dispensers?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for feeder dispensers. It can be anodized for enhanced durability and aesthetic appeal.

Pros:

– Lightweight and easy to transport.

– Good thermal conductivity, which can be beneficial for temperature-sensitive products.

– Cost-effective compared to stainless steel.

Cons:

– Less durable than stainless steel; prone to dents and scratches.

– Can react with acidic foods, affecting flavor.

Impact on Application: Aluminum is best suited for dry food applications but may require coatings to ensure compatibility with wet foods.

Considerations for International Buyers: Buyers should verify compliance with local food safety standards and consider the environmental impact of aluminum production and recycling in their region.

What Role Does Glass Play in Feeder Dispensers?

Glass is an excellent choice for feeder dispensers due to its inert nature, which does not interact with food. It is easy to clean and provides a premium look.

Pros:

– Non-reactive and safe for all types of food.

– Aesthetic appeal; often seen as a premium option.

– Easy to clean and maintain.

Cons:

– Fragile and prone to breakage.

– Heavier than other materials, affecting transport costs.

Impact on Application: Glass is ideal for wet food dispensers and can enhance the presentation of food products.

Illustrative image related to feeder dispenser

Considerations for International Buyers: Compliance with safety standards is vital, especially regarding breakage. Buyers should also consider shipping costs due to weight and fragility.

Summary Table of Material Selection for Feeder Dispensers

| Material | Typical Use Case for feeder dispenser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Dry food dispensers | Cost-effective and lightweight | Less durable, potential UV degradation | Low |

| Stainless Steel | High-end, hygienic feeders | Durable, non-reactive | Higher cost, heavier | High |

| Aluminum | Lightweight, portable feeders | Good corrosion resistance | Prone to dents, may react with acid | Medium |

| Glass | Premium wet food dispensers | Non-reactive, easy to clean | Fragile, heavier | Medium |

This strategic material selection guide offers insights into the properties and considerations of various materials used in feeder dispensers, assisting international B2B buyers in making informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for feeder dispenser

What Are the Key Stages in the Manufacturing Process of Feeder Dispensers?

The manufacturing of feeder dispensers involves several critical stages that ensure the final product is reliable, efficient, and meets customer expectations. Understanding these stages can help international B2B buyers make informed decisions when sourcing feeder dispensers.

-

Material Preparation:

The first stage involves selecting high-quality materials that are durable and safe for pets. Common materials include food-grade plastics, stainless steel, and electronic components. Material suppliers are often vetted for compliance with international safety standards to ensure that the materials are non-toxic and suitable for food contact. -

Forming:

This stage involves shaping the prepared materials into the various components of the feeder dispenser. Techniques such as injection molding for plastics and metal stamping for stainless steel parts are commonly used. Precision is crucial here, as the components must fit together seamlessly to prevent leaks and ensure functionality. -

Assembly:

After forming, the components are assembled. This can be done manually or through automated processes, depending on the scale of production. Automated assembly lines often enhance consistency and speed, while manual assembly allows for more detailed craftsmanship. Key components such as sensors, motors, and feeding mechanisms are integrated during this phase. -

Finishing:

The final stage involves applying surface treatments, such as coatings or polishing, to enhance durability and aesthetics. Finishing processes also include quality checks to ensure that all components are functioning correctly before the product is packaged for shipment.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the feeder dispensers meet specified standards and customer expectations. Here’s how QA is integrated:

Illustrative image related to feeder dispenser

-

International Standards Compliance:

Many manufacturers comply with international quality management standards such as ISO 9001. This standard focuses on ensuring consistent quality in products and services, which is crucial for maintaining customer trust. Additionally, compliance with industry-specific standards such as CE marking (for European markets) or API (American Petroleum Institute) can be essential, depending on the components used. -

Quality Control Checkpoints:

Quality control (QC) checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): This is performed on raw materials upon arrival. Each batch is inspected to ensure it meets required specifications.

– In-Process Quality Control (IPQC): During assembly, random samples are tested for functionality and compliance with specifications. This helps identify defects early in the process.

– Final Quality Control (FQC): Once assembly is complete, final products undergo rigorous testing, which may include functionality tests, safety assessments, and performance evaluations. -

Common Testing Methods:

Testing methods for feeder dispensers include:

– Functional Testing: Ensuring that the feeding mechanisms operate as intended and that electronic components function correctly.

– Durability Testing: Assessing how the product withstands wear and tear over time, including exposure to various environmental conditions.

– Safety Testing: Verifying that the materials used are safe for pets, including tests for chemical leaching and structural integrity.

How Can B2B Buyers Verify Supplier Quality Control?

International buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, should take specific steps to verify the quality control measures of their suppliers:

-

Supplier Audits:

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Audits can be performed internally or by third-party organizations specializing in supplier assessments. Look for suppliers who welcome audits and are transparent about their processes. -

Quality Assurance Reports:

Requesting detailed QA reports can help buyers assess a supplier’s commitment to quality. These reports should outline their adherence to international standards, results from recent quality tests, and any corrective actions taken in response to past issues. -

Third-Party Inspections:

Engaging third-party inspection services can be beneficial. These organizations provide unbiased evaluations of the manufacturing process and product quality before shipment, ensuring that the products meet the buyer’s requirements.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control and certification:

-

Regional Compliance Requirements:

Different regions have varying compliance requirements. For instance, European buyers must ensure products meet CE marking requirements, while buyers in the Middle East may need to comply with Gulf Standards Organization (GSO) regulations. Understanding these requirements is crucial for smooth import processes. -

Cultural Considerations:

Cultural differences can affect communication regarding quality expectations. Buyers should ensure clear communication with suppliers about quality standards and expectations to avoid misunderstandings. -

Documentation and Certification:

Ensure that suppliers provide proper documentation for all quality certifications. This includes ISO certification, test reports, and compliance certificates. Documentation should be readily available and verifiable through independent sources when necessary.

Conclusion

Understanding the manufacturing processes and quality assurance measures for feeder dispensers is crucial for B2B buyers. By knowing the key stages of production, the importance of quality control, and how to verify supplier practices, buyers can make informed decisions that lead to successful partnerships. This knowledge not only helps ensure product quality but also fosters trust and reliability in international trade relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘feeder dispenser’

When sourcing a feeder dispenser for your business, it’s essential to follow a structured approach to ensure that you select the right product that meets your needs. This guide outlines the critical steps to take during the sourcing process, helping you make informed decisions.

Illustrative image related to feeder dispenser

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the feeder dispenser. Consider factors such as the type of food (dry or wet), capacity (volume of food it can hold), and features (e.g., remote control, timers). This clarity will streamline your search and help you communicate effectively with suppliers.

- Food Type: Determine if you need a dispenser for dry, wet, or semi-moist food.

- Capacity Needs: Assess how much food you’ll need to dispense at one time to minimize refilling.

Step 2: Research Market Trends

Understanding current market trends is vital for making an informed purchase. Investigate the latest innovations in feeder dispensers, such as smart technology, app integration, and energy efficiency. This knowledge can help you select a product that not only meets your immediate needs but also aligns with future market demands.

- Smart Features: Look for dispensers with monitoring apps or RFID technology that can enhance usability.

- Sustainability: Consider products that promote energy efficiency or use eco-friendly materials.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request company profiles, product catalogs, and references from other buyers in your industry. This step ensures you are dealing with reputable suppliers who can meet your specifications.

- Supplier Reviews: Check for testimonials and case studies that demonstrate their reliability.

- Certification Verification: Confirm that suppliers have the necessary quality certifications, especially if you are importing.

Step 4: Request Product Samples

Once you’ve narrowed down your suppliers, request samples of the feeder dispensers. Testing the product in real-world conditions allows you to assess functionality, durability, and ease of use. This hands-on experience can reveal potential issues that may not be apparent from product specifications alone.

- Testing Features: Evaluate key features like remote operation, portion control, and ease of cleaning.

- Material Quality: Inspect the materials used to ensure they are suitable for long-term use.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your selected suppliers to negotiate pricing and payment terms. Understanding the total cost of ownership, including shipping and potential import duties, is crucial for budgeting. This step can also help you secure better deals or discounts for bulk purchases.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Payment Flexibility: Look for options that allow for deferred payments or financing arrangements.

Step 6: Finalize Contracts and Agreements

Once you’ve settled on a supplier and product, ensure all terms are documented in a formal contract. This agreement should include pricing, delivery timelines, warranty information, and return policies. Having everything in writing protects both parties and clarifies expectations.

- Delivery Schedules: Specify timelines to avoid delays in your supply chain.

- Warranty Coverage: Understand the warranty terms and what they cover to ensure you are protected against defects.

Step 7: Plan for After-Sales Support

Ensure that your supplier offers adequate after-sales support. This includes installation assistance, maintenance services, and troubleshooting help. Good after-sales support can significantly enhance the longevity and effectiveness of your feeder dispensers.

- Support Channels: Check for availability of customer support via phone, email, or online chat.

- Maintenance Plans: Inquire about routine maintenance services that can prevent issues in the long run.

Following this checklist will facilitate a smooth sourcing process for feeder dispensers, helping you secure products that meet your business needs effectively.

Illustrative image related to feeder dispenser

Comprehensive Cost and Pricing Analysis for feeder dispenser Sourcing

What Are the Key Cost Components in Feeder Dispenser Manufacturing?

Understanding the cost structure of feeder dispensers is crucial for B2B buyers looking to optimize their sourcing strategy. The primary components that contribute to the total cost include:

-

Materials: The selection of materials significantly impacts the overall cost. High-quality plastics, metals, and electronic components for smart features (such as RFID and app integration) can drive up expenses. Buyers should consider both the initial material cost and long-term durability.

-

Labor: Labor costs vary by region, influenced by local wage standards and skill levels. In regions like Europe and North America, labor may be more expensive than in parts of Africa or South America, which can affect pricing.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment depreciation. Efficient production processes can lower overhead, but complex designs may require additional resources.

-

Tooling: Custom designs or unique features necessitate specialized tooling, which can be a significant upfront cost. Buyers should evaluate whether the tooling costs are justified by the expected volume of orders.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, especially for electronic feeders. However, these processes can add to the overall cost. Buyers should balance quality needs with budget constraints.

-

Logistics: Shipping costs, including freight and handling, can vary significantly based on destination and shipment size. International buyers must factor in customs duties and import taxes, which can substantially affect total costs.

-

Margin: Suppliers typically apply a markup to cover costs and ensure profitability. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Impact Feeder Dispenser Costs?

Several factors can influence the pricing of feeder dispensers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or additional features (like app connectivity or dual feeding trays) can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Products with higher quality materials or certifications (like ISO or CE marking) may command higher prices but offer better durability and compliance with safety standards.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium but provide better support and quality assurance.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) affect the final pricing. Buyers should understand these terms to accurately calculate total costs, including shipping and handling.

What Buyer Tips Can Help in Negotiating Feeder Dispenser Prices?

When sourcing feeder dispensers, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if planning large orders. Leveraging volume can often lead to significant discounts.

-

Cost Efficiency: Look beyond initial purchase prices. Consider the Total Cost of Ownership (TCO), which includes maintenance, durability, and operational costs over the product’s lifecycle.

-

Pricing Nuances for International Buyers: Understand local market conditions and currency fluctuations, as these can impact prices. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify competitive pricing.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can help avoid costly mistakes and ensure the product meets your specifications.

-

Long-term Relationships: Cultivating long-term partnerships with suppliers can lead to better pricing and service. Suppliers may offer loyalty discounts or early access to new products.

Conclusion

Navigating the cost and pricing landscape of feeder dispensers requires a comprehensive understanding of the various cost components and price influencers. By employing effective negotiation strategies and considering the total cost of ownership, B2B buyers can make informed decisions that enhance their sourcing efficiency.

Alternatives Analysis: Comparing feeder dispenser With Other Solutions

Understanding Alternative Solutions to Feeder Dispensers

When evaluating solutions for pet feeding, it is crucial for B2B buyers to consider various alternatives to feeder dispensers. Each option presents unique features, benefits, and challenges. This analysis aims to provide a comparative overview of feeder dispensers against two other viable solutions: automated feeding systems and traditional manual feeding methods.

Comparison Table

| Comparison Aspect | Feeder Dispenser | Automated Feeding System | Traditional Manual Feeding |

|---|---|---|---|

| Performance | Offers scheduled and portioned feeding; often app-controlled. | Allows for remote feeding control and tracking; may include smart features. | Provides direct control over feeding times and portions. |

| Cost | Typically ranges from $50 to $500 depending on features. | Generally priced between $100 to $400. | Low-cost option; primarily involves food costs only. |

| Ease of Implementation | Requires setup and possibly app installation; straightforward for most users. | May require integration with other smart home devices; can be complex for some users. | Immediate use; no setup required beyond purchasing food. |

| Maintenance | Requires periodic cleaning and battery replacements; some models have backup power options. | Needs regular cleaning and potential software updates; generally low maintenance. | Minimal; primarily cleaning of feeding area and dishes. |

| Best Use Case | Ideal for pet owners who need scheduled feedings for multiple pets. | Best for tech-savvy pet owners who want detailed tracking and remote control. | Suitable for owners who prefer hands-on interaction and flexibility. |

Detailed Breakdown of Alternatives

Automated Feeding System

Automated feeding systems like the Feeder-Robot offer advanced features such as remote access via mobile apps, portion control, and the ability to track feeding habits. The main advantage of this system is its ability to integrate with other smart home devices, providing a comprehensive pet care solution. However, the cost can be significant, and the complexity of setup might deter some users. Additionally, not all automated systems can handle wet food, limiting their versatility.

Traditional Manual Feeding

Manual feeding remains the most straightforward method, requiring no technology or setup. It allows pet owners to control feeding times and portions directly, catering to pets that may have specific dietary needs. The primary drawback is the time commitment required for consistent feeding, which can be challenging for busy professionals or those with multiple pets. Moreover, this method does not provide any tracking or monitoring capabilities, which can lead to inconsistent feeding schedules.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the most suitable pet feeding solution, B2B buyers should assess their specific requirements, including budget, desired features, and ease of use. Feeder dispensers offer a balanced approach with automated scheduling and tracking, while automated systems provide advanced technology for those who prioritize connectivity and monitoring. In contrast, traditional manual feeding may appeal to those seeking simplicity and direct control. Ultimately, the choice will depend on individual circumstances, preferences, and the specific needs of the pets involved. By evaluating these alternatives thoroughly, buyers can make an informed decision that enhances their pet care strategy.

Essential Technical Properties and Trade Terminology for feeder dispenser

What Are the Key Technical Properties of Feeder Dispensers?

Understanding the technical properties of feeder dispensers is crucial for making informed purchasing decisions. Here are several essential specifications that buyers should consider:

-

Material Grade

Feeder dispensers are typically constructed from materials such as ABS plastic, stainless steel, or food-grade silicone. The material grade affects durability, resistance to wear and tear, and safety for food contact. For B2B buyers, selecting high-quality materials can prevent frequent replacements and ensure compliance with health and safety regulations. -

Capacity

The capacity of a feeder dispenser is often measured in liters or cups, indicating how much food it can hold. Options range from small units suitable for single pets to larger dispensers capable of serving multiple animals. Understanding capacity is vital for meeting the feeding needs of different pet sizes and types, thereby optimizing operational efficiency. -

Dispensing Mechanism

This refers to how the feeder releases food, which can include gravity-fed systems, motorized mechanisms, or app-controlled dispensers. Each type has its advantages; for instance, motorized units offer precise portion control, which is essential for managing pet diets. B2B buyers should assess the feeding habits of their target market to select the most appropriate dispensing mechanism. -

Power Source

Feeder dispensers may be powered by AC electricity, batteries, or solar energy. A reliable power source ensures consistent operation, especially in remote areas. For businesses operating in regions with unstable power supply, battery-operated or solar-powered options can mitigate risks of missed feedings. -

Programming Features

Many modern feeders come with programmable settings that allow users to set feeding schedules and portion sizes. Advanced models may offer app connectivity for remote management. This feature is particularly appealing to busy pet owners and can enhance customer satisfaction, making it a key selling point for B2B suppliers. -

Maintenance Requirements

Buyers should consider how easy it is to clean and maintain the feeder. Units with removable parts are generally easier to maintain, which can help prevent food contamination and ensure longevity. Providing clear maintenance guidelines can also improve customer satisfaction and reduce service calls.

What Are Common Trade Terms Used in the Feeder Dispenser Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of feeder dispensers, an OEM may supply components like motors or sensors used in the devices. Understanding OEM relationships can help businesses identify quality sources for parts. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. This term is critical for inventory management and budgeting. Buyers must consider their sales forecasts to negotiate favorable MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities and specifications. Issuing an RFQ helps businesses compare prices and terms, ensuring they get the best deal. This is an essential step in the procurement process. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for ensuring smooth transactions and avoiding disputes over shipping costs and responsibilities. -

SKU (Stock Keeping Unit)

An SKU is a unique identifier for each product, used for inventory management. This term helps businesses track stock levels, sales trends, and restocking needs. Efficient SKU management is crucial for ensuring that popular products remain available. -

Lead Time

This term refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is important for inventory planning and customer satisfaction. Buyers should factor lead times into their purchasing strategies to ensure timely availability of products.

By grasping these essential properties and trade terms, B2B buyers can make well-informed decisions when sourcing feeder dispensers, ensuring they meet both operational needs and market demands effectively.

Navigating Market Dynamics and Sourcing Trends in the feeder dispenser Sector

What Are the Key Market Dynamics and Trends in the Feeder Dispenser Sector?

The global feeder dispenser market is experiencing a dynamic shift driven by technological advancements, changing consumer preferences, and increased pet ownership across various regions. In particular, the rise of smart feeders—integrated with IoT technology—has transformed traditional feeding methods into automated, app-controlled solutions. This shift is particularly beneficial for international B2B buyers from Africa, South America, the Middle East, and Europe, where the demand for convenience and efficiency is growing. Features such as RFID pet recognition, camera monitoring, and portion control are becoming standard offerings, allowing pet owners to manage feeding schedules remotely and monitor their pets’ eating habits.

Another significant trend is the increasing emphasis on customization and personalization in feeder dispensers. B2B buyers are increasingly seeking products that offer adjustable portion sizes and meal timings to cater to different pet breeds and sizes. This trend is particularly relevant in emerging markets, where diverse pet ownership demographics require tailored solutions. Additionally, sustainability is becoming a crucial factor in purchasing decisions, with buyers favoring brands that demonstrate a commitment to eco-friendly practices and materials.

How Is Sustainability Shaping the Feeder Dispenser Sector and What Are Ethical Sourcing Practices?

Sustainability is now at the forefront of B2B considerations in the feeder dispenser sector. The environmental impact of manufacturing and packaging is increasingly scrutinized, leading buyers to seek suppliers who prioritize sustainable practices. This includes the use of recyclable materials, biodegradable packaging, and energy-efficient manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and the use of eco-labels are becoming essential criteria for B2B buyers looking to partner with ethical suppliers.

Moreover, ethical sourcing practices are gaining traction, as businesses recognize the importance of transparency in their supply chains. Buyers are interested in suppliers who can demonstrate a commitment to fair labor practices and responsible sourcing of materials. This is particularly relevant for international buyers who must navigate diverse regulatory environments and cultural expectations. By prioritizing suppliers with strong ethical standards, businesses not only mitigate risks but also enhance their brand reputation and appeal to environmentally conscious consumers.

What Has Been the Evolution of the Feeder Dispenser Sector Over Time?

The feeder dispenser sector has evolved significantly over the last few decades, transitioning from simple manual dispensers to sophisticated automated systems. Early models primarily focused on basic functionality—providing food at set intervals. However, with advancements in technology and an increasing understanding of pet health and nutrition, modern dispensers now incorporate features such as portion control, remote monitoring, and smart technology integration.

This evolution has been fueled by the growing pet industry and the rising trend of pet humanization, where pet owners treat their animals as family members, seeking products that ensure their pets’ well-being. As consumer expectations continue to evolve, the feeder dispenser market is poised for further innovation, making it an exciting space for B2B buyers looking to invest in high-quality, technologically advanced solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of feeder dispenser

-

How do I choose the right feeder dispenser for my business needs?

Selecting the appropriate feeder dispenser involves assessing your specific requirements, such as the type of food (dry or wet), capacity, and whether you need smart features like remote control or monitoring. Consider the number of pets or animals you’ll be feeding, as some models are designed for multi-pet households. Additionally, evaluate your budget and the potential for future scalability. Research product reviews and supplier offerings to ensure they meet your quality standards and operational needs. -

What are the key features to look for in an automatic feeder dispenser?

When sourcing an automatic feeder dispenser, prioritize features such as programmable meal schedules, portion control, and compatibility with different types of food. Smart functionalities like app connectivity, food level monitoring, and offline operation are also valuable. Ensure that the feeder has safety features, such as tamper-resistant lids and easy-to-clean components. Understanding these features will help you make informed decisions and provide better care for the animals in your operation. -

What are the minimum order quantities (MOQ) for feeder dispensers?

Minimum order quantities can vary significantly depending on the supplier and the product type. Many manufacturers offer flexible MOQs to accommodate small businesses, while larger companies may require higher volumes. It’s crucial to clarify MOQs with potential suppliers early in the negotiation process to ensure they align with your purchasing plans. Consider consolidating orders with other products to meet MOQs if necessary. -

How can I vet potential suppliers for feeder dispensers?

To effectively vet suppliers, begin by checking their credentials, including certifications and industry experience. Look for reviews and testimonials from other businesses that have purchased their products. Request samples to assess product quality firsthand and inquire about their production capacity and lead times. Additionally, verify their compliance with international trade regulations and quality assurance processes to ensure they can meet your standards consistently. -

What payment terms should I expect when sourcing feeder dispensers internationally?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, partial payments upon order confirmation, and balance due before shipment. Discuss options such as letters of credit, escrow services, or payment through secure platforms to mitigate risks. Understanding the payment terms will help you manage cash flow effectively and establish a mutually beneficial relationship with your supplier. -

What quality assurance measures should I consider for feeder dispensers?

Quality assurance is critical when sourcing feeder dispensers. Inquire about the supplier’s quality control processes, including inspections and testing protocols. Request documentation of compliance with relevant standards and certifications, such as ISO or CE markings. It may also be beneficial to establish a return policy or warranty agreement to address any defects or issues that arise post-purchase, ensuring you receive products that meet your expectations. -

How do logistics and shipping impact the sourcing of feeder dispensers?

Logistics and shipping play a significant role in the overall cost and efficiency of sourcing feeder dispensers. Assess the supplier’s shipping capabilities, including their partnerships with reliable carriers and their ability to handle customs clearance. Consider the shipping times and costs associated with different transportation methods, such as air freight versus sea freight. Understanding these factors will help you plan your inventory needs and reduce potential delays. -

What are the best practices for importing feeder dispensers to my country?

When importing feeder dispensers, familiarize yourself with your country’s regulations regarding animal feed and equipment. Ensure compliance with import duties, taxes, and any necessary permits. Work with a customs broker to navigate the complexities of international trade and streamline the clearance process. Additionally, maintain clear communication with your supplier regarding shipping timelines and documentation to avoid any delays in receiving your order.

Top 7 Feeder Dispenser Manufacturers & Suppliers List

1. Petlibro – Smart Automatic Pet Feeders

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro offers a variety of smart feeders including the Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Air Smart Feeders. Key features include RFID pet recognition, app control, vacuum sealing technology, and camera monitoring. The feeders come in various capacities (2L, 3L, 5L, 8L) and are designed for both wet and dry food. Prices r…

2. Closer Pets – Automatic Dog Feeders

Domain: closerpets.com

Registered: 2020 (5 years)

Introduction: Automatic Dog Feeders offer convenience for pet owners, allowing them to automate feeding times for their dogs. They can serve both dry and wet food, with some models capable of dispensing up to five meals automatically. Key features include:

– Free standard shipping on orders over $49 within the continental US.

– Various models available, including:

– MiBowl Automatic Microchip Pet Feeder (CP50…

3. Houndsy – Kibble Dispenser

Domain: houndsy.com

Registered: 2018 (7 years)

Introduction: Houndsy Kibble Dispenser: A mid-century modern dog kibble storage and dispenser system. Starting from $195 USD. Available in two heights: Standard (3″ off the ground, ideal for small dogs) and Elevated (8″ off the ground, ideal for medium/large dogs). Features an auto-locking mechanism to prevent unintentional servings, BPA-free plastic storage liner to keep kibble fresh, and can hold approximatel…

4. Whisker – Smart, Automatic Cat Feeder

Domain: litter-robot.com

Registered: 1999 (26 years)

Introduction: Feeder-Robot | Smart, Automatic Cat Feeder by Whisker

– Price: As low as $299

– Rating: 4.3/5.0 from 394 reviews

– Capacity: Holds up to 32 cups of dry pet food

– Features:

– Portion-controlled meal schedules via app or unit

– Remote control using Whisker app

– View food levels and track feeding habits

– Works offline

– Anti-jam technology

– Remotely dispense snacks

– Compatible wit…

5. PetSafe – Smart Feed Automatic Dog and Cat Feeder

Domain: petsafe.com

Registered: 1996 (29 years)

Introduction: [{“product_name”:”Smart Feed Automatic Dog and Cat Feeder, 2nd Generation”,”capacity”:”24 cups of food”,”price”:”$134.99″},{“product_name”:”Healthy Pet Simply Feed™”,”capacity”:”24 cups of food”,”features”:”Schedule 12 meals daily”,”price”:”$95.99″},{“product_name”:”FlexFeed Automatic Pet Feeder”,”price”:”$59.99″},{“product_name”:”5 Meal Pet Feeder”,”capacity”:”5 cups of food”,”features”:”Digital …

6. PETLIBRO – Automatic Feeders

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. PETLIBRO Automatic Feeder (Model: B09S8WMJY9) – Features: Reliable feeding schedule, stainless steel design, blockage prevention, battery backup, easy programming. 2. PETLIBRO Automatic Feeder with Camera (Model: B0B5ZGGWBQ) – Features: Includes a camera for monitoring, stainless steel design, blockage prevention, battery backup. 3. PETKIT Automatic Feeder (Model: B08GS1CPHH) – Features: Stainl…

7. Petkit – YumShare Dual-hopper Automatic Feeder

Domain: petkit.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“name”:”YumShare Dual-hopper Automatic Feeder with Camera”,”sale_price”:”$159.00″,”capacity”:”5L (2L+3L)”,”material”:”Bowl: 304 stainless steel, Container: Food-grade ABS”,”portion_control”:”10-100g”,”multiple_fresh_lock_systems”:”Quadruple”,”camera_ai_capturing”:”✓”,”app_control”:”✓”,”two_way_audio”:”✓”,”anti_blockage_technology”:”✓”,”weight_sensor”:”✓”,”proximity_sensors”:”✓”,”pers…

Strategic Sourcing Conclusion and Outlook for feeder dispenser

In today’s competitive landscape, strategic sourcing of feeder dispensers offers significant advantages for international B2B buyers. By leveraging innovative technologies such as RFID recognition, app-controlled feeding schedules, and user-friendly designs, businesses can ensure optimal pet care while enhancing operational efficiency. Buyers should prioritize suppliers who offer customizable solutions, large capacities, and robust features that cater to diverse market needs.

The demand for smart pet feeding solutions is on the rise, especially in regions such as Africa, South America, the Middle East, and Europe. Companies looking to expand their product offerings should consider partnerships with manufacturers that prioritize quality and sustainability, providing long-term value to their customers.

As we look ahead, the feeder dispenser market is poised for growth, driven by advancements in technology and shifting consumer preferences towards smart home solutions. Now is the time for international B2B buyers to seize opportunities in this evolving market, ensuring they stay ahead of the curve. Engage with reliable suppliers and explore innovative products that align with your strategic goals, positioning your business for success in the pet care industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.