Introduction: Navigating the Global Market for how often should you change your hummingbird feeder

In the vibrant world of birdwatching, the question of how often to change your hummingbird feeder can significantly impact the health and attraction of these delicate creatures. For B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Germany—understanding the nuances of hummingbird feeder maintenance is essential for sourcing quality products and ensuring customer satisfaction. This guide provides a comprehensive overview of best practices for hummingbird feeder care, including the types of feeders available, optimal nectar preparation, and the frequency of changes required based on various climatic conditions.

With insights drawn from industry experts, this resource empowers international buyers to make informed purchasing decisions. It addresses critical challenges such as sourcing reliable suppliers, understanding cost implications, and vetting product quality. By implementing the recommendations outlined in this guide, businesses can enhance their offerings, cater to the needs of eco-conscious consumers, and establish themselves as trusted providers in the growing market for bird feeding products. Whether you are looking to expand your inventory or refine your product knowledge, this guide serves as an invaluable tool for navigating the complexities of the hummingbird feeder market.

Table Of Contents

- A Look at How Often Should You Change Your Hummingbird Feeder Manufacturers & Suppliers

- Introduction: Navigating the Global Market for how often should you change your hummingbird feeder

- Understanding how often should you change your hummingbird feeder Types and Variations

- Key Industrial Applications of how often should you change your hummingbird feeder

- 3 Common User Pain Points for ‘how often should you change your hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often should you change your hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often should you change your hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should you change your hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often should you change your hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often should you change your hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often should you change your hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often should you change your hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often should you change your hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often should you change your hummingbird feeder

- Important Disclaimer & Terms of Use

Understanding how often should you change your hummingbird feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Variation | Changes based on temperature and seasonal patterns | Retailers and distributors in varying climates | Pros: Aligns with natural bird behavior; reduces waste. Cons: Requires monitoring and adjustment based on local climate. |

| Climate-Based Frequency | Nectar change frequency determined by local humidity | Businesses in humid regions | Pros: Ensures freshness in humid areas; attracts more birds. Cons: Increased labor for frequent changes. |

| Fixed Interval | Regular schedule regardless of weather conditions | Standardized operations in retail | Pros: Simplifies inventory management; predictable maintenance. Cons: May lead to waste if not adjusted for climate. |

| Emergency Change Protocol | Guidelines for immediate nectar changes during spoilage | Emergency response for bird care | Pros: Ensures bird health; can prevent loss of clientele. Cons: Requires quick response and additional resources. |

| Customizable Frequency | Tailored schedules based on specific feeder types | Specialty feeder manufacturers | Pros: Optimizes feeder performance; enhances customer satisfaction. Cons: May require more complex inventory management. |

What Are the Key Characteristics of Seasonal Variation for Hummingbird Feeders?

Seasonal variation in changing hummingbird nectar is influenced by temperature and seasonal patterns, making it vital for businesses that operate in different climates. Retailers and distributors can leverage this knowledge to optimize their product offerings and ensure that they meet the needs of their customers throughout the year. This approach reduces waste and aligns with natural bird behaviors, promoting a healthier ecosystem.

How Does Climate Impact Nectar Change Frequency?

Climate-based frequency emphasizes adjusting nectar change intervals based on local humidity levels. For businesses located in humid regions, this approach can significantly enhance the attractiveness of feeders by ensuring that the nectar remains fresh and appealing to birds. While this method may increase labor costs due to the need for more frequent changes, it can also lead to higher customer satisfaction and increased sales as birds flock to well-maintained feeders.

What Are the Benefits of a Fixed Interval Approach?

A fixed interval for changing nectar simplifies operations for businesses, providing a standardized approach to feeder maintenance. This method is particularly beneficial for retailers with multiple locations, as it allows for predictable inventory management and maintenance schedules. However, businesses must remain vigilant to avoid nectar spoilage, especially in varying climates, which could lead to waste and diminished customer trust.

Why Is an Emergency Change Protocol Important?

An emergency change protocol is critical for businesses that prioritize bird welfare. This protocol outlines immediate actions to take when nectar is found to be spoiled, ensuring that birds remain healthy and that businesses maintain their reputation. While implementing such a protocol requires quick responses and additional resources, it ultimately fosters customer loyalty and enhances the overall experience for birdwatchers.

How Can Customizable Frequency Benefit B2B Buyers?

Customizable frequency allows businesses to tailor nectar change schedules based on specific feeder types or customer needs. This flexibility can optimize feeder performance and enhance customer satisfaction, especially for specialty feeder manufacturers. However, it may necessitate more complex inventory management, requiring businesses to balance operational efficiency with customer demand.

Key Industrial Applications of how often should you change your hummingbird feeder

| Industry/Sector | Specific Application of how often should you change your hummingbird feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Wildlife Conservation Organizations | Establishing feeding stations for migratory birds | Enhances bird population health and visitor engagement | Sourcing high-quality feeders and nectar; understanding local regulations on wildlife feeding |

| Eco-Tourism and Hospitality | Creating bird-friendly environments at resorts and lodges | Attracts tourists, enhances guest experience | Selection of aesthetically pleasing feeders; maintenance services for nectar changes |

| Agriculture and Crop Pollination | Utilizing hummingbirds as natural pollinators in crop fields | Improves crop yields and reduces pesticide reliance | Feeder placement strategies; nectar formulation specific to local flora |

| Retail and E-commerce | Selling hummingbird feeders and supplies | Increases sales through education on product care | Understanding consumer behavior; inventory management for seasonal demand |

| Educational Institutions | Implementing educational programs on avian ecology for students | Fosters environmental awareness and engagement | Development of curriculum materials; sourcing feeders for educational use |

How Do Wildlife Conservation Organizations Use Hummingbird Feeders?

Wildlife conservation organizations often establish hummingbird feeding stations to support migratory bird populations. By ensuring the nectar is changed regularly, these organizations can provide a reliable food source that encourages healthy bird populations. Buyers in this sector must consider the quality of feeders, nectar formulation, and compliance with local wildlife regulations to ensure the sustainability of their efforts.

What Role Do Eco-Tourism and Hospitality Play in Hummingbird Feeding?

Eco-tourism businesses and hospitality providers create bird-friendly environments at their locations to attract tourists and enhance the guest experience. Regularly changing hummingbird nectar is crucial in maintaining the feeders, which in turn fosters an engaging atmosphere for guests. B2B buyers in this sector should focus on aesthetically pleasing feeder designs and maintenance services to keep the nectar fresh and appealing.

How Can Agriculture Benefit from Hummingbirds as Pollinators?

In agriculture, farmers can utilize hummingbirds as natural pollinators by strategically placing feeders in crop fields. Regularly changing the nectar not only attracts these birds but also boosts crop yields while reducing reliance on chemical pesticides. Buyers in this industry should consider optimal feeder placement strategies and nectar formulations that mimic local flora to attract hummingbirds effectively.

Why is Retail and E-commerce Important for Hummingbird Feeder Sales?

Retailers and e-commerce platforms have the opportunity to increase sales by educating consumers on the importance of regularly changing hummingbird nectar. Providing clear guidelines on nectar freshness can enhance customer satisfaction and loyalty. Key considerations for these businesses include understanding consumer behavior, managing inventory for seasonal demand, and offering a range of feeder options that cater to various customer needs.

How Do Educational Institutions Incorporate Hummingbird Feeders into Their Curriculum?

Educational institutions can implement hummingbird feeders as part of programs aimed at teaching students about avian ecology and environmental stewardship. By regularly changing the nectar, schools can create a living laboratory that fosters engagement and learning. Buyers in this sector should focus on developing curriculum materials that incorporate the use of feeders and sourcing durable, easy-to-maintain products for educational purposes.

3 Common User Pain Points for ‘how often should you change your hummingbird feeder’ & Their Solutions

Scenario 1: The Dilemma of Nectar Spoilage in Warm Climates

The Problem: B2B buyers operating in regions with high temperatures and humidity often encounter the challenge of nectar spoilage. When nectar is left unchanged for too long, it can ferment, leading to health risks for hummingbirds and ultimately deterring these birds from visiting feeders. This situation can result in significant losses for businesses that rely on birdwatching tourism or sales of bird-related products. Buyers may feel overwhelmed trying to balance feeder maintenance with customer satisfaction and bird welfare, leading to a drop in patronage if the feeders are not well-maintained.

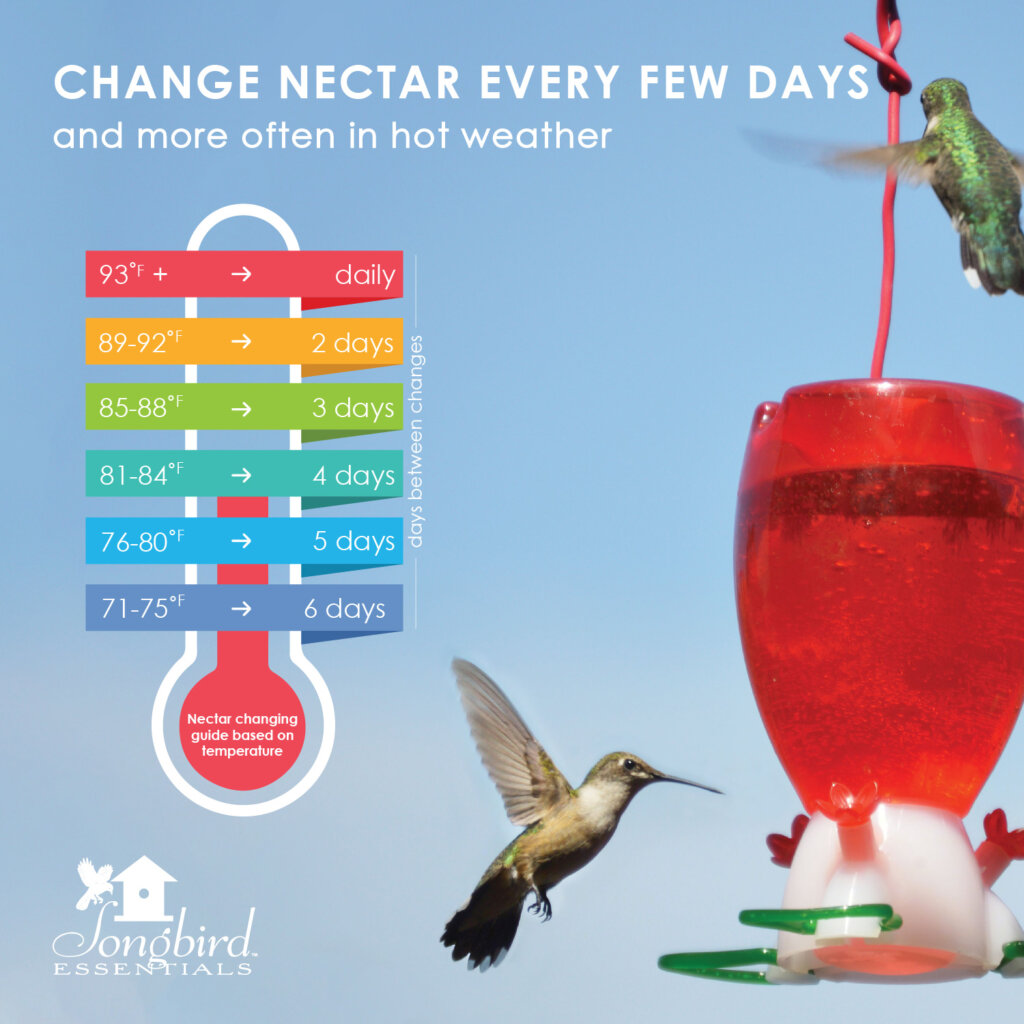

The Solution: Establish a regular maintenance schedule based on environmental conditions. In warmer climates, nectar should be changed every 1-2 days, while in cooler conditions, every 2-4 days is acceptable. To streamline this process, consider implementing a digital reminder system for your team. Use mobile apps or calendar alerts to notify staff when it’s time to change the nectar. Additionally, educate your team on how to properly clean feeders to prevent the build-up of mold and bacteria, which can further compromise nectar quality. By proactively managing nectar freshness, businesses can enhance customer experiences and promote healthier feeding environments for hummingbirds.

Scenario 2: Inconsistent Hummingbird Visits Due to Improper Nectar Maintenance

The Problem: Many B2B buyers may experience inconsistent hummingbird visits to their feeders, leading to frustration and financial implications. This inconsistency often stems from improper nectar maintenance, where buyers either fail to change the nectar frequently enough or do not clean the feeders properly. When hummingbirds encounter spoiled nectar, they quickly learn to avoid that feeder, significantly reducing the potential for repeat visits. This scenario can be particularly detrimental for businesses that rely on attracting birds for eco-tourism or educational programs.

The Solution: Create a comprehensive training program for staff focused on the importance of nectar maintenance. This program should cover the optimal nectar-to-water ratio, the frequency of changes based on local climate conditions, and proper cleaning techniques. Incorporate visual aids, such as charts or checklists, that outline when and how to change the nectar. Furthermore, consider sourcing high-quality feeders that are easy to disassemble and clean, which can simplify maintenance tasks. By ensuring that feeders are consistently stocked with fresh nectar, businesses can establish a reliable feeding station that keeps hummingbirds returning.

Scenario 3: Attracting Hummingbirds While Minimizing Pests

The Problem: B2B buyers may find themselves struggling to attract hummingbirds to their feeders while also dealing with pest issues, such as bees and wasps. These pests are often attracted to the nectar, leading to competition for feeding and discouraging hummingbirds from visiting. This can be particularly problematic for businesses that want to create a welcoming environment for birdwatching enthusiasts but are hindered by pest invasions that compromise the overall experience.

The Solution: Implement strategic placement and design modifications to your feeders to deter pests while attracting hummingbirds. Position feeders away from yellow flowers and other sources of attraction for bees. Additionally, consider using bee-proof feeder designs that only allow hummingbirds access to the nectar. Regularly changing the nectar and cleaning the feeder helps minimize the presence of pests by removing sugary residues. Educate staff on using natural deterrents, such as placing bowls of sugar water away from feeders to draw bees away. By creating a pest-free environment, businesses can enhance the attractiveness of their feeders, ensuring a steady stream of hummingbird visitors.

Strategic Material Selection Guide for how often should you change your hummingbird feeder

When considering the optimal materials for hummingbird feeders, it’s essential to evaluate how these materials influence the frequency of nectar changes, as well as their overall performance and suitability for different markets. Below is an analysis of common materials used in hummingbird feeders, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Plastic in Hummingbird Feeders?

Plastic is a prevalent material for hummingbird feeders due to its lightweight nature and affordability. It typically offers good resistance to weathering and UV radiation, which is crucial for outdoor use. However, the quality of plastic can vary significantly, with some grades being more prone to cracking or fading over time.

Pros: Plastic feeders are generally low-cost and easy to manufacture, making them accessible for a wide range of consumers. They are also lightweight, which simplifies shipping and handling.

Cons: Lower-quality plastics may not withstand extreme temperatures or UV exposure, leading to a shorter lifespan. Additionally, they can be less environmentally friendly compared to other materials.

Impact on Application: Plastic feeders may require more frequent cleaning and nectar changes, especially in warmer climates, to prevent mold and spoilage.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should be aware of local temperature extremes, which may necessitate higher-quality plastics. Compliance with local environmental regulations regarding plastic use is also essential.

How Does Glass Compare for Hummingbird Feeders?

Glass is another popular option for hummingbird feeders, known for its durability and aesthetic appeal. It is non-porous, making it easier to clean and less likely to harbor bacteria or mold.

Pros: Glass feeders are typically more durable than plastic and can withstand higher temperatures without deforming. They also offer a premium look that can attract more customers.

Cons: The weight of glass can increase shipping costs and complicate handling. Additionally, glass can break more easily than plastic, posing a risk during transport and use.

Impact on Application: Glass feeders can maintain nectar freshness longer, reducing the frequency of changes in cooler climates. However, in hot conditions, nectar may still spoil quickly.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer glass for its environmental benefits and recyclability. Compliance with European safety standards for glass products is crucial.

What Role Does Metal Play in Hummingbird Feeders?

Metal, often used in combination with glass or plastic, can enhance the durability and aesthetic of hummingbird feeders. Common metals include aluminum and stainless steel, which offer excellent corrosion resistance.

Pros: Metal feeders are robust and can withstand harsh weather conditions. They also provide a sleek, modern look that appeals to many consumers.

Cons: Metals can conduct heat, potentially leading to warmer nectar in hot climates. Additionally, they may be more expensive than plastic options.

Illustrative image related to how often should you change your hummingbird feeder

Impact on Application: Metal feeders may require less frequent nectar changes in cooler climates but can still lead to spoilage if not monitored closely in warmer areas.

Considerations for International Buyers: Buyers from regions like South America should consider local corrosion factors, especially in coastal areas. Compliance with local metal standards and regulations is important.

How Do Composite Materials Affect Hummingbird Feeders?

Composite materials, which combine plastic and metal elements, offer a balance of durability and cost-effectiveness. These materials can be engineered for specific performance characteristics, such as UV resistance and temperature stability.

Pros: Composite feeders can provide the best of both worlds, offering durability, lightweight properties, and aesthetic appeal.

Cons: The manufacturing complexity of composites can lead to higher costs. Additionally, not all composites are recyclable, which may deter environmentally conscious consumers.

Impact on Application: Composite feeders can maintain nectar quality effectively, reducing the frequency of changes needed.

Considerations for International Buyers: Buyers from various regions should evaluate the environmental impact and recyclability of composite materials, as well as compliance with local regulations.

Summary Table

| Material | Typical Use Case for how often should you change your hummingbird feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Ideal for budget-friendly feeders requiring frequent nectar changes | Lightweight and cost-effective | Prone to UV damage and cracking | Low |

| Glass | Suitable for premium feeders with less frequent nectar changes | Durable and easy to clean | Heavier and more fragile | Med |

| Metal | Best for robust feeders in harsh weather conditions | Excellent durability | Conducts heat, can be expensive | High |

| Composite | Effective for versatile feeders balancing cost and performance | Combines benefits of plastic and metal | Manufacturing complexity, recyclability issues | Med |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for hummingbird feeders, their implications on nectar management, and considerations relevant to various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for how often should you change your hummingbird feeder

What Are the Key Stages in the Manufacturing Process of Hummingbird Feeders?

Manufacturing hummingbird feeders involves several critical stages, each designed to ensure quality, functionality, and safety for both the birds and the end-users. Understanding these processes can help B2B buyers select suppliers that adhere to high standards.

Material Preparation: What Materials Are Used in Hummingbird Feeders?

The initial stage of manufacturing involves sourcing high-quality materials suitable for outdoor use. Common materials include:

- Plastic: Durable, UV-resistant plastics are often used due to their lightweight nature and resistance to weathering. BPA-free options are preferred to ensure safety.

- Glass: Some feeders utilize glass for the nectar container, which is easy to clean and doesn’t absorb odors.

- Metal: Stainless steel or aluminum components may be used for durability, especially in feeder bases or hanging mechanisms.

Sourcing these materials should comply with local and international regulations regarding safety and environmental impact. Buyers should inquire about the sustainability of materials used in production.

What Techniques Are Employed During the Forming and Assembly Stages?

Once materials are prepared, manufacturers utilize various forming techniques to create feeder components. These may include:

Illustrative image related to how often should you change your hummingbird feeder

- Injection Molding: Commonly used for plastic parts, this technique allows for precision and consistency in shape and size.

- Blow Molding: Often employed for hollow structures, such as nectar containers, ensuring they are lightweight yet strong.

- Die Casting: Used for metal components, this technique provides high strength and durability.

After forming, the assembly stage involves integrating different components, such as attaching the feeder base to the nectar container. Automated assembly lines are often used to increase efficiency and reduce labor costs.

What Finishing Techniques Are Utilized to Ensure Product Quality?

Finishing processes enhance the appearance and functionality of hummingbird feeders. These techniques may include:

- Surface Treatment: Applying coatings that enhance UV resistance and prevent fading.

- Quality Printing: Using UV-resistant inks for branding or instructional labels, ensuring they remain legible over time.

- Final Assembly Checks: Ensuring all components fit together correctly and function as intended before packaging.

How Is Quality Assurance Managed in the Manufacturing of Hummingbird Feeders?

Quality assurance is crucial to maintaining product standards and ensuring consumer safety. Manufacturers typically implement a multi-tiered QC process that aligns with international standards.

What International Standards Should B2B Buyers Be Aware Of?

Adhering to international standards is essential for ensuring quality and safety. Some relevant standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring manufacturers have processes in place for continuous improvement.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant if any metal components are involved, ensuring that they meet safety and performance requirements.

B2B buyers should request documentation verifying compliance with these standards from potential suppliers.

What Are the Key QC Checkpoints During Manufacturing?

Quality control checkpoints throughout the manufacturing process help catch defects early. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring production processes to detect deviations from quality standards during manufacturing.

- Final Quality Control (FQC): Conducting thorough inspections and tests on finished products before they are packaged and shipped.

These checkpoints are crucial in ensuring that the feeders are safe for hummingbirds and consumers.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following strategies:

Illustrative image related to how often should you change your hummingbird feeder

What Auditing Methods Are Effective for Assessing Supplier Quality?

- On-Site Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality assurance measures. This allows buyers to assess compliance with international standards firsthand.

- Supplier Reports: Requesting detailed reports on past quality control performance and any corrective actions taken can help buyers gauge reliability.

- Third-Party Inspections: Engaging independent inspection services to evaluate products before shipment can further ensure quality and compliance.

What Are the Unique QC Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of the following nuances:

- Regulatory Differences: Each region may have different regulations governing product safety and quality. Understanding these can help avoid compliance issues.

- Cultural Differences in Business Practices: Approaches to quality assurance may vary by region, influencing expectations and standards. Building strong relationships with suppliers can facilitate better communication and adherence to quality expectations.

- Logistics and Transportation: Quality can be affected during shipping. Buyers should ensure that suppliers have robust packaging and handling processes to minimize damage during transit.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Important for B2B Buyers?

For B2B buyers in the hummingbird feeder market, understanding the intricacies of manufacturing processes and quality assurance is essential. It enables them to select reliable suppliers who prioritize quality, safety, and compliance with international standards. By focusing on these aspects, buyers can ensure that their products meet the expectations of their customers while contributing to the well-being of hummingbirds in various regions around the world.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should you change your hummingbird feeder’

In the pursuit of ensuring optimal hummingbird feeder maintenance, this practical sourcing guide serves as a detailed checklist for B2B buyers. Understanding the frequency of nectar replacement is crucial for maintaining the health of hummingbirds and ensuring their continued attraction to feeders. This guide will help you navigate the essential steps to establish a successful hummingbird feeding program.

Step 1: Assess Local Climate Conditions

Understanding your local climate is fundamental in determining how frequently to change hummingbird nectar. In warmer and more humid regions, nectar can spoil more quickly, necessitating changes every 1-2 days. Conversely, in cooler climates, a 2-4 day interval may suffice. This knowledge will help you adjust your procurement strategy based on environmental factors.

Illustrative image related to how often should you change your hummingbird feeder

Step 2: Determine Feeder Location and Accessibility

Evaluate where the feeders will be placed and ensure they are accessible for regular maintenance. Hummingbird feeders should be positioned in shaded areas to minimize spoilage due to heat. Additionally, consider the proximity to water sources and flowering plants to attract more birds, which may influence the frequency of nectar changes.

Step 3: Define Nectar Composition Requirements

Clarify the specifications for the nectar you will be providing. A common homemade recipe is a mixture of one part sugar to four parts water, but you may also consider commercial products. Ensure that any nectar used is free of artificial dyes, as these can be harmful to hummingbirds. This specification is crucial for maintaining the health of the birds and attracting them effectively.

Step 4: Establish a Cleaning Protocol

Create a routine for cleaning feeders to prevent mold and bacteria growth. Clean feeders should be rinsed with hot water and scrubbed with a brush to ensure all residues are removed. A consistent cleaning protocol will not only enhance the lifespan of your feeders but also ensure that hummingbirds are drawn to a safe feeding environment.

Step 5: Monitor Nectar Levels and Spoilage

Implement a system for regularly checking nectar levels and the condition of the nectar. If you notice any cloudiness or foul odors, it’s a clear sign that the nectar needs to be changed immediately. Keeping a close eye on the feeder will prevent birds from avoiding your feeders due to spoiled nectar, ensuring a consistent visiting population.

Step 6: Engage with Supplier Support Services

When sourcing your feeders and nectar supplies, ensure that your suppliers offer robust support services. This can include guidance on proper feeder maintenance, nectar formulations, and troubleshooting common issues. Engaging with knowledgeable suppliers can enhance your overall procurement experience and ensure that you have access to timely information and resources.

Step 7: Establish a Feedback Loop with Users

Finally, create a feedback mechanism for those utilizing the feeders. Gathering insights from users about the effectiveness of the feeders and the nectar will help you make informed adjustments to your sourcing strategy. This engagement can lead to better bird visitation rates and overall success in your hummingbird feeding initiative.

By following this checklist, B2B buyers can effectively manage their hummingbird feeder programs, ensuring a healthy and inviting environment for these beautiful birds while optimizing procurement processes.

Comprehensive Cost and Pricing Analysis for how often should you change your hummingbird feeder Sourcing

In the hummingbird feeder market, understanding the cost structure and pricing dynamics is crucial for B2B buyers aiming to optimize their supply chain and product offerings. This analysis focuses on the various components that contribute to the overall costs and pricing strategies for hummingbird feeder sourcing.

What Are the Key Cost Components for Hummingbird Feeders?

-

Materials: The primary costs associated with hummingbird feeders include the raw materials used in their production, such as plastic, glass, and metal components. Higher quality materials that are durable and resistant to weather conditions can increase initial costs but may lead to lower replacement rates and better customer satisfaction.

-

Labor: Labor costs depend on the manufacturing location and the complexity of the feeder designs. For instance, intricate designs that require skilled labor will increase production costs. Buyers should consider sourcing from regions with lower labor costs while maintaining quality standards.

-

Manufacturing Overhead: This encompasses indirect costs related to production, including utilities, equipment maintenance, and factory management. Efficient manufacturing processes can minimize overhead, allowing for competitive pricing.

-

Tooling: Initial tooling costs for mold creation can be significant, especially for custom designs. Buyers looking for unique feeder styles should factor in these costs when negotiating with suppliers.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is essential, particularly for international buyers who must adhere to specific safety and quality standards. This can involve additional costs but is critical for maintaining brand reputation.

-

Logistics: Transportation costs can vary greatly based on the origin of the products and the chosen Incoterms. Factors such as shipping distance, freight method, and customs duties can significantly impact the total cost.

-

Margin: Suppliers will incorporate a profit margin into their pricing, which can fluctuate based on market demand, competition, and perceived value. Understanding the margin expectations of suppliers can help buyers negotiate more effectively.

What Influences Pricing for Hummingbird Feeders?

-

Volume/MOQ: Minimum Order Quantities (MOQ) can influence pricing significantly. Higher volume orders often lead to discounts, allowing buyers to reduce their per-unit costs.

-

Specifications and Customization: Custom designs or specific features can lead to higher costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials and Quality Certifications: The choice of materials directly affects the price. Premium materials that offer durability and aesthetic appeal can attract a higher price point. Additionally, products with recognized quality certifications may command a premium.

-

Supplier Factors: The reliability and reputation of suppliers also play a role. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is vital for international transactions. Incoterms dictate the responsibilities of buyers and sellers, influencing overall costs. For example, CIF (Cost, Insurance, and Freight) pricing can lead to higher costs if not managed properly.

What Are Essential Buyer Tips for Cost Efficiency?

-

Negotiation: Leverage volume purchasing to negotiate better terms. Establish relationships with suppliers to gain insights into pricing strategies and potential discounts.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the feeders, including maintenance, replacement, and logistics. A slightly higher initial cost may result in lower TCO if the product is more durable.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that can impact pricing. Engage local agents or distributors who understand the regional market dynamics.

-

Quality versus Cost: While it may be tempting to choose the lowest-priced option, consider the implications of quality on customer satisfaction and brand reputation. Investing in better quality products can lead to repeat business and lower return rates.

Disclaimer on Pricing

Prices for hummingbird feeders can vary widely based on the factors discussed. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting competitive pricing that reflects their specific needs and circumstances.

Alternatives Analysis: Comparing how often should you change your hummingbird feeder With Other Solutions

Understanding Alternative Solutions for Hummingbird Feeders

In the realm of avian care, particularly for hummingbirds, maintaining optimal feeder conditions is essential for attracting and nurturing these delicate creatures. While the traditional method emphasizes changing the nectar in feeders every 2 to 4 days, especially in warmer climates, several alternative solutions can enhance efficiency and reduce maintenance efforts. This analysis will compare the conventional nectar-changing practice against two viable alternatives: automated nectar dispensers and nectar replacement services.

Comparison Table

| Comparison Aspect | How Often Should You Change Your Hummingbird Feeder | Automated Nectar Dispenser | Nectar Replacement Service |

|---|---|---|---|

| Performance | Effective for attracting birds when changed regularly | Consistent supply of fresh nectar; reduces spoilage risks | High-quality nectar delivered regularly; professional oversight |

| Cost | Low initial cost but requires continuous nectar purchase | Higher upfront cost; potential savings on nectar | Subscription-based pricing; may vary based on frequency and quantity |

| Ease of Implementation | Simple; manual process but requires regular attention | Moderate; setup required but minimal ongoing effort | Very easy; service handles all logistics |

| Maintenance | Requires regular cleaning and monitoring | Low; occasional refill and cleaning needed | Minimal; service handles maintenance |

| Best Use Case | Ideal for casual bird watchers in stable climates | Best for high-traffic areas or commercial settings | Suitable for businesses or organizations with limited time for maintenance |

Analyzing Automated Nectar Dispensers

Automated nectar dispensers offer a technologically advanced approach to feeding hummingbirds. These devices are designed to deliver a consistent supply of nectar, which minimizes spoilage and the need for frequent manual changes. One of the main advantages is their ability to maintain optimal nectar freshness, ensuring that birds are consistently attracted to the feeder. However, the initial investment can be significant, and they may require technical know-how for setup and maintenance. Additionally, they still need occasional cleaning to prevent mold and bacteria growth.

Evaluating Nectar Replacement Services

Nectar replacement services provide a convenient solution for businesses and organizations that may lack the time or resources to manage feeders manually. These services typically deliver high-quality nectar on a scheduled basis, ensuring that the feeders are always stocked with fresh supplies. The major advantage is the minimal effort required on the part of the buyer, as the service handles all aspects of maintenance and logistics. However, this option may come with a higher ongoing cost, and businesses must weigh the value of convenience against their budgetary constraints.

Making the Right Choice for Your Hummingbird Feeding Needs

When considering how often to change your hummingbird feeder versus alternative solutions, it is crucial for B2B buyers to assess their specific needs and resources. For those operating in environments with high visitor traffic or limited time for maintenance, automated dispensers or replacement services may offer considerable advantages. Conversely, for casual settings or businesses with lower demands, the traditional method of changing nectar regularly may suffice. Ultimately, the decision should align with operational goals, budget considerations, and the desired level of engagement with nature.

Essential Technical Properties and Trade Terminology for how often should you change your hummingbird feeder

What are the Key Technical Properties Influencing Hummingbird Feeder Maintenance?

Understanding the technical properties associated with hummingbird feeders can significantly enhance their operational effectiveness and longevity. Here are several critical specifications relevant to B2B buyers:

-

Material Grade

The material used in hummingbird feeders often includes plastic, glass, or metal. Each material has distinct advantages and disadvantages. For example, glass feeders are typically more durable and resistant to UV degradation but can be heavier and more prone to breakage. Plastic feeders may be lighter and less expensive but can degrade over time with exposure to sunlight. Choosing the right material is crucial for ensuring product durability, especially in diverse climates across Africa, South America, the Middle East, and Europe. -

Nectar Capacity

The nectar capacity of a feeder directly affects how often the nectar needs to be changed. Feeders with larger capacities can hold more nectar, reducing the frequency of changes. However, in warmer climates, nectar can spoil quickly, necessitating more frequent changes even in larger feeders. This balance is essential for maintaining the health of hummingbirds and ensuring that feeders remain attractive to them. -

Feeder Port Design

The design and number of feeding ports influence not only the ease of access for birds but also the potential for spoilage. Feeders with multiple ports may allow for more birds to feed simultaneously, but they also require more frequent cleaning to prevent mold and bacteria build-up. Understanding the implications of port design helps buyers select feeders that maximize bird visitation while minimizing maintenance. -

Cleaning Ease

The ability to easily clean a feeder is a critical specification. Feeders that disassemble quickly and have smooth surfaces are more user-friendly and promote better hygiene. This is especially important in humid climates where mold can develop rapidly. Buyers should prioritize feeders designed for easy cleaning to ensure they can maintain optimal nectar conditions. -

UV Resistance

Feeders exposed to direct sunlight should ideally be made from materials that offer UV resistance. UV rays can degrade plastics, causing them to become brittle and discolored over time. This specification is vital for maintaining aesthetic appeal and functionality, particularly in regions with high sun exposure.

What are Common Trade Terms Related to Hummingbird Feeders?

Understanding industry jargon is essential for effective communication and negotiation in the B2B market. Here are some common trade terms relevant to hummingbird feeder procurement:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of hummingbird feeders, OEM suppliers may provide customized designs or specific features tailored to a buyer’s requirements. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For businesses looking to stock hummingbird feeders, understanding MOQ is crucial for inventory management and cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing and availability of products. When sourcing hummingbird feeders, submitting an RFQ can help businesses compare costs and features across different suppliers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for managing shipping logistics and costs when importing hummingbird feeders from different regions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time for hummingbird feeders is essential for inventory planning and ensuring that products are available when needed. -

Distribution Channels

These are the various pathways through which products reach the end consumer. In the hummingbird feeder market, understanding the distribution channels can help businesses strategize their marketing and sales efforts to effectively reach their target audience.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, leading to better product selection and enhanced operational efficiency in the hummingbird feeder market.

Navigating Market Dynamics and Sourcing Trends in the how often should you change your hummingbird feeder Sector

Market Overview & Key Trends in Hummingbird Feeder Maintenance

The global market for hummingbird feeders is influenced by several key drivers, including increasing interest in backyard birding, environmental awareness, and the growing trend of eco-friendly gardening. In regions such as Africa, South America, the Middle East, and Europe, particularly in countries like Saudi Arabia and Germany, there is a notable rise in consumer demand for products that support biodiversity. This shift is prompting businesses to prioritize the quality and sustainability of their offerings, including nectar solutions that cater to the diverse climatic conditions of these markets.

Emerging B2B technology trends include the adoption of smart feeders equipped with monitoring systems that notify users when nectar needs to be changed. This innovation addresses the critical need for maintaining freshness, particularly in warmer climates where spoilage occurs rapidly. Additionally, suppliers are increasingly focusing on sourcing high-quality, natural ingredients for nectar formulations, minimizing the use of artificial dyes and preservatives. Such advancements not only enhance product appeal but also align with consumer preferences for healthier, more natural options.

International buyers are also navigating market dynamics that require a keen understanding of local regulations regarding wildlife conservation and product safety. As markets evolve, businesses must adapt to these regulations while ensuring that their hummingbird feeders are competitively priced and accessible. This adaptability is crucial for sustaining growth in diverse international markets.

How Can Sustainability & Ethical Sourcing Impact Hummingbird Feeder Products?

Sustainability plays a pivotal role in the hummingbird feeder sector, as consumers increasingly prioritize environmentally friendly products. The environmental impact of feeder maintenance, particularly in terms of nectar spoilage and waste, underscores the importance of ethical sourcing practices. Suppliers should focus on utilizing responsibly sourced materials and ingredients that minimize ecological footprints.

Certifications such as the Rainforest Alliance or Fair Trade can enhance product credibility, appealing to eco-conscious buyers. Furthermore, incorporating biodegradable materials in feeder construction can reduce plastic waste and resonate with customers who are invested in sustainable living. By prioritizing sustainability, businesses can not only meet regulatory standards but also cultivate a loyal customer base that values ethical practices.

Moreover, the trend towards organic nectar solutions is gaining traction. Offering nectar without artificial additives or preservatives not only meets the growing demand for natural products but also aligns with the broader movement towards health-conscious consumerism. This approach can enhance brand reputation and foster trust among B2B buyers looking for reliable suppliers.

What is the Historical Context of Hummingbird Feeder Maintenance?

Historically, the maintenance of hummingbird feeders has evolved significantly, influenced by changing consumer preferences and advancements in product design. Initially, feeders were simplistic, often made from glass or metal with basic functionality. Over time, the introduction of plastic materials and innovative designs improved usability and cleaning ease, addressing common issues such as nectar spoilage and pest attraction.

In recent years, there has been a noticeable shift towards incorporating advanced materials that enhance durability and reduce environmental impact. As awareness around the importance of sustainability grows, manufacturers have begun to focus on creating products that not only serve their functional purpose but also contribute positively to the environment. This evolution reflects a broader trend within the B2B sector, where businesses are increasingly aligning their product offerings with ethical and sustainable practices to meet the expectations of modern consumers.

By understanding these dynamics, international B2B buyers can make informed decisions when sourcing hummingbird feeders that not only satisfy customer demands but also support ecological sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of how often should you change your hummingbird feeder

-

1. How often should I change the nectar in my hummingbird feeder?

Changing the nectar in your hummingbird feeder is crucial for the health of the birds. In warmer climates or during hot weather, it is advisable to change the nectar every 1 to 2 days to prevent spoilage. In cooler conditions, every 2 to 4 days is acceptable. Regular changes not only ensure the well-being of the birds but also encourage them to visit your feeders consistently. -

2. What are the best materials for hummingbird feeders?

When sourcing hummingbird feeders, consider those made from durable materials like glass or high-quality plastic. Glass feeders are easy to clean and do not retain odors, while sturdy plastic options are lightweight and often more affordable. Ensure that the feeders have no harmful dyes or materials that could affect the nectar quality, as this is crucial for attracting hummingbirds effectively. -

3. How can I verify the quality of hummingbird feeders from suppliers?

To ensure quality, request product samples from potential suppliers before committing to large orders. Additionally, check for certifications or compliance with safety and environmental standards. Reading reviews and testimonials from other buyers can also provide insights into the reliability and durability of the feeders, helping you make an informed decision. -

4. What are the minimum order quantities (MOQ) for hummingbird feeders?

MOQ can vary significantly between suppliers and regions. It’s essential to discuss this upfront to ensure it aligns with your purchasing capacity. Some manufacturers may offer lower MOQs for first-time buyers or bulk orders, while others might have strict limits. Always clarify these terms during negotiations to avoid misunderstandings later. -

5. What payment terms should I expect when sourcing hummingbird feeders internationally?

Payment terms can vary by supplier, but common practices include advance payments, letters of credit, or payment upon delivery. Always clarify these terms before finalizing any agreements. Negotiating favorable payment terms can help manage cash flow and reduce risks associated with international transactions, particularly in regions with fluctuating currencies. -

6. How do I handle logistics for importing hummingbird feeders?

When importing, partner with a reliable logistics provider experienced in international shipping. Discuss shipping methods, customs clearance, and delivery timelines to ensure a smooth process. Additionally, consider the impact of tariffs and taxes on your overall costs, and factor these into your pricing strategy to maintain competitiveness in your market. -

7. Can I customize hummingbird feeders for my brand?

Many manufacturers offer customization options, including colors, sizes, and branding elements such as logos. This can enhance your product’s marketability. Discuss your specific requirements with potential suppliers and inquire about their capabilities to ensure that the final product aligns with your brand image and customer preferences. -

8. How do I ensure my hummingbird feeders comply with international standards?

To ensure compliance with international standards, ask suppliers about their certifications and testing procedures. Look for products that meet safety, environmental, and quality standards relevant to your target market. Conducting due diligence and possibly third-party inspections can further safeguard your business against potential liability issues related to non-compliance.

A Look at How Often Should You Change Your Hummingbird Feeder Manufacturers & Suppliers

We are currently compiling a detailed list of top how often should you change your hummingbird feeder suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for how often should you change your hummingbird feeder

What Are the Key Takeaways for International Buyers on Changing Hummingbird Feeders?

In conclusion, understanding the frequency of changing hummingbird feeder nectar is essential for maintaining healthy feeding environments. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, sourcing high-quality feeders and nectar solutions can enhance customer satisfaction and promote responsible bird feeding practices. The general guideline is to change the nectar every 2 to 4 days, with more frequent changes in warmer climates. This not only prevents spoilage but also ensures that hummingbirds continue to visit, thus supporting local ecosystems.

How Can Strategic Sourcing Enhance Your Hummingbird Feeder Offerings?

Strategic sourcing plays a vital role in ensuring that your supply chain is equipped to provide the best products for your customers. By prioritizing quality and efficiency in your procurement processes, you can offer superior feeders and nectar solutions that meet the specific needs of your market. Moreover, collaborating with reputable suppliers can provide insights into best practices and innovations in bird feeding.

What Should International Buyers Do Next?

As you consider your next steps, evaluate your current suppliers and explore opportunities for partnerships that align with sustainable practices and customer education. Invest in training and resources that will empower your team to promote responsible bird feeding. Together, we can create environments that support not only hummingbirds but also the broader avian community, contributing to biodiversity and ecological balance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.