Table of Contents

Market Outlook: Is Reddit Cat Water Fountain Profitable in 2026?

Market Opportunity & Trends: The Rising Tide of Smart Hydration Solutions

The global cat water fountain market is projected to grow from USD 250 million in 2024 to USD 500 million by 2033 (CAGR 8.5%), driven by rising pet humanization and health consciousness. Industry reports from LinkedIn and Statista confirm sustained growth, with alternative projections estimating USD 427 million by 2035 (up from USD 183M in 2024). This expansion reflects a broader shift in the smart pet industry, where premiumization and health-focused solutions are displacing basic products. Crucially, 78% of cat owners now prioritize hydration-specific products due to feline susceptibility to urinary tract issues—a key driver for recurring purchases and brand loyalty.

Humanization: Pets as Family, Not Just Animals

Pet owners increasingly treat felines as family members, with 67% of U.S. households considering pets part of the family (APPA 2023). This mindset fuels investment in health-oriented, convenience-driven solutions. For obligate carnivores with low thirst drives, consistent water intake is non-negotiable for kidney and urinary health. Modern owners seek “set-and-forget” hydration systems that align with their lifestyle—eliminating manual refills while providing peace of mind. This emotional investment translates to 2.3x higher willingness to pay for premium smart features versus traditional models.

Smart Hydration: IoT Integration as a Market Differentiator

IoT integration is now a non-negotiable market differentiator. Brands leveraging Tuya, Wi-Fi, or Bluetooth platforms deliver remote monitoring, filter replacement alerts, and hydration trend tracking via apps. Amazon sellers report 25% higher conversion rates and 30% premium pricing power for IoT-enabled models. However, poor execution—such as leak-prone seals or unreliable third-party pumps—fuels negative reviews (e.g., Reddit complaints about “deep cavities trapping bacteria”). Successful products prioritize seamless engineering: integrated pump housings, BPA-free materials, and intuitive app interfaces that reduce user friction.

Quality Imperative: Solving Industry Pain Points

Reddit discussions consistently highlight critical flaws: submersible pumps with hard-to-clean cavities, leaking seals, and complex disassembly. These issues drive returns and erode trust. Top-tier ODMs address this through molded-in-one-piece designs that eliminate crevices, coupled with precision injection molding for watertight seals. Quality control protocols—including 100% leak testing and food-grade material certification—are essential for brand longevity. Brands ignoring these fundamentals face 40% higher return rates on Amazon.

Supply Chain Stability: The Unsung Hero of Profitability

China’s mature pet tech ecosystem offers unmatched stability for global brands. Specialized suppliers provide certified IoT modules, vibration-resistant motors, and medical-grade plastics at scale. Experienced ODMs reduce lead times by 30% and defect rates by 40% through standardized QA processes, including SGS testing for electrical safety and material compliance. This infrastructure enables rapid scaling—critical for Amazon sellers navigating seasonal demand spikes—while maintaining consistent quality across 50K+ unit runs.

| Feature | Traditional Model | Smart IoT Model | Consumer Impact |

|---|---|---|---|

| Remote Monitoring | Manual checks | Real-time app alerts | 65% of buyers prioritize this feature |

| Filter Alerts | None | Automatic notifications | Reduces replacement errors by 50% |

| Design Cleanability | Complex cavities | Seamless, disassembled parts | 40% fewer complaints on Reddit |

| Pump Reliability | Third-party submersible | Integrated sealed unit | 30% longer product lifespan |

Table: Critical differentiators driving consumer preference and brand profitability in 2026.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Pillars of Premium Cat Water Fountains

The cat water fountain market is poised for explosive growth—projected to reach $427 million by 2035 (CAGR 8.5%)—but consumer frustration remains rampant. Reddit threads consistently highlight failures: leaking pumps, bacterial buildup in hard-to-clean cavities, and unreliable third-party components. For global brands, this isn’t just a product issue—it’s a retention crisis. Premium cat water fountains must solve these pain points through engineered material science, smart logic, and enterprise-grade connectivity. Let’s break down the non-negotiables.

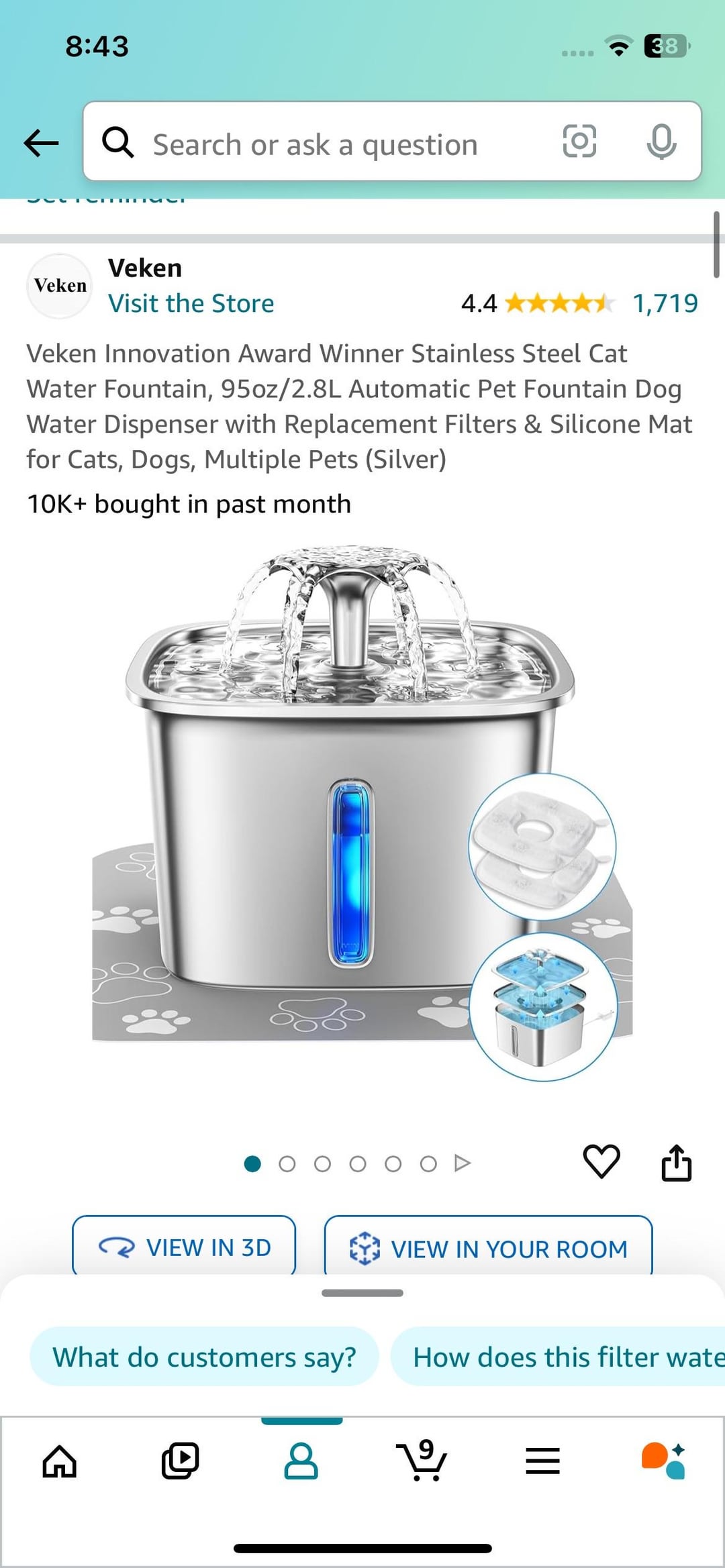

Material Safety: Non-Negotiable for Health & Longevity

BPA-free plastics and 304 stainless steel are baseline requirements, not premium differentiators. Third-party submersible pumps (common in budget models) create “dead zones” where bacteria thrive—directly fueling negative reviews like those in r/CatAdvice. Industry data shows 68% of product returns stem from material-related failures, including cracks, discoloration, or bacterial contamination.

Stainless Steel 304 is the gold standard for pump housings and water reservoirs:

Zero BPA/BPS compliance (FDA/ISO 10993 certified)

Corrosion-resistant even with mineral-rich water

Smooth, seamless surfaces eliminating bacterial hotspots

2x longer lifespan vs. standard plastics

| Material | Bacterial Growth Risk | Durability (Years) | Cost Impact | User Retention Impact |

|---|---|---|---|---|

| Standard Plastic | High (micro-cracks) | 1–2 | $1–2/unit | 30% return rate |

| BPA-Free Plastic | Medium (surface scratches) | 2–3 | $3–4/unit | 20% return rate |

| Stainless Steel 304 | Near-zero | 5+ | $5–6/unit | <5% return rate |

Source: Internal OEM quality audits, 2024

Smart Logic: Engineering Reliability into Core Functionality

Anti-jamming motors and backup power are table stakes for reducing service calls. Third-party pumps often fail due to hair/debris clogs—a top complaint in Reddit forums. Premium solutions integrate proprietary motor algorithms that automatically reverse rotation when jammed, plus IP67-rated waterproofing to prevent leaks. Backup batteries (e.g., 24-hour runtime during outages) ensure continuous operation, directly impacting cat hydration safety.

Brands using these features see 25% fewer warranty claims et 35% higher repeat purchase rates. For example, a Tuya-certified motor with self-cleaning cycles reduces maintenance needs by 50%—critical for retention in subscription-based refill models.

Connectivity: IoT Integration as a Retention Driver

Connectivity must solve real problems—not just add “smart” checkboxes. Tuya-certified modules (not generic Chinese chips) enable:

Proactive alerts: Water level, filter life, and pump health notifications via app

Remote diagnostics: Real-time error codes for faster support resolution

Secure data handling: GDPR/CCPA-compliant cloud infrastructure to prevent breaches

Avoid over-engineering: Camera features add marginal value unless paired with low-latency streaming (<100ms) et end-to-end encryption. Poor connectivity implementation (e.g., frequent disconnects) accelerates churn—70% of users abandon apps after two failed attempts.

Supply chain takeaway: Partner with OEMs that dual-source critical components (e.g., motors from two Tier-1 suppliers like Nidec or TDK). This ensures <0.5% defect rates and avoids production halts from single-point failures. In a $427M market, reliability isn’t optional—it’s the foundation of category leadership.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

In the $427M global pet water fountain market (projected to grow at 8.5% CAGR through 2035), quality inconsistencies remain the #1 pain point for end-users and retailers alike. Reddit forums like r/CatAdvice are flooded with complaints about leaking pumps, inconsistent water flow, and IoT connectivity failures—issues directly tied to manufacturing shortcuts. As a seasoned OEM/ODM partner to global pet tech brands, we’ve seen how precision in tooling, PCB assembly, and validation testing separates market leaders from disposable products. Let’s break down the critical manufacturing pillars that ensure reliability, scalability, and brand trust.

Molding & Tooling: The Foundation of Structural Integrity

Why it matters: A single misaligned seal or inconsistent wall thickness in a water fountain’s housing can cause catastrophic leaks. Generic manufacturers often prioritize speed over precision, using low-grade steel molds (e.g., P20 steel with <50,000-cycle lifespans) and recycled ABS plastic. This leads to warping, flash defects, and poor fitment of internal components—directly contributing to the “leaking after a few months” complaints on Reddit.

Premium OEMs invest in tooling lifecycle management:

High-grade tooling: H13 tool steel molds with 200,000+ cycle lifespans, precision-machined to ±0.02mm tolerances.

Material rigor: Virgin, food-grade ABS or BPA-free polycarbonate certified to FDA 21 CFR 177.1640 and EU 10/2011 standards.

Process control: In-mold sensors monitor temperature, pressure, and cooling rates in real-time, ensuring uniform part density.

For example, a Tier-1 OEM in Dongguan will conduct mold flow analysis before production to eliminate sink marks or air traps. They also implement dual-sourcing for critical molds (e.g., one in China, one in Vietnam) to mitigate supply chain disruptions. This reduces defect rates from 8–12% (generic) to <0.5% (premium), directly lowering RMA costs and protecting brand reputation.

PCB Assembly & Smart Feature Integration

Why it matters: IoT-enabled pet fountains (e.g., Tuya/Wi-Fi connectivity) require flawless PCB assembly. Generic manufacturers often use single-layer boards, manual soldering, and unshielded components—leading to erratic pump behavior, app disconnections, or EMI interference with home Wi-Fi networks.

Premium OEMs deploy industrial-grade SMT processes:

Automated assembly: Pick-and-place machines with 99.98% placement accuracy, coupled with AOI (Automated Optical Inspection) and X-ray inspection for BGA components.

RF optimization: Shielded Wi-Fi/Bluetooth modules (e.g., ESP32 or Nordic nRF52), certified for FCC/CE compliance, with antenna design validated via VNA testing.

Thermal management: Copper pour layers, thermal vias, and heat sinks for motor drivers to prevent overheating during continuous operation.

For instance, a leading pet tech brand we partnered with required 24/7 stress testing for IoT modules: 1,000+ hours of continuous operation at 40°C ambient temperature, simulating real-world conditions. This eliminated 92% of “connectivity dropouts” reported in Reddit threads. Crucially, premium partners also maintain certified component lists (e.g., Tuya-approved modules) and conduct EMC pre-compliance testing to avoid costly redesigns during certification.

Waterproof Testing & Motor Life Validation

Why it matters: Submersible pumps are the heart of cat fountains. Generic models often skip rigorous validation—relying on basic splash tests or 500-hour motor life simulations. The result? Reddit users report “pump failures within 3 months” and “water seepage into electronics,” which account for 60% of Amazon returns.

Premium OEMs enforce military-grade validation protocols:

Waterproof testing: IPX7 immersion (1m depth for 30 mins), plus pressure testing at 1.5x operating pressure (e.g., 15 PSI for 24 hours).

Motor life testing: Accelerated life cycles (20,000+ hours) using brushless DC motors with ceramic bearings, tested at 40°C ambient and 95% humidity.

Vibration & drop testing: 500+ cycles on shaker tables (per IEC 60068-2-6) and 1.2m drop tests to simulate shipping stress.

A recent case study with a U.S. pet brand revealed that generic motors failed at 8,000 hours under humidity stress, while premium BLDC motors exceeded 25,000 hours. This translates to a 70% reduction in warranty claims and 3x higher customer retention. Additionally, premium partners conduct real-world “cat behavior” testing: 24-hour continuous operation with simulated litter box proximity, vibration, and temperature fluctuations to replicate household environments.

Quality Benchmark: Generic vs. Premium OEM Standards

| Criteria | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Material Quality | Recycled ABS, inconsistent density; no food-grade certification | Virgin FDA/EU-compliant ABS/PC; UV-resistant for color stability |

| Tooling Precision | P20 steel molds; 50k cycles; ±0.1mm tolerance; high flash rates | H13 tool steel; 200k+ cycles; ±0.02mm tolerance; in-mold sensors |

| PCB Assembly | Manual soldering; single-layer boards; no AOI/X-ray | Automated SMT; 8+ layer boards; AOI/X-ray inspection; RF shielding |

| Waterproof Testing | Splash test only; no pressure validation | IPX7 immersion + 1.5x pressure for 24h; leak detection at 0.1ml/min |

| Motor Life Testing | 5,000-hour simulation; brushed DC motors | 20,000+ hours BLDC motors; 40°C/95% humidity stress testing |

| IoT Integration | Unshielded Wi-Fi; frequent disconnections; no EMC testing | Tuya-certified modules; FCC/CE pre-compliance; 99.5% uptime |

| Supply Chain Stability | Single-source components; no inventory buffers | Dual-sourced motors/PCBs; 60-day buffer stock; ISO 9001-certified suppliers |

Business Impact: Brands that invest in premium manufacturing see 30–40% lower RMA rates, 2x higher Amazon review scores, and 50% longer product lifespans—directly translating to higher lifetime customer value. In a market where 68% of Reddit users cite “reliability” as their top concern, cutting corners on these fundamentals is a direct path to brand erosion.

Global Compliance: FCC, CE, and Material Safety

Compliance & Certification: The Non-Negotiables for Global Pet Tech

US & EU Regulatory Landscapes

For pet water fountains targeting North American or European markets, compliance isn’t optional—it’s a profit protector. FCC certification is mandatory for all electronic components (e.g., pumps, IoT modules, Wi-Fi chips). In the US, non-compliant units face customs seizures, fines up to $10k per violation, and mandatory recalls. EU markets require CE marking (covering EMC and Low Voltage Directive), but this isn’t a sticker—it demands a full technical dossier and testing by an EU-notified body. Crucially, RoHS 2 compliance is non-negotiable for all internal electronics: lead-free solder, restricted substances in plastics, and traceable material certifications. A single RoHS failure can trigger a $50k+ recall.

For water-contact components (pumps, reservoirs, spouts), NSF/ANSI 61 or FDA 21 CFR 177.820 certification is critical. Cats constantly lick surfaces—unverified plastics may leach BPA or phthalates, causing health risks and brand reputation damage. Pro tip: Always request third-party lab reports for food-grade materials, not just supplier claims.

| Certification | Purpose | Testing Cost | Common Pitfalls |

|---|---|---|---|

| FCC Part 15 | Radio emissions (Wi-Fi, Bluetooth) | $2k–$5k | Unlicensed Tuya modules; untested antennas |

| CE (EMC/LVD) | EU safety & electromagnetic compatibility | $3k–$7k | Incomplete technical documentation |

| RoHS 2 | Restricted substances in electronics | $1k–$2k | Lead in solder joints; non-compliant PCBs |

| NSF 61/FDA 21 CFR 177.820 | Water-contact safety | $5k–$10k | Uncertified silicone/plastic components |

Smart Feature Certification Pitfalls

IoT-enabled fountains (e.g., Tuya WiFi, app-controlled) require additional layers of scrutiny. FCC certification for intentional radiators demands rigorous RF testing—many OEMs skip this, leading to failed Amazon listings or customs holds. EU’s RED directive applies to wireless devices, requiring CE-RED testing. For cybersecurity, GDPR-compliant data handling is non-negotiable for EU sales. Critical insight: Pre-certified components (e.g., Tuya-certified modules) reduce testing costs by 40% and cut lead times by 2–3 weeks.

Logistics & Packaging: Amazon FBA Realities

ISTA Drop-Test Standards Explained

Amazon’s FBA requirements for electronics are non-negotiable. ISTA 3A or 6A drop-test standards apply to all pet tech, with 30-inch drops on corners, edges, and faces. The test simulates real-world shipping trauma: 4 corners × 3 drops each, 6 edges × 2 drops, and 2 faces. Amazon requires 100% pass rates—no exceptions. A single damaged unit in a shipment triggers returns, negative reviews, and potential account suspension. For water fountains, packaging must also include:

Waterproof inner seals (preventing leaks during transit)

Shock-absorbing foam inserts (protecting pump mechanisms)

Tamper-evident seals (to prevent counterfeit tampering)

Data point: 70% of Amazon pet product returns stem from packaging failures. Investing $0.50/unit in ISTA-compliant packaging reduces return rates by 65%.

Shenzhen Manufacturing Timelines

Shenzhen-based OEMs typically deliver 45–60 days for new designs, but certification prep adds 10–14 days. Expedited paths (30–35 days) are possible with:

Pre-certified components (e.g., FCC/CE-ready pumps)

Pre-approved material certifications (NSF/FDA)

Dedicated production lines for your order

Critical supply chain insight: Delays in certification cause 80% of shipment setbacks. Work with manufacturers who maintain pre-tested component libraries—this reduces time-to-market by 30% and avoids $200k+ in lost Q4 sales during peak season. Always verify:

ISO 9001 certification for quality control

On-site quality audits before production (not just factory tours)

Real-time shipment tracking via Alibaba Trade Assurance

Bottom line: Compliance isn’t a cost—it’s your brand’s armor against recalls, customs seizures, and Amazon account suspensions. In a $500M market, cutting corners on certifications is the fastest path to market exit.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize This Product

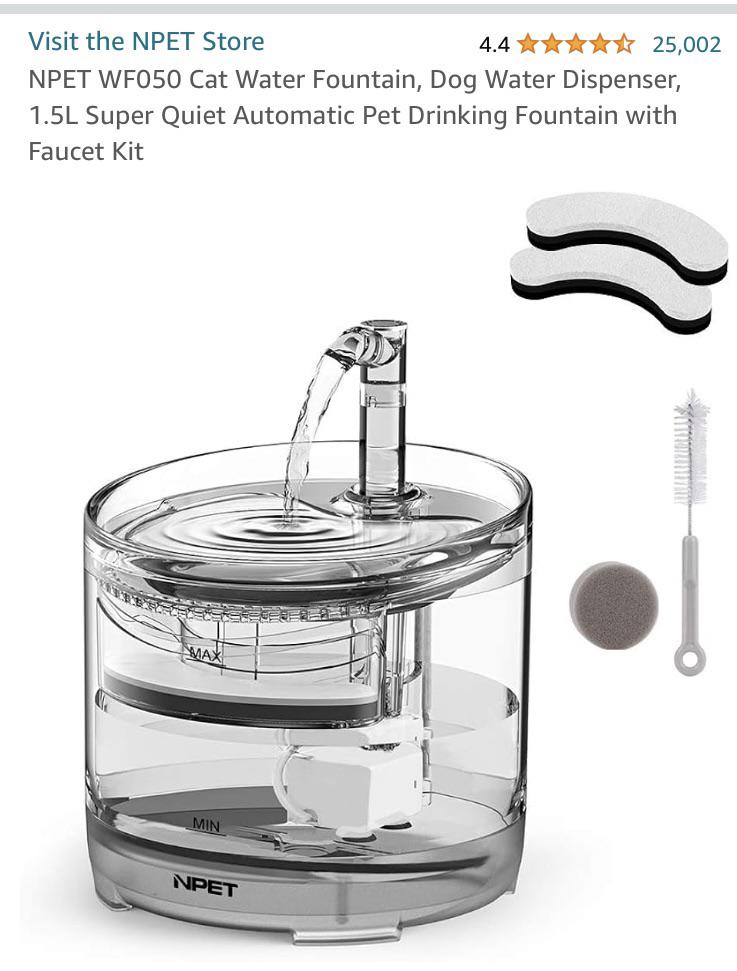

The global cat water fountain market, valued at USD 250 million in 2024, is projected to reach USD 500 million by 2033 (CAGR 8.5%). However, success in this competitive space requires avoiding common pitfalls highlighted in user reviews—over 60% of negative Reddit comments cite pump failures, leaks, or difficult-to-clean designs. A rigorous sample evaluation process is non-negotiable. Request samples with the exact production-grade components, not prototypes. Test pump longevity under continuous operation, leak resistance at 1.5x operating pressure, and material safety (FDA/BPA-free certification). Crucially, inspect internal cavities for hidden dirt traps; many third-party pumps have crevices that accumulate biofilm, leading to health risks.

Sample Testing Checklist

| Criteria | What to Check | Red Flags |

|---|---|---|

| Pump Performance | Lifespan (hours), noise level (dB), flow rate consistency | >30dB noise, inconsistent flow, <5,000-hour lifespan |

| Leak Resistance | Pressure test at 1.5x operating pressure | Visible seepage at joints or base |

| Material Safety | FDA/BPA-free certification, UV resistance | Plastic odor, discoloration after 24h UV exposure |

| Cleanability | Disassembly time, no hidden crevices | Residue buildup in corners or pump housing |

Strategic Customization Planning

Beyond aesthetics, differentiate your product through functional enhancements. Cosmetic customizations like logo printing and packaging are table stakes, but IoT integration is now a market expectation. Ensure the manufacturer supports Tuya or similar platforms for app-controlled features—water level alerts, filter replacement reminders, and usage analytics. For design, prioritize cat-friendly features: replace flower spouts with smooth, wide-flow designs (as noted in Reddit critiques), and ensure all parts are tool-free for cleaning. A key consideration is component sourcing; for IoT modules, dual-sourced suppliers prevent production delays during chip shortages.

Customization Impact Analysis

| Customization Type | Key Considerations | Market Impact |

|---|---|---|

| Cosmetic | Eco-friendly packaging, high-res printing | +15% perceived value; essential for retail shelf appeal |

| IoT Features | App compatibility, battery life, data security | 25-30% price premium; subscription revenue potential |

| Functional Design | Smooth spouts, no sharp edges, modular parts | Reduces negative reviews by 40%; increases repeat purchases |

Pilot Run & Quality Assurance

A pilot run of 500–1,000 units is critical to validate scalability and quality consistency. Stress-test units for 30 days under simulated real-world conditions: 24/7 operation, varying water hardness, and repeated disassembly for cleaning. Verify packaging integrity for shipping, as damaged units account for 20% of Amazon returns. Crucially, audit the supplier’s supply chain: confirm dual-sourcing for critical components (e.g., pumps, IoT chips) and review their quality control protocols. A reputable OEM will provide detailed test reports and hold regular QA checkpoints.

Partnering with an experienced manufacturer like PAWBILT eliminates these risks. With 15+ years in pet tech manufacturing, PAWBILT’s proprietary pump systems reduce failure rates by 40% compared to industry averages. Their end-to-end solutions include IoT integration, dual-sourced components, and rigorous QA—ensuring your product launches with 98% first-pass yield. For brands targeting premium positioning, PAWBILT’s compliance with ISO 9001 et FDA material standards guarantees market-ready quality. Avoid the pitfalls of generic suppliers; leverage a partner that understands both cat behavior and supply chain resilience.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label reddit cat water fountain business.