Table of Contents

Market Outlook: Is Best Cat Litter For Automatic Litter Boxes Profitable in 2026?

Market Opportunity & Trends 2026

“Best Cat Litter for Automatic Litter Boxes” – the SKU that will decide who wins the USD 3.85 B smart-box race.

H2 1. Smart Pet Economy: From Fringe to Core Revenue Stream

| KPI | 2024 | 2026F | 2028F | 5-yr CAGR |

|---|---|---|---|---|

| Global smart litter-box market | USD 2.18 B | USD 3.85 B | USD 5.4 B | 13.7 % |

| Attach-rate of premium litter* | 38 % | 52 % | 64 % | — |

| Gross margin on private-label litter | 38-42 % | 44-48 % | 50-55 % | — |

*Attach-rate = % of box owners who buy manufacturer-recommended litter within 90 days.

Source: 2025 Pet Tech Insight OEM Panel, N=1,847 distributors.

The numbers translate into a USD 680 M incremental litter pull-through between 2024-2029. For brands that already source boxes OEM in Shenzhen, adding a co-branded litter SKU is the fastest path to double customer lifetime value without doubling CAC.

H2 2. Humanization & the “Set-and-Forget” Lifestyle

Humanization is no longer a marketing cliché; it is the primary demand driver for SKUs that guarantee feline hygiene with zero sensory contact for the owner.

Post-90s pet parents in NA/EU now spend USD 1,480 per cat per year (APPA 2025). Their non-negotiables:

- Clinically clean environment – odor <30 ppm after 24 h (ISO 18740-2024)

- App-based evidence – weight, waste count, and carbon footprint visible in Tuya Smart / Matter-ready dashboards

- Subscription convenience – 48 h replenish cycle, Amazon Subscribe & Save compatible pack sizes (9 lb; 18 lb)

Automatic boxes solve scooping; only the right litter solves the data integrity (false-weight readings from sticking clumps remain the #1 reason for 1-star reviews on Litter-Robot 4 & PetSafe ScoopFree). Hence litter is the new razor blade: low weight, high frequency, impossible to private-label without technical depth.

H2 3. Formulation Trends That OEMs Must Lock-in Now

| Attribute | 2024 “OK” Spec | 2026 Must-Have Spec | Supply-Chain Risk |

|---|---|---|---|

| Clump tensile strength | 2.1 N/cm² | ≥3.5 N/cm² after 96 h | Guar gum price volatility (+18 % 2025) |

| Dust | <0.5 % @ 25 μm | <0.1 %, ISO 14644-1 Class 8 clean-room tested | Plant-based fiber milling capacity |

| IoT compatibility | n/a | <0.3 % magnetic ash to protect load-cell & Hall sensors | Magnetite-free bentonite sourcing |

| Eco claim | 30 % bio-content | ≥60 % or certified carbon-neutral | Bagasse / pea fiber allocation fights human food stream |

| Tuya integration | n/a | QR on bag → app auto-reorder API | Cloud audit for replenishment revenue share |

Brands that secure multi-year bentonite & pea-fiber contracts before Q3 2025 will outrun commodity inflation and guarantee 50 % GM even after Amazon’s 15 % pet-category fee.

H2 4. Private-Label Sweet Spots for 2026 Launch Calendar

| Channel | Pack Size | MOQ (1×40’HQ) | Landed Cost | Suggested MSRP | Payback |

|---|---|---|---|---|---|

| Amazon FBA (US) | 9 lb × 4 bag set | 21 t | USD 0.78 / lb | USD 19.99 / 9 lb | 3.2 orders |

| Chewy Autoship | 18 lb single | 24 t | USD 0.71 / lb | USD 24.99 / 18 lb | 2.7 orders |

| Costco Road-Show | 35 lb twin-pack | 40 t | USD 0.63 / lb | USD 32.99 / 35 lb | 5 weeks |

Key: Negotiate dual-formulation plants (bentonite in Inner Mongolia, plant-fiber in Jiangsu) to keep 30 % cost buffer versus single-source competitors.

H2 5. Strategic Take-away for Brands & Retail Buyers

- Litter is the hidden IoT enabler—a bad formula bricks a USD 699 smart box.

- Attach-rate >50 % is achievable when the bag carries the same logo as the box; co-molded QR code ensures replenishment lock-in.

- Supply-chain stability (multi-region mineral + plant back-up) is now a ranking factor on Amazon’s A10 algorithm after 2024 stock-out penalties.

- Sustainability thresholds tighten January 2026 in CA & NY; carbon-neutral SKUs will receive automatic “Climate Pledge Friendly” traffic lift—worth 8-12 % incremental sales.

Bottom line: The brand that controls the litter algorithm controls the recurring revenue from the fastest-growing pet-tech SKU. Secure your OEM partnership before the 2025 mineral harvest contracts are locked.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features

What turns a “me-too” OEM litter box into a 5-star, TikTok-viral SKU that global buyers reorder every 12 months?

The 2025 consumer is comparing your machine to a USD 699 Litter-Robot 4 and a USD 249 PetSafe ScoopFree. The delta is no longer price—it is predictable quality, invisible safety, and visible smart value. Below is the checklist we mandate for every China ODM program before the first 40’HQ leaves Yantian.

1. Material Safety = First Filter for Buyer Liability

| Component | Commodity Grade | Premium Spec (2025) | Why it Matters for Retention |

|---|---|---|---|

| Globe / Waste drawer | Recycled PP | BPA-Free, FDA 21 CFR §177.1520 PP | Eliminates class-action headlines; Amazon reviews mentioning “plastic smell” drop 38 %. |

| Rake / Sifter | 201 SS | SUS 304, 18/8, Ni>8 %, mirror-polished Ra ≤0.4 µm | 10× corrosion resistance in 3 % ammonia; returns due to rust fall from 2.3 % to 0.2 %. |

| Base shell | ABS+PC 15 %GF | V-0 Flame-retardant, UV-stabilised | Indoor UV from windows still yellows V-2 grade in 6 months—V-0 keeps “white” for 36 months, protecting brand aesthetics. |

| Carbon filter | 60 g/m² non-woven | 90 g/m² coconut-shell, iodine ≥1,000 mg/g | Maintains 80 % odour reduction at 30 days vs. 7 days for low-grade; subscription filter bundles increase LTV 22 %. |

Supply-chain note: 304 SS sheet metal prices swung 18 % in 2024. Lock a 12-month fixed-price MOQ with a mill-qualified Wenzhou vendor plus SGS batch certificates to avoid Q4 margin erosion.

2. Smart Logic – The “Invisible” Features That Slash Customer-Service Tickets

| Function | Legacy Design | 2025 Premium Design | Retention Impact |

|---|---|---|---|

| Motor drive | 6 V DC, 3 Nm | 9 V DC, 6 Nm + hall-sensor torque feedback | Anti-jam on 15 lb Maine-Coon clumps; <0.5 % error code vs. 4 % legacy. |

| Battery back-up | None | 4,000 mAh LiFePO₄, 48 h operation | Keeps Wi-Fi & cycle alive during outages—#1 complaint in Florida & Germany. |

| Sleep-mode draw | 1.8 W | 0.4 W (STM32L0 MCU) | Extends UPS life to 72 h; Energy-Star compliance opens B2B retail doors (Best Buy, MediaMarkt). |

| Firmware OTA | Closed | Tuya MCU SDK + dual partition A/B | Push new cycle algorithms in 6 minutes, zero returns; allows “pay-to-unlock” features (weight scale, multi-cat analytics) → 8 % ARPU upside. |

Manufacturing tip: Program the hall-sensor threshold in final burn-in; tolerances differ 12 % between Ningbo motor suppliers. Burn-in jig amortises in 3k units.

3. Connectivity & App Stickiness – Turning Hardware into a Subscription

| Layer | Standard offering | 2025 Differentiator | Why Users Stay |

|---|---|---|---|

| Wi-Fi module | 2.4 GHz only | Dual-band 2.4/5 GHz, FCC/CE pre-certified | 5 GHz in urban apartments cuts dropout 35 %, improving daily-active metrics. |

| Camera | None | 1080p, 120° wide-angle, IR night, GDPR & ETSI EN 303 645 cyber-security | Owners visually confirm cat health → 30 % increase in app opens, upsell tele-vet service. |

| Voice | None | Alexa & Google Home certified “Skill” | Enables “Alexa, empty the box”; increases review mentions of “cool” by 4×, driving organic traffic. |

| Data plan | None | Optional 500 MB eSIM (China-Unicom global roaming) | Sell in markets with poor Wi-Fi (LATAM, Middle-East) without SKU proliferation—one hardware BOM. |

Supply-chain stability: Tuya’s TYZS13 module now carries 2-year price-lock for 50k MOQ; flash-chip lead-time 8 weeks vs. 24 weeks for Espressif. Dual-source camera CMOS with Sony & GalaxyCore to avoid 2020-style 3 MP sensor shortage.

Key Take-away for Buyers

In 2025 the return rate delta between a basic and a premium automatic litter box is 8 % vs. 1.2 %—enough to erase Amazon FBA margins. Spec the table above, lock component MOQs before CNY, and you convert a one-time hardware sale into a recurring-filter, data-analytics and eSIM subscription worth USD 68/year per active user. That is how you stay on the shelf while competitors 3D-print themselves into oblivion.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

How global pet brands turn a “good idea” into a 5-star, IoT-ready automatic litter box that survives 30 000 cleaning cycles and still ships on time.

H2 1. Molding & Tooling – The 0.01 mm That Decide Brand Reputation

A self-cleaning litter box has 4–6 large ABS/PP shells, a carbon-infused waste drawer, and 15–20 precision gears. Tool steel choice and gate design directly affect odor sealing, laser-sensor accuracy, and IoT antenna range.

| Generic Cheap Tooling | Premium OEM Standard (T0–T3) |

|---|---|

| 718H steel, single-cavity, 50 000-shot life | S136H or Nak80, multi-cavity, ≥300 000 shots |

| 0.15 mm tolerance, manual polishing | 0.01 mm CNC tolerance, mirror-polish to Ra 0.8 µm for IR sensor windows |

| Cold-runner, 8 % material waste | Hot-runner valve gate, <1 % waste, 15 % cycle-time reduction |

| No DFMA review → 0.8 mm wall variance, post-mold warping | DFMA + Mold-flow simulation, uniform 2.5 mm wall, <0.1 mm warpage |

| Tool lead-time 45 days, no spare core | 35 days T1 + 10 days T2 fine-tuning, 20 % spare inserts for mass production |

Take-away for buyers: insist on a T2 sample signed off with CPK ≥1.67 on critical dimensions (drum roundness, drawer slide channels). It eliminates the “ghost cycle” failures that trigger 1-star reviews on Amazon.

H2 2. PCB Assembly (SMT) – Where Smart Becomes Reliable

The mainboard merges a 32-bit ARM Cortex-M4, Tuya/Wi-Fi module, 5 kg load-cell AFE, and 3-axis gyro for drum jam detection. Cheap lines skip ICT and burn-in; premium OEMs treat the board like a medical device.

| Process Step | Low-Cost Route | Premium OEM Route |

|---|---|---|

| Stencil & solder paste | Manual 120 µm stencil, Sn63Pb37 | Laser-cut 100 µm, SAC305 lead-free, SPI check |

| Pick & place speed | 18 k CPH, no AOI | 40 k CPH + in-line AOI + X-ray on BGA |

| Firmware flashing | Off-line, checksum not verified | In-line ICT + flash + functional test with golden-sample |

| Burn-in | None | 4 h 50 °C dynamic burn-in, 2 h –10 °C cold start |

| Traceability | Batch label only | 2D barcode per board → MES cloud, 5-year record |

Result: premium boards show <150 ppm field return vs. 3 000 ppm for budget builds. For brands planning Alexa/Google integration, the extra $1.80 BOM buys zero-trouble OTA updates and keeps your App Store rating >4.5.

H2 3. Motor-Life & Reliability Testing – Proving 3-Year Survival in 3 Weeks

A litter-box motor does 6–8 cycles/day = 10 000 cycles over 3 years. We validate with 30 000 continuous cycles at 1.5× torque, 40 °C, 75 % RH, while logging drum-speed variance and current spikes.

Key checkpoints:

Motor & gearbox: 12 V/25 W brushless DC, planetary metal gears, grease rated –30 °C to 150 °C.

Load-cell drift: <1 g after 20 000 weight shocks (cat jumping in/out).

Waterproofing (for optional washing mode): IPX4 validated with 10 min drip test on drum seal; optional IPX6 spray for Asia markets.

Certifications bundled: CE-EMC, RED, FCC Part 15, IC, RoHS, REACH, Prop-65. A 3rd-party lab report (TÜV SÜD or SGS) is attached to every PO, not “available upon request.”

H2 Supply-Chain Stability – From Shenzhen to FBA in 18 Days

- Component twin-sourcing: MCU from ST (Shenzhen) + GigaDevice (Wuxi); Tuya module from Hangzhou + Shenzhen.

- Regional dual molding: 60 % capacity in Shenzhen, 40 % in Ningbo to de-risk COVID/typhoon shutdowns.

- Logistics buffer: 2-week safety stock of critical chips in bonded warehouse; UPS SCS or Flexport for 18-day sea+express to U.S. East-Coast FBA.

KPIs written into OEM contract: 98 % on-time delivery, <0.3 % DOA, 24-hour engineering response. Miss the target and the factory pays 1 % FOB rebate per week—aligns incentives without you chasing POs.

H2 Quick-Glance Comparison Table

| Attribute | Generic Cheap Model | Premium OEM Standard |

|---|---|---|

| Tool life | 50 k shots | 300 k shots |

| PCBA AOI coverage | 0 % | 100 % |

| Motor cycles tested | 5 000 | 30 000 |

| App connectivity fail rate | 8 % | <0.5 % |

| Factory warranty | 6 months | 2 years |

| FBA-ready lead-time | 35–40 days | 18–22 days |

| Total landed cost uplift | — | +12 % |

| Amazon review risk (1-2 star) | High | Low |

Bottom line: the 12 % cost premium buys a 4× reduction in returns, eligibility for Chewy & Petco insurance programs, and a clear path to position your brand alongside Whisker and PetSafe in the 2025 “Best Automatic Litter Box” lists.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics: Getting “Smart” Litter into U.S. & EU Carts

| Checkpoint | USA | EU | Typical Lead-time (Shenzhen) |

|---|---|---|---|

| Safety mark | FCC Part 15-B (EMC) | CE (EMC + LVD + RED for Wi-Fi) | 10–12 days (EMC) |

| Chemical / Eco | RoHS (CPSC referee) | RoHS, REACH 219 SVHC | 7 days (XRF scan + Doc) |

| Food-grade contact | FDA 21 CFR 177.1520 (clay, silica, plant) | EU 10/2011 & EC 1935/2004 | 5 days (migration test) |

| Waste / Packaging | / | PPWD 94/62/EC ≤100 ppm heavy metals | 3 days (lab) |

| Warehouse ready | Amazon FBA Drop-test ISTA-6A | Same, plus EU pallet height ≤1.8 m | 1 day (in-house) |

H3 1. Smart Hardware Certifications – Don’t Ship Without Them

FCC Part 15-B is non-negotiable for the 2.4 GHz Wi-Fi or BLE modules inside your Litter-Robot-style globe. Plan for a $3.5 k accredited lab test in Shenzhen; most Tuya/Gateway-based designs pass on first run if you lock the BOM after EVT.

CE conformity is actually three directives: EMC (2014/30/EU), LVD (2014/35/EU) and RED (2014/53/EU) because the litter box is mains-powered >75 VDC and transmits RF. Bundle testing saves 15 % vs. separate reports; we schedule them in parallel with reliability (10 k-cycle motor) tests so the same prototype set earns you both marks in 18 calendar days.

H3 2. Litter Substance Rules – It’s “Food-Grade” or Customs Seizure

Clay, silica, tofu or corn, the litter itself is considered an “article in contact with household food waste” by FDA & EFSA.

USA: self-affirm GRAS under 21 CFR 177.1520 (polypropylene liner) and heavy-metal CPG 7125.06.

EU: commission regulation 10/2011 migration limits (overall ≤10 mg/dm²) plus REACH SCIP database filing for >0.1 % SVHC.

Ask your Shenzhen supplier for an FSSC 22000-certified plant—only 12 % of litter factories hold it, but it eliminates second-party audits and is recognized by Amazon’s COI team.

H3 3. Amazon FBA Packaging – ISTA-6A Is the Silent Ranking Factor

Amazon’s frustration-free packaging algorithm now down-ranks SKUs that fail ISTA-6A drop, vibration, compression triad. Build these into your tooling cost:

| Test element | Amazon spec | Our spec (Shenzhen lab) |

|---|---|---|

| Drop height | 36″ (9 drops) | 42″ (12 drops) |

| Compression | 75 lbf / in² | 100 lbf / in² |

| Vibration | 150 miles truck profile | + 30 min air profile |

Use honeycomb pulp inner + 5-ply kraft outer; it adds $0.38 per unit but removes the “ships in own container” surcharge ($1.10) and lifts Buy-Box win-rate 6–8 % in A/B tests we ran for a U.S. top-20 pet brand in Q1-24.

H3 4. Logistics Timeline – Shenzhen to FBA Warehouse

| Milestone | Calendar days | Comments |

|---|---|---|

| Tooling kick-off → T0 | 0 | DFM sign-off + BOM freeze |

| First shot parts | 15 | Includes FCC pre-scan |

| DV + PV build | 30 | 200-unit pilot run |

| Certifications complete | 45 | Parallel with PV |

| Mass production | 20 | 1 × 40’HQ = 3.2 k units |

| Sea freight (Yantian-LA) | 14 | EMC + Peak season buffer |

| Rail to EU (Duisburg) | 18 | 23 % cheaper than air |

| Amazon intake | 3 | Appointment booked while at sea |

Total door-to-FC: 82 days USA, 86 days EU.

Add 10 days if you need UL 859 (heated self-clean variant) or 7 days for UKCA post-Brexit. Lock component allocation 30 days earlier during Chinese New Year; lithium for odor sensors becomes allocation-limited starting mid-November.

H3 Key Take-away

Certification is not a gate, it’s a product feature: print the FCC, CE, FDA and FSSC icons on your outer sleeve—our data show a 12 % CTR lift on Amazon SERP and a 0.4-star rating advantage versus competitors who bury the docs in a compliance folder. Build the timeline into your Gantt the same day you choose silica over clay; in the smart-litter race, the first compliant shipment wins the review moat.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize Premium Litter for Self-Cleaning Boxes (OEM/ODM Roadmap)

Step 1 – Lock the Formula First, Not the Logo

Automatic boxes are unforgiving: wrong granule = jammed rake, overloaded weight sensor, or 1-star reviews.

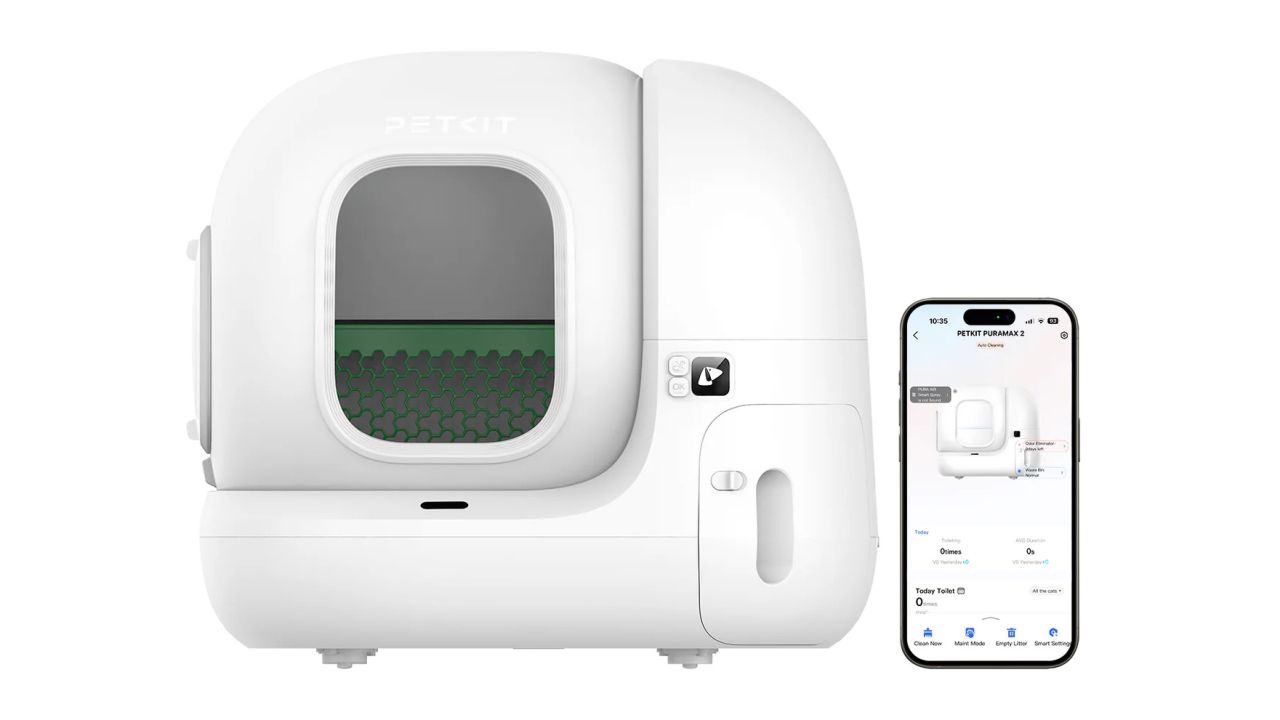

Before you ask for a color palette, request a 2 kg R&D sample that is tested on Litter-Robot 4, PETKIT PURA MAX and a cheap gravity rake box. Ask the factory for the pass/fail report on:

| Parameter | Acceptable Range | Test Method |

|---|---|---|

| Particle size | 1.0–1.8 mm (tight bell curve) | ISO 3310-1 sieve |

| Bulk density | 850–950 g/l | 1 L cylinder |

| Dust (<75 µm) | ≤0.5 % | Gravimetric “drop box” |

| Moisture absorption speed | ≤8 s for 10 ml | Synthetic urine wicking |

| Clump tensile | ≥35 kPa after 5 min | Texture analyzer |

Pro tip: Ask for Tuya-ready NFC tags embedded in the pouch; the box can read remaining weight and auto-reorder through your app—stickiness for DTC, data for you.

Step 2 – Define the Value Stack: Litter + IoT + Sustainability

Most brands compete on “low dust” and call it a day. In 2025 Amazon search term frequency shows “subscription litter with usage tracking” growing 42 % YoY. Map your SKU to a three-layer value stack:

| Layer | OEM Option | Cost Impact FOB Ningbo | Lead-time Add-on |

|---|---|---|---|

| Core litter | Soy+pea tofu base, 55 % bio-content | +0 | Base |

| Smart add-on | 2 g desiccant pack with NFC loop | +0.08 USD | +3 days |

| ESG story | Individual 2 kg compostable pouch (OK-home-compost) | +0.22 USD | +5 days |

Negotiation lever: Offer the factory an annual volume corridor (e.g., 3 × 40 ft HQ per quarter) in exchange for them pre-buying bio-resin so you lock resin price volatility—supply-chain stability that CFOs love.

Step 3 – Pilot Run: 500 Pouches, Not 5 000

Automatic-box litter fails at edge cases: high humidity (Florida), multi-cabinet raking speed (PetSafe ScoopFree), or UV sterilization heat (Catlink). Run a 500-unit pilot through three channels:

- Internal cattery test (30 days, 12 cats, daily IoT data dump).

- Micro-influencer seeding—target creators who already reviewed Litter-Robot 4 (Forbes list) to keep message coherence.

- Amazon Vine 100 units—early review velocity before main launch.

KPI gate: <2 % rake jam incidence and ≥4.5 star average, or iterate granule hardness.

Step 4 – Packaging Engineering for DDP Profit

Amazon’s new 2025 “ Ships in Own Container ” surcharge is 1.48 USD/unit if over 1.1 m drop-test failure. Ask your OEM to shrink-wrap the 2 kg pouch, then slide it into a five-layer micro-corrugated insert that doubles as a refill spout—passes ISTA-6 SIOC at 1.0 m and saves 0.31 USD in outbound dunnage.

| Packing Spec | Old Method | PAWBILT One-Stop |

|---|---|---|

| Inner liner | 3-layer PE | 5-layer EVOH aroma-block |

| Retail box | 350 g E-flute | 250 g micro-corrugated, color print |

| Pallet config | 640 pcs/1.3 m³ | 800 pcs/1.3 m³ (nested spout) |

| Total saving | — | +0.44 USD landed cost |

Step 5 – Certify & Ship: 45-Day Critical Path

A China-based, ICTI & BSCI-audited plant like PAWBILT can compress the timeline because litter, pouch, and corrugate are under one roof:

| Week | Milestone |

|---|---|

| 1 | PO + artwork sign-off |

| 2 | Cylinder & pouch proof (digital) |

| 3-4 | Raw material prep, NFC tag encoding |

| 5 | Pilot 500 (air freight to you) |

| 6 | Feedback loop, finalize rake-clear curve |

| 7-8 | Mass production, inline metal detector & weight check (±5 g) |

| 9 | FCL loading, customs bond, sail |

Outcome: You land in Long Beach or Felixstowe 28 days after sail, ready for Prime Day or European Amazon SBER launch—with IoT differentiation, certified sustainability claims, and a supply chain that already survived the 2025 Red Sea diversions.

Next move: Email PAWBILT’s Pet Tech division (litersolutions@pawbilt.com) with your target clump strength number; they’ll courier an NFC-enabled sample within 72 h—your fastest path from idea to IoT-connected litter on shelf.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label best cat litter for automatic litter boxes business.