Introduction: Navigating the Global Market for molypet automatic pet feeder

In the evolving landscape of pet care, sourcing the right automatic pet feeder, such as the Molypet Automatic Pet Feeder, has become a critical challenge for international B2B buyers. With the increasing demand for efficient pet care solutions, businesses must navigate a plethora of options while ensuring they meet the specific needs of their markets. This comprehensive guide delves into the intricacies of the Molypet Automatic Pet Feeder, exploring its diverse applications, features, and benefits. From understanding the technical specifications to evaluating supplier credibility and cost considerations, this resource equips buyers with the knowledge necessary to make informed decisions.

The guide is tailored for B2B buyers across Africa, South America, the Middle East, and Europe, including emerging markets like Nigeria and Vietnam. It provides actionable insights into the procurement process, including tips for assessing product quality and supplier reliability. Additionally, it highlights the importance of understanding regional market trends and consumer preferences, ensuring that businesses can effectively cater to their target demographics. By leveraging this guide, international buyers can confidently navigate the global market, enhance their product offerings, and ultimately drive customer satisfaction in the competitive pet care industry.

Table Of Contents

- Top 2 Molypet Automatic Pet Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for molypet automatic pet feeder

- Understanding molypet automatic pet feeder Types and Variations

- Key Industrial Applications of molypet automatic pet feeder

- 3 Common User Pain Points for ‘molypet automatic pet feeder’ & Their Solutions

- Strategic Material Selection Guide for molypet automatic pet feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for molypet automatic pet feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘molypet automatic pet feeder’

- Comprehensive Cost and Pricing Analysis for molypet automatic pet feeder Sourcing

- Alternatives Analysis: Comparing molypet automatic pet feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for molypet automatic pet feeder

- Navigating Market Dynamics and Sourcing Trends in the molypet automatic pet feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of molypet automatic pet feeder

- Strategic Sourcing Conclusion and Outlook for molypet automatic pet feeder

- Important Disclaimer & Terms of Use

Understanding molypet automatic pet feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Automatic Feeder | Basic timed feeding, single bowl, no app connectivity | Small pet stores, individual retailers | Pros: Cost-effective, easy setup. Cons: Limited features, less control over feeding. |

| WiFi-Enabled Feeder | Smart app control, dual feeding bowls, meal scheduling | E-commerce platforms, tech-savvy retailers | Pros: Remote management, customizable schedules. Cons: Higher price point, requires WiFi. |

| Slow Feeder | Dispenses food slowly to prevent overeating | Veterinary clinics, pet health stores | Pros: Promotes healthy eating habits. Cons: Slower dispensing may frustrate pets. |

| Multi-Pet Feeder | Adjustable two-way splitter for simultaneous feeding | Pet care facilities, shelters | Pros: Efficient for multiple pets, reduces competition. Cons: More complex setup, higher maintenance. |

| Portable Feeder | Battery-operated, compact design for travel | Pet travel retailers, mobile pet services | Pros: Convenient for on-the-go feeding. Cons: Limited capacity, may require frequent refills. |

What Are the Characteristics of the Standard Automatic Feeder?

The Standard Automatic Feeder is designed for simplicity, featuring a single bowl and basic timed feeding functionality. It is ideal for small pet stores and individual retailers looking for cost-effective solutions. Buyers should consider its ease of use and setup, but be aware of its limitations in terms of feeding control and features, which may not meet the needs of more sophisticated pet owners.

How Does the WiFi-Enabled Feeder Stand Out in the Market?

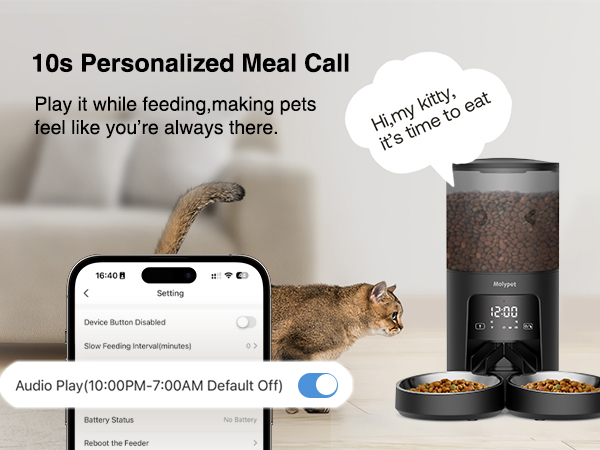

The WiFi-Enabled Feeder allows for remote management via a smartphone app, enabling users to schedule meals and monitor their pet’s eating habits. This type is particularly appealing to e-commerce platforms and tech-savvy retailers. While it offers advanced features like dual bowls and customizable meal schedules, the higher price point and reliance on a stable WiFi connection may deter some buyers.

Why Choose a Slow Feeder for Health-Conscious Pets?

The Slow Feeder is designed to dispense food gradually, promoting healthy eating habits and preventing overeating. This feeder is suitable for veterinary clinics and pet health stores that prioritize pet wellness. Although it encourages better digestion, buyers should consider that the slower dispensing may frustrate pets accustomed to quicker meals.

What Benefits Does a Multi-Pet Feeder Provide for Pet Care Facilities?

The Multi-Pet Feeder features an adjustable two-way splitter, allowing it to serve multiple pets simultaneously. This design is ideal for pet care facilities and shelters, as it minimizes competition for food. While it enhances feeding efficiency, potential buyers should note that the setup is more complex and may require higher maintenance.

When Is a Portable Feeder the Best Option for Pet Owners?

A Portable Feeder is compact and battery-operated, making it ideal for travel or outdoor activities. This type is particularly relevant for pet travel retailers and mobile pet services. While it offers convenience for on-the-go feeding, buyers should be mindful of its limited capacity, which may necessitate more frequent refills during extended trips.

Key Industrial Applications of molypet automatic pet feeder

| Industry/Sector | Specific Application of molypet automatic pet feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care Services | Automated feeding in boarding kennels and pet hotels | Ensures timely feeding schedules, reducing staff workload | Reliability of technology, ease of use, and capacity to handle multiple pets |

| Veterinary Clinics | Post-surgery recovery feeding | Controlled feeding for recovery, minimizing stress on animals | Compatibility with various pet sizes, ease of cleaning, and monitoring features |

| Animal Shelters | Feeding multiple animals simultaneously | Efficient feeding reduces labor costs and improves animal welfare | Durability, ease of refilling, and ability to monitor food intake remotely |

| E-commerce Retail | Online sales of automatic feeders | Expands product offerings, meets growing demand for smart pet products | Competitive pricing, warranty options, and after-sales support |

| Agricultural Enterprises | Feeding for farm cats or other small animals | Streamlines feeding processes, promoting animal health and productivity | Adaptability to different food types, weather resistance, and power options |

How is the Molypet Automatic Pet Feeder Used in Pet Care Services?

In boarding kennels and pet hotels, the Molypet automatic pet feeder automates meal distribution, allowing businesses to maintain consistent feeding schedules without requiring constant human oversight. This is particularly beneficial during peak periods when staff may be overwhelmed. The feeder’s programmable features ensure that pets receive the right portion sizes at set intervals, enhancing their well-being. For international buyers, especially in regions like Africa and South America, it’s essential to consider the feeder’s reliability and ease of use to accommodate varying levels of technical expertise among staff.

What Role Does the Molypet Feeder Play in Veterinary Clinics?

Veterinary clinics utilize the Molypet automatic pet feeder for post-surgery recovery, providing controlled feeding to minimize stress on recovering animals. The ability to set specific portion sizes and feeding times is crucial in ensuring that pets receive the necessary nutrition without overindulgence. Clinics in the Middle East and Europe should prioritize features like easy cleaning and compatibility with different pet sizes, ensuring that the feeder can accommodate a range of animals in recovery.

How Can Animal Shelters Benefit from the Molypet Feeder?

Animal shelters can implement the Molypet automatic pet feeder to provide simultaneous feeding for multiple animals, significantly reducing labor costs and improving operational efficiency. With its dual bowl feature, shelters can cater to different dietary needs while ensuring that all animals receive adequate nutrition. For buyers in regions like Nigeria and Vietnam, sourcing durable feeders that can withstand frequent use and are easy to refill is essential to maintain a high standard of care for sheltered animals.

Why is E-commerce Retail Vital for Automatic Feeders?

E-commerce retailers can benefit from adding the Molypet automatic pet feeder to their product lines, meeting the increasing demand for smart pet care solutions. This feeder not only enhances customer satisfaction through innovative features but also provides retailers with a competitive edge in the market. Buyers from Europe should focus on sourcing products with robust warranty options and reliable after-sales support to ensure customer loyalty and satisfaction.

How Does the Molypet Feeder Assist Agricultural Enterprises?

In agricultural settings, the Molypet automatic pet feeder is an efficient solution for feeding farm cats or other small animals. It streamlines feeding processes, promoting better animal health and productivity while saving time and labor. For international buyers, especially in developing regions, the adaptability of the feeder to different food types and its weather-resistant features are critical considerations for effective long-term use.

3 Common User Pain Points for ‘molypet automatic pet feeder’ & Their Solutions

Scenario 1: Navigating Connectivity Issues with Smart Features

The Problem: B2B buyers often face challenges when integrating smart devices like the Molypet Automatic Pet Feeder into their existing technological ecosystems. In regions where WiFi connectivity is inconsistent, the feeder’s app functionality can become unreliable. This not only disrupts feeding schedules but also leads to frustration among users who rely on remote monitoring and control for pet care.

The Solution: To address connectivity issues, B2B buyers should consider sourcing the Molypet feeder in conjunction with high-quality WiFi extenders or mesh networks. Ensure that the feeder is within the optimal range of the router, and confirm that it supports both 2.4GHz and 5GHz connections, as many devices may only operate on the former. Additionally, users should familiarize themselves with the app’s functionality, including how to reset the device and troubleshoot connectivity issues. Providing training for staff on setup and maintenance can also mitigate future problems, ensuring a smoother user experience.

Scenario 2: Managing Feeding Schedules for Multiple Pets

The Problem: For businesses such as pet care facilities or multi-pet households, managing feeding schedules can be complex and time-consuming. The Molypet feeder’s capability to program multiple meals is a significant advantage; however, users may struggle with configuring these settings correctly, leading to improper feeding times or portion sizes.

The Solution: B2B buyers should leverage the feeder’s advanced programming capabilities by carefully reviewing the user manual and utilizing video tutorials provided in the app. When setting up the feeder, users should take advantage of the dual feeding bowls and adjustable two-way splitter to cater to different pets’ dietary needs. Establishing a consistent feeding routine by setting up meal schedules for each pet can also help. For facilities, consider creating a centralized feeding plan that integrates with the feeder’s app, allowing staff to monitor and adjust meal portions as needed. This strategic approach will ensure each pet receives the appropriate care while minimizing operational hassles.

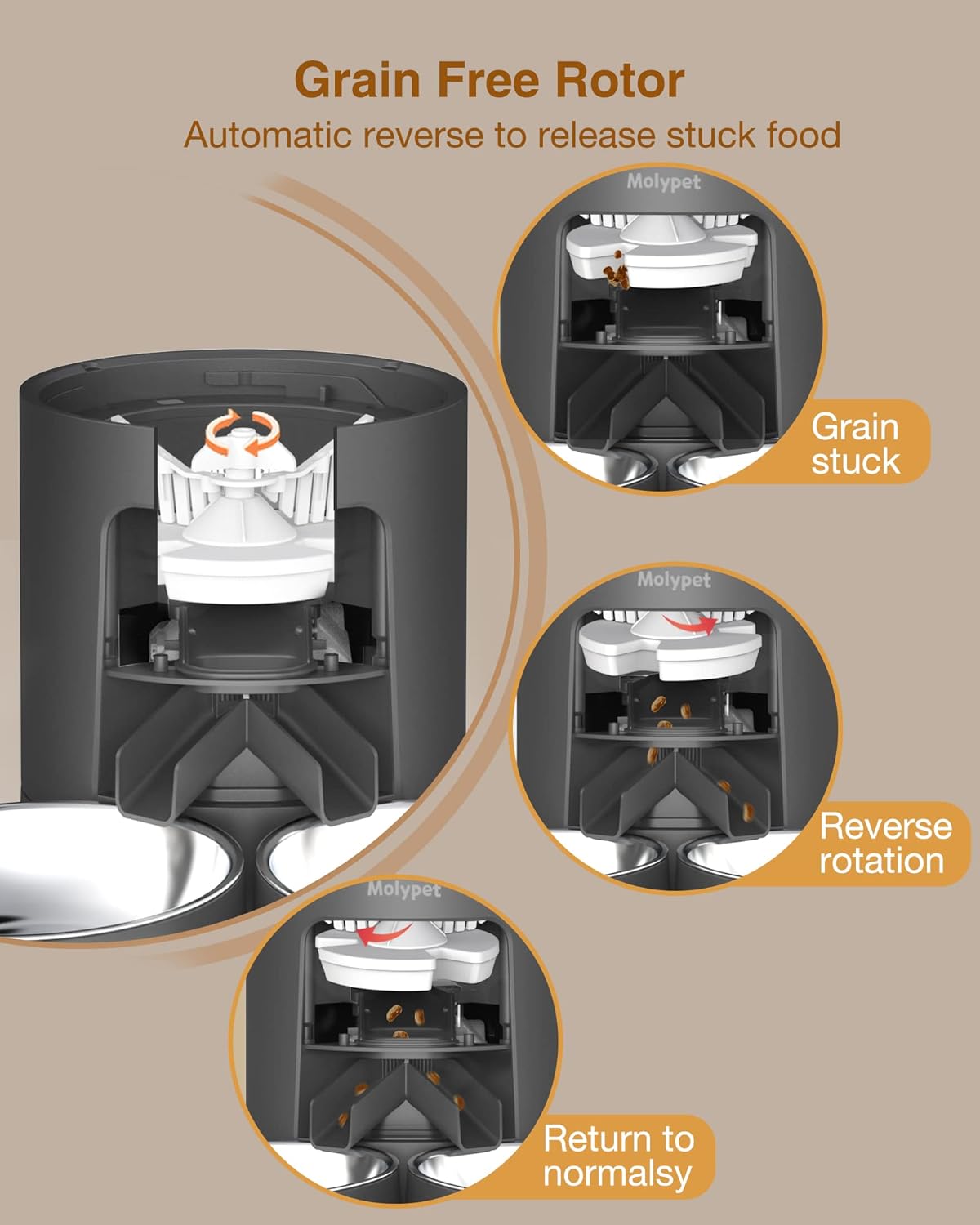

Scenario 3: Ensuring Consistent Maintenance and Cleanliness

The Problem: The maintenance of automatic feeders is a common concern, especially in commercial settings. A lack of regular cleaning can lead to food blockages and unsanitary conditions, impacting the health of pets. B2B buyers may find it challenging to maintain cleanliness without disrupting feeding schedules, especially when dealing with multiple feeders.

The Solution: To streamline maintenance, B2B buyers should implement a scheduled cleaning routine that aligns with the feeder’s capacity and usage. The Molypet feeder is designed for easy disassembly and cleaning, with dishwasher-safe stainless steel bowls. Create a maintenance checklist that includes regular checks for blockages and food freshness. Additionally, consider sourcing additional feeders to rotate during cleaning cycles, ensuring pets always have access to food. Training staff on proper cleaning techniques and the importance of maintaining hygiene standards can significantly enhance the reliability and longevity of the feeders, ensuring a healthier environment for pets.

Illustrative image related to molypet automatic pet feeder

Strategic Material Selection Guide for molypet automatic pet feeder

What Are the Key Materials Used in the Molypet Automatic Pet Feeder?

The Molypet Automatic Pet Feeder is designed with several materials that contribute to its functionality and durability. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, especially those operating in diverse international markets.

How Does Plastic Contribute to the Feeder’s Performance?

Plastic is a primary material used in the Molypet Automatic Pet Feeder, particularly for its body and components. Key properties include lightweight, corrosion resistance, and ease of molding into complex shapes. Plastics can withstand typical operating temperatures but may degrade under extreme heat.

Pros: The affordability and versatility of plastic make it an attractive option for manufacturers. It is easy to produce and can be designed in various colors and finishes to appeal to different markets.

Cons: While plastic is durable, it may not withstand prolonged exposure to UV light, leading to potential brittleness over time. Additionally, cheaper plastics may not comply with international safety standards, which is a concern for buyers in regions with strict regulations.

Impact on Application: Plastic is suitable for housing components that do not come into direct contact with food, but it should be food-grade to ensure safety.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with standards such as FDA regulations in the U.S. or EU food safety standards. Countries like Nigeria and Vietnam may have specific import regulations regarding plastic materials.

What Role Does Stainless Steel Play in the Feeder’s Design?

Stainless steel is utilized for the feeder’s bowls and some internal components due to its excellent corrosion resistance and durability. It can withstand high temperatures and is less likely to harbor bacteria compared to plastic.

Pros: Stainless steel is highly durable and resistant to rust and staining, making it an ideal choice for food contact surfaces. It also has a premium aesthetic that appeals to consumers.

Cons: The primary drawback is the higher cost of stainless steel compared to plastic. Additionally, it is heavier, which may impact shipping costs for international buyers.

Impact on Application: Stainless steel bowls are suitable for all types of pet food and can be easily cleaned, promoting hygiene.

Considerations for International Buyers: Buyers should verify that the stainless steel used is of food-grade quality and meets international standards such as ASTM or JIS. In regions with high humidity, like parts of South America and the Middle East, corrosion resistance is particularly important.

Illustrative image related to molypet automatic pet feeder

How Does Electronic Component Material Affect Functionality?

The Molypet feeder incorporates electronic components for smart features, such as app connectivity and portion control. These components are typically made from a combination of plastics and metals.

Pros: The integration of smart technology provides convenience and enhances the user experience, allowing for remote feeding schedules and monitoring.

Cons: Electronic components can be sensitive to environmental factors such as moisture and temperature, which may affect reliability. Additionally, the complexity of manufacturing these components can lead to higher production costs.

Impact on Application: The use of electronic components enables advanced features but requires careful consideration of the operating environment to ensure longevity.

Illustrative image related to molypet automatic pet feeder

Considerations for International Buyers: Buyers should ensure that the electronic components comply with local electrical safety standards and certifications, which can vary significantly across regions.

What Are the Implications of Using Rubber for Seals and Gaskets?

Rubber is often used for seals and gaskets in the Molypet Automatic Pet Feeder to prevent leaks and maintain freshness.

Pros: Rubber provides an excellent seal, is flexible, and can accommodate various shapes and sizes, ensuring that the feeder remains airtight.

Cons: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures, which can lead to failure of the sealing function.

Impact on Application: Effective sealing is crucial for maintaining the freshness of pet food, which is essential for pet health.

Illustrative image related to molypet automatic pet feeder

Considerations for International Buyers: Buyers should look for rubber materials that meet international standards for durability and safety, particularly in regions with extreme weather conditions.

Summary Table of Material Selection for Molypet Automatic Pet Feeder

| Material | Typical Use Case for molypet automatic pet feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Body and components | Lightweight and cost-effective | May degrade under UV exposure | Low |

| Stainless Steel | Bowls and food contact surfaces | Durable and corrosion-resistant | Higher cost and weight | High |

| Electronic Components | Smart features and controls | Enhances user experience with app connectivity | Sensitive to environmental factors | Med |

| Rubber | Seals and gaskets | Excellent sealing properties | Can degrade over time | Med |

This detailed analysis of materials used in the Molypet Automatic Pet Feeder provides B2B buyers with critical insights necessary for making informed purchasing decisions, especially in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for molypet automatic pet feeder

What Are the Key Stages in the Manufacturing Process of the Molypet Automatic Pet Feeder?

The manufacturing process of the Molypet Automatic Pet Feeder involves several critical stages, each designed to ensure the product meets high-quality standards.

Material Preparation: Sourcing and Quality Control

The first step involves sourcing high-quality materials such as BPA-free plastic and stainless steel for the feeder’s construction. Suppliers are carefully vetted to ensure compliance with international safety standards. Materials undergo incoming quality control (IQC) checks to confirm they meet specifications before they are accepted for production. This initial inspection is crucial as it sets the foundation for the entire manufacturing process.

Forming: Precision Engineering Techniques

Once materials are verified, the forming stage begins. This typically involves advanced techniques such as injection molding for plastic components and stamping for metal parts. The use of precise molds ensures that each component fits perfectly, reducing the likelihood of defects during assembly. Additionally, technologies like computer numerical control (CNC) machining may be employed for intricate parts, ensuring high accuracy and repeatability.

Assembly: Streamlined Processes for Efficiency

The assembly of the Molypet feeder is conducted in a controlled environment to minimize contamination. Automated assembly lines often handle repetitive tasks, while skilled workers manage intricate assembly processes that require human oversight. Quality checkpoints are integrated into the assembly line to catch any defects early, ensuring that only products meeting quality standards proceed to the next phase.

Finishing: Quality and Aesthetic Considerations

The finishing stage includes processes such as surface treatment, painting, and assembly of electronic components. This stage not only enhances the aesthetic appeal of the feeder but also improves its durability. For example, stainless steel parts might undergo polishing to prevent rust and corrosion. Final inspections are conducted to ensure the product is both visually appealing and mechanically sound before packaging.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance is a pivotal aspect of the Molypet feeder’s manufacturing, ensuring that the final product meets both international standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

The Molypet Automatic Pet Feeder adheres to several international quality standards, including ISO 9001 for quality management systems. Compliance with these standards demonstrates a commitment to consistent quality and customer satisfaction. Additionally, certifications like CE mark (for European markets) and compliance with American National Standards Institute (ANSI) regulations ensure the product meets safety and performance benchmarks.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint verifies the quality of materials before production begins.

- In-Process Quality Control (IPQC): During assembly, regular checks are conducted to identify defects early. This includes functionality tests for electronic components and visual inspections of assembled parts.

- Final Quality Control (FQC): Before packaging, the completed feeders undergo a thorough inspection, including performance tests to verify functionality, safety checks for electrical components, and aesthetic evaluations.

What Common Testing Methods Are Used?

Testing methods for the Molypet feeder include:

- Functional Testing: Ensures that all features, such as portion control and WiFi connectivity, operate as intended.

- Durability Testing: Assesses the product’s performance under various environmental conditions, simulating long-term use.

- Safety Testing: Evaluates the feeder’s electrical components to prevent hazards, ensuring compliance with relevant safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control processes of suppliers.

What Audit Practices Should Buyers Consider?

Conducting on-site audits of the manufacturing facility is an effective way to assess quality control practices. Buyers can evaluate the supplier’s adherence to international standards and observe their production processes firsthand. This transparency builds trust and ensures that the supplier is committed to maintaining high-quality standards.

What Documentation Should Be Requested?

Buyers should request comprehensive documentation, including:

- Quality Control Reports: These documents should detail the results of inspections and tests conducted at various stages of production.

- Certification Copies: Proof of compliance with international standards, such as ISO and CE certifications.

- Traceability Records: Documentation that traces materials from suppliers through the manufacturing process, which is particularly important for ensuring accountability.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards for pet products. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply with these standards. For instance, certain countries may have stricter requirements regarding materials used in pet products, which could affect sourcing decisions.

What Role Does Third-Party Inspection Play?

Engaging third-party inspection services can provide an additional layer of assurance for buyers. These independent entities can conduct thorough inspections and audits, providing unbiased reports on the supplier’s quality control practices. This step can be particularly beneficial when dealing with suppliers in regions where direct audits may not be feasible.

Conclusion: Ensuring Quality in Your Supply Chain

Understanding the manufacturing processes and quality assurance practices of the Molypet Automatic Pet Feeder is crucial for B2B buyers. By focusing on key manufacturing stages and implementing robust quality control measures, suppliers can deliver reliable and high-quality products. Buyers must actively engage in verifying these practices to ensure they partner with suppliers who prioritize quality and compliance, ultimately leading to satisfied end-users and successful business outcomes.

Illustrative image related to molypet automatic pet feeder

Practical Sourcing Guide: A Step-by-Step Checklist for ‘molypet automatic pet feeder’

The following guide serves as a practical checklist for B2B buyers interested in sourcing the Molypet Automatic Pet Feeder. This comprehensive approach will ensure that you make informed decisions, optimize procurement processes, and establish long-lasting supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, clearly outline the technical specifications required for the Molypet Automatic Pet Feeder. Consider factors such as capacity (6L), connectivity options (5G and 2.4G WiFi), and specific features like programmable meal schedules and dual bowls. This clarity will help you evaluate whether potential products meet your operational needs.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers of the Molypet Automatic Pet Feeder. Look for companies with a proven track record in the pet product industry, particularly those with experience in your target markets (Africa, South America, Middle East, Europe). Utilize online platforms, trade shows, and industry publications to compile a list of potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality assurance processes, and customer service responsiveness. This due diligence will help mitigate risks associated with procurement.

Illustrative image related to molypet automatic pet feeder

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the Molypet Automatic Pet Feeder. Testing samples allows you to evaluate the product’s quality, functionality, and user experience first-hand. Pay attention to specific features like portion control and app connectivity to ensure they align with your expectations and operational requirements.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with selected suppliers to secure favorable pricing and payment terms. Consider bulk purchase discounts, shipping costs, and warranty conditions. Transparent negotiations will help establish a foundation for a mutually beneficial relationship while ensuring budget adherence.

Step 6: Verify Compliance and Certifications

Ensure that the Molypet feeders comply with relevant safety and quality standards applicable in your target markets. Request documentation for certifications such as ISO, CE, or others relevant to pet products. Compliance not only assures product safety but also enhances your brand reputation in the marketplace.

Step 7: Establish a Logistics Plan

Develop a logistics plan to manage the procurement and distribution of the Molypet Automatic Pet Feeders. Consider factors such as shipping methods, lead times, and inventory management. A well-structured logistics plan will streamline operations and ensure timely delivery to your customers.

Illustrative image related to molypet automatic pet feeder

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for the Molypet Automatic Pet Feeder, ensuring that they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for molypet automatic pet feeder Sourcing

What Are the Key Cost Components for Sourcing the Molypet Automatic Pet Feeder?

When sourcing the Molypet Automatic Pet Feeder, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary materials used in the Molypet feeder include stainless steel for the bowls and durable plastic for the body. The choice of materials affects not only the cost but also the quality and longevity of the product. Higher-quality materials can lead to increased costs but may reduce long-term replacement expenses.

-

Labor: Labor costs will vary based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can sometimes correlate with lower quality standards. It’s essential to balance labor costs with the expected quality.

-

Manufacturing Overhead: This encompasses expenses related to factory maintenance, utilities, and equipment depreciation. Manufacturers may pass these costs onto buyers, impacting the final price.

-

Tooling: Initial tooling costs for molds and machinery set-up can be significant, especially for custom or specialized feeders. Buyers should inquire about these costs, as they may be reflected in the unit price.

-

Quality Control (QC): Rigorous QC processes ensure product reliability. However, comprehensive QC can increase costs. Buyers should assess the balance between QC expenditures and the assurance of product quality.

-

Logistics: Shipping costs can vary widely based on the origin of the product and destination. Factors such as shipping method, distance, and customs duties must be considered when calculating total costs.

-

Margin: Supplier margins are typically factored into the final price. These margins can vary based on the supplier’s market position, brand reputation, and the level of service provided.

How Do Price Influencers Impact the Cost of the Molypet Automatic Pet Feeder?

Several factors influence the pricing of the Molypet Automatic Pet Feeder, which international buyers should carefully consider.

-

Volume/MOQ: Minimum order quantities (MOQs) often impact pricing significantly. Higher volume orders can lead to lower per-unit costs, providing leverage for buyers seeking to optimize their budgets.

-

Specifications and Customization: Custom features or specifications can increase costs. If buyers require specific branding or additional functionalities, they should discuss these needs upfront to understand the associated costs.

-

Materials and Quality Certifications: The choice of materials and any required certifications (such as safety and environmental standards) can impact pricing. Buyers should ensure that the materials meet local regulations, particularly in regions with stringent import standards.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge a premium for their products but often offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is essential for international buyers as they define responsibilities for shipping, insurance, and tariffs. This knowledge can help avoid unexpected costs.

What Tips Can Help Buyers Negotiate Better Prices for the Molypet Automatic Pet Feeder?

Buyers looking to source the Molypet Automatic Pet Feeder should consider several strategies to enhance their negotiating position and ensure cost-efficiency.

-

Negotiation: Building a strong relationship with suppliers can lead to better pricing and terms. Engage in open discussions about potential discounts for bulk orders or long-term contracts.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the purchase price. Consider factors such as maintenance, durability, and replacement frequency to make a more informed decision.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional market conditions that may affect pricing. Negotiating based on local market trends can yield favorable terms.

In summary, a comprehensive understanding of the cost structure, price influencers, and negotiation strategies is vital for international buyers sourcing the Molypet Automatic Pet Feeder. Being well-informed can lead to better purchasing decisions, ensuring both quality and value in their investments.

Illustrative image related to molypet automatic pet feeder

Alternatives Analysis: Comparing molypet automatic pet feeder With Other Solutions

Exploring Alternatives to the Molypet Automatic Pet Feeder

When considering automated feeding solutions for pets, it’s essential to evaluate various options available in the market. The Molypet Automatic Pet Feeder is a popular choice due to its advanced features and user-friendly design. However, there are several alternatives that may better suit specific needs or budgets. This analysis compares the Molypet feeder with two other viable solutions: the PetSafe Smart Feed and the WOPET Automatic Pet Feeder.

| Comparison Aspect | Molypet Automatic Pet Feeder | PetSafe Smart Feed | WOPET Automatic Pet Feeder |

|---|---|---|---|

| Performance | Supports up to 10 meals/day; customizable portion control (1-50 portions) | Up to 12 meals/day; flexible portion sizes | Up to 4 meals/day; adjustable portions |

| Cost | Moderate ($100-$130) | Higher ($150-$200) | Lower ($50-$80) |

| Ease of Implementation | User-friendly app; dual bowl option; setup via WiFi | Intuitive app; easy installation; WiFi connectivity | Simple setup; not WiFi enabled |

| Maintenance | Easy to clean; dishwasher-safe bowls; low food alerts | Moderate maintenance; requires regular cleaning | Simple cleaning; less frequent refills |

| Best Use Case | Ideal for multi-pet households; busy owners needing flexibility | Best for tech-savvy users wanting advanced features | Suitable for budget-conscious pet owners |

In-Depth Analysis of Alternatives

PetSafe Smart Feed

The PetSafe Smart Feed is a premium option that stands out for its advanced connectivity features. It allows pet owners to control feeding schedules and portions via a user-friendly mobile app. This feeder supports up to 12 meals a day and offers flexible portion sizes, making it ideal for pets with specific dietary needs. However, its higher price point may deter budget-conscious buyers, and the setup process, while intuitive, may require a slightly longer learning curve for some users.

WOPET Automatic Pet Feeder

The WOPET Automatic Pet Feeder is a more economical choice that provides essential feeding functionalities without the complexities of smart technology. It can dispense up to 4 meals a day and features adjustable portion sizes, making it a reliable option for pet owners who prefer simplicity. While it lacks WiFi connectivity, which limits remote control capabilities, it is straightforward to set up and maintain. This makes it particularly appealing for pet owners who are looking for a cost-effective solution without sacrificing quality.

Making the Right Choice for Your Needs

When selecting an automatic pet feeder, B2B buyers should consider their specific requirements, including budget, the number of pets, and desired features. The Molypet Automatic Pet Feeder excels in providing advanced functionalities, making it suitable for those who value flexibility and control. On the other hand, for businesses catering to budget-conscious customers, the WOPET feeder offers a solid alternative without the frills. The PetSafe Smart Feed appeals to tech-savvy users willing to invest in more sophisticated features. Ultimately, understanding the unique needs of the target market will guide buyers in choosing the most appropriate feeding solution.

Illustrative image related to molypet automatic pet feeder

Essential Technical Properties and Trade Terminology for molypet automatic pet feeder

What Are the Key Technical Properties of the Molypet Automatic Pet Feeder?

1. Capacity (6L)

The Molypet Automatic Pet Feeder has a food storage capacity of 6 liters, approximately equivalent to 25.4 cups of dry food. This large capacity is significant for B2B buyers as it reduces the frequency of refills, making it ideal for pet owners with busy schedules or those who manage multiple pets. A larger capacity also appeals to retailers looking to offer convenience to their customers.

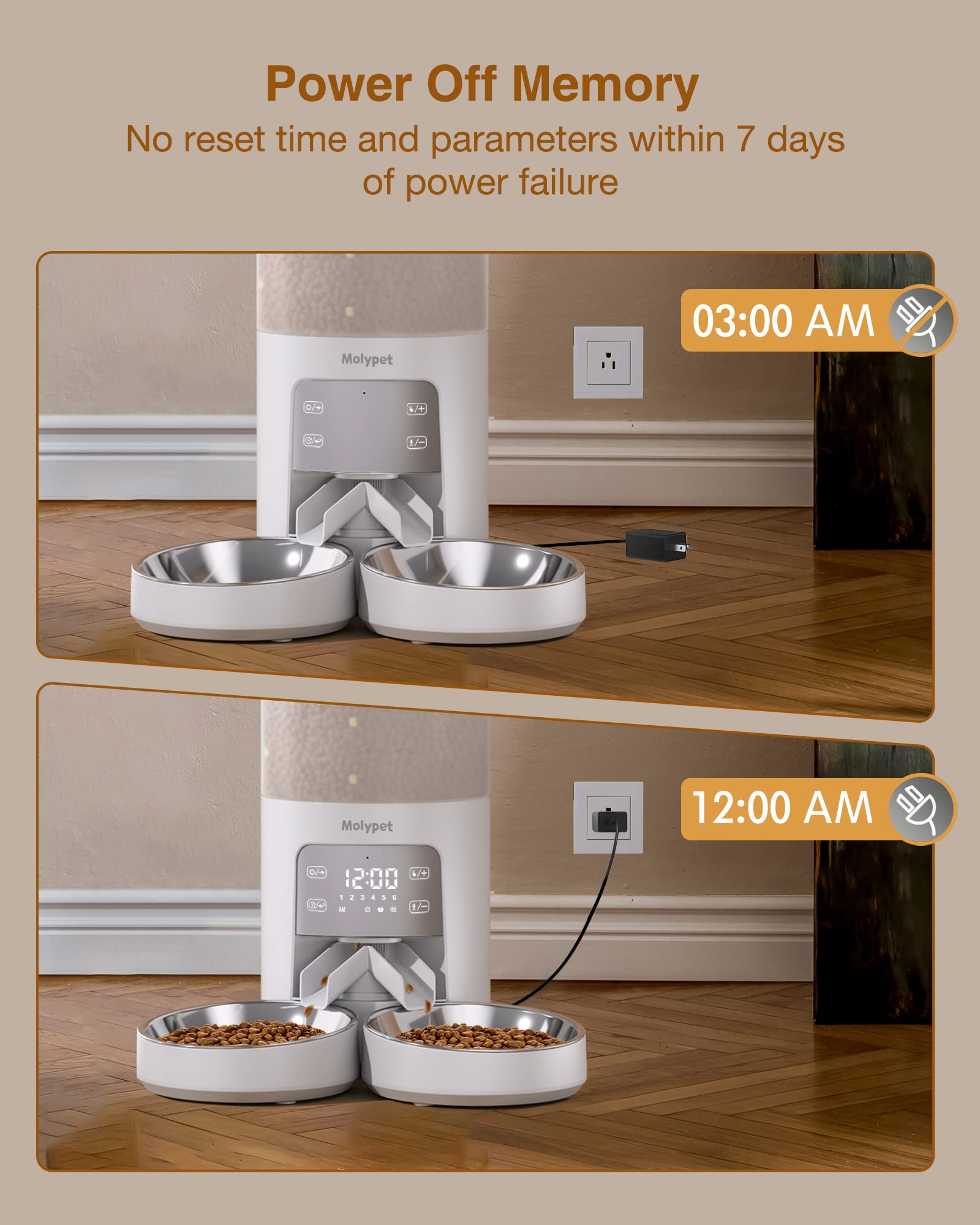

2. Power Supply Options (5V USB and Battery Backup)

This feeder operates using a 5V USB adapter and can also be powered by three D-cell alkaline batteries (not included). The dual power supply is essential for ensuring uninterrupted operation, particularly in regions with unstable electricity supply. For B2B buyers, this feature enhances product reliability and can be a key selling point in markets where power outages are common.

3. Connectivity (5G & 2.4GHz WiFi)

Equipped with both 5G and 2.4GHz WiFi connectivity, the feeder allows users to control it via a dedicated smartphone app. This feature is vital for tech-savvy consumers and pet owners who prioritize smart home integration. B2B buyers should consider this specification as it opens opportunities for partnerships with smart home product distributors.

4. Programmable Feeding Schedule (Up to 10 Meals)

The Molypet feeder can be programmed to dispense up to 10 meals per day, with portion sizes adjustable from 1 to 50 servings. This capability is important for pet health management, enabling precise dietary control. For retailers, promoting this feature can attract health-conscious pet owners, a growing demographic in the pet care market.

Illustrative image related to molypet automatic pet feeder

5. Material Composition (Stainless Steel and BPA-Free Plastic)

Constructed from stainless steel and BPA-free plastic, the feeder is designed for durability and safety. Stainless steel is resistant to corrosion and bacteria, making it a hygienic choice. B2B buyers should emphasize this aspect to assure customers of the product’s quality and longevity, especially in competitive markets.

Which Trade Terminology Should B2B Buyers Know Regarding Molypet Automatic Pet Feeder?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed by another company under its own brand. Understanding OEM relationships is crucial for B2B buyers as it can affect pricing, customization options, and supply chain dynamics.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers to understand, as it impacts inventory management and cash flow. Buyers must negotiate favorable MOQs to ensure they can meet market demand without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This term is vital for B2B transactions, enabling buyers to compare offers and negotiate better deals. A well-crafted RFQ can streamline procurement and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is essential for B2B buyers engaged in global trade, as they clarify who bears costs and risks at various stages of the shipping process.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each product and variant. It is important for inventory management and sales tracking. B2B buyers should leverage SKUs to optimize their supply chain and maintain accurate stock levels, ensuring they meet customer demands efficiently.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing the Molypet Automatic Pet Feeder, enhancing their business operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the molypet automatic pet feeder Sector

What are the Current Market Dynamics and Key Trends in the Molypet Automatic Pet Feeder Sector?

The global pet care market is experiencing substantial growth, driven by increasing pet ownership and a growing focus on pet wellness. In regions such as Africa, South America, the Middle East, and Europe, the demand for innovative pet care solutions, including automatic feeders like the Molypet, is rising. Key trends include the integration of technology in pet products, such as smart feeders that can be controlled via mobile apps, enabling pet owners to manage feeding schedules remotely. This tech-savvy approach appeals particularly to younger demographics who value convenience and connectivity.

Moreover, the rising trend of dual feeding solutions, as seen in the Molypet Automatic Pet Feeder, caters to households with multiple pets, enhancing user experience and reducing competition among pets. Sustainability is also becoming a significant factor; consumers are increasingly seeking products that align with their environmental values. As a result, suppliers must be prepared to meet the demand for eco-friendly materials and manufacturing processes.

International B2B buyers should also be aware of regional market dynamics. For instance, in countries like Nigeria and Vietnam, the rapid urbanization and the shift towards western-style pet care practices present unique opportunities. Local distributors and retailers are increasingly looking for reliable partners that can provide not only quality products but also ongoing support and training for effective product usage.

How is Sustainability and Ethical Sourcing Shaping the Molypet Automatic Pet Feeder Market?

Sustainability and ethical sourcing have become pivotal in the pet product industry, influencing purchasing decisions among B2B buyers. The environmental impact of pet feeders, including materials used and manufacturing processes, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recyclable materials and reducing carbon footprints during production.

Illustrative image related to molypet automatic pet feeder

For the Molypet Automatic Pet Feeder, incorporating sustainable materials like BPA-free plastics and stainless steel not only meets consumer demand but also enhances brand reputation. Suppliers that can provide certifications for sustainability, such as ISO 14001, or product-specific certifications that verify eco-friendly claims, will stand out in the competitive market.

Additionally, ethical sourcing practices that ensure fair labor conditions throughout the supply chain are gaining importance. Buyers should prioritize partnerships with manufacturers that are transparent about their sourcing practices, demonstrating a commitment to social responsibility. This focus on sustainability and ethics not only attracts environmentally conscious consumers but also aligns with the global shift towards responsible business practices.

How Has the Molypet Automatic Pet Feeder Evolved Over Time?

The Molypet Automatic Pet Feeder has evolved significantly from basic manual feeders to advanced automated systems that cater to the needs of modern pet owners. Initially, pet feeders primarily focused on simplicity and functionality. However, as technology advanced and consumer expectations grew, features such as programmable feeding schedules, portion control, and smart app connectivity were introduced.

Illustrative image related to molypet automatic pet feeder

This evolution reflects a broader trend in the pet care industry towards automation and convenience, driven by the fast-paced lifestyles of pet owners. Today’s Molypet feeders not only ensure timely feeding but also promote healthier eating habits through features like slow feeding modes. This transition highlights the importance of innovation in maintaining competitiveness in the pet care market, especially for B2B buyers looking to provide their customers with the latest solutions in pet care technology.

Frequently Asked Questions (FAQs) for B2B Buyers of molypet automatic pet feeder

-

How do I troubleshoot issues with the Molypet Automatic Pet Feeder?

To troubleshoot issues with the Molypet Automatic Pet Feeder, first check for common problems such as food blockages, power supply issues, or app connectivity. Ensure the food container is not empty and that the outlet is clear of obstructions. If the feeder is unresponsive, verify that it is connected to a stable WiFi network (5G or 2.4G). The app provides notifications for low food and blockages, so monitor these alerts closely. For persistent issues, consult the user manual or contact the supplier for technical support. -

What is the best way to ensure timely delivery of Molypet feeders in international markets?

To ensure timely delivery of Molypet feeders, establish clear communication with your supplier regarding shipping terms and timelines. Utilize reputable logistics partners who specialize in international shipping to avoid delays. It’s essential to understand the customs regulations of your target market, as this can affect delivery times. Consider ordering in bulk to take advantage of faster shipping options and reduced costs. Tracking shipments and maintaining open lines of communication with logistics providers can also help manage delivery expectations. -

What customization options are available for the Molypet Automatic Pet Feeder?

Customization options for the Molypet Automatic Pet Feeder may include branding, color variations, and specific features tailored to different market needs. When sourcing, inquire about the possibility of adding your company logo or packaging designs that resonate with your target audience. Discussing minimum order quantities (MOQs) for customized products is crucial, as many suppliers may have specific requirements. Ensure that any modifications align with the product’s functionality and maintain quality standards. -

What are the minimum order quantities (MOQs) for purchasing Molypet feeders?

The minimum order quantities (MOQs) for Molypet feeders can vary based on the supplier and the specific model. Typically, MOQs may range from a few dozen to several hundred units. When negotiating with suppliers, clarify the MOQs early in the discussion to avoid misunderstandings. Consider consolidating orders with other products or collaborating with other businesses to meet MOQs, which can also enhance your purchasing power. -

What payment terms can I expect when sourcing Molypet feeders?

Payment terms for sourcing Molypet feeders will depend on the supplier’s policies and your negotiation. Common terms include a deposit upfront (usually 30%) with the balance due before shipment, or payment in full prior to production. Some suppliers may offer credit terms for established customers, which could include net 30 or net 60 days. Always ensure that payment methods are secure and consider using escrow services for larger transactions to mitigate risks. -

How can I ensure the quality of Molypet feeders before making a bulk purchase?

To ensure quality before making a bulk purchase of Molypet feeders, request samples for testing. Conduct thorough inspections to assess the product’s materials, functionality, and durability. It is also beneficial to review the supplier’s quality assurance processes and certifications. Establish a quality control agreement that outlines specific standards and inspection protocols for your order. Building a relationship with the supplier can also facilitate better transparency regarding product quality. -

What logistics considerations should I keep in mind when importing Molypet feeders?

When importing Molypet feeders, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Evaluate whether air freight or sea freight is more suitable for your delivery timelines and budget. Understanding the import duties and taxes for your specific country is essential to avoid unexpected costs. Collaborate with a freight forwarder to streamline the logistics process and ensure compliance with local regulations. -

Are there warranty and support options for the Molypet Automatic Pet Feeder?

Yes, the Molypet Automatic Pet Feeder typically comes with a manufacturer’s warranty, often covering defects in materials and workmanship for a specified period (usually one year). As a B2B buyer, it’s important to clarify the warranty terms with your supplier and understand the process for claims. Additionally, inquire about ongoing support options, including technical assistance and replacement parts, to ensure that you can address any issues that arise post-purchase efficiently.

Top 2 Molypet Automatic Pet Feeder Manufacturers & Suppliers List

1. Molypet – Automatic Pet Cat Feeder

Domain: petscathouse.com

Registered: 2023 (2 years)

Introduction: Molypet Automatic Pet Cat Feeder; designed for easy setup and operation; includes instructions for assembly and programming meal schedules; features portion control, voice recording, and power options (battery or USB); troubleshooting tips included; user-friendly guide for consistent feeding routine.

2. Molypet – F02W Smart Pet Feeder

Domain: manuals.plus

Introduction: {‘Brand’: ‘Molypet’, ‘Model_Name’: ‘F02W’, ‘Capacity’: ‘6L (approx. 25.4 cups)’, ‘Connectivity’: ‘5G & 2.4GHz WiFi’, ‘App_Control’: ‘Yes’, ‘Meals_Per_Day’: ‘Up to 10’, ‘Portions_Per_Meal’: ‘1-50 portions’, ‘Power_Supply’: ‘5V USB Adapter (included), 3 x D-cell batteries (not included)’, ‘Material’: ‘Stainless Steel, Plastic’, ‘Item_Dimensions’: ‘7.71 x 7.72 x 17.72 inches’, ‘Item_Weight’: ‘6.49 po…

Strategic Sourcing Conclusion and Outlook for molypet automatic pet feeder

In summary, the Molypet Automatic Pet Feeder offers significant advantages for B2B buyers looking to enhance their product offerings in the pet care market. Key features such as smart app control, dual feeding capabilities, and reliable portion management cater to the growing demand for convenient and efficient pet feeding solutions. The user-friendly design, coupled with robust customer support resources, ensures that both retailers and end-users can maximize the product’s utility.

Strategic sourcing of the Molypet Automatic Pet Feeder not only allows businesses to tap into a burgeoning market but also positions them to meet the diverse needs of pet owners across various regions, including Africa, South America, the Middle East, and Europe. By leveraging competitive pricing and high-quality manufacturing, businesses can create value for their customers while driving profitability.

Looking ahead, international B2B buyers should consider integrating the Molypet feeder into their product lines to capitalize on the increasing pet ownership trends. As consumer preferences shift towards smart and automated solutions, now is the opportune time to invest in reliable products that can enhance the pet care experience. Engage with suppliers today to explore partnership opportunities and elevate your offerings in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to molypet automatic pet feeder

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.