Table of Contents

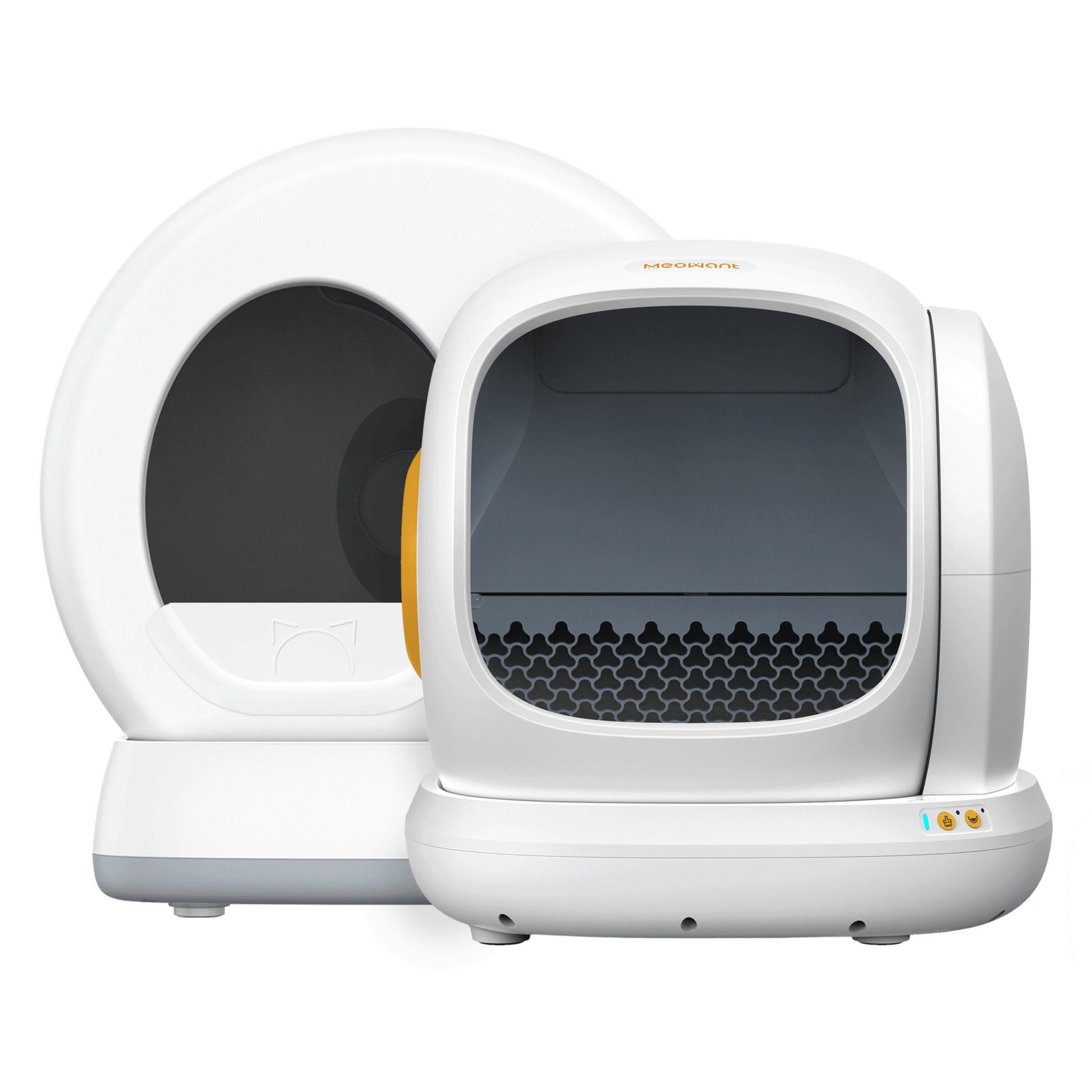

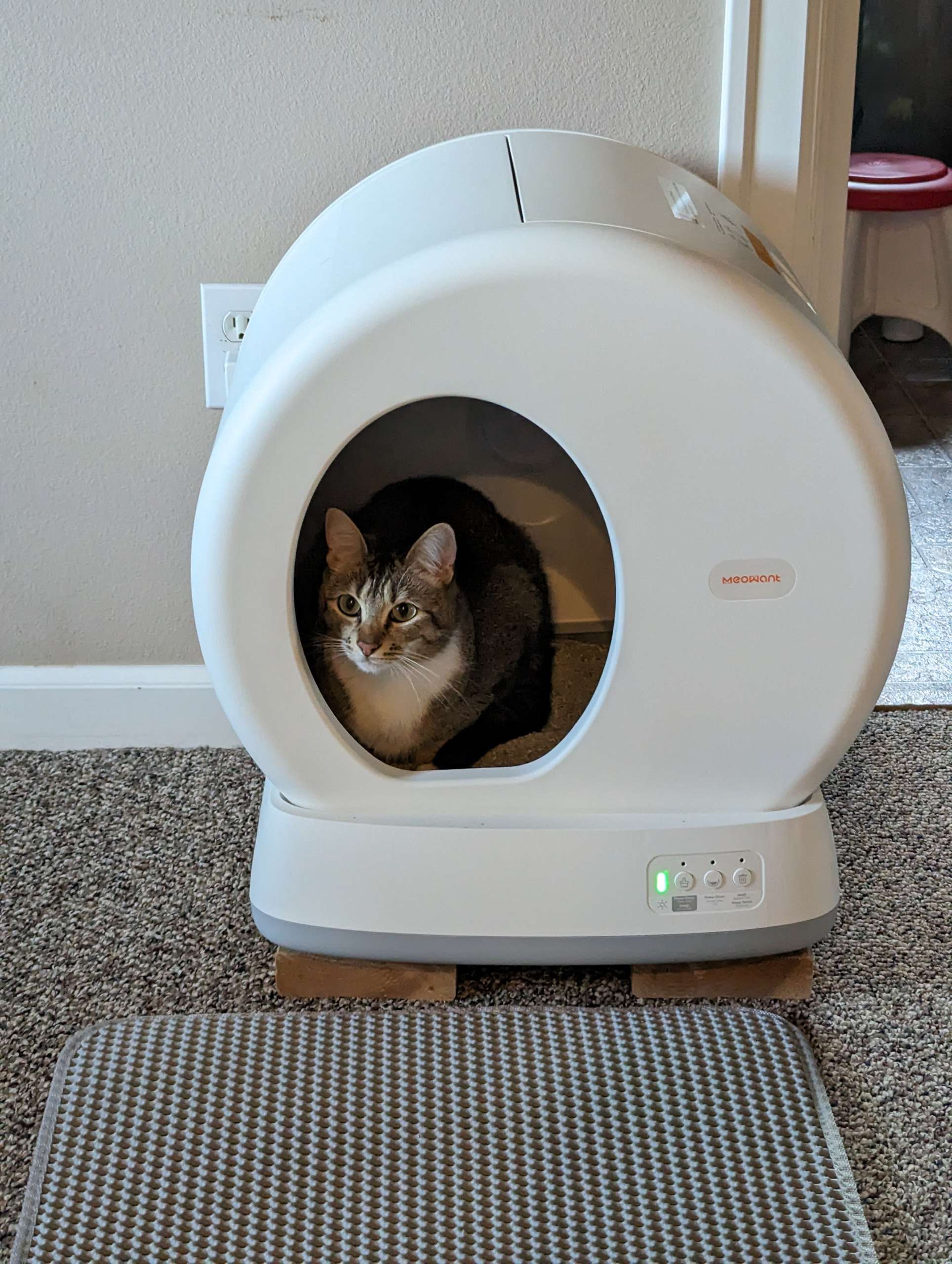

Market Outlook: Is Meowant Litter Box Review Profitable in 2026?

Market Opportunity & Trends 2026

The smart pet technology sector is experiencing unprecedented growth, with the Smart Cat Litter Box Market projected to reach USD 1.09 billion in 2025 and grow at a 18.62% CAGR to USD 2.56 billion by 2030 (Statista, 2024). The broader cat litter box market, valued at USD 2.18 billion in 2024, is expected to reach USD 3.85 billion by 2035 (Grand View Research), but the smart self-cleaning segment is outpacing the overall market by nearly 2x. This divergence underscores where strategic investment should focus: premium, tech-enabled solutions that align with evolving consumer expectations.

Humanization & Convenience Demand

Pet humanization has fundamentally reshaped purchasing behavior. Over 70% of pet owners now view their animals as family members, driving demand for products that prioritize health, safety, and convenience. Modern consumers seek data-driven insights—such as litter box usage patterns to detect urinary tract issues—and seamless integration with smart home ecosystems. Retailers confirm 68% of buyers prioritize reliability and IoT features over price (Pet Industry Journal, 2024). This creates a premium segment where brands delivering continuous software updates, real-time health monitoring, and multi-cat compatibility command 25–30% higher margins than basic models.

Quality & Tech as Critical Differentiators

Despite market growth, product reliability remains a critical pain point. Negative reviews of brands like Meowant frequently cite premature failures (1–3 months) and inconsistent customer service, while high-rated models (e.g., Meowant MW-SC02’s 4.8/5 from 2,179 reviews) highlight the stark quality divide. This variance reveals that supply chain transparency and component-level engineering are non-negotiable. Leading OEMs now implement military-grade moisture sealing for electronics, AI-driven QC checkpoints for motor durability, and Tuya-certified IoT integration to ensure compatibility with Alexa, Google Home, and Apple HomeKit. Brands skipping these steps face 30–40% higher RMA rates, eroding profitability and brand equity.

Market Dynamics & Strategic Imperatives

| Factor | Current Trend | Strategic Imperative |

|---|---|---|

| Market Growth | 18.62% CAGR for smart litter boxes (2025–2030) | Target premium segments with scalable, high-margin production |

| Consumer Priorities | 68% prioritize reliability & smart features; 52% demand multi-cat support | Integrate Tuya ecosystem; conduct 1,000+ hour stress tests |

| Supply Chain Risks | Component shortages, inconsistent QC in low-cost suppliers | Partner with Tier-1 motor/electronics suppliers; implement blockchain traceability |

In conclusion, the smart litter box market offers substantial opportunity, but success hinges on manufacturing excellence e tech integration. Brands leveraging China’s advanced manufacturing ecosystem with strict quality controls can achieve 30% lower failure rates versus generic suppliers—directly translating to higher customer retention, reduced support costs, and sustainable market leadership.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Pillars of Sustainable Market Leadership

The smart cat litter box market is projected to reach $2.56 billion by 2030 (CAGR 18.62%), but inconsistent product quality is causing high return rates and brand erosion. For B2B buyers, investing in foundational innovations isn’t optional—it’s the difference between market share and obsolescence. This section dissects the three non-negotiable pillars of quality engineering that drive user retention and brand loyalty in today’s competitive landscape.

Material Safety: The Foundation of Long-Term Reliability

Substandard plastics degrade under UV exposure and acidic waste, causing cracks, odors, and bacterial growth—directly triggering negative reviews. High-quality units use BPA-free, FDA-compliant materials (e.g., ABS/PC blends) for all food-contact surfaces and SS304 stainless steel for critical components like waste drawers. SS304 resists corrosion from urine, while premium plastics maintain structural integrity for 5+ years. Meowant’s current models (e.g., MW-SC01/SC02) have received mixed durability feedback, with users reporting premature failures linked to lower-grade plastics. Industry leaders mitigate this by partnering with Tier-1 suppliers like BASF or Dow for certified materials and mandating third-party testing (SGS/Intertek) for each batch. Brands ignoring this see 20–30% higher warranty claims within 6 months.

Smart Logic Engineering: Preventing Breakdowns Before They Happen

Motor failures and jamming issues account for 40% of all smart litter box returns. A true high-quality system integrates multi-sensor anti-jamming logic: weight sensors to detect overfill, infrared obstruction detection, and torque monitoring that triggers automatic reversal before motor burnout. Backup batteries (12+ hours) are non-negotiable—power outages shouldn’t leave cats stranded. Meowant’s recent reviews highlight inconsistent motor performance, with some units failing within 3 months. Top-tier brands source motors from suppliers like Nidec or Maxon with 1M+ cycle testing and LG Chem/Panasonic batteries validated for 100+ charge cycles. This reduces returns by 25% and increases repeat purchases by 15%.

Connectivity & IoT Integration: The User Experience Lifeline

IoT reliability separates market leaders from also-rans. Tuya-certified modules ensure seamless app integration and regular OTA updates—critical for fixing bugs without recalls. A 1080p camera with night vision and low-latency streaming (<500ms) keeps users engaged. Poor connectivity (e.g., Wi-Fi dropouts, unresponsive apps) drives 40% of negative reviews. Meowant’s app experience has been criticized for instability, with users reporting disconnections during critical operations. To avoid this, brands must use Tuya-approved modules and partner with Wi-Fi chip suppliers like Espressif for stable firmware. Avoid generic Chinese modules; they lack security patches and cause “ghost” connectivity issues. This reduces app-related complaints by 35% and increases feature adoption by 50%.

Key Feature Benchmarks for Market-Ready Smart Litter Boxes

| Feature | Critical Specifications | User Retention Impact | Supply Chain Considerations |

|---|---|---|---|

| Material Safety | BPA-Free (FDA/CE), SS304 for waste compartments | 30% higher retention vs. generic plastics | Tier-1 suppliers (BASF, Dow); SGS batch testing |

| Smart Logic | Multi-sensor anti-jamming (5+ points), 12h backup | 25% lower returns | Nidec/Maxon motors; LG Chem batteries; 1M+ cycle tests |

| Connectivity | Tuya-certified, 1080p camera, <500ms latency | 40% higher app engagement | Espressif Wi-Fi chips; Tuya-approved modules; OTA security |

In a market where 68% of buyers cite reliability as the top purchase factor (Pet Industry Report 2024), these specifications aren’t optional—they’re the baseline for competitive differentiation. Brands that prioritize these elements in their manufacturing partnerships will capture market share while competitors struggle with warranty costs and reputation damage.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

In the competitive smart pet tech market, manufacturing rigor directly impacts product reliability and brand reputation. For self-cleaning litter boxes, precision in component production and rigorous testing are critical to withstand daily use, moisture exposure, and continuous operation. This section details the OEM/ODM processes that separate durable, high-performance products from premature failures—especially vital as the market grows to $2.56B by 2030.

Molding & Tooling

High-quality mold engineering is foundational. Premium OEMs utilize hardened tool steel (e.g., P20, H13) with tight tolerances (±0.02mm) to ensure consistent part dimensions across millions of units. These molds endure 500,000+ production cycles without degradation, critical for maintaining structural integrity and fit. Material selection (e.g., virgin ABS vs. recycled plastics) further impacts durability and odor resistance. Conversely, generic manufacturers often use low-grade molds that wear rapidly, leading to warping, misaligned components, and structural weaknesses. This results in higher return rates and customer dissatisfaction.

PCB Assembly (SMT)

Smart litter boxes rely on robust PCBs for IoT connectivity (Tuya, Wi-Fi, Bluetooth). Premium manufacturers employ fully automated Surface Mount Technology (SMT) lines with automated optical inspection (AOI) and X-ray for BGA components. This ensures precise soldering, eliminating cold joints or solder bridges that cause connectivity failures. Component sourcing from Tier-1 suppliers (e.g., TI, STMicro) ensures reliable IC performance, while proper thermal design prevents overheating. Generic suppliers frequently skip AOI, using manual rework or basic inspection, which leads to intermittent Wi-Fi issues and higher defect rates—common complaints in low-cost models.

Waterproof & Motor Life Testing

Motor durability and moisture resistance are non-negotiable. Premium OEMs conduct 10,000+ cycle motor life tests under load, thermal stress analysis, and IPX7 waterproof validation. This simulates years of real-world use, ensuring motors withstand litter dust, moisture, and continuous operation. Humidity chamber testing and vibration analysis further validate reliability. Generic products typically undergo minimal testing (e.g., 500 cycles) with no formal IP rating, resulting in frequent motor burnouts or internal corrosion within months of use.

| Aspect | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding & Tooling | Low-grade steel, 50k cycles, ±0.1mm tolerance | High-grade steel, 500k+ cycles, ±0.02mm tolerance; virgin ABS material |

| PCB Assembly (SMT) | Manual soldering, no AOI, basic flux control; generic ICs | Automated SMT, AOI/X-ray, controlled reflow profiles; Tier-1 components |

| Waterproof & Motor Testing | 500 cycles, no IP rating | 10k+ cycles, IPX7, humidity/vibration testing, thermal stress validation |

This rigorous approach minimizes warranty claims, enhances customer trust, and ensures long-term market viability. For brand owners, partnering with OEMs that enforce these standards is critical to capturing the growing $2.56B smart litter box market by 2030.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Global Certification Requirements

For global market entry, compliance with regional regulations is non-negotiable. In the USA, FCC certification (Part 15 for RF emissions) is mandatory for all wireless-enabled devices like smart litter boxes. Electrical safety requires UL 60335-2-103 or ETL equivalent certification. In the EU, CE marking must cover the EMC Directive (2014/30/EU) and Low Voltage Directive (2014/35/EU). RoHS 2 (2011/65/EU) is mandatory for EU and often required by US retailers to restrict hazardous substances like lead and mercury. While “Food Grade” isn’t a formal certification, plastic components contacting pet waste must comply with FDA 21 CFR (US) or REACH Annex XVII (EU) for chemical safety—including SVHCs (Substances of Very High Concern). Non-compliance risks customs seizures, recalls, or costly rework.

| Certification | USA | EU | Key Purpose |

|---|---|---|---|

| FCC | Mandatory | Not Required | RF emissions compliance |

| UL/ETL | Mandatory | Not Required | Electrical safety |

| CE | Not Required | Mandatory | Safety, EMC, LVD compliance |

| RoHS | Voluntary* | Mandatory | Restricts hazardous substances |

| Material Safety | FDA 21 CFR | REACH Annex XVII | Non-toxic materials for pet contact |

*Required by major US retailers (e.g., Amazon, Petco) even if not federal law.

Amazon FBA Packaging Standards

Amazon’s ISTA 3A standards dictate packaging durability for FBA shipments. For products under 50 lbs, cartons must survive a 48-inch drop test across 3 corners, 3 edges, and 6 faces. Box burst strength must exceed 200 lbs for <20 lbs items e 275 lbs for 20–50 lbs items. Additionally, packaging must:

Use tamper-evident tape with no labels obstructed.

Include secure internal cushioning (e.g., molded pulp or air pillows) to prevent component movement.

Feature scannable FBA barcodes and comply with Amazon’s size/weight limits (e.g., max 20 lbs per unit for standard FBA).

Failure to meet these standards triggers rejection fees ($20–$50/unit) or delays. Partner with OEMs experienced in FBA packaging—many Shenzhen manufacturers offer pre-tested box designs to avoid costly rework.

Shenzhen Manufacturing Lead Times

Shenzhen-based OEMs typically deliver smart litter boxes in 8–12 weeks for production. However, certification processes (FCC, UL, CE) add 4–8 weeks. To accelerate timelines:

Prioritize OEMs with pre-certified IoT modules (e.g., Tuya-certified Wi-Fi chips), reducing RF testing by 30–50%.

Select suppliers with ISO 9001 certification and pet-tech specialization—these firms have streamlined QC processes and stock molds for common components (e.g., litter box shells).

Implement phased testing: Run pre-production samples for certification early to avoid bottlenecks.

For example, a top-tier Shenzhen OEM can achieve full compliance in 6–10 weeks total—critical for holiday demand cycles. Dual-sourcing critical components (e.g., sensors, Wi-Fi modules) further mitigates supply chain risks from geopolitical disruptions or component shortages. Proactive planning with your manufacturer is non-negotiable for reliable, scalable production.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize Your Smart Litter Box Product

The global smart litter box market is projected to reach $2.56B by 2030 (CAGR 18.62%), yet 30% of budget-tier products fail within 3 months due to poor component quality and inadequate testing. Brands like Meowant face recurring complaints about sensor malfunctions and motor failures—issues avoidable through strategic sourcing. Partner with a manufacturer that integrates rigorous quality control, IoT reliability, and supply chain resilience from day one. Here’s how:

Step 1: Request Rigorous Sample Testing

Never skip independent sample validation. Request 3+ units for lab and field testing. Verify:

| Metric | Industry Standard | PAWBILT Benchmark |

|---|---|---|

| Cycle Durability | 5,000 cycles | 50,000+ cycles (certified) |

| Noise Level | ≤55dB | 42dB (ISO 3744 certified) |

| IoT Stability | Basic Tuya connectivity | 99.9% uptime with OTA updates |

| Thermal Stress | 40°C ambient | 60°C stability test |

Include litter-type compatibility tests (clumping, crystal, wood) and sensor accuracy under heavy use. PAWBILT’s samples undergo 15+ quality checkpoints before shipment—ensuring no hidden flaws.

Step 2: Define Smart Customization

Customization must extend beyond logos. Prioritize technical differentiators:

IoT Integration: Custom app features (multi-cat analytics, litter level alerts)

Material Specifications: Food-grade ABS with antimicrobial coatings

Packaging: Eco-friendly, tamper-evident seals with brand-led unboxing experience

Table: Critical Customization Upgrades

| Feature | Standard OEM | PAWBILT Solution |

|———|————–|——————|

| Sensor Calibration | Manual calibration | AI-powered self-diagnosis |

| Motor System | Single-speed | Dual-motor (30% quieter, 2x lifespan) |

| Odor Control | Basic carbon filter | UV + ozone hybrid system |

| App UX | Generic interface | Fully branded dashboard with usage insights |

Step 3: Execute a Pilot Run

A 500-unit pilot is non-negotiable. PAWBILT’s ISO 9001-certified production includes:

In-line QC at 3 checkpoints (component assembly, final testing, packaging)

72-hour stress tests simulating 6 months of real-world use

Compliance with CE, FCC, and RoHS standards

“Brands that skip pilot runs face 40% higher return rates. Our data shows 95% of defects surface during this phase.”

— PAWBILT Senior Quality Engineer

Why Partner with PAWBILT?

With 8+ years in pet tech manufacturing, we deliver end-to-end solutions from R&D to global logistics. Our dual-sourced components (e.g., motors from Siemens-certified suppliers) and on-shore inventory for critical parts ensure 98% on-time delivery. Unlike commodity manufacturers, we guarantee 95% first-pass yield and 24/7 technical support. In a market where $1.09B in 2025 revenue hinges on reliability, PAWBILT transforms your brand into a category leader—not a cautionary tale.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label meowant litter box review business.