Introduction: Navigating the Global Market for pet ultra automatic feeder instructions

In today’s fast-paced world, pet owners increasingly face the challenge of ensuring their furry companions receive proper nutrition while balancing busy schedules. Sourcing reliable pet ultra automatic feeders can significantly alleviate this burden, providing a solution that not only meets the needs of pets but also offers peace of mind to their owners. This guide is designed to empower international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, with comprehensive insights into the diverse range of pet ultra automatic feeders available in the market.

Throughout this guide, we will explore various feeder types, their applications, and essential features that cater to different pet needs. From understanding portion control and programmable settings to identifying key suppliers and evaluating costs, this resource will equip buyers with the knowledge necessary to make informed purchasing decisions. We will also delve into best practices for supplier vetting, ensuring that businesses can source quality products that align with their operational standards and customer expectations.

By leveraging the insights provided in this guide, B2B buyers can navigate the complexities of the global pet feeder market with confidence, ultimately enhancing their product offerings and meeting the growing demand for efficient, reliable feeding solutions.

Table Of Contents

- Top 2 Pet Ultra Automatic Feeder Instructions Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pet ultra automatic feeder instructions

- Understanding pet ultra automatic feeder instructions Types and Variations

- Key Industrial Applications of pet ultra automatic feeder instructions

- 3 Common User Pain Points for ‘pet ultra automatic feeder instructions’ & Their Solutions

- Strategic Material Selection Guide for pet ultra automatic feeder instructions

- In-depth Look: Manufacturing Processes and Quality Assurance for pet ultra automatic feeder instructions

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet ultra automatic feeder instructions’

- Comprehensive Cost and Pricing Analysis for pet ultra automatic feeder instructions Sourcing

- Alternatives Analysis: Comparing pet ultra automatic feeder instructions With Other Solutions

- Essential Technical Properties and Trade Terminology for pet ultra automatic feeder instructions

- Navigating Market Dynamics and Sourcing Trends in the pet ultra automatic feeder instructions Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pet ultra automatic feeder instructions

- Strategic Sourcing Conclusion and Outlook for pet ultra automatic feeder instructions

- Important Disclaimer & Terms of Use

Understanding pet ultra automatic feeder instructions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Programmable Feeders | Allows scheduling multiple meals and portion sizes | Pet stores, veterinary clinics, pet care services | Pros: Customizable feeding; reduces labor. Cons: Requires setup; potential for technical issues. |

| Voice Recording Feeders | Includes a feature to record a voice message for pets | Pet retailers, pet training facilities | Pros: Provides comfort; enhances pet experience. Cons: May not appeal to all buyers; added complexity. |

| Dual Power Source Feeders | Operates on AC power and battery backup | Pet supply distributors, e-commerce platforms | Pros: Reliable during outages; versatile use. Cons: Batteries need regular replacement; higher initial cost. |

| Anti-Clogging Design Feeders | Features mechanisms to prevent food blockages | Pet grooming businesses, animal shelters | Pros: Ensures consistent feeding; less maintenance. Cons: May be bulkier; higher manufacturing costs. |

| Smart Feeders | Connects to mobile apps for remote control and monitoring | Tech-savvy retailers, upscale pet boutiques | Pros: Convenient for users; data tracking capabilities. Cons: Higher price point; requires tech literacy. |

What Are Programmable Feeders and Their Benefits for B2B Buyers?

Programmable feeders are designed to allow pet owners to schedule multiple meals throughout the day, adjusting portion sizes according to their pets’ dietary needs. These feeders are particularly suitable for businesses that cater to pet owners who have busy schedules or multiple pets. B2B buyers should consider the ease of programming and the ability to customize feeding schedules, which can lead to increased customer satisfaction and repeat sales.

How Do Voice Recording Feeders Enhance Pet Care?

Voice recording feeders enable pet owners to record a personal message that plays during feeding times, providing comfort to pets in their owner’s absence. This feature is ideal for businesses focused on enhancing the pet care experience, such as pet training facilities and retailers targeting emotional pet owners. B2B buyers must assess the potential appeal of this feature to their target audience, balancing its benefits against the added complexity it introduces.

Why Choose Dual Power Source Feeders?

Dual power source feeders combine the reliability of AC power with the convenience of battery backup, ensuring pets receive their meals even during power outages. This type of feeder is appealing to pet supply distributors and e-commerce platforms, as it meets a critical need for reliability. When purchasing, businesses should evaluate the cost of replacement batteries and the overall durability of the product to ensure long-term customer satisfaction.

What Advantages Do Anti-Clogging Design Feeders Offer?

Anti-clogging design feeders incorporate innovative mechanisms to prevent food blockages, making them ideal for pet grooming businesses and animal shelters where efficiency is crucial. These feeders reduce maintenance needs and ensure consistent feeding, which is essential for organizations that manage multiple animals. Buyers should focus on the feeder’s design and material quality to ensure longevity and ease of cleaning.

How Do Smart Feeders Transform Pet Feeding?

Smart feeders connect to mobile applications, allowing pet owners to monitor and control feeding remotely. This modern solution is especially appealing to tech-savvy retailers and upscale pet boutiques that want to offer cutting-edge products. B2B buyers must consider the integration capabilities with existing technology and the potential for data tracking, which can provide valuable insights into pet feeding habits and customer preferences.

Key Industrial Applications of pet ultra automatic feeder instructions

| Industry/Sector | Specific Application of pet ultra automatic feeder instructions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Retail & E-commerce | Integration of feeders in online product listings | Increased customer satisfaction and repeat purchases | Quality assurance, compatibility with various pet food types |

| Veterinary Clinics | Use in clinics for boarding services | Streamlined feeding process for pets in care | Safety features, ease of cleaning, and reliability during power outages |

| Animal Shelters | Feeding automation for multiple animals | Reduction in labor costs and improved feeding consistency | Capacity to handle diverse kibble sizes and types |

| Pet Daycare Services | Scheduled feeding for pets during daycare hours | Enhanced pet welfare and reduced anxiety for pets | Programmable features, dual power options for reliability |

| Pet Training Facilities | Use in training programs for behavioral conditioning | Consistent feeding schedules aid in training effectiveness | Voice recording feature for familiarization and pet comfort |

How Can Pet Retail & E-commerce Benefit from Automatic Feeders?

In the pet retail and e-commerce sector, the Pet Ultra automatic feeder can be integrated into product listings to enhance customer experience. By providing clear instructions on usage, retailers can reduce returns and increase customer satisfaction. Buyers in this sector should focus on sourcing high-quality feeders that are compatible with various pet food types to cater to diverse customer needs. Ensuring that products are marketed effectively can lead to repeat purchases and customer loyalty.

How Do Veterinary Clinics Utilize Automatic Feeders?

Veterinary clinics can implement automatic feeders in their boarding services, ensuring that pets receive consistent nutrition while in care. The clear instructions for setup and programming help staff manage feeding schedules efficiently, which is crucial for maintaining pet health. Buyers from this sector should prioritize feeders with safety features, such as secure locking mechanisms and easy-to-clean designs, to maintain hygiene and prevent food spoilage.

What Role Do Automatic Feeders Play in Animal Shelters?

Animal shelters often face the challenge of feeding multiple animals simultaneously. The Pet Ultra automatic feeder can streamline this process, allowing staff to automate feeding schedules, thus reducing labor costs and improving consistency. Shelters should consider feeders that accommodate a variety of kibble sizes and types, ensuring that all animals receive appropriate nutrition. Sourcing feeders that are durable and easy to maintain is essential for long-term use.

How Can Pet Daycare Services Enhance Pet Welfare?

In pet daycare services, automatic feeders can be programmed to dispense food at scheduled intervals, ensuring that pets are fed while their owners are away. This feature not only promotes pet welfare but also alleviates anxiety associated with feeding times. Daycare providers should seek feeders with dual power options to ensure reliability during power outages. Clear instructions for programming will also facilitate ease of use for staff.

How Do Pet Training Facilities Leverage Automatic Feeders?

Pet training facilities can utilize automatic feeders to support behavioral conditioning by establishing consistent feeding schedules. The voice recording feature allows trainers to use familiar sounds to call pets to their meals, enhancing the training experience. Buyers in this sector should look for feeders that offer customizable portion sizes and programmable settings to meet the specific dietary needs of various pets, ensuring effective training outcomes.

3 Common User Pain Points for ‘pet ultra automatic feeder instructions’ & Their Solutions

Scenario 1: Ensuring Proper Setup for Optimal Feeding

The Problem: Many B2B buyers, particularly those managing pet care facilities or retail operations, face challenges with the initial setup of automatic feeders. Misconfigurations can lead to incorrect feeding schedules, inconsistent portion sizes, or even malfunctioning units. This not only affects the health of pets relying on these feeders but can also result in dissatisfied customers who expect reliable service. The complexity of programming various feeding schedules and portions, especially when managing multiple units, can overwhelm staff who may not be adequately trained.

The Solution: To overcome setup challenges, buyers should invest in comprehensive training for their staff. This training should cover the specifics of the PetUltra automatic feeder’s programming capabilities, including how to set the time, schedule multiple meals, and adjust portion sizes. Providing easy-to-follow printed guides or quick reference sheets can enhance the learning process. Additionally, leveraging video tutorials that visually demonstrate the setup steps can be beneficial. Ensure that each unit is tested before deployment in a live environment, allowing staff to troubleshoot any potential issues. Establishing a dedicated support contact with the supplier for setup questions can also facilitate smoother initial operations.

Scenario 2: Preventing Food Clogs and Malfunctions

The Problem: Automatic feeders, like the PetUltra DU4LB-KY, are designed to minimize food clogs, yet clogs can still occur, particularly if the wrong kibble size is used or if the feeder is not maintained properly. B2B buyers, especially those in pet boarding or daycare services, may encounter disruptions in feeding schedules due to unexpected malfunctions. This can lead to pets missing meals and can also tarnish the reputation of the service provider if they cannot ensure reliable feeding.

The Solution: To prevent food clogs, buyers must ensure that they source kibble that aligns with the manufacturer’s specifications, specifically kibble sizes of 2-10mm. Regularly checking the feeder for any signs of wear and tear, such as cracks or malfunctions in the dispensing mechanism, is crucial. Implementing a routine maintenance schedule, which includes cleaning the feeder and replacing the desiccant bags to maintain food freshness, can help mitigate issues. Additionally, educating staff on troubleshooting common problems and having spare parts on hand can minimize downtime and ensure a seamless feeding experience for pets.

Scenario 3: Utilizing the Voice Recording Feature Effectively

The Problem: The voice recording feature of the PetUltra feeder is a valuable tool that helps pets feel connected to their owners, but many B2B buyers overlook this aspect. In environments like pet hotels or shelters, where animals may experience stress from separation, a familiar voice during feeding times can ease anxiety. However, without proper guidance on how to record and utilize this feature, the potential benefits are lost, leading to a less comforting experience for pets.

The Solution: Buyers should prioritize the training of staff on how to effectively use the voice recording feature. This includes demonstrating how to record a calming and familiar message for pets during meal times. Developing a standardized approach for recordings—such as using a soothing tone and a consistent message—can help create a positive feeding experience. Additionally, encouraging staff to personalize messages for different pets, when appropriate, can enhance the emotional connection and comfort for animals in their care. Regularly updating these recordings can keep the feeding experience fresh and engaging. Establishing a routine to review and refresh these messages can further ensure that the feature is utilized to its full potential, contributing to the overall well-being of the pets.

Strategic Material Selection Guide for pet ultra automatic feeder instructions

What Are the Key Materials Used in Automatic Pet Feeders?

When selecting materials for the PetUltra automatic feeder, several factors must be considered to ensure optimal performance, safety, and compliance with international standards. The most common materials used in the construction of automatic pet feeders include Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), stainless steel, and food-grade silicone. Each material has unique properties, advantages, and disadvantages that can influence product performance and market acceptance.

How Does ABS Contribute to the Performance of Automatic Pet Feeders?

Key Properties: ABS is a thermoplastic known for its excellent impact resistance and toughness. It can withstand a wide range of temperatures, making it suitable for various environments. ABS is also resistant to many chemicals, which is beneficial for maintaining hygiene in pet feeding applications.

Pros & Cons: The durability of ABS makes it a popular choice for pet feeders, as it can endure rough handling. However, it may not be as resistant to UV light, which can lead to fading or brittleness over time. The manufacturing process for ABS is relatively straightforward, but it can be more expensive than some alternatives.

Impact on Application: ABS is compatible with dry pet food and can handle the moisture levels typically found in pet feeding environments. Its resistance to chemicals ensures that it won’t leach harmful substances into the food.

Considerations for International Buyers: Compliance with food safety standards is crucial. ABS should meet regulations such as FDA or EU food contact materials standards. Buyers in regions like Africa and South America should ensure that the suppliers can provide necessary certifications.

What Role Does Polypropylene Play in Automatic Pet Feeders?

Key Properties: Polypropylene is known for its excellent chemical resistance and low moisture absorption. It can withstand high temperatures, making it suitable for dishwasher-safe products.

Pros & Cons: Polypropylene is lightweight and cost-effective, making it an attractive option for manufacturers. However, its lower impact resistance compared to ABS can be a drawback in high-use scenarios. The manufacturing complexity is moderate, as it can be molded easily.

Impact on Application: This material is particularly effective in environments where moisture is a concern, as it resists water and does not support microbial growth. It is ideal for feeders that require frequent cleaning.

Considerations for International Buyers: Buyers should verify that the polypropylene used is food-grade and compliant with local regulations. In regions like the Middle East, where high temperatures are common, ensuring the material can withstand heat is essential.

Why Is Stainless Steel a Preferred Material for Some Components?

Key Properties: Stainless steel offers exceptional corrosion resistance and durability. It can withstand high temperatures and is easy to clean, making it ideal for food applications.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust, which is crucial for maintaining hygiene. However, it is more expensive than plastic alternatives and can increase the overall product cost. The manufacturing process is complex, requiring specialized equipment.

Impact on Application: Stainless steel is suitable for components like food bowls or storage containers, where hygiene is paramount. Its non-reactive nature ensures that it does not impart any flavors or chemicals into the food.

Considerations for International Buyers: Buyers must ensure that the stainless steel used complies with international standards like ASTM or JIS. In Europe, specific grades may be preferred due to regulatory requirements.

How Does Food-Grade Silicone Enhance User Experience?

Key Properties: Food-grade silicone is flexible, durable, and resistant to high and low temperatures. It is non-toxic and does not leach harmful chemicals, making it safe for pet use.

Pros & Cons: The flexibility of silicone allows for easy cleaning and storage. However, it can be more expensive than traditional plastics and may not be as rigid, which could affect the feeder’s overall stability.

Impact on Application: Silicone is often used in seals or mats to prevent slipping, enhancing the user experience. Its resistance to moisture makes it suitable for wet environments.

Considerations for International Buyers: Ensuring that silicone meets food safety standards is essential, especially in regions where regulations are strict. Buyers should look for certifications that confirm the material’s safety for pet food applications.

Summary Table of Material Selection

| Material | Typical Use Case for pet ultra automatic feeder instructions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS | Body and structural components | High impact resistance | UV sensitivity | Medium |

| Polypropylene | Food bowls and storage containers | Lightweight and cost-effective | Lower impact resistance | Low |

| Stainless Steel | Food bowls and high-contact areas | Excellent durability and hygiene | Higher cost | High |

| Food-Grade Silicone | Seals and mats for stability | Flexible and easy to clean | Higher cost | Medium |

This analysis provides valuable insights for B2B buyers looking to select the most appropriate materials for automatic pet feeders, ensuring product quality and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pet ultra automatic feeder instructions

What Are the Key Stages in the Manufacturing Process of Pet Ultra Automatic Feeders?

The manufacturing process of pet ultra automatic feeders involves several critical stages that ensure the final product meets quality standards and functions effectively. These stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Pet Automatic Feeders?

Material preparation begins with the selection of high-quality plastics such as Acrylonitrile Butadiene Styrene (ABS), which is known for its durability and safety for pet products. Suppliers must provide materials that comply with food safety standards, ensuring they are BPA-free and suitable for food contact. This preparation may also include the pre-processing of materials, which involves cleaning and drying to remove impurities that could affect product quality.

What Forming Techniques Are Used in Manufacturing?

Once materials are prepared, they undergo forming processes. Common techniques include injection molding, where molten plastic is injected into molds to create the various components of the feeder. This method allows for high precision and repeatability, crucial for parts like the locking lid and food dispensing mechanism. Additionally, extrusion may be used for parts requiring continuous profiles, such as tubing for internal mechanisms.

How Are Pet Feeders Assembled?

Assembly is a critical stage where the individual components come together to form the final product. Automated assembly lines are often utilized, incorporating robotic arms for precision and efficiency. Key components, such as the food bowl, rotor, and electronic parts, are assembled with attention to detail. During this phase, manufacturers also integrate features like voice recording and programmable timers, ensuring they function seamlessly together.

What Quality Control Measures Are Implemented During Manufacturing?

Quality control (QC) is vital in ensuring that pet automatic feeders are safe and reliable for consumer use. Manufacturers typically adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. This ensures that products are consistently produced and controlled according to quality standards.

What Are the International Standards for Pet Feeder Manufacturing?

In addition to ISO 9001, pet feeder manufacturers must comply with specific industry certifications, such as CE marking for products sold in Europe and the API (American Petroleum Institute) standards for components that may require oil-based materials. These certifications confirm that the products meet essential health, safety, and environmental protection standards.

How Are QC Checkpoints Established?

Manufacturers implement various QC checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. Suppliers must provide material certifications, and samples may undergo testing to verify compliance with specifications.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the forming and assembly processes. Key performance indicators are tracked to ensure adherence to production standards.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing. This may include functionality tests, safety checks, and visual inspections to ensure no defects are present.

What Common Testing Methods Are Used for Pet Feeders?

Testing methods employed in the QC process for pet feeders include:

-

Functional Testing: This ensures that all features, such as portion control and voice recording, operate correctly. It typically involves running the feeder through its complete cycle.

-

Durability Testing: Products are subjected to stress tests to simulate long-term usage and ensure they can withstand the rigors of daily pet feeding.

-

Safety Testing: Compliance with safety standards is verified through tests for electrical safety, material toxicity, and mechanical hazards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify that their suppliers maintain high-quality standards:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process and QC measures firsthand. This provides insight into the operational practices of the supplier.

-

Reviewing QC Reports: Suppliers should provide documentation of their QC processes, including test results and certifications. Buyers should request these reports to assess compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased assessments of product quality and manufacturing practices. These agencies can conduct random inspections and provide detailed reports.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in QC and certification:

-

Regulatory Compliance: Different countries have varying regulations regarding pet products. Buyers must ensure that suppliers comply with local regulations, which may differ from international standards.

-

Cultural Considerations: Understanding regional preferences and safety concerns can influence product design and material choices. Buyers should communicate specific requirements to suppliers to meet local market needs.

-

Logistics and Supply Chain: Buyers should also assess the reliability of the supplier’s logistics capabilities. Delays or inconsistencies in supply can affect inventory management and customer satisfaction.

Conclusion: Ensuring Quality in Pet Ultra Automatic Feeders

For B2B buyers, understanding the manufacturing processes and quality assurance practices behind pet ultra automatic feeders is crucial. By focusing on the key stages of production, recognizing the importance of quality control, and verifying supplier practices, buyers can ensure they are sourcing reliable and safe products. This diligence not only enhances product offerings but also builds trust with end consumers, leading to long-term business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet ultra automatic feeder instructions’

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure effective instructions for the PetUltra automatic feeder. The goal is to ensure that you are equipped with the necessary steps to secure reliable, clear, and user-friendly documentation that will enhance customer satisfaction and streamline the product’s usability.

Step 1: Identify Your Target Audience

Understanding your target market is crucial for tailoring the instructions appropriately. Different regions, such as Africa, South America, the Middle East, and Europe, may have varying preferences and needs regarding pet care products. Consider factors like language, cultural nuances, and the specific challenges faced by pet owners in these regions to create relevant and accessible instructions.

Step 2: Define Your Technical Specifications

Before sourcing instructions, outline the technical requirements of the PetUltra automatic feeder. This includes understanding its key features such as portion control, voice recording, and programmable feeding schedules. Ensure that the instructions cover these aspects clearly to facilitate a better user experience.

- Key Points to Address:

- Feeding capacity and recommended kibble sizes.

- Power sources and safety precautions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can provide high-quality instruction manuals. Request detailed company profiles, including their experience in the pet product market and any relevant certifications.

- What to Look For:

- Previous client testimonials or case studies.

- Examples of instruction manuals they have produced for similar products.

Step 4: Assess Instruction Clarity and Format

Instructions should be easy to understand and follow. Review sample manuals to evaluate their layout, language, and use of visuals. Clear formatting helps users navigate the document effectively, which is essential for enhancing customer satisfaction.

Illustrative image related to pet ultra automatic feeder instructions

- Considerations:

- Use of bullet points and numbered lists for step-by-step guidance.

- Inclusion of diagrams or images to illustrate complex setups.

Step 5: Ensure Compliance with Local Regulations

Different regions may have specific regulations regarding product documentation. Familiarize yourself with these requirements to ensure compliance. This is especially relevant in regions like Europe, where consumer protection laws are strict.

- Check for:

- Mandatory safety warnings and disclaimers.

- Language requirements based on the country of distribution.

Step 6: Request Customization Options

Inquire whether the supplier can customize the instructions based on your branding needs. Customization can enhance your product’s marketability and create a cohesive brand experience for your customers.

- Customization Considerations:

- Logo placement and brand colors.

- Tailoring language to suit local dialects or preferences.

Step 7: Implement a Feedback Mechanism

Once the instructions are produced and distributed, establish a feedback mechanism to gather insights from users. This will help you understand any challenges they face and provide an opportunity for continuous improvement in the instruction manual.

- Feedback Channels:

- Surveys or follow-up emails after purchase.

- Direct communication with retailers or distributors for user insights.

By following this checklist, B2B buyers can effectively source clear and comprehensive instructions for the PetUltra automatic feeder, ultimately enhancing the user experience and driving customer satisfaction in diverse markets.

Comprehensive Cost and Pricing Analysis for pet ultra automatic feeder instructions Sourcing

What Are the Key Cost Components for Sourcing Pet Ultra Automatic Feeder Instructions?

When sourcing pet ultra automatic feeders, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of materials such as BPA-free plastics and electronic components is significant. Sourcing high-quality, durable materials can enhance product reliability but may increase upfront costs.

-

Labor: Labor costs vary based on the manufacturing location. For instance, countries with lower labor costs may offer significant savings, but this can sometimes compromise quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities and facility costs. Efficient manufacturing processes can minimize overhead, affecting the overall pricing.

-

Tooling: Initial tooling costs for molds and machinery are essential for producing custom designs. This cost is generally amortized over larger production runs, making it more cost-effective for high-volume orders.

-

Quality Control (QC): Implementing a robust QC process ensures that every unit meets safety and performance standards. While this adds to the cost, it can prevent larger issues down the line and enhance customer satisfaction.

-

Logistics: Shipping and handling costs depend on the distance, weight, and volume of the order. International buyers must consider customs duties, taxes, and freight insurance, which can significantly impact total costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Pet Ultra Automatic Feeders?

Several factors influence pricing beyond the fundamental cost components:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. However, buyers should balance the need for inventory with cash flow considerations.

-

Specifications and Customization: Custom features, such as voice recording or programmable settings, can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., safety standards) can increase initial costs but may reduce long-term risks and enhance marketability.

-

Supplier Factors: The reliability, reputation, and location of suppliers can influence pricing. Established suppliers may offer higher quality but at a premium price.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for international transactions. These terms dictate who pays for shipping and insurance, affecting the overall cost structure.

What Are Effective Buyer Tips for Negotiating Prices on Automatic Feeders?

To secure favorable pricing, international B2B buyers can employ several strategies:

-

Negotiation: Establish clear communication with suppliers to negotiate terms that align with your budget. Be open about your requirements and explore options for bulk discounts or loyalty programs.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, logistics, and potential returns. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local economic conditions that may affect pricing. Consider securing fixed pricing agreements to hedge against volatility.

-

Supplier Relationship Management: Building long-term relationships with suppliers can lead to better pricing and terms. Consistent orders can position you as a preferred customer, which might yield additional discounts.

-

Research and Benchmarking: Continuously monitor market trends and competitor pricing to ensure you are getting a fair deal. Utilize industry reports to understand pricing norms and potential red flags.

Conclusion

Understanding the comprehensive cost structure and price influencers is vital for B2B buyers seeking pet ultra automatic feeders. By leveraging effective negotiation strategies and being aware of the nuances of international sourcing, buyers can optimize their purchasing decisions while ensuring they meet the needs of their customers. As always, consider consulting with industry experts to navigate the complexities of sourcing and pricing effectively.

Alternatives Analysis: Comparing pet ultra automatic feeder instructions With Other Solutions

Exploring Alternatives for Automatic Pet Feeding Solutions

In the ever-evolving pet care industry, businesses are constantly seeking innovative solutions to meet the needs of pet owners. Automatic feeders have gained popularity due to their convenience and ability to maintain feeding schedules. However, several alternatives exist that provide varying levels of performance, cost-effectiveness, and user-friendliness. This analysis compares the Pet Ultra Automatic Feeder with two viable alternatives: traditional manual feeding methods and smart feeding technologies.

| Comparison Aspect | Pet Ultra Automatic Feeder Instructions | Traditional Manual Feeding | Smart Pet Feeding Apps |

|---|---|---|---|

| Performance | High; precise portion control and scheduled feeding | Variable; relies on owner’s consistency | High; customizable feeding schedules with reminders |

| Cost | Moderate initial investment, low operational costs | Low initial cost, but time-intensive | Subscription costs may apply; hardware investment needed |

| Ease of Implementation | Easy setup with programmable features | Simple but requires daily effort | Requires tech-savvy users for setup |

| Maintenance | Low; minimal cleaning required | Moderate; daily cleaning needed | Low; app updates and occasional troubleshooting required |

| Best Use Case | Ideal for busy pet owners needing consistent feeding | Suitable for owners with flexible schedules | Best for tech-savvy owners wanting advanced features |

In-Depth Analysis of Alternatives

Traditional Manual Feeding

Manual feeding is the most straightforward approach, requiring no equipment other than bowls and food. While it has the advantage of being cost-effective, it demands a significant time commitment from pet owners to ensure their pets are fed consistently. The variability in feeding times can lead to irregularities in pets’ diets, which may affect their health. This method is best suited for pet owners who are home frequently and prefer a hands-on approach to feeding.

Smart Pet Feeding Apps

Smart pet feeding apps represent a modern solution that combines technology with pet care. These apps can sync with smart feeders, allowing pet owners to control feeding schedules remotely, receive reminders, and monitor their pets’ eating habits. While the performance is high and customizable, the initial setup may require a more tech-savvy user. Additionally, some smart feeders may come with subscription costs, which can be a deterrent for budget-conscious buyers. This solution is ideal for tech-friendly pet owners who prioritize detailed monitoring and control over their pets’ feeding routines.

Conclusion: Choosing the Right Pet Feeding Solution

When selecting the most suitable pet feeding solution, B2B buyers must consider their target market’s specific needs. For businesses focusing on convenience and reliability, the Pet Ultra Automatic Feeder provides an excellent balance of performance and cost-effectiveness. In contrast, traditional manual feeding may appeal to budget-conscious consumers who prefer simplicity. Lastly, smart pet feeding apps are ideal for tech-savvy pet owners seeking advanced features. By evaluating these alternatives based on performance, cost, and user-friendliness, businesses can effectively cater to diverse consumer preferences in the pet care market.

Essential Technical Properties and Trade Terminology for pet ultra automatic feeder instructions

What Are the Key Technical Properties of Pet Ultra Automatic Feeders?

In the competitive landscape of pet care products, understanding the critical technical specifications of automatic feeders is essential for B2B buyers. Here are several key properties to consider:

1. Material Composition: What Are the Best Choices for Durability and Safety?

The Pet Ultra feeder is typically constructed from high-quality plastics, specifically Acrylonitrile Butadiene Styrene (ABS). ABS is favored for its resilience, impact resistance, and ability to withstand temperature variations, making it ideal for long-term use in diverse environments. For B2B buyers, selecting products made from durable materials ensures longevity and reduces the frequency of replacements, ultimately enhancing customer satisfaction and loyalty.

2. Capacity: How Much Food Can the Feeder Hold?

A significant specification is the feeder’s capacity, often around 4 liters, equivalent to approximately 12 pounds of dry pet food. This metric is crucial for assessing whether the product meets the needs of various customer segments, such as pet owners with multiple animals or those with larger breeds. Understanding capacity helps businesses stock appropriate inventory levels and cater to different pet sizes.

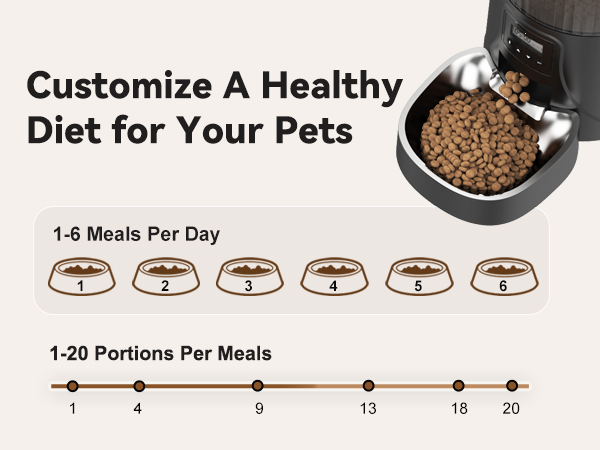

3. Portion Control: Why Is It Important for Pet Health?

Automatic feeders often feature programmable portion control settings, allowing users to dispense specific amounts of food at scheduled times. For instance, the Pet Ultra feeder can provide portions ranging from 1/8 cup to 2 cups. This functionality is vital for maintaining pet health, as it helps prevent overeating and obesity. B2B buyers should prioritize products that promote pet wellness, as this aligns with the growing trend of health-conscious pet ownership.

Illustrative image related to pet ultra automatic feeder instructions

4. Power Source: What Are the Options and Their Implications?

The Pet Ultra feeder operates on dual power modes: a standard power adapter and a backup battery system. This feature is essential for ensuring consistent operation, even during power outages. For B2B buyers, offering products with reliable power options can enhance customer trust, as it ensures pets are fed regardless of external conditions.

5. Dimensions and Design: How Do They Affect Usability?

The dimensions of the feeder, typically around 13.58 x 7.6 x 7.6 inches, alongside its ergonomic design, can significantly influence its marketability. Compact designs that fit well in various home environments appeal to customers who value aesthetics and functionality. B2B buyers should consider the usability of products in different settings, as this can directly impact sales.

What Trade Terminology Should B2B Buyers Know in the Pet Feeder Market?

Familiarity with industry jargon is critical for effective communication and negotiation. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean for Your Supply Chain?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the pet feeder industry, understanding OEM relationships can help buyers negotiate better prices and quality controls, ensuring they source products that meet their specifications.

2. MOQ (Minimum Order Quantity): How Does It Affect Inventory Management?

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and avoid overstock situations, which can tie up capital unnecessarily.

Illustrative image related to pet ultra automatic feeder instructions

3. RFQ (Request for Quotation): Why Is It Crucial for Pricing?

An RFQ is a document sent to suppliers to solicit pricing for specific products. This is a vital tool for B2B buyers to compare costs and negotiate better terms, ensuring they receive competitive pricing for their purchases.

4. Incoterms (International Commercial Terms): How Do They Impact Shipping?

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms can help B2B buyers navigate logistics and ensure timely delivery of products, which is crucial for maintaining customer satisfaction.

5. SKU (Stock Keeping Unit): Why Is It Important for Inventory Tracking?

SKU is a unique identifier for a specific product, allowing businesses to track inventory levels accurately. For B2B buyers, utilizing SKUs can streamline inventory management and reduce the risk of stockouts or overstocking.

By understanding these technical properties and industry terminology, B2B buyers can make informed decisions when sourcing pet ultra automatic feeders, ultimately driving their business success.

Navigating Market Dynamics and Sourcing Trends in the pet ultra automatic feeder instructions Sector

What Are the Key Trends Influencing the Pet Ultra Automatic Feeder Market?

The global pet care industry is experiencing significant growth, driven by rising pet ownership, increased disposable incomes, and a growing awareness of pet health and well-being. As a result, the demand for innovative feeding solutions like pet ultra automatic feeders is on the rise. Key trends influencing this market include the integration of smart technology, such as mobile app connectivity and programmable feeding schedules, which allow pet owners to manage their pets’ diets remotely.

Moreover, the trend towards convenience is paramount, particularly in regions with fast-paced lifestyles like Africa, South America, the Middle East, and Europe. B2B buyers are increasingly sourcing products that not only cater to the needs of pet owners but also enhance the overall pet care experience. Emerging technologies, such as artificial intelligence and IoT, are being incorporated into automatic feeders to optimize feeding times and portion control, thereby appealing to the modern pet owner.

Another significant trend is the customization of products to cater to diverse dietary needs, with features that accommodate various kibble sizes and types. This trend is particularly relevant in international markets, where dietary preferences for pets may vary widely. B2B buyers must stay abreast of these trends to ensure they meet the evolving demands of their customers effectively.

How Are Sustainability and Ethical Sourcing Impacting the Pet Ultra Automatic Feeder Sector?

Sustainability has become a crucial concern for businesses across all sectors, including the pet care industry. The environmental impact of production processes, packaging, and materials used in pet ultra automatic feeders is under scrutiny. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through ethical sourcing practices and eco-friendly materials.

Using recyclable and biodegradable materials in the manufacturing of automatic feeders can significantly reduce their environmental footprint. Additionally, obtaining certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems can enhance the credibility of suppliers in the eyes of buyers.

The emphasis on ethical supply chains is not merely a trend but a necessity. Consumers are more aware than ever of the importance of sustainability, and they often prefer brands that align with their values. Therefore, B2B buyers must consider suppliers who are transparent about their sourcing methods and environmental impact. This focus on sustainability not only helps in meeting regulatory requirements but also positions businesses favorably in the competitive pet care market.

How Has the Pet Ultra Automatic Feeder Market Evolved Over Time?

The evolution of pet ultra automatic feeders reflects broader trends in pet care and technology. Initially, pet feeders were simple mechanical devices designed to dispense food at set intervals. However, as consumer expectations evolved, so did the technology. The introduction of programmable features allowed pet owners to customize feeding schedules, while advancements in materials improved safety and durability.

Over the past decade, the integration of smart technology has revolutionized the market. Many modern feeders now offer app connectivity, enabling pet owners to monitor and control feeding remotely. This shift towards automation and connectivity caters to the busy lifestyles of pet owners worldwide, particularly in urban regions.

The market has also seen a shift towards designs that prioritize both functionality and aesthetics, appealing to pet owners who view these devices as integral to their home decor. As the sector continues to innovate, B2B buyers must remain vigilant and adaptable to these changes, ensuring they offer products that meet the growing demands of conscientious consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of pet ultra automatic feeder instructions

-

How do I solve issues with food getting stuck in the PetUltra automatic feeder?

To address food clogging issues in the PetUltra automatic feeder, ensure that the kibble size is compatible with the device’s specifications, ideally between 2-10mm. Regular maintenance, such as cleaning the food passage and checking for blockages, is crucial. Additionally, utilizing the feeder’s anti-clogging features, like the double rotor design and wide-angle food passage, can significantly reduce the likelihood of food getting stuck. Educating your customers about these features will enhance their user experience and satisfaction. -

What is the best automatic pet feeder for large dogs?

For large dogs, the PetUltra DU4LB-KY automatic feeder is an excellent choice due to its 4L capacity, which holds approximately 12 pounds of dry food. Its portion control settings allow for customizable servings, ensuring that larger breeds receive adequate nutrition without overfeeding. Furthermore, the feeder’s dual power mode provides reliability, even during power outages, making it a dependable solution for pet owners with larger dogs. -

How can I customize the PetUltra automatic feeder for my market?

Customization options for the PetUltra automatic feeder may include branding, color variations, and packaging tailored to your target market. Discussing these specifications with the manufacturer can lead to product adaptations that resonate with local preferences. Additionally, consider offering different food compatibility options or unique features that cater to specific regional pet care practices, enhancing your product’s appeal in diverse markets. -

What are the minimum order quantities (MOQ) for purchasing PetUltra feeders?

The minimum order quantity (MOQ) for PetUltra feeders typically varies by supplier and region. It is advisable to directly contact the manufacturer or authorized distributors to obtain specific MOQ details. Understanding MOQ is crucial for planning inventory and ensuring that you can meet local demand without overextending your financial resources. Negotiating MOQs can also lead to better pricing and terms for larger orders. -

What payment terms should I expect when sourcing PetUltra feeders?

Payment terms for sourcing PetUltra feeders can vary widely among suppliers. Common practices include a deposit upfront (usually 30-50%) with the balance due prior to shipping. Some suppliers may offer net payment terms based on your business relationship or order volume. Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms, to ensure smooth transactions and mitigate risks. -

How do I ensure quality assurance (QA) for the PetUltra feeders?

To ensure quality assurance for PetUltra feeders, request certifications and quality control documentation from the manufacturer. Conducting factory audits, if feasible, can provide insight into production processes and adherence to quality standards. Additionally, consider ordering samples before placing a large order to evaluate product quality firsthand. Establishing clear QA protocols and communication with your supplier will help maintain consistent product quality. -

What logistics considerations should I keep in mind when importing PetUltra feeders?

When importing PetUltra feeders, it is vital to consider shipping methods, customs duties, and delivery timelines. Evaluate whether air freight or sea freight is more suitable based on urgency and budget. Additionally, ensure compliance with local import regulations and any necessary certifications for pet products. Collaborating with a reliable logistics partner can streamline the import process and help avoid unexpected delays or costs. -

How can I effectively market PetUltra automatic feeders in my region?

To effectively market PetUltra automatic feeders, tailor your marketing strategies to resonate with local pet owners. Utilize social media platforms, local pet expos, and partnerships with pet shops to increase visibility. Highlight the feeder’s unique features, such as programmable feeding schedules and voice recording capabilities, in your promotional materials. Additionally, consider offering introductory promotions or loyalty programs to attract and retain customers in your target market.

Top 2 Pet Ultra Automatic Feeder Instructions Manufacturers & Suppliers List

1. PETULTRA – PetUltra DU4LB-KY Pet Dry Food Dispenser

Domain: manuals.plus

Introduction: {“Product Name”: “PetUltra DU4LB-KY Pet Dry Food Dispenser”, “Brand”: “PETULTRA”, “Target Species”: [“Cats”, “Dogs”], “Material”: [“Plastic”, “Acrylonitrile Butadiene Styrene (ABS)”], “Dimensions”: “13.58 x 7.6 x 7.6 inches”, “Weight”: “3.6 Pounds”, “Capacity”: “4L (16 cups)”, “Equivalent to”: {“12-pound pet”: “Approximately 25 days of feeding”, “22-pound pet”: “Approximately 15 days of feeding”},…

2. Pets Cat House – Automatic Pet Feeder

Domain: petscathouse.com

Registered: 2023 (2 years)

Introduction: {“Capacity”:”4 L (≈16 cups), holds up to ~12 lb kibble”,”Food type”:”Dry kibble 2–10 mm (up to 12 mm on newer models)”,”Power”:”DC 5 V/1 A adapter + 3×D-size alkaline batteries (for backup)”,”Setup & Programming”:{“Assembly”:”Attach the food tray to the base; add dry kibble to the tank and close the lid”,”Power On”:”Plug in adapter; install batteries if needed”,”Set Current Time”:”Unlock (long pre…

Strategic Sourcing Conclusion and Outlook for pet ultra automatic feeder instructions

In conclusion, the PetUltra DU4LB-KY Pet Dry Food Dispenser represents a significant advancement in pet care technology, offering features that cater to the needs of both pets and their owners. B2B buyers should take note of its programmable feeding schedules, portion control, and dual power options, which enhance convenience and reliability. These characteristics not only improve the user experience but also ensure that pets receive consistent nourishment, promoting their health and well-being.

Illustrative image related to pet ultra automatic feeder instructions

Strategic sourcing of such innovative products is essential for businesses aiming to meet the growing demand for high-quality pet care solutions. By investing in reliable and user-friendly automatic feeders, distributors can enhance their product offerings and gain a competitive edge in international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

As the pet care industry continues to evolve, the importance of adopting advanced feeding technologies cannot be overstated. We encourage international B2B buyers to explore partnerships with reputable manufacturers to integrate the PetUltra DU4LB-KY into their portfolios, paving the way for future growth and customer satisfaction. Together, let’s ensure that pets worldwide receive the care they deserve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pet ultra automatic feeder instructions