Introduction: Navigating the Global Market for 3 bowl dog feeding station

In today’s competitive pet supply market, sourcing a reliable and stylish 3 bowl dog feeding station can be a daunting challenge for B2B buyers. With a growing demand for elevated feeding solutions that cater to various dog sizes and dietary needs, understanding the nuances of this product category is essential. This guide offers a comprehensive exploration of the diverse types of 3 bowl dog feeding stations available on the market, their applications in both residential and commercial settings, and key considerations for supplier vetting.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including regions like Saudi Arabia and Germany—will find valuable insights into cost structures, shipping logistics, and market trends that influence purchasing decisions. By delving into factors such as material quality, ergonomic designs, and multifunctional features like storage options, this guide empowers businesses to make informed choices that enhance their product offerings and customer satisfaction.

Furthermore, the guide aims to simplify the sourcing process by providing actionable tips on identifying reputable manufacturers and understanding regional market preferences. In a landscape where pet ownership continues to rise, investing in high-quality dog feeding stations can significantly impact customer loyalty and brand reputation.

Table Of Contents

- Top 6 3 Bowl Dog Feeding Station Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 3 bowl dog feeding station

- Understanding 3 bowl dog feeding station Types and Variations

- Key Industrial Applications of 3 bowl dog feeding station

- 3 Common User Pain Points for ‘3 bowl dog feeding station’ & Their Solutions

- Strategic Material Selection Guide for 3 bowl dog feeding station

- In-depth Look: Manufacturing Processes and Quality Assurance for 3 bowl dog feeding station

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 bowl dog feeding station’

- Comprehensive Cost and Pricing Analysis for 3 bowl dog feeding station Sourcing

- Alternatives Analysis: Comparing 3 bowl dog feeding station With Other Solutions

- Essential Technical Properties and Trade Terminology for 3 bowl dog feeding station

- Navigating Market Dynamics and Sourcing Trends in the 3 bowl dog feeding station Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 3 bowl dog feeding station

- Strategic Sourcing Conclusion and Outlook for 3 bowl dog feeding station

- Important Disclaimer & Terms of Use

Understanding 3 bowl dog feeding station Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Elevated Triple Bowl Stand | Adjustable heights, durable materials, stainless steel bowls | Pet supply retailers, e-commerce platforms | Pros: Promotes better digestion; easy to clean. Cons: Higher upfront cost; requires space. |

| Triple Bowl Feeder with Storage | Integrated storage for food, stylish design | Pet furniture retailers, home goods stores | Pros: Reduces clutter; aesthetically pleasing. Cons: Assembly may be required; heavier. |

| Outdoor Triple Bowl Feeder | Weather-resistant materials, designed for outdoor use | Outdoor pet supply distributors | Pros: Durable; suitable for various weather conditions. Cons: Limited to outdoor settings; may require maintenance. |

| Slow Feed Triple Bowl Station | Specially designed bowls to slow down eating | Specialty pet stores, veterinary clinics | Pros: Promotes healthy eating; reduces choking risk. Cons: May not suit all dog breeds; can be more expensive. |

| Decorative Triple Bowl Diner | Unique designs, customizable aesthetics | Boutique pet shops, luxury pet brands | Pros: Attractive; can enhance home decor. Cons: Higher price point; may lack functional features. |

What Are the Key Characteristics of Elevated Triple Bowl Stands?

Elevated triple bowl stands are designed to improve the dining experience for dogs by raising the bowls to a comfortable height. These feeders often come in adjustable heights to accommodate different dog sizes and are typically made from durable materials like wrought iron and stainless steel. B2B buyers should consider the health benefits, such as improved digestion and reduced strain on pets, alongside the ease of cleaning and maintenance. These stands are ideal for pet supply retailers looking to offer high-quality solutions to customers.

How Do Triple Bowl Feeders with Storage Enhance User Experience?

Triple bowl feeders equipped with storage are designed to integrate functionality and style. They often feature a chic design with an integrated drawer for storing pet food, reducing clutter in the home. This type of feeder is particularly appealing to pet furniture retailers and home goods stores looking to attract customers interested in aesthetic solutions for pet care. Buyers should assess the quality of materials and assembly requirements, as these products may require more effort to set up.

What Makes Outdoor Triple Bowl Feeders Suitable for Various Environments?

Outdoor triple bowl feeders are constructed from weather-resistant materials, making them ideal for patios, decks, or gardens. They are particularly suited for outdoor pet supply distributors who cater to customers with active lifestyles. When purchasing, B2B buyers should evaluate the durability against environmental factors and the need for maintenance, as these feeders may require cleaning or repositioning due to weather conditions.

Why Are Slow Feed Triple Bowl Stations Important for Dog Health?

Slow feed triple bowl stations are specifically designed to promote healthy eating habits by slowing down the rate at which dogs consume their food. This type of feeder is particularly beneficial for specialty pet stores and veterinary clinics focused on promoting pet health. B2B buyers should consider the effectiveness of the design for different breeds and the potential for higher costs compared to standard feeders.

How Do Decorative Triple Bowl Diners Appeal to Luxury Pet Markets?

Decorative triple bowl diners offer unique designs that can enhance a home’s decor while providing functional feeding solutions for pets. These products are particularly attractive to boutique pet shops and luxury pet brands. Buyers should weigh the aesthetic appeal against the price point and whether the product offers the necessary functionality for pet owners.

Key Industrial Applications of 3 bowl dog feeding station

| Industry/Sector | Specific Application of 3 bowl dog feeding station | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care Facilities | Used in kennels and pet hotels for feeding multiple dogs | Enhances feeding efficiency, reduces mess, promotes health | Durability, ease of cleaning, adjustable heights |

| Veterinary Clinics | Provides a hygienic feeding solution for recovering pets | Supports recovery by ensuring proper nutrition and hydration | Materials safety, size variety for different breeds |

| Animal Shelters | Facilitates feeding of multiple dogs in a shared space | Streamlines feeding processes, improves animal welfare | Cost-effectiveness, ease of maintenance, storage options |

| Retail Pet Stores | Displayed as a premium product for pet owners | Attracts customers seeking quality and stylish solutions | Supplier reliability, design variety, local market trends |

| Dog Training Centers | Utilized for structured feeding during training sessions | Aids in behavioral training by establishing routine | Customization options, stability, and safety features |

How is the 3 Bowl Dog Feeding Station Used in Pet Care Facilities?

In pet care facilities such as kennels and pet hotels, the 3 bowl dog feeding station is invaluable for feeding multiple dogs simultaneously. Its design allows for organized feeding, reducing mess and ensuring that each pet has access to food and water. For international buyers, particularly in regions like Africa and the Middle East, sourcing durable materials that can withstand heavy use is crucial. Additionally, stations that are easy to clean and maintain help in promoting a hygienic environment, essential for pet health.

Illustrative image related to 3 bowl dog feeding station

Why is the 3 Bowl Dog Feeding Station Essential in Veterinary Clinics?

Veterinary clinics utilize 3 bowl dog feeding stations to provide a hygienic and efficient feeding solution for pets recovering from surgery or illness. These stations can be adjusted to accommodate various dog sizes, ensuring that all patients receive the appropriate care. Buyers from Europe, such as Germany, may prioritize materials that are safe and easy to disinfect, as well as designs that can facilitate monitoring food and water intake, which is critical for recovery.

How Do Animal Shelters Benefit from 3 Bowl Dog Feeding Stations?

Animal shelters benefit significantly from the use of 3 bowl dog feeding stations, as they streamline the feeding process for multiple dogs in shared spaces. This efficiency not only improves the welfare of the animals by ensuring they receive adequate nutrition but also aids staff in managing feeding times effectively. For buyers in South America, where resources may be limited, cost-effective options that do not compromise on quality are essential, alongside features that allow for easy storage and transport.

What Role Do Retail Pet Stores Play with 3 Bowl Dog Feeding Stations?

Retail pet stores can leverage the 3 bowl dog feeding station as a premium product offering to attract discerning pet owners. By showcasing these stylish and functional feeding solutions, retailers can differentiate themselves in a competitive market. For B2B buyers in regions like Europe, understanding local market trends and customer preferences is key to selecting designs that resonate with consumers, while also ensuring reliability from suppliers to maintain stock levels.

Illustrative image related to 3 bowl dog feeding station

How Are 3 Bowl Dog Feeding Stations Used in Dog Training Centers?

In dog training centers, 3 bowl dog feeding stations are employed to establish structured feeding routines that can aid in behavioral training. By using these stations during training sessions, trainers can create a consistent environment that helps dogs learn proper eating habits. Buyers from diverse regions, including Africa and the Middle East, should consider customization options that cater to specific training needs, alongside features that ensure stability and safety during use.

3 Common User Pain Points for ‘3 bowl dog feeding station’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable and Functional Dog Feeders

The Problem: Many B2B buyers encounter challenges when sourcing three-bowl dog feeding stations that are both durable and functional. In regions like Africa and South America, where local suppliers may not offer high-quality products, buyers often find themselves choosing between low-cost options that lack durability or overpriced items that don’t meet their needs. This situation can lead to dissatisfaction among end consumers, who expect reliable and long-lasting pet products. Furthermore, the lack of standardized sizes and designs complicates the selection process, making it difficult for buyers to find suitable products for various dog breeds.

The Solution: To overcome sourcing challenges, B2B buyers should prioritize suppliers that specialize in high-quality, customizable dog feeding stations. When evaluating suppliers, consider their material choices—look for options like stainless steel and durable wrought iron, which offer longevity and resistance to wear and tear. Additionally, buyers can request samples to assess the product’s quality before making bulk purchases. Engaging with manufacturers that allow for customization in bowl sizes and heights can also ensure that the feeding stations cater to a diverse range of dog breeds. Lastly, building relationships with suppliers who have a solid reputation and positive customer reviews can provide insights into the long-term performance of their products.

Scenario 2: Managing Mess and Cleanliness Issues

The Problem: One significant concern for buyers is the mess associated with traditional dog feeding solutions. Spills and food waste can create unhygienic conditions, particularly in environments like pet daycare centers or grooming facilities. Buyers often struggle to find three-bowl feeding stations that minimize mess while being easy to clean, which can lead to increased operational costs and reduced customer satisfaction.

The Solution: To address cleanliness concerns, B2B buyers should look for elevated three-bowl feeding stations that feature integrated spill-proof designs, such as rubberized edges that keep bowls in place and prevent tipping. Additionally, selecting models with removable bowls can simplify the cleaning process and ensure that hygiene standards are met. Suppliers that offer feeders with trays to catch spills can further reduce mess and make cleanup easier. Buyers should also consider investing in products made from non-porous materials, as these are less likely to harbor bacteria and are generally easier to maintain. Lastly, providing customers with guidance on proper cleaning methods for the feeders can enhance user experience and prolong the product’s lifespan.

Illustrative image related to 3 bowl dog feeding station

Scenario 3: Catering to Diverse Pet Sizes and Breeds

The Problem: In markets with a wide variety of dog breeds, buyers often face the challenge of selecting feeding stations that accommodate different sizes and feeding habits. A one-size-fits-all approach can lead to discomfort for pets, as smaller dogs may struggle with elevated feeders designed for larger breeds, while larger dogs may require more substantial bowls. This mismatch can result in negative experiences for both pets and their owners, ultimately affecting sales and brand loyalty.

The Solution: To effectively cater to diverse pet sizes, B2B buyers should prioritize suppliers that offer a range of height options and bowl sizes in their three-bowl dog feeding stations. Engaging with manufacturers that provide adjustable-height feeders can allow for versatility and accommodate various breeds. Additionally, consider sourcing feeders with slow-feed designs that promote healthy eating habits, particularly for large breeds prone to gulping their food. Offering a variety of color and style options can also appeal to different customer preferences, enhancing the product’s marketability. Buyers should conduct market research to identify popular breeds in their target regions, enabling them to stock products that meet the specific needs of their clientele.

Strategic Material Selection Guide for 3 bowl dog feeding station

What Are the Key Materials for a 3 Bowl Dog Feeding Station?

When selecting materials for a 3 bowl dog feeding station, it is essential to consider various factors such as durability, cost, manufacturing complexity, and compliance with international standards. Here, we explore four common materials used in the construction of these feeding stations: stainless steel, wrought iron, recycled plastic, and wood.

How Does Stainless Steel Perform in Dog Feeding Stations?

Stainless steel is a popular choice for dog feeding stations due to its high corrosion resistance and durability. It can withstand various environmental conditions, making it suitable for both indoor and outdoor use. Stainless steel bowls are easy to clean and maintain, which is crucial for hygiene. However, the cost of stainless steel can be relatively high compared to other materials, and it may not provide the aesthetic appeal some buyers desire.

For international buyers, compliance with food safety standards is essential. Stainless steel products should meet ASTM and FDA regulations, ensuring they are safe for pet use. Additionally, its sleek design aligns with modern aesthetics, appealing to European markets like Germany, where style and functionality are paramount.

Illustrative image related to 3 bowl dog feeding station

What Are the Advantages of Wrought Iron in Feeding Stations?

Wrought iron offers a robust and stylish option for elevated dog feeders. Known for its strength and longevity, wrought iron can support heavy bowls and withstand rough use. Its aesthetic versatility allows it to fit into various decor styles, from rustic to contemporary. However, wrought iron can be susceptible to rust if not properly coated, especially in humid climates found in parts of Africa and the Middle East.

For B2B buyers, understanding the local climate is crucial. In regions with high humidity, selecting a wrought iron feeder with a protective finish can mitigate rust concerns. Additionally, compliance with local manufacturing standards, such as DIN in Germany, is necessary to ensure product quality and safety.

Why Choose Recycled Plastic for Dog Feeding Stations?

Recycled plastic is gaining traction as an eco-friendly alternative for dog feeding stations. It is lightweight, resistant to moisture, and does not rust or corrode, making it ideal for outdoor use. The cost of recycled plastic is generally lower than that of metal options, which can attract budget-conscious buyers. However, it may not offer the same level of durability as metal materials, particularly under extreme conditions.

International buyers should consider the environmental regulations in their regions. In South America and Africa, where sustainability is increasingly valued, recycled plastic products can enhance a brand’s reputation. Compliance with local recycling and material standards can also be a selling point.

How Does Wood Compare as a Material for Dog Feeding Stations?

Wood is often chosen for its aesthetic appeal and natural look. It can be crafted into various designs, providing a warm and inviting feel. However, wood is less durable than metal options and can be prone to warping, splintering, or rotting, especially in damp environments. Regular maintenance is required to ensure longevity.

Illustrative image related to 3 bowl dog feeding station

For B2B buyers in regions with varying climates, selecting treated or sealed wood can enhance durability. Compliance with local standards related to wood treatment and safety is also essential, particularly in Europe, where regulations around chemical treatments are stringent.

Summary of Material Considerations for 3 Bowl Dog Feeding Stations

| Material | Typical Use Case for 3 bowl dog feeding station | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Indoor and outdoor feeding stations | High corrosion resistance | Higher cost | High |

| Wrought Iron | Elevated feeders for large dogs | Strong and durable | Susceptible to rust without coating | Medium |

| Recycled Plastic | Eco-friendly outdoor feeders | Lightweight and moisture-resistant | Less durable under extreme conditions | Low |

| Wood | Aesthetic indoor feeders | Natural look and design flexibility | Prone to warping and requires maintenance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions that align with their target markets and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 bowl dog feeding station

What Are the Main Stages of Manufacturing a 3 Bowl Dog Feeding Station?

The manufacturing process of a 3 bowl dog feeding station typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final product meets quality standards and consumer expectations.

Material Preparation

The process begins with selecting appropriate materials, which may include stainless steel for the bowls, wrought iron or recycled plastic for the stand, and rubber for anti-slip features. Suppliers must ensure that these materials comply with health and safety regulations, particularly when food contact is involved. Materials are then cut and shaped to the required specifications, often using advanced machinery for precision.

Forming Techniques

During the forming stage, various techniques may be employed depending on the material. For metal components, processes such as stamping, bending, and welding are common. These techniques ensure the structural integrity of the feeding station. For plastic components, injection molding is often used, allowing for intricate designs and durability. The forming process is critical, as it determines the product’s strength and usability.

Illustrative image related to 3 bowl dog feeding station

Assembly of Components

Once the components are formed, the next step is assembly. This process can be manual or automated, depending on the scale of production. For elevated feeders with multiple bowls, careful alignment and secure fastening are essential to prevent spills and ensure stability. Quality assurance checks are often conducted at this stage to identify any defects in assembly.

Finishing Touches

The final stage involves finishing processes, which may include surface treatments, painting, or powder coating. These not only enhance aesthetic appeal but also provide additional protection against rust and corrosion. For example, stainless steel bowls may undergo polishing to achieve a high-gloss finish that is also easy to clean. This stage is vital for ensuring that the product is visually appealing and functionally robust.

How Is Quality Assurance Implemented in the Manufacturing of Dog Feeding Stations?

Quality assurance (QA) is an integral part of the manufacturing process, particularly in the pet product industry, where safety and durability are paramount. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system.

International Standards and Certifications

Adherence to standards like CE marking is crucial for products sold in Europe, ensuring that they meet safety, health, and environmental protection requirements. For manufacturers targeting markets in Africa and South America, compliance with regional standards is equally important. Certifications such as API (American Petroleum Institute) may also be relevant, particularly if the materials are sourced from specific industrial sectors.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet specified standards. Any non-conforming materials are rejected at this stage to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor the quality of work in progress. This includes assessing the forming techniques and assembly practices to ensure compliance with design specifications.

-

Final Quality Control (FQC): Once the product is assembled, a thorough inspection is conducted to evaluate its overall quality and functionality. This may involve testing the stability of the feeding station, checking for any sharp edges, and ensuring that the bowls are securely fastened.

What Testing Methods Are Commonly Used for Dog Feeding Stations?

Testing methods for dog feeding stations vary based on their design and materials, but several standardized approaches are commonly employed to ensure product safety and effectiveness.

Common Testing Methods

– Durability Testing: This assesses the ability of the feeding station to withstand daily use, including weight load tests and stress tests to evaluate structural integrity.

-

Safety Testing: Products are tested for sharp edges, pinch points, and overall safety to ensure they are safe for pets. This includes checking the stability of the feeding station to prevent tipping.

-

Material Testing: Bowls are often tested for food safety, ensuring that they do not leach harmful substances. This includes tests for corrosion resistance and ease of cleaning.

-

Functional Testing: This includes evaluating the design’s effectiveness in preventing spills and ensuring that the bowls are easy for pets to access.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those sourcing products internationally, verifying a supplier’s quality control processes is essential to ensure that they receive products that meet required standards.

Conducting Supplier Audits

One of the most effective ways to verify quality control is through supplier audits. Buyers can request to visit manufacturing facilities to observe the production processes and quality control measures in place. This provides firsthand insight into the supplier’s commitment to quality.

Requesting Quality Assurance Documentation

Buyers should also request documentation related to quality assurance practices, including reports on IQC, IPQC, and FQC processes. Certifications and compliance documents related to international standards should be readily available from reputable suppliers.

Illustrative image related to 3 bowl dog feeding station

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct inspections at various stages of production and verify that the products meet the specified quality standards. This is particularly important for buyers from regions with stringent import regulations, such as Europe.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control and certification requirements.

Regional Standards and Regulations

Buyers should familiarize themselves with local regulations governing pet products. For instance, European buyers must ensure compliance with EU regulations regarding pet food safety, while buyers in the Middle East may encounter specific import regulations that dictate product standards.

Cultural Considerations

Cultural preferences can also influence product design and functionality. For example, certain regions may prioritize eco-friendly materials, while others may focus on aesthetic appeal. Understanding these nuances can guide buyers in selecting suppliers that align with their target market’s preferences.

Illustrative image related to 3 bowl dog feeding station

Building Long-Term Relationships with Suppliers

Establishing long-term relationships with reliable suppliers can facilitate better communication regarding quality control practices. Regular interactions allow buyers to stay updated on any changes in manufacturing processes and quality assurance measures.

Conclusion

The manufacturing processes and quality assurance measures for 3 bowl dog feeding stations are critical for ensuring that these products meet the expectations of B2B buyers. By understanding the stages of production, quality control checkpoints, and testing methods, buyers can make informed decisions when sourcing these essential pet products. Additionally, being aware of regional standards and the nuances of international trade can further enhance the purchasing experience, leading to successful partnerships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 bowl dog feeding station’

To effectively source a 3 bowl dog feeding station, international B2B buyers must consider various factors that will ensure they select a product that meets both quality and market demand. This guide provides a structured checklist to facilitate a successful procurement process.

1. Identify Market Demand and Trends

Understanding the current market demand and trends is essential for successful sourcing. Research the preferences of dog owners in your target regions, such as Africa, South America, the Middle East, and Europe. Look for trends regarding materials (e.g., stainless steel vs. plastic), design aesthetics, and functionality (like elevated feeders for large breeds).

2. Define Your Technical Specifications

Before approaching suppliers, establish clear technical specifications for the feeding stations. Consider factors such as size (height and bowl capacity), material durability, and design features (e.g., anti-slip bases or storage options). This will help ensure that the products you source align with your customers’ needs.

- Size Considerations: Ensure the feeding station accommodates various dog breeds.

- Material Selection: Prioritize materials that offer longevity and ease of cleaning.

3. Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in dog feeding stations. Use online platforms, trade shows, and industry directories to gather a list of manufacturers and wholesalers. Focus on suppliers with a strong reputation and positive customer reviews.

- Supplier Capabilities: Ensure they can meet your volume and customization needs.

- Geographical Considerations: Assess suppliers based on their ability to deliver to your target markets efficiently.

4. Evaluate Product Quality and Safety Standards

Quality assurance is paramount when sourcing pet products. Request samples to evaluate the durability and design of the feeding stations. Additionally, verify that the products comply with safety regulations and standards in your target regions.

- Material Safety: Ensure that materials used are non-toxic and safe for pets.

- Quality Certifications: Look for certifications that validate the quality of the manufacturing process.

5. Verify Supplier Certifications

Before finalizing any agreements, verify that your chosen suppliers possess the necessary certifications. This includes ISO certifications, compliance with local regulations, and any specific pet industry standards. These certifications provide assurance of the supplier’s commitment to quality and safety.

Illustrative image related to 3 bowl dog feeding station

- Documentation Review: Request copies of relevant certifications and documentation.

- Compliance Checks: Ensure that suppliers are familiar with the regulations applicable to your target markets.

6. Assess Pricing and Payment Terms

Once you have shortlisted suppliers, request detailed quotes that outline pricing, payment terms, and shipping costs. Compare these offers carefully to determine the best value for your business. Be mindful of any hidden costs that could affect your profit margins.

- Bulk Discounts: Inquire about bulk order pricing to maximize profitability.

- Payment Flexibility: Look for suppliers who offer favorable payment terms that suit your cash flow needs.

7. Establish Clear Communication and Support Channels

Effective communication is crucial for a smooth sourcing process. Ensure that your suppliers provide reliable support and clear lines of communication. Establish expectations regarding response times and support for any issues that may arise post-purchase.

- Language Considerations: Consider language barriers and ensure that communication is effective.

- After-Sales Support: Confirm that the supplier offers after-sales support and product warranties.

By following this checklist, B2B buyers can make informed decisions when sourcing 3 bowl dog feeding stations, ensuring they meet market demands and maintain high standards of quality and safety.

Comprehensive Cost and Pricing Analysis for 3 bowl dog feeding station Sourcing

What Are the Key Cost Components in Sourcing a 3 Bowl Dog Feeding Station?

When evaluating the cost structure of a 3 bowl dog feeding station, several key components contribute to the overall pricing. These include:

Illustrative image related to 3 bowl dog feeding station

-

Materials: The primary materials used, such as stainless steel, wrought iron, or recycled plastics, significantly impact the cost. High-quality materials not only increase durability but also enhance aesthetic appeal, which can justify a higher price point.

-

Labor: The cost of labor varies by region. For instance, manufacturing in countries with higher labor costs, such as Germany, will be reflected in the final price. Conversely, lower labor costs in regions like Africa or South America may offer more competitive pricing.

-

Manufacturing Overhead: This encompasses costs associated with facilities, equipment, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling and Setup: Initial costs for molds and tools can be substantial, especially for customized designs. These expenses are often amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Investing in stringent QC processes ensures product reliability and safety, which can influence overall costs. Certifications (e.g., ISO, CE) may add to expenses but can enhance marketability and compliance in various regions.

-

Logistics: Shipping costs, including freight charges, customs duties, and insurance, can vary significantly based on the shipping method and distance. Incoterms (International Commercial Terms) will also dictate who bears these costs, impacting the total price.

-

Margin: Suppliers typically incorporate a profit margin into the pricing. This margin can vary widely based on market conditions, competition, and perceived value.

How Do Price Influencers Affect the Cost of 3 Bowl Dog Feeding Stations?

Several factors can influence the pricing of 3 bowl dog feeding stations, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally attract lower per-unit costs due to economies of scale. Negotiating higher MOQs can lead to significant savings.

-

Specifications and Customization: Customized designs, such as specific dimensions or color options, often result in higher costs due to unique tooling and production processes. Standardized products tend to be more economical.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., food safety standards) can increase costs but also provide assurance of product longevity and safety, appealing to discerning buyers.

-

Supplier Factors: Supplier reputation, reliability, and service level can impact pricing. Established suppliers with a proven track record may charge a premium, but they often provide better quality and customer service.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, influencing overall costs.

What Are Effective Buyer Tips for Negotiating Prices on 3 Bowl Dog Feeding Stations?

International B2B buyers should adopt several strategies to ensure cost-efficiency when sourcing 3 bowl dog feeding stations:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Leverage bulk ordering as a negotiation point to secure discounts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs such as maintenance, durability, and potential replacement needs. Investing in higher-quality products may result in lower TCO.

-

Research Market Rates: Compare prices from various suppliers across different regions to understand market trends and establish a baseline for negotiations.

-

Factor in Regional Differences: Be aware of how local economic conditions, tariffs, and exchange rates can affect pricing. This knowledge can help in negotiating better deals.

-

Explore Multiple Suppliers: Engaging with a range of suppliers allows for better price comparisons and can lead to improved terms as suppliers compete for business.

Disclaimer on Indicative Prices

It is important to note that prices for 3 bowl dog feeding stations can vary widely based on the aforementioned factors and are subject to change. Therefore, buyers should seek updated quotes directly from suppliers to get the most accurate and relevant pricing information for their specific requirements.

Alternatives Analysis: Comparing 3 bowl dog feeding station With Other Solutions

Introduction: Exploring Alternatives to the 3 Bowl Dog Feeding Station

When it comes to dog feeding solutions, the 3 bowl dog feeding station is a popular choice for many pet owners and businesses alike. However, various alternatives can also meet the needs of dogs and their owners, each offering distinct advantages and disadvantages. This analysis will compare the 3 bowl dog feeding station with alternative solutions, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 3 Bowl Dog Feeding Station | Elevated Single Bowl Feeder | Automatic Dog Feeder |

|---|---|---|---|

| Performance | Provides multiple feeding options simultaneously; promotes better digestion. | Suitable for single-dog households; encourages proper posture while eating. | Offers timed feeding; ideal for busy owners or multi-pet households. |

| Cost | $80 – $225 depending on materials and design. | $40 – $120 based on height and material. | $50 – $200 depending on features and capacity. |

| Ease of Implementation | Requires assembly; straightforward installation. | Typically easy to assemble; fewer components. | May require programming; some models need a power source. |

| Maintenance | Requires regular cleaning of bowls; durable materials reduce wear. | Low maintenance; easy to clean; fewer parts. | Requires regular refills and occasional cleaning; depends on technology. |

| Best Use Case | Ideal for multi-dog households or dogs with diverse dietary needs. | Best for single-dog homes; promotes healthy eating posture. | Suitable for busy lifestyles or for owners who travel frequently. |

Detailed Breakdown of Alternatives

Elevated Single Bowl Feeder

The elevated single bowl feeder is a simplified version of the 3 bowl dog feeding station, designed primarily for one dog. Its primary advantage is the ergonomic design that encourages healthy eating habits by reducing strain on the dog’s neck and back. Additionally, these feeders are generally less expensive and easier to maintain, making them an attractive option for individual pet owners. However, they may not cater to the needs of multi-dog households or dogs with specific dietary requirements, limiting their appeal.

Automatic Dog Feeder

An automatic dog feeder represents a modern solution for pet feeding, particularly appealing for busy pet owners or those with multiple dogs. These devices can be programmed to dispense food at specific times, ensuring pets are fed even when their owners are away. The convenience of automatic feeding helps in maintaining a consistent feeding schedule, which is beneficial for dogs with dietary restrictions. However, these feeders can be more expensive and may require more maintenance in terms of refilling and cleaning. Additionally, they may not suit dogs that prefer variety in their meals, which the 3 bowl feeding station provides.

Conclusion: Making the Right Choice for Your Business Needs

When selecting the right dog feeding solution for your business, it’s essential to consider the specific needs of your customers and their pets. The 3 bowl dog feeding station excels in providing versatility and accommodating multiple dogs, making it ideal for pet stores, dog daycares, or grooming facilities. In contrast, the elevated single bowl feeder offers an economical choice for individual pet owners, while the automatic dog feeder caters to those with busy lifestyles. By evaluating performance, cost, maintenance, and best use cases, B2B buyers can choose the solution that aligns best with their business model and customer preferences.

Essential Technical Properties and Trade Terminology for 3 bowl dog feeding station

What Are the Key Technical Properties of a 3 Bowl Dog Feeding Station?

When selecting a 3 bowl dog feeding station, understanding its technical specifications is crucial for ensuring product quality, durability, and suitability for various markets. Here are some essential properties:

-

Material Composition

The most common materials used in the construction of dog feeding stations include stainless steel, wrought iron, and recycled plastic. Stainless steel is favored for its rust resistance and easy cleaning, making it ideal for both indoor and outdoor use. Wrought iron offers durability and aesthetic appeal, while recycled plastic provides a lightweight and eco-friendly alternative. Knowing the material helps buyers assess the product’s longevity and maintenance needs. -

Dimensions and Height Variability

The dimensions of the feeding station, including the height of the stands, are critical for accommodating dogs of different sizes. Elevated feeders typically come in various heights (e.g., 5.5″, 8″, or adjustable) to promote better digestion and reduce strain on a dog’s neck and back. Buyers should consider their target market’s dog sizes to ensure the product meets their needs. -

Bowl Capacity and Design

Bowl sizes often vary, with common configurations including two-quart and three-quart options. The design should facilitate easy access for pets while minimizing spills. Features like rubber rims can help stabilize bowls and prevent noise, which is particularly important for multi-dog households. Understanding bowl capacity and design will help buyers cater to different feeding preferences. -

Weight Tolerance and Stability

A feeding station must withstand the weight of food, water, and the dogs using it. Weight tolerance is a key specification that affects stability; products should be robust enough to prevent tipping. This is particularly important for larger breeds, which may exert more force during feeding. Buyers should assess the stability features to ensure safety and usability. -

Ease of Assembly and Maintenance

Many feeding stations require assembly, so the number of components and the complexity of assembly instructions can impact the purchasing decision. Additionally, ease of cleaning is essential for hygiene. Products designed for quick disassembly or with dishwasher-safe bowls can appeal to buyers looking for convenience. -

Aesthetic and Functional Design

The style and color options available can significantly affect consumer preference. Modern aesthetics, like farmhouse or contemporary designs, can influence marketability. Additionally, features such as built-in storage for pet food can enhance functionality. Buyers should consider the design’s appeal to their target demographic.

What Are Common Trade Terms Related to 3 Bowl Dog Feeding Stations?

Navigating the B2B landscape involves understanding specific trade terminology that can impact purchasing decisions and negotiations. Here are some common terms:

Illustrative image related to 3 bowl dog feeding station

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For dog feeding stations, an OEM might provide the bowls or stands that a brand assembles and sells under its label. Understanding OEM relationships can help buyers identify quality sources for components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the pet product industry, MOQs can vary widely, affecting inventory management and cash flow. Buyers need to negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of 3 bowl dog feeding stations, a well-structured RFQ can help buyers obtain competitive pricing and understand the supplier’s capabilities. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade that define the responsibilities of buyers and sellers. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps buyers manage shipping costs and responsibilities effectively. -

Lead Time

This term refers to the time it takes from placing an order to receiving it. Lead time can affect inventory management and sales strategies. Buyers should inquire about lead times to plan their inventory effectively. -

Warranty and Return Policy

Warranties guarantee the product’s performance for a specified period, while return policies outline the conditions under which a product can be returned. Understanding these terms is essential for mitigating risks associated with product defects or customer dissatisfaction.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the 3 bowl dog feeding station Sector

What Are the Current Market Dynamics and Key Trends Influencing the 3 Bowl Dog Feeding Station Sector?

The global market for 3 bowl dog feeding stations is experiencing significant growth, driven by an increase in pet ownership and the rising demand for innovative and ergonomic pet products. B2B buyers in regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing high-quality, versatile feeding solutions that cater to multiple dog breeds and sizes. Key trends include the elevation of dog feeders to promote better digestion and reduce strain on pets, as well as the integration of stylish designs that complement modern home aesthetics.

Emerging technologies are influencing the sourcing process, with an increasing number of suppliers offering customizable options through digital platforms. This trend is particularly relevant for B2B buyers looking for tailored solutions that meet specific market needs. Additionally, the rise of e-commerce and online marketplaces is streamlining the procurement process, allowing international buyers to access a wider range of products and suppliers with ease.

Market dynamics are also shifting due to consumer preferences for sustainable and ethical products. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainability, which includes using eco-friendly materials and ethical manufacturing practices. As a result, the competitive landscape is evolving, with businesses that adapt to these trends likely to gain a significant advantage in the marketplace.

Illustrative image related to 3 bowl dog feeding station

How Can Sustainability and Ethical Sourcing Impact the 3 Bowl Dog Feeding Station Market?

Sustainability and ethical sourcing are becoming increasingly important in the 3 bowl dog feeding station sector. The environmental impact of manufacturing processes is under scrutiny, prompting B2B buyers to seek suppliers who prioritize eco-friendly practices. Products made from recycled materials or sustainably sourced wood are gaining traction, appealing to environmentally conscious consumers.

Ethical supply chains are not just a preference but a necessity in today’s market. Suppliers that can demonstrate transparency in their sourcing practices and labor conditions are more likely to attract business from international buyers. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management can enhance a supplier’s credibility.

Moreover, the growing demand for ‘green’ materials, such as biodegradable plastics and organic finishes, is reshaping product offerings. B2B buyers should look for suppliers who invest in sustainable innovations, as these products not only meet consumer demand but also contribute to a positive brand image. Ultimately, aligning with sustainable practices can lead to increased customer loyalty and open up new market opportunities.

Illustrative image related to 3 bowl dog feeding station

How Has the 3 Bowl Dog Feeding Station Evolved Over Time?

The evolution of the 3 bowl dog feeding station reflects broader trends in pet care and consumer preferences. Historically, pet feeders were basic and functional, often made from low-cost materials. However, as pet ownership has risen and the humanization of pets has accelerated, there has been a significant shift towards more sophisticated designs that prioritize both functionality and aesthetics.

In the past decade, the introduction of elevated feeding stations has revolutionized the market. These designs not only enhance the dining experience for pets but also address health concerns related to feeding posture. Innovations such as built-in storage solutions and customizable heights further illustrate the trend towards multifunctional products that meet the diverse needs of pet owners.

As international B2B buyers navigate this evolving landscape, understanding these historical shifts can provide valuable insights into consumer preferences and market demands, enabling them to make informed sourcing decisions.

Illustrative image related to 3 bowl dog feeding station

Frequently Asked Questions (FAQs) for B2B Buyers of 3 bowl dog feeding station

-

How do I choose the right supplier for a 3 bowl dog feeding station?

Selecting the right supplier involves evaluating their experience, production capacity, and reputation in the market. Look for suppliers who specialize in pet products and have a proven track record of quality and reliability. Request product samples to assess material quality and craftsmanship. Additionally, consider their communication responsiveness and ability to meet your specific needs, including customization options. Checking references and reviews from other B2B buyers can also provide insight into the supplier’s reliability. -

What customization options are available for 3 bowl dog feeding stations?

Many manufacturers offer customization in terms of size, color, material, and design. You can often choose between different heights to accommodate various dog sizes, as well as materials such as stainless steel, wood, or recycled plastic. Some suppliers may also allow for branding options, such as logo placement or unique design features. Be sure to discuss your specific requirements during negotiations to ensure that the final product aligns with your brand’s image and customer preferences. -

What is the minimum order quantity (MOQ) for a 3 bowl dog feeding station?

The MOQ can vary significantly among suppliers, typically ranging from 50 to several hundred units. Factors influencing MOQ include production capabilities, material availability, and the supplier’s business model. It’s advisable to clarify MOQ during your initial discussions with potential suppliers. If you are looking to test the market, inquire if the supplier can accommodate smaller orders for a trial run before committing to larger quantities. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely, but common practices include a deposit (usually 30-50%) upfront and the balance upon shipment or delivery. Some suppliers may offer letter of credit (L/C) options for larger orders, which can provide security for both parties. Always confirm payment methods accepted, such as wire transfers or credit cards, and ensure that the terms are clearly outlined in your purchase agreement to avoid any misunderstandings. -

How can I ensure the quality of the 3 bowl dog feeding stations?

To ensure quality, consider implementing a quality assurance (QA) process that includes pre-production samples, in-process inspections, and final product checks. Request certifications for materials used, such as food safety standards for stainless steel bowls. Collaborating with third-party inspection services can also help verify that the products meet your specifications before shipment. Establishing clear quality expectations upfront with your supplier will facilitate a smoother QA process. -

What logistics considerations should I keep in mind when sourcing internationally?

Logistics can be complex, particularly when dealing with international shipments. Key considerations include shipping methods, customs regulations, and potential tariffs or taxes. Work with a freight forwarder experienced in handling pet products to navigate these challenges. Additionally, clarify delivery timelines with your supplier to ensure that you can meet your market demands. It’s also beneficial to discuss incoterms (e.g., FOB, CIF) to understand the responsibilities of each party in the shipping process. -

What are the most common materials used in 3 bowl dog feeding stations?

Common materials include stainless steel for bowls, which is durable and easy to clean, and various metals or woods for the stand. Stainless steel is preferred for its resistance to rust and bacteria, making it a hygienic choice for pet feeding. Wrought iron and recycled plastic are also popular for their sturdiness and aesthetic appeal. When sourcing, consider the environmental impact of materials and look for suppliers who prioritize sustainability in their production processes. -

How do I handle potential disputes with international suppliers?

To manage disputes effectively, establish clear communication channels and document all agreements in detail. Use contracts that outline terms, including delivery schedules, quality standards, and payment terms. If disputes arise, attempt to resolve them through direct negotiation first. If needed, consider mediation or arbitration as alternatives to legal action, which can be costly and time-consuming. Familiarizing yourself with international trade laws and regulations can also provide a framework for resolving issues amicably.

Top 6 3 Bowl Dog Feeding Station Manufacturers & Suppliers List

1. The Love Made Home – 3 Bowl Elevated Pet Feeder

Domain: thelovemadehome.com

Registered: 2021 (4 years)

Introduction: 3 bowl elevated pet feeder with storage drawer; Price: $314.99 USD; Dimensions: Length 36 in., Depth 14 ¼ in., Height Varies; Includes 3 stainless steel bowls (2 two-quart and 1 three-quart); Made in the USA; Requires simple assembly (approx. 10 pieces excluding hardware); Designed to match tilt-out trash cabinet and pet food storage (sold separately); Free shipping to contiguous U.S.; Family-owne…

2. Official Doghouse – Elevated Dog Feeders for Large Dogs

Domain: officialdoghouse.com

Registered: 2005 (20 years)

Introduction: Elevated Dog Feeders for Large Dogs include various models such as Duke’s Delight Elevated Dog Feeder ($76.99, sale price from $74.99), Laddies Best Elevated Feeder (from $144.99), Outdoor/Indoor Metal Feeder for Dogs – White (from $76.99), Extra Tall Elevated Dog Bowl Stand ($149.99, sale price $147.99), Cherry Elevated Dog Feeder ($109.99, sale price from $98.99), Noblesse Elevated Dog Feeder ($…

3. Etsy – 3 Bowl Dog Feeder

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – 3 Bowl Dog Feeder, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Pinterest – Large Personalized 3 Bowl Dog Feeder

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Large Personalized 3 Bowl Dog Feeder, Farmhouse Style, Rustic Design, Raised Dog Bowl Feeder, Handmade wooden box for bowls, Lower part made of 4.4 x 4.4 cm thick wood, Removable metal (inox) bowls for easy cleaning, Bowls fit perfectly into holes in the box, Customizable color and height options, Dimensions: Height: 26 cm (10.23 inches), Length: 76 cm (29.92 inches), Width: 25 cm (9.84 inches)

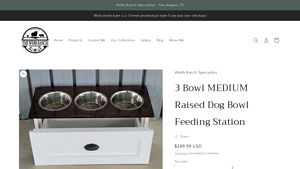

5. The Web Branch – 3 Bowl Medium Raised Dog Bowl Feeding Station

Domain: shop.thewebbranch.com

Registered: 2021 (4 years)

Introduction: Product Name: 3 Bowl MEDIUM Raised Dog Bowl Feeding Station

Price: $289.99 USD (Regular price $349.99 USD)

Dimensions: Approx. 29.25″L x 11.75″H x 12.5″W

Suitable for: Medium dog breeds (e.g., Boxers, Basset Hounds, Australian Shepherds) measuring at least 10 inches from the floor to the middle of the chest.

Bowls: Comes with two 2-quart stainless steel bowls.

Materials: 3/4″ plywood for bases, he…

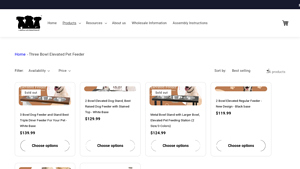

6. Bearwood Essentials – Three Bowl Elevated Pet Feeder

Domain: bearwoodessentials.com

Registered: 2022 (3 years)

Introduction: Three Bowl Elevated Pet Feeder – Regular price: $139.99. Available in stock (4 products). Free shipping on all U.S. orders over $35. Other related products include 2 Bowl Elevated Dog Stand ($129.99), Metal Bowl Stand with Larger Bowl ($124.99), and various 2 Bowl Elevated Regular Feeders ranging from $109.99 to $119.99. The mission of Bearwood Essentials is to provide quality elevated pet feeders…

Strategic Sourcing Conclusion and Outlook for 3 bowl dog feeding station

In the competitive landscape of pet products, the strategic sourcing of three-bowl dog feeding stations presents a unique opportunity for B2B buyers to capitalize on a growing market segment. By prioritizing quality materials, such as stainless steel and durable wrought iron, businesses can offer products that not only enhance the dining experience for dogs but also cater to the aesthetic preferences of pet owners. The inclusion of innovative features, like elevated designs and storage solutions, adds value and differentiates offerings in a crowded marketplace.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, focusing on suppliers who provide customization options and sustainable materials will be crucial. This approach not only meets the diverse needs of various consumer demographics but also aligns with global trends toward eco-consciousness.

Looking ahead, the demand for premium pet products is expected to continue rising. By establishing partnerships with reliable manufacturers and leveraging market insights, businesses can position themselves advantageously. Engage with suppliers today to enhance your product line and meet the evolving demands of pet owners worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.