Introduction: Navigating the Global Market for how often to clean hummingbird feeder

In the competitive landscape of avian supply, understanding how often to clean hummingbird feeders is crucial for businesses aiming to attract and maintain a healthy population of these vibrant birds. The challenge lies in sourcing feeders that not only meet aesthetic and functional demands but also align with best practices for cleanliness and bird health. This comprehensive guide delves into the various types of hummingbird feeders available in the global market, their applications across different climates, and critical considerations for supplier vetting, including quality assurance and compliance with environmental standards.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—this guide serves as an essential resource. It empowers decision-makers by providing actionable insights on the frequency of feeder cleaning based on environmental conditions, the implications of feeder design on maintenance, and the potential costs associated with poor hygiene practices. By equipping businesses with knowledge about proper care and maintenance protocols, this guide not only enhances product offerings but also fosters a commitment to avian welfare, ensuring that your supply chain remains competitive and responsible in a global marketplace.

Table Of Contents

- Top 2 How Often To Clean Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often to clean hummingbird feeder

- Understanding how often to clean hummingbird feeder Types and Variations

- Key Industrial Applications of how often to clean hummingbird feeder

- 3 Common User Pain Points for ‘how often to clean hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often to clean hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often to clean hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to clean hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often to clean hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often to clean hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often to clean hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often to clean hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often to clean hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often to clean hummingbird feeder

- Important Disclaimer & Terms of Use

Understanding how often to clean hummingbird feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Daily Cleaning | Required in hot climates; prevents mold and spoilage. | Retailers in tropical regions. | Pros: Ensures fresh nectar; attracts more birds. Cons: Time-consuming; requires frequent stocking. |

| Every 3 Days | Suitable for temperate climates; balances maintenance and care. | Garden centers in moderate climates. | Pros: Less frequent cleaning; manageable workload. Cons: Risk of nectar spoilage in warm spells. |

| Twice a Week | Ideal for cooler temperatures; reduces maintenance burden. | Suppliers in seasonal markets. | Pros: Reduced cleaning frequency; easier inventory management. Cons: May not support high bird traffic. |

| As Needed | Clean when feeder is empty or shows signs of mold/insects. | Custom feeder manufacturers. | Pros: Flexible; tailored maintenance schedule. Cons: Inconsistent quality; potential neglect. |

| Weekly Cleaning | Standard for year-round feeding; maintains feeder hygiene. | Year-round bird feeding retailers. | Pros: Regular upkeep promotes bird health; good for customer satisfaction. Cons: Requires regular labor input. |

What are the characteristics of Daily Cleaning for Hummingbird Feeders?

Daily cleaning is essential for feeders located in hot climates where nectar can ferment quickly. This method ensures that the sugar solution remains fresh and free from mold, which is vital for attracting hummingbirds. For B2B buyers, especially retailers in tropical regions, this approach emphasizes the importance of quality control in maintaining customer satisfaction. However, the frequency of cleaning can be labor-intensive and may require consistent stocking of nectar supplies.

How does Every 3 Days Cleaning benefit businesses?

Cleaning every three days strikes a balance suitable for temperate climates. This schedule allows businesses, such as garden centers in moderate climates, to maintain feeder hygiene without overwhelming their staff. The manageable cleaning frequency helps prevent spoilage while ensuring that feeders remain attractive to birds. However, B2B buyers must be cautious during warm spells as nectar can spoil more quickly than expected, necessitating more frequent checks.

Why is Twice a Week Cleaning a viable option?

For cooler temperatures, a twice-a-week cleaning schedule is effective in reducing maintenance efforts while still ensuring a healthy feeding environment for hummingbirds. This method is particularly beneficial for suppliers operating in seasonal markets, as it aligns with the reduced bird activity seen in colder months. While this option eases the cleaning burden, it may not support high bird traffic, which could impact sales during peak seasons.

What are the advantages of As Needed Cleaning?

The “as needed” cleaning approach allows for flexibility, enabling businesses to clean feeders when they are empty or when mold or insect presence is detected. This method is ideal for custom feeder manufacturers who can tailor their maintenance schedules to customer needs. However, it carries the risk of inconsistent quality if feeders are neglected, potentially leading to customer dissatisfaction and loss of business.

How does Weekly Cleaning support year-round feeding?

Weekly cleaning is a standard practice for businesses that provide year-round bird feeding solutions. This regular maintenance schedule helps ensure that feeders remain hygienic and appealing, promoting bird health and enhancing customer satisfaction. Retailers focusing on year-round sales must account for the labor input required for this cleaning frequency, balancing it against the benefits of maintaining a quality product that attracts and retains customers.

Key Industrial Applications of how often to clean hummingbird feeder

| Industry/Sector | Specific Application of how often to clean hummingbird feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Ornithology Research | Regular cleaning schedules for feeders in research sites | Ensures accurate data collection on hummingbird behavior | Availability of cleaning solutions and tools suitable for fieldwork |

| Eco-Tourism | Maintenance of feeders in tourist attractions | Enhances visitor experience by attracting diverse bird species | Sustainable cleaning products that align with eco-friendly practices |

| Agriculture (Crop Pollination) | Feeding stations for pollinators in agricultural settings | Increases crop yields by supporting pollinator populations | Access to feeders that are easy to clean and maintain in various climates |

| Wildlife Rehabilitation | Hygiene protocols for feeders in animal care facilities | Prevents disease transmission among rehabilitating birds | Compliance with health standards and availability of specialized cleaning products |

| Retail (Garden Supplies) | Selling hummingbird feeders with cleaning kits | Increases sales through value-added services | Quality assurance for cleaning kits and feeder durability in diverse environments |

How is ‘how often to clean hummingbird feeder’ utilized in Ornithology Research?

In ornithology research, maintaining a consistent cleaning schedule for hummingbird feeders is crucial for accurate data collection. Researchers monitor the feeding habits and behaviors of hummingbirds, and unclean feeders can lead to skewed results due to mold or contamination. Buyers in this sector need access to effective cleaning solutions that are portable and easy to use in field conditions, ensuring they can maintain feeders without impacting their research timelines.

What role does ‘how often to clean hummingbird feeder’ play in Eco-Tourism?

In eco-tourism, hummingbird feeders are often placed in natural reserves or parks to attract visitors. Regular cleaning is essential to maintain the feeders, ensuring they remain appealing and safe for birds. This enhances the visitor experience by increasing the likelihood of observing a variety of bird species. Tour operators must source sustainable cleaning products that align with their environmental ethos, making it critical to consider the ecological impact of their maintenance practices.

How does ‘how often to clean hummingbird feeder’ support Agriculture?

For agricultural businesses, hummingbird feeders can serve as supplemental feeding stations to support pollinator populations. Regular cleaning is necessary to prevent diseases that could affect both the birds and crops. By maintaining feeders, farmers can enhance pollination, leading to improved crop yields. Buyers should seek feeders that are easy to clean and maintain, particularly in varying climates, to ensure the health of both the feeders and the surrounding ecosystem.

Why is ‘how often to clean hummingbird feeder’ important in Wildlife Rehabilitation?

In wildlife rehabilitation, cleanliness of hummingbird feeders is vital to prevent the spread of diseases among rehabilitating birds. Establishing strict hygiene protocols ensures that feeders are regularly cleaned and disinfected, promoting the health of the birds in care. Facilities must consider sourcing specialized cleaning products that meet health standards while being effective in removing contaminants, ensuring a safe environment for the birds.

How does ‘how often to clean hummingbird feeder’ enhance Retail opportunities?

Retail businesses specializing in garden supplies can benefit significantly from offering hummingbird feeders along with cleaning kits. Educating customers on the importance of regular cleaning can enhance sales and customer satisfaction. Retailers should focus on sourcing high-quality cleaning kits that provide added value, ensuring that customers have the necessary tools to maintain their feeders effectively in diverse climates, thereby fostering repeat business.

3 Common User Pain Points for ‘how often to clean hummingbird feeder’ & Their Solutions

Scenario 1: The Dilemma of Timely Cleaning for Seasonal Demand

The Problem: For businesses that sell hummingbird feeders or related products, understanding the appropriate cleaning frequency can be a significant challenge. Many B2B buyers may not realize that the cleaning schedule varies significantly based on environmental conditions. For instance, in tropical regions of Africa or South America, high temperatures can lead to rapid fermentation of sugar solutions, resulting in mold growth that can harm hummingbirds. This lack of awareness can lead to unsanitary conditions for birds, damaging the business’s reputation and potentially leading to customer dissatisfaction.

The Solution: To address this issue, B2B buyers should implement a comprehensive cleaning schedule that aligns with local weather patterns. It is advisable to establish a tiered cleaning protocol: in hot climates, feeders should be cleaned daily or every other day, while in temperate regions, a three-day cleaning cycle may suffice. Businesses can also educate their customers about these practices through detailed guides or labeling on the product packaging. Providing a checklist with cleaning frequency recommendations based on local climates can enhance customer trust and ensure that the birds remain healthy, fostering positive brand associations.

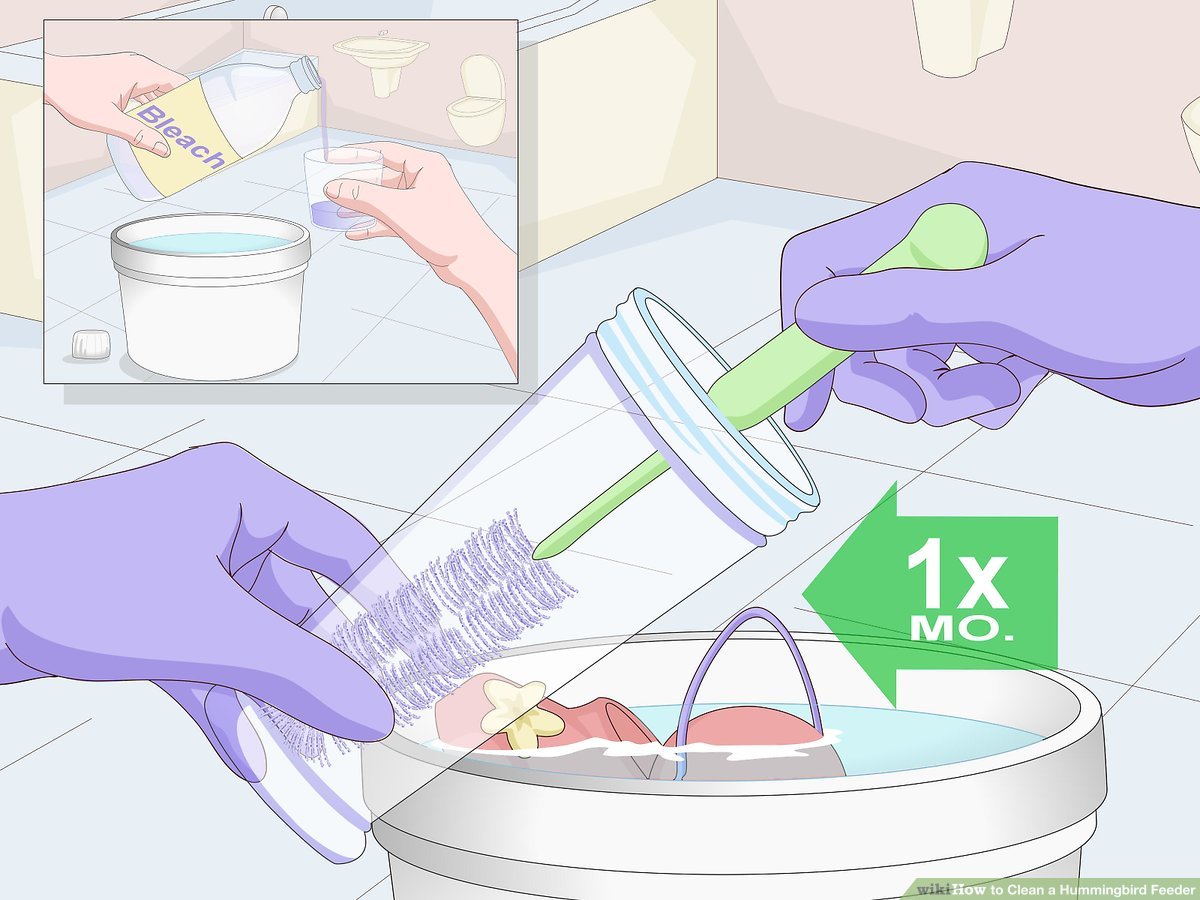

Illustrative image related to how often to clean hummingbird feeder

Scenario 2: Overcoming Customer Confusion About Cleaning Methods

The Problem: Many buyers may struggle with confusion regarding the appropriate cleaning agents and methods for hummingbird feeders. Some may mistakenly believe that household cleaners or soaps are suitable, which can leave harmful residues that affect the birds. This misunderstanding can lead to health issues for the birds and a negative experience for the customers, ultimately resulting in returns or complaints about the product.

The Solution: To combat this confusion, businesses should offer clear guidance on safe cleaning methods. An effective strategy is to create instructional content that specifies only using hot water and safe solutions like vinegar or hydrogen peroxide for cleaning. Including visual aids or videos demonstrating the cleaning process can further enhance understanding. Additionally, businesses can consider providing complimentary cleaning tools, such as brushes specifically designed for hummingbird feeders, with every purchase. This proactive approach not only ensures the proper maintenance of feeders but also fosters customer loyalty by enhancing their experience.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: For B2B buyers who manage inventory for hummingbird feeders, the seasonal fluctuations in demand can create challenges. During peak seasons, particularly in spring and summer, there is often a surge in sales, leading to increased inquiries about cleaning frequency and practices. Without a strategy to manage these inquiries and maintain stock levels, businesses risk losing potential sales and damaging customer relationships.

The Solution: A robust inventory management system that aligns with seasonal trends can mitigate this challenge. Businesses should analyze historical sales data to predict peak demand periods and stock accordingly. Additionally, creating a proactive customer service strategy that includes automated responses to common questions about cleaning frequency can streamline operations. Providing resources such as an FAQ section on the company website, complete with information on cleaning schedules, can also help manage customer expectations. Offering bundled packages that include feeders with a recommended cleaning kit can further enhance sales and ensure customer satisfaction during peak periods.

Strategic Material Selection Guide for how often to clean hummingbird feeder

What Are the Best Materials for Hummingbird Feeders and Their Cleaning Frequency?

When selecting materials for hummingbird feeders, it’s essential to consider how often they will need to be cleaned. This is influenced by factors such as the climate, the feeder’s design, and the specific needs of the hummingbirds. Below are analyses of four common materials used for hummingbird feeders, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Glass

Key Properties: Glass is non-porous, easy to clean, and resistant to staining. It can withstand a wide range of temperatures, making it suitable for various climates.

Pros & Cons: Glass feeders are durable and provide a clear view of the nectar level, which is appealing for both birds and consumers. However, they can be heavier and more fragile than other materials, leading to potential breakage during transport or handling. The manufacturing process can also be more complex, increasing costs.

Impact on Application: Glass is compatible with all types of nectar solutions and does not leach chemicals into the food, ensuring safety for the birds. However, in regions with extreme temperatures, glass feeders may require additional insulation or protection.

Illustrative image related to how often to clean hummingbird feeder

Considerations for International Buyers: Compliance with safety standards such as ASTM or DIN is crucial. Buyers in Europe may prefer glass due to its perceived quality, while those in warmer regions like Africa or South America might consider the weight and fragility in their logistics.

2. Plastic

Key Properties: Plastic feeders are lightweight and can be molded into various shapes and designs. They are generally resistant to corrosion and UV degradation.

Pros & Cons: The primary advantage of plastic is its affordability and versatility. It is less likely to break than glass, making it easier to handle and transport. However, lower-quality plastics can warp or discolor over time, especially when exposed to sunlight. Additionally, some plastics may not be as easy to clean thoroughly, leading to potential health risks for the birds.

Impact on Application: Plastic feeders may require more frequent cleaning due to potential residue buildup. They are compatible with most nectar solutions but may not be suitable for long-term use if they degrade quickly.

Illustrative image related to how often to clean hummingbird feeder

Considerations for International Buyers: Ensuring that the plastic complies with international safety standards is essential. Buyers should be aware of the type of plastic used (e.g., BPA-free) and its environmental impact, especially in regions with strict regulations.

3. Metal (Aluminum or Stainless Steel)

Key Properties: Metal feeders are highly durable and resistant to corrosion, especially if made from stainless steel. They can withstand extreme temperatures and are less likely to break.

Pros & Cons: Metal feeders are generally easy to clean and can last for many years. However, they can be heavier and more expensive than plastic options. Additionally, if not coated properly, they may rust or corrode over time.

Illustrative image related to how often to clean hummingbird feeder

Impact on Application: Metal is compatible with all nectar types, but care must be taken to prevent rust. Regular cleaning is necessary to avoid any buildup that could affect the feeder’s longevity.

Considerations for International Buyers: Compliance with international metal standards is critical, particularly in regions like Europe where regulations may be stricter. Buyers should also consider the weight and shipping costs associated with metal feeders.

4. Silicone

Key Properties: Silicone is flexible, lightweight, and resistant to extreme temperatures. It is also non-toxic and easy to clean.

Pros & Cons: The flexibility of silicone allows for innovative designs, and it is less likely to break compared to glass or plastic. However, silicone may not be as durable in the long term, especially under constant exposure to sunlight, which can lead to degradation.

Impact on Application: Silicone feeders can be designed to be easily disassembled for cleaning, which is beneficial for maintaining hygiene. However, they may not hold up as well in harsh environmental conditions.

Illustrative image related to how often to clean hummingbird feeder

Considerations for International Buyers: Buyers should ensure that silicone materials meet food safety standards and are free from harmful chemicals. Preferences may vary by region, with some markets favoring traditional materials like glass or metal.

Summary Table

| Material | Typical Use Case for how often to clean hummingbird feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Ideal for high-quality feeders requiring frequent cleaning | Durable and easy to clean | Heavy and fragile | High |

| Plastic | Common for budget-friendly feeders needing regular cleaning | Lightweight and versatile | Can warp and discolor | Low |

| Metal | Suitable for long-lasting feeders with moderate cleaning | Highly durable and corrosion-resistant | Heavier and potentially more expensive | Med |

| Silicone | Great for innovative designs needing regular maintenance | Flexible and non-toxic | May degrade under sunlight | Med |

This analysis provides a comprehensive overview of material selection for hummingbird feeders, emphasizing the importance of cleaning frequency and international considerations for B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for how often to clean hummingbird feeder

What Are the Key Manufacturing Processes for Hummingbird Feeders?

Understanding the manufacturing processes involved in producing hummingbird feeders is crucial for B2B buyers aiming to source high-quality products. This knowledge not only aids in ensuring product quality but also helps in negotiating with suppliers effectively.

What are the Main Stages of Hummingbird Feeder Manufacturing?

The manufacturing of hummingbird feeders typically involves several key stages, including material preparation, forming, assembly, and finishing.

-

Material Preparation: The choice of materials is paramount. Most hummingbird feeders are made from glass or durable plastics. Raw materials undergo rigorous quality checks to ensure they meet industry standards. For instance, plastics must be BPA-free and UV-resistant to withstand outdoor conditions. Suppliers should provide material safety data sheets (MSDS) to verify compliance.

-

Forming: This stage includes processes like molding, cutting, or blowing. Glass feeders may require glass-blowing techniques, while plastic feeders are often produced via injection molding. Each method has specific tolerances and quality requirements that must be adhered to during production.

-

Assembly: After forming, components such as feeding ports, hangers, and nectar reservoirs are assembled. This stage often employs automated machinery to ensure precision. Quality control measures are critical at this point to ensure that all parts fit seamlessly and function as intended.

-

Finishing: The final stage includes surface treatments, labeling, and packaging. Aesthetics are important in attracting buyers; therefore, the finishing touches must align with market preferences. Additionally, feeders should be tested for leaks and durability before packaging to ensure they meet quality expectations.

How is Quality Assurance Implemented in Hummingbird Feeder Production?

Quality assurance (QA) is integral to the manufacturing of hummingbird feeders, ensuring that the final product meets safety and performance standards.

Illustrative image related to how often to clean hummingbird feeder

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are crucial for ensuring a consistent quality management system. Compliance with ISO standards indicates that the manufacturer has established processes to enhance customer satisfaction through effective process management.

For specific product safety, look for certifications like CE marking in Europe, which indicates compliance with health and safety standards, or API certification for products intended for use in certain environments.

What Are the Key QC Checkpoints During Production?

Quality control (QC) checkpoints are essential throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected to ensure they meet specified requirements. This step prevents defects from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, random samples may be tested to ensure that production processes are within specified limits. This could involve measuring dimensions or testing for leaks in assembled feeders.

-

Final Quality Control (FQC): Once production is complete, finished products undergo thorough inspections. This may include stress testing, cleaning procedures, and visual inspections to ensure that the feeders are free from defects.

What Common Testing Methods Are Used for Hummingbird Feeders?

Various testing methods are employed to ensure the quality and safety of hummingbird feeders. Common tests include:

-

Material Integrity Testing: Assessing the strength and durability of materials under different conditions (e.g., UV exposure, temperature fluctuations).

-

Leak Testing: Ensuring that feeders do not leak nectar, which could attract insects and mold. This is typically done through pressure testing or submersion testing.

-

Toxicology Testing: Verifying that materials used in the feeders do not leach harmful substances into the nectar. This is particularly important for plastic feeders.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers adhere to rigorous quality control processes:

-

Supplier Audits: Conducting regular audits can help verify that suppliers comply with quality standards and maintain their certifications. This includes checking production processes, employee training, and equipment maintenance.

-

Requesting Quality Reports: Suppliers should provide documentation of quality control measures, including testing results and compliance certificates. This transparency is crucial for building trust.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality assurance processes. This can be particularly useful for buyers from regions where they may not have direct oversight.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of QC and certification is vital. Each region may have different regulations that affect product acceptance:

-

Regional Compliance: For instance, European buyers should be aware of REACH regulations concerning chemical safety, while buyers in the Middle East might need to comply with local standards that differ from international norms.

-

Cultural Considerations: B2B buyers from regions like Africa and South America should consider cultural factors that might affect product usage and preferences. Manufacturers should be able to adapt their offerings based on these insights.

-

Logistical Challenges: Ensure that suppliers can manage logistics effectively, particularly concerning shipping and delivery timelines. This is especially important when importing products across continents.

In conclusion, understanding the manufacturing processes and quality assurance measures for hummingbird feeders not only equips B2B buyers with the knowledge to make informed purchasing decisions but also enhances their ability to engage effectively with suppliers. By focusing on quality and compliance, buyers can ensure that they provide safe and reliable products that meet the needs of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to clean hummingbird feeder’

Introduction

This guide is designed to assist B2B buyers in understanding the best practices for maintaining hummingbird feeders, focusing specifically on cleaning frequency. Proper maintenance is essential not only for the health of the birds but also for ensuring a reliable and appealing product for customers. By following this checklist, businesses can enhance their offerings and support responsible bird feeding.

Step 1: Understand Local Climate Conditions

Understanding the climate in your target market is crucial for determining cleaning frequency. Different regions experience varying temperatures, which can affect how quickly nectar spoils.

– In hot climates, plan for daily or every-other-day cleaning, while temperate regions may require cleaning every three days.

– For cooler climates, cleaning twice a week is often sufficient.

Illustrative image related to how often to clean hummingbird feeder

Step 2: Define Cleaning Protocols

Establish clear cleaning protocols that align with industry standards. This ensures consistency and reliability in maintenance practices.

– Use solutions such as hot water with hydrogen peroxide or vinegar, avoiding harsh chemicals that could harm the birds.

– Provide training materials for staff on the appropriate cleaning techniques to ensure compliance.

Step 3: Evaluate Cleaning Equipment Needs

Consider the necessary tools and equipment for effective cleaning. Having the right supplies can significantly streamline the cleaning process.

– Invest in specialized brushes for reaching small feeding ports and nooks.

– Ensure that cleaning solutions are readily available and that staff are trained on their safe use.

Step 4: Monitor Hummingbird Activity

Keep track of hummingbird visitation patterns to adjust cleaning schedules accordingly. Observing when birds are most active can inform when feeders are likely to need replenishing and cleaning.

– Use data collection methods to record visitation rates and nectar consumption.

– Adjust cleaning frequency based on observed patterns to maintain feeder appeal.

Illustrative image related to how often to clean hummingbird feeder

Step 5: Communicate with Customers

Educate your customers on the importance of regular cleaning and maintenance of hummingbird feeders. Providing clear communication can enhance customer satisfaction and promote responsible feeding practices.

– Develop informative materials that outline cleaning frequency based on regional climates.

– Offer tips on troubleshooting common issues, such as mold or insect presence, to empower customers.

Step 6: Establish a Feedback Loop

Create a feedback system to gather insights from customers about their experiences with feeder maintenance. This can inform product development and customer support strategies.

– Regularly survey customers on their cleaning practices and challenges.

– Use this data to refine your offerings and enhance customer education.

Step 7: Stay Updated on Best Practices

Continuously research and stay informed about the latest best practices in hummingbird feeder maintenance. Industry standards can evolve, and staying current can give you a competitive edge.

– Subscribe to relevant publications or join birding associations for ongoing education.

– Attend workshops or webinars that focus on bird feeding and maintenance techniques.

Illustrative image related to how often to clean hummingbird feeder

By following this checklist, B2B buyers can ensure they are equipped to maintain hummingbird feeders effectively, thereby enhancing the health of local bird populations and improving customer satisfaction.

Comprehensive Cost and Pricing Analysis for how often to clean hummingbird feeder Sourcing

What Are the Key Cost Components for Cleaning Hummingbird Feeders?

When analyzing the cost structure of sourcing hummingbird feeders, several key components come into play:

-

Materials: The primary material used in hummingbird feeders is typically high-grade plastic or glass, which must be durable and safe for birds. Costs can fluctuate based on the quality and sourcing location. Additionally, cleaning solutions (like vinegar or bleach) should be factored into the overall cost.

-

Labor: Labor costs encompass the wages for workers involved in manufacturing, assembling, and cleaning feeders. In regions with lower labor costs, such as parts of Africa and South America, overall expenses can be reduced, impacting the final pricing structure favorably for buyers.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Overhead costs can vary significantly based on geographic location and the efficiency of the production process.

-

Tooling: The initial investment in molds and tools for creating unique feeder designs can impact pricing. Customization requests, such as specific colors or shapes, will also increase tooling costs.

-

Quality Control (QC): Ensuring that products meet safety and quality standards is crucial. This may involve additional testing and inspections, which contribute to the overall cost.

-

Logistics: Transportation costs, including shipping and handling, are critical, especially for international buyers. Factors such as distance, mode of transport, and customs duties can significantly influence logistics costs.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Hummingbird Feeder Sourcing?

Several factors influence the pricing of hummingbird feeders, particularly for international buyers:

-

Volume/MOQ: Bulk purchases can lead to lower unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to benefit from these savings.

-

Specifications and Customization: Custom designs or special features (like UV-resistant materials) can increase costs. Buyers must weigh the benefits of customization against the potential for higher prices.

-

Materials and Quality Certifications: The choice of materials significantly affects pricing. Feeders made from premium materials or those with eco-friendly certifications may command higher prices but offer longer-lasting solutions.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more due to perceived quality, while emerging manufacturers may offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping (like FOB, CIF, etc.) can help buyers anticipate additional costs, such as insurance and freight charges, which are integral to the total cost of ownership.

What Are the Best Negotiation and Cost-Efficiency Tips for International Buyers?

International buyers should consider the following strategies to enhance cost-efficiency when sourcing hummingbird feeders:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and bulk pricing. A well-structured negotiation can lead to significant savings.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, cleaning frequency, and potential replacements. A feeder that requires less frequent cleaning may save costs in the long run.

-

Understand Regional Pricing Nuances: Prices may differ based on local market conditions and demand. For example, buyers in Europe may face different pricing structures compared to those in Africa or South America due to shipping routes and import tariffs.

-

Evaluate Supplier Relationships: Establishing long-term relationships with reliable suppliers can lead to better pricing and priority service. Building trust can also facilitate smoother negotiations.

Disclaimer on Indicative Prices

Prices for hummingbird feeders and their cleaning solutions are subject to change based on market dynamics, material costs, and supplier pricing strategies. Buyers are encouraged to conduct thorough market research and request quotes from multiple suppliers to ensure they receive competitive pricing.

Alternatives Analysis: Comparing how often to clean hummingbird feeder With Other Solutions

When considering how often to clean a hummingbird feeder, it’s essential to evaluate various alternatives that can achieve similar objectives. This analysis aims to provide a comprehensive comparison of traditional cleaning methods against emerging solutions that can enhance the feeding experience for hummingbirds while ensuring their health and safety.

| Comparison Aspect | How Often To Clean Hummingbird Feeder | Alternative 1: Self-Cleaning Feeders | Alternative 2: Nectar Guard Feeders |

|---|---|---|---|

| Performance | High; ensures nectar is fresh and safe | Moderate; relies on technology | High; reduces contamination risk |

| Cost | Low; minimal supplies needed | High initial investment | Moderate; slightly higher than standard feeders |

| Ease of Implementation | Simple; requires manual effort | User-friendly, but tech-dependent | Easy to use; minimal maintenance required |

| Maintenance | Regular cleaning required (daily to weekly) | Low; self-cleaning feature reduces effort | Moderate; occasional cleaning needed |

| Best Use Case | Ideal for all environments | Best for busy users or commercial setups | Great for reducing insect interference |

What Are Self-Cleaning Feeders and Their Benefits?

Self-cleaning feeders utilize advanced technology to keep the nectar fresh by using UV light or heating elements to prevent mold and bacterial growth. The primary advantage of this solution is the significant reduction in maintenance time and effort. However, the initial investment can be substantial, making it less appealing for individual users or small-scale operations. For larger enterprises or commercial birdwatching businesses, the long-term savings on labor and cleaning supplies may justify the cost.

How Do Nectar Guard Feeders Work and What Are Their Advantages?

Nectar guard feeders are designed with unique feeding ports that prevent insects and larger birds from accessing the nectar while still allowing hummingbirds to feed. This feature minimizes the need for frequent cleaning due to reduced contamination. Although these feeders are generally more expensive than traditional models, they are easier to maintain and can significantly enhance the feeding experience for hummingbirds. Their efficiency in reducing pest interference makes them an excellent choice for environments with high insect populations.

Conclusion: How to Choose the Right Hummingbird Feeder Solution

For B2B buyers evaluating feeder solutions, the decision should be based on specific operational needs and environmental conditions. If regular maintenance and manual cleaning are manageable, traditional feeders may suffice. However, for operations with limited time or resources, investing in self-cleaning or nectar guard feeders could provide long-term benefits. Assessing factors such as performance, cost, ease of implementation, and maintenance will guide buyers toward the most suitable option for their hummingbird feeding needs. Ultimately, selecting the right solution not only supports the health of the birds but can also enhance the overall experience for customers and visitors.

Essential Technical Properties and Trade Terminology for how often to clean hummingbird feeder

What Are the Key Technical Properties for Cleaning Hummingbird Feeders?

When considering the cleaning and maintenance of hummingbird feeders, several technical properties play a crucial role in ensuring effective use and longevity of the product. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

-

Material Composition

The material of the feeder significantly influences its durability and ease of cleaning. Common materials include glass, plastic, and metal. Glass feeders are often preferred for their non-porous surface, which resists mold and bacteria buildup. Plastic feeders may be lighter and less fragile but can degrade over time with UV exposure. Metal feeders can offer longevity but may require special coatings to prevent rust. B2B buyers should prioritize feeders made of materials that are both durable and easy to sanitize. -

Feeder Capacity

The volume of nectar a feeder can hold is a critical specification. Larger capacity feeders reduce the frequency of refilling, which is advantageous for retailers or businesses with multiple feeders. However, larger feeders may require more maintenance, especially in warmer climates where nectar can spoil quickly. Understanding the balance between capacity and cleaning frequency helps businesses optimize their operations and cater to customer needs. -

Ease of Disassembly

Feeders designed for easy disassembly enable thorough cleaning, which is essential for maintaining bird health. Features such as wide openings and detachable components facilitate access to all parts of the feeder. For B2B buyers, investing in feeders that prioritize easy cleaning can enhance customer satisfaction and reduce return rates due to maintenance issues. -

Cleaning Recommendations

Each feeder type may come with specific cleaning guidelines that influence how often they should be maintained. For instance, some materials may require more frequent cleaning due to their propensity to harbor mold or bacteria. Understanding these recommendations allows buyers to provide accurate information to their clients, ensuring they maintain the feeders properly. -

Temperature Resistance

The ability of a feeder to withstand various temperature conditions is also vital. In regions with extreme heat, feeders must resist warping or degradation, while those in colder climates should prevent nectar from freezing. Buyers should consider feeders that can perform reliably across diverse environments to cater to a wider market.

What Are the Common Trade Terms Related to Hummingbird Feeders?

Familiarity with industry jargon is essential for B2B buyers to navigate transactions effectively and communicate with suppliers.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. For hummingbird feeders, understanding OEM relationships can help buyers source high-quality products tailored to specific market needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of the MOQ for hummingbird feeders, as it can affect inventory management and cash flow, especially for smaller retailers. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific quantities of products. For hummingbird feeders, submitting an RFQ can ensure that buyers receive competitive pricing and terms that align with their purchasing strategy. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international shipping. Knowledge of these terms helps buyers understand shipping costs, delivery responsibilities, and risk management when importing hummingbird feeders from global suppliers. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times for hummingbird feeders is crucial for inventory planning and ensuring timely availability for customers. -

SKU (Stock Keeping Unit)

A SKU is a unique identifier for each product variant. For businesses selling hummingbird feeders, having a clear SKU system helps in inventory tracking and sales analysis, enabling better decision-making regarding stocking and promotions.

By grasping these technical properties and trade terms, B2B buyers can enhance their operational efficiency, ensure customer satisfaction, and make strategic purchasing decisions in the hummingbird feeder market.

Navigating Market Dynamics and Sourcing Trends in the how often to clean hummingbird feeder Sector

Market Overview & Key Trends: How Often Should Hummingbird Feeders Be Cleaned?

The global market for hummingbird feeders is influenced by several factors, including increased interest in birdwatching, the rise of eco-tourism, and a growing awareness of wildlife conservation. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly sourcing products that cater to the needs of environmentally-conscious consumers. This trend is propelled by a desire for sustainable practices and the ethical treatment of wildlife.

Emerging technologies in this sector include smart feeders equipped with sensors that monitor nectar levels and cleanliness, alerting users when cleaning is necessary. This innovation addresses the critical aspect of feeder maintenance, as cleanliness directly affects hummingbird health. Moreover, the rise of e-commerce platforms is reshaping sourcing dynamics, allowing suppliers to reach a broader audience and streamline distribution channels.

In terms of market dynamics, the demand for effective cleaning solutions is paramount. Cleanliness of feeders is not just a matter of aesthetics; it is crucial for preventing mold and bacteria that could harm hummingbirds. Thus, B2B buyers should prioritize suppliers who offer comprehensive cleaning solutions and educational resources on feeder maintenance, ensuring a sustainable approach to attracting and caring for these vibrant birds.

How Can Sustainability & Ethical Sourcing Impact Hummingbird Feeder Maintenance?

The environmental impact of hummingbird feeders cannot be overlooked. Buyers are increasingly aware that the materials used in feeder production—such as plastics and metals—can have long-term effects on ecosystems. Ethical sourcing has become a priority, and companies that provide feeders made from recycled or sustainably sourced materials are gaining traction in the market. Certifications such as Forest Stewardship Council (FSC) for wood products or Global Recycle Standard (GRS) for recycled materials can enhance a supplier’s credibility.

Moreover, the cleaning solutions used for maintaining hummingbird feeders must also be environmentally friendly. Traditional cleaning agents can leave harmful residues; thus, buyers are seeking suppliers who offer natural or biodegradable options that are safe for wildlife. The importance of educating end-users about proper cleaning intervals—daily in hot weather, every three days in temperate conditions, and twice a week in cooler climates—also falls under the umbrella of sustainable practices. By advocating for responsible cleaning habits, suppliers can contribute to the overall health of hummingbird populations and promote a more sustainable market.

What Is the Brief Evolution of Hummingbird Feeders and Their Maintenance?

The concept of feeding hummingbirds began in the early 20th century, initially using simple homemade feeders. As interest in birdwatching grew, manufacturers began producing specialized feeders designed to attract these birds more effectively. Over the decades, advancements in materials and designs have improved durability and ease of maintenance, making it easier for users to provide a safe feeding environment.

Illustrative image related to how often to clean hummingbird feeder

In recent years, the focus has shifted towards maintaining cleanliness and hygiene in feeders. This evolution reflects a broader understanding of wildlife care and the responsibilities that come with attracting birds to our environments. B2B buyers should be aware of these historical trends, as they inform current preferences for both product quality and responsible sourcing practices. As the market continues to evolve, those who prioritize effective cleaning solutions and sustainable materials will be well-positioned to meet the needs of an increasingly conscientious consumer base.

Frequently Asked Questions (FAQs) for B2B Buyers of how often to clean hummingbird feeder

-

How often should hummingbird feeders be cleaned in hot climates?

In hot climates, it’s crucial to maintain a high standard of cleanliness for hummingbird feeders to prevent mold growth and maintain nectar quality. It is recommended to clean and refill the feeder every day or every other day during high temperatures. This ensures the nectar remains fresh and safe for the birds, which is essential for suppliers targeting regions with intense heat, such as parts of Africa and the Middle East. -

What is the best method for cleaning hummingbird feeders?

The best method for cleaning hummingbird feeders involves emptying the feeder and using a solution of hot water with either vinegar or hydrogen peroxide. Avoid using dish soap, as it can leave harmful residues. Scrubbing the feeding ports with a pipe cleaner ensures they are free of mold and debris. Suppliers should emphasize these cleaning guidelines in product instructions to ensure the health of the birds and the quality of their products. -

How can I ensure the hummingbird feeders I source are durable and easy to clean?

When sourcing hummingbird feeders, prioritize suppliers that offer products made from high-quality materials such as glass or durable plastics. Look for feeders designed with wide openings for easy access during cleaning and those with detachable parts for thorough maintenance. Request samples to evaluate the product’s durability and ease of cleaning before committing to larger orders. -

What are the typical minimum order quantities (MOQs) for hummingbird feeders?

Minimum order quantities can vary significantly depending on the supplier and the region. For hummingbird feeders, MOQs typically range from 100 to 500 units. However, it’s advisable to negotiate terms with suppliers, especially if you are entering a new market. Understanding the market demand in your region can also help in negotiating favorable terms. -

What payment terms should I expect when sourcing hummingbird feeders internationally?

Payment terms can differ based on the supplier’s policies and the buyer’s creditworthiness. Common terms include a 30% deposit upon order confirmation and the balance before shipping. Some suppliers may offer favorable terms such as net 30 or net 60 days, especially for established buyers. It’s essential to clarify payment terms upfront to avoid any misunderstandings during the transaction. -

How do I vet suppliers for quality assurance in hummingbird feeders?

To vet suppliers effectively, request certifications such as ISO or compliance with international safety standards. Conduct audits or site visits if possible to assess their manufacturing processes. Additionally, ask for references or testimonials from previous buyers. Utilizing third-party inspection services can also provide an added layer of assurance regarding product quality. -

What logistics considerations should I keep in mind when importing hummingbird feeders?

When importing hummingbird feeders, consider factors such as shipping methods, customs regulations, and potential tariffs. Evaluate both air and sea freight options for cost-effectiveness, especially for bulk orders. Working with a reliable freight forwarder can simplify the logistics process and ensure that your products arrive on time and in good condition. -

How can I customize hummingbird feeders for my market?

Customization can enhance product appeal in local markets. Engage with suppliers to explore options for colors, sizes, and branding on the feeders. Conduct market research to determine preferences in your target regions, such as specific colors or designs that attract local hummingbird species. Ensure that any customizations adhere to quality standards to maintain the product’s integrity and appeal.

Top 2 How Often To Clean Hummingbird Feeder Manufacturers & Suppliers List

1. Facebook – Hummingbird Feeder Care

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Hummingbird Feeder Care, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Southern Living – Hummingbird Feeder Care

Domain: southernliving.com

Registered: 1998 (27 years)

Introduction: To keep hummingbird feeders clean and safe, it is recommended to clean them every time the nectar solution is changed. In hot weather, clean the feeder daily; in cooler weather, clean it twice a week or before every refill if the birds empty it quickly. Signs that the nectar has gone bad include cloudiness, visible mold or mildew, and dead insects. For cleaning, disassemble the feeder and use a mi…

Strategic Sourcing Conclusion and Outlook for how often to clean hummingbird feeder

How Can Regular Cleaning of Hummingbird Feeders Enhance Your Business?

In summary, maintaining a consistent cleaning schedule for hummingbird feeders is crucial for the health of these birds and the effectiveness of your feeding strategy. Buyers should aim to clean feeders every 1-2 days in hot climates, every 3 days in moderate conditions, and at least twice a week in cooler weather. This diligence not only supports the well-being of hummingbirds but also strengthens your brand’s reputation as a conscientious supplier of quality bird feeding solutions.

Strategic sourcing plays a pivotal role in ensuring that businesses can access high-quality materials for feeder production and cleaning supplies. By investing in reliable suppliers and eco-friendly cleaning solutions, you can enhance product offerings and attract a broader customer base across diverse regions, including Africa, South America, the Middle East, and Europe.

Illustrative image related to how often to clean hummingbird feeder

As we look to the future, the demand for responsible and sustainable hummingbird feeding practices will continue to grow. Now is the time to position your business at the forefront of this trend. Engage with suppliers who prioritize quality and sustainability, and ensure that your products not only meet but exceed customer expectations. Together, we can foster a thriving ecosystem for both hummingbirds and businesses alike.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.