Introduction: Navigating the Global Market for auto pet feeders

In the fast-evolving pet care industry, sourcing reliable and innovative auto pet feeders poses a significant challenge for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. As pet ownership rises globally, so does the demand for automated feeding solutions that cater to various needs, from multi-pet households to specialized dietary requirements. This guide delves into the intricate landscape of auto pet feeders, exploring different types such as dry food dispensers, wet food feeders, and multifunctional units equipped with smart technology.

We will also cover essential applications, supplier vetting processes, and an analysis of cost structures, ensuring that businesses can make informed purchasing decisions. By understanding the nuances of the auto pet feeder market, international buyers can identify suitable suppliers who not only meet quality standards but also align with their operational goals. This comprehensive resource empowers B2B buyers to navigate the complexities of sourcing, ultimately enhancing their product offerings and customer satisfaction in a competitive marketplace. Whether you’re operating in the bustling markets of Nigeria or the affluent pet care sectors of Saudi Arabia, this guide serves as a vital tool in your quest for quality and innovation in pet care solutions.

Table Of Contents

- Top 5 Auto Pet Feeders Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for auto pet feeders

- Understanding auto pet feeders Types and Variations

- Key Industrial Applications of auto pet feeders

- 3 Common User Pain Points for ‘auto pet feeders’ & Their Solutions

- Strategic Material Selection Guide for auto pet feeders

- In-depth Look: Manufacturing Processes and Quality Assurance for auto pet feeders

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto pet feeders’

- Comprehensive Cost and Pricing Analysis for auto pet feeders Sourcing

- Alternatives Analysis: Comparing auto pet feeders With Other Solutions

- Essential Technical Properties and Trade Terminology for auto pet feeders

- Navigating Market Dynamics and Sourcing Trends in the auto pet feeders Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of auto pet feeders

- Strategic Sourcing Conclusion and Outlook for auto pet feeders

- Important Disclaimer & Terms of Use

Understanding auto pet feeders Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Programmable Timed Feeders | Allows scheduling of multiple meals; digital timers; suitable for dry food. | Pet stores, veterinary clinics, pet hotels. | Pros: Customizable feeding schedules; reduces overfeeding. Cons: Limited to dry food; may malfunction if not set up correctly. |

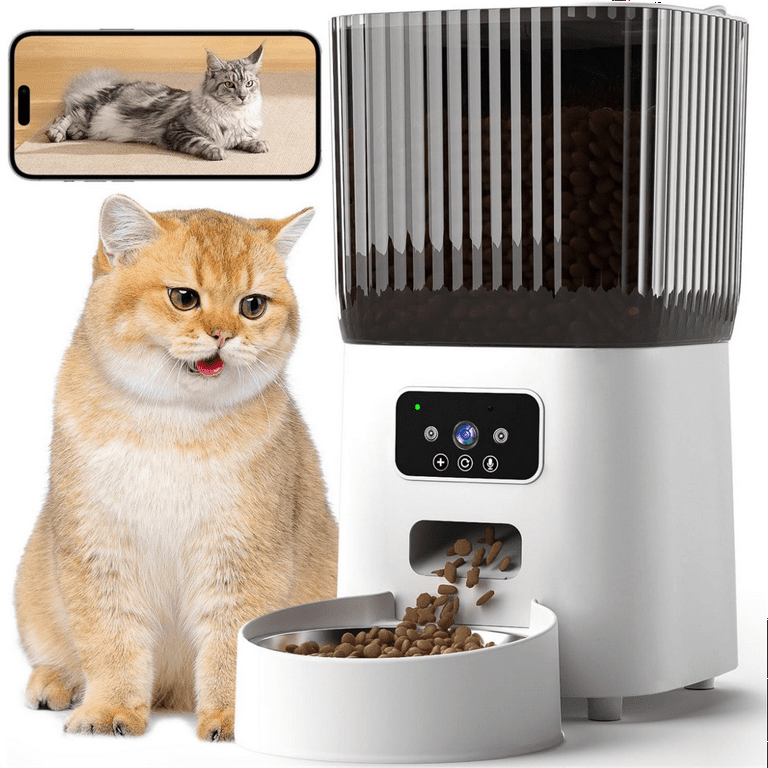

| Smart Automatic Feeders | Wi-Fi connectivity; app-controlled; often includes cameras for monitoring. | E-commerce platforms, tech-savvy pet retailers. | Pros: Remote monitoring and control; ideal for multi-pet households. Cons: Higher price point; requires reliable internet connection. |

| Gravity Feeders | Uses gravity to dispense food; simple design; suitable for dry food. | Budget retailers, rural pet supply stores. | Pros: No power needed; easy to refill. Cons: Less control over portion sizes; food may become stale. |

| Wet Food Feeders | Refrigeration options; designed for moist food; often includes ice packs. | Specialty pet shops, high-end pet services. | Pros: Keeps wet food fresh; caters to pets with specific dietary needs. Cons: Higher maintenance; may require more frequent cleaning. |

| Microchip Feeders | RFID technology to recognize pets; prevents food theft among multiple pets. | Veterinary clinics, pet training facilities. | Pros: Personalized feeding; prevents food stealing. Cons: Requires pet microchipping; can be expensive to implement. |

What Are Programmable Timed Feeders and Their B2B Relevance?

Programmable timed feeders are designed to dispense predetermined amounts of dry food at scheduled times. These feeders are particularly suitable for businesses that cater to pets with strict dietary needs, such as pet stores and veterinary clinics. When considering B2B purchases, buyers should evaluate the feeder’s programming capabilities, ease of use, and reliability to ensure it meets customer expectations. Additionally, these feeders can help reduce overfeeding, making them an attractive option for pet hotels or boarding facilities that manage multiple animals.

How Do Smart Automatic Feeders Enhance Pet Care?

Smart automatic feeders leverage technology to allow remote feeding management via smartphone applications. These feeders often include features such as camera monitoring, making them ideal for tech-savvy retailers and e-commerce platforms. When selecting smart feeders for resale, B2B buyers should consider factors such as the feeder’s connectivity options, ease of app integration, and customer support for troubleshooting. The ability to monitor pets remotely adds significant value, especially for multi-pet households, enhancing customer satisfaction and loyalty.

Illustrative image related to auto pet feeders

What Advantages Do Gravity Feeders Offer to Retailers?

Gravity feeders are straightforward devices that dispense food as pets eat, making them a cost-effective option for budget retailers and rural pet supply stores. These feeders are easy to refill and require no electricity, appealing to customers in areas with unstable power supplies. B2B buyers should assess the durability and material quality of gravity feeders, as these factors affect their longevity and customer satisfaction. However, the lack of portion control may deter some customers, making it essential to communicate these limitations clearly.

Why Are Wet Food Feeders Important for Specialty Pet Shops?

Wet food feeders are designed to keep moist food fresh, often incorporating refrigeration or ice packs. These feeders cater to pets with specific dietary requirements and are essential for specialty pet shops that focus on premium products. B2B buyers need to consider the maintenance requirements and cleaning ease of these feeders, as they can be more demanding than their dry food counterparts. Offering wet food feeders can differentiate retailers in a competitive market by addressing the needs of discerning pet owners.

How Do Microchip Feeders Cater to Unique Pet Needs?

Microchip feeders utilize RFID technology to recognize individual pets, providing personalized feeding options that prevent food theft among multiple animals. These feeders are particularly relevant for veterinary clinics and training facilities where pet owners seek tailored solutions. When purchasing microchip feeders, B2B buyers should evaluate the compatibility with different microchip systems and the overall cost of implementation. While they offer unique advantages, the higher price point may limit their appeal to budget-conscious customers.

Key Industrial Applications of auto pet feeders

| Industry/Sector | Specific Application of auto pet feeders | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Automated feeding for hospitalized pets | Ensures timely and precise nutrition, improving recovery | Need for reliable, easy-to-clean feeders with programmable settings |

| Pet Boarding Facilities | Scheduled feeding for multiple pets | Streamlines operations, reduces staff workload | Capacity for multiple pets, remote monitoring features |

| Pet Retailers | Enhanced customer offerings with smart feeders | Attracts tech-savvy pet owners, increases sales | Product variety, warranty, and compatibility with different pet types |

| Animal Shelters | Efficient feeding for large numbers of animals | Reduces labor costs, ensures consistent feeding | Durability, ease of use, and capacity for different food types |

| Pet Training Facilities | Controlled feeding schedules for training programs | Supports behavioral training, aids in weight management | Programmable features and adaptability for various pets |

How Are Auto Pet Feeders Used in Veterinary Clinics?

In veterinary clinics, auto pet feeders play a crucial role in managing the dietary needs of hospitalized pets. These feeders ensure that animals receive their meals on a strict schedule, which is vital for recovery and rehabilitation. By automating feeding, clinics can reduce human error and enhance the precision of nutritional intake. Buyers in this sector should prioritize feeders that are easy to clean, offer programmable settings, and can handle various types of pet food, including wet and dry options.

What Benefits Do Pet Boarding Facilities Gain from Auto Feeders?

Pet boarding facilities benefit significantly from auto pet feeders by streamlining their operations. These feeders allow for scheduled feeding of multiple pets simultaneously, thus reducing the need for constant staff supervision. This efficiency not only saves time but also minimizes the risk of overfeeding or underfeeding. When sourcing feeders for boarding facilities, it is essential to consider models that can accommodate different pet sizes, offer remote monitoring capabilities, and have large food capacities to cater to various dietary needs.

How Can Pet Retailers Enhance Their Offerings with Smart Feeders?

Pet retailers can enhance their product offerings by incorporating smart auto pet feeders into their inventory. These technologically advanced feeders attract tech-savvy pet owners looking for convenience and control over their pets’ feeding schedules. By offering a range of feeders equipped with features such as app connectivity and RFID recognition, retailers can differentiate themselves in a competitive market. Key sourcing considerations include ensuring product variety, competitive pricing, warranties, and compatibility with various pet types to meet diverse customer needs.

Why Are Auto Feeders Important for Animal Shelters?

Animal shelters often face the challenge of feeding large numbers of animals efficiently. Auto pet feeders can alleviate this burden by providing a consistent and reliable feeding solution, which is crucial for the health and well-being of the animals. These feeders help reduce labor costs and ensure that all animals receive their meals on time, regardless of staff availability. Shelters should focus on sourcing durable feeders that can withstand heavy use, are easy to operate, and can accommodate various food types to meet the needs of different animals.

How Do Auto Pet Feeders Support Training Facilities?

In pet training facilities, auto pet feeders can be utilized to establish controlled feeding schedules that support behavioral training programs. By regulating food intake, trainers can manage pet weight and improve discipline during training sessions. These feeders can help implement specific feeding regimens that align with training goals. Buyers in this sector should seek feeders with programmable features, adaptability for different pet types, and easy-to-use interfaces to facilitate training and behavior management.

3 Common User Pain Points for ‘auto pet feeders’ & Their Solutions

Scenario 1: Managing Diverse Pet Diets Across Multiple Locations

The Problem: Many B2B buyers, particularly those operating pet care facilities or multi-pet households, face the challenge of managing diverse dietary requirements for different pets. For instance, a buyer managing a pet boarding facility may have cats and dogs with specific dietary needs, such as wet versus dry food or grain-free diets. This complexity can lead to confusion during feeding times, inconsistent nutrition, and ultimately dissatisfaction among clients who expect their pets to receive tailored care.

Illustrative image related to auto pet feeders

The Solution: To address these dietary challenges, buyers should invest in automatic pet feeders that offer customizable settings and multi-compartment designs. Look for feeders that allow programming for different types of food and portion sizes. For example, a feeder with a dual food tray can be programmed to dispense wet food for cats while simultaneously providing dry kibble for dogs. Additionally, utilizing RFID technology can ensure that the correct pet is fed the appropriate meal at the designated time. By sourcing feeders that integrate with mobile apps, buyers can monitor feeding schedules remotely, adjust settings on the fly, and ensure every pet receives the right nutrition, enhancing client satisfaction.

Scenario 2: Ensuring Food Freshness and Safety in Hot Climates

The Problem: In regions like Africa and parts of the Middle East, where high temperatures are common, maintaining the freshness and safety of pet food can be a significant concern. Automatic feeders that do not adequately protect food from heat can lead to spoilage, posing health risks to pets and potential liability for businesses. Buyers must find solutions that not only dispense food but also preserve its quality in challenging climates.

The Solution: Buyers should prioritize automatic feeders designed with insulation or refrigeration features to maintain food freshness. For example, selecting feeders with vacuum-sealing technology or those that include ice packs can help keep wet food cool and safe for consumption. Additionally, investing in feeders with built-in cameras can allow pet owners to monitor their pets’ eating habits and food conditions in real-time, providing peace of mind. Buyers should also consider sourcing feeders that are easy to clean and maintain, ensuring hygiene and safety. By focusing on these features, businesses can enhance the quality of care provided to pets, which can lead to increased customer loyalty and positive referrals.

Illustrative image related to auto pet feeders

Scenario 3: Overcoming Technical Issues and User Resistance

The Problem: B2B buyers may encounter resistance from staff or clients when implementing automatic pet feeders, often due to technical issues or a lack of understanding of how to operate these devices. This can lead to frustration, improper use, and diminished efficiency in feeding routines. Additionally, the potential for device malfunctions can cause anxiety about relying on technology for pet care.

The Solution: To mitigate these issues, it is essential to select automatic feeders that offer robust customer support, easy setup, and user-friendly interfaces. Buyers should seek out brands that provide comprehensive training resources, such as video tutorials and manuals, to help staff familiarize themselves with the equipment. Additionally, opting for feeders with a simple app interface can facilitate smoother operation and monitoring. Establishing a reliable communication channel with suppliers for troubleshooting can also alleviate concerns about device reliability. By investing in products that emphasize ease of use and providing thorough training, businesses can create a seamless integration of automatic feeders into their operations, thereby enhancing staff confidence and improving pet care quality.

Strategic Material Selection Guide for auto pet feeders

When selecting materials for automatic pet feeders, several factors must be considered, including durability, cost, and compliance with international standards. This guide analyzes four common materials used in the manufacturing of auto pet feeders: plastic, stainless steel, silicone, and glass. Each material has distinct properties, advantages, and limitations that can significantly impact product performance and marketability.

What Are the Key Properties of Plastic for Auto Pet Feeders?

Plastic is one of the most widely used materials in the production of automatic pet feeders due to its versatility and cost-effectiveness. Common types include polypropylene and polyethylene, which can withstand a range of temperatures and are resistant to moisture and corrosion. However, plastics can degrade over time under UV exposure and may not be suitable for high-temperature applications.

Pros and Cons:

– Pros: Lightweight, low manufacturing cost, and available in various colors and designs.

– Cons: Less durable than metal options, potential for scratches, and can harbor bacteria if not cleaned properly.

Impact on Application: Plastic is suitable for dry food storage but may not be ideal for wet food feeders due to potential leaching of chemicals over time.

Considerations for International Buyers: Compliance with food safety standards such as FDA or EU regulations is crucial. Buyers in regions like Africa and South America should also consider the availability of recycling facilities for plastic waste.

How Does Stainless Steel Enhance the Performance of Auto Pet Feeders?

Stainless steel is highly regarded for its durability and resistance to corrosion, making it an excellent choice for automatic pet feeders. It can handle high temperatures and is generally dishwasher safe, which simplifies cleaning. The material is non-porous, reducing the risk of bacterial growth.

Pros and Cons:

– Pros: Long lifespan, hygienic, and aesthetically appealing.

– Cons: Higher manufacturing costs and weight compared to plastic.

Impact on Application: Stainless steel is particularly suitable for both wet and dry food applications, offering excellent compatibility with various media.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM for material quality. In regions like the Middle East, where high temperatures are prevalent, stainless steel’s heat resistance is a significant advantage.

What Role Does Silicone Play in Auto Pet Feeders?

Silicone is increasingly used in automatic pet feeders, particularly for components like seals and food dispensing mechanisms. It is flexible, durable, and resistant to extreme temperatures, making it suitable for various feeding applications.

Illustrative image related to auto pet feeders

Pros and Cons:

– Pros: Excellent flexibility, easy to clean, and resistant to mold and mildew.

– Cons: Generally more expensive than plastic and may not be suitable for all structural components.

Impact on Application: Silicone is ideal for gaskets and seals, ensuring that food remains fresh and preventing leaks.

Considerations for International Buyers: Buyers should look for silicone that meets FDA standards for food safety. In Europe, compliance with REACH regulations is also critical.

Illustrative image related to auto pet feeders

How Does Glass Compare in Terms of Use for Auto Pet Feeders?

Glass is less common but can be an attractive option for certain designs of automatic pet feeders. It is non-reactive, meaning it won’t leach chemicals into food, and is easy to clean.

Pros and Cons:

– Pros: Non-toxic, aesthetically pleasing, and does not absorb odors.

– Cons: Fragile and heavier than other materials, which can complicate shipping and handling.

Impact on Application: Glass is suitable for feeders designed for dry food but may not be practical for outdoor or multi-pet environments due to the risk of breakage.

Considerations for International Buyers: Buyers should consider the fragility of glass in transit, particularly in regions with less developed shipping infrastructure, such as parts of Africa.

Illustrative image related to auto pet feeders

Summary Table of Material Selection for Auto Pet Feeders

| Material | Typical Use Case for auto pet feeders | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Dry food feeders | Lightweight and cost-effective | Less durable, potential for scratches | Low |

| Stainless Steel | Wet and dry food feeders | Durable and hygienic | Higher cost, heavier | High |

| Silicone | Seals and flexible components | Flexible and mold-resistant | More expensive than plastic | Medium |

| Glass | Dry food feeders | Non-toxic and easy to clean | Fragile and heavy | Medium |

In conclusion, selecting the right material for automatic pet feeders involves balancing performance, cost, and compliance with international standards. Each material offers unique benefits and challenges that B2B buyers must consider based on their target markets and product applications.

In-depth Look: Manufacturing Processes and Quality Assurance for auto pet feeders

What Are the Main Stages of Manufacturing Auto Pet Feeders?

The manufacturing process of automatic pet feeders involves several critical stages to ensure that the final product meets quality standards and customer expectations. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing automatic pet feeders is the selection and preparation of raw materials. Common materials include high-quality plastics, metals, and electronic components. These materials are sourced from reliable suppliers to ensure durability and safety. Before manufacturing begins, materials undergo inspections to confirm they meet the required specifications.

How Are Auto Pet Feeders Formed?

Once the materials are prepared, they undergo forming processes. This involves shaping the plastics and metals into the various parts of the feeder, such as the food dispensers, bowls, and housing. Techniques like injection molding are commonly used for plastic components, while metal parts may be stamped or machined. Each method requires precision to ensure that parts fit together seamlessly during assembly.

What Does the Assembly Process Involve?

After forming, the individual parts are assembled. This stage involves integrating mechanical components, electronic circuits, and sensors, particularly for smart feeders that utilize RFID recognition or app connectivity. Automated assembly lines often enhance efficiency, but manual assembly is also used for complex components. Quality checks during this stage are crucial to catch any defects before moving on to finishing.

How Is the Finishing Process Conducted?

Finishing processes are applied to enhance the aesthetics and functionality of the auto pet feeders. This may include surface treatments, painting, or applying coatings that provide resistance to wear and tear. Additionally, final inspections are conducted to ensure that the product meets both visual and functional standards before packaging.

What Are the Key Quality Assurance Standards for Auto Pet Feeders?

Quality assurance (QA) is an integral part of the manufacturing process for automatic pet feeders. Various international and industry-specific standards guide manufacturers in ensuring product quality.

Illustrative image related to auto pet feeders

What Are the Relevant International Standards?

ISO 9001 is one of the most recognized international standards for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has processes in place to consistently provide products that meet customer and regulatory requirements. Other certifications, such as CE marking for products sold in Europe, ensure that the feeders meet essential health and safety requirements.

How Do Industry-Specific Standards Apply?

Certain industry-specific standards, like API (American Petroleum Institute) for pet food safety, may also apply depending on the feeder’s design and intended use. These standards ensure that the materials and components are safe for animal consumption. For B2B buyers, verifying these certifications is crucial when selecting suppliers.

What Quality Control Checkpoints Are Essential in Manufacturing Auto Pet Feeders?

Quality control (QC) is implemented at various stages of the manufacturing process to maintain high standards. Key checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

How Does Incoming Quality Control (IQC) Work?

IQC involves inspecting raw materials and components upon arrival at the manufacturing facility. This step is vital to ensure that only materials that meet specified criteria are used in production. Any defective materials are rejected or returned to the supplier.

What Role Does In-Process Quality Control (IPQC) Play?

IPQC occurs during the manufacturing process. It involves monitoring assembly lines and conducting tests on components as they are produced. For example, electronic components may undergo functionality tests to ensure they operate correctly. Regular audits during this stage help identify and rectify issues early, minimizing waste and rework.

How Is Final Quality Control (FQC) Conducted?

FQC is the last line of defense before products are packaged and shipped. This stage includes comprehensive testing of finished products to ensure they operate as intended. Tests may cover functionality, durability, and safety. Any units failing to meet quality standards are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are some actionable strategies to ensure supplier reliability:

What Are the Benefits of Conducting Supplier Audits?

Regular supplier audits provide insights into the manufacturing processes and quality assurance measures in place. During these audits, buyers can assess compliance with international standards, review QC documentation, and evaluate the overall quality management system. This proactive approach can mitigate risks associated with poor product quality.

Illustrative image related to auto pet feeders

How Can Buyers Request Quality Control Reports?

Buyers should request detailed QC reports from suppliers, which may include information on testing methods, inspection results, and corrective actions taken for any defects. These reports provide transparency and help buyers make informed decisions based on the supplier’s quality history.

What Is the Role of Third-Party Inspections?

Engaging third-party inspection services can further validate a supplier’s quality control practices. These independent organizations perform inspections at various stages of the manufacturing process, ensuring that products meet specified standards before shipment. This step is particularly beneficial for buyers in regions with stringent import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing auto pet feeders internationally, it’s crucial to understand the nuances of quality control across different regions. Compliance with local regulations and standards can vary significantly, impacting product acceptance in the target market.

How Do Regional Regulations Affect Quality Assurance?

For example, pet products sold in the European Union must comply with strict regulations regarding materials and safety. Similarly, countries in the Middle East may have specific import requirements that necessitate additional certifications. Buyers should familiarize themselves with these regulations to ensure compliance and avoid delays in product delivery.

What Should Buyers Consider Regarding Cultural and Market Differences?

Cultural differences can also influence quality expectations. For instance, buyers in Africa may prioritize cost-effectiveness, while those in Europe may focus more on sustainability and eco-friendly materials. Understanding these market dynamics can guide buyers in selecting suppliers that align with their specific needs.

Illustrative image related to auto pet feeders

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is vital for B2B buyers in the auto pet feeder market. By implementing rigorous QC measures and verifying supplier capabilities, businesses can ensure they source high-quality products that meet international standards and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto pet feeders’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring automatic pet feeders, an increasingly popular product in the pet care industry. With a range of options available, understanding the critical factors in selecting the right supplier and product is essential to meet the needs of your market while ensuring quality and reliability.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the technical specifications that your automatic pet feeders must meet. This includes considerations such as capacity, feeding mechanism (dry or wet food), power source (battery-operated or mains), and smart features like app control or RFID recognition. Clearly defined specifications will help streamline the selection process and ensure that potential suppliers can meet your requirements.

Step 2: Research Market Trends and Demand

Understanding current market trends is crucial for making informed purchasing decisions. Conduct market research to identify popular features, such as camera monitoring or vacuum sealing, that appeal to consumers in your target regions like Africa, South America, and the Middle East. This insight will help you choose products that are not only in demand but also have a competitive edge.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can deliver quality products consistently. Request company profiles, product samples, and references from other businesses that have sourced similar items. Pay attention to suppliers’ certifications and compliance with international standards, particularly if you’re importing products across borders.

Step 4: Compare Pricing Structures

Pricing can vary significantly among suppliers, so it is essential to compare pricing structures carefully. Consider not just the unit price but also shipping costs, bulk discounts, and warranty terms. Understanding the total cost of ownership will help you make a more informed financial decision and find the best value for your investment.

Step 5: Assess After-Sales Support and Warranty Policies

Evaluate the after-sales support and warranty policies offered by suppliers. Reliable customer service can be a crucial factor in maintaining your business operations, especially when dealing with defective products or logistical issues. Ensure that the supplier provides clear warranty terms and responsive support to address any concerns that may arise post-purchase.

Step 6: Review Compliance with Regional Regulations

Different regions have varying regulations regarding pet products. Ensure that the automatic pet feeders comply with local safety and health regulations in your target markets. This step is vital to avoid potential legal issues and to enhance consumer trust in your products.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier, finalize the contracts and terms of purchase. Pay attention to delivery timelines, payment terms, and conditions for order cancellations or returns. A well-drafted contract will protect your interests and establish clear expectations for both parties involved.

Illustrative image related to auto pet feeders

By following these steps, B2B buyers can navigate the complexities of sourcing automatic pet feeders effectively, ensuring a successful procurement process that aligns with market needs and operational goals.

Comprehensive Cost and Pricing Analysis for auto pet feeders Sourcing

What are the Key Cost Components in Auto Pet Feeders Manufacturing?

When sourcing automatic pet feeders, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. High-quality plastics, stainless steel for bowls, and advanced electronics for smart features (like RFID or app control) can elevate production costs. Sourcing sustainable or eco-friendly materials may also come at a premium.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may help reduce overall expenses, but this can be balanced by the potential for quality issues. Skilled labor for electronics assembly is particularly important for smart feeders.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient production processes can minimize overhead costs, making it essential for manufacturers to optimize their operations.

-

Tooling: The initial investment in tooling for molds and assembly lines can be substantial. However, these costs are amortized over high production volumes, making them less impactful on unit costs in the long run.

-

Quality Control (QC): Implementing robust QC processes ensures that products meet safety and performance standards. This may involve additional costs but is necessary to maintain brand reputation and reduce returns.

-

Logistics: Shipping and handling costs can fluctuate based on shipping methods, distances, and the volume of the order. For international buyers, understanding Incoterms is vital for assessing total logistics costs.

-

Margin: Suppliers typically mark up prices to cover their costs and generate profit. This margin can be negotiated based on order size and long-term partnerships.

How Do Price Influencers Affect Auto Pet Feeders Sourcing?

Several factors influence the pricing of automatic pet feeders, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts. Understanding a supplier’s MOQ is crucial for cost management, especially for startups or smaller retailers.

-

Specifications and Customization: Custom designs or features (e.g., unique branding, specific functionalities) can lead to higher costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like CE, RoHS) can increase costs but may be necessary for compliance in certain markets. Buyers should evaluate the importance of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more due to their proven quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is crucial for calculating the total landed cost. This affects budgeting, particularly when importing from countries with varying shipping regulations.

What Negotiation Strategies Can B2B Buyers Use for Auto Pet Feeders?

Negotiation is essential in securing favorable pricing for automatic pet feeders. Here are some strategies for B2B buyers:

Illustrative image related to auto pet feeders

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and terms. Regular communication fosters trust and may result in exclusive offers.

-

Leverage Volume: If possible, commit to larger orders or longer contracts to negotiate better prices. Suppliers are often willing to offer discounts for guaranteed business.

-

Understand Total Cost of Ownership (TCO): Evaluate the overall costs associated with the product, including maintenance, warranty, and shipping. This understanding can provide leverage in negotiations, as lower-priced items may incur higher TCO.

-

Consider Alternative Suppliers: Research multiple suppliers to compare pricing and offerings. This knowledge can strengthen your negotiating position and provide backup options if negotiations stall.

What Are Pricing Nuances for International B2B Buyers?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, pricing nuances include:

-

Currency Fluctuations: Exchange rates can impact costs significantly. Buyers should consider currency risk when negotiating prices.

-

Import Duties and Taxes: Understanding local tariffs and import duties is crucial, as these can add substantial costs to the final price of the feeders.

-

Cultural Considerations: Different regions may have varying expectations regarding pricing and negotiation styles. Familiarity with local business customs can enhance communication and negotiation effectiveness.

-

Regulatory Compliance: Ensure that products meet local regulations and standards, which can affect sourcing decisions and pricing.

Conclusion

Understanding the comprehensive cost and pricing analysis for automatic pet feeders is essential for international B2B buyers. By focusing on key cost components, price influencers, effective negotiation strategies, and regional nuances, buyers can make informed sourcing decisions that align with their business goals. Always remember that indicative prices can vary based on market conditions, so continuous research and supplier engagement are vital.

Alternatives Analysis: Comparing auto pet feeders With Other Solutions

Understanding Alternatives to Auto Pet Feeders

In the growing market of pet care solutions, auto pet feeders have gained significant traction due to their convenience and efficiency. However, it is essential for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, to consider viable alternatives that could meet the same needs. This analysis compares auto pet feeders against two notable alternatives: manual feeding solutions and gravity-fed feeders.

Comparison Table

| Comparison Aspect | Auto Pet Feeders | Manual Feeding Solutions | Gravity-Fed Feeders |

|---|---|---|---|

| Performance | Programmable; precise portion control | Human-dependent; variable portioning | Dispenses food as bowl empties |

| Cost | Typically ranges from $50 to $450 | Initial low cost, but labor-intensive | Generally lower cost ($20-$100) |

| Ease of Implementation | Requires setup and connectivity | Simple, requires no technology | Easy setup; no power needed |

| Maintenance | Requires regular cleaning and battery changes | Minimal upkeep | Low maintenance; occasional refilling |

| Best Use Case | Ideal for busy pet owners with multiple pets | Suitable for small households | Good for free-feeding scenarios |

Pros and Cons of Alternatives

Manual Feeding Solutions

Manual feeding involves the pet owner physically providing meals at designated times. This approach is straightforward and requires no technology, making it accessible for all pet owners. However, it can be labor-intensive and inconsistent, particularly for busy professionals or those managing multiple pets. The variability in portion sizes may lead to overfeeding or underfeeding, which can adversely affect pet health.

Gravity-Fed Feeders

Gravity-fed feeders are designed to dispense food continuously as the pet eats, making them suitable for pets that graze. They are generally more affordable than auto pet feeders and require minimal maintenance. However, they lack the precision of portion control, which can result in overeating. Additionally, they may not be ideal for pets with specific dietary needs or feeding schedules, as they do not allow for controlled meal times.

Making the Right Choice for Your Business

When deciding between auto pet feeders and their alternatives, B2B buyers must consider their specific operational needs and the demographics of their target market. Auto pet feeders are ideal for businesses catering to busy pet owners seeking convenience and precise feeding solutions. In contrast, manual feeding solutions may attract smaller households or those looking for low-tech options. Gravity-fed feeders could appeal to customers preferring a more hands-off approach to feeding.

Ultimately, understanding the unique advantages and limitations of each solution will enable B2B buyers to align their product offerings with market demand, ensuring they meet the diverse needs of pet owners across various regions.

Essential Technical Properties and Trade Terminology for auto pet feeders

What Are the Essential Technical Properties of Auto Pet Feeders?

When evaluating auto pet feeders for B2B procurement, understanding the technical specifications is crucial for ensuring product quality and suitability for market needs. Here are some key properties to consider:

-

Material Grade

The material used in pet feeders can significantly affect durability, safety, and hygiene. Common materials include stainless steel, BPA-free plastic, and silicone. Stainless steel is often preferred for its resistance to bacteria and ease of cleaning, while BPA-free plastics ensure the safety of pets. Understanding material grades helps buyers assess the longevity and safety of the product, which is vital for consumer trust and compliance with health regulations. -

Feeding Capacity

This specification indicates how much food the feeder can hold, typically measured in liters (L). Ranging from small (2L) to large (8L) capacities, feeders must cater to different pet sizes and dietary needs. For B2B buyers, selecting the right capacity can help target specific market segments, such as multi-pet households or larger breeds, maximizing sales opportunities. -

Power Source

Auto pet feeders may be battery-operated, plug-in, or rechargeable. Battery-operated models offer portability, while plug-in feeders provide continuous power. Understanding the power source is essential for buyers, as it impacts the product’s usability and the potential for customer satisfaction. Battery life and charging time are also critical factors to consider. -

Programmable Features

The ability to set feeding schedules and portion sizes through programmable settings enhances user convenience. Features such as app control or digital timers allow pet owners to manage their pets’ diets remotely. For B2B buyers, offering feeders with advanced programmable features can differentiate their product offerings in a competitive market. -

Safety Features

Safety features such as anti-jamming mechanisms, secure lids, and pet-proof designs are essential for preventing accidents and ensuring pet welfare. These features can significantly influence purchasing decisions for retailers and distributors, as they enhance the overall value proposition of the product. -

Ease of Cleaning

Feeders that are easy to disassemble and clean are favored by pet owners. Components like dishwasher-safe parts or removable bowls can significantly impact user experience. B2B buyers should prioritize products that emphasize ease of maintenance, as this can lead to higher customer satisfaction and repeat purchases.

What Are the Common Trade Terms in the Auto Pet Feeder Industry?

Understanding industry-specific terminology is vital for effective communication and negotiation in B2B transactions. Here are some essential terms:

Illustrative image related to auto pet feeders

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the pet feeder industry, OEM relationships can help businesses offer customized products or expand their product lines without incurring high manufacturing costs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Understanding MOQs can help buyers negotiate better terms and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products. In the context of auto pet feeders, an RFQ can help buyers compare costs, terms, and lead times from different manufacturers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers dealing with overseas suppliers, as they dictate who is responsible for shipping, insurance, and tariffs, thereby influencing total landed costs. -

Lead Time

This refers to the amount of time it takes for a supplier to fulfill an order. In the pet feeder industry, lead times can vary based on production capacity and shipping logistics. Understanding lead times is critical for buyers to manage inventory levels and meet customer demand efficiently. -

Warranty Period

The warranty period defines the duration in which the manufacturer is responsible for repairing or replacing defective products. In the auto pet feeder market, clear warranty terms can enhance product appeal and build trust with B2B buyers, as they indicate product quality and reliability.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing auto pet feeders, ultimately driving successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the auto pet feeders Sector

What Are the Current Market Dynamics and Key Trends Influencing Auto Pet Feeders?

The global market for automatic pet feeders is experiencing significant growth, driven by increasing pet ownership, particularly in emerging markets like Africa and South America. As urbanization rises, pet owners are seeking convenience in managing their pets’ feeding schedules, aligning with busy lifestyles. Key trends shaping this market include the integration of technology in pet care products, such as Wi-Fi connectivity, app control, and smart features like RFID recognition. These innovations allow pet owners to remotely manage their pets’ feeding, making it easier for them to monitor dietary habits and ensure consistent nutrition.

Additionally, sustainability is becoming a focal point for B2B buyers in this sector. Manufacturers are responding to consumer demands for eco-friendly products by utilizing sustainable materials and implementing ethical sourcing practices. This shift not only appeals to environmentally conscious consumers but also aligns with international regulatory trends pushing for greater corporate responsibility. International buyers, particularly from regions like the Middle East and Europe, are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

How Is Sustainability and Ethical Sourcing Shaping the Auto Pet Feeders Market?

Sustainability and ethical sourcing are crucial considerations for international B2B buyers in the auto pet feeders sector. The environmental impact of pet products, from production to disposal, is under scrutiny. Buyers are looking for manufacturers that utilize recyclable materials, energy-efficient production methods, and sustainable packaging solutions. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming essential for suppliers aiming to meet the expectations of conscious consumers.

Illustrative image related to auto pet feeders

Moreover, ethical supply chains that emphasize fair labor practices are gaining traction. Buyers are more likely to engage with companies that can demonstrate transparency in their sourcing processes and commitment to social responsibility. By prioritizing suppliers who adhere to these principles, B2B buyers not only align with consumer values but also mitigate risks associated with supply chain disruptions and reputational damage.

How Has the Auto Pet Feeders Sector Evolved Over Time?

The evolution of the auto pet feeders sector has been marked by rapid technological advancements and changing consumer preferences. Initially, automatic feeders were simple devices designed to dispense food at predetermined times. However, the introduction of smart technologies has revolutionized the market. Modern feeders now feature connectivity options that allow pet owners to program feeding schedules, monitor food levels, and even interact with their pets remotely via integrated cameras.

This transformation reflects broader trends in the pet care industry, where consumers increasingly seek products that enhance their pets’ well-being while fitting seamlessly into their lifestyles. As the market continues to evolve, B2B buyers must stay informed about emerging technologies and consumer demands to make strategic sourcing decisions that will drive business growth.

Frequently Asked Questions (FAQs) for B2B Buyers of auto pet feeders

-

How do I choose the right automatic pet feeder for my business needs?

Selecting the right automatic pet feeder involves considering the specific requirements of your target market. Assess the types of pets commonly owned in your region—cats, dogs, or both—and their feeding habits. Evaluate features such as programmable settings, portion control, and connectivity options like app integration. Additionally, consider the capacity and material durability, especially for wet or dry food. Engaging with suppliers who offer a variety of models can help ensure you meet diverse customer needs. -

What are the key features to look for in an automatic pet feeder?

When sourcing automatic pet feeders, prioritize features that enhance usability and pet health. Look for models with programmable timers for scheduled feeding, portion control for preventing overfeeding, and compatibility with various food types. Advanced options include RFID pet recognition for personalized feeding, camera monitoring for remote observation, and vacuum-sealing technology to preserve food freshness. These features not only appeal to pet owners but also help differentiate your offerings in a competitive market. -

What is the typical minimum order quantity (MOQ) for automatic pet feeders?

Minimum order quantities (MOQs) for automatic pet feeders can vary significantly based on the manufacturer and model. Generally, MOQs range from 50 to 500 units, depending on the complexity of the feeder design and the supplier’s production capabilities. It’s advisable to negotiate MOQs based on your initial sales forecasts and market demand. Many suppliers may offer flexibility for first-time buyers or bulk orders, so establishing a good relationship can lead to favorable terms. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can differ widely among international suppliers. Common arrangements include partial upfront payments (usually 30-50%) with the balance due before shipment. Some suppliers might offer credit terms for established relationships. It’s crucial to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Additionally, consider the implications of currency exchange rates and transaction fees, especially when dealing with suppliers in different countries. -

How can I ensure quality assurance for automatic pet feeders?

To ensure quality assurance, request samples from potential suppliers before placing large orders. Conduct thorough inspections for materials, functionality, and safety standards. Verify if the supplier holds certifications like ISO or CE, which indicate adherence to quality management systems. Additionally, consider establishing a quality control process that includes third-party inspections during production and pre-shipment to ensure that products meet your specifications and international standards. -

What logistics considerations should I keep in mind for international shipping of pet feeders?

When planning logistics for international shipping, consider factors like shipping costs, lead times, and customs regulations. Choose a reliable freight forwarder who understands the pet product market and can navigate import/export requirements. Ensure that your supply chain includes contingency plans for delays, especially during peak seasons. Additionally, familiarize yourself with your country’s regulations regarding imported pet products to avoid compliance issues. -

How do I vet suppliers for automatic pet feeders effectively?

Vetting suppliers requires a comprehensive approach. Start by researching their business history, customer reviews, and product range. Request references from other B2B clients to assess reliability and service quality. Conduct background checks on their manufacturing processes and certifications. Engaging in direct communication helps gauge their responsiveness and willingness to accommodate your needs. Consider visiting their facilities if possible, as this can provide valuable insights into their operations and quality control measures. -

What customization options are typically available for automatic pet feeders?

Customization options for automatic pet feeders can include branding, color choices, and specific feature modifications. Many manufacturers offer the ability to incorporate logos or unique designs to align with your brand identity. Additionally, inquire about custom configurations like bowl sizes or feeding schedules tailored to regional preferences. Discussing your requirements early in the sourcing process can help manufacturers accommodate your requests and enhance your product’s appeal in the market.

Top 5 Auto Pet Feeders Manufacturers & Suppliers List

1. Petlibro – Automatic Pet Feeders

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro includes various models such as the Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Space Smart Feeder. Key features include RFID pet recognition, app control, vacuum-sealing technology, and options for both wet and dry food. Capacities range from 2L to 8L. Prices vary from $89.99 to $449.97. Free shipping on orders over $75 in…

2. Closer Pets – MiBowl Automatic Microchip Pet Feeder

Domain: closerpets.com

Registered: 2020 (5 years)

Introduction: Pet Feeders Collection: 19 products available. Features automatic pet feeders designed for cats and small dogs with timer-operated compartments and integrated ice packs. Key products include: 1. MiBowl Automatic Microchip Pet Feeder (CP500) – Sale price: $129.99 (Regular price: $199.99) 2. Closer Pets Five-Meal Automatic Pet Feeder with Stainless Steel Bowl Inserts and Ice Packs (C500) – Sale pric…

3. PetSmart – Automatic Cat Feeders

Domain: petsmart.com

Registered: 1995 (30 years)

Introduction: PetSmart offers a variety of automatic cat feeders designed to help pet parents manage their cats’ feeding schedules. Key features include:

– Programmable timers for scheduled feeding

– Options for dry food dispensing

– Ability to portion food to prevent overeating

– Gravity-fed models for cats that prefer grazing

– Brands available include PETLIBRO, PetSafe, Whisker City, Catit, and more.

– Price…

4. PETLIBRO – Automatic Feeders with Advanced Features

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. PETLIBRO Automatic Feeder (Model with Blockage Prevention) – Reliable, easy to program, battery backup, good for portion control. 2. PETLIBRO Automatic Feeder with Camera – Offers the ability to monitor feeding via an app, useful for those who travel. 3. PETKIT Automatic Feeder – Features stainless steel design, 2.8L capacity, and an indicator for food levels.

5. Super Feeder Store – Cat Auto Feeder, CSF-3 Basic

Domain: superfeederstore.com

Registered: 2014 (11 years)

Introduction: Automatic pet feeder for cats and other small animals. Available packages include basic and combos. Free shipping on orders. Key products include: 1. Cat Auto Feeder, CSF-3 Basic for Custom Mount – $129.95, free shipping. 2. Auto Cat Feeder, CSF-3, Basic WITH Chute Cover (blemished) – MSRP: $149.95, sale price $121.79, free shipping. 3. Cat Feeder, CSF-3, Only with Stand and Bowl – MSRP: $169.90, …

Strategic Sourcing Conclusion and Outlook for auto pet feeders

What Are the Key Takeaways for Strategic Sourcing of Auto Pet Feeders?

In conclusion, the strategic sourcing of automatic pet feeders presents significant opportunities for B2B buyers across diverse international markets. With the increasing demand for innovative feeding solutions, driven by pet owners’ busy lifestyles, suppliers are responding with advanced features such as app control, RFID recognition, and dual food trays. Buyers must prioritize partnerships with manufacturers that not only offer cutting-edge technology but also ensure reliable supply chains and robust customer support.

How Can International Buyers Leverage These Insights?

The value of strategic sourcing extends beyond mere procurement; it encompasses the ability to adapt to market trends and consumer preferences. As regions like Africa, South America, the Middle East, and Europe experience growth in the pet care industry, it’s crucial for businesses to stay ahead of the curve. By investing in high-quality, feature-rich automatic feeders, companies can enhance their product offerings and meet the evolving needs of pet owners.

What Does the Future Hold for Auto Pet Feeders?

Looking ahead, the auto pet feeder market is poised for continued innovation and expansion. B2B buyers should actively seek partnerships that align with their growth strategies and customer demands. Embrace this trend by exploring the latest technologies and fostering strong relationships with suppliers, ensuring your business thrives in the competitive landscape of pet care.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to auto pet feeders

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.