Introduction: Navigating the Global Market for pet ultra automatic feeder

In the evolving landscape of pet care, sourcing an efficient pet ultra automatic feeder has emerged as a significant challenge for international B2B buyers. As the demand for automated feeding solutions increases, so does the complexity of navigating this global market. Buyers must consider various factors, including product specifications, compatibility with diverse pet food types, and the growing need for features like programmable feeding schedules and portion control. This guide serves as a comprehensive resource, detailing the different types of pet feeders available, their applications in various markets, and essential strategies for supplier vetting.

From understanding the nuances of product features to evaluating cost implications, our guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Germany and Nigeria—to make informed purchasing decisions. We delve into the critical aspects of the market, offering insights on how to select reliable suppliers, assess product quality, and leverage trends in pet care technology. By equipping buyers with the necessary knowledge and tools, this guide aims to simplify the procurement process, ensuring businesses can meet the growing expectations of pet owners while enhancing their operational efficiency.

Table Of Contents

- Top 4 Pet Ultra Automatic Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pet ultra automatic feeder

- Understanding pet ultra automatic feeder Types and Variations

- Key Industrial Applications of pet ultra automatic feeder

- 3 Common User Pain Points for ‘pet ultra automatic feeder’ & Their Solutions

- Strategic Material Selection Guide for pet ultra automatic feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for pet ultra automatic feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet ultra automatic feeder’

- Comprehensive Cost and Pricing Analysis for pet ultra automatic feeder Sourcing

- Alternatives Analysis: Comparing pet ultra automatic feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for pet ultra automatic feeder

- Navigating Market Dynamics and Sourcing Trends in the pet ultra automatic feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pet ultra automatic feeder

- Strategic Sourcing Conclusion and Outlook for pet ultra automatic feeder

- Important Disclaimer & Terms of Use

Understanding pet ultra automatic feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Feeders | Simple design using gravity to dispense food; no power required. | Pet stores, veterinary clinics, rural areas. | Pros: Low cost, no power needed. Cons: Less control over portion sizes. |

| Programmable Timed Feeders | Allows scheduling of multiple meals; customizable portion sizes. | Pet supply retailers, online marketplaces. | Pros: Convenience, customizable. Cons: Higher initial investment. |

| Smart Feeders | Connects to Wi-Fi; app-controlled; can monitor pet feeding habits remotely. | Tech-savvy pet shops, e-commerce platforms. | Pros: Advanced features, real-time monitoring. Cons: Reliance on technology, higher cost. |

| Dual Power Feeders | Operates on both AC power and batteries; ensures functionality during power outages. | Pet service providers, pet care facilities. | Pros: Reliability, peace of mind. Cons: More complex design, potential for battery issues. |

| Multi-Pet Feeders | Designed to serve multiple pets; features separate feeding compartments. | Animal shelters, multi-pet households. | Pros: Efficient for multiple pets, reduces competition for food. Cons: Bulkier, potentially higher price point. |

What Are the Characteristics of Gravity Feeders?

Gravity feeders are among the simplest types of automatic pet feeders, utilizing gravity to dispense food without the need for electrical power. They are ideal for locations where electricity may not be consistently available, such as rural areas or outdoor environments. B2B buyers should consider the low cost and minimal maintenance required for these feeders, but they may lack the precise portion control that some pet owners desire.

Why Choose Programmable Timed Feeders?

Programmable timed feeders allow pet owners to schedule multiple meals throughout the day, making them suitable for businesses that cater to pets with specific dietary needs. These feeders often feature customizable portion sizes, which can help maintain a pet’s health. B2B buyers should assess the initial investment against the long-term convenience and potential for improved pet health that these feeders provide.

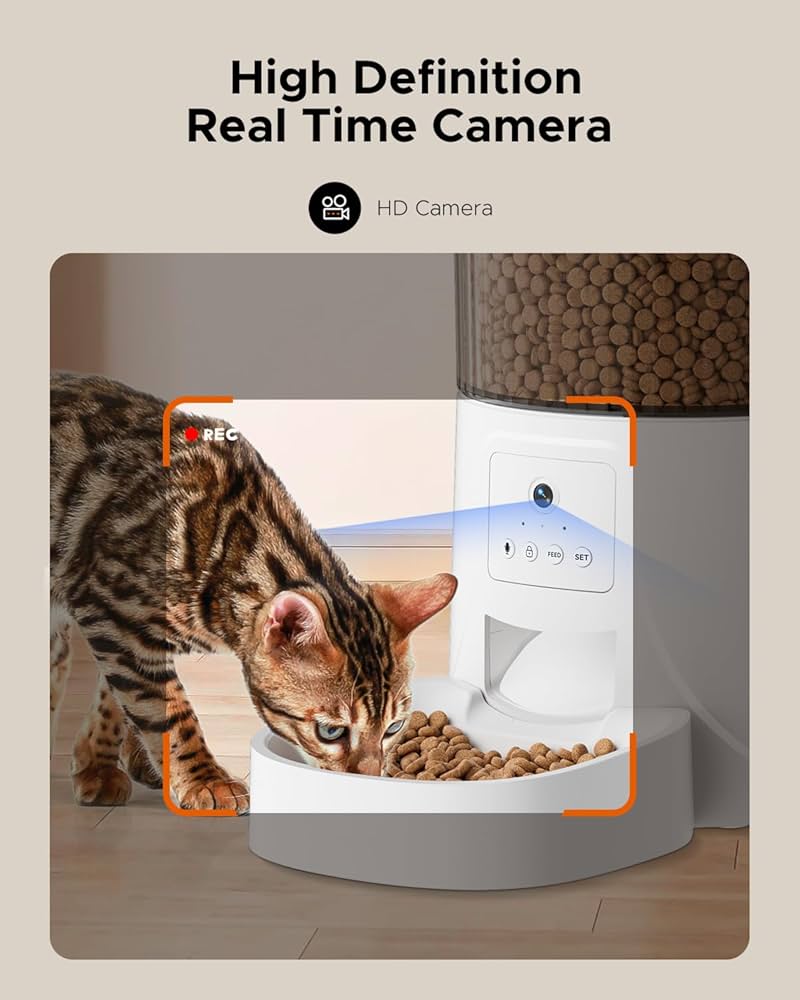

What Benefits Do Smart Feeders Offer?

Smart feeders connect to Wi-Fi and can be controlled via a mobile app, enabling pet owners to monitor feeding habits remotely. This technology is particularly appealing to tech-savvy consumers and can be a unique selling point for retailers. B2B buyers should weigh the advanced features and real-time monitoring capabilities against the higher cost and reliance on technology that may deter some customers.

How Do Dual Power Feeders Ensure Reliability?

Dual power feeders are designed to operate on both AC power and batteries, providing a reliable feeding solution even during power outages. This feature is particularly valuable for pet service providers and care facilities that require uninterrupted feeding schedules. Buyers should consider the added peace of mind this feature offers, while also being aware of the more complex design that may require additional maintenance.

What Are the Advantages of Multi-Pet Feeders?

Multi-pet feeders are engineered to serve several pets simultaneously, featuring separate compartments to reduce competition for food. This is especially beneficial for animal shelters and households with multiple pets. While they can be bulkier and more expensive than standard feeders, B2B buyers should evaluate the efficiency and convenience they offer in managing feeding for multiple animals.

Key Industrial Applications of pet ultra automatic feeder

| Industry/Sector | Specific Application of pet ultra automatic feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care Services | Automated feeding solutions for pet boarding facilities | Ensures consistent feeding schedules, enhancing pet health and reducing staff workload | Reliability, capacity to handle various kibble sizes, and ease of cleaning |

| Veterinary Clinics | Post-operative care for pets needing controlled diets | Allows precise portion control, aiding in recovery and preventing overfeeding | Compliance with veterinary standards, durability, and ease of use |

| Pet Retailers | Retail display for automatic feeders in stores | Attracts customers with innovative solutions, increasing sales potential | Product quality, warranty, and customer support options |

| Animal Shelters | Feeding solutions for multiple pets in care | Streamlines feeding process, saving time and resources while ensuring proper nutrition | Capacity, programmable features, and safety mechanisms |

| Pet Training Facilities | Use in training sessions to establish feeding routines | Reinforces discipline in feeding habits, assisting trainers in managing multiple pets | Programmable settings, reliability, and ease of operation |

How Can Pet Care Services Benefit from Automated Feeding Solutions?

Pet care services, such as boarding facilities, can utilize pet ultra automatic feeders to streamline their operations. By ensuring consistent feeding schedules, these feeders help maintain the health and well-being of pets in their care, reducing the burden on staff who otherwise would need to manually feed each animal. Buyers in this sector should consider the reliability of the feeder, its capacity to handle various kibble sizes, and ease of cleaning to maintain hygiene standards.

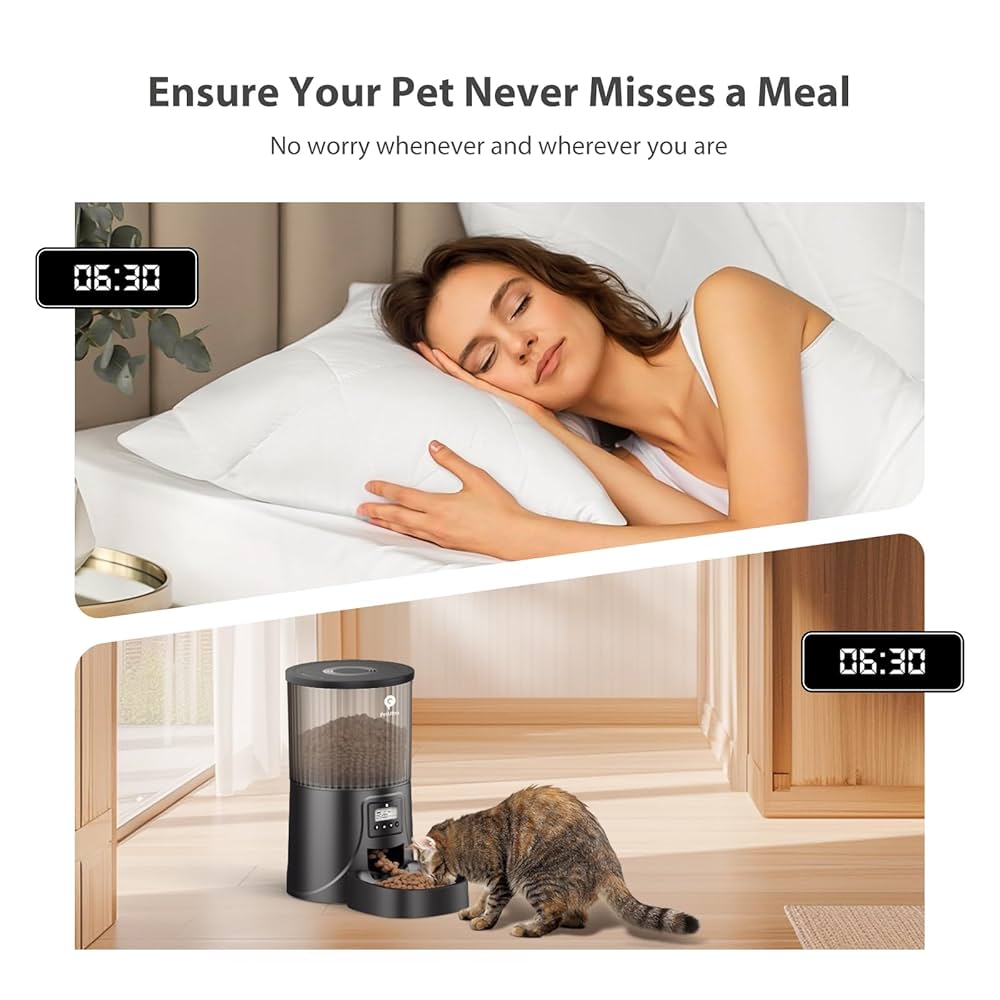

Illustrative image related to pet ultra automatic feeder

Why Are Veterinary Clinics Adopting Automated Feeders for Post-operative Care?

Veterinary clinics often face challenges when managing the dietary needs of pets recovering from surgery. The pet ultra automatic feeder allows for precise portion control, which is crucial during the recovery phase to prevent complications associated with overfeeding. When sourcing these feeders, clinics should focus on compliance with veterinary standards, durability to withstand frequent use, and user-friendly features to ensure staff can operate them efficiently.

How Do Pet Retailers Leverage Automatic Feeders in Their Stores?

Pet retailers can enhance their product offerings by showcasing pet ultra automatic feeders. These innovative solutions attract customers looking for convenience and reliability in pet care, thus increasing sales potential. Retailers should prioritize product quality, warranty options, and customer support when sourcing these feeders to ensure customer satisfaction and repeat business.

What Advantages Do Animal Shelters Gain from Using Automatic Feeders?

Animal shelters often care for multiple pets simultaneously, making feeding a time-consuming task. The pet ultra automatic feeder can streamline this process, ensuring that all animals receive proper nutrition without excessive labor. Shelters should consider the feeder’s capacity, programmable features for varied feeding schedules, and safety mechanisms to prevent overfeeding when making purchasing decisions.

How Can Pet Training Facilities Utilize Automatic Feeders for Effective Training?

Pet training facilities can employ pet ultra automatic feeders to reinforce feeding routines and discipline among pets. By using these feeders during training sessions, trainers can manage multiple pets effectively and establish consistent feeding habits. Buyers in this sector should look for feeders with programmable settings, reliability, and ease of operation to ensure they meet the demands of a busy training environment.

3 Common User Pain Points for ‘pet ultra automatic feeder’ & Their Solutions

Scenario 1: Difficulty in Customizing Feeding Schedules for Different Pets

The Problem: In a B2B context, businesses that provide pet services often face challenges when trying to cater to a variety of pets with differing dietary needs and feeding schedules. For instance, a pet care facility may house multiple animals, each requiring specific feeding times and portion sizes. This complexity can lead to inconsistencies in feeding, which may affect the health and well-being of the pets, as well as the reputation of the service provider.

The Solution: To effectively manage diverse feeding requirements, businesses should opt for pet ultra automatic feeders that offer programmable feeding schedules and portion controls. The PetUltra DU4LB-KY model, for example, allows for up to six meals per day with customizable portion sizes ranging from 1/8 cup to 2 cups. B2B buyers should look for suppliers who can provide guidance on setting these features during the setup process. Additionally, investing in training for staff on how to use the feeders efficiently can ensure that feeding schedules are adhered to, thus improving overall pet care quality. A systematic approach to recording each pet’s specific needs in a centralized database can further streamline the process, allowing for quick adjustments as needed.

Scenario 2: Overcoming Food Clogging Issues During Operation

The Problem: Automatic feeders can sometimes face operational issues, such as food getting stuck, which can lead to missed meals for pets and frustration for pet owners or service providers. This problem is particularly acute for businesses that rely on these feeders to maintain a consistent feeding routine, impacting both service efficiency and animal health.

The Solution: When selecting a pet ultra automatic feeder, it is crucial to choose models designed with anti-clogging features. The PetUltra DU4LB-KY, for instance, incorporates a double rotor design and a wide-angle food passage that helps prevent food from clogging. B2B buyers should prioritize suppliers that offer robust product support, including troubleshooting guides and maintenance tips. Regularly inspecting and cleaning the feeder, as recommended in the user manual, is essential to ensure optimal operation. Additionally, educating staff about the appropriate kibble sizes (2-10mm) can further minimize the risk of clogs, ensuring that the feeder operates smoothly and effectively.

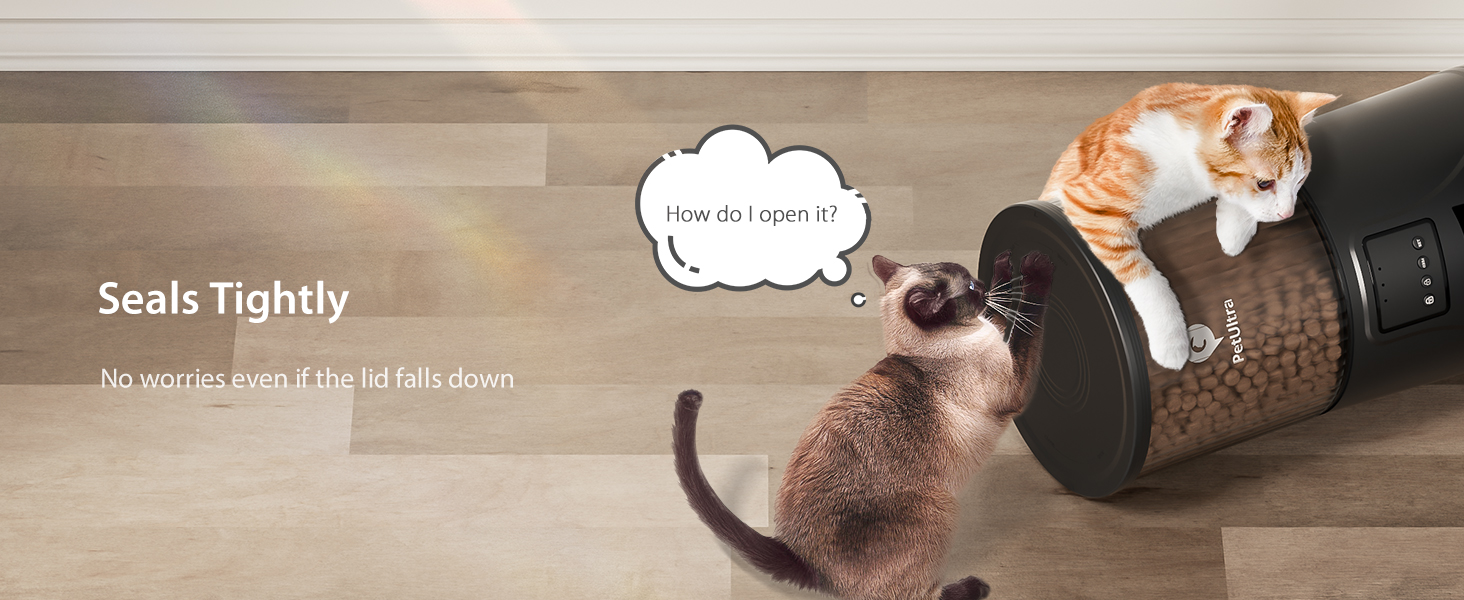

Scenario 3: Ensuring Food Freshness and Safety for Pets

The Problem: Maintaining food freshness and safety is a critical concern for businesses that handle pet feeding, especially in environments where food may be stored for extended periods. Improperly stored food can lead to spoilage or contamination, posing health risks to pets and liability issues for the business.

The Solution: B2B buyers should look for pet ultra automatic feeders that come equipped with features designed to preserve food quality. The PetUltra DU4LB-KY includes a desiccant bag and a secure locking lid that keeps food fresh and prevents access by pets. When sourcing these feeders, businesses should also inquire about the recommended maintenance practices, such as regular desiccant replacement and cleaning schedules. Implementing a routine for checking food quality before filling the feeder can help prevent issues related to stale or spoiled food. Furthermore, establishing clear guidelines for food storage and handling among staff can enhance food safety protocols, ensuring that pets receive only the best quality nutrition.

Strategic Material Selection Guide for pet ultra automatic feeder

What Materials Are Commonly Used in Pet Ultra Automatic Feeders?

When selecting materials for pet ultra automatic feeders, it is crucial to consider the properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of these feeders: Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), Stainless Steel, and Polycarbonate (PC).

How Does Acrylonitrile Butadiene Styrene (ABS) Perform in Pet Feeders?

ABS is a widely used thermoplastic known for its strength and impact resistance. It has a good temperature rating, typically up to 80°C (176°F), making it suitable for the internal components of automatic feeders that may experience heat from electronics.

Pros: ABS is relatively inexpensive, easy to mold, and provides a good balance of rigidity and toughness. Its lightweight nature contributes to lower shipping costs, making it an attractive option for international buyers.

Cons: While ABS is durable, it can be susceptible to UV degradation if exposed to sunlight over extended periods. Additionally, it may not be as chemically resistant as other materials, which could be a concern if pet food contains certain additives.

Impact on Application: ABS is compatible with dry pet food and is often used in parts that require structural integrity, such as the feeder body and food bowl.

Considerations for International Buyers: Compliance with food safety standards, such as FDA regulations in the U.S. or EU regulations in Europe, is essential. Buyers from Africa and South America should also consider local regulations regarding plastics in pet products.

What Role Does Polypropylene (PP) Play in Automatic Feeders?

Polypropylene is another thermoplastic known for its excellent chemical resistance and low moisture absorption. It can withstand temperatures up to 100°C (212°F), making it suitable for components that may come into contact with warm food or cleaning solutions.

Illustrative image related to pet ultra automatic feeder

Pros: PP is lightweight, cost-effective, and offers good flexibility. Its resistance to various chemicals makes it ideal for food applications, ensuring that it does not react with pet food.

Cons: While PP is durable, it can become brittle over time if exposed to UV light. It may also not provide the same level of structural strength as ABS.

Impact on Application: PP is often used for food storage compartments and lids due to its chemical resistance and safety profile.

Illustrative image related to pet ultra automatic feeder

Considerations for International Buyers: Buyers should ensure that the PP used is food-grade and complies with relevant international standards, such as ASTM or DIN.

Why Choose Stainless Steel for Pet Feeders?

Stainless steel is renowned for its durability and corrosion resistance, making it an excellent choice for pet feeders that require longevity and hygiene.

Pros: Stainless steel is extremely durable, resistant to rust, and easy to clean. It is also non-reactive, ensuring that it does not alter the taste or quality of pet food.

Cons: The primary drawback is its higher cost compared to plastics. Additionally, stainless steel can be heavier, which may increase shipping costs.

Impact on Application: Stainless steel is often used for food bowls and parts that require frequent cleaning, as it can withstand repeated exposure to water and cleaning agents.

Considerations for International Buyers: Compliance with food safety regulations is critical, especially in regions with strict hygiene standards. Buyers should also consider the cost implications of importing stainless steel products.

How Does Polycarbonate (PC) Enhance Feeder Design?

Polycarbonate is a strong, transparent thermoplastic known for its impact resistance and clarity. It can withstand temperatures up to 120°C (248°F), making it suitable for various feeder components.

Pros: PC is highly durable and can be molded into complex shapes, allowing for innovative designs. Its transparency can be advantageous for monitoring food levels.

Cons: Polycarbonate can be more expensive than other plastics and may yellow over time when exposed to UV light.

Illustrative image related to pet ultra automatic feeder

Impact on Application: PC is often used for viewing windows or transparent sections of feeders, allowing pet owners to easily see food levels.

Considerations for International Buyers: Compliance with international safety standards is vital. Buyers should ensure that the polycarbonate used is BPA-free and suitable for food contact.

Summary Table of Material Selection for Pet Ultra Automatic Feeders

| Material | Typical Use Case for pet ultra automatic feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylonitrile Butadiene Styrene (ABS) | Feeder body, food bowl | Cost-effective, lightweight | UV degradation, limited chemical resistance | Low |

| Polypropylene (PP) | Food storage compartments, lids | Excellent chemical resistance | Can become brittle with UV exposure | Low |

| Stainless Steel | Food bowls, high-wear components | Durable, easy to clean | Higher cost, heavier weight | High |

| Polycarbonate (PC) | Transparent sections, viewing windows | Impact-resistant, allows for monitoring | Higher cost, potential UV yellowing | Med |

This strategic material selection guide provides valuable insights for international B2B buyers in the pet feeder market, helping them make informed decisions based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for pet ultra automatic feeder

What Are the Main Stages in the Manufacturing Process of Pet Ultra Automatic Feeders?

The manufacturing process of pet ultra automatic feeders encompasses several key stages, each crucial for ensuring the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to pet ultra automatic feeder

Material Preparation: Sourcing and Quality Control

The first step involves sourcing high-quality materials such as plastics, particularly Acrylonitrile Butadiene Styrene (ABS), which is commonly used for its durability and safety. Suppliers often undergo stringent vetting processes to ensure compliance with international safety standards. Materials are usually inspected upon arrival to verify quality, ensuring they meet specifications for pet safety and environmental compliance.

Forming: Advanced Techniques for Precision

Once the materials are prepared, they undergo forming processes, typically involving injection molding for plastic components. This technique allows for high precision in shaping complex parts, such as the feeder’s body and internal mechanisms. Advanced robotics may be employed to enhance efficiency and reduce human error. Key techniques during this stage include:

- Injection Molding: Essential for producing uniform and complex shapes.

- Thermoforming: Used for creating the feeder’s outer casing, ensuring a smooth finish.

Assembly: Ensuring Functionality

Following the forming stage, components are assembled. This phase may involve manual and automated processes, particularly for integrating electronic parts such as timers, sensors, and voice recorders. Attention to detail is crucial here, as misalignment or improper connections can affect the functionality of the feeder. Quality checkpoints during assembly ensure that each component fits correctly and operates as intended.

Finishing: Quality Enhancement and Safety

The finishing stage involves surface treatments and final inspections. This may include polishing, painting, or applying protective coatings to enhance aesthetics and durability. Each feeder undergoes a thorough quality check to confirm that it meets design specifications and safety standards before packaging. This stage also includes testing for functionality and reliability, ensuring that the feeder operates correctly under various conditions.

What Quality Assurance Measures Are Implemented in the Production of Pet Feeders?

Quality assurance (QA) is integral to the manufacturing process of pet ultra automatic feeders, ensuring that products meet both customer expectations and regulatory standards. Various international standards and industry-specific certifications guide these processes.

What International Standards Should B2B Buyers Consider?

For international B2B buyers, understanding the relevant quality standards is crucial. The following certifications are typically considered:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: These are particularly relevant for electronic components, ensuring safety and reliability in electrical systems.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that each feeder meets the required standards. The main QC checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before production begins.

- In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC monitors processes and components to identify any deviations from quality standards.

- Final Quality Control (FQC): At this stage, finished products undergo comprehensive testing for functionality, safety, and compliance with specifications.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to validate the quality and safety of pet feeders. Common methods include:

- Functional Testing: Ensures that all features, such as portion control and voice recording, operate correctly.

- Durability Testing: Evaluates the product’s resilience to wear and tear, especially in components that will be frequently used.

- Safety Testing: Checks for potential hazards, such as sharp edges or electrical malfunctions, ensuring that the feeder is safe for pets.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards.

- Request Quality Reports: Ask suppliers for documentation of their QC processes, including IQC, IPQC, and FQC reports, to gain insights into their quality management practices.

- Third-Party Inspections: Consider engaging third-party inspection services to evaluate supplier facilities and processes, providing an unbiased assessment of quality control measures.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control and certification processes that may vary by region:

- Regional Compliance: Different regions may have distinct safety and compliance requirements. For instance, products sold in Europe must adhere to CE standards, while those in the U.S. may need to meet different safety regulations.

- Local Testing Labs: Buyers should consider utilizing local testing laboratories that are recognized in their respective regions for compliance testing, reducing shipping time and costs.

- Cultural Considerations: Understanding cultural expectations regarding quality can also influence buyer-supplier relationships, particularly in regions with diverse markets.

By comprehensively understanding the manufacturing processes and quality assurance measures for pet ultra automatic feeders, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and safety.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet ultra automatic feeder’

In today’s fast-paced world, sourcing the right automatic pet feeder is crucial for ensuring that pets receive timely and adequate nutrition, especially for B2B buyers catering to pet owners. This practical checklist serves as a comprehensive guide to help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outlining the technical requirements for the pet feeder is vital. Consider factors such as capacity, portion control settings, and compatible kibble sizes. This will not only streamline your sourcing process but also ensure that the feeders meet the dietary needs of various pets.

- Capacity: Aim for models that hold sufficient food for the intended use, such as a 4L capacity for larger breeds.

- Kibble Size Compatibility: Ensure the feeder can accommodate different kibble sizes, typically ranging from 2mm to 10mm.

Step 2: Research Market Trends and Consumer Preferences

Understanding current market trends and what pet owners prioritize can significantly influence your sourcing decisions. Analyze consumer reviews and feedback to identify features that are in demand, such as programmable feeding schedules and voice recording capabilities.

- Consumer Insights: Look for products that offer convenience, such as meal scheduling and portion control, which are increasingly sought after by busy pet owners.

- Regional Preferences: Different markets may have unique preferences; for instance, European consumers might prioritize energy efficiency and design aesthetics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct thorough evaluations. Request detailed company profiles, including their manufacturing processes, quality control measures, and customer service policies.

- Supplier Reputation: Look for suppliers with positive reviews and testimonials from other B2B buyers in your target regions.

- Certifications: Verify that suppliers have the necessary certifications for quality and safety standards, especially for pet products.

Step 4: Assess Product Features and Innovations

Different models of automatic pet feeders come with a variety of features. Carefully evaluate these to ensure they align with your specifications and market demands.

- Innovative Features: Prioritize feeders with anti-clog designs and dual power sources to cater to different environments and potential power outages.

- User-Friendly Design: Ensure that the product is easy to clean and maintain, which will be a significant selling point for end-users.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples of the pet feeders. Conduct testing to assess their functionality, durability, and user experience.

- Functionality Testing: Check the feeder’s performance in dispensing food accurately and consistently.

- Durability Assessment: Evaluate materials used in the feeder, ensuring they are BPA-free and safe for pet use.

Step 6: Negotiate Terms and Conditions

Once you have selected potential suppliers and tested their products, proceed to negotiate the terms of purchase. Discuss pricing, minimum order quantities, and delivery timelines.

- Pricing Strategy: Ensure that the pricing aligns with your budget and market positioning.

- Delivery and Support: Clarify delivery timelines and after-sales support, as reliable customer service is crucial for maintaining business relationships.

Step 7: Finalize Your Procurement Strategy

With all information gathered, outline your procurement strategy, including inventory management and marketing plans for the automatic feeders. This will ensure a smooth transition from sourcing to sales.

- Inventory Planning: Determine how many units to stock based on market demand and sales forecasts.

- Marketing Approach: Develop a marketing plan that highlights the unique features of the feeders to attract your target audience.

By following this checklist, B2B buyers can effectively navigate the sourcing process for pet ultra automatic feeders, ensuring they procure high-quality products that meet market needs.

Comprehensive Cost and Pricing Analysis for pet ultra automatic feeder Sourcing

What Are the Key Cost Components for Sourcing Pet Ultra Automatic Feeders?

When sourcing pet ultra automatic feeders, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials, such as BPA-free plastics and electronic components, significantly affects the overall cost. High-quality, durable materials may incur higher upfront costs but can lead to long-term savings due to reduced returns and warranty claims.

-

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs can offer competitive pricing, but it’s essential to assess the skill level and experience of the workforce to ensure product quality.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making it essential to consider minimum order quantities (MOQ) when negotiating prices.

-

Quality Control (QC): Implementing strict QC measures is critical in ensuring product reliability. While this may add to the cost, it is a necessary investment to maintain brand reputation and customer satisfaction.

-

Logistics: Shipping costs, including freight and customs duties, must be factored into the total cost. International buyers should consider the implications of different shipping methods and Incoterms, which can significantly influence delivery timelines and costs.

-

Margin: Supplier profit margins can vary widely. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Impact the Sourcing of Pet Automatic Feeders?

Several factors influence the pricing of pet automatic feeders:

-

Volume/MOQ: Bulk orders often lead to discounts, making it beneficial for buyers to consolidate orders. Understanding the supplier’s MOQ can assist in optimizing procurement strategies.

-

Specifications and Customization: Custom features, such as programmable settings and unique designs, can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Material Quality and Certifications: Premium materials and safety certifications (like CE or RoHS) can justify higher prices. Buyers should ensure that the materials used comply with local regulations in their markets.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge higher prices but offer better warranties and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining responsibilities and costs associated with shipping and delivery. This can affect the total landed cost of the product.

What Are the Best Buyer Tips for Negotiating Prices on Pet Feeders?

To maximize value when sourcing pet ultra automatic feeders, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Flexible payment options can ease cash flow, particularly for international transactions.

-

Assess Total Cost of Ownership: Evaluate not just the purchase price but also the long-term costs associated with maintenance, shipping, and potential returns. A lower initial price may lead to higher costs down the line if the product is not durable.

-

Understand Pricing Nuances for International Buyers: When sourcing from regions such as Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, trade tariffs, and local market conditions. This knowledge can enhance negotiation leverage.

-

Request Samples: Before committing to large orders, request samples to assess quality and functionality. This step can prevent costly mistakes and ensure that the product meets your specifications.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Consider long-term partnerships that benefit both parties.

Disclaimer on Indicative Prices

Prices for pet ultra automatic feeders can vary widely based on the factors discussed. It is advisable for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing tailored to their specific needs.

Alternatives Analysis: Comparing pet ultra automatic feeder With Other Solutions

Exploring Alternatives to the Pet Ultra Automatic Feeder

In the quest for optimal pet care solutions, businesses must evaluate various feeding technologies to find the best fit for their operational needs. The Pet Ultra Automatic Feeder stands out for its advanced features, but it’s essential to consider other viable alternatives that may also meet the demands of pet owners. This analysis presents a comparison of the Pet Ultra Automatic Feeder with two alternative solutions: Traditional Manual Feeding and Smart Pet Feeding Apps.

| Comparison Aspect | Pet Ultra Automatic Feeder | Traditional Manual Feeding | Smart Pet Feeding Apps |

|---|---|---|---|

| Performance | Programmable, precise portion control, voice recording for pet comfort | Inconsistent portions, relies on owner’s presence | Flexible scheduling, remote monitoring of pet feeding |

| Cost | Moderate initial investment; potential long-term savings on pet food | Low initial cost; ongoing time investment | Low to moderate cost; subscription fees may apply |

| Ease of Implementation | Simple setup with programmable features | Requires owner’s time and effort | User-friendly interface, requires smartphone or device |

| Maintenance | Regular cleaning needed; battery checks for backup | Minimal maintenance; depends on owner’s diligence | Updates required for app; minimal hardware maintenance |

| Best Use Case | Ideal for busy pet owners needing automation | Best for small households or those with flexible schedules | Suitable for tech-savvy owners who want remote control |

What are the Advantages and Disadvantages of Traditional Manual Feeding?

Traditional manual feeding is the most basic approach and involves simply filling the pet’s bowl at designated times. This method is cost-effective and requires minimal investment. However, it relies heavily on the owner’s presence, which can lead to inconsistent feeding schedules and portions. Additionally, this approach may not suit pet owners with busy lifestyles or those who travel frequently, as it lacks automation and can disrupt the pet’s routine.

How Do Smart Pet Feeding Apps Enhance Pet Care?

Smart pet feeding apps offer a modern solution by allowing pet owners to schedule feeding times and monitor their pets remotely. These apps can be integrated with smart feeders, providing flexibility and control over feeding routines. While they offer convenience, the reliance on technology may not appeal to all users. Additionally, some apps may require subscription fees, which could be a drawback for budget-conscious pet owners.

Conclusion: How Should B2B Buyers Choose the Right Feeding Solution?

When choosing between the Pet Ultra Automatic Feeder and its alternatives, B2B buyers must consider their specific operational needs and the lifestyles of the pet owners they serve. The Pet Ultra Automatic Feeder excels in automation and precision, making it ideal for busy professionals. In contrast, traditional manual feeding may suit smaller operations where human interaction is prioritized, while smart pet feeding apps appeal to tech-savvy customers seeking convenience and remote access. Evaluating these factors will help businesses make informed decisions that align with their customers’ preferences and operational requirements.

Essential Technical Properties and Trade Terminology for pet ultra automatic feeder

What Are the Key Technical Properties of a Pet Ultra Automatic Feeder?

When assessing the technical specifications of a pet ultra automatic feeder, certain properties are crucial for ensuring quality, reliability, and user satisfaction. Here are several important specifications that B2B buyers should consider:

Illustrative image related to pet ultra automatic feeder

-

Material Composition

Automatic feeders are typically made from materials like Acrylonitrile Butadiene Styrene (ABS) and BPA-free plastics. These materials are chosen for their durability, safety, and ease of cleaning. For B2B buyers, understanding material properties can aid in evaluating product longevity and compliance with safety regulations, especially in regions with strict pet product standards. -

Capacity and Dimensions

The capacity of an automatic feeder, such as the 4L (16 cups) capacity in the PetUltra model, is critical for determining how often it needs to be refilled. Larger capacities cater to multiple pets or longer periods between refills, which is appealing in B2B scenarios where convenience and efficiency are paramount. Dimensions (e.g., 13.58 x 7.6 x 7.6 inches) also impact shelf space and shipping logistics. -

Feeding Portion Control

The ability to customize portion sizes is a vital feature that promotes responsible pet feeding. Automatic feeders that allow settings such as 1/8 cup to 2 cups per serving enable pet owners to adhere to dietary guidelines. For B2B buyers, this translates into potential value-added services, such as educational resources on pet nutrition. -

Power Supply Options

A dual power mode that includes both a power adapter and battery backup ensures continuous operation, even during power outages. This feature enhances reliability, which is essential for B2B buyers concerned about customer satisfaction and product dependability in diverse markets. -

Programmable Feeding Schedule

The ability to program multiple meals per day allows for flexibility in feeding routines. Products that can dispense food at set intervals (up to six meals a day) cater to various pet dietary needs. For wholesalers and retailers, this feature can enhance product appeal in markets where pet owners seek convenience and customization. -

Safety Features

Features like a locking lid and desiccant bag are crucial for maintaining food freshness and preventing unauthorized access by pets. Understanding these safety mechanisms can be a selling point for B2B buyers focused on the health and well-being of pets.

What Are Common Trade Terms Related to Pet Ultra Automatic Feeders?

Familiarity with industry jargon can significantly enhance communication and transactions in the pet product market. Here are several key terms relevant to B2B buyers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of pet feeders, buyers may engage with OEMs to customize products that meet specific market needs or branding requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers utilize RFQs to compare pricing, terms, and conditions from multiple vendors, ensuring they secure the best deal for their purchasing needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk, and insurance responsibilities, which are crucial for accurate budgeting and logistics planning. -

Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled after it is placed. Understanding lead time is vital for B2B buyers to manage their inventory effectively and ensure timely delivery to customers. -

Warranty Period

The warranty period is the duration for which a product is guaranteed against defects. A strong warranty can indicate product quality and reliability, making it a key consideration for B2B buyers assessing long-term value.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing pet ultra automatic feeders, ensuring they meet market demands and enhance customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the pet ultra automatic feeder Sector

What Are the Key Drivers and Trends in the Global Pet Ultra Automatic Feeder Market?

The global pet ultra automatic feeder market is experiencing significant growth, driven by evolving consumer lifestyles and a heightened focus on pet health and well-being. As pet owners become increasingly busy, the demand for automated feeding solutions that ensure pets receive consistent, timely meals is on the rise. This trend is particularly prominent in regions like Africa, South America, the Middle East, and Europe, where urbanization and dual-income households are common.

Emerging technologies such as smart feeders equipped with app integration allow pet owners to monitor and control feeding schedules remotely, enhancing convenience and user engagement. Additionally, features like portion control and programmable meal settings are gaining traction, as they cater to the diverse dietary needs of pets. B2B buyers should also note the rising interest in voice recording features that provide a personalized touch, reinforcing the bond between pets and their owners.

In terms of market dynamics, competitive pricing strategies and product innovation are crucial. International buyers should focus on sourcing from manufacturers that emphasize quality and reliability, particularly those who offer robust customer support and warranty services. With the proliferation of e-commerce platforms, buyers can access a wider range of products and suppliers, facilitating easier comparisons and informed purchasing decisions.

How Is Sustainability Shaping Sourcing Trends for Pet Ultra Automatic Feeders?

Sustainability has become a cornerstone of sourcing strategies in the pet ultra automatic feeder sector. As environmental concerns grow, buyers are increasingly prioritizing products made from eco-friendly materials and those that adhere to sustainable manufacturing practices. The importance of ethical supply chains cannot be overstated; B2B buyers are more likely to partner with suppliers that demonstrate transparency and responsibility in their sourcing methods.

For instance, utilizing BPA-free plastics and recyclable materials in pet feeders not only reduces environmental impact but also appeals to eco-conscious consumers. Additionally, manufacturers are adopting ‘green’ certifications that validate their commitment to sustainability, which can be a strong selling point in competitive markets. Buyers should seek suppliers who provide clear information on their sustainability practices and product certifications, ensuring that their procurement aligns with both market demands and corporate social responsibility goals.

What Is the Brief History of Automatic Feeders and Their Evolution in the Market?

The evolution of automatic feeders can be traced back to the early 20th century when the first rudimentary models were developed to assist pet owners in managing feeding schedules. Initially, these devices were simple gravity-fed dispensers that lacked precision and control. However, technological advancements in the late 20th and early 21st centuries transformed the sector, leading to the introduction of programmable timers and portion control mechanisms.

As consumer preferences shifted towards convenience and customization, manufacturers began incorporating smart technology into feeders, enabling remote management through mobile applications. This evolution reflects a broader trend towards integrating technology into pet care, as owners seek innovative solutions that enhance their pets’ health and well-being. Today, the market features a diverse array of automatic feeders, catering to various pet sizes and dietary needs, thereby providing B2B buyers with extensive options for their sourcing requirements.

In summary, the pet ultra automatic feeder market is characterized by a dynamic interplay of technological innovation, sustainability, and evolving consumer preferences. B2B buyers must navigate these trends carefully to capitalize on opportunities and meet the demands of modern pet owners.

Frequently Asked Questions (FAQs) for B2B Buyers of pet ultra automatic feeder

-

How do I solve issues with the PetUltra automatic feeder getting clogged?

To prevent clogging in the PetUltra automatic feeder, ensure you use kibble that fits the recommended size of 2-10mm. The feeder features a double rotor design and a 40-degree slope to facilitate smooth dispensing. Regular maintenance, such as cleaning the food passage and ensuring the locking lid is secure, can also help avoid blockages. If you encounter persistent issues, consult the user manual for troubleshooting steps or contact customer support for assistance. -

What is the best automatic feeder for small to medium-sized pets?

The PetUltra DU4LB-KY is an excellent choice for small to medium-sized pets, as it has a 4L capacity, accommodating up to 12 pounds of dry food. This feeder supports various kibble sizes and allows for customizable portion settings, ensuring your pet receives the right amount of food at scheduled intervals. Its programmable features, including up to six meals per day, make it ideal for maintaining a consistent feeding routine. -

What are the minimum order quantities (MOQ) for bulk purchasing of PetUltra feeders?

Minimum order quantities (MOQ) can vary by supplier and region. Typically, for PetUltra feeders, the MOQ may range from 50 to 100 units for wholesale buyers. It’s advisable to directly contact the manufacturer or authorized distributor to discuss specific MOQ details and negotiate terms based on your purchasing needs. This ensures you can meet your market demand while optimizing your investment. -

What payment terms can I expect when purchasing PetUltra feeders internationally?

Payment terms for international purchases usually depend on the supplier’s policies and the buyer’s creditworthiness. Common arrangements include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer flexible terms, such as letters of credit or payment upon delivery, particularly for established business relationships. Always ensure to clarify payment methods and terms prior to finalizing the order to avoid any misunderstandings. -

How can I vet suppliers of PetUltra automatic feeders?

When vetting suppliers, consider evaluating their reputation through online reviews, industry certifications, and references from other businesses. Request samples to assess product quality and compliance with safety standards. Additionally, verify their manufacturing capabilities, lead times, and customer service responsiveness. Engaging in direct communication and site visits, if feasible, can also provide insights into their operational practices and reliability. -

What logistics considerations should I keep in mind when importing PetUltra feeders?

Logistics for importing PetUltra feeders involves planning for shipping methods, customs clearance, and local regulations. Assess the best shipping options (air vs. sea) based on your timeline and budget. Ensure all necessary documentation, such as import licenses and customs declarations, are in order. Working with a freight forwarder can streamline the process, helping to navigate potential challenges and ensuring timely delivery. -

Can I customize the PetUltra feeder for my brand?

Yes, many suppliers offer customization options for PetUltra feeders, including branding, colors, and packaging design. Discuss your requirements with the manufacturer to explore the possibilities for branding your product line. Keep in mind that customizations may affect MOQs and lead times, so be prepared to align your marketing strategy with these factors. -

What quality assurance measures are in place for PetUltra feeders?

Quality assurance for PetUltra feeders typically includes rigorous testing for safety and performance standards. Manufacturers often adhere to international quality certifications, such as ISO or CE, ensuring that the products meet safety regulations. Request documentation on quality control processes from your supplier, including test results and compliance certifications, to ensure that the feeders will perform reliably in your market.

Top 4 Pet Ultra Automatic Feeder Manufacturers & Suppliers List

1. Pets Cat House – Automatic Pet Feeder

Domain: petscathouse.com

Registered: 2023 (2 years)

Introduction: {“Capacity”:”4 L (≈16 cups), holds up to ~12 lb kibble”,”Food type”:”Dry kibble 2–10 mm (up to 12 mm on newer models)”,”Power”:”DC 5 V/1 A adapter + 3×D-size alkaline batteries (for backup)”,”Setup & Programming”:{“Assembly”:”Attach the food tray to the base; add dry kibble to the tank and close the lid”,”Power On”:”Plug in adapter; install batteries if needed”,”Set Current Time”:”Unlock (long pre…

2. PETULTRA – PetUltra DU4LB-KY Pet Dry Food Dispenser

Domain: manuals.plus

Introduction: {‘product_name’: ‘PetUltra DU4LB-KY Pet Dry Food Dispenser’, ‘brand’: ‘PETULTRA’, ‘material’: ‘Plastic, Acrylonitrile Butadiene Styrene (ABS)’, ‘target_species’: ‘Cats, Dogs’, ‘recommended_uses’: ‘Indoor’, ‘special_features’: [‘Portion Control’, ‘Voice Recording’, ‘Feeding Schedule’, ‘Programmable’, ‘Food-Grade Material’], ‘dimensions’: ‘13.58 x 7.6 x 7.6 inches’, ‘weight’: ‘3.6 Pounds’, ‘capacity…

3. Heartwood – WiFi Automatic Cat Feeder

Domain: heartwood.church

Introduction: This company, Heartwood – WiFi Automatic Cat Feeder, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Geeni – PetConnect Feeder

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Geeni – PetConnect Feeder, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pet ultra automatic feeder

In conclusion, the strategic sourcing of pet ultra automatic feeders presents a significant opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The PetUltra DU4LB-KY model exemplifies the innovative features that cater to modern pet owners’ needs, such as customizable portion control, programmable feeding schedules, and dual power modes. These attributes not only enhance pet welfare but also streamline the feeding process for busy pet owners.

By leveraging strategic sourcing, businesses can benefit from improved cost management, access to high-quality products, and the ability to respond swiftly to market demands. As the pet care industry continues to evolve, investing in advanced feeding solutions like the PetUltra DU4LB-KY can set your business apart, ensuring customer satisfaction and fostering loyalty.

Looking ahead, now is the time for international B2B buyers to explore partnerships with reliable suppliers of innovative pet products. Embrace the growing demand for automated feeding solutions to meet consumer expectations and drive your business success. The future of pet care is bright, and your strategic sourcing decisions today will pave the way for sustainable growth and competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pet ultra automatic feeder

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.