Introduction: Navigating the Global Market for how to clean automatic litter box

In today’s competitive pet care market, understanding how to clean automatic litter boxes is essential for businesses aiming to offer exceptional products that enhance pet owners’ lives. With the increasing adoption of self-cleaning litter boxes, the challenge lies not only in sourcing high-quality units but also in ensuring they are maintained effectively. This comprehensive guide will equip international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe (including Nigeria and Brazil)—with the knowledge needed to navigate the complexities of automatic litter box cleaning.

Covering a range of topics, from various types of automatic litter boxes and their specific cleaning requirements to best practices for supplier vetting, cost considerations, and maintenance schedules, this guide is designed to empower informed purchasing decisions. By understanding the nuances of cleaning these innovative products, businesses can enhance customer satisfaction, reduce return rates, and foster brand loyalty.

Additionally, we will explore the latest trends in the market, helping you identify the most efficient and effective cleaning solutions that resonate with your target audience. With the right insights, you can position your offerings as not only necessary tools for pet care but also as essential components of a hassle-free lifestyle for pet owners worldwide.

Table Of Contents

- Top 4 How To Clean Automatic Litter Box Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to clean automatic litter box

- Understanding how to clean automatic litter box Types and Variations

- Key Industrial Applications of how to clean automatic litter box

- 3 Common User Pain Points for ‘how to clean automatic litter box’ & Their Solutions

- Strategic Material Selection Guide for how to clean automatic litter box

- In-depth Look: Manufacturing Processes and Quality Assurance for how to clean automatic litter box

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to clean automatic litter box’

- Comprehensive Cost and Pricing Analysis for how to clean automatic litter box Sourcing

- Alternatives Analysis: Comparing how to clean automatic litter box With Other Solutions

- Essential Technical Properties and Trade Terminology for how to clean automatic litter box

- Navigating Market Dynamics and Sourcing Trends in the how to clean automatic litter box Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to clean automatic litter box

- Strategic Sourcing Conclusion and Outlook for how to clean automatic litter box

- Important Disclaimer & Terms of Use

Understanding how to clean automatic litter box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Litter-Robot 4 | Self-cleaning, automated globe rotation, waste drawer system | Pet supply retailers, e-commerce platforms | Pros: Low maintenance, efficient waste disposal. Cons: Initial investment is high, requires regular deep cleaning. |

| ChillX AutoEgg | Zig-zag litter tray, horizontal raking system | Pet product distributors, veterinary clinics | Pros: Easy disassembly, effective cleaning. Cons: Limited to specific litter types, not waterproof. |

| PetSafe ScoopFree | Disposable litter trays, rake-based cleaning mechanism | Pet supply chains, online marketplaces | Pros: Minimal mess, convenient for busy pet owners. Cons: Ongoing cost for disposable trays, less durable. |

| CatGenie | Washable granules, self-flushing capability | Retailers focused on eco-friendly products | Pros: Eco-friendly, no need for traditional litter. Cons: Requires plumbing access, higher maintenance. |

| Omega Paw Roll’N Clean | Roll-to-clean design, no electricity required | Eco-conscious retailers, pet care services | Pros: Energy-efficient, simple to use. Cons: Manual operation, may require physical strength. |

What Are the Key Characteristics of the Litter-Robot 4?

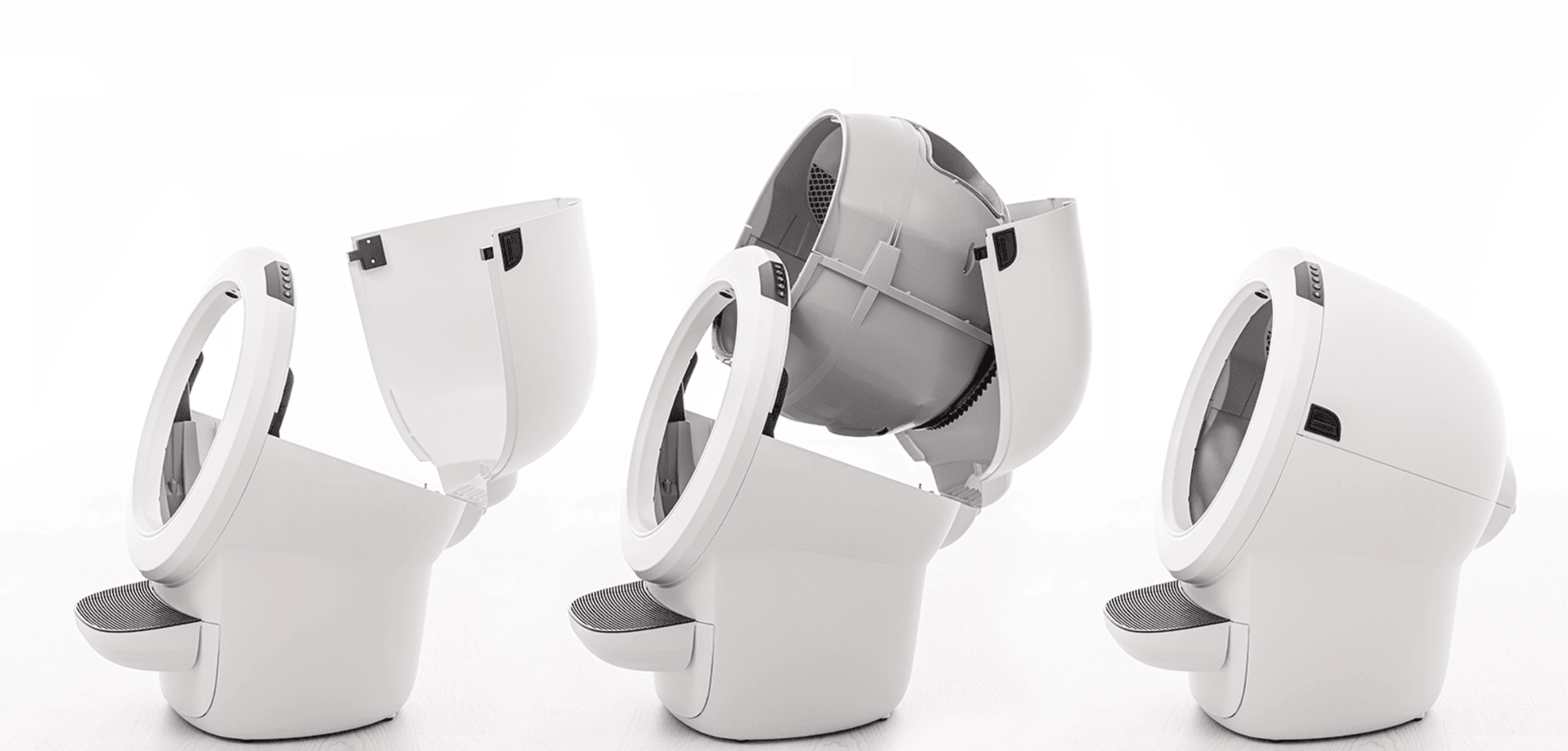

The Litter-Robot 4 is an advanced self-cleaning litter box featuring an automated globe rotation that efficiently sifts waste into a drawer. It is particularly suitable for businesses catering to pet owners who prioritize convenience and hygiene. B2B buyers should consider the product’s reliability and the necessity for periodic deep cleaning to maintain optimal performance, which can affect customer satisfaction and repeat sales.

How Does the ChillX AutoEgg Stand Out?

ChillX AutoEgg employs a unique zig-zag litter tray combined with a horizontal raking system, ensuring thorough cleaning. Ideal for pet product distributors and veterinary clinics, this model is designed for ease of use and disassembly, facilitating quick maintenance. B2B buyers should evaluate the compatibility of this model with various litter types, as this could impact its marketability and customer feedback.

What Makes PetSafe ScoopFree a Popular Choice?

The PetSafe ScoopFree litter box uses disposable trays that simplify waste management and cleaning. This feature appeals to busy pet owners and can be effectively marketed through pet supply chains and online platforms. B2B buyers must weigh the ongoing costs of disposable trays against the convenience and cleanliness benefits when considering this product for their inventory.

Why Is CatGenie Considered Eco-Friendly?

CatGenie utilizes washable granules and has a self-flushing mechanism, making it a sustainable alternative to traditional litter boxes. It is particularly suitable for retailers focusing on eco-conscious products. B2B buyers should assess the plumbing requirements and maintenance needs, as these factors can influence customer adoption and satisfaction.

What Are the Benefits and Limitations of Omega Paw Roll’N Clean?

The Omega Paw Roll’N Clean features a simple roll-to-clean design that does not require electricity, appealing to eco-conscious retailers and pet care services. While it is energy-efficient and easy to use, it does require manual operation, which may not suit all customers. B2B buyers should consider the product’s physical usability and market it to customers who value low-maintenance solutions.

Key Industrial Applications of how to clean automatic litter box

| Industry/Sector | Specific Application of how to clean automatic litter box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care Services | Regular maintenance services for automatic litter boxes | Ensures hygiene and reduces health risks for pets | Reliability of cleaning solutions; availability of parts |

| Veterinary Clinics | Cleaning protocols for in-house litter box systems | Enhances patient care by maintaining a clean environment | Compliance with health regulations; non-toxic cleaning agents |

| Pet Retailers | Offering cleaning kits and services alongside products | Increases customer satisfaction and repeat business | Quality of cleaning products; competitive pricing |

| Animal Shelters | Maintenance of litter boxes in shelter facilities | Promotes better living conditions for animals | Cost-effective cleaning solutions; bulk purchasing options |

| Hospitality Industry | Litter box cleaning for pet-friendly accommodations | Enhances guest experience and promotes cleanliness | Eco-friendly cleaning options; service reliability |

How Can Pet Care Services Benefit from Cleaning Automatic Litter Boxes?

Pet care services can leverage the cleaning of automatic litter boxes as a value-added service. By providing regular maintenance, these businesses ensure that the litter boxes remain hygienic, thereby reducing health risks associated with unclean environments. For international buyers, particularly in regions like Africa and South America, sourcing reliable cleaning solutions that cater to local pet care standards is essential. Additionally, the availability of spare parts for various models can enhance service efficiency.

Why Is Cleaning Protocol Important in Veterinary Clinics?

In veterinary clinics, maintaining cleanliness in litter boxes is critical for patient care. Regular cleaning protocols not only improve the environment for pets but also help in preventing the spread of diseases. Buyers from the Middle East and Europe should consider compliance with local health regulations when sourcing cleaning agents and tools. Utilizing non-toxic and effective cleaning products will ensure a safe environment for both animals and staff.

How Can Pet Retailers Enhance Customer Experience with Cleaning Solutions?

Pet retailers have the opportunity to enhance customer satisfaction by offering cleaning kits and maintenance services for automatic litter boxes. This not only helps in promoting hygiene but also encourages repeat business as customers seek comprehensive solutions for their pets. In markets like Nigeria and Brazil, understanding local preferences for cleaning products and establishing competitive pricing will be vital for success.

What Role Do Animal Shelters Play in Maintaining Litter Box Hygiene?

Animal shelters rely heavily on the maintenance of litter boxes to provide a clean living space for animals. Regular cleaning not only improves the welfare of the animals but also makes the shelter more appealing to potential adopters. For B2B buyers in these sectors, sourcing cost-effective cleaning solutions and considering bulk purchasing options can significantly reduce operational costs.

How Does the Hospitality Industry Benefit from Clean Litter Boxes?

In the hospitality industry, maintaining clean litter boxes in pet-friendly accommodations is essential for enhancing guest experiences. A clean environment promotes guest satisfaction and can lead to positive reviews and repeat visits. Buyers in this sector should prioritize eco-friendly cleaning options that align with sustainability goals, ensuring that their cleaning practices do not negatively impact the environment. Reliability of service providers is also a key consideration for maintaining high standards.

3 Common User Pain Points for ‘how to clean automatic litter box’ & Their Solutions

Scenario 1: Maintaining Efficiency in High-Volume Environments

The Problem: B2B buyers, such as pet care businesses or veterinary clinics, often manage multiple automatic litter boxes. These environments require regular cleaning to maintain efficiency and hygiene. The challenge lies in establishing a cleaning routine that minimizes downtime while ensuring the units remain functional and sanitary. Failure to maintain the litter boxes can lead to unpleasant odors, decreased performance, and ultimately, customer dissatisfaction.

The Solution: To effectively manage cleaning in high-volume settings, implement a structured cleaning schedule tailored to the usage rates of the litter boxes. For example, establish a bi-weekly deep cleaning routine for high-traffic units, while those with lighter usage can follow a monthly schedule. Utilize specialized cleaning solutions designed for automatic litter boxes to enhance efficiency and minimize residue build-up. Train staff on quick disassembly and cleaning techniques to reduce downtime. This proactive approach not only ensures cleanliness but also extends the lifespan of the equipment, thereby enhancing customer satisfaction and retention.

Scenario 2: Navigating Complex Cleaning Procedures

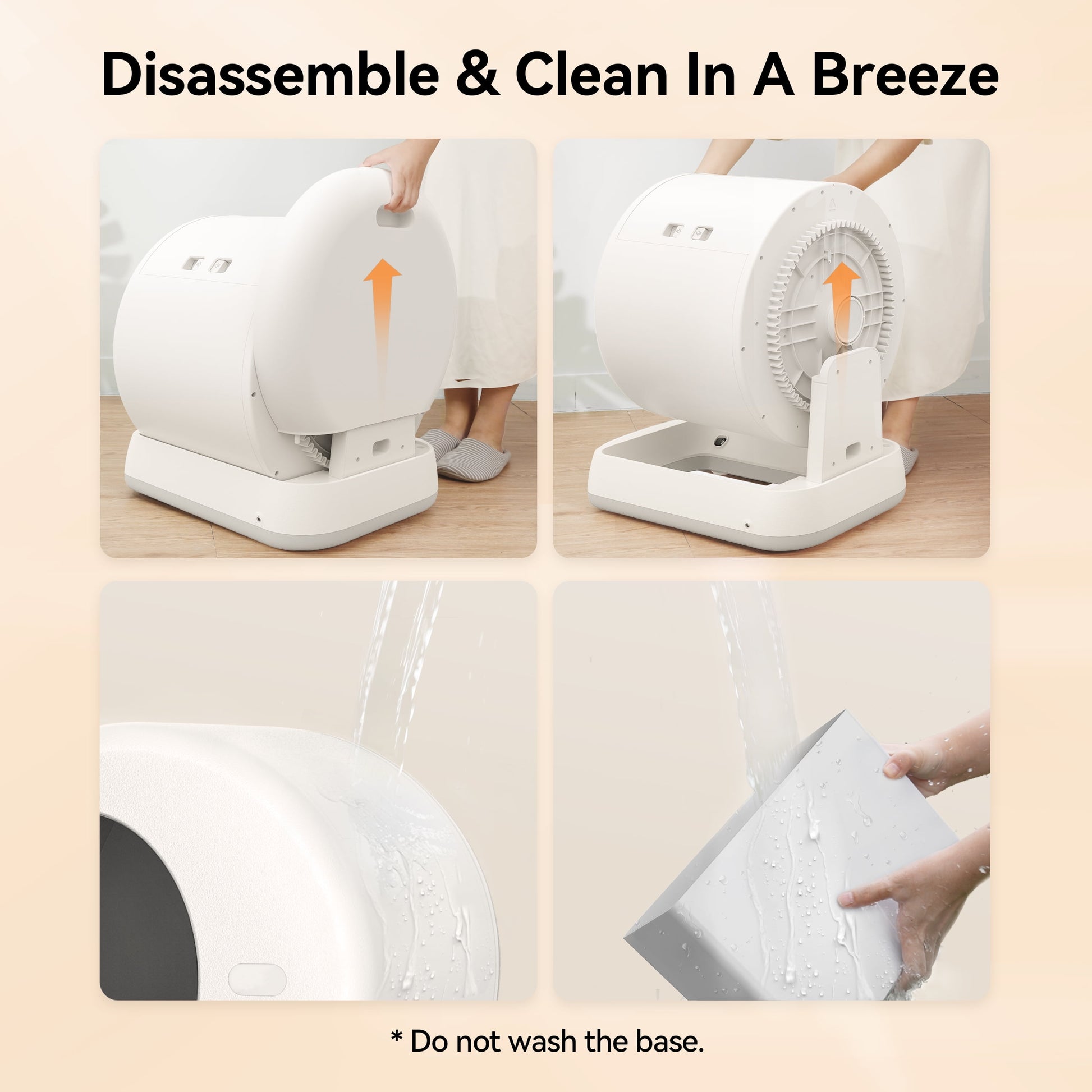

The Problem: Many automatic litter boxes come with intricate components that require careful handling during the cleaning process. B2B buyers may struggle with understanding the proper disassembly and cleaning steps, leading to potential damage to sensitive parts or incorrect reassembly. This not only wastes time but can also result in costly repairs or replacements.

The Solution: To mitigate confusion and facilitate a seamless cleaning process, create detailed, step-by-step cleaning manuals specific to the models in use. Incorporate visual aids such as diagrams or instructional videos that illustrate disassembly and reassembly procedures. Consider hosting training sessions for staff to practice these techniques in a controlled environment. Additionally, sourcing high-quality cleaning tools and solutions that are compatible with the litter box components will simplify the maintenance process, ensuring that all parts are cleaned effectively without damage.

Scenario 3: Addressing Odor Control and Hygiene Issues

The Problem: In environments where multiple cats use the same automatic litter box, odor control becomes a pressing concern. B2B buyers may find that even with self-cleaning mechanisms, persistent odors can develop if the litter boxes are not maintained correctly. This can deter potential customers from using the facility or purchasing the products.

Illustrative image related to how to clean automatic litter box

The Solution: To effectively combat odor issues, integrate advanced odor control strategies into your cleaning routine. Invest in high-quality litter that offers superior clumping and odor-neutralizing properties. Encourage regular inspection and cleaning of the waste drawer and other components to prevent waste build-up, which is often the source of unpleasant smells. Consider implementing an air filtration system in the vicinity of the litter boxes to further enhance odor management. By maintaining a rigorous cleaning protocol and utilizing odor-neutralizing products, B2B buyers can ensure a fresh environment that attracts customers and enhances their overall experience.

Strategic Material Selection Guide for how to clean automatic litter box

When considering materials for cleaning automatic litter boxes, it’s essential to evaluate options based on their properties, advantages, and limitations. Here, we analyze four common materials: plastics, stainless steel, silicone, and glass. Each material has unique characteristics that affect performance, cost, and suitability for international markets.

What Are the Key Properties of Plastics in Cleaning Automatic Litter Boxes?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene (PP), are widely used in the construction of automatic litter boxes. These materials are lightweight, resistant to moisture, and have good chemical resistance, making them suitable for cleaning applications. They can withstand temperatures up to 80°C (176°F) without deforming, which is beneficial during cleaning processes involving hot water or steam.

Pros & Cons: Plastics are generally cost-effective and easy to manufacture, allowing for high-volume production. However, they may not be as durable as metals and can scratch or become discolored over time. Additionally, they are less environmentally friendly, which can be a consideration for buyers in regions with strict environmental regulations.

How Does Stainless Steel Compare for Automatic Litter Box Cleaning?

Stainless steel is another popular material choice for components of automatic litter boxes, particularly for parts that require durability and resistance to corrosion. With a temperature tolerance exceeding 300°C (572°F), stainless steel can handle rigorous cleaning methods, including high-temperature sterilization.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and staining. It is also easier to sanitize than plastics. However, stainless steel is more expensive and heavier, which can increase shipping costs and complicate manufacturing processes. Buyers need to consider the balance between durability and cost when selecting stainless steel components.

Illustrative image related to how to clean automatic litter box

What Role Does Silicone Play in Cleaning Automatic Litter Boxes?

Silicone is often used for seals and gaskets in automatic litter boxes due to its flexibility and resistance to temperature extremes. It can withstand temperatures from -60°C to 200°C (-76°F to 392°F), making it suitable for various cleaning methods.

Pros & Cons: Silicone is durable and resistant to degradation from UV light and chemicals, which is beneficial for maintaining the integrity of cleaning components. However, it can be more expensive than traditional plastics and may not be suitable for all applications due to its softer nature, which can lead to wear over time.

Why Is Glass Considered for Cleaning Automatic Litter Boxes?

Glass is sometimes used for specific components due to its non-porous surface, making it easy to clean and resistant to staining. It can handle high temperatures and is inert to most chemicals, providing a safe cleaning surface.

Pros & Cons: The main advantage of glass is its aesthetic appeal and ease of cleaning. However, it is fragile and can break easily, which poses a risk in environments where litter boxes are frequently handled. The cost of glass components is also typically higher than that of plastics or metals, which may deter some buyers.

Illustrative image related to how to clean automatic litter box

Summary Table of Material Selection for Cleaning Automatic Litter Boxes

| Material | Typical Use Case for how to clean automatic litter box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastics | Waste drawers, litter trays | Lightweight and cost-effective | Less durable, potential environmental concerns | Low |

| Stainless Steel | Structural components, cleaning tools | Durable and corrosion-resistant | Higher cost, heavier weight | High |

| Silicone | Seals and gaskets | Flexible and temperature resistant | More expensive, wear over time | Medium |

| Glass | Cleaning surfaces | Easy to clean and non-porous | Fragile and higher cost | High |

In conclusion, selecting the right material for cleaning automatic litter boxes involves balancing performance, cost, and suitability for the target market. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider local regulations and consumer preferences when making their choices.

In-depth Look: Manufacturing Processes and Quality Assurance for how to clean automatic litter box

What Are the Main Stages of Manufacturing Automatic Litter Boxes?

The manufacturing process of automatic litter boxes involves several critical stages that ensure the final product is both functional and durable. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first stage involves selecting high-quality materials that are resistant to wear and easy to clean. Common materials include durable plastics for the body, stainless steel for internal components, and specialized polymers for the litter tray. Suppliers often need to meet specific industry standards, such as those set by the American Society for Testing and Materials (ASTM), to ensure the materials are suitable for pet use.

-

Forming: This stage utilizes techniques such as injection molding and blow molding to shape the components of the litter box. Injection molding is commonly used for creating the body and lid, while blow molding may be employed for parts like the waste drawer. Precision in this stage is crucial, as the fit and finish of these components affect the overall performance and safety of the product.

-

Assembly: The assembly process integrates all the components, including motors, sensors, and electronic circuitry. Automated assembly lines are often used to ensure consistency and efficiency. Each unit is assembled with attention to detail, ensuring that all parts fit correctly and function as intended. This stage may also involve testing the mechanical and electronic components to verify proper operation.

-

Finishing: The finishing stage includes surface treatments, such as coating and polishing, to enhance durability and aesthetics. This may involve applying UV-resistant coatings to prevent fading from sunlight exposure. Quality control checks are conducted to ensure that all surface finishes meet the required standards.

What Key Techniques Are Used in Manufacturing Automatic Litter Boxes?

Several key techniques are employed throughout the manufacturing process to ensure the quality and reliability of automatic litter boxes.

-

Precision Engineering: Utilizing computer-aided design (CAD) software allows manufacturers to create detailed models of each component. This ensures that every part fits together perfectly, minimizing issues during assembly.

-

Robotic Automation: Many manufacturers implement robotic systems for repetitive tasks such as assembly and packaging. This not only speeds up the production process but also reduces human error.

-

Quality Testing: Throughout the manufacturing process, various testing methods are employed to ensure that components meet performance specifications. This includes stress testing for durability, electrical testing for safety, and functionality tests for automatic features.

What Are the Relevant International Standards for Quality Assurance in Automatic Litter Boxes?

Quality assurance in the manufacturing of automatic litter boxes is guided by several international standards that ensure product safety, reliability, and environmental compliance.

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to organizations in any industry. Adhering to ISO 9001 helps manufacturers ensure consistent quality and continuous improvement.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards. Manufacturers must ensure that their products meet the essential requirements set forth by the European Union.

-

API Standards: In some regions, manufacturers may also adhere to specific American Petroleum Institute (API) standards for materials used in components that may come into contact with waste, ensuring safety and hygiene.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is a vital aspect of the manufacturing process, ensuring that products meet specified standards before they reach the market. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certification and test reports to verify that materials meet quality standards.

-

In-Process Quality Control (IPQC): During production, various inspections are conducted at different stages to identify defects early. This may include checking dimensions, functionality, and assembly quality.

-

Final Quality Control (FQC): Once the assembly is complete, each unit undergoes a final inspection. This includes testing for proper operation of all features, ensuring that the litter box functions as intended and meets safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing automatic litter boxes, B2B buyers must conduct thorough due diligence to verify the quality control practices of potential suppliers. Here are several methods to ensure supplier reliability:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational efficiency of the supplier. This provides insight into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should request detailed quality control reports, including IQC, IPQC, and FQC documentation. This will provide transparency into the supplier’s QC processes and help buyers understand the level of quality assurance maintained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing practices. These inspections can validate compliance with international standards and assess overall product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

Illustrative image related to how to clean automatic litter box

-

Regulatory Compliance: Different regions may have varying regulations regarding pet products. Buyers should familiarize themselves with local requirements, such as import regulations, safety standards, and labeling requirements.

-

Cultural Considerations: Cultural factors can influence consumer preferences and product expectations. Buyers should consider local market demands, such as preferred materials and designs, when evaluating suppliers.

-

Language Barriers: Communication can be challenging when dealing with international suppliers. Buyers should ensure that all documentation is available in a language they understand, and consider using translators if necessary.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing automatic litter boxes, ensuring they select suppliers that meet their quality standards and market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to clean automatic litter box’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to understand the process of cleaning automatic litter boxes. Maintaining these units is essential not only for hygiene but also for prolonging their lifespan and ensuring optimal functionality. Proper cleaning protocols can enhance customer satisfaction and minimize maintenance costs, which is crucial for businesses operating in the pet care industry.

Step 1: Understand the Cleaning Requirements

Before procuring cleaning solutions or services, familiarize yourself with the specific cleaning requirements of various automatic litter boxes. Each model may have unique components and materials that dictate the cleaning approach. Knowing these details helps in sourcing appropriate cleaning agents and tools that won’t damage the equipment.

- Research Manufacturer Guidelines: Consult the manuals from manufacturers like Litter-Robot or ChillX for recommended cleaning practices.

- Identify Common Issues: Understand prevalent issues like clogs or odor control that may require specific cleaning solutions.

Step 2: Identify Suitable Cleaning Products

Choosing the right cleaning products is vital to maintain the integrity of automatic litter boxes. Opt for biodegradable and non-toxic cleaners that effectively remove waste without harming the materials.

- Evaluate Product Safety: Ensure the cleaners are safe for pets and do not leave harmful residues.

- Check Efficacy: Look for products specifically designed for pet hygiene to guarantee effective cleaning.

Step 3: Evaluate Supplier Certifications

Before finalizing any purchase, verify that your suppliers possess the necessary certifications. This ensures that the products meet industry standards and regulations, which is crucial for maintaining your business’s reputation.

- Request Documentation: Ask for certifications related to safety, efficacy, and environmental impact.

- Check Compliance with Local Regulations: Ensure that the products comply with regulations in your target regions, especially in diverse markets like Africa and South America.

Step 4: Assess Supplier Experience and Reputation

A supplier’s experience in the pet care industry can significantly impact the quality of products and services offered. Look for suppliers with a proven track record in providing cleaning solutions for automatic litter boxes.

Illustrative image related to how to clean automatic litter box

- Review Case Studies: Seek out case studies or testimonials from other businesses in your industry.

- Evaluate Longevity: Consider suppliers who have been in the market for several years, as they are likely to have refined their products and services.

Step 5: Establish a Regular Cleaning Schedule

Developing a cleaning schedule is essential for maintaining the performance of automatic litter boxes. This proactive approach reduces the likelihood of malfunctions and enhances the user experience.

- Frequency Based on Usage: Determine cleaning frequency based on the number of pets using the litter box; more pets typically necessitate more frequent cleanings.

- Document Procedures: Create a clear checklist of cleaning steps to ensure consistency and thoroughness in each cleaning session.

Step 6: Implement Training for Staff

If your business operates in a setting where staff members will handle the cleaning, proper training is critical. Well-trained staff can perform cleaning tasks efficiently and effectively, minimizing errors.

- Provide Training Materials: Develop or source training manuals that outline cleaning processes and safety protocols.

- Conduct Hands-On Training: Ensure staff undergo practical training sessions to familiarize themselves with the cleaning procedures specific to each model of litter box.

Conclusion

By following this checklist, B2B buyers can ensure they are well-equipped to maintain automatic litter boxes effectively. From understanding cleaning requirements to training staff, each step is crucial for enhancing product longevity and customer satisfaction in the pet care sector.

Comprehensive Cost and Pricing Analysis for how to clean automatic litter box Sourcing

Understanding the cost structure and pricing dynamics for cleaning automatic litter boxes is essential for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will delve into the components that influence costs and pricing, providing actionable insights for international buyers.

Illustrative image related to how to clean automatic litter box

What Are the Key Cost Components for Cleaning Automatic Litter Boxes?

-

Materials: The primary materials involved in the cleaning process include cleaning agents, replacement parts, and packaging materials. Eco-friendly cleaning solutions are increasingly preferred, which may come at a premium. Additionally, components like waste drawer liners and carbon filters also contribute to material costs.

-

Labor: Labor costs encompass both the workforce involved in manufacturing cleaning products and those engaged in the maintenance and cleaning services of the automatic litter boxes. Labor rates can vary significantly based on the region, with higher costs in developed markets compared to emerging economies.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs are incurred in the production of cleaning kits and components. Suppliers may need to invest in specialized tools for manufacturing high-quality parts, which can affect the overall pricing structure.

-

Quality Control (QC): Ensuring that cleaning products and components meet safety and performance standards is critical. QC processes may add to the cost but are necessary for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on the destination. Factors such as freight costs, tariffs, and shipping times are crucial, especially for international buyers. Understanding Incoterms can help buyers negotiate better shipping terms.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on competition, brand positioning, and market demand. Buyers should be aware that higher quality often correlates with higher margins.

How Do Price Influencers Affect Cleaning Solutions for Automatic Litter Boxes?

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can lead to significant cost savings. Suppliers often provide discounts for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Customized cleaning solutions tailored to specific models of automatic litter boxes may come at a higher price. Buyers should evaluate whether the added cost aligns with their needs.

-

Material Quality and Certifications: Premium materials and environmentally friendly certifications can increase costs. However, they can also enhance brand reputation and customer loyalty.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding shipping terms is vital for international transactions. Buyers should negotiate terms that minimize their total cost, considering risks and responsibilities associated with delivery.

What Tips Can Help Buyers Negotiate Better Prices and Ensure Cost-Efficiency?

-

Negotiation Tactics: Engage in discussions about pricing flexibility, especially for bulk orders. Presenting a long-term partnership approach may incentivize suppliers to offer better rates.

-

Total Cost of Ownership (TCO): Assess the long-term costs associated with cleaning solutions, including maintenance, replacement parts, and potential downtime. A higher upfront cost may be justified if it leads to lower TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and economic conditions in your region. These factors can impact pricing and should be considered when budgeting for purchases.

-

Market Research: Conduct thorough market analysis to understand competitive pricing. This information can empower buyers during negotiations and help them identify fair pricing benchmarks.

Conclusion

While the cleaning of automatic litter boxes involves various cost components and pricing influencers, B2B buyers can optimize their procurement strategies through informed decisions. Understanding the market dynamics, leveraging negotiation tactics, and focusing on the total cost of ownership can lead to better purchasing outcomes. As always, indicative prices should be approached with caution, as they can fluctuate based on market conditions and supplier capabilities.

Alternatives Analysis: Comparing how to clean automatic litter box With Other Solutions

Understanding Alternatives for Maintaining Litter Hygiene

When it comes to maintaining cleanliness in automatic litter boxes, various methods and technologies exist. For international B2B buyers, particularly in emerging markets like Africa and South America, understanding these alternatives can lead to informed purchasing decisions. Below, we compare the cleaning process of automatic litter boxes with other viable solutions to highlight key differences and advantages.

| Comparison Aspect | How To Clean Automatic Litter Box | Manual Litter Box | Traditional Self-Cleaning Litter Box |

|---|---|---|---|

| Performance | High; automated cleaning reduces odor and mess | Moderate; requires regular scooping | High; automated but requires manual maintenance |

| Cost | Higher initial investment, lower long-term costs | Low initial cost, ongoing costs for litter and cleaning supplies | Moderate to high; potential for more frequent repairs |

| Ease of Implementation | Requires user manual for setup and maintenance | Simple; no setup needed, but labor-intensive | Requires manual setup and occasional repairs |

| Maintenance | Low; regular deep cleaning every few months | High; daily scooping and frequent deep cleaning | Moderate; needs regular maintenance and cleaning |

| Best Use Case | Households with multiple cats or busy lifestyles | Budget-conscious consumers or single cat households | Cat owners seeking automation but willing to invest in upkeep |

What Are the Pros and Cons of Manual Litter Boxes?

Manual litter boxes are the traditional choice for cat owners, offering a straightforward solution without the complexities of technology. The main advantages include low initial costs and simplicity in setup. However, they require daily maintenance, which can be time-consuming and less hygienic, especially in households with multiple pets. This method often leads to odors and can be less appealing for users looking for a more automated solution.

How Do Traditional Self-Cleaning Litter Boxes Compare?

Traditional self-cleaning litter boxes aim to automate the cleaning process, providing convenience similar to automatic models. These devices can efficiently remove waste after each use, reducing odor and keeping the litter cleaner. However, they often require more frequent manual maintenance than fully automatic models, including emptying waste drawers and cleaning components. Additionally, the initial investment can be significant, and users may face repair costs if parts malfunction.

Conclusion: Which Litter Cleaning Solution Should B2B Buyers Choose?

For B2B buyers, the choice between automatic litter boxes and their alternatives hinges on several factors, including budget, ease of use, and maintenance capabilities. Automatic litter boxes excel in performance and reduce manual labor, making them ideal for busy households or those with multiple pets. However, traditional manual boxes and self-cleaning models can serve budget-conscious buyers or those who prefer a lower-tech approach. Ultimately, assessing the specific needs of the target market—whether focusing on cost, ease of maintenance, or technological innovation—will guide the selection of the most suitable litter cleaning solution.

Essential Technical Properties and Trade Terminology for how to clean automatic litter box

What Are the Critical Technical Properties for Cleaning Automatic Litter Boxes?

When considering the cleaning and maintenance of automatic litter boxes, several technical properties are essential for ensuring effective operation and longevity. Below are some of the critical specifications that B2B buyers should consider:

-

Material Grade

The materials used in the construction of automatic litter boxes significantly affect their durability and ease of cleaning. Common materials include high-grade plastics (like ABS or polycarbonate) that resist scratches and chemical damage from cleaning agents. Understanding the material grade helps buyers assess the product’s lifespan and maintenance requirements. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in the dimensions of components within the litter box. Precise tolerances ensure that parts fit together correctly, preventing malfunctions during operation. Buyers should look for products with tight tolerances to minimize the risk of litter leakage or mechanical failure. -

Cleaning Frequency Recommendations

Manufacturers often provide guidelines on how frequently each component should be cleaned or replaced. This information is critical for B2B buyers who need to establish maintenance schedules for their customers. Adhering to these recommendations can enhance the performance and lifespan of the equipment. -

Weight Capacity

Each automatic litter box has a specified weight capacity, which is crucial for ensuring the unit operates effectively without mechanical strain. This specification is particularly important for businesses that cater to multiple pet owners or facilities with large cats. Knowing the weight capacity allows buyers to match the product with their target customer demographics. -

Power Specifications

Automatic litter boxes typically operate on specific power requirements, which include voltage and wattage. Understanding these specifications ensures compatibility with local power supply standards, minimizing the risk of electrical issues. This aspect is vital for international buyers who need to comply with regional electrical regulations.

Which Common Trade Terms Should B2B Buyers Understand?

Navigating the procurement and supply chain for automatic litter boxes involves familiarity with specific trade terminology. Here are some essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who maintain high-quality standards in their products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and purchasing decisions. Knowing the MOQ helps businesses plan their stock levels and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to solicit price quotes for specific products or services. This process allows businesses to compare costs and negotiate terms. Familiarity with the RFQ process streamlines procurement and ensures competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping transactions. These terms specify who is responsible for costs related to transportation, insurance, and customs clearance. Understanding Incoterms is essential for B2B buyers engaged in international trade, as it influences the total landed cost of products. -

SKU (Stock Keeping Unit)

A SKU is a unique identifier for each distinct product and service that can be purchased. For B2B buyers, SKUs facilitate inventory tracking and management. Recognizing and utilizing SKUs can enhance order accuracy and streamline inventory processes.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing and maintaining automatic litter boxes, ultimately enhancing their operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the how to clean automatic litter box Sector

What Are the Current Market Dynamics and Key Trends in the Automatic Litter Box Cleaning Sector?

The automatic litter box sector is witnessing significant transformation, driven by advancements in technology and changing consumer preferences. As pet ownership rises globally, particularly in regions such as Africa, South America, the Middle East, and Europe, so does the demand for solutions that simplify pet care. International B2B buyers are increasingly interested in self-cleaning litter boxes that promise less maintenance and improved hygiene. Emerging technologies, such as integrated cleaning systems that utilize innovative raking mechanisms and self-diagnosing features, are becoming standard offerings.

Illustrative image related to how to clean automatic litter box

Additionally, the trend towards subscription-based models for litter supply and cleaning products is gaining traction. This approach not only ensures consistent revenue for manufacturers but also enhances customer loyalty. Moreover, as urbanization increases, particularly in densely populated regions, the convenience offered by automatic litter boxes appeals to busy professionals seeking hassle-free solutions.

Buyers are also focusing on the longevity and durability of products, leading to a preference for high-quality materials and components that can withstand regular use. In response, manufacturers are prioritizing robust designs and offering easy disassembly for cleaning and maintenance.

How Does Sustainability and Ethical Sourcing Impact the Automatic Litter Box Cleaning Sector?

Sustainability has become a pivotal consideration in the automatic litter box sector. As consumers grow increasingly aware of environmental issues, B2B buyers are seeking products that reflect eco-conscious values. The environmental impact of manufacturing processes, packaging, and the lifecycle of cleaning products is under scrutiny. Companies are responding by adopting sustainable practices, such as using biodegradable materials for litter and recyclable packaging for cleaning supplies.

Illustrative image related to how to clean automatic litter box

Ethical sourcing is also gaining importance, with buyers favoring suppliers who demonstrate transparency in their supply chains. Certifications that indicate environmentally friendly practices, such as ISO 14001 for environmental management and Cradle to Cradle for material health, are becoming essential for gaining market trust. Moreover, manufacturers are exploring partnerships with suppliers of green cleaning agents, reducing the reliance on harmful chemicals that can impact both pet health and the environment.

By prioritizing sustainability, companies can not only meet regulatory demands but also appeal to the growing demographic of eco-conscious consumers, enhancing their market position.

What Is the Brief Evolution and History of the Automatic Litter Box Cleaning Industry?

The automatic litter box cleaning industry has evolved significantly over the past few decades. Initially, traditional litter boxes required manual scooping, which posed challenges in hygiene and convenience. The introduction of self-cleaning models in the late 1990s marked a pivotal shift, with innovations focusing on automated raking systems to simplify waste disposal.

As technology advanced, the integration of smart features, such as weight sensors and mobile app connectivity, became prevalent in the 2010s. These advancements not only improved user experience but also provided valuable data on pet behavior and health. The modern automatic litter box is now designed to address the needs of pet owners who prioritize cleanliness, convenience, and technological integration, creating a robust market for B2B buyers looking to invest in this growing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of how to clean automatic litter box

-

How do I solve common cleaning issues with automatic litter boxes?

To address cleaning issues with automatic litter boxes, begin by following the manufacturer’s cleaning guidelines. Regularly disassemble the unit and clean individual components such as the waste drawer, litter tray, and rake. Use mild soap and warm water for washing, avoiding bleach or harsh chemicals that could harm the unit. If the litter is clumping or sticking, ensure the litter type is compatible with your model. Regular maintenance every 2-6 weeks, depending on usage, will help prevent more severe cleaning challenges. -

What is the best cleaning solution for automatic litter boxes?

The best cleaning solutions for automatic litter boxes are those specifically designed for pet products, such as enzyme-based cleaners or mild soap. These options effectively neutralize odors and break down waste without leaving harmful residues. Avoid using bleach or ammonia, as these can create harmful fumes and irritate pets. For quick touch-ups, disposable cleaning wipes formulated for pet areas can also be handy. Always ensure components are thoroughly rinsed and dried before reassembly. -

How often should automatic litter boxes be cleaned for optimal performance?

Automatic litter boxes should ideally be cleaned every 2-6 weeks, depending on factors such as the number of cats and their litter habits. For single-cat households, a cleaning every 4-6 weeks may suffice, while multi-cat households should aim for biweekly cleanings to maintain hygiene. Regular cleaning not only keeps the litter box functioning effectively but also promotes a healthier environment for pets. -

What are the logistics of sourcing automatic litter boxes internationally?

When sourcing automatic litter boxes internationally, consider factors such as shipping times, tariffs, and import regulations specific to your region. It’s crucial to partner with reliable suppliers who can provide documentation for customs clearance. Building relationships with local distributors can streamline logistics and reduce lead times. Additionally, ensure your supply chain can handle potential disruptions by having contingency plans in place. -

How can I vet suppliers for automatic litter boxes?

To vet suppliers, conduct thorough research to assess their reputation, product quality, and reliability. Request samples to evaluate the product firsthand and review customer testimonials. Check for certifications that ensure compliance with safety and quality standards. Additionally, consider visiting the supplier’s manufacturing facilities, if possible, to observe their production processes and quality control measures. -

What are the minimum order quantities (MOQ) for automatic litter boxes?

Minimum order quantities (MOQ) for automatic litter boxes can vary significantly based on the manufacturer and model. Typically, MOQs may range from 50 to several hundred units. When negotiating, inquire about flexibility in order size, especially for new partnerships or trial orders. Understanding MOQ is essential for budgeting and inventory management, particularly in international markets where logistics can add complexity. -

What payment terms are commonly used in international B2B transactions?

Common payment terms in international B2B transactions include options like Letter of Credit (LC), telegraphic transfer (TT), and PayPal for smaller orders. Payment terms may be negotiated based on order size and buyer-supplier relationships. It’s advisable to establish clear terms upfront, including payment schedules and penalties for late payments, to avoid misunderstandings. Additionally, consider currency fluctuations when negotiating prices. -

How can I ensure quality assurance (QA) when sourcing automatic litter boxes?

To ensure quality assurance when sourcing automatic litter boxes, implement a robust QA process that includes pre-shipment inspections and factory audits. Specify quality standards in your purchase agreement and consider using third-party inspection services to verify compliance before shipping. Establishing clear communication channels with suppliers can help address any quality concerns promptly and maintain product standards consistently.

Top 4 How To Clean Automatic Litter Box Manufacturers & Suppliers List

1. Litter-Robot – Automatic Self-Cleaning Litter Boxes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Litter-Robot 3 Connect and Litter-Robot 4 are automatic self-cleaning litter boxes. Users recommend cleaning the unit every few months by hosing it out or washing it in a tub. A regular 13-gallon kitchen garbage bag fits the waste drawer, providing a cost-saving tip. Cleaning tips include using kitchen wipes to clean the bezel and inner globe, running a cycle to ensure waste falls into the drawer,…

2. ChillX – AutoEgg Automatic Litter Box

Domain: chillx.co

Registered: 2020 (5 years)

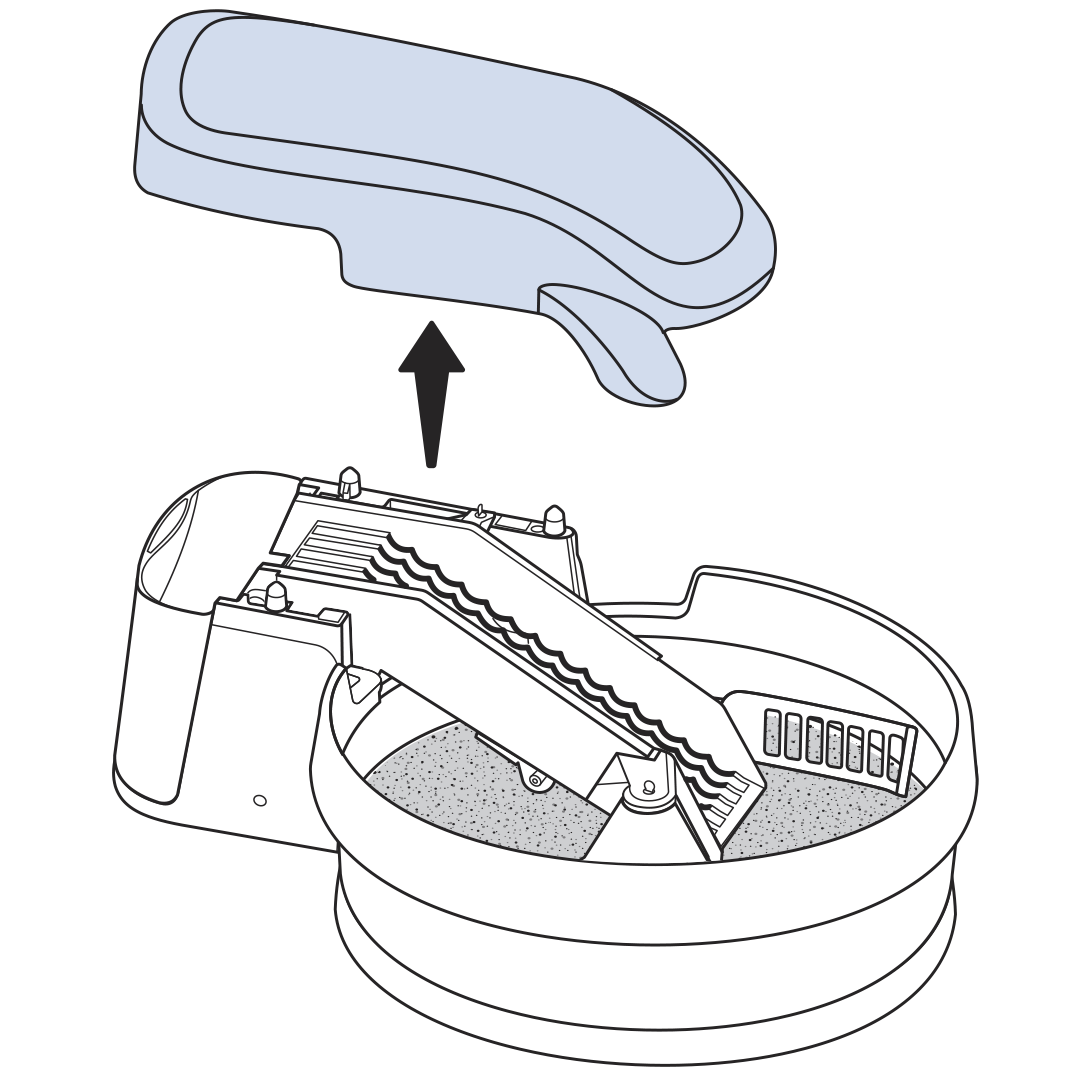

Introduction: The AutoEgg is an automatic litter box designed for easy maintenance and deep cleaning. It features a zig-zag litter tray and a horizontal raking system for effective cleaning. Key components that require washing include the top cover/hood, waste drawer cover, waste drawer, cleaning rake, tracking pad, and litter tray. It is recommended to deep clean the AutoEgg every 2 to 6 weeks, depending on th…

3. PetSafe – ScoopFree® Clumping Self-Cleaning Litter Box

Domain: support.petsafe.net

Registered: 1998 (27 years)

Introduction: ScoopFree® Clumping Self-Cleaning Litter Box; Regular monthly cleaning recommended; Avoid strong odor soaps/cleaners; Unplug power adapter before cleaning; Remove waste bin and cover; Dispose of litter and waste bin liner; Open rake covers and remove rake; Clean litter tray, waste bin, and cover by hand or dishwasher; Rake not dishwasher safe; Clean detection sensors with rubbing alcohol and cotto…

4. Whisker – Litter-Robot 4

Domain: goodhousekeeping.com

Registered: 1995 (30 years)

Introduction: Best Overall: Whisker Litter-Robot 4 – Price: $699 – Pros: Good for multiple cats, almost silent operation, hides odors well, app tracks usage and alerts when bin is full, works with any clay clumping litter, customizable controls. Cons: Expensive, 30-inch height is very tall. How it works: Cat triggers sensor by jumping in and out, waits 7 minutes, then rotates to separate waste into a bin. Recom…

Strategic Sourcing Conclusion and Outlook for how to clean automatic litter box

In conclusion, maintaining the cleanliness of automatic litter boxes is not just about hygiene but also about ensuring the longevity and performance of these innovative products. Regular deep cleaning, tailored to the number of pets and their habits, enhances user satisfaction and reduces the need for costly replacements. By leveraging strategic sourcing for high-quality cleaning supplies and accessories, businesses can ensure they are offering reliable solutions that meet the needs of their customers.

B2B buyers across Africa, South America, the Middle East, and Europe should focus on sourcing durable, easy-to-clean litter box components and effective cleaning agents. This not only enhances product offerings but also positions businesses as leaders in the market. Emphasizing the importance of maintenance in marketing strategies will resonate with pet owners who prioritize hygiene and convenience.

As the pet care industry continues to evolve, staying ahead of cleaning trends and customer preferences will be key. Invest in solutions that simplify maintenance and promote a healthier environment for pets. By doing so, businesses can cultivate long-term relationships with customers, driving growth and success in the competitive landscape of pet care.

Illustrative image related to how to clean automatic litter box

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.