Introduction: Navigating the Global Market for litter robot automatic feeder

In today’s fast-paced global market, sourcing innovative solutions like the Litter-Robot automatic feeder poses unique challenges for B2B buyers. As pet ownership continues to rise, the demand for automated pet care products has surged, making it essential for businesses to understand the advantages and specifications of these advanced feeders. This comprehensive guide delves into the multifaceted world of automatic feeders, exploring various types, applications, supplier vetting processes, and cost considerations tailored for international markets, particularly in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil.

Navigating the complexities of sourcing an automatic feeder can be daunting, especially for businesses looking to enhance their product offerings or improve customer satisfaction. This guide empowers B2B buyers by providing actionable insights and detailed information that facilitate informed purchasing decisions. From understanding the technical features and benefits of the Litter-Robot automatic feeder to evaluating potential suppliers and pricing strategies, every aspect is covered to ensure you can confidently meet your customers’ needs. By leveraging this resource, businesses can capitalize on the growing pet care market and position themselves as leaders in providing smart, efficient solutions for pet owners.

Table Of Contents

- Top 4 Litter Robot Automatic Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for litter robot automatic feeder

- Understanding litter robot automatic feeder Types and Variations

- Key Industrial Applications of litter robot automatic feeder

- 3 Common User Pain Points for ‘litter robot automatic feeder’ & Their Solutions

- Strategic Material Selection Guide for litter robot automatic feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for litter robot automatic feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘litter robot automatic feeder’

- Comprehensive Cost and Pricing Analysis for litter robot automatic feeder Sourcing

- Alternatives Analysis: Comparing litter robot automatic feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for litter robot automatic feeder

- Navigating Market Dynamics and Sourcing Trends in the litter robot automatic feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of litter robot automatic feeder

- Strategic Sourcing Conclusion and Outlook for litter robot automatic feeder

- Important Disclaimer & Terms of Use

Understanding litter robot automatic feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Feeder-Robot Standard | Holds up to 32 cups of dry food, app-controlled scheduling | Pet stores, veterinary clinics | Pros: Remote feeding control, portion management. Cons: Limited to dry food only. |

| Feeder-Robot with Backup Battery | Includes battery backup for uninterrupted feeding | Pet boarding facilities, shelters | Pros: Ensures feeding continuity during power outages. Cons: Additional cost for battery. |

| Feeder-Robot Reconditioned | Refurbished model at a lower price, same functionality | Budget-conscious retailers | Pros: Cost-effective option, reliable performance. Cons: Limited warranty and availability. |

| Feeder-Robot Multi-Pet Version | Configured for multiple pets, enhanced food distribution | Multi-pet households, pet care services | Pros: Tailored for larger pet families, reduces feeding time. Cons: Higher initial investment. |

| Feeder-Robot Smart Bundle | Combines with other smart pet devices for integrated care | Tech-savvy pet businesses | Pros: Comprehensive pet management, advanced analytics. Cons: Requires technical setup and compatibility checks. |

What are the characteristics and suitability of the Feeder-Robot Standard?

The Feeder-Robot Standard is designed to hold up to 32 cups of dry food, making it ideal for businesses with varying pet sizes and dietary needs. Its app-controlled scheduling allows for precise meal management, catering to both cats and dogs. This model is particularly suitable for pet stores and veterinary clinics that require reliable feeding solutions for their customers. Buyers should consider its limitation to dry food, which might restrict options for pets with specific dietary requirements.

Why consider the Feeder-Robot with Backup Battery for your business?

This version features a backup battery that ensures feeding continuity even during power outages, making it an excellent choice for pet boarding facilities and shelters. The battery allows for 24 hours of operation in power-saving mode, providing peace of mind for businesses that prioritize animal welfare. However, the added cost for the battery may be a consideration for budget-conscious buyers.

How does the Feeder-Robot Reconditioned model benefit B2B buyers?

The Reconditioned Feeder-Robot offers the same functionality as the new models at a reduced price, making it an attractive option for budget-conscious retailers. This model is often tested and certified for reliability, ensuring that businesses can maintain service quality without overspending. However, potential buyers should be aware of the limited warranty and availability of reconditioned units.

What advantages does the Feeder-Robot Multi-Pet Version provide?

Designed specifically for households with multiple pets, this version enhances food distribution and management, allowing for up to eight meals per day. It is particularly beneficial for multi-pet households and pet care services that need to streamline feeding processes. While it reduces the time spent on feeding, the higher initial investment may be a barrier for some buyers.

How does the Feeder-Robot Smart Bundle enhance pet management?

The Smart Bundle combines the Feeder-Robot with other smart pet devices, offering a holistic approach to pet care. This integration allows businesses to monitor feeding habits and pet health metrics through a single app, appealing to tech-savvy pet service providers. However, the necessity for technical setup and ensuring compatibility with existing systems might require additional resources and expertise.

Key Industrial Applications of litter robot automatic feeder

| Industry/Sector | Specific Application of litter robot automatic feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Automated feeding for hospitalized pets | Ensures timely nutrition for recovery, reducing staff workload | Reliability of feeding schedules and ease of remote monitoring |

| Pet Boarding Facilities | Regular feeding for multiple pets | Streamlines operations, allowing staff to focus on care | Capacity to hold large amounts of food and ease of cleaning |

| Animal Shelters | Consistent feeding for rescued animals | Improves animal welfare by ensuring proper nutrition | Durability for high usage and ability to operate offline |

| Pet Retailers | Demonstration units for customer engagement | Enhances in-store experience, showcasing smart pet technology | Availability of support and warranty options |

| Smart Home Integrators | Integration with home automation systems | Offers a seamless user experience for pet owners | Compatibility with existing smart home devices |

How Can Veterinary Clinics Benefit from the Litter Robot Automatic Feeder?

Veterinary clinics can utilize the litter robot automatic feeder to ensure timely and precise feeding for hospitalized pets. This technology alleviates the burden on staff, allowing them to focus on patient care while ensuring that pets receive the nutrition they need for recovery. For international buyers, it’s crucial to consider the feeder’s reliability and the ability to monitor feeding schedules remotely, especially in regions where staffing may be limited.

What Advantages Does the Litter Robot Automatic Feeder Offer Pet Boarding Facilities?

In pet boarding facilities, the automatic feeder provides a reliable solution for feeding multiple animals at set times. This automation not only streamlines operations but also allows staff to devote more attention to the animals’ well-being. Buyers in regions like Africa and South America should prioritize feeders with large capacity and easy cleaning features to accommodate the high turnover of pets typical in boarding environments.

Illustrative image related to litter robot automatic feeder

How Can Animal Shelters Improve Animal Welfare with the Litter Robot Automatic Feeder?

Animal shelters can implement the litter robot automatic feeder to ensure that rescued animals receive consistent and adequate nutrition. This is particularly beneficial in shelters with limited staff resources, as the feeder can operate autonomously. When sourcing, shelters should look for durable models that can withstand high usage and offer offline functionality, ensuring that feeding schedules are maintained even during power outages common in some regions.

Why Should Pet Retailers Consider Demonstration Units of the Litter Robot Automatic Feeder?

Pet retailers can enhance customer engagement by showcasing the litter robot automatic feeder as a demonstration unit. This not only highlights the convenience of smart pet technology but also encourages sales by allowing customers to see the product in action. Retailers should ensure they have access to adequate support and warranty options, particularly in emerging markets where customer service may be a concern.

How Do Smart Home Integrators Benefit from the Litter Robot Automatic Feeder?

Smart home integrators can incorporate the litter robot automatic feeder into their solutions, offering pet owners a seamless experience that integrates with other smart devices. This adds value to their offerings and appeals to tech-savvy consumers looking for convenience. Buyers should ensure compatibility with existing smart home systems, as well as the ability to control the feeder remotely, which is a key selling point in various international markets.

Illustrative image related to litter robot automatic feeder

3 Common User Pain Points for ‘litter robot automatic feeder’ & Their Solutions

Scenario 1: Managing Food Supply in High-Demand Environments

The Problem: In regions with high pet ownership, such as in parts of Africa and South America, B2B buyers often struggle with ensuring a consistent food supply for automatic feeders like the Litter-Robot Feeder-Robot. These buyers may represent pet supply stores or veterinary clinics that cater to numerous clients with diverse feeding requirements. The challenge lies in the need to maintain optimal stock levels while ensuring food quality and freshness, especially in markets where supply chains can be unpredictable.

The Solution: To address this issue, B2B buyers should establish a robust inventory management system that integrates sales forecasting with supplier communications. Utilizing the Feeder-Robot’s app features can provide insights into local consumption trends, enabling buyers to adjust orders based on real-time data. Furthermore, building relationships with multiple suppliers can mitigate risks associated with supply chain disruptions. Buyers should consider placing bulk orders for popular dry kibble types compatible with the feeder, ensuring they can meet customer demand without compromising on quality. Additionally, implementing a first-in, first-out (FIFO) system for stock rotation will help maintain food freshness and quality.

Scenario 2: Ensuring Compatibility with Diverse Pet Diets

The Problem: B2B buyers in the pet care industry often face difficulties in ensuring that the automatic feeder is suitable for a wide variety of pet diets. In markets like the Middle East and Europe, pet owners may have specific dietary preferences for their cats and dogs, including specialized or premium dry foods. The Feeder-Robot is only compatible with certain kibble sizes, which can lead to frustration for buyers trying to cater to all customer needs.

Illustrative image related to litter robot automatic feeder

The Solution: To effectively cater to diverse dietary requirements, B2B buyers should thoroughly educate themselves on the specifications of the Feeder-Robot, particularly the kibble size restrictions (5/8″ or less). This knowledge enables them to recommend suitable brands and products to their clients. Buyers can create a curated list of compatible pet food brands, showcasing their products in-store or online to help customers make informed choices. Additionally, engaging in partnerships with pet food manufacturers can lead to promotions or bundles that highlight suitable options for the Feeder-Robot. Buyers should also consider conducting customer surveys to identify dietary trends, allowing them to tailor their offerings accordingly.

Scenario 3: Addressing Technical Challenges and Customer Support

The Problem: Technical issues with the Feeder-Robot can deter potential buyers and lead to dissatisfaction among end-users. Common challenges include connectivity problems, battery failures, or misconfigurations that may arise in various environments, especially in areas with less reliable internet access, such as rural regions in Africa and parts of South America. B2B buyers representing retail outlets or veterinary practices may find themselves fielding customer complaints without adequate technical support.

The Solution: To combat these challenges, B2B buyers should invest in comprehensive training for their sales and support staff, equipping them with the knowledge to troubleshoot common issues. They can also create easy-to-follow guides or video tutorials for customers, explaining setup processes and how to use the Whisker app effectively. Additionally, establishing a direct line of communication with the manufacturer for technical support can expedite resolution times for more complex issues. Encouraging customers to utilize the offline functionality of the feeder can provide a temporary solution during internet outages, ensuring pets remain fed. Finally, consider offering a warranty or service plan to build customer trust and confidence in the product, further enhancing the overall user experience.

Strategic Material Selection Guide for litter robot automatic feeder

What are the Key Materials Used in the Litter Robot Automatic Feeder?

When selecting materials for the Litter Robot Automatic Feeder, it is crucial to consider not only the performance characteristics of the materials but also their suitability for various international markets. Below is an analysis of four common materials used in the construction of the feeder, focusing on their properties, advantages, disadvantages, and specific considerations for B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

1. BPA-Free Plastic

Key Properties:

BPA-free plastics are lightweight, durable, and resistant to moisture and chemicals. They can withstand temperatures up to 120°C (248°F) without deforming, making them suitable for various environments.

Pros & Cons:

The primary advantage of BPA-free plastic is its safety for pets, as it does not leach harmful chemicals. It is also cost-effective and easy to mold into complex shapes. However, it may not be as durable as metals and can scratch or become discolored over time.

Impact on Application:

This material is ideal for components that require frequent contact with food, ensuring safety and hygiene. However, it is essential to ensure compatibility with specific types of pet food to prevent degradation.

Considerations for International Buyers:

BPA-free plastics must comply with local regulations regarding food safety. Buyers should verify compliance with standards such as ASTM and EU regulations, particularly in the EU and Middle Eastern markets where safety standards are stringent.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand high temperatures, making it suitable for various applications. It is durable and has a high tensile strength, ensuring long-term performance.

Pros & Cons:

The main advantage of stainless steel is its durability and resistance to rust and staining, making it easy to clean and maintain. However, it is more expensive than plastic and may require more complex manufacturing processes.

Impact on Application:

Stainless steel is particularly suitable for components that require high hygiene standards, such as food bowls. Its durability ensures that it can withstand heavy use without deteriorating.

Considerations for International Buyers:

Buyers should ensure that the stainless steel used meets international standards such as ASTM A240 for corrosion resistance. In markets like Europe, compliance with EU material regulations is also critical.

3. Rubber

Key Properties:

Rubber is flexible and has excellent shock absorption properties. It can withstand a wide range of temperatures and is resistant to wear and tear.

Pros & Cons:

Rubber’s flexibility makes it ideal for components that require a snug fit or cushioning. However, it can degrade over time when exposed to UV light and may require more frequent replacement.

Illustrative image related to litter robot automatic feeder

Impact on Application:

Rubber is often used for seals and gaskets in the feeder, ensuring that food remains fresh and preventing spills. Its compatibility with various media is generally favorable, but care must be taken to avoid exposure to harsh chemicals.

Considerations for International Buyers:

Buyers should consider the local availability of high-quality rubber that meets international standards. In regions with high UV exposure, selecting UV-resistant rubber is crucial to ensure longevity.

4. Glass

Key Properties:

Glass is non-porous and chemically resistant, making it an excellent choice for food-related applications. It can withstand high temperatures but is more fragile than other materials.

Pros & Cons:

The main advantage of glass is its ability to maintain food quality without leaching chemicals. However, its fragility can be a significant drawback, especially in environments where the feeder may be subjected to impacts.

Illustrative image related to litter robot automatic feeder

Impact on Application:

Glass is often used for food storage containers within the feeder, providing excellent visibility of food levels. However, its weight and fragility may limit its use in certain components.

Considerations for International Buyers:

Buyers should ensure that glass components comply with safety standards to prevent breakage during shipping and handling. In markets like Brazil and Nigeria, where transportation conditions may be challenging, considering alternative materials may be prudent.

Summary Table

| Material | Typical Use Case for litter robot automatic feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| BPA-Free Plastic | Food storage and dispensing components | Safe for pets, cost-effective | Less durable than metals | Low |

| Stainless Steel | Food bowls and structural components | Highly durable and corrosion-resistant | Higher manufacturing complexity | High |

| Rubber | Seals and gaskets | Flexible and shock-absorbent | UV degradation over time | Medium |

| Glass | Food storage containers | Maintains food quality | Fragile and heavy | Medium |

This analysis provides valuable insights into the strategic material selection for the Litter Robot Automatic Feeder, ensuring that B2B buyers can make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for litter robot automatic feeder

What Are the Key Stages in the Manufacturing Process of the Litter Robot Automatic Feeder?

The manufacturing process of the Litter Robot Automatic Feeder is meticulously designed to ensure high-quality production while maintaining efficiency. The process can be divided into four main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to litter robot automatic feeder

-

Material Preparation: This initial stage involves sourcing high-quality materials, such as BPA-free plastics and other durable components that meet safety standards. Suppliers are vetted based on their ability to deliver consistent, high-quality materials, which is crucial for the overall performance and safety of the product.

-

Forming: In this stage, the prepared materials undergo various forming techniques, including injection molding and extrusion. These methods allow for precise shaping of components such as the feeder bowl and hopper. Advanced technologies like computer numerical control (CNC) machining may also be used to ensure accuracy and consistency in the dimensions of the parts.

-

Assembly: The assembly process combines the formed components into the final product. This stage includes integrating electronic parts such as sensors and Wi-Fi modules that enhance the feeder’s functionality. Automated assembly lines are often employed, allowing for efficient production while also enabling human oversight to ensure quality at every step.

-

Finishing: The finishing stage involves cleaning, inspecting, and packaging the assembled units. Quality checks are performed to ensure that each unit meets the design specifications. This may include surface treatments to enhance durability and aesthetics, as well as the application of tamper-resistant lids and chew-resistant power cords, ensuring safety for pets.

How is Quality Assurance Implemented in the Manufacturing of the Litter Robot Automatic Feeder?

Quality assurance (QA) is an essential aspect of the manufacturing process, particularly for products designed for pet care. The Litter Robot Automatic Feeder adheres to several international and industry-specific standards to ensure reliability and safety.

-

International Standards: Compliance with ISO 9001 is a fundamental requirement, ensuring that the manufacturing process meets global quality management principles. This standard emphasizes continuous improvement and customer satisfaction, which are critical for maintaining a competitive edge in international markets.

-

Industry-Specific Certifications: The feeder also complies with CE marking requirements, indicating that it meets European safety, health, and environmental protection standards. In markets such as Africa and South America, additional certifications may be required, depending on local regulations.

-

Quality Control Checkpoints: The quality control process includes several checkpoints, such as:

– Incoming Quality Control (IQC): Inspecting raw materials and components upon delivery to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): Monitoring production processes in real time to detect and address any deviations from quality standards.

– Final Quality Control (FQC): Conducting comprehensive inspections and tests on finished products before packaging and shipping. -

Testing Methods: Common testing methods for the Litter Robot Automatic Feeder may include functional testing, stress testing, and safety assessments. These tests ensure that the product performs as intended and is safe for use by pets.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial to ensure they receive reliable products. Here are some actionable insights:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and industry best practices firsthand.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the effectiveness of the supplier’s quality control processes. These reports should include information on defect rates, testing outcomes, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and audits, providing unbiased assessments of the supplier’s quality control practices.

-

Certifications Verification: Buyers should ensure that suppliers possess relevant certifications, such as ISO 9001 and CE marking. Verifying these certifications through official channels can help confirm that the suppliers adhere to recognized quality standards.

What Are the Specific Quality Control Nuances for International Buyers?

When sourcing the Litter Robot Automatic Feeder from international suppliers, buyers must consider specific nuances related to quality control and compliance:

-

Regulatory Variations: Different regions may have unique regulatory requirements. For instance, buyers in the European market should ensure compliance with the EU’s General Product Safety Directive, while buyers in African countries may need to navigate varying import regulations.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and collaborations. Buyers should be aware of how quality is perceived in different markets and adapt their communication accordingly.

-

Supply Chain Transparency: In international transactions, maintaining transparency throughout the supply chain is essential. Buyers should establish clear communication channels with suppliers to address any quality concerns promptly.

-

Local Support: Considering suppliers with local representatives or support teams can enhance post-purchase service and facilitate quicker resolution of any quality-related issues.

By understanding the manufacturing processes and quality assurance measures behind the Litter Robot Automatic Feeder, B2B buyers can make informed decisions and ensure they procure reliable, high-quality products for their markets.

Illustrative image related to litter robot automatic feeder

Practical Sourcing Guide: A Step-by-Step Checklist for ‘litter robot automatic feeder’

In the competitive landscape of pet care products, sourcing the right automatic feeder, such as the Litter-Robot Feeder-Robot, requires a systematic approach. This guide outlines essential steps for B2B buyers to ensure a successful procurement process, focusing on quality, functionality, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors like capacity, compatibility with different pet food types, and connectivity features (e.g., app integration). This clarity will help you communicate your needs effectively to potential suppliers.

- Capacity Requirements: Ensure the feeder can hold enough food for your target market, typically accommodating up to 32 cups of dry kibble.

- Technological Features: Look for smart features like remote control via a mobile app, meal scheduling, and feeding habit tracking.

Step 2: Research Market Trends and Demand

Understanding current market trends is crucial for making informed purchasing decisions. Analyze consumer preferences in your target regions, such as Africa, South America, the Middle East, and Europe, to identify what features are most appealing.

Illustrative image related to litter robot automatic feeder

- Regional Preferences: Different regions may have varying demands; for instance, pet owners in urban areas might prioritize compact designs.

- Competitive Analysis: Look at competitors’ offerings to identify gaps in the market that your procurement can fill.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly to ensure they can meet your requirements. Request company profiles, case studies, and references from businesses in a similar industry or region.

- Supplier Credentials: Confirm certifications and quality assurance processes to ensure product reliability.

- Product Reviews: Analyze customer feedback and ratings to gauge satisfaction and performance.

Step 4: Verify Product Compliance and Safety Standards

Ensuring that the Feeder-Robot meets international safety and compliance standards is non-negotiable. This protects your business and builds trust with your customers.

- Safety Certifications: Check for certifications like CE, RoHS, and others relevant to your target markets.

- Material Safety: Ensure the feeder is made from BPA-free plastics and has tamper-resistant features.

Step 5: Assess Warranty and Support Options

A strong warranty and customer support system is vital for post-purchase satisfaction. Look for suppliers that offer comprehensive support and warranty terms.

- Warranty Duration: Aim for at least a one-year warranty to safeguard your investment.

- Customer Service: Evaluate the supplier’s responsiveness and availability for technical support.

Step 6: Negotiate Pricing and Terms

Once you have identified suitable suppliers, engage in negotiations to secure favorable pricing and payment terms. Understanding market pricing will help you make competitive offers.

- Bulk Purchase Discounts: Inquire about discounts for bulk orders or long-term contracts.

- Payment Terms: Negotiate flexible payment options that align with your cash flow needs.

Step 7: Plan for Logistics and Distribution

Lastly, consider the logistics of shipping and distribution. Ensure that your suppliers can meet your delivery timelines and that you have a robust distribution plan in place.

Illustrative image related to litter robot automatic feeder

- Shipping Options: Assess various shipping methods and costs to find the most efficient solution.

- Inventory Management: Develop a strategy for managing inventory to avoid stockouts or excess stock.

By following these steps, B2B buyers can confidently navigate the sourcing process for the Litter-Robot Feeder-Robot, ensuring they procure a product that meets the needs of their market while aligning with their business goals.

Comprehensive Cost and Pricing Analysis for litter robot automatic feeder Sourcing

What Are the Key Cost Components for Sourcing the Litter Robot Automatic Feeder?

When sourcing the Litter Robot Automatic Feeder, understanding the cost structure is crucial for B2B buyers. The cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The primary materials used in the production of the Feeder-Robot include BPA-free plastics, electronic components, and metal parts for the structure and mechanisms. The quality of these materials significantly impacts the overall cost, with premium materials generally leading to higher prices.

-

Labor: Labor costs vary based on the region of manufacturing. Countries with lower labor costs can provide a competitive advantage. However, it’s essential to consider the trade-off between labor costs and the quality of workmanship, as this can affect product reliability.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, including utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Initial tooling costs can be significant, especially if custom molds or tools are required for unique designs. This is particularly relevant if buyers request customization or specific features.

-

Quality Control (QC): Investing in robust QC processes ensures that the feeder meets safety and functionality standards, which is critical for maintaining brand reputation and minimizing returns.

-

Logistics: Transportation and shipping costs can add to the final price. Factors such as distance, shipping method, and freight charges play vital roles in logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. The margin can vary based on competition, market demand, and product positioning.

How Do Price Influencers Impact the Sourcing of Litter Robot Automatic Feeders?

Several factors influence the pricing of the Litter Robot Automatic Feeder, particularly for international B2B buyers.

Illustrative image related to litter robot automatic feeder

-

Volume/MOQ: Ordering in larger quantities can lead to significant discounts. Manufacturers often have a minimum order quantity (MOQ), and negotiating this can be beneficial for buyers looking to reduce per-unit costs.

-

Specs and Customization: Buyers looking for specific features or modifications may incur additional costs. Customization can enhance product value but also complicate pricing negotiations.

-

Materials and Quality Certifications: Sourcing high-quality materials or products with recognized certifications (like ISO) may increase costs but can enhance product reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge premium prices due to their reliability and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and logistics, affecting overall costs.

What Are Some Effective Buyer Tips for Negotiating the Best Price?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing outcomes.

-

Research and Benchmarking: Conduct market research to benchmark prices and understand industry standards. This knowledge can empower buyers during negotiations.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront cost. Factors such as maintenance, warranty services, and potential returns should be factored into the overall investment.

-

Leverage Relationships: Building strong relationships with suppliers can yield better pricing and favorable terms. Long-term partnerships often lead to trust and flexibility in negotiations.

-

Be Prepared to Walk Away: If a supplier is unwilling to meet your budget or needs, be prepared to explore other options. This mindset can strengthen your negotiating position.

-

Understand Regional Differences: Recognize that pricing may vary significantly based on geographical location. Be aware of local market conditions, import duties, and taxes that can affect overall costs.

Disclaimer on Indicative Prices

Prices for the Litter Robot Automatic Feeder can vary based on the aforementioned factors. The base price is approximately $299, but this may fluctuate based on volume, customization, and other considerations. It’s advisable for buyers to obtain detailed quotations from suppliers to understand the total cost involved fully.

Alternatives Analysis: Comparing litter robot automatic feeder With Other Solutions

Exploring Alternatives to the Litter Robot Automatic Feeder

In the rapidly evolving landscape of pet care technology, the Litter Robot Automatic Feeder stands out for its innovative features and user-friendly design. However, businesses seeking to optimize pet feeding solutions may benefit from exploring alternative products that also promise efficiency and ease of use. Here, we compare the Litter Robot Automatic Feeder with other viable options to help B2B buyers make informed decisions.

Illustrative image related to litter robot automatic feeder

| Comparison Aspect | Litter Robot Automatic Feeder | PetSafe Healthy Pet Automatic Feeder | Cat Mate C500 Automatic Pet Feeder |

|---|---|---|---|

| Performance | Remote control, portion control, and food tracking via app | Programmable meals and portion control; suitable for dry food | Multi-meal dispenser for both wet and dry food |

| Cost | $299 | $119 | $99 |

| Ease of Implementation | Requires app setup and WiFi connection | Easy setup; no app required | Simple setup; battery-operated |

| Maintenance | Weekly cleaning recommended; parts are removable | Low maintenance; easy to clean | Requires regular cleaning; dishwasher-safe parts |

| Best Use Case | Ideal for tech-savvy pet owners needing precise feeding schedules | Suitable for budget-conscious pet owners looking for basic automation | Best for pets that require multiple small meals throughout the day |

Detailed Breakdown of Alternatives

PetSafe Healthy Pet Automatic Feeder

The PetSafe Healthy Pet Automatic Feeder is a budget-friendly option that offers essential features such as programmable meal schedules and portion control. It is designed for dry food, accommodating various pet sizes. The product is straightforward to set up without the need for a mobile app, making it accessible for users who prefer simplicity. However, the lack of advanced features like remote monitoring may limit its appeal to tech-savvy consumers.

Cat Mate C500 Automatic Pet Feeder

The Cat Mate C500 is a versatile feeder that can dispense both wet and dry food, making it ideal for varied pet diets. It features a multi-meal capability, allowing users to schedule multiple small feedings throughout the day. The device is easy to clean, with dishwasher-safe parts, and operates on batteries, which eliminates the need for a power source. However, its performance may vary with larger pets, and it lacks smart technology integrations found in more advanced feeders.

Conclusion: How to Choose the Right Pet Feeding Solution

Selecting the appropriate automatic feeder for your business involves evaluating the specific needs of your clientele. Consider factors such as the type of pets they own, their feeding habits, and the technological capabilities they desire. For businesses targeting tech-savvy pet owners, the Litter Robot Automatic Feeder may be the best choice due to its advanced features and app integration. Conversely, for those catering to a budget-conscious audience or clients with diverse feeding requirements, the PetSafe Healthy Pet and Cat Mate C500 feeders present viable alternatives. Ultimately, understanding the unique demands of your target market will guide you in making the most suitable investment in pet feeding technology.

Essential Technical Properties and Trade Terminology for litter robot automatic feeder

What Are the Key Technical Properties of the Litter Robot Automatic Feeder?

When evaluating the Litter Robot Automatic Feeder, several technical properties become essential for B2B buyers to understand, ensuring they make informed purchasing decisions. Here are some critical specifications:

-

Capacity (32 Cups)

– The feeder holds up to 32 cups of dry pet food, making it suitable for various pet sizes and feeding schedules. This large capacity minimizes the frequency of refills, which is particularly advantageous for businesses managing multiple pets or those providing pet care services. -

Portion Control (Up to ½ Cup)

– The feeder dispenses food in increments of 1/8 cup, allowing precise control over portion sizes. This feature is vital for maintaining pet health, especially in businesses focused on nutrition, as it helps prevent overfeeding and associated health issues. -

Connectivity (WiFi Enabled)

– The device connects to a 2.4 GHz WiFi network, allowing users to control feeding schedules remotely through the Whisker app. This capability is essential for modern pet care businesses aiming to offer tech-savvy solutions that enhance customer convenience and engagement. -

Material Composition (BPA-Free Plastics)

– Constructed from BPA-free plastics, the feeder ensures pet safety and compliance with health regulations. For B2B buyers, this is crucial as it reflects a commitment to quality and safety standards that resonate with health-conscious consumers. -

Power Backup (Optional 12V Battery)

– The feeder can operate with a 12V backup battery (sold separately), providing continuous functionality even during power outages. This reliability is a selling point for businesses that prioritize uninterrupted pet care services. -

Offline Functionality

– The feeder retains programmed schedules even when offline, ensuring pets are fed as planned. For B2B operations, this feature guarantees consistency and reliability, crucial for maintaining client trust and satisfaction.

Which Trade Terms Are Commonly Used in the Context of the Litter Robot Automatic Feeder?

Understanding trade terminology is equally important for B2B buyers. Here are several key terms relevant to the purchase and distribution of the Litter Robot Automatic Feeder:

Illustrative image related to litter robot automatic feeder

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In this context, understanding OEM relationships can help buyers assess the quality and origin of components used in the feeder. -

MOQ (Minimum Order Quantity)

– The minimum number of units a buyer must purchase in a single order. Knowing the MOQ is crucial for businesses as it affects inventory management and cash flow, particularly for small or startup pet care operations. -

RFQ (Request for Quotation)

– A document sent to suppliers asking for a price quote on specific products. B2B buyers should use RFQs to gather pricing and terms from multiple suppliers, ensuring they secure the best deal for automatic feeders. -

Incoterms (International Commercial Terms)

– A set of international trade terms that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and logistics associated with importing the feeder from manufacturers. -

Lead Time

– The time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring that businesses can meet customer demand without delays. -

Warranty

– A guarantee provided by the manufacturer regarding the condition of the product. The warranty period (e.g., 1 year for the Feeder-Robot) is crucial for B2B buyers as it indicates the manufacturer’s confidence in the product’s quality and durability.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the purchasing process more effectively and make strategic decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the litter robot automatic feeder Sector

What Are the Key Drivers and Trends in the Litter Robot Automatic Feeder Market?

The global market for automatic pet feeders, particularly the Litter Robot automatic feeder, is being propelled by several key drivers. Firstly, the rising pet ownership rates in regions such as Africa, South America, the Middle East, and Europe are enhancing demand. According to recent studies, urbanization and changing lifestyles have led to an increased need for convenient pet care solutions. B2B buyers are particularly interested in smart technology integration, as the Feeder-Robot allows for remote control via a mobile app, enabling pet owners to manage feeding schedules effortlessly.

Emerging trends include a significant shift toward automation and the Internet of Things (IoT) in pet care. Features such as portion control, feeding habit tracking, and notifications for food levels are gaining traction among buyers. Additionally, the emphasis on multi-functionality—where the feeder can serve both cats and dogs—makes it an attractive option for retailers and distributors looking to diversify their product offerings. Competitive pricing and attractive warranty options, such as the WhiskerCare™ 1-Year Warranty, further influence sourcing decisions.

International buyers must remain vigilant about market dynamics, including fluctuating supply chain costs and technological advancements. Collaborating with manufacturers that offer robust customer support and a clear understanding of local market needs can provide a competitive edge.

Illustrative image related to litter robot automatic feeder

How Do Sustainability and Ethical Sourcing Impact the Litter Robot Automatic Feeder Market?

Sustainability is becoming a crucial consideration for B2B buyers in the litter robot automatic feeder sector. As environmental concerns rise, companies are increasingly held accountable for their sourcing practices. The use of BPA-free plastics and recyclable materials in the Feeder-Robot’s design is a significant selling point, aligning with the growing consumer demand for eco-friendly products.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly favoring suppliers who demonstrate a commitment to social responsibility, including fair labor practices and reduced environmental footprints. Certifications like ISO 14001 for environmental management can serve as a valuable differentiator in the market, providing assurance to buyers about the sustainability of their purchases.

Furthermore, integrating sustainable practices into the manufacturing process can lead to cost savings in the long run. For instance, adopting energy-efficient production methods not only lowers emissions but can also reduce operational costs. B2B buyers should prioritize partnerships with manufacturers who are transparent about their sustainability efforts, as this aligns with the values of modern consumers and enhances brand reputation.

What Is the Evolution of the Litter Robot Automatic Feeder and Its Relevance to B2B Buyers?

The evolution of automatic feeders, particularly the Litter Robot automatic feeder, reflects a growing trend towards smart pet care solutions. Initially designed for basic feeding functions, these devices have rapidly advanced to incorporate sophisticated technology, such as IoT connectivity and app integration. This transformation underscores the increasing consumer demand for convenience and efficiency in pet care.

For B2B buyers, understanding this evolution is critical when sourcing products that align with current market expectations. The Feeder-Robot not only meets the basic needs of pet feeding but also offers advanced features like real-time monitoring and customizable feeding schedules. This evolution represents an opportunity for distributors to cater to a tech-savvy consumer base that prioritizes intelligent solutions for pet care.

As the market continues to evolve, staying informed about technological advancements and consumer preferences will be essential for B2B buyers looking to thrive in the competitive landscape of automatic pet feeders.

Frequently Asked Questions (FAQs) for B2B Buyers of litter robot automatic feeder

-

How do I solve issues related to the Feeder-Robot’s connectivity?

Connectivity issues can arise due to various factors, including Wi-Fi signal strength and compatibility. Ensure that the Feeder-Robot is connected to a 2.4 GHz network, as it does not support 5 GHz. If you encounter persistent issues, check your router settings and consider relocating the feeder closer to your router. If the feeder goes offline, it will still operate on its pre-programmed schedule, allowing you to maintain feeding routines. Always consult the user manual for troubleshooting tips specific to your situation. -

What is the best payment method for international orders of the Feeder-Robot?

For international transactions, it is advisable to use secure payment methods such as wire transfers, credit cards, or reputable payment platforms like PayPal. These methods provide a level of buyer protection and can help mitigate fraud risks. Ensure that the payment terms are clearly defined in your agreement with the supplier, including any required deposits or payment timelines. Always confirm the currency exchange rates and potential additional fees associated with international transactions. -

How do I determine the minimum order quantity (MOQ) for the Feeder-Robot?

The minimum order quantity can vary by supplier and is influenced by factors such as production capacity and shipping logistics. To determine the MOQ, directly communicate with potential suppliers and inquire about their specific policies. Some may offer flexibility for first-time buyers or bulk orders, while others may have strict MOQs. Understanding the MOQ is crucial for budgeting and ensuring that your business can meet market demand effectively. -

What customization options are available for the Feeder-Robot?

Customization options may include branding the unit with your company logo, selecting specific colors, or even modifying certain features to better suit your market. Discuss your requirements with the supplier during the negotiation process to understand what is feasible. Keep in mind that customization may impact production timelines and costs, so it’s essential to factor these into your planning. -

How can I ensure quality assurance (QA) for the Feeder-Robot?

Implementing a robust quality assurance process involves requesting samples before bulk orders and conducting thorough inspections upon arrival. Engage with suppliers who adhere to international quality standards and certifications. Additionally, consider establishing a clear QA checklist that includes functionality tests, durability checks, and compliance with safety regulations. Regular communication with suppliers about your QA expectations is vital for maintaining product quality. -

What logistics considerations should I keep in mind when sourcing the Feeder-Robot internationally?

When sourcing internationally, consider shipping methods, lead times, and customs regulations specific to your region. Evaluate the total landed cost, which includes shipping, duties, and taxes, to avoid unexpected expenses. Partnering with a reliable logistics provider can streamline the process and help navigate any complexities associated with cross-border shipping. Always ensure that the supplier is experienced in international shipping to mitigate potential delays or issues. -

What are the warranty and support terms for the Feeder-Robot?

Most suppliers offer a warranty that covers defects in materials and workmanship for a specific period, typically one year. It’s essential to review the warranty terms carefully, including what is covered and the process for claims. Additionally, inquire about post-purchase support options, such as troubleshooting assistance and access to replacement parts. A supplier with strong customer service can significantly enhance your experience and ensure long-term satisfaction with the product. -

How do I vet potential suppliers for the Feeder-Robot?

To effectively vet suppliers, start by reviewing their reputation through online platforms and trade references. Check for certifications and compliance with international standards. Request case studies or testimonials from other businesses that have sourced from them. Conducting a factory visit or a virtual tour can also provide insights into their production capabilities and working conditions. Ensure that the supplier has clear communication channels and a responsive customer service team, as these factors are crucial for a successful partnership.

Top 4 Litter Robot Automatic Feeder Manufacturers & Suppliers List

1. Litter-Robot – Feeder-Robot

Domain: litter-robot.com

Registered: 1999 (26 years)

Introduction: Feeder-Robot – Automatic Pet Feeder & Cat Food Dispenser

– Price: As low as $299

– Rating: 4.3/5.0 based on 394 reviews

– Capacity: Holds up to 32 cups of dry pet food (25 cups with hopper insert)

– Features:

– Set portion-controlled meal schedules via app or unit

– Remote control using Whisker app

– View food levels and track feeding habits

– Works offline

– Anti-jam technology

– Rem…

2. Feeder-Robot – Key Features and User Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Feeder-Robot, priced at $299, features a wide dish to alleviate whisker fatigue, a clear LED indicator, and is designed to prevent jamming. Users have noted that the ramp may not be steep enough, causing food to get stuck if the bowl is partially full. Some users find it expensive compared to other automatic feeders, citing simpler and cheaper alternatives that have worked reliably. The product is…

3. Whisker – Litter-Robot 4

Domain: whisker.com

Registered: 2000 (25 years)

Introduction: Whisker offers two main products: Litter-Robot 4 and Feeder-Robot. Litter-Robot 4 is an automatic litter box that eliminates the need for manual scooping, featuring QuietSift® technology for minimal noise during cleaning. It is designed for up to 4 indoor cats, with a drawer that needs to be emptied based on the number of cats. The Feeder-Robot provides smart, easy feeding with automatic litter re…

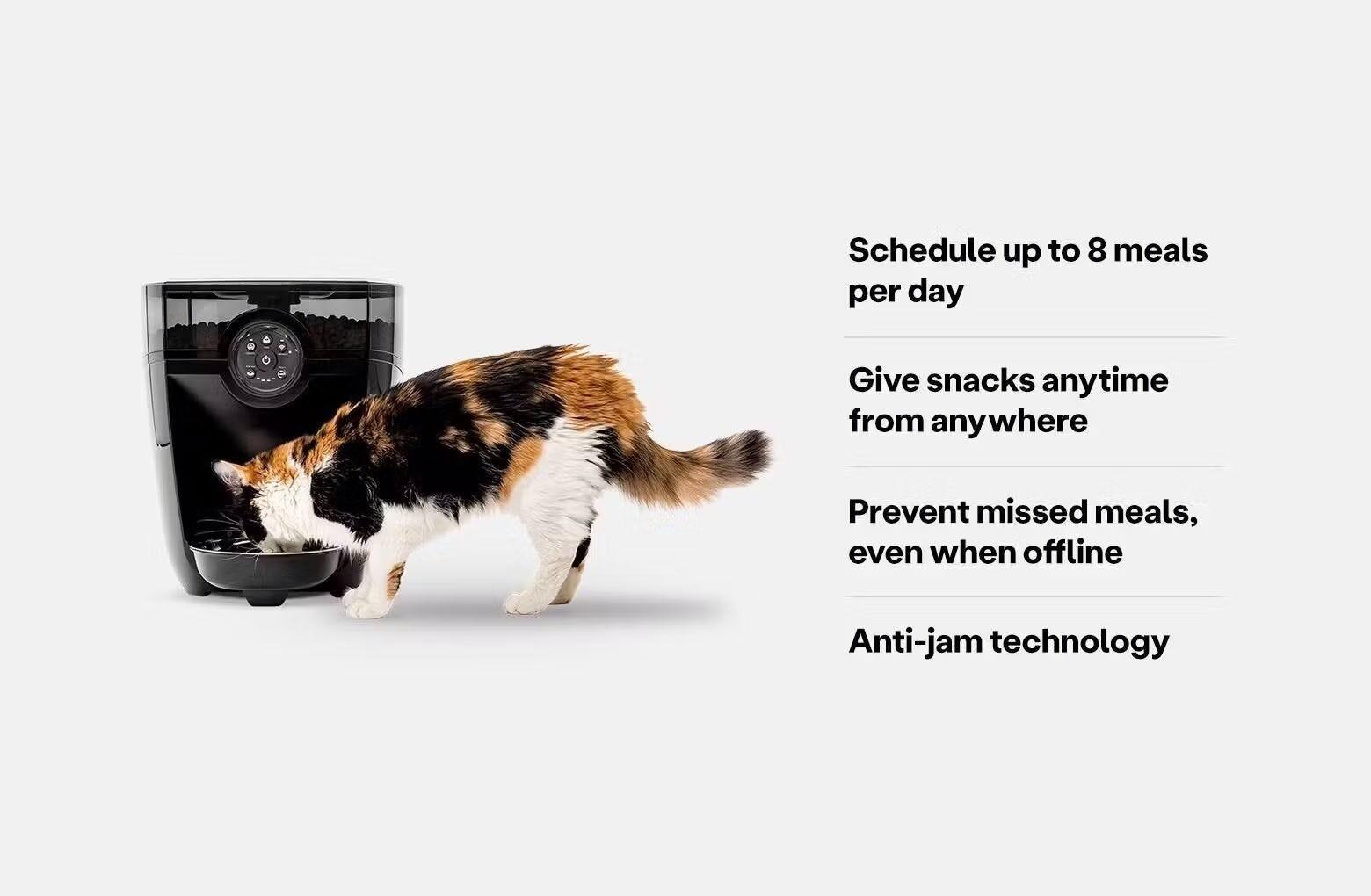

4. Feeder-Robot – Automatic Pet Food Dispenser

Domain: litterbox.com

Registered: 1995 (30 years)

Introduction: Feeder-Robot – Automatic Pet Food & Snack Dispenser

– Price: As low as $299

– Rating: 4.3/5.0 based on 394 reviews

– Capacity: Holds up to 32 cups of dry food (25 cups with hopper insert)

– Portion Control: Dispenses up to 1/2 cup of pet food in 1/8-cup increments, 1 to 8 times per day

– Features: Anti-jam technology, suitable for cats and dogs, app connectivity for monitoring feeding habits, cust…

Strategic Sourcing Conclusion and Outlook for litter robot automatic feeder

In the evolving landscape of pet care technology, the Litter-Robot Automatic Feeder stands out as an essential investment for B2B buyers targeting the international market. Its advanced features, including remote scheduling, anti-jam technology, and substantial food capacity, provide significant advantages in meeting the diverse needs of pet owners across regions such as Africa, South America, the Middle East, and Europe. By strategically sourcing this innovative product, businesses can enhance their offerings and cater to a growing consumer demand for smart pet care solutions.

The value of strategic sourcing cannot be overstated; it enables businesses to optimize their supply chains, reduce costs, and deliver high-quality products that resonate with their target audiences. The Feeder-Robot not only simplifies feeding routines but also integrates seamlessly with the Litter-Robot, creating a comprehensive smart home experience for pet owners.

As the pet care industry continues to expand, now is the time for international B2B buyers to consider the Litter-Robot Automatic Feeder as a pivotal addition to their product lineup. Embrace this opportunity to enhance your portfolio and meet the demands of a tech-savvy consumer base eager for reliable, automated solutions in pet care.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to litter robot automatic feeder

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.