Introduction: Navigating the Global Market for pet feeder with chip

In the rapidly evolving pet care industry, sourcing a reliable pet feeder with chip technology presents unique challenges for international B2B buyers. As pet ownership rises globally, the demand for smart feeding solutions that prevent food theft and manage dietary needs has surged, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This guide serves as an essential resource, addressing critical aspects of microchip pet feeders, including various types, applications, and features that cater to multi-pet households.

From understanding the technology behind microchip integration to evaluating supplier credibility and pricing strategies, this comprehensive guide equips B2B buyers with the insights necessary for informed purchasing decisions. It highlights the importance of selecting feeders that not only meet the health and dietary requirements of pets but also offer user-friendly technology for pet owners. With sections dedicated to the advantages of these feeders, including remote monitoring capabilities and customizable feeding schedules, buyers can confidently navigate the global market landscape.

By leveraging the information provided, businesses can enhance their product offerings, ensuring they meet the demands of modern pet owners seeking convenience and precision in pet care. Ultimately, this guide empowers B2B buyers to align their sourcing strategies with the latest innovations in pet feeding technology, fostering growth and customer satisfaction in their respective markets.

Table Of Contents

- Top 4 Pet Feeder With Chip Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pet feeder with chip

- Understanding pet feeder with chip Types and Variations

- Key Industrial Applications of pet feeder with chip

- 3 Common User Pain Points for ‘pet feeder with chip’ & Their Solutions

- Strategic Material Selection Guide for pet feeder with chip

- In-depth Look: Manufacturing Processes and Quality Assurance for pet feeder with chip

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet feeder with chip’

- Comprehensive Cost and Pricing Analysis for pet feeder with chip Sourcing

- Alternatives Analysis: Comparing pet feeder with chip With Other Solutions

- Essential Technical Properties and Trade Terminology for pet feeder with chip

- Navigating Market Dynamics and Sourcing Trends in the pet feeder with chip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pet feeder with chip

- Strategic Sourcing Conclusion and Outlook for pet feeder with chip

- Important Disclaimer & Terms of Use

Understanding pet feeder with chip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microchip Pet Feeder | Recognizes embedded ISO microchips; prevents food stealing; customizable portion control. | Veterinary clinics, pet supply retailers | Pros: Reduces food theft; supports dietary needs. Cons: Limited to pets with compatible microchips. |

| RFID Tag Pet Feeder | Uses RFID tags for pet recognition; ideal for pets without microchips; app connectivity. | Pet stores, pet technology distributors | Pros: Versatile for all pets; remote monitoring. Cons: Requires RFID tags for unchipped pets. |

| Automatic Portion Control Feeder | Programmable feeding schedules; tracks feeding data; backup battery for reliability. | Pet care services, animal shelters | Pros: Ensures proper nutrition; reduces waste. Cons: Higher initial investment; may require setup time. |

| 스마트 애완동물 피더 | Integrates with smart home systems; real-time monitoring via mobile app; customizable alerts. | High-end pet product retailers, tech shops | Pros: Advanced features; appeals to tech-savvy consumers. Cons: Complexity may deter less tech-oriented buyers. |

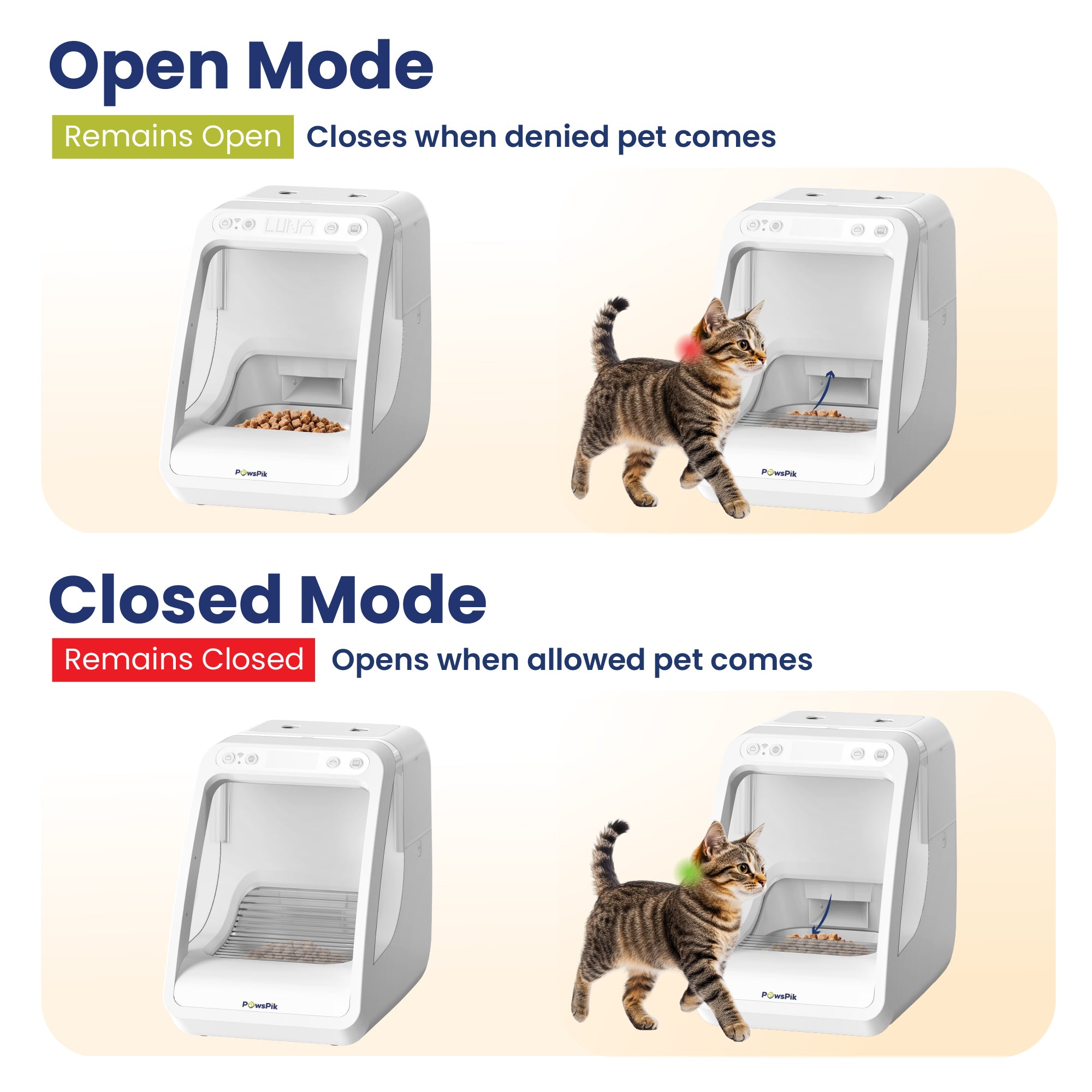

| Multi-Pet Access Control Feeder | Allows individualized access for multiple pets; prevents food competition; easy to clean. | Multi-pet households, boarding facilities | Pros: Supports various diets; reduces stress among pets. Cons: Higher cost; may require specific training for pets. |

What Are the Key Characteristics of Microchip Pet Feeders?

Microchip pet feeders are designed to recognize embedded ISO microchips, making them ideal for pet owners concerned about food theft among multiple pets. These feeders typically include customizable portion control features and can be programmed to dispense food at specific times. B2B buyers, such as veterinary clinics and pet supply retailers, should consider the compatibility of the microchip with pets in their market, as this limits their applicability to pets already microchipped.

How Do RFID Tag Pet Feeders Benefit B2B Buyers?

RFID tag pet feeders are particularly advantageous for households with pets lacking microchips. These feeders utilize RFID tags that can be attached to collars for easy identification. They often come with app connectivity that allows pet owners to monitor feeding habits remotely. For pet stores and technology distributors, offering RFID feeders expands the product range to cater to a broader audience, though they must ensure that customers are aware of the need for RFID tags for unchipped pets.

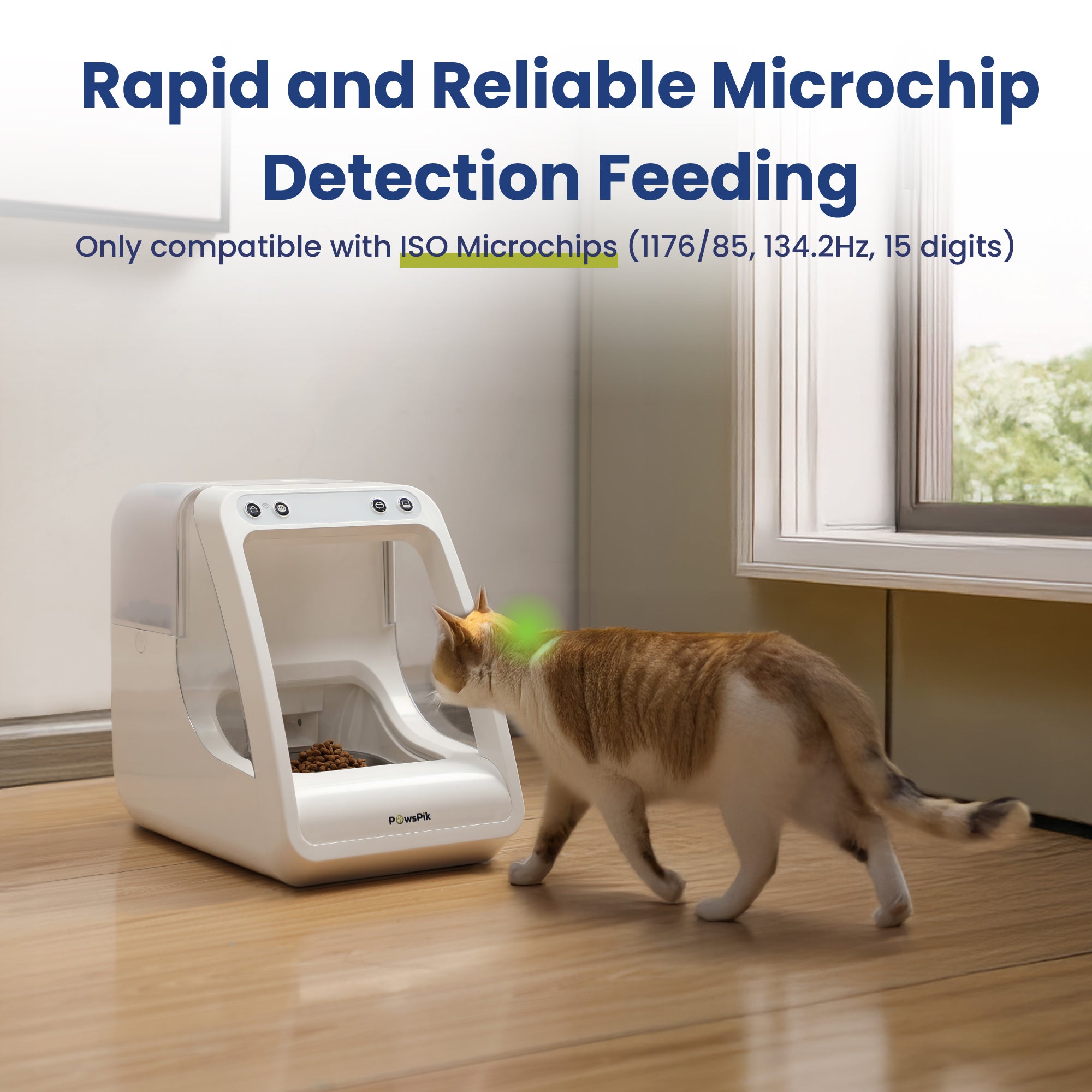

Illustrative image related to pet feeder with chip

Why Are Automatic Portion Control Feeders Essential for Pet Care Services?

Automatic portion control feeders are equipped with programmable feeding schedules and tracking capabilities, making them essential for pet care services and animal shelters. These feeders help ensure that pets receive the correct nutrition while minimizing food waste. B2B buyers should evaluate the reliability of the backup battery features to maintain feeding schedules during power outages, which is critical for businesses that operate around the clock.

What Advantages Do Smart Pet Feeders Offer for Retailers?

Smart pet feeders integrate with smart home systems, allowing for real-time monitoring and customizable alerts via mobile apps. These advanced features cater to tech-savvy consumers, making them appealing in high-end pet product retail environments. However, retailers should be mindful that the complexity of smart feeders may deter less tech-oriented buyers, necessitating effective customer education and support.

How Do Multi-Pet Access Control Feeders Support Diverse Diets?

Multi-pet access control feeders are designed to allow individualized access for multiple pets, preventing food competition and stress among animals. These feeders are especially beneficial for multi-pet households and boarding facilities that need to manage different dietary requirements. While they offer significant advantages in pet health management, B2B buyers should weigh the higher costs against the potential benefits of reduced stress and improved nutrition for their clients’ pets.

Illustrative image related to pet feeder with chip

Key Industrial Applications of pet feeder with chip

| Industry/Sector | Specific Application of pet feeder with chip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Veterinary Clinics | Monitoring dietary intake for patients | Provides precise dietary control, aiding in pet health | Compatibility with various microchip types and ease of use |

| Pet Boarding Facilities | Customized feeding schedules | Reduces feeding errors, enhances pet care quality | Durability, capacity for multiple pets, and remote management capabilities |

| Pet Retailers | Selling advanced pet feeding solutions | Attracts tech-savvy customers, increasing sales potential | Product training, warranty support, and after-sales service |

| Animal Shelters | Ensuring proper nutrition for adoptable pets | Streamlines feeding processes, improves animal health | Cost-effectiveness, ease of cleaning, and reliability |

| Pet Training Centers | Managing feeding for pets with specific diets | Supports specialized training programs and health regimens | Customization options, tracking capabilities, and user-friendliness |

How Can Veterinary Clinics Use Pet Feeders with Chips to Enhance Pet Care?

Veterinary clinics can utilize microchip pet feeders to monitor the dietary intake of their patients. These feeders allow veterinarians to set specific feeding schedules and portion sizes tailored to each pet’s health needs. By ensuring that pets receive the correct amount of food, clinics can help manage conditions such as obesity or diabetes more effectively. International buyers should consider compatibility with various microchip types and the ease of integration into existing clinic systems.

In What Ways Can Pet Boarding Facilities Benefit from Smart Feeding Solutions?

Pet boarding facilities can implement microchip pet feeders to create customized feeding schedules for the animals in their care. This technology minimizes feeding errors and ensures that pets adhere to their specific diets, which is crucial for their health and well-being. For international buyers, factors such as the feeder’s durability, capacity to cater to multiple pets, and remote management capabilities are essential considerations to enhance operational efficiency.

Why Should Pet Retailers Invest in Advanced Pet Feeding Solutions?

Pet retailers stand to gain significantly by offering advanced pet feeders with microchip technology. These innovative products attract tech-savvy consumers seeking reliable solutions for their pets. Retailers can boost their sales potential by highlighting the benefits of these feeders, such as portion control and dietary management. When sourcing, retailers should focus on product training for staff, warranty support, and after-sales service to ensure customer satisfaction and repeat business.

Illustrative image related to pet feeder with chip

How Can Animal Shelters Improve Nutrition Management with Microchip Feeders?

Animal shelters can enhance their feeding processes using microchip pet feeders, ensuring that each animal receives the proper nutrition. This technology streamlines feeding routines and helps maintain the health of adoptable pets, increasing their chances of finding a home. For buyers in this sector, cost-effectiveness, ease of cleaning, and reliability are crucial factors to consider when selecting suitable feeding solutions.

What Role Do Pet Training Centers Play in Utilizing Pet Feeders with Chips?

Pet training centers can leverage microchip pet feeders to manage feeding for pets with specialized diets, supporting various training programs and health regimens. This ensures that pets are adequately nourished while undergoing training, which can improve their performance and well-being. Buyers should look for customization options, tracking capabilities, and user-friendly designs to facilitate seamless integration into their training programs.

3 Common User Pain Points for ‘pet feeder with chip’ & Their Solutions

Scenario 1: Managing Multiple Pets with Different Dietary Needs

The Problem: In households with multiple pets, it can be challenging to ensure that each animal receives the correct portion of food tailored to their specific dietary requirements. Buyers, especially those running pet care facilities or veterinary clinics, often face issues where one pet steals food from another, leading to obesity or health complications. This not only affects the pets’ health but also causes stress for owners who want to maintain a balanced diet for each animal.

Illustrative image related to pet feeder with chip

The Solution: When sourcing a microchip pet feeder, prioritize models that offer customizable access controls for multiple pets. Look for feeders that allow you to program specific feeding schedules and portions for each pet based on their microchip identification. For instance, feeders like the PawsPik Automatic Microchip RFID Pet Feeder provide the option to set unique feeding permissions, ensuring that only the designated pet can access their food. This feature not only prevents food theft but also allows for precise tracking of each pet’s eating habits, enabling pet care providers to share this data with veterinarians for better health monitoring.

Scenario 2: Power Outages Disrupting Feeding Schedules

The Problem: In regions where power outages are common, pet owners may worry about their pets missing meals, which can lead to anxiety and health issues. For B2B buyers operating in areas susceptible to electrical instability, ensuring consistent feeding schedules is vital to maintaining pet health and customer satisfaction.

The Solution: Invest in microchip pet feeders that come equipped with backup battery systems. These systems ensure that even during power outages, the feeder can continue to dispense food as scheduled. When selecting a feeder, check for features like low battery indicators and manual overrides that allow for continued functionality during interruptions. Additionally, educate your clients about the importance of regular maintenance checks on the feeder’s battery life and scheduling options to ensure that their pets are consistently fed, regardless of power supply issues.

Scenario 3: Incompatibility with Existing Microchip Systems

The Problem: Many B2B buyers encounter frustration when the microchip feeders they purchase are not compatible with the existing microchip systems of their clients’ pets. This can lead to wasted investment and dissatisfied customers who cannot utilize the technology they purchased. Compatibility issues can be particularly pronounced in diverse markets, where various microchip standards are prevalent.

Illustrative image related to pet feeder with chip

The Solution: Before finalizing any bulk purchase, conduct thorough research on the microchip compatibility of the feeders you intend to sell. Opt for feeders that are compatible with multiple microchip types, particularly the ISO-standard microchips, which are widely recognized. Additionally, consider offering a range of RFID tag options for pets without embedded chips. Providing clear guidelines and resources for identifying compatible microchips can help streamline the purchasing process and ensure that customers are satisfied with their investment. Implementing an education campaign for both your sales team and customers about the importance of microchip compatibility can significantly reduce the likelihood of returns and increase overall satisfaction with the product.

By addressing these scenarios effectively, B2B buyers can enhance their offerings, improve customer satisfaction, and ensure the well-being of pets under their care.

Strategic Material Selection Guide for pet feeder with chip

What Are the Key Materials Used in Pet Feeders with Chips?

When selecting materials for pet feeders equipped with microchip technology, it is crucial to consider factors such as durability, safety, and compatibility with various pet food types. Below is an analysis of four common materials used in the manufacturing of these innovative feeders.

How Does Plastic Perform as a Material for Pet Feeders?

Plastic is one of the most widely used materials in the production of pet feeders. It offers excellent flexibility and can be molded into various shapes, which is essential for creating user-friendly designs. Key properties of plastic include resistance to moisture and a good temperature range, making it suitable for indoor and outdoor use.

Pros: Plastic is lightweight, cost-effective, and can be produced in large quantities with relative ease. It is also resistant to corrosion and can be designed to be pet-proof.

Cons: However, plastic may not be as durable as other materials and can become brittle over time, especially when exposed to UV light. Additionally, lower-quality plastics may leach harmful chemicals, raising safety concerns.

Impact on Application: Plastic feeders are generally suitable for dry food but may not be ideal for wet food applications due to potential degradation.

Illustrative image related to pet feeder with chip

Considerations for International Buyers: Compliance with international safety standards, such as ASTM and REACH, is critical. Buyers from regions like Africa and South America should ensure that the plastic used meets local regulations regarding food safety.

What Role Does Stainless Steel Play in Pet Feeder Design?

Stainless steel is often favored for its durability and aesthetic appeal. It is highly resistant to corrosion, making it an excellent choice for feeders exposed to moisture.

Pros: The material is exceptionally durable, easy to clean, and does not retain odors, which is beneficial for maintaining hygiene. Stainless steel also withstands high temperatures, making it suitable for various feeding environments.

Cons: The primary drawback is the higher cost compared to plastic. Additionally, stainless steel can be heavier, which may be a consideration for portable feeders.

Impact on Application: Stainless steel is compatible with both dry and wet foods, providing versatility in feeding options.

Considerations for International Buyers: Buyers should verify that the stainless steel used complies with international standards, such as ISO and DIN, particularly in regions where food safety is stringently regulated.

How Does Silicone Enhance the Functionality of Pet Feeders?

Silicone is increasingly being used in pet feeder designs, particularly for components such as seals and mats. Its flexibility and non-toxic nature make it an attractive option.

Illustrative image related to pet feeder with chip

Pros: Silicone is highly durable, resistant to extreme temperatures, and easy to clean. It provides excellent sealing capabilities, which can help maintain food freshness.

Cons: The main limitation is the cost, as silicone can be more expensive than other materials. Additionally, silicone components may not be as structurally robust as plastic or stainless steel.

Impact on Application: Silicone is well-suited for applications requiring flexibility and sealing, enhancing the overall functionality of the feeder.

Considerations for International Buyers: Ensure that silicone materials comply with FDA and EU regulations for food contact materials, especially for buyers in Europe and North America.

What Benefits Does Glass Offer in Pet Feeder Applications?

Glass is less common but can be used for specific parts of pet feeders, such as bowls or storage containers. It offers a premium feel and excellent durability.

Illustrative image related to pet feeder with chip

Pros: Glass is non-porous, easy to clean, and does not leach chemicals, making it a safe option for pet food storage. It also provides a more upscale appearance.

Cons: The weight of glass can be a disadvantage, especially for portable feeders. It is also prone to breaking, which poses safety risks.

Impact on Application: Glass is suitable for dry food storage but may not be ideal for active feeding environments due to its fragility.

Illustrative image related to pet feeder with chip

Considerations for International Buyers: Glass products must meet safety standards to avoid breakage during shipping and handling. Buyers should also consider the logistics of shipping heavier materials.

Summary Table of Material Selection for Pet Feeders with Chips

| Material | Typical Use Case for pet feeder with chip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Main body of feeder | Lightweight and cost-effective | May degrade under UV exposure | Low |

| Stainless Steel | Bowls and structural components | Durable and easy to clean | Higher cost and weight | High |

| Silicone | Seals and mats | Flexible and excellent sealing | More expensive than plastic | Med |

| Glass | Food storage containers | Non-porous and upscale appearance | Heavy and prone to breakage | High |

This strategic material selection guide provides insights that can assist international B2B buyers in making informed decisions when sourcing pet feeders with microchip technology, ensuring they choose materials that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pet feeder with chip

What Are the Main Stages of Manufacturing a Pet Feeder with Chip?

The manufacturing process of a pet feeder equipped with microchip technology involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure that the final product meets quality standards and performs reliably.

Material Preparation: Sourcing High-Quality Components

The first step is sourcing high-quality materials, which typically includes durable plastics for the body, stainless steel for the food bowl, and electronic components for the microchip and sensors. Suppliers must be vetted to ensure they provide materials that comply with international safety and quality standards. During this stage, manufacturers often conduct incoming quality control (IQC) checks to verify that materials meet specifications before they are used in production.

Forming: Utilizing Advanced Manufacturing Techniques

Once materials are prepared, the forming process begins. This involves various techniques such as injection molding for plastic components and stamping or CNC machining for metal parts. Advanced technology, including 3D printing, may also be employed for prototyping and creating complex designs. The use of robotics in this stage can enhance precision and reduce the risk of human error, which is particularly important for components that must integrate seamlessly with electronic systems.

Assembly: Integrating Technology and Functionality

The assembly stage is where the feeder comes to life. Components are meticulously put together, ensuring that the microchip reader, control panel, and food dispensing mechanisms function correctly. This stage often includes in-process quality control (IPQC) checkpoints where assembly workers test components for alignment, connectivity, and functionality. Effective training programs for assembly staff can significantly reduce defects and improve the overall quality of the finished product.

Finishing: Ensuring Aesthetic and Functional Quality

The finishing stage involves surface treatments, such as polishing, painting, or applying coatings to enhance durability and aesthetics. It’s essential that the product meets aesthetic expectations, especially in consumer markets. Quality assurance checks, including final inspections (FQC), ensure that all features, such as the microchip reader and food dispensing mechanisms, operate smoothly before the product is packaged and shipped.

How Is Quality Assurance Implemented in the Manufacturing of Pet Feeders?

Quality assurance is a critical aspect of the manufacturing process for pet feeders with microchip technology. Manufacturers must adhere to international standards and industry-specific guidelines to ensure product reliability and safety.

What Are the Relevant International Standards for Pet Feeders?

One of the key international standards applicable to the manufacturing of pet feeders is ISO 9001. This standard outlines the requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Compliance with ISO standards assures B2B buyers that the manufacturer has a robust system in place for managing quality.

In addition to ISO 9001, other certifications may be relevant depending on the market. For example, CE marking is crucial for products sold in Europe, indicating compliance with health, safety, and environmental protection standards. Manufacturers targeting specific markets may also need to comply with regional standards such as API for pet-related products in certain jurisdictions.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to maintain high standards. Common checkpoints include:

- Incoming Quality Control (IQC): Verifying the quality of raw materials and components upon arrival.

- In-Process Quality Control (IPQC): Monitoring assembly processes to detect defects during production.

- Final Quality Control (FQC): Conducting thorough inspections and testing of finished products before shipping.

These checkpoints help identify issues early, reducing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure that pet feeders function as intended. These methods include:

- Functional Testing: Verifying that the microchip reader detects chips accurately and that the food dispensing mechanism operates correctly.

- Durability Testing: Assessing the product’s resilience under various conditions, including temperature fluctuations and exposure to moisture.

- Safety Testing: Ensuring that all materials are non-toxic and safe for pets. This often includes testing for harmful substances and compliance with regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure product reliability. Here are some effective strategies:

- Supplier Audits: Conducting regular audits of the manufacturing facility can provide insight into the supplier’s quality management practices. Audits can assess compliance with international standards and evaluate the effectiveness of quality control checkpoints.

- Quality Control Reports: Requesting detailed quality control reports can help buyers understand the supplier’s testing methods and outcomes. This information can highlight the supplier’s commitment to quality assurance.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly valuable for buyers in regions with less stringent oversight.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing pet feeders with microchip technology from different regions, B2B buyers should be aware of specific nuances in quality control and certification.

Illustrative image related to pet feeder with chip

- Regional Regulations: Different regions may have varying regulations governing pet products. For instance, products intended for the EU market must meet CE marking requirements, while those for the U.S. may need to comply with FDA regulations.

- Cultural Considerations: Buyers from regions such as Africa, South America, and the Middle East may encounter different quality expectations. Understanding local market demands and regulatory requirements is crucial for successful sourcing.

- Language and Communication Barriers: Effective communication with suppliers is essential. Buyers should ensure that all documentation, including quality control reports and certifications, is available in a language they understand.

In conclusion, the manufacturing processes and quality assurance for pet feeders with microchip technology are comprehensive and multifaceted. By understanding these processes, B2B buyers can make informed decisions and select reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pet feeder with chip’

In today’s competitive pet care market, sourcing a reliable microchip pet feeder is essential for businesses looking to enhance pet health management solutions. This guide provides a practical checklist for B2B buyers seeking to procure microchip-enabled pet feeders, ensuring that you make informed purchasing decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical requirements is the first step in your sourcing process. Consider the specific needs of your target market, such as the types of pets that will use the feeder and any special dietary requirements. Important specifications may include compatibility with ISO microchips, remote monitoring capabilities, and portion control features.

- Key Considerations:

- Compatibility with multiple pets (e.g., customizable access for different animals).

- Capacity and size to accommodate various pet breeds.

Step 2: Research Market Trends

Understanding current market trends is crucial for aligning your product offerings with consumer demand. Analyze industry reports, customer reviews, and competitor products to identify popular features and pricing strategies.

- Key Insights:

- Look for emerging technologies in pet feeders, such as app integration for remote feeding.

- Consider feedback from pet owners regarding usability and functionality.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request detailed company profiles, product catalogs, and references from other businesses in your region or industry.

- Important Aspects:

- Check for established relationships with logistics partners to facilitate international shipping.

- Assess their production capabilities and quality control processes.

Step 4: Verify Supplier Certifications

Confirm that suppliers possess the necessary certifications to ensure product quality and safety. Look for compliance with international standards, especially if you are sourcing from overseas.

- Certification Types:

- ISO certifications for manufacturing processes.

- Safety certifications related to pet product standards.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the pet feeders to evaluate their functionality and quality firsthand. Testing the products in real-world scenarios will help identify any potential issues.

- Testing Parameters:

- Ensure the microchip recognition works reliably with different pets.

- Evaluate the ease of cleaning and maintenance.

Step 6: Analyze Pricing and Terms

Once you have identified potential suppliers, analyze their pricing structures and payment terms. Look for flexibility in bulk purchase discounts and favorable shipping terms.

- Cost Considerations:

- Include additional costs such as shipping, taxes, and duties in your calculations.

- Compare pricing against competitors to ensure competitiveness.

Step 7: Finalize the Purchase Agreement

After completing your due diligence, negotiate and finalize the purchase agreement with the chosen supplier. Ensure that all terms, including delivery timelines and warranty conditions, are clearly outlined.

Illustrative image related to pet feeder with chip

- Key Elements:

- Specify return policies and support for defective products.

- Establish clear communication channels for order tracking and customer support.

By following this checklist, B2B buyers can effectively navigate the sourcing process for microchip pet feeders, ensuring that they select high-quality products that meet the needs of their customers while enhancing their business offerings in the pet care market.

Comprehensive Cost and Pricing Analysis for pet feeder with chip Sourcing

What Are the Key Cost Components for Pet Feeders with Chips?

When sourcing pet feeders equipped with microchip technology, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly influence the cost. For example, stainless steel bowls and high-grade plastics are preferable for durability and hygiene but come at a higher price point. The choice of components, such as electronic parts for microchip detection, also adds to the expense.

-

Labor: Labor costs can vary by region. In countries with lower labor costs, such as Vietnam or Nigeria, manufacturing expenses may be reduced. However, skilled labor for electronics assembly may still command higher wages.

-

Manufacturing Overhead: This encompasses costs associated with running production facilities, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing practices can lower overhead, impacting the final price.

-

Tooling: Initial setup costs for molds and machinery required to produce the feeders can be significant, especially for custom designs. Buyers should consider these costs when evaluating pricing.

-

Quality Control (QC): Implementing robust QC processes is essential to ensure product reliability and safety. This may increase costs but is vital for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation and shipping costs can vary based on distance, mode of transport, and import/export regulations. For international buyers, understanding local tariffs and shipping fees is essential.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market positioning and perceived product value.

How Do Price Influencers Affect the Cost of Pet Feeders?

Several factors can influence the pricing of pet feeders with chips:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes generally result in lower per-unit costs. Buyers should negotiate MOQs with suppliers to achieve better pricing.

-

Specifications and Customization: Custom features, such as specific color options or tailored software for app integration, can increase costs. Buyers should assess the need for these customizations against their budget.

-

Material Quality and Certifications: Feeders with higher quality materials or those that comply with specific certifications (e.g., ISO standards) may command higher prices. International buyers should ensure that products meet local regulatory requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers may offer premium prices due to their quality assurance and customer service.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon can clarify who bears transportation costs and risks, affecting overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency in sourcing pet feeders with microchip technology, consider the following tips:

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate prices based on volume, payment terms, and long-term partnerships. Leverage competitive quotes to strengthen your bargaining position.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs, including maintenance, potential replacements, and logistics. A lower upfront cost may lead to higher TCO if the product is less durable or efficient.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, shipping fees, and local market conditions that may impact pricing. Consider using local suppliers or regional distributors to mitigate these costs.

-

Conduct Thorough Supplier Research: Investigate potential suppliers’ backgrounds, production capabilities, and customer reviews. Reliable suppliers will often provide better long-term value through consistent quality and service.

In conclusion, understanding the intricate cost structure and price influencers for pet feeders with chips can empower B2B buyers to make informed purchasing decisions. Careful consideration of these factors will lead to better negotiation outcomes and a more favorable total cost of ownership.

Alternatives Analysis: Comparing pet feeder with chip With Other Solutions

Exploring Alternative Solutions to the Pet Feeder with Chip

As the demand for smart pet care solutions continues to grow, many businesses are evaluating the effectiveness of various technologies. Among these, the pet feeder with a chip offers unique advantages, particularly in multi-pet households. However, there are alternative solutions that also aim to address feeding management, each with its own set of features and benefits. This analysis compares the pet feeder with a chip against two viable alternatives: traditional automatic pet feeders and manual feeding methods.

Illustrative image related to pet feeder with chip

| Comparison Aspect | Pet Feeder With Chip | Traditional Automatic Pet Feeder | Manual Feeding Method |

|---|---|---|---|

| Performance | High precision with microchip recognition | Basic timing functions, less accurate | Complete control over feeding |

| Cost | Higher upfront investment (e.g., $200+) | Moderate cost (typically $50-$150) | Minimal cost (food only) |

| Ease of Implementation | Requires setup of microchip/tag system | Simple setup, plug-and-play | No setup required, straightforward |

| Maintenance | Requires regular cleaning and battery checks | Generally low maintenance, easy to clean | Minimal maintenance, dependent on user |

| Best Use Case | Ideal for multi-pet households needing portion control | Suitable for single-pet households or those needing basic automation | Great for owners who prefer hands-on feeding |

What Are the Advantages and Disadvantages of Traditional Automatic Pet Feeders?

Traditional automatic pet feeders are designed to dispense food at pre-set times, ensuring that pets receive meals even when their owners are unavailable. These feeders are typically more affordable than chip-based options, making them accessible for single-pet households. However, they lack the precision of microchip recognition, which can lead to food stealing among pets. Moreover, while they are easy to set up, they may require regular cleaning to prevent food buildup.

How Does Manual Feeding Compare to Technologically Advanced Solutions?

Manual feeding involves directly providing food to pets at designated times, allowing owners complete control over portion sizes and meal timing. This method is cost-effective since it only requires food and a feeding bowl. However, it can be time-consuming and may not fit well with busy lifestyles. Additionally, manual feeding lacks the automated features that can help manage feeding schedules, particularly in households with multiple pets.

In What Situations Is a Pet Feeder With Chip the Best Choice?

The pet feeder with a chip is particularly advantageous for multi-pet households where different pets may require specific diets or portion sizes. Its ability to recognize individual pets through microchips or RFID tags ensures that each animal receives the correct amount of food without the risk of food stealing. While the initial investment is higher, the long-term benefits in terms of pet health and convenience can justify the cost.

How Can B2B Buyers Choose the Right Pet Feeding Solution?

When selecting the right pet feeding solution, B2B buyers should consider their specific needs, such as the number of pets, dietary requirements, and budget constraints. For businesses catering to multi-pet households, investing in a pet feeder with a chip may provide significant advantages in managing feeding schedules and preventing obesity. Conversely, for businesses targeting single-pet owners or those with budget limitations, traditional automatic feeders or manual feeding options may be more appropriate. Ultimately, understanding the unique needs of their customer base will guide buyers in making informed decisions that align with market demands.

Essential Technical Properties and Trade Terminology for pet feeder with chip

What Are the Essential Technical Properties of a Pet Feeder with Chip?

When sourcing a pet feeder with chip technology, understanding its critical technical properties is vital for making informed purchasing decisions. Here are key specifications to consider:

Illustrative image related to pet feeder with chip

1. Material Grade

The materials used in pet feeders, such as high-grade plastics and stainless steel, are crucial for durability and safety. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, while BPA-free plastics ensure that no harmful chemicals leach into the pet food. For B2B buyers, selecting products made from high-quality materials can lead to better product longevity and reduced returns.

2. Microchip Compatibility

Most advanced pet feeders are designed to be compatible with specific microchip standards, such as ISO 11784/85. This compatibility ensures that the feeder can accurately recognize pets, allowing for controlled access to food. Understanding microchip compatibility is essential for B2B buyers, as it affects the feasibility of integration into existing pet management systems.

3. Capacity and Portion Control

The capacity of the feeder, often measured in cups, is critical for determining how many pets can be fed and how often refills are needed. Features like customizable portion sizes (e.g., 1/8 cup to 1/2 cup) allow for precise feeding, which is particularly beneficial for managing diets in multi-pet households. B2B buyers should evaluate these features to cater to various customer needs and preferences.

4. Power Supply and Backup Systems

Most pet feeders operate on standard mains electricity (100-240VAC), but the inclusion of backup battery systems is a significant advantage. This feature ensures that feeding schedules remain uninterrupted during power outages. For B2B distributors, offering products with robust power options can enhance customer satisfaction and reliability.

Illustrative image related to pet feeder with chip

5. User-Friendly Design

Ease of use is a key property that includes features like intuitive control panels and easy-clean components. A user-friendly design can significantly reduce the learning curve for pet owners, making it more appealing to potential buyers. B2B buyers should prioritize products that enhance customer experience and satisfaction.

6. Monitoring and App Integration

Advanced pet feeders often come equipped with smart technology that allows for remote monitoring and scheduling through dedicated applications. This feature enables pet owners to manage feeding times and portion sizes from their smartphones. For B2B buyers, this represents an opportunity to market tech-savvy solutions that appeal to modern consumers.

What Are Common Trade Terms Associated with Pet Feeders with Chip?

Understanding industry jargon is essential for navigating B2B transactions effectively. Here are key terms to familiarize yourself with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pet feeders, partnering with an OEM can help you source high-quality components or complete units tailored to specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest order quantity a supplier is willing to accept. This term is critical for B2B buyers as it directly impacts inventory management and cash flow. Knowing the MOQ helps you plan your purchases according to market demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. When considering bulk purchases of pet feeders, issuing an RFQ can help you obtain competitive pricing and better understand supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is crucial for B2B transactions, as they clarify who bears the costs and risks during shipping, thus avoiding potential disputes.

5. SKU (Stock Keeping Unit)

An SKU is a unique identifier for each distinct product and service that can be purchased. In the context of pet feeders, having SKUs for various models can streamline inventory management and sales tracking, making it easier for B2B buyers to manage stock levels.

Illustrative image related to pet feeder with chip

6. Warranty and Return Policy

Understanding the warranty terms and return policies of suppliers is essential for B2B transactions. A robust warranty can provide assurance of product quality, while a clear return policy helps mitigate risks associated with product defects or incompatibilities.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing pet feeders with chip technology, ensuring they meet market demands while maintaining high standards of quality and service.

Navigating Market Dynamics and Sourcing Trends in the pet feeder with chip Sector

What Are the Current Market Dynamics and Key Trends in the Pet Feeder with Chip Sector?

The pet feeder with chip market is experiencing robust growth driven by several global factors, including the rising pet ownership rates, an increasing focus on pet health, and advancements in technology. Internationally, particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing demand for smart pet products that facilitate better pet care management. Emerging trends such as the integration of IoT capabilities in pet feeders allow for remote monitoring and control, enhancing convenience for pet owners.

In Africa and South America, where urbanization is on the rise, many consumers are seeking innovative solutions that cater to their fast-paced lifestyles. This creates opportunities for B2B buyers to source products that not only meet functional needs but also align with the tech-savvy preferences of modern pet owners. In Europe and the Middle East, sustainability is becoming a significant purchasing criterion. Buyers are increasingly looking for products that incorporate eco-friendly materials and practices, reflecting the global push towards sustainable consumption.

Illustrative image related to pet feeder with chip

Furthermore, the market is witnessing a shift towards personalized pet care solutions. Features such as customizable feeding schedules and portion control are becoming standard in pet feeders, addressing specific dietary needs and preventing issues like obesity. This trend is particularly relevant for multi-pet households where food-stealing is a concern, making smart feeders a preferred choice.

How Important Is Sustainability and Ethical Sourcing in the Pet Feeder with Chip Industry?

Sustainability and ethical sourcing are paramount in today’s pet feeder with chip market. The environmental impact of manufacturing processes and materials used in pet products is under scrutiny, prompting buyers to consider suppliers who prioritize eco-friendly practices. The demand for sustainable materials, such as recycled plastics and biodegradable components, is on the rise, reflecting a broader consumer shift towards environmental consciousness.

In addition to material sourcing, ethical supply chains are critical. International B2B buyers are increasingly focused on ensuring that their suppliers adhere to fair labor practices and responsible sourcing methods. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can provide assurance that suppliers are committed to sustainable practices.

Incorporating sustainability into product offerings not only enhances brand reputation but also appeals to a growing segment of environmentally conscious consumers. Pet product manufacturers that embrace green certifications and ethical sourcing will likely find a competitive edge in the marketplace, particularly among buyers in regions like Europe, where regulatory frameworks are increasingly focused on sustainability.

What Is the Brief Evolution and History of Pet Feeders with Chips?

The evolution of pet feeders with chips can be traced back to the growing intersection of technology and pet care. Initially designed for convenience, early models focused primarily on automated feeding. However, as pet ownership increased and owners became more concerned about their pets’ health, the concept evolved to integrate microchip technology. This innovation allows feeders to recognize pets individually, preventing food-stealing and ensuring that each animal receives its correct portion.

The introduction of RFID (Radio Frequency Identification) technology marked a significant milestone in the evolution of pet feeders. These feeders began to offer features like remote monitoring through mobile applications, enabling pet owners to manage feeding schedules and track their pets’ eating habits from anywhere. This technological advancement has not only improved pet care but has also transformed how manufacturers approach product design, leading to a more sophisticated and user-friendly market.

As the demand for smarter, more efficient pet care solutions continues to rise, the pet feeder with chip sector is poised for further innovation, driven by advancements in technology and changing consumer preferences. This evolution highlights the importance of continuous adaptation in product offerings to meet the needs of modern pet owners.

Frequently Asked Questions (FAQs) for B2B Buyers of pet feeder with chip

-

How do I choose the right microchip pet feeder for my business?

When selecting a microchip pet feeder, consider factors such as compatibility with various microchip types, feeding capacity, and the ability to customize feeding schedules. Assess the technology used for pet recognition and ensure it meets your target market’s needs, such as multi-pet households. Additionally, look for features like remote monitoring, portion control, and ease of cleaning. Research suppliers’ reputations and product reviews to ensure reliability and quality, which will enhance your brand’s credibility in the marketplace. -

What are the benefits of using microchip pet feeders in a B2B setting?

Microchip pet feeders offer several advantages, including the prevention of food stealing among pets, which is crucial for multi-pet households. They enable precise portion control to combat obesity and support therapeutic diets for pets with special needs. From a B2B perspective, these feeders can differentiate your product line by integrating advanced technology, appealing to tech-savvy customers and pet owners seeking convenience. This innovative solution can also enhance your brand’s reputation for promoting pet health and well-being. -

What is the typical lead time for ordering microchip pet feeders from suppliers?

Lead times can vary significantly based on the supplier, order quantity, and manufacturing processes. Generally, expect a lead time of 4 to 12 weeks for bulk orders, especially if customization is involved. It’s essential to communicate with potential suppliers to obtain a precise timeline, considering factors like shipping times and any potential customs delays, particularly for international shipments. Establishing clear expectations can help you plan your inventory and meet customer demands effectively. -

What minimum order quantities (MOQ) should I expect when sourcing microchip pet feeders?

Minimum order quantities for microchip pet feeders typically range from 50 to 500 units, depending on the supplier’s policies and production capabilities. Some manufacturers may offer lower MOQs for initial orders or samples, while others may require larger quantities to justify production costs. When negotiating with suppliers, inquire about the possibility of lower MOQs for trial runs or promotional purposes, especially if you’re entering a new market or testing customer interest. -

How can I ensure the quality of microchip pet feeders from international suppliers?

To ensure product quality, conduct thorough due diligence on potential suppliers. Request certifications, such as ISO, and seek references from other businesses they supply. Consider ordering samples for testing before committing to larger orders, allowing you to assess the feeder’s functionality, durability, and overall design. Additionally, establish quality assurance protocols and request regular updates on production processes to maintain standards throughout the manufacturing and shipping phases. -

What payment terms should I expect when sourcing microchip pet feeders?

Payment terms for microchip pet feeders can vary widely among suppliers. Common arrangements include a 30% deposit upon order confirmation with the remaining balance due before shipment, or full payment in advance for smaller orders. Some suppliers may offer credit terms or payment plans for larger purchases. It’s advisable to clarify payment terms early in negotiations to avoid misunderstandings and ensure you have the necessary cash flow to manage your inventory effectively. -

What logistics considerations should I keep in mind when importing microchip pet feeders?

When importing microchip pet feeders, consider shipping methods, customs duties, and potential tariffs that may apply based on your country’s trade agreements. Choose reliable freight forwarders who specialize in international shipping to navigate the complexities of customs clearance efficiently. Additionally, factor in lead times for shipping and customs processing to avoid delays in product availability. Regular communication with suppliers about shipping schedules can help ensure timely delivery and customer satisfaction. -

How can I customize microchip pet feeders to meet my market’s needs?

Customization options for microchip pet feeders may include branding, color variations, and specific features tailored to local preferences. Discuss your requirements with suppliers who offer flexible manufacturing processes. Consider the unique needs of your target market, such as dietary concerns or pet ownership trends, to create a product that resonates with consumers. Collaborating with suppliers during the design phase can also lead to innovative features that set your offerings apart from competitors.

Top 4 Pet Feeder With Chip Manufacturers & Suppliers List

1. Petlibro – One RFID Smart Feeder

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Petlibro One RFID Smart Feeder

– Price: $439.99 (originally $449.97)

– Schedules up to 6 meals or snacks a day

– Quadruple sealed for freshness

– Dual power supply

– Available capacities: 3L or 5L

– Battery life lasts up to 180 days (batteries not included)

– Rotor design locks in freshness

– Pestproof and spillproof

– Wi-Fi connected, app-powered

– Keeps you informed with feeding logs

2. HolistaPet – SureFeed Microchip Pet Feeder Connect

Domain: holistapet.com

Registered: 2017 (8 years)

Introduction: Best Overall – SureFeed Microchip Pet Feeder Connect: Tracks eating habits, pairs with Sure Petcare app, manages portions, holds up to 13.5 fl. oz., seals tightly to keep food fresh. Best Budget Option – PortionPro RX Automatic Pet Feeder: Uses patented RFID tag, holds up to 32 cups of dry food, schedules up to 6 meals a day, built-in portion control. Best for Wet Food – ISENVO Wet and Dry Food Pe…

3. Feline Diabetes – Microchip Timed Feeder

Domain: felinediabetes.com

Registered: 1999 (26 years)

Introduction: Microchip timed feeder concept: A feeder that works like a timed feeder with a rotating multi-compartment tray. At each programmed time, the tray rotates to place a meal under a feeding slot door, which only opens when it detects the microchip of the approved cat. The door does not open for other pets. Current options discussed include the SurePet microchip feeder (not timed) and DIY solutions lik…

4. SureFlap – Microchip Cat Feeder

Domain: technomeow.com

Registered: 2017 (8 years)

Introduction: SureFeed Microchip Cat Feeder from SureFlap is an automated cat feeder equipped with a collar sensor that recognizes your cat’s microchip. It is compatible with embedded microchips or microchips attached to collars, designed for SureFlap RFID collar tags. The feeder holds 13.5 fl. oz. of wet or dry food, sealing to keep it fresh, and is ideal for multi-pet households to prevent food theft and stre…

Strategic Sourcing Conclusion and Outlook for pet feeder with chip

In conclusion, the strategic sourcing of microchip-enabled pet feeders presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These innovative products not only cater to the growing demand for pet care solutions but also address critical issues such as pet obesity and dietary management in multi-pet households. By sourcing high-quality feeders that integrate advanced technology, businesses can ensure precise nutrition and enhance customer satisfaction.

Moreover, leveraging the benefits of strategic sourcing—such as cost efficiencies, supplier reliability, and product innovation—can significantly enhance your competitive advantage in the pet care market. With the increasing global focus on pet health and welfare, aligning your sourcing strategy with suppliers that emphasize quality and technological advancements will position your business for future growth.

As you explore your options, consider engaging with manufacturers and distributors who are committed to sustainability and ethical practices. The future of pet feeding technology is bright, and by investing in these solutions today, you can play a pivotal role in shaping the pet care landscape of tomorrow. Take action now to secure your place in this thriving market!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.