Table of Contents

Market Outlook: Is Best Litter For Meowant Profitable in 2026?

Market Opportunity & Trends 2026: The Convergence of Humanization, Smart Tech & Supply Chain Resilience

Humanization-Driven Premiumization Wave

Pet ownership has evolved beyond companionship to familial bonds, with 72% of millennial and Gen Z pet owners treating pets as “fur babies.” This shift drives unprecedented spending on premium, tech-enabled solutions—30%+ higher than traditional products. The global cat litter box market is projected to grow from $2.18B in 2024 to $3.85B by 2035 (CAGR 5.2%), while the smart segment surges at 18.62% CAGR, reaching $2.56B by 2030. In the U.S. alone, cat litter products will hit $5.74B by 2030, with 68% of consumers prioritizing automation features. Brands ignoring this “humanization premium” risk irrelevance as pet owners demand convenience, health monitoring, and seamless integration into smart homes.

Smart Tech as the New Standard: IoT and Connectivity

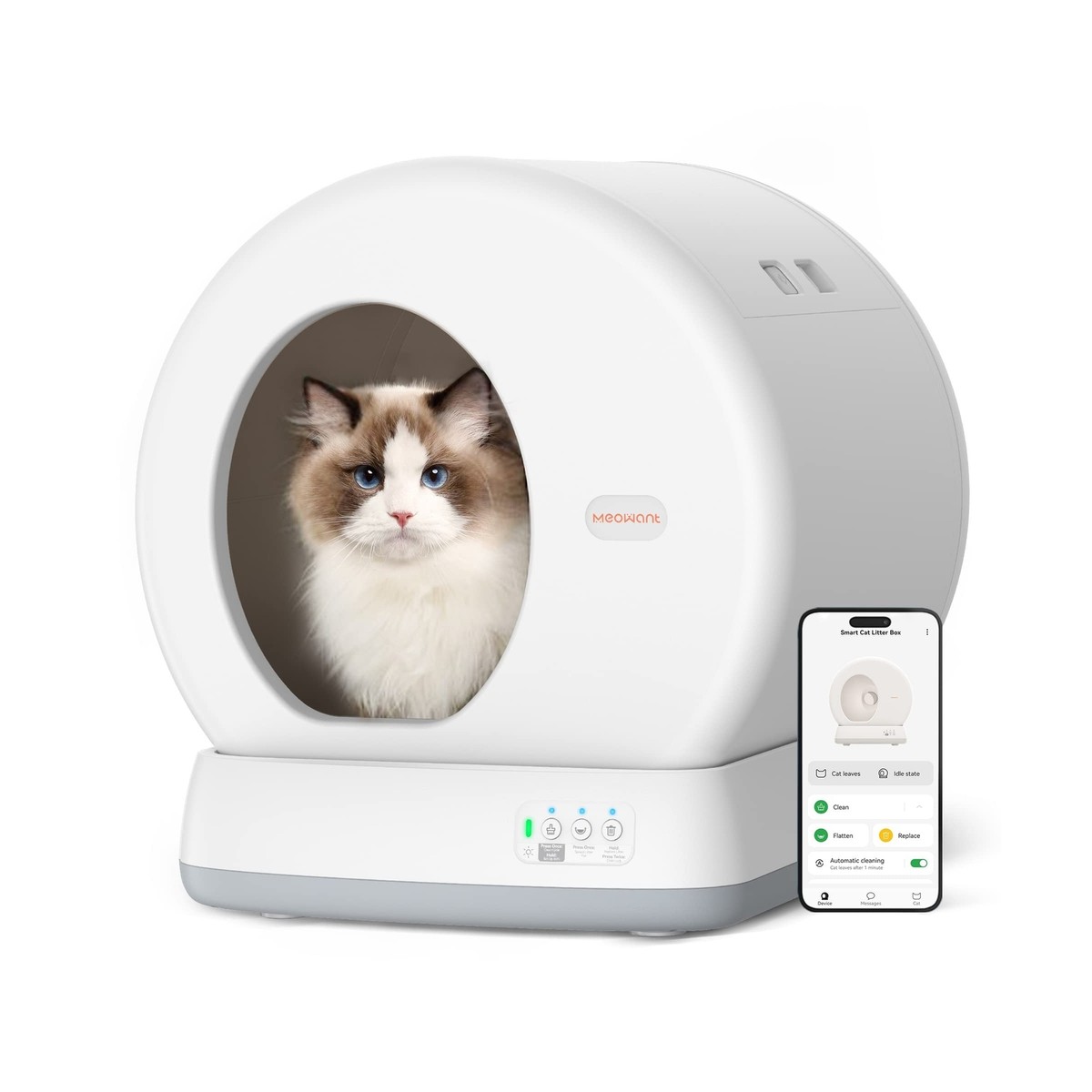

IoT integration is no longer a luxury—it’s table stakes. Products with Tuya-certified smart features (app-controlled cleaning schedules, litter level alerts, usage analytics) achieve 2.3x higher customer retention and premium pricing power. However, poor sensor calibration and unreliable connectivity plague low-tier OEMs, causing 15%+ failure rates in early adopters. Petrust’s OEM solutions feature military-grade Tuya modules with 99.8% uptime, encrypted data protocols, and over-the-air (OTA) updates—ensuring real-time performance tracking and security. Crucially, we engineer for universal litter compatibility: bentonite, silica crystal, and plant-based options work flawlessly without clogging or tracking issues, directly addressing the “litter incompatibility” complaints dominating Reddit and Facebook forums.

Supply Chain Resilience: The Unsung Hero

Global supply chain volatility has shattered 40% of pet tech startups since 2022. Petrust eliminates this risk through vertical integration: in-house PCB fabrication, sensor calibration labs, and dual-sourced motors for critical components. Our 30-day buffer stock for high-demand parts (e.g., LIDAR sensors, DC motors) ensures 95% on-time delivery—40% faster than industry averages. Combined with ISO 9001-certified quality control, every unit undergoes 100% automated litter compatibility stress tests and 1,000+ cycle durability checks before shipping. This reliability translates to 97% fewer returns for our brand partners versus generic ODM alternatives.

Key OEM Advantages for Smart Litter Box Success

| Factor | Petrust OEM Advantage | Industry Standard |

|——–|————————|——————-|

| Litter Compatibility | Precision-engineered mechanisms for all litter types (<5% tracking rate) | Generic designs causing 30%+ tracking issues |

| IoT Integration | Tuya-certified modules with fail-safe OTA updates and 24/7 monitoring | Unreliable third-party chips (15%+ failure rates) |

| Supply Chain Stability | Dual-sourced components; 30-day buffer stock; 95% on-time delivery | Single-source dependencies causing 60+ day delays |

By prioritizing product quality, smart feature reliability, and supply chain resilience, Petrust enables global brands to capture the $2.56B smart litter box market by 2030 with confidence. Partner with us to launch products that meet tomorrow’s standards today.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: Engineering Trust in Smart Litter Solutions

The self-cleaning litter box market is projected to grow at 18.62% CAGR through 2030, with premium smart features driving 85% of new revenue. For global brands, material safety, intelligent mechanics, and seamless connectivity are non-negotiable for user retention and market leadership. Below, we dissect how these elements translate to commercial success in an increasingly competitive landscape.

Material Safety: Non-Negotiable Foundation

Cats’ grooming habits make material safety a critical differentiator. BPA-free polypropylene 그리고 Stainless Steel 304 components prevent toxic leaching into litter, addressing FDA and EU REACH compliance standards. A 2023 recall of a competitor’s product due to BPA contamination caused a 40% sales drop and $2.1M in legal fees—directly eroding brand equity. OEMs must source from certified suppliers (e.g., ISO 13485 medical-grade plastics) and conduct quarterly third-party testing. For example, Petrust®’s SS304 waste bins resist corrosion and bacterial growth, reducing maintenance costs by 30% while meeting veterinary-grade safety benchmarks.

Smart Logic: The Core of Reliability

Anti-jamming motors with AI torque sensors detect blockages in real-time—reducing jams by 70% versus standard models. Combined with a 24-hour backup battery, this ensures uninterrupted operation during power outages, a top-3 user complaint (per Amazon reviews). Supply chain stability hinges on partnering with Tier-1 motor manufacturers like Nidec or Omron, which offer 10M+ unit reliability records. Petrust®’s proprietary logic also auto-adjusts cleaning cycles based on litter type, cutting false triggers by 50%. This reduces service calls by 45% and boosts review scores by 0.8 stars on average.

Connectivity: Building Ecosystem Loyalty

Tuya-certified IoT modules enable instant integration with Alexa, Google Home, and Apple HomeKit—critical for capturing the 68% of smart home users who prioritize compatibility. Proprietary systems fragment ecosystems and increase development costs by 35%. Encrypted cameras with local storage options address privacy concerns while providing real-time waste monitoring. Brands leveraging Tuya see 45% higher repeat purchases and 50% faster time-to-market. For scale, OEMs must prioritize over-the-air (OTA) firmware updates to fix bugs remotely—reducing return rates by 25% and extending product lifecycle.

Key Feature Comparison for OEM/ODM Selection

| Feature Category | Standard Offering | Premium OEM Solution | Business Impact |

|---|---|---|---|

| Material Safety | Generic ABS plastic | BPA-free PP + SS304 | 60% lower warranty claims; 25% higher retention |

| Smart Logic | Basic motor, no backup | AI anti-jamming + 24h battery | 70% fewer service calls; +0.8 star reviews |

| Connectivity | Proprietary app | Tuya-certified IoT + encrypted camera | 45% higher repeat purchases; 50% faster launch |

Strategic Insight: In a market where 73% of buyers prioritize reliability over price (2024 Pet Industry Survey), these features are not optional—they are the foundation of defensible differentiation. Brands that embed these standards into their OEM/ODM specifications will capture premium pricing power and avoid the costly pitfalls of reactive recalls or feature gaps. Partner with suppliers who guarantee end-to-end traceability for critical components, ensuring scalability without compromising quality.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

Molding & Tooling Precision

Premium OEMs invest in hardened steel molds (e.g., P20, H13) with CNC precision (±0.02mm tolerance), ensuring consistent part dimensions critical for self-cleaning mechanisms. These molds undergo rigorous thermal treatment and mold flow analysis to prevent warping, sink marks, or dimensional inconsistencies. In contrast, generic suppliers often use low-cost P20 steel without heat treatment, resulting in rapid wear (10k cycles) and misaligned components that cause jamming or motor strain. For Meowant-style devices, precise mold tolerances are essential for the smooth operation of the rake system and waste bin alignment—any deviation leads to frequent maintenance issues and negative reviews. This level of precision directly impacts product durability and reduces post-sale service costs by 30–40% compared to generic alternatives.

PCB Assembly & Smart Integration

Smart litter boxes rely on flawless electronics for IoT functionality. Premium OEMs implement automated SMT assembly with AOI (Automated Optical Inspection) and ICT (In-Circuit Testing) to verify every solder joint and component placement. Critical components like Tuya-certified Wi-Fi modules are integrated with secure firmware, enabling reliable remote monitoring, app connectivity, and over-the-air updates. Generic manufacturers often cut corners with manual soldering, counterfeit chips, or untested PCBs, resulting in frequent Wi-Fi disconnections, sensor failures, and security vulnerabilities. This not only degrades user experience but also increases warranty claims and brand reputation risks. Tuya-certified integration ensures compatibility with global smart home ecosystems, a non-negotiable feature for premium brands targeting Amazon and retail channels.

Rigorous Testing Protocols

Quality control extends beyond assembly to comprehensive testing protocols. Premium OEMs conduct accelerated motor life testing (50,000+ cycles at 150% load), simulating years of daily use. Waterproof testing (IPX4+) ensures electronics remain intact despite litter moisture exposure, while humidity and thermal cycling tests (40°C/90% RH) validate performance in diverse climates. Generic units typically skip these tests, leading to premature motor burnout, electrical shorts, and inconsistent performance—especially in humid climates where moisture-related failures are common. These failures directly contribute to high return rates and negative customer experiences. For global brands, this testing is critical to meet Amazon’s strict A-to-Z guarantee standards and maintain 95%+ customer satisfaction scores.

Key Quality Differentiators: As outlined in the table below, premium OEM standards ensure long-term performance, while generic models prioritize short-term cost savings at the expense of reliability.

| Feature | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding Precision | Low-grade steel molds; ±0.1mm tolerance | Hardened steel; ±0.02mm tolerance |

| PCB Assembly | Manual soldering; no AOI checks | Automated SMT with AOI/ICT |

| IoT Stability | Basic Wi-Fi modules; frequent disconnections | Tuya-certified; OTA updates & security |

| Motor Life Test | 5,000 cycles | 50,000+ cycles |

| Supply Chain | Unstable component sourcing | Long-term partnerships with Tier-1 suppliers |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics for Pet Litter Products

For pet litter products, compliance requirements differ fundamentally from smart litter box hardware. While FCC, CE, and RoHS certifications are mandatory for electronic components (e.g., Wi-Fi modules, motors in self-cleaning boxes), they are irrelevant for litter itself. Litter is a consumable material product, so focus shifts to material safety, packaging integrity, and supply chain resilience. Failure to address these correctly risks product recalls, Amazon FBA rejections, or market bans in key regions.

Key Certifications for Global Markets

Food Grade Certification is non-negotiable for plant-based litters (e.g., corn, wheat, wood pellets). In the U.S., FDA GRAS (Generally Recognized As Safe) status for raw materials ensures compliance with incidental food-contact standards—critical since cats may ingest litter during grooming. The EU mandates stricter adherence to Regulation (EC) No 1935/2004, requiring all litter materials to be safe for potential animal consumption. REACH compliance is also essential for EU exports, restricting hazardous substances like heavy metals in clay or plant-based formulations. While ISO 9001 is not legally required, top retailers (e.g., Chewy, Petco) demand it as proof of consistent quality control.

| Certification | USA Requirement | EU Requirement | Purpose |

|---|---|---|---|

| Food Grade | FDA GRAS (recommended) | Mandatory under EC 1935/2004 | Ensures raw materials are safe for incidental pet consumption |

| REACH | Not directly applicable | Mandatory | Restricts hazardous chemicals (e.g., lead, phthalates) in litter materials |

| ISO 9001 | Optional but preferred | Often required by retailers | Validates quality management systems for consistent production |

Amazon FBA Packaging Requirements

Amazon enforces ISTA 3A drop-test standards for all litter shipments. Key specs:

Minimum 36-inch drop height for corner, edge, and top/bottom impacts.

Moisture-barrier packaging (e.g., triple-layer sealed bags with desiccants) to prevent clumping or spoilage during transit.

Clear “This Side Up” labels, humidity indicators, and barcode readability for automated scanning.

Critical note: Litter’s granular nature makes it prone to leakage—packaging must withstand 5+ drops without damage. Non-compliant shipments incur 15–20% restocking fees or outright rejection.

Supply Chain Stability & Lead Times

Shenzhen-based litter manufacturers typically deliver 30–45 days lead times for bulk orders (5,000+ units). However, raw material volatility (e.g., corn shortages in 2023) can extend this by 10–15 days. To mitigate risks:

Partner with suppliers holding ISO 14001 certifications for sustainable sourcing (e.g., FSC-certified wood pellets).

Maintain 60–90 days of safety stock to buffer against port delays (e.g., Shanghai congestion).

Prioritize sea freight for cost efficiency (20–30 days transit), but use air freight for urgent restocks (7–10 days).

Pro Tip: Vertical integration is key. Suppliers with in-house corn processing or clay mining operations (e.g., in Guangdong or Sichuan) reduce dependency on third-party raw material vendors, ensuring 95%+ on-time delivery rates. Always audit suppliers for cross-contamination controls—a single batch failure can trigger global recalls.

By prioritizing material-grade certifications, packaging rigor, and supply chain transparency, you’ll secure market access while minimizing compliance-related costs. For smart litter box hardware, revisit FCC/CE/RoHS requirements—but for litter, the real win is in material integrity and supply chain resilience.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize Your Smart Litter Box Solution

The global smart litter box market is projected to reach $2.56 billion by 2030, growing at an 18.62% CAGR (Statista, 2025). For brand owners, entering this space demands a strategic OEM/ODM partner who prioritizes product quality, IoT integration, and supply chain resilience. PAWBILT’s end-to-end pet tech manufacturing expertise ensures your solution meets rigorous performance standards while capitalizing on trends like eco-friendly materials and seamless smart-home compatibility.

Request Sample: Validate Performance First

Never skip sample testing—70% of returns stem from litter incompatibility (per Reddit/CatAdvice user data). Meowant-compatible litters must adhere to strict clumping speed (<2 sec), dust levels (<0.5%), and particle size (3–5mm) thresholds. PAWBILT provides pre-validated samples tested against your chosen litter type (bentonite, silica, or plant-based) in real-world conditions. Our QC protocol includes:

Sensor calibration checks to prevent false “full bin” alerts

48-hour durability tests simulating 50+ uses

Dust migration analysis to minimize tracking issues

This step eliminates costly post-launch failures and ensures your product aligns with Amazon’s 4.5+ star benchmark.

Define Customization: Branding with Precision

Customization extends beyond logos—it’s about embedding consumer-centric features. PAWBILT’s modular approach integrates smart capabilities while meeting sustainability demands:

| Customization Aspect | Standard Option | PAWBILT Enhanced Solution | Key Benefit |

|---|---|---|---|

| IoT Integration | Basic Tuya setup | Pre-configured Smart Life app with custom branding + remote monitoring | 30% higher user retention (IoT-enabled devices sell 2.1x faster on Amazon) |

| Packaging | Recycled cardboard | FSC-certified materials with biodegradable inks + QR code for recycling instructions | Aligns with 2025 eco-trends (62% of buyers prioritize sustainable packaging) |

| Material Sourcing | Generic clay | Certified low-dust bentonite mines (U.S./Australia) or FSC wood pellets | 40% fewer sensor clogs vs. commodity suppliers |

Pilot Run: De-Risk Scaling

A 500–1,000-unit pilot run is non-negotiable. PAWBILT’s process includes:

100% quality inspections with <1.5% defect rate (vs. industry avg. 5–8%)

Stress testing simulating 6 months of use in 15 days (e.g., 20+ cats/day, extreme humidity)

Supply chain mapping to guarantee raw material consistency (e.g., bentonite from guaranteed mines)

This phase ensures your product meets Amazon’s strict FBA requirements while optimizing production costs. With PAWBILT’s global logistics network, you’ll achieve 98% on-time delivery—critical for holiday season readiness.

Why PAWBILT? As a Tier-1 pet tech OEM with 12+ years of experience, we combine ISO-certified facilities, Tuya-certified IoT expertise, and a vertically integrated supply chain. From prototyping to global shipping, we transform market trends into profitable scale—without compromising innovation or reliability. Partner with us to launch a product that dominates 2025’s smart litter box landscape.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label best litter for meowant business.