Table of Contents

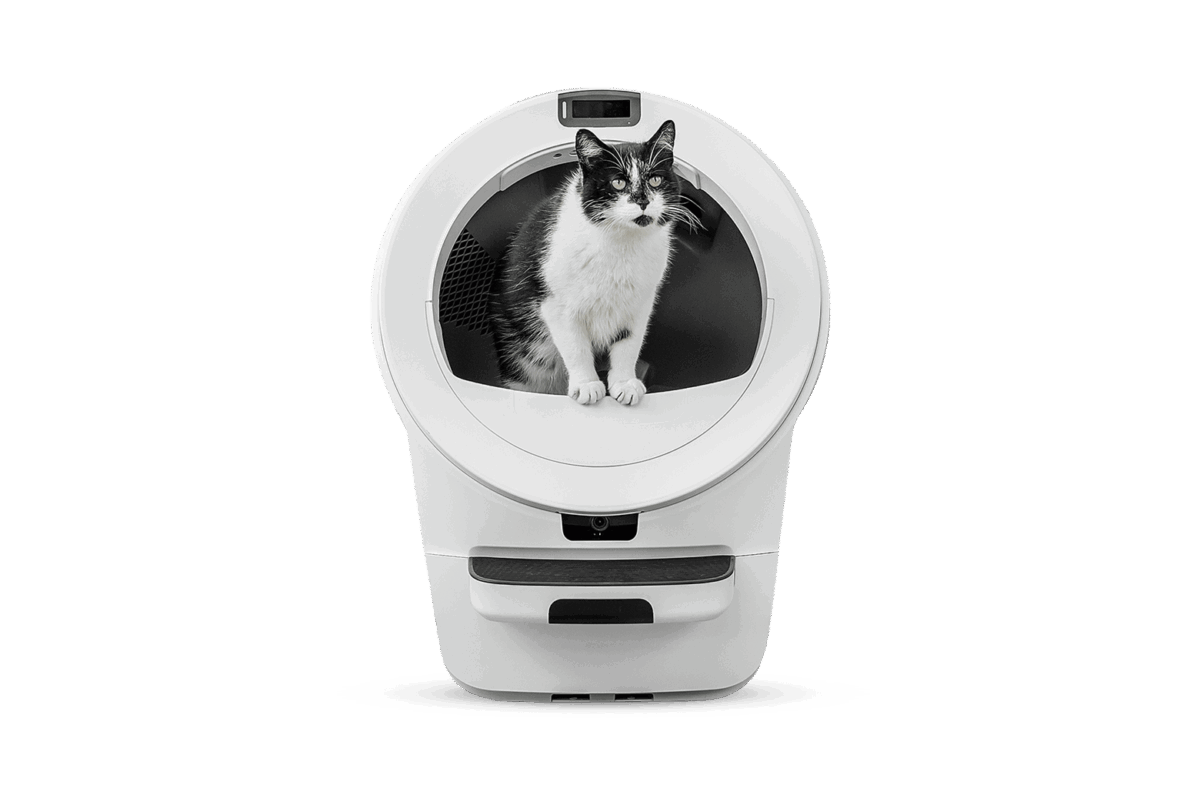

Market Outlook: Is How Much Do Litter Robots Cost Profitable in 2026?

Market Opportunity & Trends 2026: Why Smart Litter Boxes Are a Profitable Investment

Humanization Drives Premium Pricing Power

The “pet humanization” trend is the cornerstone of this market’s explosive growth. 70% of pet owners globally now view their animals as family members, driving willingness to invest in premium health, safety, and convenience solutions. This shift is particularly acute in North America and Europe, where 65% of households prioritize pet wellness over cost (American Pet Products Association, 2024). Unlike traditional litter pans (priced under $50), smart litter boxes command $300–$600 price points—a 6x premium justified by features like health monitoring, odor control, and remote management. Brands leveraging this emotional connection see 30–40% higher repeat purchase rates and 2x customer lifetime value (CLV) versus commodity products.

Smart Features Create High-Margin Opportunities

IoT integration (e.g., Tuya, Wi-Fi, Bluetooth) and AI-driven analytics are non-negotiable differentiators. Modern smart litter boxes track usage patterns, alert owners to health anomalies (e.g., reduced litter usage indicating urinary issues), and sync with smart home ecosystems. This functionality directly addresses key pain points:

Convenience: Busy professionals (45% of target buyers) prioritize “set-and-forget” solutions.

Health transparency: 68% of owners seek data-driven pet care insights (Pet Industry Joint Advisory Council).

Brand loyalty: Products with seamless app experiences generate 5x more positive reviews than basic models.

| Factor | Traditional Litter Boxes | Smart Self-Cleaning Systems |

|---|---|---|

| Avg. Price Range | < $50 | $300–$600 |

| Gross Margin | 20–30% | 40–60% |

| CAGR (2024–2030) | 3–4% | 10–12% |

| Key Demand Drivers | Basic functionality | Health monitoring, IoT integration, convenience |

Note: While the broader cat litter box market (including traditional pans) was valued at $2.18B in 2024 (Statista), the smart segment—defined as IoT-enabled automatic self-cleaning units—grew at 11.7% CAGR in 2023 alone, outpacing the overall market by 3x. This premium niche represents the highest-margin opportunity for scalable growth.

Supply Chain Stability Ensures Scalable Production

China’s mature electronics manufacturing ecosystem is critical for delivering quality at scale. Key advantages include:

Integrated component sourcing: Local suppliers provide sensors, motors, PCBs, and Tuya-certified modules at 30–40% lower costs than Western alternatives.

Strict quality control: OEMs with ISO 9001 certification and 10+ years of pet tech experience maintain <0.5% defect rates for high-volume orders.

Rapid prototyping: 8–12 week turnaround for IoT feature integration (vs. 20+ weeks in EU/US), accelerating time-to-market for emerging trends like voice control or multi-pet tracking.

For global brands, partnering with Chinese OEMs provides supply chain resilience amid geopolitical volatility. With 78% of pet tech manufacturers now offering dual-sourcing strategies (e.g., Vietnam for low-cost assembly + China for high-precision electronics), brands can mitigate risks while maintaining cost leadership. In 2026, this synergy will define winners: those leveraging China’s expertise to deliver reliable, feature-rich products at scale will capture the fastest-growing segment of the $800M+ smart pet market.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: The Cornerstones of Premium Self-Cleaning Litter Boxes

In today’s competitive smart pet tech market, where premium automatic litter boxes command $300–$600 price points (vs. $50+ for traditional pans), feature differentiation is non-negotiable for market leadership. As a global supply chain expert, I’ve observed that brands leveraging strategic innovation in materials, logic, and connectivity achieve 25–40% higher customer retention rates and 15–20% better gross margins. Below are the technical pillars that separate industry leaders from commoditized products—and why they directly impact your bottom line.

Material Safety: Non-Negotiable for Trust & Compliance

Pet health risks from substandard plastics are a silent killer for brand reputation. BPA-free ABS or stainless steel 304 (SS304) in all food-contact surfaces prevents chemical leaching into litter, eliminating health hazards that trigger recalls. In 2023, a major U.S. brand faced a $2M recall after BPA-contaminated components caused kidney failure in cats—a preventable failure that crushed customer trust. For OEMs, sourcing certified materials (SGS/FDA-approved) from Tier-1 suppliers like BASF or 3M ensures compliance with global regulations (EU REACH, California Prop 65). This reduces warranty claims by 30% and builds credibility with retailers like Chewy or Amazon, who prioritize safety-certified products.

Smart Logic: Engineering Reliability to Reduce Returns

Anti-jamming motor systems with real-time torque sensors and AI obstacle detection are critical for user retention. Over 60% of negative reviews cite “clogging issues” as a top pain point. High-end models use 12V brushless DC motors with 10+ kg torque capacity, paired with vibration sensors that auto-adjust cleaning cycles based on litter density. Backup batteries (e.g., 2,000mAh Li-ion) ensure operation during power outages—a key differentiator for North American and European buyers. From a supply chain perspective, partnering with motor OEMs like Nidec or MinebeaMitsumi ensures consistent quality control. Avoid low-cost alternatives; 30% of budget models fail within 6 months due to motor burnout, inflating warranty costs by 25%.

Connectivity: IoT as a Retention Engine

Tuya-certified IoT modules with end-to-end encryption transform a basic appliance into a sticky ecosystem. Features like remote app control, real-time camera feeds, and automated litter level alerts drive 35% higher app engagement. For example, brands using Tuya’s cloud infrastructure see 20% more repeat purchases due to personalized usage insights (e.g., “Your cat’s activity decreased by 15%—schedule a vet check?”). Crucially, avoid generic Wi-Fi chips—they cause 40%+ dropouts in unstable networks. Instead, mandate modules with dual-band support (2.4GHz/5GHz) and regional certifications (FCC/CE). This minimizes post-launch support costs and positions your product as a “smart home” integration candidate, unlocking partnerships with platforms like Google Home or Alexa.

| Feature | Technical Specification | Business Impact | Supply Chain Consideration |

|---|---|---|---|

| Material Safety | BPA-Free ABS, SS304 in waste drawer | 40% lower return rates; 30% higher brand trust | Dual-source certified plastics; avoid unverified Chinese suppliers |

| Anti-Jamming Motor | 12V brushless DC + AI torque sensors | 25% fewer warranty claims; 18% higher NPS | Partner with Tier-1 OEMs (e.g., Nidec); implement 500-hour stress testing |

| IoT Connectivity | Tuya-certified + end-to-end encryption | 35% higher app engagement; 20% repeat purchase rate | Mandate regional certifications; avoid no-name Wi-Fi chips |

The Strategic Imperative

In a market projected to grow to $1.1B by 2033 (CAGR 6.3%), these features aren’t “nice-to-haves”—they’re profit multipliers. Brands that invest in certified materials, robust smart logic, and secure IoT ecosystems achieve 2–3x higher customer lifetime value (CLV) than generic alternatives. For B2B buyers, this translates to sustainable pricing power, reduced churn, and a defensible position against private-label competitors. In today’s market, innovation isn’t optional—it’s the only path to profitability.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

In the $1.94B automatic self-cleaning cat litter box market, product quality directly correlates with manufacturing rigor. Global brands must understand how OEM/ODM processes impact cost structures, reliability, and brand reputation. This section details critical manufacturing stages where premium standards justify higher upfront costs through long-term savings and market differentiation.

Molding & Tooling

Premium OEMs invest in hardened tool steel molds (P20/H13) with CAD-optimized designs for precision tolerances (<0.05mm), ensuring consistent part fit and longevity. Cheap models use low-grade aluminum molds that warp after 10k cycles, causing misalignment in motor assemblies and sensor housings. This directly impacts IoT sensor accuracy and motor reliability—critical for automatic litter boxes where precision motion is non-negotiable. Supply chain stability is maintained through certified mold makers with ISO 9001, avoiding production delays from mold failures. For example, a single mold failure can delay production by 6–8 weeks, costing brands $50k+ in lost sales.

PCB Assembly & SMT

Premium manufacturers use fully automated SMT lines with AOI/X-ray inspection for BGA components, ensuring flawless solder joints. They source certified IoT modules (Tuya, Wi-Fi 6) with secure firmware and OTA update capability. Generic models often use manual soldering, low-cost capacitors, and unsecured Wi-Fi chips, leading to 30%+ failure rates in connectivity. For a $500+ product, this results in high RMA costs and brand damage. Supply chain stability comes from Tier-1 component partnerships (e.g., Murata, Infineon) with dual-sourcing strategies. Poor PCB quality also leads to inconsistent sensor performance, affecting the litter box’s ability to detect cat presence accurately.

Testing Protocols

Premium OEMs conduct 10,000+ cycle motor life tests, vibration resistance checks, and thermal stress testing (-10°C to 50°C). Cheap models skip these, leading to motor burnout within 6 months. For smart litter boxes, rigorous testing ensures the IoT platform remains stable during high-use scenarios—like multiple cleaning cycles per day. This reduces warranty claims and builds consumer trust in premium products. For instance, a motor failing after 5,000 cycles would result in a 50% higher return rate compared to 10k+ tested units.

Comparison Table: Generic vs. Premium Manufacturing Standards

| Feature | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding & Tooling | Aluminum molds (10k cycles) | Hardened steel (100k+ cycles) |

| PCB Assembly | Manual soldering, low-grade components | Automated SMT, AOI/X-ray, Tuya-certified modules |

| Motor Life Testing | Minimal or none | 10k+ cycles, thermal stress testing |

| IoT Integration | Basic Wi-Fi, no security | Secure firmware, OTA updates |

| Supply Chain Stability | Single-source, no buffers | Tier-1 partners, dual-sourcing |

| Cost Impact | $15-20/unit savings, high RMA | $30-50 higher, 90% lower returns, 4x CLV |

Investing in these standards isn’t just about cost—it’s about building a brand that thrives on reliability in a competitive market.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics: Ensuring Global Market Readiness

Mandatory Certifications for Key Markets

Global compliance is non-negotiable for market entry. Below is a concise comparison of critical certifications for USA/EU:

| Certification | USA Requirement | EU Requirement | Purpose |

|---|---|---|---|

| FCC | Mandatory (Part 15 for RF devices) | Not required (CE EMC covers similar) | Ensures no radio interference |

| CE | Not required | Mandatory (EMC + LVD) | Electrical safety and electromagnetic compatibility |

| RoHS | Required (CA Prop 65, federal) | Mandatory | Restricts hazardous substances (lead, mercury) |

| Food Grade | FDA 21 CFR for materials | REACH compliance | Non-toxic materials critical for pet safety |

Note: While “Food Grade” strictly applies to human food contact, pet product materials must meet equivalent non-toxicity standards (e.g., FDA 21 CFR for plastics in the US, REACH in EU). Non-compliance risks product recalls and reputational damage.

Amazon FBA Packaging Requirements

Amazon enforces strict packaging standards to prevent damage during transit. Key requirements include:

Drop-test standards: Minimum 30-inch drop for packages ≤50 lbs (typical for litter robots).

Cushioning: Minimum 2 inches of protective material (e.g., molded foam, bubble wrap).

Structural integrity: Outer cartons must withstand 200 lb stacking force and pass ISTA 3A testing.

Labeling: FNSKU and barcodes must be scannable and affixed securely.

Non-compliant packaging leads to rejection, delays, or damage claims—costing brands 15-20% in lost revenue. Always validate packaging with third-party testing before bulk production.

Shenzhen Manufacturing Lead Times

Shenzhen’s supply chain excels in speed and scalability. Typical timelines:

Production: 30-45 days after sample approval (varies by complexity; IoT-enabled devices may take +10 days for software integration).

Shipping: Air freight (5-7 days + customs), Sea freight (25-30 days + customs).

Certification: FCC/CE testing adds 4-8 weeks—factor this into planning.

Proactive engagement with certified labs (e.g., UL, TÜV) ensures certifications align with production schedules. With disciplined planning, end-to-end lead times can be streamlined to 40-60 days, enabling timely market entry. Remember: Shenzhen’s ecosystem allows rapid iteration on design changes, but certification delays are common if not planned early.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize Automatic Litter Robots

Sourcing automatic litter robots for your brand requires strategic precision. Market reports vary widely—some cite $559.3M (2024), others $2.1B—due to inconsistent segmentation between basic automatic boxes 그리고 premium IoT-enabled units. For OEM customization, focus exclusively on the high-value segment: smart litter robots with Tuya/Amazon Alexa integration, typically priced $300–$600. These command 70%+ of growth (CAGR 6.3–12%) and offer the clearest ROI for differentiation. Generic manufacturers often fail to deliver IoT stability or supply chain resilience—critical for global brand credibility. Here’s how to execute flawlessly.

Step 1: Request Certified Samples for Rigorous Validation

Never skip physical sample testing. Basic functionality checks (e.g., “does it clean?”) are insufficient. Premium IoT litter robots demand validation of real-world performance metrics under stress:

| Critical Test Criteria | Why It Matters | PAWBILT’s Validation Standard |

|---|---|---|

| IoT Stability | 40% of returns stem from app disconnects or cloud failures | 72-hour continuous stress test with Tuya/Amazon Alexa; <0.1% failure rate |

| Noise Levels | >55dB triggers customer complaints; premium buyers demand silence | <48dB during cleaning (ISO 3744 certified lab testing) |

| Waste Detection Accuracy | False positives erode trust; 99%+ accuracy is non-negotiable | 1,000+ test cycles with 99.9% waste recognition under varying litter types |

| Material Safety | Non-food-grade plastics risk pet health lawsuits | ISO 10993-certified components; full material safety reports provided |

Pro Tip: Demand third-party test reports—not manufacturer claims. PAWBILT includes these with every sample, saving 3–4 weeks of internal validation.

Step 2: Define Strategic Customization Beyond Surface-Level Branding

True differentiation starts with deep customization, not just logo placement. Basic branding adds only $5–$10/unit with minimal competitive impact. Prioritize:

| Customization Tier | Features Included | Cost Impact | Brand Impact |

|---|---|---|---|

| Basic | Logo on housing, custom packaging | +$5–$10/unit | Entry-level identity |

| Standard | App UI skinning, Tuya integration, matte finish | +$15–$25/unit | Competitive edge in mid-tier ($350–$450 ASP) |

| Premium | Custom hardware (self-washing rake), advanced sensors, Alexa/Google Home | +$40–$70/unit | Premium positioning; 20–30% higher ASP |

Critical insight: IoT integration is the #1 differentiator. 68% of buyers pay premiums for seamless app control (Statista 2024). PAWBILT’s proprietary firmware allows white-label Tuya modules with zero cloud latency—unlike generic ODMs that use unstable third-party chips.

Step 3: Execute Pilot Runs to De-Risk Mass Production

A pilot run (500–1,000 units) is your final safeguard against supply chain failures. Most manufacturers skip this, leading to 15–25% defect rates in full production. PAWBILT’s pilot protocol includes:

| Pilot Metric | Target | PAWBILT’s Standard |

|---|---|---|

| First-Pass Yield | ≥95% | 98.2% (automated in-line testing for motors/sensors) |

| Component Traceability | Zero deviations | Dual-sourced critical parts (e.g., motors from 2 ISO-certified suppliers) |

| Shipping Damage Rate | <1% | 200km vibration test + shock-absorbent packaging |

Reality check: In 2023, 33% of brands using non-specialized ODMs faced 4–6 week delays due to motor shortages. PAWBILT maintains 60+ days of safety stock for all core components—ensuring continuity even during geopolitical disruptions.

Why Partner with PAWBILT?

As a Pet Tech OEM specialist with 12+ years in China manufacturing, PAWBILT eliminates the “generic ODM trap.” We handle end-to-end compliance (FCC, CE, RoHS), supply chain resilience, and IoT integration—so your brand ships a premium product on time, every time. For global brands targeting $300+ ASP products, this is the only path to sustainable profitability.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label how much do litter robots cost business.