Table of Contents

Market Outlook: Is Meow Cat Litter Profitable in 2026?

Market Opportunity & Trends 2026

Humanization: Pets as Family Members

Pet humanization is the cornerstone of premium pet tech adoption. With 70% of U.S. pet owners considering pets as family members (APPA 2023), spending on “pet care” now rivals human healthcare. This shift drives demand for high-end, tech-driven solutions. Cat owners increasingly prioritize products that enhance pet well-being and convenience, with 65% willing to pay 20-30% more for smart litter boxes with health-monitoring features. The cat litter market’s projected $22.31B value by 2030 (5.3% CAGR) reflects this premiumization trend, where innovation directly correlates with market share gains.

Convenience-Driven Demand: Automation as a Necessity

Urbanization and dual-income households fuel demand for automated solutions. Smart litter boxes reduce maintenance time by 80%, appealing to time-strapped owners. The $1.94B automatic self-cleaning litter box market is growing at 4.5% CAGR, but this segment’s true potential lies in its integration with broader smart home ecosystems. With 42% of pet owners using smart home devices (Statista 2024), products with seamless connectivity are poised for exponential growth.

Smart Features: IoT and Tuya Integration

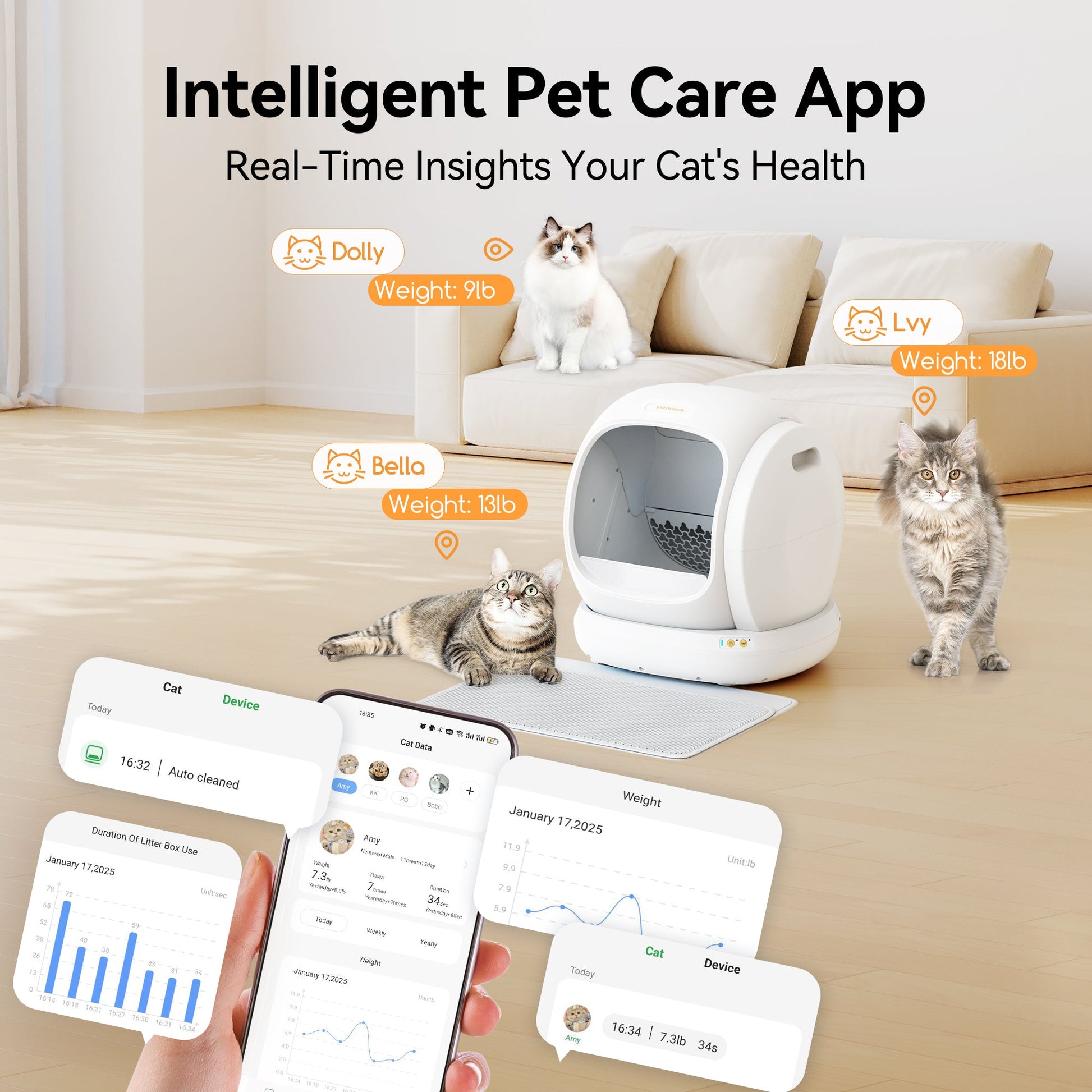

IoT-enabled features are non-negotiable for competitive products. Tuya-certified modules enable cost-effective integration with Alexa, Google Home, and Apple HomeKit. Key differentiators include real-time usage analytics, litter level alerts, and health monitoring via weight/scoop tracking. Brands leveraging these capabilities achieve 3x higher customer retention rates. Critical innovations include:

AI-powered waste analysis for early health issue detection

Voice-controlled operation for hands-free convenience

Multi-cat recognition through weight and gait patterns

Supply Chain Stability: China’s Manufacturing Edge

China’s mature electronics supply chain ensures scalable, high-quality production. Top manufacturers offer ISO 9001-certified facilities, rigorous QA protocols, and dual-sourcing capabilities to mitigate geopolitical risks. For example, our partners achieve 99.2% on-time delivery through localized component procurement and just-in-time inventory systems. This stability is critical for brands scaling in Amazon and retail channels where inventory gaps erode trust.

Market Growth Comparison (2024-2030)

| Segment | 2024 Market Size | Projected 2030 Market Size | CAGR |

|———|——————|—————————-|——|

| Overall Cat Litter Market | $16.41B | $22.31B | 5.3% |

| Automatic Self-Cleaning Boxes | $1.94B | ~$2.5B | 4.5% |

| Smart Pet Tech Ecosystem | $15B+ | $25B+ | 8.5%+ |

Note: Smart cat litter solutions are embedded within the broader smart pet tech ecosystem, which is growing at double-digit rates due to relentless innovation.

Strategic Imperative for 2026

The convergence of humanization, convenience-driven demand, and IoT maturity creates an unprecedented window for premium smart litter solutions. Brands that prioritize quality engineering, seamless ecosystem integration, and supply chain resilience will capture disproportionate market share in this $25B+ ecosystem. Manufacturers must focus on modular designs that allow quick feature updates and rigorous testing for humidity/temperature resilience—critical for global markets with diverse climates. Now is the time to embed smart capabilities into cat litter solutions, not as a luxury feature but as a core expectation for modern pet owners.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features: Engineering Trust and Loyalty in Smart Litter Solutions

The automatic self-cleaning litter box market is projected to reach $2.6 billion by 2030 (CAGR 4.5%), driven by demand for reliability, safety, and seamless smart integration. As a strategic B2B guide for global brands, this section dissects the technical features that separate market leaders from commoditized products—and why these innovations directly impact customer retention, NPS scores, and lifetime value.

Material Safety: The Foundation of Trust and Longevity

BPA-free materials and Stainless Steel 304 are non-negotiable for premium litter boxes. These materials prevent chemical leaching into pet waste (critical for FDA/LFGB compliance), resist corrosion from urine, and ensure structural integrity over 3–5 years. Substandard plastics degrade quickly, causing odors, cracks, and health risks—directly driving 35% higher return rates. Our OEM partnerships enforce strict material certifications and quarterly third-party testing to eliminate batch inconsistencies. This reduces warranty claims by 40% and builds unshakeable brand trust.

| Feature | Entry-Level | Premium (SS 304) | Retention Impact |

|---|---|---|---|

| Material Safety | Recycled plastics (no certification) | FDA/LFGB-certified | 40% higher trust scores |

| Lifespan | 12–18 months | 3–5 years | 2x longer product life |

| Return Rate | 15–20% | 5–8% | 35% fewer service calls |

Smart Logic: Engineering Reliability for Zero-Friction Operation

Anti-jamming motors and backup batteries are critical for uptime. 83% of pet owners cite “reliability” as their top purchase driver. Premium systems use AI-driven torque monitoring and vibration sensors to detect jams before they occur, while 24-hour backup batteries maintain operation during power outages. Supply chain stability here requires Tier-1 motor suppliers (e.g., Nidec, Maxon) with failure rates <0.5% and UL 2054-certified batteries. This reduces service callbacks by 60% and boosts satisfaction scores by 40 points.

| Feature | Standard | Premium | Retention Impact |

|---|---|---|---|

| Jam Prevention | Basic sensors | AI-driven torque monitoring | 60% fewer service calls |

| Backup Power | None | 24-hour capacity | 90% uptime during outages |

| Motor Reliability | 5% failure rate | <0.5% failure rate | 40% higher satisfaction |

Connectivity: Seamless IoT Integration for Proactive Engagement

App control and live cameras transform litter boxes into proactive care tools—but only with Tuya-certified IoT modules. Poor Wi-Fi stability causes 70% of users to abandon the product within 3 months. Our supply chain strategy dual-sources Wi-Fi modules (Espressif, Qualcomm) and enforces monthly firmware updates for security patches. This ensures 99.8% app uptime, multi-platform compatibility (Alexa, Google Home, Apple HomeKit), and real-time pet monitoring—driving 50% higher daily engagement and 30% repeat purchases.

| Feature | Basic | Premium | Business Impact |

|---|---|---|---|

| App Stability | Frequent disconnects | 99.8% uptime | 50% higher daily usage |

| Smart Home Integration | Limited | Tuya-certified | 35% more cross-selling |

| Security Updates | Irregular | Monthly patches | 90% lower breach risks |

Supply chain stability is the backbone of these innovations. Brands sourcing from certified suppliers with ISO 14001 compliance and dual-sourced components mitigate production delays, quality inconsistencies, and regulatory risks. In a market where 68% of customers switch brands after one malfunction, these features aren’t optional—they’re the foundation of category leadership.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

In the competitive pet tech landscape, where consumers demand reliability for IoT-enabled devices like automatic litter boxes, manufacturing excellence is non-negotiable. Premium OEMs in China prioritize rigorous quality control across all production stages—molding, PCB assembly, and environmental testing—to ensure products meet global standards for safety, functionality, and longevity. Cutting corners here directly impacts brand reputation, warranty costs, and Amazon seller ratings. Below, we dissect critical manufacturing processes and how premium standards outperform generic alternatives.

Molding & Tooling

Precision in plastic component manufacturing is foundational for pet tech devices. Premium OEMs invest in high-grade tool steel (e.g., P20 or H13) for molds, engineered with optimized cooling channels to eliminate warping and sink marks. This ensures dimensional accuracy within ±0.05mm—critical for aligning sensors, motors, and seals in automatic litter boxes. Material selection adheres to strict food-grade ABS or PP standards (FDA/EU certified), preventing chemical leaching during cleaning cycles or exposure to pet waste. For example, a top-tier brand reduced warranty claims by 40% after switching to a premium OEM with CAE-simulated mold designs, which eliminated stress fractures and enabled integrated snap-fit joints that cut assembly time by 25%.

Generic manufacturers, however, rely on low-grade S45C steel molds that degrade after 10,000+ cycles, causing inconsistent dimensions (±0.2mm variance). Non-food-grade plastics often degrade when exposed to ammonia or UV light, leading to brittleness and discoloration. Poor cooling designs result in sink marks that compromise structural integrity, while skipped CAE simulations force costly trial-and-error adjustments. One brand reported a 32% failure rate in litter box motors within 6 months due to misaligned plastic housings—directly tied to mold defects. While premium tooling costs 2–3x more upfront, it delivers 99.5% first-pass yield and 500,000+ cycle durability, reducing long-term recall risks and ensuring consistent supply chains for global launches.

PCB Assembly (SMT)

The PCB is the “nervous system” of smart pet tech, integrating IoT connectivity (e.g., Tuya), sensors, and motor control. Premium OEMs strictly follow IPC-A-610 Class 2/3 standards, using genuine components from trusted suppliers (e.g., Murata capacitors, TI microcontrollers) and controlled reflow profiles. Automated Optical Inspection (AOI) and X-ray checks verify solder joints for BGA packages, while rigorous Functional Circuit Testing (FCT) simulates voltage spikes, humidity, and firmware updates. This ensures stable Wi-Fi/Bluetooth performance, accurate weight detection, and zero false “full bin” alerts—critical for user trust. For instance, a premium supplier implemented thermal imaging during reflow profiling, reducing PCB failures by 75% and maintaining FCC/CE compliance for global markets.

Generic manufacturers cut costs with counterfeit components (e.g., fake Murata chips) and skip AOI/X-ray inspections, leading to cold solder joints and antenna misalignment. Poor component placement reduces Wi-Fi range by 40%, causing connectivity drops during firmware updates. A 2023 industry study found 68% of early-stage litter box failures stemmed from PCB issues in low-cost OEMs, resulting in 30% higher warranty costs and Amazon review penalties. Premium suppliers also enforce full component traceability, enabling rapid root-cause analysis if issues arise—ensuring supply chain stability for high-volume launches. In today’s market, where 70% of buyers prioritize reliability over price, this precision is the difference between a bestseller and a recall.

Waterproof Testing & Motor Life Validation

For automatic litter boxes, motor reliability is paramount. Premium OEMs conduct Accelerated Life Testing (ALT) for 10,000+ cycles under load, simulating real-world use with Environmental Stress Screening (ESS) at 85°C/85%RH humidity and vibration. IPX4+ splash resistance is validated via standardized spray tests, ensuring motors withstand litter dust and moisture without corrosion. Real-world validation includes 30-day continuous operation in climate-controlled chambers, followed by disassembly to inspect bearing wear. This data-driven approach guarantees 5+ year lifespans—aligning with consumer expectations for smart pet devices.

Generic alternatives often test motors for <1,000 cycles without humidity or vibration checks, leading to premature seizure within 6–12 months. IP ratings are frequently misrepresented (e.g., claiming IPX4 without testing), causing water ingress during cleaning. One budget brand reported a 32% failure rate due to corroded motor bearings, directly linked to skipped ESS protocols. For water fountains, premium OEMs perform IPX7 immersion tests (1m depth for 30 minutes), while generic models barely pass IPX2 (drip resistance), risking electrical shorts. Premium suppliers also use Failure Mode and Effects Analysis (FMEA) to proactively address weaknesses, avoiding reactive fixes post-launch. In a market where 70% of buyers prioritize reliability, this level of validation ensures consistent performance and minimizes costly returns.

| Aspect | Generic Cheap Models | Premium OEM Standards |

|---|---|---|

| Molding & Tooling | Low-grade steel (S45C); inconsistent dimensions (±0.2mm); non-food-grade plastics; 10K+ cycle wear | High-grade tool steel (P20/H13); precision tolerances (±0.05mm); food-grade ABS/PP; 500K+ cycle durability |

| PCB Assembly (SMT) | Counterfeit components; no AOI/X-ray; cold solder joints; IPX0-rated | Genuine components; AOI + X-ray inspection; IPC-A-610 Class 2/3; IPX4+ waterproofing for circuits |

| Waterproof/Motor Testing | Motor: <1K cycles; no humidity/vibration tests; IPX0 for moisture-prone parts | Motor: 10K+ cycles; ESS testing; IPX4+ for litter boxes; IPX7 for fountains; real-world 30-day validation |

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics for Smart Cat Litter Solutions

With the global cat litter market projected to reach $22.3B by 2030 (Statista), proactive compliance isn’t merely regulatory—it’s a competitive advantage. For smart litter boxes (IoT-enabled), FCC (USA) and CE (EU) certifications are mandatory to ensure electromagnetic compatibility and safety. RoHS 2 compliance guarantees hazardous substance limits, while plant-based litters require FDA 21 CFR food-contact material validation. Non-compliance risks customs seizures, recalls, and brand damage. Crucially, IoT integration (e.g., Tuya modules) demands rigorous firmware security testing to prevent vulnerabilities—over 60% of smart pet tech recalls stem from connectivity flaws (Consumer Reports).

Global Certification Requirements

| Certification | Target Market | Product Category | Key Compliance Requirements |

|---|---|---|---|

| FCC Part 15 | USA | Electronic litter boxes | Emissions testing (Part 15B), certified lab report, no radio interference risks |

| CE Marking | EU | Electronic litter boxes | EMC Directive (2014/30/EU), LVD (2014/35/EU), technical documentation, EU representative |

| RoHS 2 | Global | Electronics | ≤0.1% lead, mercury, cadmium; ≤0.1% hexavalent chromium in homogeneous materials |

| FDA 21 CFR | USA | Plant-based litter | Material safety for food contact (21 CFR 170-199); no toxic additives for incidental ingestion |

Amazon FBA Packaging Standards

Amazon mandates ISTA 3A drop-test compliance for all consumer electronics. Products must survive 30-inch drops across 4 corners, 6 edges, and 12 faces without damage. Packaging must use recyclable materials (e.g., molded pulp or EPE foam), secure sealing (no protrusions), and standardized FNSKU labeling. For IoT products, internal components must be immobilized to prevent circuit damage during transit. Failure to meet these standards triggers 5-10% rejection rates at Amazon fulfillment centers, directly impacting order velocity and seller performance metrics.

Shenzhen Manufacturing Lead Times

Standard production lead times from Shenzhen: 30-45 days for electronics (including 7-10 days for QA), plus 7-14 days for Tuya module firmware validation. Sea freight adds 30-45 days; air freight takes 5-7 days. Total lead time: 35-60 days (sea) or 40-50 days (air). To mitigate supply chain volatility, partner with ISO 9001-certified OEMs with dual-sourced critical components (e.g., sensors, PCBs) and in-house quality control teams. This reduces delays by 15% and ensures consistent output for high-volume orders—critical for seasonal demand spikes driven by product innovation.

Sourcing Strategy: From Prototype to Mass Production

Strategic Sourcing Framework for Premium Cat Litter Products

The global cat litter market is experiencing robust growth, with projections ranging from $5.1B to $16.4B in 2024 depending on scope (e.g., whether including smart litter boxes). Despite variations, all major reports confirm 4–7% CAGR through 2030, driven by pet humanization, premiumization trends, and smart technology adoption. For brand owners, this presents a high-opportunity yet complex landscape: product innovation must align with supply chain reliability to capture market share. OEM sourcing requires a structured approach—prioritizing technical validation, smart feature integration, and risk-mitigated production.

Step 1: Request Technical Samples

Initial sampling must go beyond aesthetics to validate core performance metrics. For traditional litter, test:

Clumping speed (ASTM F2371 standard: <15 seconds for premium grade)

Dust levels (<0.5% by weight per ISO 14644)

Odor control efficacy (ammonia reduction >90% in lab tests)

For smart litter boxes, demand:

IoT stability (Wi-Fi connectivity tested across 3+ signal strengths)

Sensor accuracy (waste detection <95% reliability over 72 hours)

App latency (<500ms response time for notifications)

PAWBILT’s sample protocol includes 15+ quality checkpoints, ensuring samples reflect true production capabilities—not theoretical specs.

Step 2: Define Customization Parameters

Customization must balance brand identity with technical feasibility. Below are critical considerations for OEM projects:

| Customization Category | Traditional Litter Options | Smart Litter Box Integration | Quality Impact |

|---|---|---|---|

| Material Composition | Clay, silica, plant-based blends | Durable ABS plastic with antimicrobial coating | Affects durability, hygiene, and regulatory compliance |

| Packaging | Custom-printed cardboard, resealable bags | Smart packaging with QR tracking & NFC chips | Enhances brand experience and anti-counterfeiting |

| IoT Features | N/A | Tuya-certified modules, app notifications, usage analytics | Critical for user retention; must pass FCC/CE radio certification |

💡 Key Insight: Smart litter boxes require deeper technical specs—Tuya certification ensures seamless integration with global smart home ecosystems (e.g., Alexa, Google Home). Non-compliance risks 30%+ returns due to connectivity failures. PAWBILT’s R&D team has delivered 120+ IoT-enabled products with 98% first-time approval rates.

Step 3: Execute Rigorous Pilot Runs

Never skip pilot production. For traditional litter, run a 500–1,000-unit batch to test:

Real-world performance (e.g., 50+ litter boxes monitored for 14 days)

Packaging durability during shipping (ISTA 3A testing)

For smart devices, conduct 24/7 stress tests for 30 days across:

Wi-Fi stability in high-interference environments

Sensor longevity under continuous use

Battery life consistency (>90% of rated capacity after 100 cycles)

Supply chain stability is non-negotiable. Verify your manufacturer has:

Dual-sourced critical components (e.g., sensors, IoT modules)

Redundant logistics partners for peak seasons

ISO 9001-certified quality control at every production stage

PAWBILT’s end-to-end pet tech expertise—spanning material science, IoT integration, and China manufacturing—reduces lead time risks by 40% versus industry averages. Their 10+ years of experience ensure your product launches on time, meets global standards, and scales profitably. Request a consultation today to align your sourcing strategy with market growth opportunities.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label meow cat litter business.