Introduction: Navigating the Global Market for animal waterer mold

In the competitive landscape of animal husbandry, sourcing high-quality animal waterer molds is a pivotal challenge that can significantly impact operational efficiency and animal welfare. Mold contamination in waterers not only poses health risks to livestock but can also lead to costly downtime and product losses for businesses. This guide aims to equip international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the insights needed to navigate the complexities of the animal waterer mold market.

Throughout this comprehensive guide, we will explore various types of animal waterer molds, their applications across different agricultural sectors, and effective strategies for supplier vetting. Additionally, we will provide insights into pricing structures, enabling buyers to make informed decisions based on quality and cost-effectiveness. By addressing critical factors such as mold prevention, maintenance best practices, and the implications of mold growth on animal health, this guide empowers businesses to enhance their purchasing strategies and ensure the longevity of their investments.

With a focus on actionable insights, we will help you identify reliable suppliers and optimize your procurement processes, paving the way for better health outcomes for your animals and increased productivity for your operations.

Inhoudsopgave

- Top 5 Animal Waterer Mold Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for animal waterer mold

- Understanding animal waterer mold Types and Variations

- Key Industrial Applications of animal waterer mold

- 3 Common User Pain Points for ‘animal waterer mold’ & Their Solutions

- Strategic Material Selection Guide for animal waterer mold

- In-depth Look: Manufacturing Processes and Quality Assurance for animal waterer mold

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘animal waterer mold’

- Comprehensive Cost and Pricing Analysis for animal waterer mold Sourcing

- Alternatives Analysis: Comparing animal waterer mold With Other Solutions

- Essential Technical Properties and Trade Terminology for animal waterer mold

- Navigating Market Dynamics and Sourcing Trends in the animal waterer mold Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of animal waterer mold

- Strategic Sourcing Conclusion and Outlook for animal waterer mold

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding animal waterer mold Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Black Mold | Dark, circular spots; thrives in damp, warm environments. | Poultry farms, livestock barns. | Voordelen: Often indicates poor water management; Minpunten: Can cause health issues in animals. |

| Green Algae | Slimy, green coating; thrives in sunlight and stagnant water. | Aquaculture, fish farms. | Voordelen: Generally harmless to animals; Minpunten: Affects water quality and aesthetics. |

| White Mold | Cotton-like appearance; grows in high humidity. | Animal shelters, veterinary clinics. | Voordelen: Easy to identify; Minpunten: Indicates moisture issues that may require structural fixes. |

| Fungal Spores | Microscopic spores; may not be visible until symptoms appear. | Dog kennels, pet grooming facilities. | Voordelen: Can be treated with antifungal solutions; Minpunten: May lead to respiratory issues in pets. |

| Mycotoxin-Producing Mold | Produces toxic substances; can affect animal health severely. | Livestock feed production, dairy farms. | Voordelen: Awareness can prevent contamination; Minpunten: Requires strict monitoring and management. |

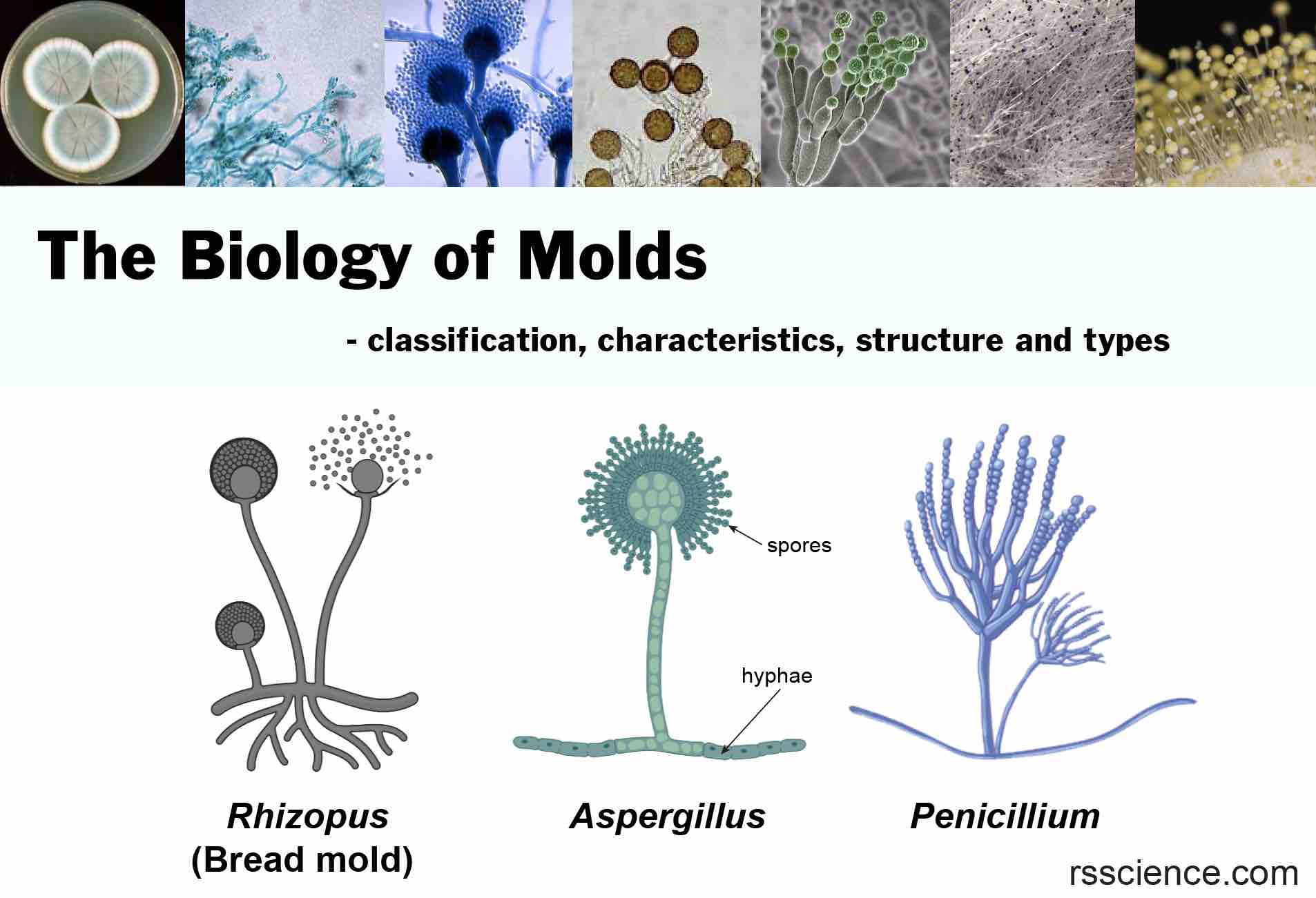

What Are the Characteristics and Suitability of Black Mold in Animal Waterers?

Black mold is characterized by dark, circular spots that often appear in damp, warm environments. This type of mold thrives in stagnant water, making it a significant concern for poultry farms and livestock barns. B2B buyers must consider the health implications associated with black mold, as it can lead to respiratory issues and other health problems in animals. Regular cleaning and proper water management practices are essential to prevent its growth.

How Does Green Algae Impact Aquaculture and Fish Farms?

Green algae presents as a slimy, green coating that often develops in sunlight and stagnant water conditions. While it is generally harmless to animals, it can significantly affect water quality and aesthetics, making it a concern for aquaculture and fish farms. Buyers should consider the implications of algae growth on water filtration systems and the overall health of aquatic life. Implementing proper water circulation and filtration can mitigate its growth.

What Should Buyers Know About White Mold in Animal Shelters?

White mold appears as a cotton-like substance and typically grows in areas with high humidity. This type of mold is commonly found in animal shelters and veterinary clinics. It serves as an indicator of moisture problems that may require structural fixes. For B2B buyers, it’s crucial to address the underlying causes of humidity to maintain a healthy environment for animals. Regular inspections and moisture control measures are recommended.

Why Are Fungal Spores a Concern in Pet Grooming Facilities?

Fungal spores are microscopic and may not be visible until they cause symptoms in animals. They can thrive in various environments, particularly in dog kennels and pet grooming facilities. B2B buyers should be aware that exposure to these spores can lead to respiratory issues in pets. Regular cleaning and the use of antifungal solutions can help manage their presence, ensuring a safer environment for both animals and staff.

What Are the Risks of Mycotoxin-Producing Mold in Livestock Feed Production?

Mycotoxin-producing mold generates toxic substances that can severely affect animal health. It is particularly relevant in livestock feed production and dairy farms, where contamination can lead to significant economic losses. B2B buyers must prioritize monitoring and management strategies to prevent mycotoxin contamination. This includes regular testing of feed and water sources to ensure the safety and health of livestock, thereby protecting their investment.

Key Industrial Applications of animal waterer mold

| Industrie/sector | Specific Application of animal waterer mold | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Poultry Farming | Production of automatic waterers for chickens | Reduces labor costs and ensures consistent hydration | Durability of mold, ease of cleaning, and resistance to algae |

| Aquaculture | Molds for fish and shrimp feeding systems | Enhances water quality management and reduces waste | Material safety, compatibility with aquatic environments |

| Livestock Management | Custom molds for cattle and sheep waterers | Promotes animal health and reduces disease transmission | Adaptability to different climates and ease of maintenance |

| Pet Care Products | Molds for automatic pet water dispensers | Increases pet health and convenience for owners | Non-toxic materials and ease of use for diverse pet types |

| Agricultural Equipment | Molds for multifunctional watering systems | Streamlines operations and improves water efficiency | Versatility in design and material longevity under various conditions |

How is Animal Waterer Mold Utilized in Poultry Farming?

In poultry farming, animal waterer molds are crucial for creating automatic watering systems that ensure chickens receive a steady supply of fresh water. This application significantly reduces labor costs, as farmers do not need to refill water containers manually. Additionally, these systems help maintain optimal hydration levels, which is vital for poultry health and productivity. Buyers should consider the durability of the mold and its resistance to algae, especially in warm climates prevalent in regions like Africa and South America.

What Role Does Animal Waterer Mold Play in Aquaculture?

In aquaculture, molds are used to manufacture feeding systems that also provide water to fish and shrimp. These systems enhance water quality management by minimizing waste and preventing the buildup of harmful substances. For international buyers, particularly in the Middle East, sourcing molds that are made from safe, non-toxic materials is essential to ensure the health of aquatic life. The design must also accommodate various aquatic environments, which can vary significantly based on location.

How is Animal Waterer Mold Applied in Livestock Management?

For livestock management, custom molds are employed to produce waterers tailored for cattle and sheep. These molds address the need for consistent water supply, which is crucial for animal health and productivity. They also help reduce the transmission of diseases by maintaining cleaner water. Buyers in Europe, particularly in Germany, should look for molds that are adaptable to different climates and easy to maintain, as these factors can greatly impact the effectiveness of the watering systems.

How Do Animal Waterer Molds Benefit the Pet Care Industry?

In the pet care industry, molds are utilized to create automatic water dispensers that provide pets with a constant supply of fresh water. This application not only enhances pet health by ensuring proper hydration but also offers convenience for pet owners. When sourcing these molds, it is vital to select non-toxic materials and designs that accommodate various pet types. International buyers should also consider the ease of use and cleaning, as these factors can influence customer satisfaction.

What Advantages Does Animal Waterer Mold Offer in Agricultural Equipment?

Animal waterer molds are increasingly used in agricultural equipment to create multifunctional watering systems that streamline operations. These systems improve water efficiency and can be integrated into larger agricultural setups. Buyers should prioritize versatility in design and the longevity of materials, especially in diverse environmental conditions. This is particularly important for buyers from regions like South America and Africa, where climate variations can impact equipment performance.

3 Common User Pain Points for ‘animal waterer mold’ & Their Solutions

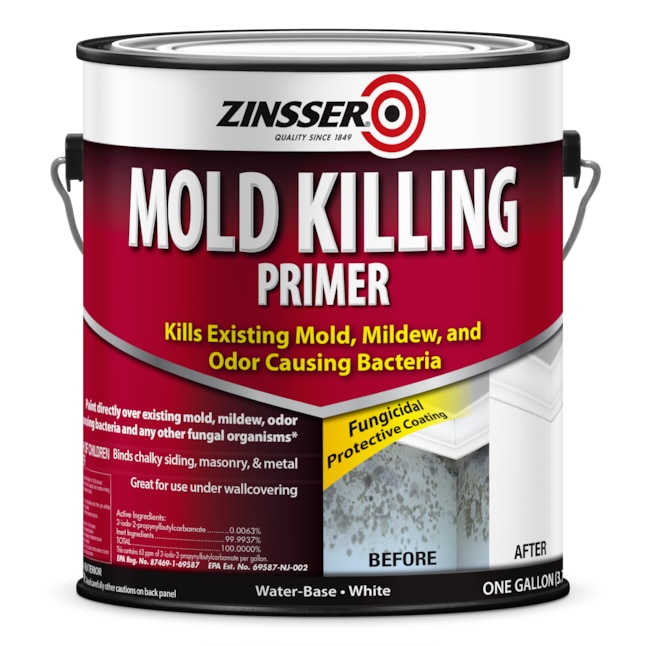

Scenario 1: Mold Growth in Automatic Waterers During Hot Weather

Het probleem: B2B buyers, such as farmers or pet suppliers, often face significant challenges with mold growth in automatic waterers, particularly in warmer climates. The combination of heat and humidity creates an ideal environment for mold spores to thrive, leading to contamination of the water supply. This not only jeopardizes the health of the animals relying on these waterers but can also result in costly downtime, requiring frequent cleaning and maintenance.

De oplossing: To combat mold growth effectively, it’s essential to invest in high-quality waterers designed with anti-microbial materials. These materials can inhibit mold development and provide a safer drinking environment for livestock or pets. Additionally, implementing a regular cleaning schedule is crucial. Use a diluted solution of vinegar and water to clean the waterers weekly, ensuring that any residual spores are eliminated. Consider adding a lid to the waterer to reduce exposure to airborne spores. By sourcing durable, mold-resistant products and maintaining cleanliness, B2B buyers can significantly reduce the risk of mold-related issues.

Scenario 2: Health Risks from Mold Contamination in Pet Water Bowls

Het probleem: Mold in water bowls can pose serious health risks to pets, including gastrointestinal disturbances and respiratory issues. B2B buyers, particularly those in the pet care industry, need to be aware that mold can release mycotoxins, which are harmful substances produced by certain molds. This can lead to costly health complications for the animals, as well as liability issues for the businesses involved in their care.

De oplossing: To mitigate these risks, B2B buyers should prioritize sourcing water bowls made from non-porous materials that are easier to clean and less likely to harbor mold. Regular maintenance is key; water bowls should be cleaned daily, and fresh water should be provided regularly to prevent stagnation. Implementing a system for tracking cleaning schedules can also enhance accountability among staff. Additionally, educating customers on the importance of maintaining clean water sources will foster better care practices and promote healthier pets.

Scenario 3: Cost Implications of Mold-Related Product Failures

Het probleem: The presence of mold in animal waterers not only affects animal health but can also lead to product failures and increased operational costs. For B2B buyers, this translates into financial losses due to the need for frequent replacements and potential legal ramifications from animal health issues. The challenge lies in balancing cost-effectiveness with ensuring high standards of hygiene and safety.

De oplossing: To address this, buyers should consider investing in waterers with built-in mold-resistant technology. While these may have a higher upfront cost, they can significantly reduce long-term expenses by minimizing maintenance and replacement needs. Additionally, conducting regular inspections and implementing preventive measures, such as using water treatment solutions that inhibit mold growth, can extend the lifespan of these products. Buyers should also evaluate their suppliers carefully, opting for those who provide guarantees and support for mold-resistant products, ensuring that their investment is protected. By strategically choosing high-quality, durable products, B2B buyers can safeguard their operations against the financial implications of mold contamination.

Illustrative image related to animal waterer mold

Strategic Material Selection Guide for animal waterer mold

What Are the Key Properties of Common Materials Used in Animal Waterer Molds?

When selecting materials for animal waterer molds, several factors must be considered, including durability, safety, and environmental resistance. Below, we analyze four common materials used in the production of these molds, focusing on their properties, advantages, and disadvantages.

1. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its high melting point (around 160°C) and excellent chemical resistance. It is lightweight yet strong, making it suitable for various applications, including animal waterers.

Pros & Cons:

The durability of polypropylene is a significant advantage, as it can withstand repeated use without degrading. It is also relatively inexpensive and easy to mold. However, it has lower UV resistance, which can lead to degradation when exposed to sunlight over time. Additionally, while it is resistant to many chemicals, it can be affected by certain solvents.

Invloed op de toepassing:

Polypropylene is compatible with water and is generally safe for animals. However, care must be taken to ensure that it does not come into contact with harsh chemicals that could compromise its integrity.

Overwegingen voor internationale kopers:

In regions like Europe and South America, compliance with food safety standards is critical. Buyers should ensure that the polypropylene used meets relevant regulations, such as those set by the European Food Safety Authority (EFSA) or local equivalents.

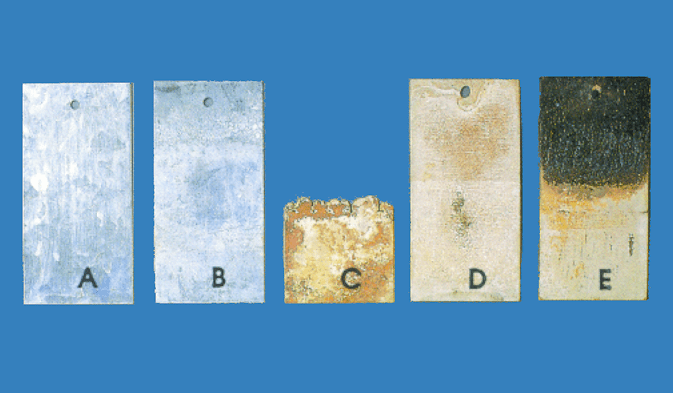

2. Stainless Steel

Key Properties:

Stainless steel is known for its high corrosion resistance and strength, with a melting point of approximately 1400-1450°C. It is highly durable and can withstand extreme temperatures and pressures.

Illustrative image related to animal waterer mold

Pros & Cons:

The main advantage of stainless steel is its longevity and resistance to rust and corrosion, making it ideal for outdoor applications. However, it is more expensive than plastic alternatives and can be heavier, which may affect transport and installation costs. Additionally, it may require special manufacturing processes, increasing production complexity.

Invloed op de toepassing:

Stainless steel is non-reactive, ensuring that it does not leach harmful substances into the water. This makes it an excellent choice for maintaining water quality, especially in regions with high temperatures that can promote bacterial growth.

Overwegingen voor internationale kopers:

Buyers in the Middle East and Africa should be aware of the varying grades of stainless steel and their respective corrosion resistance in saline environments. Compliance with standards such as ASTM or DIN is also essential.

Illustrative image related to animal waterer mold

3. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a thermoplastic known for its high strength-to-density ratio and resistance to impact and chemicals. It has a melting point of about 120°C and is highly resistant to UV radiation.

Pros & Cons:

HDPE is lightweight, cost-effective, and has excellent resistance to moisture, making it suitable for outdoor waterers. However, it can become brittle at low temperatures and may not be as durable as stainless steel in extreme conditions.

Invloed op de toepassing:

HDPE is safe for animal use and does not impart any taste or odor to the water. Its UV resistance makes it ideal for sunny climates, but it should be monitored for wear and tear over time.

Overwegingen voor internationale kopers:

In regions like Brazil, where humidity is high, HDPE’s moisture resistance is beneficial. Buyers should ensure that the material complies with local health regulations regarding food-grade plastics.

4. Silicone Rubber

Key Properties:

Silicone rubber is known for its flexibility and high-temperature resistance, with a service temperature range of -60°C to 230°C. It is also resistant to UV light and ozone.

Pros & Cons:

The flexibility of silicone makes it easy to mold into various shapes, which can be advantageous for creating custom waterer designs. However, it is generally more expensive than other materials and may not be as durable in the long term, especially when exposed to constant moisture.

Invloed op de toepassing:

Silicone is non-toxic and safe for animals, making it suitable for waterers. However, its susceptibility to wear from constant exposure to water can be a concern.

Overwegingen voor internationale kopers:

In Europe, compliance with REACH regulations is crucial for silicone products. Buyers should also consider the environmental impact of silicone disposal.

Summary Table of Material Selection for Animal Waterer Mold

| Materiaal | Typical Use Case for animal waterer mold | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Polypropylene (PP) | Indoor and outdoor waterers | Cost-effective and lightweight | Lower UV resistance | Laag |

| Stainless Steel | Durable outdoor waterers | High corrosion resistance | Higher cost and weight | Hoog |

| High-Density Polyethylene (HDPE) | Outdoor waterers in humid climates | Excellent moisture and UV resistance | Brittle at low temperatures | Medium |

| Silicone Rubber | Flexible, custom-designed waterers | Non-toxic and flexible | Higher cost and potential durability issues | Medium |

This analysis provides a comprehensive overview of the materials used in animal waterer molds, helping international B2B buyers make informed decisions based on their specific needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for animal waterer mold

What Are the Main Stages of the Manufacturing Process for Animal Waterer Molds?

The manufacturing process for animal waterer molds typically consists of several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers as they assess suppliers and their capabilities.

How is Material Prepared for Animal Waterer Molds?

Material preparation is the foundational step in the manufacturing process. It involves selecting high-quality plastics or metals that will withstand various environmental conditions, such as moisture, UV exposure, and temperature fluctuations. Common materials include polyethylene and polypropylene, known for their durability and resistance to mold growth.

Before fabrication, raw materials must be cleaned and dried to eliminate contaminants that could affect the final product’s quality. This step is critical, especially in regions with high humidity, where mold growth can compromise the integrity of the waterer.

What Techniques are Used in the Forming Stage of Animal Waterer Mold Manufacturing?

The forming stage employs various techniques, depending on the complexity of the design and material properties. Common methods include injection molding, blow molding, and rotational molding:

Illustrative image related to animal waterer mold

-

Injection Molding: This is the most prevalent method for producing plastic molds. It involves injecting molten plastic into a mold cavity, allowing for precise and intricate designs. It is efficient for high-volume production.

-

Blow Molding: Suitable for hollow shapes, blow molding involves inflating a heated plastic tube within a mold. This method is often used for larger waterers requiring a lightweight yet sturdy design.

-

Rotational Molding: This technique allows for the production of larger, seamless water containers. The plastic is heated and rotated in a mold, ensuring even distribution and thickness.

Each technique has its advantages, and the choice depends on factors such as the desired volume, complexity, and material.

How Does Assembly Work in the Production of Animal Waterer Molds?

Assembly involves integrating various components of the waterer, which may include fittings, spouts, and lids. This stage often requires precision to ensure that all parts fit together seamlessly, preventing leaks and ensuring functionality. Automated assembly lines are common for high-volume production, allowing for consistent quality and reduced labor costs.

What Finishing Processes Are Applied to Animal Waterer Molds?

Finishing processes enhance the product’s appearance and performance. These may include surface treatments to improve UV resistance, color application, and the addition of anti-microbial coatings to reduce mold growth. Quality control checks during the finishing stage ensure that all specifications are met before the products are packaged for distribution.

Illustrative image related to animal waterer mold

What Quality Assurance Measures Are Important for Animal Waterer Mold Production?

Quality assurance (QA) is critical in ensuring that animal waterer molds meet international standards and customer expectations. B2B buyers must be aware of the various QA measures that suppliers implement throughout the manufacturing process.

Which International Standards Should Buyers Consider for Quality Assurance?

International standards such as ISO 9001 play a significant role in quality management systems. ISO 9001 outlines requirements for a quality management system that can help organizations ensure consistent quality in their products and services. For the animal waterer mold industry, compliance with such standards indicates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications like CE marking in Europe and API (American Petroleum Institute) certification in certain markets can provide further assurance of product quality and safety.

Wat zijn de belangrijkste kwaliteitscontrolepunten in het productieproces?

Quality control checkpoints are essential for maintaining product integrity. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During production, random samples are tested to monitor quality at various stages. This helps identify any deviations early in the process.

-

Final Quality Control (FQC): Before shipping, the final products undergo rigorous testing, including dimensional checks, material integrity tests, and functional assessments.

These checkpoints help ensure that the final products meet the required specifications and are free from defects.

Hoe kunnen B2B-inkopers de kwaliteitscontroleprocessen van leveranciers controleren?

B2B buyers should take proactive steps to verify a supplier’s quality control processes to ensure reliability. Here are some effective methods:

What Auditing Processes Can Buyers Implement?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality control practices. Audits can be scheduled or surprise visits and should assess the supplier’s compliance with international standards, operational efficiency, and adherence to safety protocols.

How Important Are Quality Control Reports?

Requesting quality control reports from suppliers can help buyers evaluate performance metrics and compliance with standards. These reports should detail the outcomes of various quality checks and any corrective actions taken in case of deviations. Regular reporting indicates a transparent relationship and a commitment to quality.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough evaluations at different production stages, providing unbiased assessments of the supplier’s capabilities. This is particularly relevant for international transactions, where buyers may not have direct oversight.

What Are the Nuances of Quality Control Certification for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control certification is essential. Different regions may have specific regulations and standards that must be met. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations regarding product safety and quality.

Illustrative image related to animal waterer mold

Additionally, cultural differences in business practices can affect quality assurance expectations. Buyers should maintain open communication with suppliers, establishing clear quality requirements and timelines to ensure mutual understanding.

In conclusion, an in-depth understanding of the manufacturing processes and quality assurance measures for animal waterer molds is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions that ensure high-quality products for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘animal waterer mold’

In the competitive landscape of B2B procurement, sourcing high-quality animal waterer mold is essential for ensuring the health and well-being of livestock. This guide offers a practical checklist for international buyers, especially those in Africa, South America, the Middle East, and Europe, to streamline their sourcing process.

Step 1: Identify Your Specific Requirements

Before initiating the procurement process, clearly define the specifications for the animal waterer mold you need. Consider factors such as material durability, resistance to mold growth, and compatibility with your existing systems. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Illustrative image related to animal waterer mold

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in animal waterer mold. Look for companies with a solid reputation and experience in the industry. Utilize online platforms, trade shows, and industry associations to gather a list of potential suppliers.

- Consider regional suppliers: Local suppliers may offer advantages in terms of shipping costs and lead times.

- Check online reviews and testimonials: These can provide insights into supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that your selected suppliers comply with relevant industry standards and regulations. Certifications such as ISO 9001 or specific agricultural safety standards indicate a commitment to quality and safety.

- Request documentation: Ask for proof of compliance and certifications.

- Understand regional regulations: Familiarize yourself with any specific regulations that may apply in your target market.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the animal waterer mold from shortlisted suppliers. Testing these samples in your operational environment will help assess their performance and durability.

Illustrative image related to animal waterer mold

- Conduct performance tests: Evaluate the mold’s resistance to wear, ease of cleaning, and ability to prevent mold growth.

- Gather feedback from end-users: Involve staff who will be using the products to ensure they meet practical needs.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to finalize terms and conditions. Discuss pricing, delivery timelines, payment options, and warranty provisions.

- Be clear about expectations: Ensure that both parties have a mutual understanding of delivery schedules and product quality standards.

- Explore bulk purchase discounts: If you plan to order large quantities, negotiate for favorable pricing.

Step 6: Establish a Quality Control Process

Implement a quality control process to monitor the performance of the animal waterer mold upon delivery and during use. This step is crucial for maintaining product standards and ensuring the health of your animals.

- Set inspection criteria: Define what constitutes acceptable quality and performance.

- Monitor for mold growth: Regularly check for any signs of mold or deterioration and address issues promptly.

Step 7: Maintain Strong Supplier Relationships

Building strong relationships with suppliers can lead to better service and collaboration in the long run. Regular communication about performance and expectations can help in addressing any challenges that arise.

- Provide feedback: Share your experiences with the supplier to foster improvements.

- Explore long-term contracts: Consider establishing long-term agreements for consistent supply and support.

By following this checklist, B2B buyers can effectively navigate the procurement process for animal waterer mold, ensuring they select the best products for their needs while maintaining compliance and quality standards.

Comprehensive Cost and Pricing Analysis for animal waterer mold Sourcing

What Are the Key Cost Components in Animal Waterer Mold Sourcing?

When sourcing molds for animal waterers, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to animal waterer mold

-

Materialen: The primary materials used in mold production, such as high-density polyethylene (HDPE) or polypropylene, significantly affect the overall cost. Prices for these materials can fluctuate based on global supply chain dynamics, impacting your sourcing budget.

-

Arbeid: Labor costs vary by region, influenced by local wage standards and skill levels. In regions with higher labor costs, such as Europe, expect to pay more compared to countries in Africa or South America.

-

Productie Overhead: This includes costs associated with running production facilities, such as utilities, rent, and equipment depreciation. Efficient production processes can help mitigate overhead costs.

-

Gereedschap: The initial investment in tooling can be substantial but is essential for high-quality mold production. Custom tooling for unique designs will add to upfront costs.

-

Kwaliteitscontrole (QC): Ensuring that molds meet safety and quality standards is vital. QC processes may increase costs but can prevent expensive recalls and enhance product reliability.

-

Logistiek: Transportation and shipping costs vary widely depending on the distance from the manufacturing site and the chosen logistics provider. Incoterms will also influence these costs, affecting who bears responsibility for shipping and insurance.

-

Marge: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on supplier reputation, market demand, and competitive landscape.

How Do Price Influencers Affect Sourcing Decisions?

Several price influencers can significantly impact the final cost of animal waterer molds:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Negotiating for better pricing on bulk orders can enhance cost-efficiency.

-

Specificaties en aanpassingen: Customized molds tailored to specific requirements can incur additional costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Materialen: The choice of materials directly influences both the quality and cost. Premium materials may offer durability but come at a higher price point.

-

Quality and Certifications: Molds that meet specific industry certifications (e.g., FDA compliance for food safety) may cost more but can provide a competitive edge in the market.

-

Factoren van leveranciers: Supplier reliability, reputation, and experience play a critical role in pricing. Established suppliers may charge higher prices due to their track record but can offer better quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are the Best Practices for Negotiating Animal Waterer Mold Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Conduct Market Research: Understand the pricing landscape and benchmark against competitors to gain leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Assess not just the initial purchase price but also factors like maintenance, lifespan, and potential for mold contamination. This holistic view can guide better decision-making.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Regular communication and feedback foster trust.

-

Be Open to Compromise: Flexibility in order sizes, payment terms, or delivery schedules can encourage suppliers to offer better pricing.

What Should Buyers Be Aware of Regarding Indicative Prices?

It is important to note that prices for animal waterer molds can vary widely based on the factors discussed. Indicative prices should be treated as a starting point for negotiation rather than fixed costs. Fluctuations in material costs, labor rates, and shipping fees can all influence final pricing, making it essential for buyers to stay informed and adaptable in their sourcing strategies.

Alternatives Analysis: Comparing animal waterer mold With Other Solutions

When evaluating solutions to manage animal waterer mold, it’s essential to consider alternatives that address the same issue of maintaining clean, safe drinking water for livestock and pets. This analysis will compare animal waterer mold against two viable alternatives: automatic waterers and traditional water management practices. Each solution offers unique advantages and drawbacks that can significantly impact operational efficiency and animal health.

| Vergelijkingsaspect | Animal Waterer Mold | Automatic Waterers | Traditional Water Management |

|---|---|---|---|

| Prestaties | Effective in reducing mold growth under certain conditions | Provides continuous access to fresh water; reduces manual intervention | Dependence on manual cleaning and refilling; variable water quality |

| Kosten | Low initial cost, but potential high maintenance | Higher upfront investment, but low ongoing costs | Minimal investment, but labor-intensive and time-consuming |

| Gemak van implementatie | Simple to implement; requires minimal setup | Requires installation and possibly infrastructure changes | Easy to implement with existing resources |

| Onderhoud | Requires regular cleaning and monitoring | Low maintenance once set up; periodic checks needed | High maintenance due to manual cleaning and water replacement |

| Beste gebruikscasus | Suitable for small farms or hobbyists | Ideal for large-scale operations needing efficiency | Effective for small-scale or traditional farming methods |

How Do Automatic Waterers Compare to Animal Waterer Mold?

Automatic waterers are designed to deliver a constant supply of fresh water, minimizing the chance for mold growth. This solution significantly reduces the manual labor required for refilling and cleaning, making it ideal for larger operations or farms where time and labor costs are critical. However, the initial investment can be higher, and installation might require adjustments to existing infrastructure. The long-term benefits, such as reduced labor and improved animal health, often justify the cost.

What Are the Advantages and Disadvantages of Traditional Water Management Practices?

Traditional water management involves manually filling and cleaning water containers. This approach is straightforward and requires minimal investment, making it accessible for small-scale farmers. However, it is labor-intensive and may result in inconsistent water quality, especially if not managed regularly. Mold can easily develop if water is left stagnant or if containers are not cleaned frequently. While this method might suit hobbyists or smaller operations, it can lead to increased health risks for animals due to poor water quality.

Conclusion: Which Solution Should B2B Buyers Choose for Their Needs?

B2B buyers must assess their specific operational requirements when choosing a water management solution. For large farms or operations where efficiency and animal health are paramount, automatic waterers represent a superior choice despite their higher initial cost. Conversely, for smaller farms or hobbyists, traditional methods or animal waterer mold solutions may suffice, provided they are diligent in maintenance. Ultimately, understanding the balance between cost, ease of implementation, and long-term performance will guide buyers in selecting the most suitable option for their livestock management needs.

Essential Technical Properties and Trade Terminology for animal waterer mold

What Are the Key Technical Properties of Animal Waterer Mold?

When selecting molds for animal waterers, understanding the essential technical properties is crucial for ensuring product quality, durability, and compliance with industry standards. Here are some critical specifications to consider:

1. Material Grade

The material used in mold manufacturing significantly impacts the performance and lifespan of the waterer. Common materials include high-density polyethylene (HDPE) and polypropylene, both known for their durability and resistance to UV light and chemicals. Selecting the right material grade ensures the waterer can withstand harsh environmental conditions, making it a vital consideration for buyers, especially in regions with extreme weather.

2. Tolerance Levels

Tolerance refers to the permissible limits of variation in the dimensions of the mold. High precision in tolerance levels (typically ±0.01 mm for animal waterers) is essential to ensure that components fit together correctly and function as intended. Poor tolerance can lead to leaks or malfunctions, resulting in higher maintenance costs and reduced product lifespan. For B2B buyers, understanding tolerance requirements helps in sourcing reliable and efficient products.

3. Surface Finish

The surface finish of the mold affects not only the aesthetic appeal but also the hygiene of the waterer. A smooth finish reduces the likelihood of bacteria and mold growth, which is particularly important in animal husbandry. Buyers should prioritize molds with a high-quality finish to ensure ease of cleaning and maintenance, thus promoting animal health.

4. Heat Resistance

Animal waterers often operate in varying temperatures, and heat resistance is a critical property. Materials that can withstand high temperatures without deforming are necessary for outdoor applications. Understanding heat resistance helps buyers ensure that the waterer will maintain structural integrity under different climate conditions, especially in regions with high heat exposure.

5. Chemical Resistance

Waterers may be exposed to various cleaning agents and environmental pollutants. Selecting molds with high chemical resistance prevents degradation over time, ensuring the longevity of the product. This property is especially important for international buyers who must comply with local regulations regarding materials used in animal care.

Illustrative image related to animal waterer mold

What Common Trade Terms Should B2B Buyers Know in the Animal Waterer Mold Industry?

Familiarity with industry jargon can greatly enhance communication and negotiation processes in the B2B landscape. Here are some common terms that buyers should be aware of:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of animal waterers, understanding OEM relationships can help buyers identify quality suppliers who can provide customized solutions based on specific needs.

2. MOQ (minimale bestelhoeveelheid)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to avoid excess inventory and manage costs effectively. For smaller businesses or startups, negotiating MOQs can lead to better cash flow management.

3. RFQ (Offerteaanvraag)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This process helps buyers compare options and make informed purchasing decisions. Being familiar with the RFQ process allows buyers to effectively communicate their needs and receive competitive offers.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for ensuring clarity regarding shipping, risk, and insurance. This knowledge helps buyers avoid misunderstandings and ensures smooth logistics when importing waterer molds from different countries.

5. Doorlooptijd

Lead time refers to the time taken from placing an order to receiving the product. In the animal waterer mold industry, understanding lead times is essential for planning and inventory management. Buyers should consider lead times when making purchasing decisions to ensure they have the necessary supplies on hand, particularly during peak seasons.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in the animal waterer mold market, ultimately leading to better product performance and satisfaction.

Navigating Market Dynamics and Sourcing Trends in the animal waterer mold Sector

What Are the Key Market Drivers and Trends for Animal Waterer Mold?

The global market for animal waterer molds is experiencing significant growth, driven by a rising demand for efficient and sustainable livestock management practices. The increasing awareness of animal welfare, particularly in regions such as Africa, South America, the Middle East, and Europe, is pushing for innovations in water delivery systems that prioritize hygiene and functionality. Notably, the integration of technology, such as IoT-enabled smart waterers, is emerging as a key trend. These devices not only monitor water levels but also ensure the quality of water, reducing the risk of mold growth and contamination.

International buyers are increasingly focused on sourcing molds that facilitate easy cleaning and maintenance, as they recognize that hygiene directly impacts animal health and productivity. The demand for durable, high-quality materials is also rising, with manufacturers exploring advanced polymers that resist mold growth, thus minimizing health risks for livestock. Additionally, the trend towards customization is gaining momentum, allowing businesses to tailor molds to specific animal needs and environmental conditions, which is particularly important in diverse climates across the globe.

How Important Is Sustainability and Ethical Sourcing in the Animal Waterer Mold Industry?

Sustainability is becoming a pivotal consideration in the animal waterer mold sector. The environmental impact of production processes and materials is under scrutiny, with buyers increasingly seeking suppliers that adhere to sustainable practices. This includes the use of recyclable materials and the reduction of waste during manufacturing. Ethical sourcing is not just a trend but a necessity, as consumers and businesses alike are more informed and demanding about the origins of their products.

Illustrative image related to animal waterer mold

Certifications such as ISO 14001 for environmental management and the use of biodegradable materials can significantly enhance a supplier’s marketability. Moreover, buyers are looking for suppliers who can demonstrate a commitment to social responsibility, ensuring fair labor practices throughout the supply chain. This focus on sustainability not only meets regulatory requirements but also aligns with the values of end consumers, thus enhancing brand reputation and loyalty in a competitive market.

What Is the Historical Context of Animal Waterer Mold Development?

The development of animal waterer molds has evolved significantly over the past few decades. Initially, designs were rudimentary, focusing primarily on functionality rather than hygiene or sustainability. However, as agricultural practices advanced and the importance of animal health became more pronounced, manufacturers began to innovate. The introduction of materials that resist mold and bacterial growth has transformed the landscape, enabling producers to offer safer options for livestock.

In recent years, the emphasis has shifted towards integrating technology into waterer designs, with smart solutions providing real-time monitoring and control of water quality. This evolution reflects a broader trend in the agricultural sector, where efficiency, animal welfare, and environmental sustainability are increasingly intertwined. As the market continues to evolve, the focus will likely remain on creating innovative, effective, and sustainable solutions that meet the diverse needs of international buyers across various regions.

Frequently Asked Questions (FAQs) for B2B Buyers of animal waterer mold

-

How do I solve mold growth in animal waterers?

To effectively combat mold growth in animal waterers, regular cleaning is essential. Use a diluted bleach solution or a vinegar-water mix to scrub the surfaces, ensuring that all residues are removed. After cleaning, allow the waterer to dry completely before refilling it with fresh water. Additionally, consider incorporating anti-fungal agents or natural remedies like apple cider vinegar (ACV) in moderation. It’s also advisable to keep waterers in shaded, cooler areas to minimize heat exposure, which can promote mold growth. -

What is the best material for animal waterer mold?

The best materials for animal waterer molds are typically food-grade plastics or stainless steel. Food-grade plastics are lightweight and resistant to corrosion, making them ideal for outdoor use. Stainless steel offers durability and ease of cleaning, reducing the likelihood of mold buildup. When sourcing molds, ensure they meet international safety standards and are compliant with local regulations in your target markets, such as the EU or FDA standards in the U.S. -

How can I ensure quality when sourcing animal waterer molds internationally?

To ensure quality when sourcing animal waterer molds, conduct thorough due diligence on potential suppliers. Request samples to evaluate their product quality firsthand. Look for manufacturers with ISO certifications or those that adhere to international quality standards. Establish clear communication regarding your specifications and expectations, and consider visiting the supplier’s facility if feasible. Additionally, consider employing third-party quality assurance services to inspect products before shipment. -

What are typical minimum order quantities (MOQs) for animal waterer molds?

Minimum order quantities (MOQs) for animal waterer molds can vary significantly depending on the supplier and the complexity of the mold. Generally, MOQs can range from 100 to 1,000 units. It’s crucial to discuss your specific requirements with potential suppliers to negotiate favorable terms. Some manufacturers may offer lower MOQs for first-time buyers or if you are willing to pay a premium for smaller batches. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers. Common practices include a 30% deposit upon order confirmation and the remaining 70% prior to shipment. Some suppliers may offer letters of credit or payment through platforms like PayPal for added security. It’s essential to clarify payment terms upfront and ensure they align with your cash flow capabilities. Always use secure payment methods to protect your investment. -

How do I vet potential suppliers for animal waterer molds?

Vetting potential suppliers involves several steps. Start by researching their company background, including their years in business and reputation in the industry. Request references from previous clients to gauge their reliability and product quality. Additionally, assess their production capabilities and certifications. Online platforms like Alibaba provide reviews and ratings, which can be helpful in evaluating suppliers. Conducting a factory audit can also provide insights into their operational standards and practices. -

What logistics considerations should I keep in mind when importing animal waterer molds?

When importing animal waterer molds, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose between air freight for speed or sea freight for cost-effectiveness based on your urgency. Familiarize yourself with import duties and taxes applicable in your region. Collaborating with a freight forwarder can streamline the logistics process, ensuring compliance with all shipping documentation and regulations. -

How can I customize animal waterer molds to meet my specific needs?

Customization of animal waterer molds is often possible, depending on the manufacturer’s capabilities. Discuss your specific requirements, such as design modifications, material preferences, or branding options, during initial conversations with suppliers. Many manufacturers can accommodate custom designs with adequate lead times. Be prepared to provide detailed specifications and, if necessary, prototypes to ensure that the final product aligns with your expectations.

Top 5 Animal Waterer Mold Manufacturers & Suppliers List

1. Reddit – Chicken Waterers

Domein: reddit.com

Registered: 2005 (20 years)

Inleiding: Plastic waterers for chickens, prone to mold growth, especially in high temperatures. Users recommend regular cleaning with dish soap and water, using sanitizing wipes, and adding apple cider vinegar to the water. Alternatives include galvanized metal waterers, which can rust but are corrosion resistant, and glass waterers, which are easier to clean but more fragile. It’s suggested to elevate wate…

2. Facebook – Copper Pipe Chicken Waterer

Domein: facebook.com

Registered: 1997 (28 years)

Inleiding: copper pipe, chicken waterer, mold prevention, 5 months effectiveness

3. Braggs – Apple Cider Vinegar

Domein: backyardchickens.com

Registered: 2000 (25 years)

Inleiding: Braggs ACV (Apple Cider Vinegar)

4. Petwant – Smart Pet Feeders

Domein: petwant.com

Registered: 2011 (14 years)

Inleiding: Petwant offers various pet products including feeders, pet bowls, smart pet feeders, and drinking fountains made from plastic, stainless steel, and ceramic. The blog emphasizes the importance of regularly cleaning water bowls to prevent mold growth, which can make dogs sick by causing gastrointestinal disturbances, respiratory issues, allergic reactions, and neurological symptoms.

5. Country Homesteading – Stock Tanks & Algae Control Solutions

Domein: countryhomesteading.com

Registered: 2013 (12 years)

Inleiding: 60 gallon Rubbermaid stock tank; 100 gallon stock tanks; Copper sulfate (Stock Plex) for algae control; Rubbermaid automatic filler; Comet cleaner; Clorox for cleaning; Nylon brush for scrubbing; Fish for tank cleaning; Plastic tanks preferred over metal for safety and ease of cleaning.

Strategic Sourcing Conclusion and Outlook for animal waterer mold

In navigating the complexities of sourcing animal waterer molds, international buyers must prioritize quality, sustainability, and hygiene to ensure the health and well-being of livestock. Mold growth in waterers not only poses risks to animal health but can also impact operational efficiency and product quality. Regular cleaning and maintenance, along with the use of suitable materials, are essential strategies to mitigate these risks.

Investing in high-quality molds that are resistant to mold growth can lead to long-term savings and improved animal welfare. Buyers should engage with reputable suppliers who demonstrate a commitment to innovation and sustainability, offering products that align with international standards. Additionally, leveraging strategic sourcing practices can enhance supply chain resilience, ensuring timely availability of essential components while minimizing risks associated with contamination.

As the global market continues to evolve, it is crucial for buyers from regions such as Africa, South America, the Middle East, and Europe to stay informed about emerging trends and technologies in animal waterer mold production. This proactive approach will not only safeguard their investments but also foster healthier livestock and sustainable agricultural practices. Collaborate with industry leaders and make informed sourcing decisions to lead the way in responsible animal husbandry.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.