Introduction: Navigating the Global Market for how often to change nectar in hummingbird feeder

In the competitive landscape of bird care products, understanding how often to change nectar in hummingbird feeders is crucial for businesses aiming to cater to the needs of avian enthusiasts globally. This guide addresses a significant challenge faced by B2B buyers: ensuring optimal nectar freshness to attract and sustain hummingbird populations. The frequency of nectar changes can vary widely based on climate conditions, with warmer and humid environments necessitating changes every one to two days, while cooler climates may allow for up to four days.

In this comprehensive resource, we delve into various aspects of nectar management, including types of nectar, applications for different regions, and supplier vetting processes. Additionally, we will explore cost considerations and the impact of quality nectar on customer satisfaction and sales. By equipping international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Vietnam)—with the knowledge needed to make informed purchasing decisions, this guide aims to enhance product offerings and improve market competitiveness.

Ultimately, understanding the nuances of hummingbird nectar management not only promotes the well-being of these remarkable birds but also empowers businesses to meet the growing demand for quality bird care products, fostering a sustainable and profitable market.

Inhoudsopgave

- Top 4 How Often To Change Nectar In Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often to change nectar in hummingbird feeder

- Understanding how often to change nectar in hummingbird feeder Types and Variations

- Key Industrial Applications of how often to change nectar in hummingbird feeder

- 3 Common User Pain Points for ‘how often to change nectar in hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often to change nectar in hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often to change nectar in hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change nectar in hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often to change nectar in hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often to change nectar in hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often to change nectar in hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often to change nectar in hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often to change nectar in hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often to change nectar in hummingbird feeder

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding how often to change nectar in hummingbird feeder Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Temperature-Based Changing | Nectar change frequency varies with temperature. | Retailers in regions with fluctuating climates. | Voordelen: Tailored approach; Minpunten: Requires monitoring local weather. |

| Humidity Consideration | Adjusts nectar change frequency based on humidity levels. | Businesses in tropical and humid regions. | Voordelen: Prevents spoilage; Minpunten: May require additional resources for humidity tracking. |

| Seasonal Adjustments | Nectar change frequency varies seasonally. | Suppliers catering to different hemispheres. | Voordelen: Aligns with bird behavior; Minpunten: Requires knowledge of seasonal patterns. |

| Volume-Based Adjustments | Change frequency based on feeder capacity and visitor volume. | High-traffic feeding stations or parks. | Voordelen: Efficient use of resources; Minpunten: May underestimate or overestimate needs. |

| Type of Nectar | Different nectar types (commercial vs. homemade) affect spoilage rates. | Manufacturers and retailers of nectar products. | Voordelen: Customization for consumer preferences; Minpunten: Variability in quality control. |

What Are the Key Characteristics of Temperature-Based Nectar Changing?

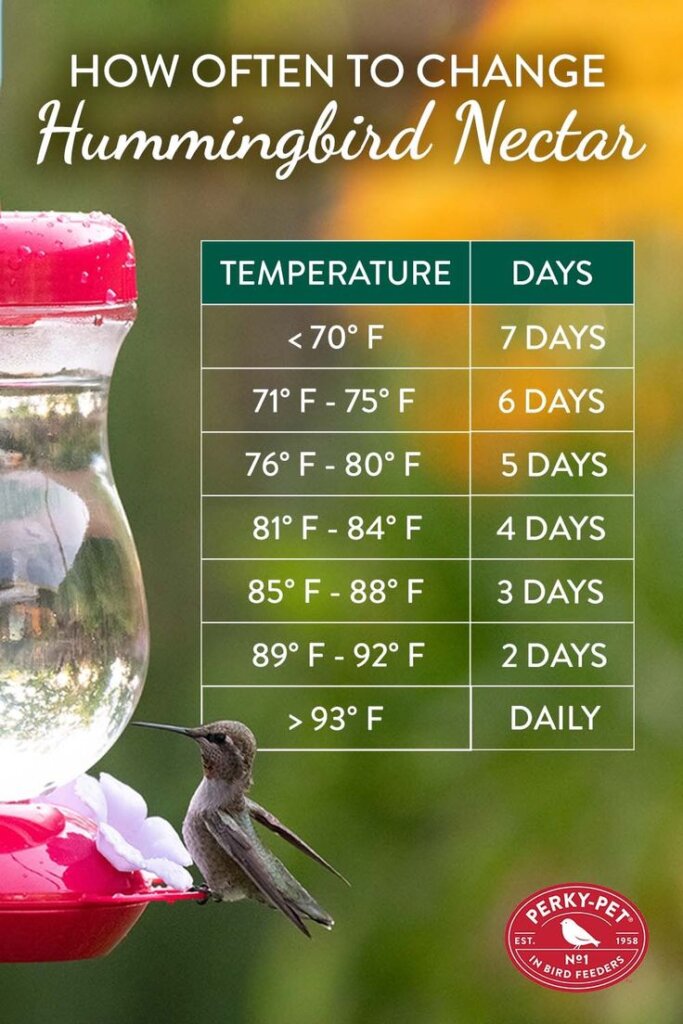

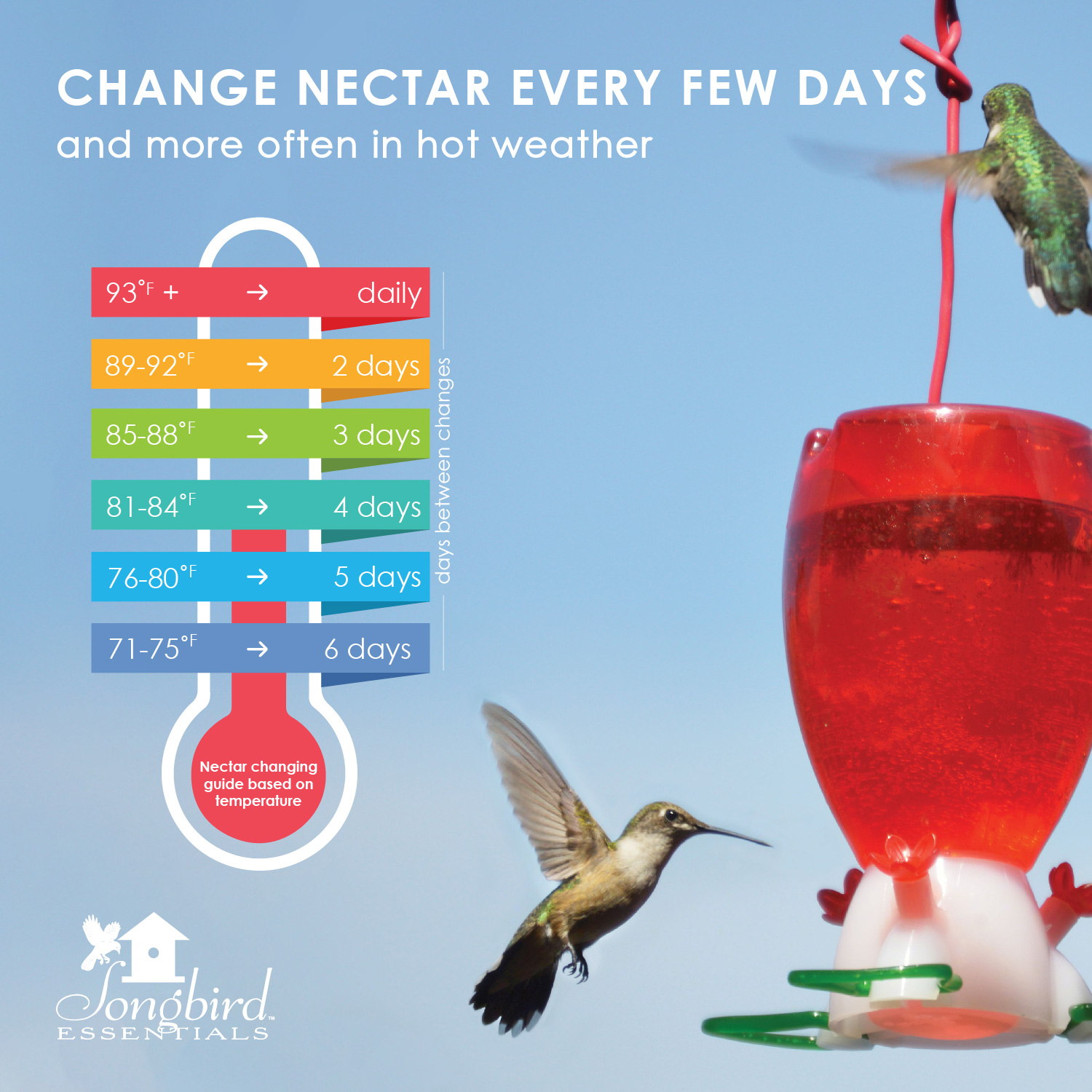

Temperature-based changing dictates that nectar should be replaced more frequently as temperatures rise. For example, in cooler climates, nectar can last 2-3 days, while in temperatures exceeding 90°F, changing it daily is crucial. This approach is particularly beneficial for retailers located in regions with drastic temperature fluctuations. Buyers should consider thermoregulation strategies to ensure optimal nectar quality, which can enhance customer satisfaction and bird visitation rates.

How Does Humidity Affect Nectar Change Frequency?

Humidity significantly impacts nectar spoilage; higher humidity levels can accelerate fermentation and mold growth. Businesses operating in humid environments, such as tropical regions, should adopt a more aggressive nectar changing schedule, potentially every 1-2 days. B2B buyers must invest in humidity monitoring tools to maintain nectar quality, ensuring that their offerings remain appealing to local bird populations and, in turn, attract more customers.

Why Are Seasonal Adjustments Important for Nectar Management?

Seasonal adjustments in nectar changing frequency align with the natural behaviors of hummingbirds, which may vary by region and time of year. Businesses serving different hemispheres or regions with distinct seasonal patterns should adopt flexible nectar management strategies. Understanding these seasonal variations can help suppliers optimize their inventory and improve customer engagement, as birds are more likely to visit feeders when nectar is fresh and readily available.

What Are the Benefits of Volume-Based Adjustments?

Volume-based adjustments consider the feeder’s capacity and the number of birds visiting it. High-traffic areas, such as parks and nature reserves, may require more frequent nectar changes to accommodate increased demand. This approach allows businesses to maximize resource efficiency while ensuring that they meet the needs of their customers. Buyers must assess visitor patterns and feeder capacities to effectively manage nectar supplies and maintain high service levels.

How Do Different Types of Nectar Influence Change Frequency?

The type of nectar—commercial versus homemade—can affect how quickly it spoils. Commercial products often contain preservatives that may extend shelf life, while homemade versions without additives may require more frequent changes. Suppliers and retailers should educate their customers about the differences to help them make informed choices. This knowledge can enhance customer loyalty and satisfaction, as consumers appreciate the transparency and quality assurance in their bird feeding products.

Key Industrial Applications of how often to change nectar in hummingbird feeder

| Industrie/sector | Specific Application of how often to change nectar in hummingbird feeder | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Agriculture | Optimizing nectar change frequency for pollinator attraction | Enhances crop yield through improved pollination rates | Local climate conditions and flower types influence nectar needs |

| Eco-Tourism | Providing accurate feeder maintenance schedules to enhance visitor experiences | Increases customer satisfaction and wildlife visibility | Availability of educational materials and feeder supplies |

| Wildlife Conservation | Implementing nectar management strategies for habitat restoration projects | Supports healthy hummingbird populations and biodiversity | Compliance with environmental regulations and sourcing native plants |

| Retail and E-commerce | Selling feeder maintenance products and nectar solutions | Drives sales through repeat purchases of nectar and cleaning supplies | Quality assurance of nectar ingredients and feeder materials |

| Research Institutions | Conducting studies on nectar spoilage and hummingbird behavior | Contributes to scientific knowledge and conservation efforts | Access to reliable data and collaboration with field experts |

How Can Agriculture Benefit from Nectar Change Frequency in Hummingbird Feeders?

In the agricultural sector, understanding the optimal nectar change frequency can significantly impact pollination efficiency. Farmers can attract more hummingbirds, which are vital pollinators, by ensuring feeders are regularly maintained. This leads to improved crop yields and healthier plants. Buyers in this sector should consider local climate conditions and the types of flora they cultivate, as these factors dictate how often nectar should be replenished.

What Role Does Eco-Tourism Play in Nectar Management for Hummingbird Feeders?

Eco-tourism businesses rely on creating memorable experiences for visitors, often centered around wildlife observation. By effectively managing nectar in hummingbird feeders, these businesses can enhance visitor interactions with hummingbirds, increasing customer satisfaction and repeat visits. It is essential for these enterprises to source educational materials and high-quality feeders that align with conservation practices, ensuring they provide accurate information to their guests.

How Does Wildlife Conservation Utilize Nectar Management Strategies?

Wildlife conservation efforts can benefit from implementing nectar management strategies in restoration projects. By ensuring that feeders are regularly cleaned and refilled, conservationists can support hummingbird populations and promote biodiversity in restored habitats. Buyers in this field must navigate environmental regulations and ensure that any nectar solutions used are safe for local wildlife, fostering a sustainable approach to conservation.

Why Is Retail and E-commerce Important in Nectar Supply Chains?

Retailers and e-commerce platforms that specialize in bird feeding products can capitalize on the demand for high-quality nectar and feeder maintenance supplies. By educating customers on the importance of changing nectar regularly, these businesses can encourage repeat purchases and build brand loyalty. Key considerations for sourcing include the quality of nectar ingredients, packaging, and the durability of feeder materials to withstand various climates.

How Can Research Institutions Leverage Nectar Change Frequency Data?

Research institutions focusing on avian studies can utilize data on nectar spoilage and hummingbird behavior to advance scientific understanding of these species. By conducting controlled studies on how nectar freshness affects hummingbird visitation rates, researchers can contribute valuable insights to conservation strategies. Collaborating with field experts and ensuring access to reliable data is critical for these institutions to maintain credibility and effectiveness in their research endeavors.

3 Common User Pain Points for ‘how often to change nectar in hummingbird feeder’ & Their Solutions

Scenario 1: Inconsistent Nectar Freshness Affects Bird Visits

Het probleem: Many B2B buyers, such as garden centers or wildlife conservation organizations, often face challenges ensuring that the nectar in their hummingbird feeders remains fresh. Inconsistent nectar freshness can deter hummingbirds from visiting, leading to a negative customer experience for those relying on birdwatching opportunities. This issue is particularly acute in warmer climates where nectar can spoil quickly, resulting in wasted resources and potential loss of customers who may turn to more reliable alternatives.

De oplossing: Establish a systematic approach to nectar management. Implement a schedule for changing nectar every 1-3 days, depending on the local climate conditions. For regions experiencing higher humidity or temperatures, a daily change is advisable. Educate staff on the importance of checking nectar levels and spoilage signs. Create an inventory system to ensure that fresh nectar is readily available and that feeders are cleaned regularly to prevent mold build-up. Providing clear signage around feeders to inform visitors about nectar freshness can enhance the overall experience and maintain bird traffic.

Scenario 2: Difficulty in Sourcing Quality Nectar Ingredients

Het probleem: Buyers, especially those operating in emerging markets, may struggle to find quality ingredients for homemade nectar or reliable commercial products without additives like dyes or preservatives. This challenge can lead to inconsistent nectar quality, potentially harming local bird populations and damaging the reputation of the business. Furthermore, a lack of understanding about the proper sugar-to-water ratio can lead to ineffective nectar solutions.

De oplossing: Build partnerships with reputable suppliers who specialize in bird feeding products. Look for vendors who offer organic or natural ingredients, and ensure they provide clear labeling and specifications on their products. For homemade nectar, adopt a standard recipe of four parts water to one part sugar and communicate this effectively to your team. Consider creating educational resources, such as workshops or informational pamphlets, to share best practices for preparing and storing nectar. This not only ensures quality but also enhances customer trust in your offerings.

Scenario 3: Seasonal Variability in Hummingbird Activity

Het probleem: Many businesses overlook the seasonal fluctuations in hummingbird activity, leading to either over-preparation or under-preparation of nectar supplies. During migration periods, hummingbird visitation can spike, while at other times, it may dwindle significantly. This inconsistency can affect inventory management and lead to losses if supplies are not aligned with actual demand.

De oplossing: Implement a data-driven approach to track hummingbird activity patterns in your region. Collaborate with local ornithological societies or utilize online resources to understand migration trends and peak feeding times. Use this information to adjust nectar preparation schedules and inventory levels accordingly. Consider creating promotional campaigns during peak migration periods to increase customer engagement and sales. By aligning your operations with the natural behavior of hummingbirds, you can optimize resource allocation and enhance customer satisfaction, ensuring that your feeders are always ready for their feathered visitors.

Strategic Material Selection Guide for how often to change nectar in hummingbird feeder

What Materials Are Best for Hummingbird Feeders and Nectar Management?

When considering the optimal materials for hummingbird feeders, particularly in relation to how often to change the nectar, several factors come into play. The choice of material affects not only the durability and functionality of the feeder but also the safety and health of the hummingbirds. Here, we analyze four common materials: glass, plastic, metal, and silicone.

How Does Glass Impact Nectar Management in Hummingbird Feeders?

Key Properties: Glass is non-porous and resistant to staining, making it an excellent choice for maintaining nectar quality. It can withstand high temperatures and is generally easy to clean, which is crucial for preventing mold and bacteria growth.

Pros & Cons: Glass feeders are durable and often aesthetically pleasing, appealing to consumers looking for decorative options. However, they can be heavy and prone to breakage, especially in outdoor settings. Additionally, the cost of glass feeders tends to be higher than plastic alternatives.

Impact on Application: Glass is compatible with all types of nectar, and its inert nature ensures that no harmful chemicals leach into the nectar. For international buyers, glass is often compliant with food safety standards, making it a preferred choice in regions with strict regulations.

What Role Does Plastic Play in Hummingbird Feeders?

Key Properties: Plastic feeders are lightweight and often designed to be weather-resistant, which is beneficial in varying climates. They can be molded into various shapes and sizes, providing flexibility in design.

Pros & Cons: The primary advantage of plastic is its affordability and ease of production. However, lower-quality plastics may degrade over time, especially under UV exposure, leading to potential chemical leaching. Buyers should be cautious about selecting BPA-free plastics to ensure safety.

Illustrative image related to how often to change nectar in hummingbird feeder

Impact on Application: Plastic feeders may require more frequent cleaning due to their susceptibility to mold and bacteria. International buyers should consider local regulations regarding plastic use, as some regions are moving towards more sustainable materials.

How Do Metal Feeders Affect Nectar Freshness?

Key Properties: Metal feeders, often made of aluminum or stainless steel, are highly durable and resistant to weathering. They can withstand extreme temperatures and are generally easy to clean.

Pros & Cons: The main advantage of metal feeders is their longevity and resistance to damage. However, they can become hot in direct sunlight, potentially affecting nectar temperature. Additionally, they may be more expensive than plastic options.

Impact on Application: Metal feeders are compatible with various nectar types but may require special coatings to prevent corrosion. International buyers should ensure compliance with local metal safety standards, particularly in regions with high humidity or salt exposure.

What Benefits Do Silicone Components Offer in Hummingbird Feeders?

Key Properties: Silicone is flexible, durable, and resistant to temperature extremes. It is often used in sealing applications to prevent leaks and maintain nectar freshness.

Pros & Cons: Silicone components can enhance the longevity of feeders by preventing leaks and ensuring a tight seal. However, they may not be as aesthetically pleasing as glass or metal options and can sometimes be more expensive to manufacture.

Impact on Application: Silicone is compatible with all types of nectar and is easy to clean. International buyers should consider the availability of silicone products in their region, as well as any specific regulations regarding food-safe materials.

Summary Table of Material Selection for Hummingbird Feeders

| Materiaal | Typical Use Case for how often to change nectar in hummingbird feeder | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Glass | Ideal for high-end feeders; requires changing nectar every 2-4 days depending on climate | Durable and aesthetically pleasing | Heavy and prone to breakage | Hoog |

| Kunststof | Commonly used for budget-friendly feeders; nectar should be changed every 1-3 days | Lightweight and affordable | May degrade and leach chemicals | Laag |

| Metal | Suitable for long-lasting feeders; nectar should be changed every 2-4 days | Highly durable and weather-resistant | Can become hot in the sun | Medium |

| Silicone | Used in seals and gaskets; helps maintain nectar freshness | Flexible and leak-proof | Less visually appealing | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers in the hummingbird feeder market, helping them choose the most suitable materials based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for how often to change nectar in hummingbird feeder

What Are the Key Stages in the Manufacturing Process of Hummingbird Nectar?

When it comes to the production of hummingbird nectar, understanding the manufacturing process is crucial for B2B buyers. The stages typically involve material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality ingredients, primarily refined sugar and purified water. For commercial products, it’s vital to ensure that the sugar is free from additives and dyes that may be harmful to birds. Suppliers must adhere to food safety regulations and may require certification from organizations like the FDA or EFSA.

-

Forming: In this stage, the sugar is dissolved in boiling water to create a concentrated nectar solution. The process must maintain a consistent ratio, usually four parts water to one part sugar, to mimic the natural nectar found in flowers. Automation in this stage can help ensure uniformity and reduce human error.

-

Assembly: After the nectar is prepared, it is packaged in sterile containers that are designed to prevent contamination. These containers are typically made from food-grade plastics or glass. The assembly process may also include labeling, which should comply with local regulations regarding ingredient disclosure and nutritional information.

-

Finishing: The final stage includes quality checks and packaging. This might involve sealing the containers to ensure freshness and prevent spoilage. Some manufacturers may also include tamper-proof seals to enhance product safety for consumers.

How Is Quality Assurance Implemented in Hummingbird Nectar Production?

Quality assurance (QA) is integral to ensuring that the nectar is safe for birds and meets consumer expectations. Various international standards, such as ISO 9001, guide manufacturers in establishing effective QA systems.

Illustrative image related to how often to change nectar in hummingbird feeder

-

International Standards Compliance: ISO 9001 outlines the criteria for a quality management system. Manufacturers must implement processes to consistently deliver products that meet customer and regulatory requirements. Compliance can help B2B buyers ensure that they are sourcing from reliable suppliers.

-

Industry-Specific Certifications: Depending on the region, additional certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) may be relevant. These certifications can assure buyers of the quality and safety of the nectar, especially in markets with stringent regulations.

What Are the Key Quality Control Checkpoints in Hummingbird Nectar Manufacturing?

Quality control (QC) is essential at various checkpoints during the manufacturing process to maintain high standards.

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival. The sugar and water must be tested for purity and contaminants. Buyers should inquire about the supplier’s IQC processes to ensure that only high-quality ingredients are used.

-

In-Process Quality Control (IPQC): During production, regular checks should be conducted to ensure that the nectar is being mixed and packaged according to established protocols. This might include monitoring the temperature during sugar dissolution and ensuring the correct ratio of ingredients.

-

Final Quality Control (FQC): After packaging, the final product undergoes testing for consistency in sweetness and absence of contaminants. FQC ensures that the product meets the specifications outlined in the quality management system. B2B buyers should request FQC reports to confirm compliance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier QC practices is crucial.

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control systems. Audits allow buyers to assess compliance with international standards and identify areas for improvement.

-

Quality Control Reports: Suppliers should provide detailed QC reports that outline testing methods, results, and compliance with industry standards. Reviewing these documents can help buyers gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality practices. These services often have established methodologies for evaluating compliance and can provide certification that adds credibility to the supplier’s claims.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing hummingbird nectar internationally, buyers must be aware of regional differences in quality control and certification requirements.

-

Regulatory Variations: Different countries have distinct regulations governing food products. For example, while the EU may have stringent rules on food additives, other regions may have more lenient standards. B2B buyers should familiarize themselves with local regulations where the product will be sold.

-

Cultural Considerations: Understanding cultural preferences can also influence product specifications. For instance, some regions may prefer organic or non-GMO products, which can affect sourcing decisions. Buyers should communicate these preferences clearly to suppliers.

-

Logistical Challenges: International shipping may introduce additional quality concerns, such as temperature control and packaging integrity during transit. Buyers should discuss logistics with suppliers to ensure that products maintain their quality from the manufacturer to the end consumer.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for hummingbird nectar can empower B2B buyers to make informed sourcing decisions. By focusing on quality control checkpoints and verifying supplier practices, businesses can ensure they provide safe, high-quality products to their customers, enhancing their brand reputation in the competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change nectar in hummingbird feeder’

To ensure the well-being of hummingbirds and maintain the quality of nectar in feeders, it’s essential for B2B buyers to have a clear understanding of when and how often to change the nectar. This practical sourcing guide serves as a checklist to help businesses make informed decisions regarding their hummingbird feeder nectar supply.

Step 1: Assess Environmental Conditions

Understanding the climate in which the feeders will be used is critical. High temperatures and humidity levels can accelerate nectar spoilage, requiring more frequent changes. For example, in regions like the Middle East where temperatures can soar, nectar should be changed every day, while cooler climates may allow for changes every 2-3 days.

Step 2: Determine Nectar Composition

Choose the right nectar formulation based on local flora and hummingbird preferences. A common ratio is four parts water to one part sugar, which mimics natural flower nectar. Avoid adding dyes or other additives, as these can be harmful to birds. When sourcing, inquire about the purity and sourcing of ingredients to ensure quality.

Step 3: Establish a Regular Maintenance Schedule

Create a schedule that outlines when nectar should be changed based on the assessed environmental conditions. A general guideline is to change nectar every 2-4 days, but adjust this frequency based on temperature and humidity. Consistency in maintenance prevents nectar spoilage, which can deter hummingbirds from visiting.

Step 4: Evaluate Supplier Reliability

Before procuring nectar, evaluate potential suppliers for reliability and consistency. Look for suppliers who can guarantee fresh product delivery and have a history of customer satisfaction. Request references or testimonials from other businesses in similar climates or regions to ensure they meet your needs.

Step 5: Verify Compliance with Safety Standards

Ensure that the nectar complies with local food safety regulations. This is especially important for businesses operating in multiple regions, including Africa and Europe, where standards may vary. Checking for certifications or quality assurances can prevent potential legal issues and ensure product safety.

Step 6: Implement Quality Control Measures

Develop a quality control process to monitor the freshness of nectar upon delivery and during use. This may include visual inspections for cloudiness or mold and regular taste tests (in a non-consumable way) to check for spoilage. Having a robust quality control measure ensures that only the best nectar reaches the feeders.

Step 7: Educate Staff on Best Practices

Training staff on the importance of nectar freshness and the signs of spoilage can enhance the overall success of your hummingbird feeding program. Provide them with guidelines on how to clean feeders properly and recognize when nectar needs changing. An informed team is crucial for maintaining a thriving environment for hummingbirds.

By following this checklist, B2B buyers can ensure they provide high-quality nectar for hummingbirds, ultimately leading to healthier birds and a more successful feeding operation.

Comprehensive Cost and Pricing Analysis for how often to change nectar in hummingbird feeder Sourcing

What Are the Key Cost Components in Sourcing Nectar for Hummingbird Feeders?

When sourcing nectar for hummingbird feeders, several cost components come into play. Understanding these can help B2B buyers make informed decisions about their procurement strategies.

-

Materialen: The primary ingredients for hummingbird nectar are sugar and water. The cost of sugar can fluctuate based on global market conditions, impacting the overall price. Buyers should consider sourcing high-quality, refined sugar to ensure the nectar’s consistency and appeal to hummingbirds.

-

Arbeid: Labor costs encompass the workforce required for production, packaging, and quality control. In regions with higher labor costs, such as parts of Europe, this could significantly influence the pricing structure. Conversely, countries with lower labor costs might offer competitive pricing.

-

Productie Overhead: This includes all indirect costs associated with the production process, such as utilities, facility rent, and equipment maintenance. For B2B buyers, understanding these overheads can provide insights into supplier pricing strategies.

-

Gereedschap: If a supplier uses specialized equipment for nectar production, the costs associated with maintaining and upgrading this tooling can be passed onto buyers. Negotiating tooling costs upfront can lead to better pricing agreements.

-

Kwaliteitscontrole (QC): Ensuring that the nectar is free from contaminants and meets safety standards is critical. Suppliers with stringent QC measures may charge higher prices, but this investment is vital for maintaining product integrity and customer satisfaction.

-

Logistiek: Transportation costs vary based on the distance from the production facility to the buyer’s location. International shipping can introduce additional complexities, such as tariffs and customs fees, which can inflate overall costs. Understanding these logistics is crucial for budget planning.

-

Marge: Suppliers will typically add a profit margin to cover their costs and generate revenue. Buyers should be aware of this margin when negotiating prices, as it can vary significantly between suppliers.

How Do Price Influencers Affect Nectar Sourcing for Hummingbird Feeders?

Several factors influence the pricing of nectar for hummingbird feeders, impacting the total cost of ownership.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to bulk discounts, making it beneficial for businesses with higher consumption rates. Buyers should negotiate MOQs that align with their consumption patterns to optimize costs.

-

Specificaties en aanpassingen: Custom formulations or packaging can lead to increased costs. Buyers should assess whether customized solutions are necessary or if standard offerings will suffice, as this can affect price negotiations.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as organic or non-GMO) can increase costs. However, these attributes can also enhance marketability and customer trust, making them worth the investment.

-

Factoren van leveranciers: The supplier’s reputation, production capabilities, and location can all influence pricing. Buyers should conduct thorough evaluations of potential suppliers to ensure they are receiving competitive pricing without compromising on quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, risks, and logistics, which can significantly impact overall pricing.

What Are Some Buyer Tips for Cost-Efficiency in Nectar Sourcing?

B2B buyers can employ several strategies to enhance cost-efficiency in sourcing hummingbird feeder nectar:

-

Negotiate Terms: Leverage volume purchasing and long-term contracts to negotiate better pricing and payment terms. Building a solid relationship with suppliers can yield favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider all associated costs, including shipping, storage, and handling, to determine the true cost of the nectar. This holistic view can help in making more informed purchasing decisions.

-

Prijsnuances voor internationale kopers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local market conditions that can affect pricing. Establishing relationships with local suppliers or distributors can mitigate some of these risks.

Disclaimer on Indicative Prices

Prices for hummingbird nectar can vary widely based on the aforementioned factors, and this analysis provides a general overview. Buyers should conduct detailed market research and supplier evaluations to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing how often to change nectar in hummingbird feeder With Other Solutions

Exploring Alternatives for Hummingbird Nectar Management

In the realm of maintaining hummingbird feeders, the frequency of nectar changes is a critical consideration. Various solutions exist that can either supplement or replace the traditional method of changing nectar regularly. Understanding these alternatives is essential for B2B buyers, especially those looking to optimize their operations in environments where hummingbirds are prevalent.

| Vergelijkingsaspect | How Often To Change Nectar In Hummingbird Feeder | Nectar Dispensing Technology | Automated Nectar Management Systems |

|---|---|---|---|

| Prestaties | High; prevents spoilage and promotes bird visits | Moderate; requires regular refills | High; minimizes human error in nectar freshness |

| Kosten | Low; primarily involves sugar and water | Moderate; initial equipment cost plus maintenance | High; initial investment and ongoing maintenance costs |

| Gemak van implementatie | Simple; mix sugar and water, refill as needed | Moderate; requires setup and calibration | Complex; requires installation and potential training |

| Onderhoud | Low; regular cleaning required | Moderate; needs routine checks and cleaning | Moderate; system checks and occasional maintenance needed |

| Beste gebruikscasus | Ideal for backyard setups or small commercial use | Suitable for medium to large facilities needing efficiency | Best for large-scale operations or commercial birdwatching sites |

What Are the Pros and Cons of Nectar Dispensing Technology?

Nectar dispensing technology automates the process of nectar distribution, reducing the need for constant manual refills. This solution typically utilizes a reservoir system that controls nectar flow based on bird activity.

Voordelen:

– Reduces labor by automating nectar dispensing.

– Can be programmed to adjust nectar levels based on weather conditions.

Minpunten:

– Requires an initial investment in technology.

– Maintenance is necessary to ensure the system operates smoothly, which can be a challenge in remote locations.

How Do Automated Nectar Management Systems Work?

Automated nectar management systems integrate advanced technology to monitor and dispense nectar automatically. These systems can include sensors to gauge nectar levels and environmental conditions, ensuring that the feeder is always stocked with fresh nectar.

Voordelen:

– Ensures optimal nectar freshness and reduces spoilage.

– Minimizes human error, which can lead to nectar going bad.

Minpunten:

– High upfront costs and potential ongoing maintenance fees.

– Complexity may require specialized training for staff to operate effectively.

Conclusie: Hoe u de juiste oplossing voor uw behoeften kiest

When selecting a method for managing hummingbird nectar, B2B buyers should consider their specific operational needs, budget, and the scale of their hummingbird feeding activities. For smaller operations, regularly changing the nectar manually may suffice and provide an economical solution. However, for larger facilities or those looking to enhance efficiency, investing in technology like nectar dispensing or automated management systems can provide significant benefits in terms of performance and ease of use. Ultimately, the decision should align with both operational capacity and strategic goals for attracting hummingbirds effectively.

Illustrative image related to how often to change nectar in hummingbird feeder

Essential Technical Properties and Trade Terminology for how often to change nectar in hummingbird feeder

What Are the Key Technical Properties for Nectar in Hummingbird Feeders?

When considering the optimal nectar for hummingbird feeders, several technical properties are crucial for ensuring the health of the birds and the longevity of the feeders. Here are some of the key specifications:

-

Nectar Composition

The nectar should consist of a specific sugar-water ratio, typically 4:1 (water to sugar). This mimics the natural nectar found in flowers, ensuring that hummingbirds receive the necessary energy. The quality of sugar used (preferably white granulated sugar) is also significant, as some sugars may not dissolve properly or can spoil quickly. -

Acidity Level

The pH level of the nectar should be neutral (around 7). An inappropriate pH can lead to spoilage and may deter birds. Monitoring acidity is crucial, particularly in warmer climates where fermentation can occur more rapidly. -

Shelf Life

The shelf life of prepared nectar varies with environmental conditions. In cooler climates, nectar can last 2-4 days, while in high temperatures or humidity, it should ideally be replaced every day. Understanding these parameters helps in managing inventory and reduces waste in commercial operations. -

Cleaning and Maintenance Requirements

The feeder’s design should facilitate easy cleaning to prevent mold and bacteria buildup. Regular cleaning intervals are vital for maintaining a healthy feeding environment, which can influence customer satisfaction and repeat business. -

Material Durability

The materials used in the feeder (e.g., plastic, glass) should be durable and safe for both the birds and the environment. Products that can withstand temperature fluctuations without degrading are preferred, especially in regions with extreme weather.

What Trade Terminology Should B2B Buyers Understand Regarding Hummingbird Feeders?

Understanding industry terminology is essential for B2B buyers in the hummingbird feeder market. Here are some common terms that are relevant:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For businesses looking to source hummingbird feeders, understanding OEM relationships can help in selecting reliable suppliers. -

MOQ (minimale bestelhoeveelheid)

MOQ indicates the smallest quantity of products that a supplier is willing to sell. Knowing the MOQ is crucial for inventory management and can influence purchasing decisions, especially for businesses looking to minimize upfront costs. -

RFQ (Offerteaanvraag)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For hummingbird feeders, submitting an RFQ can help businesses compare pricing and terms from different suppliers, ensuring they get the best deal. -

Incoterms (internationale handelsvoorwaarden)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They help clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs, which are critical when sourcing feeders from overseas. -

Doorlooptijd

Lead time is the amount of time it takes from placing an order to receiving the products. For businesses that rely on timely stock replenishment for hummingbird feeders, understanding lead times can optimize inventory management and customer service. -

B2B Marketplace

This refers to online platforms where businesses can buy and sell products directly. Familiarity with B2B marketplaces can open up new avenues for sourcing hummingbird feeders and connecting with suppliers globally.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the procurement and maintenance of hummingbird feeders, ensuring a successful operation that meets both customer satisfaction and business objectives.

Navigating Market Dynamics and Sourcing Trends in the how often to change nectar in hummingbird feeder Sector

What Are the Key Market Dynamics and Trends in Hummingbird Feeder Nectar Sourcing?

The global market for hummingbird feeders is witnessing notable growth, driven by increasing consumer interest in backyard birdwatching and wildlife conservation. Particularly in regions like Africa, South America, the Middle East, and Europe, a surge in urban gardening and eco-friendly practices is reshaping buyer behavior. The demand for high-quality nectar, which mimics natural flower offerings, is rising as consumers become more knowledgeable about the needs of hummingbirds. This creates opportunities for B2B suppliers to innovate in product formulations that align with these preferences.

Emerging trends include the use of technology to monitor nectar freshness and the implementation of smart feeders that can alert users when it’s time to change the nectar. This is especially relevant in warmer climates, where nectar spoils quickly. International buyers are increasingly seeking suppliers who can offer these advanced solutions, as they cater to a growing consumer base that prioritizes convenience and optimal bird health. Additionally, the rise of e-commerce platforms is facilitating wider access to specialized nectar products, allowing businesses to reach a broader audience.

How Does Sustainability and Ethical Sourcing Impact the Hummingbird Nectar Market?

Sustainability has become a cornerstone of the hummingbird feeder market, with an emphasis on reducing environmental impact. Ethical sourcing practices are gaining traction, particularly among B2B buyers who prioritize eco-friendly materials and processes. Suppliers are now expected to provide transparency about their sourcing methods, including the use of non-GMO sugar and organic ingredients for nectar production.

The importance of green certifications cannot be understated. Certifications such as USDA Organic or Fair Trade can significantly enhance a brand’s appeal, particularly in markets that are increasingly conscious of environmental and social issues. B2B buyers are encouraged to partner with suppliers who adhere to these standards, as this not only aligns with consumer preferences but also contributes to a more sustainable supply chain.

Moreover, the incorporation of biodegradable or recyclable packaging solutions is becoming a selling point. As consumers seek to minimize waste, products that reflect these values can lead to higher sales and customer loyalty.

What is the Historical Context of Hummingbird Feeder Nectar Sourcing?

Historically, the sourcing of hummingbird nectar has evolved from simple homemade recipes to a more complex market that includes commercially produced options. Initially, backyard enthusiasts would mix sugar and water, but with the rise of consumer education and interest in avian health, the demand for high-quality, commercially available nectar has grown.

This evolution has been influenced by advancements in food science and a deeper understanding of hummingbird dietary needs. The shift towards using refined sugars and avoiding artificial additives reflects a broader trend in food production aimed at improving quality and safety. As the market continues to evolve, B2B buyers must stay informed about these changes to ensure they are sourcing the best products for their customers.

In summary, understanding market dynamics, embracing sustainability, and recognizing the historical evolution of hummingbird feeder nectar sourcing are crucial for B2B buyers looking to thrive in this niche sector. By aligning their sourcing strategies with these insights, businesses can meet the growing demand for high-quality, ethically sourced hummingbird feeder products.

Frequently Asked Questions (FAQs) for B2B Buyers of how often to change nectar in hummingbird feeder

-

How often should I change the nectar in my hummingbird feeder?

Nectar should typically be changed every 2 to 4 days, depending on the climate. In warmer or humid conditions, it’s advisable to change it every 1 to 2 days to prevent spoilage and ensure the health of the birds. Regularly cleaning the feeder and ensuring the nectar is fresh can significantly increase hummingbird visitation, making it essential for maintaining a thriving outdoor environment. -

What are the best practices for sourcing hummingbird feeder nectar?

When sourcing nectar for hummingbird feeders, look for suppliers that offer natural and dye-free products. It’s beneficial to choose suppliers who can provide information on their manufacturing processes and ensure their nectar mimics the natural sugar concentrations found in flowers. Additionally, consider sourcing locally to reduce shipping times and costs, particularly in regions like Africa or South America. -

How do I ensure the quality of hummingbird feeder nectar?

Quality assurance can be maintained by sourcing from reputable suppliers who provide product certifications and detailed ingredient lists. Regularly request samples to assess the nectar’s consistency and sweetness. Additionally, inquire about the supplier’s production methods and storage conditions to ensure that the nectar remains fresh and safe for birds. -

What minimum order quantities (MOQs) should I expect when purchasing nectar?

MOQs can vary significantly by supplier and region. Generally, for B2B transactions, expect MOQs to range from 100 to 500 liters, depending on the supplier’s capacity and your business needs. Always discuss your specific requirements with potential suppliers to negotiate terms that suit your operational scale, especially if you are entering new markets. -

How can I customize hummingbird feeder nectar for my market?

Many suppliers offer customization options for nectar formulation, allowing you to adjust sweetness levels or packaging sizes according to regional preferences. Engage with suppliers to explore these options, and consider conducting market research to understand local tastes and trends. Custom branding on packaging can also enhance market appeal and recognition. -

What payment terms should I expect when ordering hummingbird feeder nectar?

Payment terms can vary by supplier and region but generally include options like upfront payment, net 30, or net 60 days. It’s important to establish clear terms during negotiations and consider using secure payment methods to protect your investment. Additionally, inquire about any discounts for early payments or bulk orders, which can improve your cash flow. -

What logistics should I consider when importing hummingbird feeder nectar?

Logistics involve ensuring compliance with import regulations in your country, including any necessary permits or certifications for food products. Evaluate shipping options for cost-effectiveness and reliability, especially for temperature-sensitive products. Partnering with a logistics provider familiar with international trade can streamline the process, ensuring timely delivery and maintaining product quality. -

How do I vet suppliers for hummingbird feeder nectar?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with industry standards. Request references from other clients, review customer feedback, and check for certifications related to food safety. Additionally, consider conducting site visits or audits if possible to ensure that their operations align with your quality expectations.

Top 4 How Often To Change Nectar In Hummingbird Feeder Manufacturers & Suppliers List

1. Reddit – Hummingbird Feeder Care Tips

Domein: reddit.com

Registered: 2005 (20 years)

Inleiding: Change sugar-water in feeders every day when temperatures exceed 80 degrees Fahrenheit to prevent mold and bacteria growth. In cooler weather, change every two days. Use fresh nectar for healthier hummingbirds.

2. Facebook – Hummingbird Feeder

3. Perky-Pet® – Instant Clear Hummingbird Nectar

Domein: perkypet.com

Registered: 1996 (29 years)

Inleiding: Perky-Pet® offers a variety of instant hummingbird nectars made with 100% sucrose, containing no artificial flavors or sweeteners. The Clear Hummingbird Nectar Concentrate comes in a 64 oz bottle, making up to 256 oz of hummingbird food. The Instant Clear Hummingbird Nectar is available in a 2 lb bag, making up to 192 oz of nectar. Both products are easy to mix with water and provide a high-energy…

4. BirdForum – Hummingbird Food Guide

Domein: birdforum.net

Registered: 2002 (23 years)

Inleiding: Hummingbird food should be changed every 2 to 3 days under normal conditions, and can be changed every 5 to 6 days in cooler weather. The recommended recipe for homemade hummingbird food is 1 part white table sugar to 4 parts water, without any artificial coloring or substitutes like honey or brown sugar. Store-bought nectar mixes are discouraged due to unnatural chemicals that may be harmful to h…

Strategic Sourcing Conclusion and Outlook for how often to change nectar in hummingbird feeder

In summary, the frequency of changing nectar in hummingbird feeders is critical for maintaining bird health and ensuring consistent visits. The general guideline suggests changing the nectar every 2 to 4 days, with adjustments for warmer climates requiring changes every 1 to 2 days. This regular maintenance not only prevents spoilage and the growth of harmful bacteria but also enhances the overall feeding experience for hummingbirds.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of quality nectar and feeders is paramount. By prioritizing suppliers who understand local climate conditions and can provide tailored solutions, businesses can optimize their offerings and foster healthier bird populations.

Looking ahead, as interest in birdwatching and conservation grows globally, now is the time to invest in high-quality products that meet the evolving demands of consumers. By establishing partnerships with reliable suppliers, you can ensure a steady supply of fresh nectar and feeders, positioning your business as a leader in the market. Embrace this opportunity to enhance your product range and contribute positively to the environment.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.