Introduction: Navigating the Global Market for how often should i change my hummingbird feeder

In the competitive landscape of avian care products, one critical question emerges for businesses: how often should you change your hummingbird feeder nectar? This query is more than just a matter of routine; it directly impacts the health of hummingbirds and, consequently, the satisfaction of your customers. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Nigeria and Germany) explore sourcing strategies for avian products, understanding the nuances of feeder maintenance becomes paramount.

This comprehensive guide delves into the various aspects of hummingbird feeder care, including the ideal nectar change frequency based on climate and feeder type, the implications of freshness on bird health, and best practices for supplier vetting. By examining the costs associated with quality feeders and nectar, as well as innovative solutions to common challenges, this resource equips businesses with the knowledge needed to make informed purchasing decisions.

Empowering B2B buyers with actionable insights, this guide not only enhances product offerings but also fosters a deeper connection with the avian community. By prioritizing the well-being of these remarkable creatures, businesses can ensure customer loyalty and boost their brand’s reputation in the global market for bird care products.

Inhoudsopgave

- Top 4 How Often Should I Change My Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often should i change my hummingbird feeder

- Understanding how often should i change my hummingbird feeder Types and Variations

- Key Industrial Applications of how often should i change my hummingbird feeder

- 3 Common User Pain Points for ‘how often should i change my hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often should i change my hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often should i change my hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should i change my hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often should i change my hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often should i change my hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often should i change my hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often should i change my hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often should i change my hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often should i change my hummingbird feeder

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding how often should i change my hummingbird feeder Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Seasonal Schedule | Changes based on seasonal temperature variations. | Retailers in temperate regions. | Voordelen: Aligns with natural hummingbird behavior; reduces waste. Minpunten: Requires monitoring seasonal changes. |

| Climate-Sensitive Approach | Adjusts frequency based on local climate conditions. | Businesses in varying climates. | Voordelen: Optimizes freshness for local birds; improves customer satisfaction. Minpunten: May require more frequent changes in hot areas. |

| Standard Frequency | Fixed schedule of every 2-4 days, regardless of weather. | General retailers and suppliers. | Voordelen: Easy to implement; predictable maintenance. Minpunten: May lead to waste in cooler climates. |

| Emergency Replacement | Immediate change upon spoilage or contamination signs. | Emergency supplies for bird care. | Voordelen: Ensures bird safety; prevents loss of clientele. Minpunten: Requires vigilant monitoring. |

| Customizable Frequency | Tailored schedules based on specific feeder types. | Specialty bird feeding businesses. | Voordelen: Flexibility to meet specific needs; enhances customer loyalty. Minpunten: Complexity in inventory management. |

What Are the Characteristics of a Seasonal Schedule for Changing Hummingbird Feeders?

A seasonal schedule for changing hummingbird feeders is based on temperature variations throughout the year. In regions with distinct seasons, this approach allows businesses to align their feeder maintenance with the natural behaviors of hummingbirds. For B2B buyers, implementing a seasonal schedule can minimize waste and ensure that nectar is fresh when birds are most active. This method is particularly beneficial for retailers in temperate regions, as it promotes responsible bird feeding practices.

How Does a Climate-Sensitive Approach Work for Hummingbird Feeders?

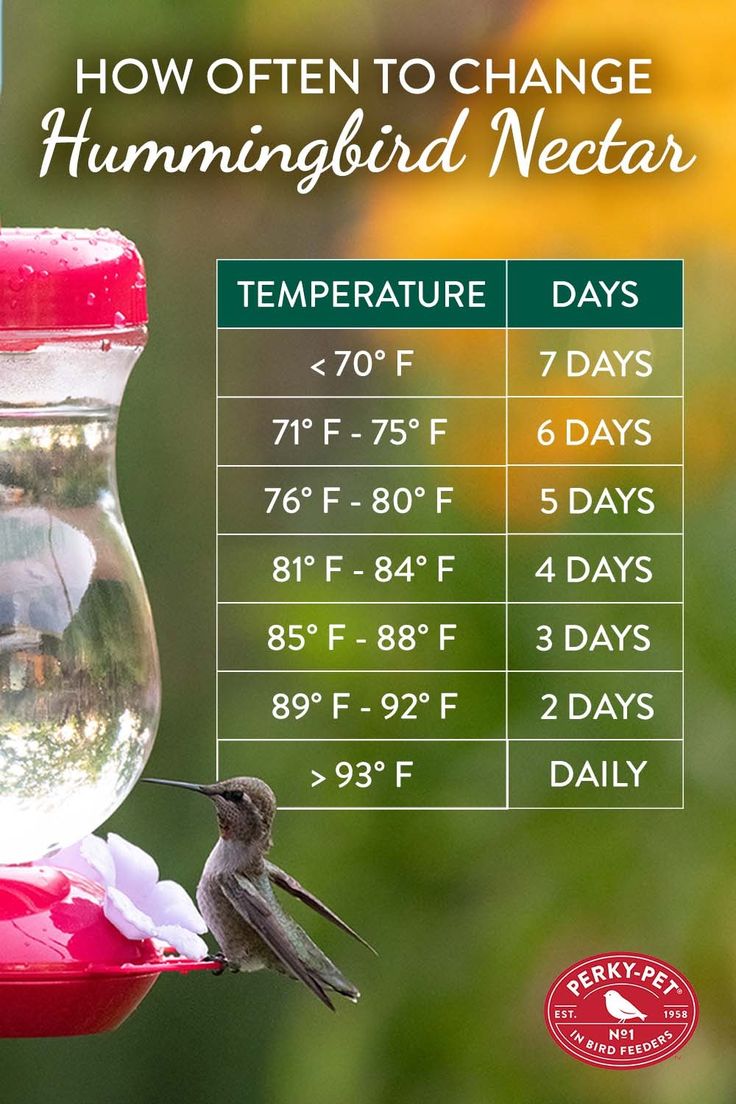

The climate-sensitive approach takes into account local weather conditions, adjusting the frequency of nectar changes accordingly. For instance, in warmer climates, nectar may need to be changed every day or two, while cooler areas can extend this to every few days. This method is ideal for businesses operating in diverse climates, as it enhances the freshness of the nectar and contributes to customer satisfaction. B2B buyers should consider local climate patterns when deciding on this approach to optimize their operations.

Why Choose a Standard Frequency for Changing Nectar?

The standard frequency model advocates for changing nectar every 2-4 days, regardless of external conditions. This straightforward approach is easy for businesses to implement and ensures a consistent supply of fresh nectar for hummingbirds. Retailers and suppliers benefit from predictable maintenance schedules, allowing them to manage inventory effectively. However, this method may lead to unnecessary waste in cooler climates, making it essential for buyers to assess their local conditions.

What Is the Importance of Emergency Replacement for Hummingbird Feeders?

Emergency replacement involves changing the nectar immediately upon noticing signs of spoilage or contamination. This approach ensures the safety and well-being of hummingbirds, which is critical for businesses that prioritize customer satisfaction and care for wildlife. B2B buyers in the bird care sector should have protocols in place for monitoring feeders to prevent negative experiences for both birds and customers. While this method requires vigilant oversight, it can significantly enhance a business’s reputation.

How Can Customizable Frequency Enhance Hummingbird Feeding Practices?

A customizable frequency approach allows businesses to tailor nectar change schedules based on specific feeder types and customer needs. This flexibility can lead to improved customer loyalty, as buyers appreciate personalized service. Specialty bird feeding businesses can benefit from this method by aligning their offerings with the unique requirements of their clientele. However, it may introduce complexity in inventory management, necessitating careful planning to ensure that supply meets demand.

Key Industrial Applications of how often should i change my hummingbird feeder

| Industrie/sector | Specific Application of how often should i change my hummingbird feeder | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Ornithology Research | Regularly changing nectar to study hummingbird feeding patterns | Accurate data collection for research and conservation | Quality of nectar, climate conditions, and feeder design for ease of cleaning |

| Eco-Tourism | Ensuring feeders are well-maintained to attract tourists | Enhanced visitor experience and wildlife observation | Availability of reliable feeder supplies, maintenance tools, and location accessibility |

| Agriculture | Utilizing hummingbird feeders for pollination studies | Improved crop yields through understanding pollinator behavior | Sourcing sustainable feeder materials and nectar recipes for local conditions |

| Wildlife Rehabilitation | Providing clean nectar for recovering hummingbirds | Facilitates recovery and rehabilitation of injured birds | Compliance with health standards for nectar preparation and feeder hygiene |

| Retail & Distribution | Selling hummingbird feeders and accessories with maintenance guidelines | Increased sales through informed customers | Supplier reliability, product variety, and educational resources for end-users |

How is Regular Nectar Change Critical for Ornithology Research?

In ornithology research, the frequency of changing hummingbird feeder nectar is vital for studying feeding patterns and behaviors. Researchers must ensure that the nectar remains fresh to avoid skewed data. Buyers in this sector should prioritize quality nectar and feeder designs that facilitate easy cleaning, especially in diverse climates across Africa and Europe, where environmental factors can affect nectar spoilage rates.

How Does Eco-Tourism Benefit from Proper Hummingbird Feeder Maintenance?

In the eco-tourism industry, maintaining hummingbird feeders is essential for attracting visitors interested in birdwatching. Clean and regularly maintained feeders enhance the visitor experience by ensuring that hummingbirds are present and active. For B2B buyers in this sector, the availability of reliable feeder supplies and maintenance tools is crucial, particularly in remote areas where accessibility can be a challenge.

What Role Do Hummingbird Feeders Play in Agriculture?

Agriculture can leverage hummingbird feeders to study pollination and its impact on crop yields. Regular nectar changes help maintain healthy hummingbird populations that contribute to pollination. Buyers in agriculture should focus on sourcing sustainable feeder materials and nectar recipes that suit local climate conditions, ensuring that the feeders are effective in various regions, including South America and Africa.

Why is Nectar Freshness Important for Wildlife Rehabilitation?

Wildlife rehabilitation centers rely on clean nectar to support the recovery of injured hummingbirds. Regular changes prevent spoilage and mold, which can hinder the healing process. Buyers in this field must ensure compliance with health standards when sourcing nectar and feeders, as the well-being of the birds is paramount. This is especially critical in regions with varying climates that can influence nectar longevity.

How Can Retailers Enhance Sales with Hummingbird Feeders?

Retailers and distributors can boost sales of hummingbird feeders by providing customers with clear maintenance guidelines, including how often to change nectar. Educating customers on the importance of regular changes can lead to increased customer satisfaction and repeat purchases. B2B buyers should consider supplier reliability and the variety of products available, ensuring they can meet the diverse needs of their customer base across different markets.

3 Common User Pain Points for ‘how often should i change my hummingbird feeder’ & Their Solutions

Scenario 1: Uncertainty About Nectar Freshness

Het probleem: B2B buyers, particularly those in regions with fluctuating temperatures and high humidity, often struggle with determining the optimal frequency for changing hummingbird feeder nectar. The fear of providing spoiled nectar can discourage businesses from effectively attracting hummingbirds to their establishments, whether they are retail locations, nature parks, or hospitality services. This uncertainty can lead to wasted resources as buyers either overchange nectar, incurring unnecessary costs, or underchange it, risking the health of the birds and the reputation of their establishment.

De oplossing: Implement a systematic schedule based on environmental conditions to manage nectar freshness effectively. Buyers should note that in cooler climates (below 60°F), nectar can last up to three days, while in warmer temperatures (above 90°F), it should ideally be changed daily. To streamline this process, businesses can use a calendar or digital reminders to track nectar changes. Additionally, investing in a temperature gauge can provide real-time data on outdoor conditions, helping to adjust nectar change intervals accordingly. Training staff on these protocols ensures consistent adherence, ultimately enhancing the visitor experience and promoting hummingbird visitation.

Scenario 2: Attracting Hummingbirds in Competitive Markets

Het probleem: In competitive environments, such as nature reserves or outdoor cafés, B2B buyers often find it challenging to attract hummingbirds consistently. Many establishments face the issue of competing with nearby locations that may have more appealing feeders or fresher nectar. This competition can lead to decreased customer satisfaction and lower foot traffic, as visitors are drawn to places where they can observe hummingbirds more readily.

De oplossing: To stand out, businesses should not only focus on changing nectar frequently but also on optimizing feeder placement and design. Conducting an assessment of the surrounding landscape can help identify ideal locations that are more visible to hummingbirds. Using multiple feeders with varied designs can cater to different species and attract a broader audience. Additionally, incorporating native flowering plants nearby can create a more inviting habitat. Regularly changing the nectar and keeping feeders clean will ensure a positive experience for both the birds and visitors, reinforcing the establishment’s reputation as a prime location for birdwatching.

Scenario 3: Maintaining Hygiene and Preventing Mold Growth

Het probleem: A significant concern for B2B buyers managing hummingbird feeders is the risk of mold growth and bacterial contamination in the nectar. This issue is particularly pressing in humid climates where nectar can spoil quickly, leading to health risks for the birds and potential backlash from environmentally-conscious customers. Without proper management, businesses may inadvertently harm the very wildlife they aim to attract, tarnishing their reputation and sustainability efforts.

De oplossing: To combat mold and bacterial growth, businesses should implement a comprehensive cleaning regimen for their feeders. This includes thoroughly washing feeders with hot water and a mild detergent every time the nectar is changed. Employing a cleaning brush specifically designed for hummingbird feeders can ensure that feeding ports are kept clear of residue. Additionally, consider using feeders with wide openings, which make cleaning easier. For added protection against spoilage, businesses can use nectar recipes that contain preservatives known to inhibit mold growth, ensuring a safer feeding environment for hummingbirds. Regularly educating staff on hygiene practices will further enhance the overall effectiveness of these measures, promoting a healthy ecosystem and a positive visitor experience.

Strategic Material Selection Guide for how often should i change my hummingbird feeder

What Are the Best Materials for Hummingbird Feeders and How Do They Affect Nectar Change Frequency?

When selecting materials for hummingbird feeders, it’s essential to consider how these materials impact the frequency of nectar changes. This is particularly relevant for international B2B buyers who need to ensure that their products meet local standards and preferences. Here, we analyze four common materials used in hummingbird feeders: plastic, glass, metal, and silicone.

How Does Plastic Influence Nectar Change Frequency?

Plastic is a widely used material for hummingbird feeders due to its lightweight nature and cost-effectiveness. It is available in various colors and designs, making it visually appealing. However, plastic can degrade under UV exposure, leading to potential leaching of harmful chemicals into the nectar. In warmer climates, such as those found in parts of Africa and South America, the nectar may spoil faster in plastic feeders, necessitating more frequent changes—ideally every 1-2 days.

Pros: Cost-effective, lightweight, and available in various designs.

Cons: Susceptible to UV degradation and potential chemical leaching.

Impact on Application: May require more frequent cleaning and nectar changes in hot climates.

Considerations for International Buyers: Ensure compliance with food safety standards, as some plastics may not be suitable for food contact.

What About Glass as a Material for Hummingbird Feeders?

Glass is another popular choice for hummingbird feeders, known for its durability and aesthetic appeal. Glass feeders do not leach chemicals into the nectar, making them a safer option. They are also easier to clean, which is crucial for maintaining nectar freshness. In cooler climates, such as Germany, nectar can last longer in glass feeders, allowing for changes every 3-4 days. However, glass feeders are heavier and more fragile, which can be a drawback for shipping and handling.

Pros: Non-toxic, easy to clean, and durable.

Cons: Heavier and more fragile than plastic.

Impact on Application: Better for maintaining nectar quality but may require careful handling.

Considerations for International Buyers: Ensure that glass feeders meet local shipping regulations to avoid breakage during transport.

How Does Metal Affect the Frequency of Nectar Changes?

Metal feeders are less common but can be effective due to their durability and resistance to UV degradation. However, metal can heat up quickly in direct sunlight, which may lead to faster spoilage of nectar. In hot regions, this could mean changing nectar every day. Metal feeders often come with protective coatings to prevent rust, but these coatings must be non-toxic to ensure the safety of the birds.

Pros: Durable and resistant to UV degradation.

Cons: Can heat up quickly, leading to faster nectar spoilage.

Impact on Application: May require more frequent nectar changes in hot climates.

Considerations for International Buyers: Look for coatings that comply with international safety standards to ensure bird safety.

What Role Does Silicone Play in Hummingbird Feeders?

Silicone is increasingly used in hummingbird feeders, especially for gaskets and feeding ports. Its flexibility and resistance to temperature fluctuations make it an excellent choice for sealing and preventing leaks. Silicone does not degrade easily and can withstand various weather conditions, which helps maintain the integrity of the feeder. However, silicone parts may still need to be cleaned regularly to prevent mold growth, especially in humid climates.

Pros: Flexible, temperature-resistant, and durable.

Cons: May require regular cleaning to prevent mold.

Impact on Application: Enhances the longevity of the feeder but requires maintenance.

Considerations for International Buyers: Ensure that silicone components meet international food safety standards.

Summary Table of Material Selection for Hummingbird Feeders

| Materiaal | Typical Use Case for how often should i change my hummingbird feeder | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Kunststof | Ideal for lightweight, cost-effective feeders; change every 1-2 days in hot climates. | Cost-effective and visually appealing. | Susceptible to UV degradation and chemical leaching. | Laag |

| Glass | Best for durability and safety; nectar can last 3-4 days in cooler climates. | Non-toxic and easy to clean. | Heavier and fragile, requiring careful handling. | Medium |

| Metal | Suitable for long-lasting feeders; change every day in high heat. | Durable and UV resistant. | Can heat up quickly, leading to faster nectar spoilage. | Medium |

| Silicone | Used for gaskets and feeding ports; enhances longevity with regular cleaning. | Flexible and temperature-resistant. | Requires maintenance to prevent mold. | Medium |

This analysis provides B2B buyers with actionable insights into material selection for hummingbird feeders, emphasizing the importance of understanding how each material affects nectar change frequency and overall product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for how often should i change my hummingbird feeder

What Are the Key Manufacturing Processes for Hummingbird Feeders?

When producing hummingbird feeders, manufacturers must follow a series of defined processes to ensure the quality, durability, and functionality of their products. These processes typically encompass material preparation, forming, assembly, and finishing.

How is Material Prepared for Hummingbird Feeders?

The initial stage involves selecting high-quality materials suitable for outdoor use. Common materials include durable plastics, glass, and metals that resist weathering and UV damage. Manufacturers often conduct tests to verify the material’s resistance to environmental factors. After selecting the raw materials, they undergo preparation, which may include cutting, shaping, or treating the materials to enhance durability and safety.

What Techniques Are Used in the Forming Process?

The forming stage involves shaping the materials into the desired feeder components. Techniques such as injection molding for plastics, blow molding for glass, and stamping for metal parts are commonly employed. Each technique has its advantages; for instance, injection molding allows for precise shapes and intricate designs, which are essential for attracting hummingbirds while also ensuring ease of cleaning for users.

Illustrative image related to how often should i change my hummingbird feeder

How Are Hummingbird Feeders Assembled?

Once the individual components are formed, the assembly process begins. This may involve manual labor or automated assembly lines, depending on the scale of production. Key components, such as the nectar reservoir, feeding ports, and base, are securely fastened together. Quality checks are performed at this stage to ensure that all parts fit correctly and function as intended. Proper assembly is crucial for preventing leaks and ensuring the feeder’s usability over time.

What Finishing Processes Are Implemented?

Finishing processes include painting, coating, or applying decals to enhance the aesthetic appeal of the feeders. These processes not only improve the visual aspect but also contribute to the longevity of the products by providing additional protective layers against the elements. Manufacturers must ensure that any coatings or paints used are non-toxic and safe for birds, aligning with industry standards.

How is Quality Assurance Managed in Hummingbird Feeder Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for hummingbird feeders. It ensures that each product meets safety and performance standards, which is vital for B2B buyers concerned about the end-user experience.

What International Standards Are Relevant for Quality Assurance?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturing processes are continuously monitored and improved. Additionally, certifications like CE mark (for European markets) and ASTM standards (for materials) are critical in validating the safety and reliability of the feeders.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints during the manufacturing stages:

- Inkomende kwaliteitscontrole (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- Kwaliteitscontrole tijdens het proces (IPQC): Continuous monitoring occurs during the production process to catch any defects early.

- Final Quality Control (FQC): Finished products undergo rigorous testing to verify their functionality, safety, and aesthetic quality.

These checkpoints help identify defects at various stages, reducing the risk of faulty products reaching the market.

Illustrative image related to how often should i change my hummingbird feeder

What Common Testing Methods Are Used for Hummingbird Feeders?

Testing methods may include:

- Durability Testing: Assessing the resilience of materials under various environmental conditions, including temperature and UV exposure.

- Leak Testing: Ensuring that the feeder can hold nectar without leaking, which is critical for user satisfaction.

- Safety Testing: Verifying that all materials are non-toxic and safe for birds and humans alike.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

What Audits and Reports Should Buyers Request?

Buyers should request regular quality audit reports from suppliers. These reports should detail the findings from IQC, IPQC, and FQC stages. An audit should also cover compliance with international standards, ensuring that the supplier maintains high manufacturing standards.

How Can Third-Party Inspections Ensure Quality?

Engaging third-party inspection services can provide an unbiased view of the manufacturing processes. These inspections can be scheduled at various production stages to ensure adherence to quality standards and specifications. This extra layer of verification is particularly valuable for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, B2B buyers must navigate several nuances:

- Cultural and Regulatory Differences: Understanding local manufacturing regulations and standards is crucial. Buyers should familiarize themselves with the specific quality certifications required in their target markets.

- Communication Barriers: Clear communication regarding quality expectations is vital. Buyers should establish a comprehensive quality checklist that aligns with their standards and ensure suppliers understand these requirements.

- Logistics Considerations: International shipments can introduce variables that affect quality, such as temperature and handling. Buyers should discuss logistics with suppliers to establish best practices for transporting sensitive items like hummingbird feeders.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing hummingbird feeders, ensuring they offer high-quality products to their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should i change my hummingbird feeder’

This guide serves as a comprehensive checklist for B2B buyers looking to understand the best practices for changing hummingbird feeders, an essential aspect of maintaining healthy and attractive feeding stations for these birds. By following these steps, businesses can ensure they are sourcing products and practices that will enhance their offerings in the birding market.

Step 1: Assess Regional Climate Conditions

Understanding the climate of your target market is crucial. Different regions, such as Africa, South America, the Middle East, and Europe, experience varying temperatures and humidity levels, which directly influence how often nectar should be changed. For instance, in hotter climates, nectar can spoil more quickly, necessitating changes every 1-2 days, while cooler areas may allow for a 3-4 day interval.

Step 2: Define Your Nectar Specifications

Specify the type of nectar that aligns with local bird species and preferences. The ideal nectar ratio is 4 parts water to 1 part sugar, and it’s important to avoid additives like dyes or honey. Ensure your suppliers provide products that meet these specifications to maintain the health of the hummingbirds and encourage their return to feeders.

Illustrative image related to how often should i change my hummingbird feeder

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a thorough evaluation. Request company profiles, product samples, and references from other buyers in similar markets. Look for suppliers who have a strong reputation for quality and reliability, as this will ensure your feeders are filled with the best nectar available.

Step 4: Inquire About Quality Control Measures

Quality control is paramount in sourcing nectar and feeders. Ask potential suppliers about their quality assurance processes, including how they test for spoilage and contamination. Ensuring that your suppliers have rigorous quality checks will help mitigate the risk of providing spoiled nectar to birds, which can deter them from visiting.

Step 5: Establish a Cleaning Protocol

Develop a routine for cleaning feeders and changing nectar. Regular cleaning prevents mold and bacteria buildup, which can be harmful to hummingbirds. Ensure that your suppliers provide guidance or products that facilitate easy cleaning, such as feeders designed for quick disassembly and thorough washing.

Step 6: Monitor Customer Feedback and Adjust Practices

Once you start supplying hummingbird feeders and nectar, actively seek customer feedback. This input can provide valuable insights into the effectiveness of your products and the satisfaction of your clients. Use this information to adjust your offerings, ensuring they meet the evolving needs of your target market.

Step 7: Stay Informed on Industry Trends

Keep abreast of the latest trends in bird feeding and nectar formulation. Join industry associations, subscribe to relevant publications, and attend trade shows to network with other professionals. Staying informed will help you adapt your sourcing strategy and maintain a competitive edge in the market.

By following this checklist, businesses can ensure they are well-prepared to meet the needs of hummingbirds and their enthusiasts, ultimately enhancing their market position in the bird feeding industry.

Comprehensive Cost and Pricing Analysis for how often should i change my hummingbird feeder Sourcing

Analyzing the costs associated with sourcing hummingbird feeders and determining how often to change the nectar involves understanding several key components that influence pricing and procurement strategies. This analysis is particularly relevant for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components Involved in Hummingbird Feeders?

-

Materialen: The primary materials for hummingbird feeders include high-quality plastics, glass, and metal components. The choice of materials significantly impacts costs. For instance, UV-resistant plastics can prolong the feeder’s life but may carry a higher upfront cost.

-

Arbeid: Labor costs encompass the wages paid to workers involved in manufacturing, assembly, and quality control. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may offer competitive pricing, but this could be offset by shipping costs to international markets.

-

Productie Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Efficient production processes can reduce overhead, allowing companies to offer more competitive pricing.

-

Gereedschap: Initial tooling costs for molds and production equipment can be significant, especially for custom designs. Buyers should consider these costs when evaluating suppliers, particularly if they require unique specifications.

-

Kwaliteitscontrole (QC): Ensuring that products meet safety and quality standards is essential. Implementing robust QC processes can add to costs but ultimately leads to higher customer satisfaction and fewer returns.

-

Logistiek: Transportation and shipping costs vary widely depending on the origin of the goods and the destination. For international buyers, understanding Incoterms (International Commercial Terms) is crucial for managing these costs effectively.

-

Marge: The profit margin is influenced by all the above factors. Buyers should be aware that lower margins may indicate lower quality or service levels, while higher margins could reflect superior products and customer support.

What Factors Influence Pricing for Hummingbird Feeders?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger orders. Suppliers may set a MOQ to ensure production efficiency, which can influence a buyer’s purchasing strategy.

-

Specificaties en aanpassingen: Custom designs or specific features (like bee guards or unique color options) can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Higher quality materials may come with certifications (e.g., eco-friendly, safety standards) that can justify a higher price point. Buyers in regions with stringent regulations should prioritize certified products.

-

Factoren van leveranciers: The reliability, reputation, and location of suppliers can affect pricing. Established suppliers may charge more but offer better warranties and customer service.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms dictate who is responsible for shipping costs, insurance, and risk during transportation, which can significantly affect the total landed cost.

What Are Some Tips for International B2B Buyers to Consider?

-

Negotiation Strategies: Engage suppliers in discussions about bulk pricing, longer-term contracts, or payment terms to secure better deals. Building a strong relationship can lead to more favorable terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only purchase price but also maintenance, replacement, and logistics costs over the product’s lifecycle.

-

Consider Local Suppliers: In regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, making it a cost-effective option.

-

Be Aware of Pricing Nuances: Different regions may have varying price points due to local market conditions, import tariffs, and currency fluctuations. Conduct thorough market research to understand these dynamics.

Disclaimer for Indicative Prices

Pricing for hummingbird feeders can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct their own research and obtain multiple quotes to ensure competitive pricing and suitable product quality.

Alternatives Analysis: Comparing how often should i change my hummingbird feeder With Other Solutions

Understanding Alternative Solutions to Changing Hummingbird Feeders

When it comes to maintaining the health and safety of hummingbirds, the frequency of changing feeder nectar plays a critical role. While the conventional guideline suggests changing nectar every 2-4 days, especially in warmer climates, businesses may explore alternative methods or technologies to enhance feeding efficiency and bird attraction. Below, we compare the traditional method of changing nectar with two alternative solutions: automatic hummingbird feeders and nectar dispensing systems.

Vergelijkende tabel

| Vergelijkingsaspect | How Often Should I Change My Hummingbird Feeder | Automatic Hummingbird Feeders | Nectar Dispensing Systems |

|---|---|---|---|

| Prestaties | Ensures fresh nectar; requires consistent monitoring | Automatically dispenses nectar, reducing spoilage risk | Provides controlled dispensing, maintaining nectar quality |

| Kosten | Low upfront cost; minimal ongoing expenses | Higher initial investment; moderate maintenance costs | Varies widely; can be low or high based on system complexity |

| Gemak van implementatie | Simple to implement; requires basic knowledge | Requires installation and setup | May require professional installation for complex systems |

| Onderhoud | Requires regular cleaning and monitoring | Low maintenance; occasional cleaning needed | Moderate maintenance; regular checks for functionality |

| Beste gebruikscasus | Ideal for casual bird watchers and small setups | Suitable for avid birders with multiple feeders | Best for commercial applications or large birding setups |

Pros and Cons of Each Alternative

Automatic Hummingbird Feeders

Automatic feeders offer the convenience of pre-set nectar dispensing, which can help maintain optimal nectar freshness without the need for daily monitoring. Their performance can be superior in humid environments where nectar spoils quickly. However, the initial investment is higher, and setup may require technical knowledge. Maintenance is generally low, but users must still clean the system periodically to prevent mold growth.

Nectar Dispensing Systems

These systems are designed for controlled nectar dispensing, which can minimize waste and reduce the frequency of nectar changes. They are particularly beneficial in commercial settings where multiple feeders are used or in areas with high bird traffic. The cost can vary significantly depending on the complexity of the system; simpler models may be affordable, while advanced systems can be quite expensive. Regular maintenance is necessary to ensure the system operates smoothly, but the benefits in terms of bird health and attraction can justify the investment.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the decision on whether to stick with the traditional method of changing hummingbird feeder nectar or to invest in alternative solutions largely depends on their specific needs and circumstances. Casual bird watchers may find that regularly changing nectar is both sufficient and cost-effective. However, businesses focused on attracting a larger bird population or enhancing the experience for their customers might benefit from automatic feeders or nectar dispensing systems, despite the higher upfront costs. By evaluating the performance, cost, ease of implementation, and maintenance of each option, buyers can select the most suitable solution to support their hummingbird feeding endeavors.

Essential Technical Properties and Trade Terminology for how often should i change my hummingbird feeder

What Key Technical Properties Should You Consider for Hummingbird Feeders?

When evaluating hummingbird feeders for your business, understanding the critical technical specifications is essential. Here are some key properties that influence performance, longevity, and safety:

1. Material Grade

The material used in hummingbird feeders significantly affects durability and resistance to environmental factors. Common materials include glass, plastic, and metal. Glass feeders offer excellent visibility and are easy to clean but can be fragile. Plastic feeders are lightweight and shatter-resistant but may degrade under UV exposure. Metal feeders provide robustness but require coatings to prevent rust. Selecting the right material ensures longevity and reduces replacement frequency, impacting overall cost-effectiveness.

2. Capacity

Capacity refers to the amount of nectar a feeder can hold, typically measured in ounces or liters. Feeders with larger capacities reduce the frequency of refills, making them ideal for businesses in high-demand regions. Conversely, smaller feeders may be more suitable for areas with fewer hummingbirds. Understanding capacity helps in selecting feeders that align with customer needs and regional bird populations.

3. Feeding Port Design

The design of feeding ports affects accessibility for hummingbirds and minimizes contamination. Ports should be sized appropriately to accommodate various hummingbird species while preventing leaks. A well-designed port reduces the risk of nectar spoilage and makes cleaning easier. For B2B buyers, evaluating port design can enhance customer satisfaction and reduce returns due to functional issues.

4. UV Resistance

UV resistance indicates a feeder’s ability to withstand sunlight exposure without degrading or fading. Feeders lacking UV protection may require more frequent replacement, increasing long-term costs. Products with high UV resistance are particularly advantageous in regions with intense sunlight, ensuring they maintain appearance and functionality over time.

5. Ease of Cleaning

The ease of cleaning is critical for maintaining nectar freshness and preventing mold growth. Feeders designed with wide openings and removable components facilitate thorough cleaning. For B2B buyers, emphasizing products that are easy to clean can drive sales, as customers prioritize hygiene in bird feeding.

6. Weather Resistance

Weather resistance refers to a feeder’s ability to withstand various climatic conditions, including rain, wind, and temperature fluctuations. Products designed for specific climates ensure reliability and durability. In B2B transactions, providing detailed specifications about weather resistance can help businesses choose appropriate feeders for their target markets.

What Trade Terminology is Important for Hummingbird Feeders?

Understanding common trade terms in the hummingbird feeder industry can enhance communication and streamline procurement processes. Here are some key terms:

Illustrative image related to how often should i change my hummingbird feeder

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hummingbird feeders, an OEM might create custom designs or specific components for brands. Understanding OEM relationships helps businesses source quality products tailored to their specifications.

2. MOQ (minimale bestelhoeveelheid)

MOQ is the smallest amount of product a supplier is willing to sell. For businesses, knowing the MOQ is crucial for budgeting and inventory planning. It can also impact initial investment costs, especially for startups or smaller enterprises.

3. RFQ (Offerteaanvraag)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. In the hummingbird feeder market, issuing an RFQ can help businesses compare costs and terms effectively, ensuring they secure the best deals.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border procurement of hummingbird feeders, ensuring clarity in shipping responsibilities and costs.

5. Doorlooptijd

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is critical for inventory management, especially for businesses that need to maintain stock levels for seasonal demand.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. In the hummingbird feeder industry, a robust warranty can enhance buyer confidence and reduce perceived risk, making it an important consideration in purchasing decisions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing hummingbird feeders, ensuring they meet market demands effectively.

Navigating Market Dynamics and Sourcing Trends in the how often should i change my hummingbird feeder Sector

Market Overview & Key Trends in Hummingbird Feeder Nectar Management

The demand for hummingbird feeders and their associated nectar products is experiencing a notable uptick globally, driven by increasing interest in backyard birding and wildlife conservation. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe. Buyers are increasingly seeking high-quality feeders that ensure the health and safety of hummingbirds, which has led to innovations in feeder design and nectar formulation.

Illustrative image related to how often should i change my hummingbird feeder

Key trends include the rise of smart feeders equipped with sensors that notify users when nectar levels are low or when the nectar needs changing. These technological advancements cater to busy consumers who prioritize convenience and the well-being of wildlife. Furthermore, the growing awareness of the importance of maintaining fresh nectar—changing it every 2 to 4 days in moderate climates, or more frequently in warmer regions—has become a focal point for product development.

International B2B buyers are also navigating the complexities of sourcing, with an emphasis on suppliers who can provide reliable logistics and support in local markets. Understanding local climate conditions and consumer preferences is crucial, as it impacts the frequency of nectar changes and the types of feeders that are most effective. The incorporation of educational resources and support from suppliers can enhance customer satisfaction and retention.

How is Sustainability & Ethical Sourcing Important in Hummingbird Feeder Production?

Sustainability is increasingly vital in the hummingbird feeder sector, impacting both sourcing decisions and consumer preferences. International buyers are prioritizing products that minimize environmental impact, such as feeders made from recycled materials or sustainably sourced components. Ethical supply chains are essential, as buyers seek to ensure that the production of hummingbird feeders does not harm local ecosystems or wildlife.

The environmental implications of nectar production are also significant. As awareness of the ecological impact of sugar production rises, there is a growing demand for organic or sustainably sourced sugar in nectar formulations. B2B buyers are encouraged to partner with suppliers who demonstrate a commitment to ethical practices, such as obtaining certifications for green materials or adopting eco-friendly manufacturing processes.

Moreover, the demand for transparency in the supply chain is increasing. Buyers are looking for suppliers who can provide detailed information about the sourcing of materials and the environmental footprint of their products. This shift towards sustainability not only aligns with global consumer trends but also enhances brand reputation and loyalty among environmentally conscious customers.

What is the Brief Evolution/History of Hummingbird Feeders?

Hummingbird feeders have evolved significantly over the years, transitioning from simple homemade solutions to sophisticated commercial products. Early feeders were often basic containers that required regular maintenance and cleaning, which posed challenges for many bird enthusiasts. The introduction of durable, easy-to-clean materials has revolutionized the market, allowing for better hygiene and easier nectar management.

In recent years, advancements in design have focused on preventing spoilage and pest intrusion, with many feeders now incorporating features such as bee guards and easy-to-clean ports. The growing emphasis on wildlife conservation has also fueled interest in the ethical sourcing of materials and environmentally friendly production processes. As the market continues to evolve, innovation and sustainability will remain at the forefront of hummingbird feeder development, catering to the needs of international B2B buyers looking to provide the best for these fascinating birds.

Frequently Asked Questions (FAQs) for B2B Buyers of how often should i change my hummingbird feeder

-

How often should I change the nectar in my hummingbird feeder?

Nectar should ideally be changed every 2 to 4 days, depending on the climate. In warmer or humid conditions, it’s advisable to change it every 1 to 2 days to prevent spoilage and ensure the health of the hummingbirds. Regularly cleaning the feeder and replacing the nectar helps maintain a safe feeding environment, which can enhance customer satisfaction and retention in your business. -

What factors influence the frequency of changing hummingbird feeder nectar?

Several factors can affect how often you should change the nectar, including temperature, humidity, and the number of birds visiting. In hotter climates, nectar can spoil quickly, necessitating more frequent changes. Additionally, if the feeder attracts many birds, the nectar may deplete faster. Understanding these factors is essential for suppliers to provide accurate recommendations to their clients. -

How can I ensure the quality of the nectar I provide?

To ensure the quality of nectar, it’s crucial to use a proper sugar-to-water ratio (typically 1:4) and avoid additives like dyes. Regular cleaning of the feeder is also necessary to prevent mold and bacteria buildup. Establishing a quality assurance process for nectar production will help maintain high standards and build trust with your B2B clients. -

What are the best practices for cleaning hummingbird feeders?

Clean hummingbird feeders with hot, soapy water and a brush to reach all crevices, especially the feeding ports. Rinse thoroughly to remove any soap residue. It’s recommended to clean the feeders every time the nectar is changed, which helps prevent the growth of harmful mold and bacteria. Offering guidance on maintenance can enhance your service offerings to clients. -

What should I consider when sourcing hummingbird feeders internationally?

When sourcing hummingbird feeders internationally, consider factors such as the supplier’s reputation, product quality, compliance with safety standards, and shipping logistics. It’s essential to vet suppliers thoroughly and possibly request samples to ensure they meet your quality expectations. Understanding local regulations in your target market can also facilitate smoother transactions. -

How do I negotiate payment terms with suppliers for hummingbird feeders?

When negotiating payment terms, consider factors like order size, supplier reliability, and your cash flow needs. Common terms include net 30, 60, or even 90 days, depending on your relationship with the supplier. Establishing clear terms upfront can prevent misunderstandings and ensure a smoother purchasing process, which is vital for maintaining strong supplier relationships. -

What is the minimum order quantity (MOQ) for hummingbird feeders, and how does it affect my business?

The MOQ can vary widely among suppliers, typically ranging from 50 to 500 units. Understanding the MOQ is crucial for inventory management and cash flow. If the MOQ is too high for your current demand, consider negotiating lower quantities or assessing the possibility of group purchasing with other businesses to meet the supplier’s requirements while minimizing your risk. -

How can I ensure timely logistics for hummingbird feeders from international suppliers?

To ensure timely logistics, establish clear communication with your suppliers regarding shipping timelines and potential delays. Utilize reliable shipping partners and consider freight insurance for high-value orders. Additionally, tracking shipments can help manage expectations and provide updates to your customers, enhancing overall service quality. This proactive approach can lead to improved customer satisfaction and repeat business.

Top 4 How Often Should I Change My Hummingbird Feeder Manufacturers & Suppliers List

1. Reddit – Hummingbird Feeder Maintenance

Domein: reddit.com

Registered: 2005 (20 years)

Inleiding: Change sugar-water in hummingbird feeders every day when temperatures exceed 80 degrees Fahrenheit to prevent mold and bacteria growth. In cooler weather, change it every two days. It’s recommended to only fill the feeders with a small amount if there are only one or two birds, and to keep the feeders clean for the health of the hummingbirds.

2. Facebook – Nectar Feeder Care

Domein: facebook.com

Registered: 1997 (28 years)

Inleiding: This company, Facebook – Nectar Feeder Care, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Backyard Chickens – Hummingbird Feeders

Domein: backyardchickens.com

Registered: 2000 (25 years)

Inleiding: Hummingbird feeders require regular maintenance to ensure the health of the birds. In warm weather, it is recommended to change the nectar (sugar water) every day or two to prevent the growth of harmful substances. If the temperature exceeds 85°F, changing the nectar every couple of days is advisable. The nectar mixture typically consists of 1 part granulated sugar to 4 parts water, which should b…

4. Perky-Pet – Clear Hummingbird Nectar Concentrate

Domein: perkypet.com

Registered: 1996 (29 years)

Inleiding: Perky-Pet® Clear Hummingbird Nectar Concentrate 64 oz Bottle: Makes up to 256 oz of hummingbird food, 100% sucrose concentrate. Perky-Pet® Instant Clear Hummingbird Nectar 2 lb bag: Makes up to 192 oz of nectar, easy to mix with water, 100% sucrose formula.

Strategic Sourcing Conclusion and Outlook for how often should i change my hummingbird feeder

In summary, maintaining optimal freshness in hummingbird feeders is essential for attracting these delicate birds and ensuring their health. As outlined, changing the nectar every 2 to 4 days is crucial, with increased frequency in warmer climates, where daily changes may be necessary. This practice not only prevents spoilage but also fosters a consistent feeding environment that can enhance customer satisfaction for businesses catering to bird enthusiasts.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of hummingbird feeder maintenance can inform product offerings and customer service strategies. Sourcing high-quality feeders that are easy to clean and maintain can set your business apart in a competitive market.

As we look ahead, the demand for eco-friendly and efficient bird feeding solutions will only grow. Engaging with suppliers who prioritize sustainability and product innovation will position your business as a leader in the industry. Let’s seize this opportunity to enhance your product lineup and support the vibrant ecosystems that hummingbirds represent.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

Illustrative image related to how often should i change my hummingbird feeder

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.