Introduction: Navigating the Global Market for smart feeder

The global market for smart feeders is evolving rapidly, presenting both opportunities and challenges for international B2B buyers. As businesses seek to enhance pet care solutions, sourcing smart feeders that combine advanced technology with practicality becomes essential. The myriad of options available, from RFID-enabled feeders to those with integrated cameras, can be overwhelming. This guide aims to demystify the selection process by providing a comprehensive overview of various smart feeder types, their applications, and key features that cater to diverse market needs.

In this guide, you will find insights into the latest innovations in smart feeding technology, detailed comparisons of popular products, and practical advice for vetting suppliers. We will also explore cost considerations and potential ROI, empowering you to make informed purchasing decisions that align with your business goals. Whether you are based in Africa, South America, the Middle East, or Europe—regions where pet ownership is on the rise—this guide is tailored to help you navigate the complexities of the smart feeder market.

By understanding the landscape of smart feeders, you can ensure your offerings meet the expectations of pet owners looking for convenience and reliability. This guide serves as your roadmap to sourcing the right smart feeders, ultimately enhancing your product portfolio and driving growth in your business.

Inhoudsopgave

- Top 6 Smart Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for smart feeder

- Understanding smart feeder Types and Variations

- Key Industrial Applications of smart feeder

- 3 Common User Pain Points for ‘smart feeder’ & Their Solutions

- Strategic Material Selection Guide for smart feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for smart feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘smart feeder’

- Comprehensive Cost and Pricing Analysis for smart feeder Sourcing

- Alternatives Analysis: Comparing smart feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for smart feeder

- Navigating Market Dynamics and Sourcing Trends in the smart feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of smart feeder

- Strategic Sourcing Conclusion and Outlook for smart feeder

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding smart feeder Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Automatic Dry Food Feeder | Programmable meal times, large capacity, Wi-Fi connectivity | Pet care facilities, veterinary clinics | Pros: Convenient, reduces labor; Cons: Limited to dry food only. |

| Wet Food Feeder | Refrigeration capabilities, dual food trays, RFID recognition | Pet hotels, grooming salons | Pros: Maintains food freshness; Cons: Higher price point. |

| Camera-Enabled Feeder | Live monitoring, two-way audio, app control | Pet training centers, remote pet care services | Pros: Enhances pet supervision; Cons: More complex setup. |

| Multi-Pet Feeder | Customizable feeding schedules, RFID technology | Multi-pet households, rescue organizations | Pros: Personalized feeding; Cons: Requires additional collars. |

| Portable Smart Feeder | Cordless design, lightweight, emergency power supply | Traveling pet services, outdoor pet activities | Pros: Flexible usage; Cons: Limited food capacity. |

What Are the Characteristics of Automatic Dry Food Feeders?

Automatic dry food feeders are designed for convenience, allowing businesses to program meal times and portion sizes for pets. Typically equipped with Wi-Fi connectivity, these feeders enable remote management via mobile apps, making them ideal for pet care facilities and veterinary clinics. Buyers should consider factors such as capacity, ease of cleaning, and compatibility with various dry food types when selecting these feeders.

How Do Wet Food Feeders Stand Out?

Wet food feeders differentiate themselves by incorporating refrigeration features that keep food fresh. Many models offer dual food trays and RFID recognition, catering to the specific dietary needs of pets. These feeders are particularly suitable for pet hotels and grooming salons, where maintaining food quality is paramount. B2B buyers should evaluate the size, price, and maintenance requirements before committing to a purchase.

What Advantages Do Camera-Enabled Feeders Provide?

Camera-enabled feeders come equipped with live monitoring capabilities and two-way audio, allowing businesses to supervise pets remotely. These features make them particularly valuable in pet training centers and remote pet care services, where monitoring pet behavior is essential. When purchasing, businesses should assess the quality of the camera, app functionality, and potential connectivity issues.

Why Choose Multi-Pet Feeders for B2B Applications?

Multi-pet feeders cater to households with several pets by offering customizable feeding schedules and RFID technology for individual pet recognition. This makes them ideal for multi-pet households and rescue organizations that need to ensure each animal receives the correct portion. Buyers should consider the ease of programming and the necessity of additional RFID collars when evaluating these feeders.

What Makes Portable Smart Feeders Ideal for On-the-Go Use?

Portable smart feeders are designed for flexibility, featuring a cordless design and lightweight construction. These feeders are perfect for traveling pet services and outdoor activities, enabling pet owners to feed their pets anywhere. Buyers should consider battery life, food capacity, and the feeder’s ability to handle different food types to ensure it meets their specific needs.

Key Industrial Applications of smart feeder

| Industrie/sector | Specific Application of smart feeder | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Pet Care Services | Automated feeding for boarding facilities | Ensures consistent feeding schedules, reduces labor costs | Capacity and adaptability for different pet sizes and food types |

| Agriculture | Livestock feeding automation | Optimizes feed distribution, minimizes waste | Durability, weather resistance, and power source options |

| Dierenklinieken | Post-operative feeding solutions | Provides controlled nutrition for recovery | Hygiene standards, ease of cleaning, and monitoring features |

| Research Institutions | Controlled feeding for animal studies | Facilitates precise dietary management | Programmability, data tracking capabilities, and reliability |

| E-commerce Platforms | Smart feeders as part of pet product offerings | Enhances product range, attracts tech-savvy consumers | Compatibility with existing systems and ease of integration |

How Are Smart Feeders Used in Pet Care Services?

In pet care services, smart feeders are employed in boarding facilities to automate the feeding process. This innovation ensures that pets receive their meals at predetermined times, reducing the need for staff intervention and minimizing the risk of overfeeding or underfeeding. For international buyers, especially in regions like Africa and the Middle East, sourcing feeders that can accommodate various pet sizes and food types is crucial. Additionally, features such as remote monitoring and programmable settings enhance operational efficiency.

What Role Do Smart Feeders Play in Agriculture?

In the agricultural sector, smart feeders are vital for automating livestock feeding. These devices ensure that animals receive the right amount of feed at scheduled intervals, optimizing feed distribution and minimizing waste. For buyers in South America and Europe, considerations such as durability and weather resistance are essential, as feeders need to withstand harsh environmental conditions. Moreover, options for solar power or battery backup can enhance functionality in remote areas.

How Are Smart Feeders Beneficial in Veterinary Clinics?

Veterinary clinics utilize smart feeders for post-operative care, providing controlled nutrition to recovering animals. These feeders allow veterinarians to set specific feeding schedules and portions, ensuring that pets receive adequate nutrition without the risk of complications. For clinics in regions like Europe and the Middle East, sourcing feeders that meet strict hygiene standards and are easy to clean is imperative. Features such as monitoring capabilities can also help track recovery progress.

How Are Smart Feeders Used in Research Institutions?

Research institutions leverage smart feeders to manage controlled feeding in animal studies. These feeders allow for precise dietary management, which is critical for the validity of research findings. Buyers in this sector should focus on feeders that offer programmability and data tracking capabilities, which facilitate accurate record-keeping and analysis. Reliability is also a key consideration, as any malfunction could compromise research outcomes.

How Do E-commerce Platforms Benefit from Smart Feeders?

E-commerce platforms are increasingly incorporating smart feeders into their product offerings, catering to the growing demand from tech-savvy pet owners. By providing advanced feeding solutions, these platforms can enhance their product range and attract a wider customer base. For businesses in Africa and South America, ensuring compatibility with existing systems and ease of integration into logistics is crucial for successful sales and customer satisfaction.

3 Common User Pain Points for ‘smart feeder’ & Their Solutions

Scenario 1: Complications with Multi-Pet Households

Het probleem: For businesses managing multi-pet facilities, such as boarding kennels or pet daycare centers, feeding multiple animals simultaneously can be chaotic. Different pets may require different diets, portion sizes, and feeding times. Without an efficient system, staff may struggle to ensure each pet receives the correct food at the right time, which can lead to overfeeding, underfeeding, or dietary conflicts. The time spent managing these feeding schedules can detract from other critical tasks within the facility.

De oplossing: B2B buyers should consider investing in smart feeders designed specifically for multi-pet environments. Look for feeders that feature RFID technology or app-controlled settings that allow individual meal portions for each pet based on their unique dietary needs. These feeders can be programmed to dispense food at specific times, ensuring that each pet is fed accurately and on schedule. Additionally, choose models with dual food trays or multiple hoppers to accommodate various food types, such as dry and wet food. By implementing these smart solutions, businesses can streamline their feeding processes, reduce human error, and ultimately enhance pet care quality.

Scenario 2: Maintenance and Food Freshness Concerns

Het probleem: In regions with varying climates, maintaining food freshness can be a significant issue for smart feeder users. High humidity and temperature fluctuations can lead to spoiled food, which not only affects pet health but also leads to increased operational costs as businesses need to frequently replace spoiled supplies. Moreover, some smart feeders lack effective sealing or insulation features, causing food to become stale or contaminated.

De oplossing: When sourcing smart feeders, prioritize models that incorporate advanced food preservation technologies, such as vacuum-sealing or insulated compartments. These features help keep both dry and wet food fresh for longer periods. Additionally, look for feeders that include built-in sensors to alert users when food levels are low or when the food is nearing spoilage. Implementing a regular maintenance schedule to clean and inspect feeders will also ensure optimal functionality and food safety. For added peace of mind, consider feeders that are easy to disassemble for thorough cleaning, which is essential in preventing mold and bacteria buildup.

Scenario 3: Technology Integration and User Training

Het probleem: As smart feeders become more technologically advanced, some B2B buyers may face challenges related to integration with existing systems or training staff to use new technologies effectively. Without proper understanding and usage, the potential benefits of these feeders can be lost, leading to frustration among staff and compromised pet care. This is particularly challenging in regions where technological literacy may vary widely among employees.

De oplossing: To overcome integration and training challenges, businesses should select smart feeders that offer intuitive interfaces and comprehensive support resources. Look for models that provide multi-device compatibility, enabling seamless integration with various smartphones or tablets. Additionally, manufacturers that offer training programs or user-friendly manuals can be invaluable. Organize training sessions for staff to familiarize them with the technology, focusing on the feeder’s features, troubleshooting, and maintenance routines. This proactive approach not only enhances operational efficiency but also empowers employees to utilize the smart feeder to its fullest potential, ultimately improving pet care services and customer satisfaction.

Strategic Material Selection Guide for smart feeder

What Are the Key Materials Used in Smart Feeders?

When selecting materials for smart feeders, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: stainless steel, food-grade plastic, silicone, and glass. Each material has distinct characteristics that influence product performance and suitability for various applications.

How Does Stainless Steel Perform in Smart Feeders?

Stainless steel is widely recognized for its durability and resistance to corrosion. It can withstand high temperatures, making it suitable for both dry and wet food applications. Key properties include a temperature rating of up to 800°F and excellent resistance to rust and staining.

Illustrative image related to smart feeder

Pros: Stainless steel is highly durable, easy to clean, and does not retain odors or flavors. Its resistance to bacteria makes it a hygienic choice for pet feeders.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than plastic. Additionally, manufacturing processes can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of pet food types, including kibble and wet food. It is also suitable for outdoor feeders due to its weather resistance.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the stainless steel used meets international standards such as ASTM or ISO certifications to guarantee quality and safety.

What Role Does Food-Grade Plastic Play in Smart Feeders?

Food-grade plastic is a popular choice for smart feeders due to its lightweight nature and cost-effectiveness. Common types include ABS and polypropylene, which are known for their impact resistance and flexibility.

Pros: The primary advantage of food-grade plastic is its affordability and ease of manufacturing. It can be molded into various shapes, allowing for innovative designs.

Cons: However, food-grade plastics may not be as durable as stainless steel and can be prone to scratching or wear over time. They may also retain odors and flavors if not properly cleaned.

Impact on Application: Food-grade plastic is suitable for dry food storage but may not be ideal for wet food due to potential degradation over time.

Considerations for International Buyers: Compliance with local regulations regarding food safety is crucial. Buyers should look for certifications such as FDA approval or equivalent standards in their region.

How Does Silicone Enhance Smart Feeder Functionality?

Silicone is often used in components like seals and mats due to its flexibility and non-slip properties. It can withstand a wide temperature range, making it suitable for various feeding conditions.

Pros: Silicone is durable, easy to clean, and resistant to extreme temperatures. Its flexibility allows for creative designs, such as collapsible feeders.

Illustrative image related to smart feeder

Cons: The main limitation is its higher cost compared to plastic. Additionally, silicone may not provide the same structural integrity as harder materials.

Impact on Application: Silicone is ideal for creating airtight seals in feeders, which helps maintain food freshness. It is also beneficial for non-slip bases to prevent spills.

Considerations for International Buyers: Ensure that the silicone used is food-grade and meets relevant safety standards. Buyers should verify compliance with regulations in their specific markets.

Why Is Glass Considered for Smart Feeders?

Glass is sometimes used in smart feeders for its aesthetic appeal and inert properties. It is non-reactive, meaning it won’t alter the taste of the food.

Pros: Glass is easy to clean and does not retain odors or flavors. Its transparency allows users to monitor food levels easily.

Illustrative image related to smart feeder

Cons: The primary drawback is its fragility; glass can break easily, making it less suitable for households with active pets.

Impact on Application: Glass is best for dry food applications where visibility is essential. It is not recommended for outdoor use due to the risk of breakage.

Considerations for International Buyers: Buyers should consider the shipping and handling requirements for glass products, particularly in regions with rough transportation conditions.

Summary Table of Material Selection for Smart Feeders

| Materiaal | Typical Use Case for Smart Feeder | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Stainless Steel | Bowls and food containers | Highly durable and corrosion-resistant | Higher cost and complex manufacturing | Hoog |

| Food-Grade Plastic | Body and hoppers | Lichtgewicht en kosteneffectief | Less durable and may retain odors | Laag |

| Silicone | Seals and non-slip bases | Flexible and easy to clean | Higher cost and less structural integrity | Medium |

| Glass | Dry food containers | Non-reactive and easy to clean | Fragile and not suitable for outdoor use | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers considering smart feeders, ensuring they choose the right materials for their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for smart feeder

What Are the Main Stages of Manufacturing Smart Feeders?

The manufacturing of smart feeders typically involves several key stages, ensuring that the final product meets both quality standards and functional requirements. Here’s a breakdown of the process:

1. Material Preparation

The first step in manufacturing smart feeders is the selection and preparation of materials. Most smart feeders are made from high-quality, food-safe plastics and stainless steel. The materials are sourced from reliable suppliers, and samples are often subjected to material testing for safety and durability. Key considerations include:

- Food Safety Standards: Materials must comply with regulations set by bodies like the FDA or EFSA, depending on the market.

- Durability Testing: The materials are evaluated for resistance to wear and tear, especially in high-use areas such as feeding bowls and hoppers.

2. Forming Processes

Once materials are prepared, they undergo various forming processes. Common techniques include:

- Injection Molding: This is widely used for creating the plastic components of smart feeders. It allows for precise designs and high-volume production.

- Metal Fabrication: Stainless steel parts, such as bowls and structural supports, are manufactured using stamping or laser cutting techniques.

These methods ensure that the parts fit together seamlessly, which is crucial for the feeder’s functionality and aesthetics.

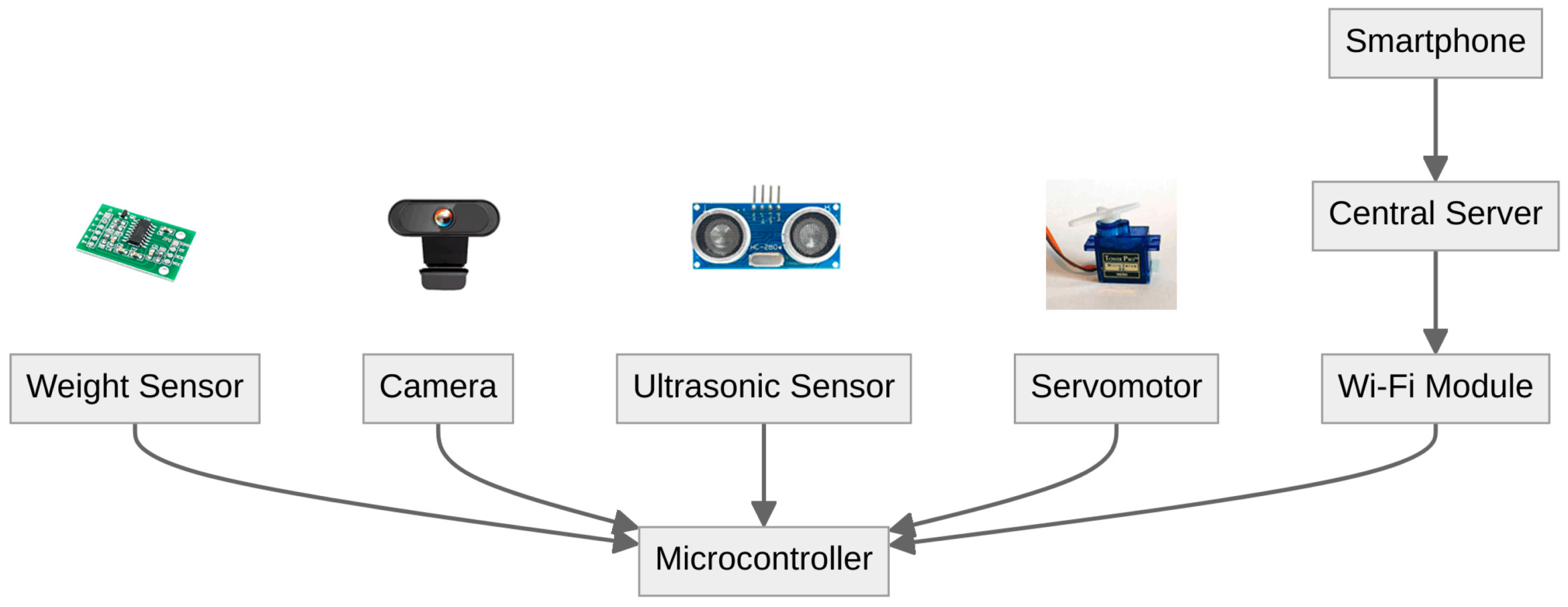

3. Assembly

The assembly stage combines all the manufactured parts into a finished product. This includes:

- Integration of Electronics: Smart feeders incorporate technology such as RFID, cameras, and sensors. Each component must be carefully installed and tested for functionality.

- Quality Checks During Assembly: Operators perform initial inspections to ensure that parts are correctly assembled and that the electronics are operational.

Automated assembly lines may also be employed for efficiency, particularly for high-demand products.

4. Finishing Touches

The final stage involves applying any necessary finishes, such as:

- Surface Treatments: These may include coatings that enhance durability or improve hygiene, such as anti-bacterial finishes.

- Final Aesthetic Touches: This may involve applying branding or decals, ensuring the product is visually appealing.

The product is then prepared for packaging, ensuring it is protected during transport.

What Quality Assurance Measures Are Essential for Smart Feeders?

Quality assurance (QA) is critical in the manufacturing of smart feeders, ensuring that products meet both international and industry-specific standards. Here’s an overview of relevant QA measures:

International Standards and Industry-Specific Certifications

Smart feeders should comply with several international standards to assure quality and safety, including:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements.

- CE Marking: In the European market, CE marking indicates that the product meets health, safety, and environmental protection standards.

- API Standards: For feeders that incorporate technology, adherence to relevant Application Programming Interface (API) standards can be crucial for ensuring compatibility and functionality.

These certifications enhance the credibility of the products in the eyes of B2B buyers.

Key Quality Control Checkpoints

Quality control is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Regular inspections are conducted during the assembly process to catch defects early.

- Final Quality Control (FQC): The completed smart feeders undergo a final inspection to verify that they meet all specifications and quality standards.

Common Testing Methods for Smart Feeders

Smart feeders undergo various testing methods to ensure functionality and safety:

- Functional Testing: This assesses whether the feeder operates as intended, including checking the accuracy of portion dispensing and electronic features.

- Durability Testing: Products are subjected to stress tests to determine how well they withstand regular use and environmental conditions.

- Safety Testing: This includes checks for sharp edges, material safety, and electrical safety for any electronic components.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital. Here are several strategies:

Leveranciersaudits uitvoeren

Buyers can perform on-site audits to evaluate the manufacturing processes and quality control systems of potential suppliers. This provides firsthand insight into their operations and adherence to quality standards.

Illustrative image related to smart feeder

Requesting Quality Reports

Suppliers should provide documented evidence of their quality control processes, including:

- Test Reports: Documentation from third-party testing laboratories that verify the quality and safety of the products.

- Certification Copies: Evidence of compliance with international standards and certifications.

Engaging Third-Party Inspection Services

Third-party inspection services can be employed to conduct independent assessments of the manufacturing process and the final products. These services can help ensure that the products meet the required standards before shipment.

Wat zijn de specifieke nuances op het gebied van kwaliteitscontrole voor internationale B2B-kopers?

International buyers must navigate several nuances when it comes to quality control:

- Cultural Differences: Understanding the quality expectations and regulations of different regions is crucial. For instance, safety standards may vary significantly between Europe and Africa.

- Regulatory Compliance: Buyers must ensure that products comply with local regulations in their respective markets, which may require additional certifications or documentation.

- Logistical Considerations: Quality control checks should consider the logistics of transporting goods across borders, as conditions during transit can affect product quality.

By being proactive in verifying quality control measures, B2B buyers can mitigate risks associated with product quality and ensure they are sourcing reliable smart feeders that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘smart feeder’

In today’s fast-paced market, sourcing a smart feeder requires careful consideration to ensure you select a product that meets your operational needs and the expectations of your clients. This guide provides a structured checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Identify Your Business Requirements

Before reaching out to suppliers, clearly define what your business needs from a smart feeder. Consider factors such as the types of pets you will be catering to (e.g., cats, dogs, or both), the feeder’s capacity, and the technology features you desire, such as app connectivity or RFID recognition. This will help narrow down your options and ensure that you select a product that aligns with your operational goals.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in smart feeder technology. Innovations such as AI integration, camera monitoring, and app-controlled feeding systems can significantly enhance user experience and operational efficiency. Understanding these trends will help you identify products that not only meet current demands but also have future growth potential.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request detailed company profiles, product catalogs, and references from other businesses in similar sectors. Look for suppliers that demonstrate a strong track record in quality, reliability, and customer service, as these factors will directly impact your business’s reputation and operational efficiency.

Step 4: Check Product Certifications and Standards

Ensure that the smart feeders meet relevant industry standards and certifications, such as safety regulations and material quality. This is particularly important if you are importing products into regions with stringent compliance laws. Certifications can also indicate the manufacturer’s commitment to quality and customer safety.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the smart feeders to evaluate their performance. Testing the feeders will allow you to assess functionality, ease of use, and durability. Pay attention to user-friendliness, as these factors will affect customer satisfaction and retention.

Step 6: Analyze Pricing and Payment Terms

Compare pricing structures among different suppliers while keeping in mind the total cost of ownership. Look for transparency in pricing, including potential hidden costs related to shipping, taxes, and duties. Additionally, negotiate favorable payment terms that align with your cash flow needs, such as payment upon delivery or extended payment periods.

Step 7: Establish a Clear Communication Channel

Maintain open lines of communication with your chosen supplier throughout the procurement process. Discuss lead times, delivery schedules, and after-sales support. A reliable communication strategy will help address any issues promptly, ensuring a smooth procurement experience.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing smart feeders, ultimately enhancing their product offerings and customer satisfaction.

Illustrative image related to smart feeder

Comprehensive Cost and Pricing Analysis for smart feeder Sourcing

What Are the Key Cost Components in Smart Feeder Manufacturing?

When evaluating the cost structure of smart feeders, several components must be taken into account. Materialen represent a significant portion of the cost, including high-quality plastics, stainless steel for bowls, and electronic components for smart functionalities like Wi-Fi connectivity and app integration. The choice of materials not only affects the initial cost but also the durability and long-term performance of the feeder.

Arbeid costs vary by region and can be influenced by local wage standards and labor laws. Manufacturing overhead, which includes utilities, rent, and administrative expenses, is another crucial factor that influences pricing. Additionally, tooling costs for custom designs can be substantial, especially if the feeder requires unique molds or complex assembly processes.

Kwaliteitscontrole (QC) is essential in ensuring that each unit meets safety and performance standards, adding another layer of cost. Lastly, logistics expenses, including shipping and handling, can vary widely based on the destination, making it crucial for international buyers to factor in these costs when budgeting.

How Do Pricing Influencers Affect Smart Feeder Costs?

Pricing for smart feeders is influenced by various factors. Volume and Minimum Order Quantity (MOQ) play a critical role; larger orders typically lead to lower per-unit costs due to economies of scale. Customization options, such as unique designs or additional features, can also increase the price, as they require additional resources and time to produce.

Illustrative image related to smart feeder

The quality of materials and certifications, such as CE or RoHS compliance, can impact costs significantly. Buyers should consider suppliers that offer high-quality components to ensure product longevity, as cheaper materials may lead to higher replacement costs down the line. Supplier factors, including reputation and reliability, can also affect pricing; reputable suppliers may charge a premium but often provide better service and quality assurance.

Furthermore, Incoterms should be clearly defined in contracts to avoid unexpected logistics costs. For example, “Delivered Duty Paid” (DDP) may seem convenient but could include hidden fees that inflate total costs.

What Negotiation Strategies Should International B2B Buyers Use?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should employ strategic negotiation techniques to secure better pricing. Understanding the supplier’s cost structure can help in negotiating terms that benefit both parties. For instance, offering to commit to larger orders can incentivize suppliers to provide discounts.

Buyers should also be aware of the Totale eigendomskosten (TCO), which includes not just the initial purchase price but also costs associated with maintenance, warranty, and logistics. This perspective allows buyers to justify a higher upfront investment if the product promises lower long-term costs.

Additionally, international buyers should be mindful of pricing nuances that may arise from currency fluctuations, import duties, and local taxes. It’s advisable to conduct thorough market research and consider engaging with local agents who understand regional pricing dynamics.

Illustrative image related to smart feeder

What Should Buyers Keep in Mind About Indicative Pricing?

While indicative prices can provide a useful benchmark, they often fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. Buyers should be cautious not to rely solely on listed prices but should seek tailored quotes that reflect their specific requirements and circumstances.

In summary, a comprehensive understanding of the cost components, pricing influencers, and strategic negotiation techniques can empower international B2B buyers to make informed decisions when sourcing smart feeders. By considering these elements, buyers can optimize their procurement strategies and ensure they receive the best value for their investments.

Alternatives Analysis: Comparing smart feeder With Other Solutions

Exploring Alternatives to Smart Feeders in Pet Care Solutions

In the evolving landscape of pet care technology, smart feeders have emerged as a popular solution for automating and enhancing pet feeding routines. However, several alternative solutions also cater to similar needs, providing various benefits depending on the specific requirements of pet owners and businesses. This analysis compares smart feeders with two viable alternatives: traditional manual feeding methods and automated gravity feeders.

| Vergelijkingsaspect | Smart Feeder | Traditional Manual Feeding | Automated Gravity Feeder |

|---|---|---|---|

| Prestaties | High efficiency with scheduling, app control, and monitoring options. | Dependent on owner availability; no automation. | Consistent feeding but lacks scheduling features. |

| Kosten | Higher upfront investment ($50-$450). | Low initial cost but can incur higher labor costs. | Moderate cost ($30-$150) with minimal maintenance. |

| Gemak van implementatie | Requires Wi-Fi setup and app installation; some technical knowledge needed. | Very simple; no setup required. | Easy setup; usually requires no electricity. |

| Onderhoud | Regular cleaning needed; software updates may be required. | Minimal maintenance; depends on feeding frequency. | Low maintenance; occasional cleaning needed. |

| Beste gebruikscasus | Ideal for busy pet owners wanting remote feeding and monitoring. | Best for owners who are home frequently and prefer hands-on care. | Suitable for owners seeking a low-cost, no-fuss solution. |

Understanding the Pros and Cons of Each Alternative

Traditional Manual Feeding

Manual feeding is the most straightforward approach, where pet owners physically feed their pets at scheduled times. This method is incredibly low-cost and requires no special equipment or technology. However, it can be labor-intensive, particularly for those with busy schedules. The primary advantage is the personal interaction it fosters between the owner and pet, which can be beneficial for pet bonding. On the downside, inconsistency in feeding times can lead to health issues in pets, such as obesity or anxiety.

Illustrative image related to smart feeder

Automated Gravity Feeders

Automated gravity feeders are a step up from manual feeding, utilizing gravity to dispense food as pets consume it. These feeders are relatively inexpensive and require minimal setup and maintenance, making them an attractive option for many pet owners. However, they lack the advanced features of smart feeders, such as scheduled feeding times and remote monitoring capabilities. This can result in overfeeding if the pet has continuous access to food, leading to potential health issues. Gravity feeders are best for pet owners who want a simple solution without the need for advanced technology.

Making the Right Choice for Your Pet Care Needs

When evaluating the right feeding solution for pets, B2B buyers should consider their unique circumstances and preferences. Smart feeders offer significant advantages in terms of convenience and technology, particularly for businesses that cater to busy pet owners or those managing multiple pets. However, for those prioritizing cost-effectiveness and simplicity, traditional manual feeding or automated gravity feeders may suffice. Ultimately, the choice should align with the pet care strategy, budget considerations, and the level of interaction desired between the pet and owner.

Essential Technical Properties and Trade Terminology for smart feeder

What Are the Key Technical Properties of Smart Feeders?

Understanding the technical specifications of smart feeders is crucial for international B2B buyers looking to invest in these advanced pet care solutions. Here are some essential technical properties to consider:

-

Material Composition: Smart feeders are often constructed from food-grade plastics and stainless steel. Food-grade ABS (Acrylonitrile Butadiene Styrene) is commonly used for the body due to its durability and resistance to impact. Stainless steel is preferred for bowls as it is hygienic and easy to clean. The choice of materials affects the product’s lifespan, safety for pets, and overall user experience.

-

Capacity: The capacity of smart feeders varies, typically ranging from 2 to 24 cups. A larger capacity means less frequent refilling, which is particularly beneficial for busy households. For B2B buyers, selecting a feeder with an appropriate capacity is essential to meet the needs of their customer base, whether for individual pet owners or larger pet care facilities.

-

Feeding Mechanism: This includes portion control systems that allow users to customize meal sizes. Advanced feeders can dispense food in varying amounts, typically from 10 to 100 grams per meal. Understanding the feeding mechanism helps buyers evaluate how well a feeder can cater to different pet sizes and dietary needs.

-

Connectivity Features: Many smart feeders come equipped with Wi-Fi capabilities, enabling remote control via mobile applications. This feature allows pet owners to manage feeding schedules and monitor food levels from anywhere. B2B buyers should assess the compatibility of these smart devices with popular operating systems (iOS and Android) to ensure broad market appeal.

-

Power Supply Options: Smart feeders often operate on AC power with battery backup options. Battery life can range from several days to weeks, depending on usage. Understanding power supply specifications is crucial for buyers to ensure reliable operation, especially in regions with unstable electricity supply.

-

Sensors and Alerts: Advanced models include sensors that notify users when food is low or when the bowl needs cleaning. These features enhance user convenience and promote better pet care. Buyers should prioritize feeders with robust sensor technology for added value to their customers.

What Are Common Trade Terms Used in the Smart Feeder Industry?

Familiarizing oneself with industry-specific jargon is essential for effective communication and negotiation in the smart feeder market. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the smart feeder industry, OEMs can provide unique designs or specifications that meet specific buyer requirements, allowing businesses to differentiate their product offerings.

-

MOQ (minimale bestelhoeveelheid): This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it affects inventory management and pricing strategies. Buyers need to assess their sales forecasts to determine if they can meet the MOQ requirements of suppliers.

-

RFQ (Offerteaanvraag): This is a standard business process where a buyer requests pricing and terms from suppliers for a specific quantity of goods. An RFQ helps buyers compare prices and terms from multiple suppliers, ensuring they make informed purchasing decisions.

-

Incoterms (internationale handelsvoorwaarden): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for buyers to understand shipping costs, risks, and responsibilities, which can significantly impact overall procurement strategies.

-

Doorlooptijd: This refers to the time it takes for an order to be fulfilled and delivered. Understanding lead times is essential for B2B buyers to manage their inventory effectively and ensure timely product availability to meet customer demands.

-

Warranty and Service Agreements: These terms outline the conditions under which a product is covered for defects or failures after purchase. A strong warranty policy can enhance buyer confidence and influence purchasing decisions, making it a critical consideration for B2B buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs and market demands in the smart feeder industry.

Navigating Market Dynamics and Sourcing Trends in the smart feeder Sector

What Are the Key Drivers and Trends Influencing the Smart Feeder Market?

The smart feeder market is experiencing significant growth, propelled by advancements in technology and changing consumer preferences. Key drivers include the increasing pet ownership rates across global markets, particularly in regions such as Africa, South America, the Middle East, and Europe. Urbanization is leading to smaller living spaces, which, in turn, has spurred the demand for automated solutions that facilitate pet care, such as smart feeders. These devices not only automate feeding but also integrate features like app connectivity, camera monitoring, and RFID recognition, catering to the needs of tech-savvy pet owners.

Moreover, as more consumers become aware of the health implications of pet nutrition, there is a rising demand for feeders that allow for portion control and dietary customization. B2B buyers are increasingly looking for smart feeders that offer flexibility in feeding schedules and portion sizes, ensuring that pets receive the appropriate nutrition. Additionally, the rise of e-commerce platforms has transformed the sourcing landscape, enabling international buyers to access a wider range of products and suppliers, thus facilitating competitive pricing and diverse offerings.

Emerging trends include a focus on multifunctionality, with products that combine feeding with hydration or health monitoring. Buyers in regions like Saudi Arabia and Brazil are particularly interested in smart feeders that can cater to multiple pets, reflecting the growing trend of pet families. As the market evolves, international B2B buyers should stay attuned to these trends to make informed sourcing decisions.

Illustrative image related to smart feeder

How Does Sustainability Impact Sourcing in the Smart Feeder Sector?

Sustainability has become a pivotal factor in the sourcing strategies of B2B buyers within the smart feeder market. With increasing awareness of environmental issues, buyers are seeking products that not only meet functional needs but also adhere to sustainable practices. This includes sourcing materials that are recyclable or biodegradable, as well as ensuring that manufacturing processes minimize environmental impact.

Ethical sourcing is increasingly important, as businesses aim to align their operations with consumer values. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can serve as indicators of a supplier’s commitment to sustainability. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring that all materials used in smart feeders are sourced responsibly.

Furthermore, the demand for energy-efficient products is on the rise, as B2B buyers recognize the long-term cost benefits associated with lower energy consumption. As smart feeders evolve, integrating renewable energy sources or energy-efficient designs will be critical in meeting the expectations of environmentally conscious consumers. Emphasizing sustainability in sourcing strategies not only enhances brand reputation but can also lead to increased customer loyalty.

What Is the Evolution of Smart Feeders in the B2B Market?

The evolution of smart feeders can be traced back to the early 2000s when basic automatic feeders began to gain popularity among pet owners. Initially designed to dispense pre-measured portions of food, these devices have rapidly transformed with the advent of smart technology. The introduction of Wi-Fi connectivity and mobile applications revolutionized the way pet owners interact with their feeders, enabling remote feeding and monitoring capabilities.

Over the past decade, the integration of features such as camera functionality, RFID recognition, and advanced portion control has further enhanced the appeal of smart feeders. Today’s devices cater not only to convenience but also to the health and well-being of pets, reflecting a broader trend in the pet care industry toward personalized and tech-driven solutions. As the market continues to innovate, B2B buyers must stay informed about these advancements to leverage opportunities for differentiation and competitive advantage in their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of smart feeder

-

How do I choose the right smart feeder for my business needs?

Selecting the right smart feeder involves evaluating several factors, including the type of pets your customers own (cats, dogs, or both), the feeder’s capacity, and specific features like app connectivity and portion control. Consider your target market’s preferences, such as design aesthetics and the need for additional functionalities like camera monitoring or RFID recognition. It’s also essential to analyze the feeder’s durability and ease of cleaning, as well as supplier reputation for quality assurance. -

What is the best smart feeder for multi-pet households?

For multi-pet households, look for feeders that offer dual or multiple food trays, allowing for simultaneous feeding. Models with smart features such as RFID pet recognition can ensure each pet receives the correct portion. Additionally, consider feeders with large capacities and customizable meal schedules, like those that can handle dry and wet food, to accommodate various dietary needs. Research customer reviews and product specifications to identify the most reliable options. -

What are the minimum order quantities (MOQs) for smart feeders?

MOQs vary by supplier and can range from as few as 10 units to over 100, depending on the manufacturer and product type. It’s advisable to communicate directly with suppliers to negotiate terms that suit your business needs. Some manufacturers may offer lower MOQs for initial orders or bulk discounts for larger purchases. Understanding the MOQ can help you manage your inventory effectively and ensure that you meet customer demand without overcommitting resources. -

What payment terms should I expect when sourcing smart feeders internationally?

Payment terms differ among suppliers and can include options like upfront payment, partial payment upon order confirmation, and balance before shipment. Common methods include bank transfers, letters of credit, or payment platforms like PayPal. It’s crucial to clarify these terms before placing an order to avoid misunderstandings. Additionally, consider the currency fluctuations that might affect your costs, especially when dealing with international suppliers. -

How can I vet suppliers of smart feeders to ensure quality?

Vetting suppliers involves researching their business credentials, including years of operation, customer reviews, and product certifications. Request samples to assess the product quality firsthand and inquire about their manufacturing processes and quality control measures. Establishing clear communication can also provide insights into their reliability and customer service. It’s advisable to ask for references from other businesses that have sourced products from them. -

What logistics should I consider when importing smart feeders?

When importing smart feeders, consider shipping methods (air vs. sea), associated costs, and transit times. Ensure that you understand customs regulations in your country, including import duties and taxes. Collaborating with experienced freight forwarders can streamline the process and help avoid delays. Additionally, plan for warehousing and distribution logistics to manage your inventory effectively once the products arrive. -

Are there customization options available for smart feeders?

Many manufacturers offer customization options for smart feeders, such as branding, color choices, and specific features tailored to your market. Discuss your requirements with potential suppliers to understand the extent of their customization capabilities and any associated costs or lead times. Customization can enhance your product’s appeal and help differentiate your offerings in competitive markets. -

What quality assurance measures should be in place for smart feeders?

Quality assurance should include rigorous testing of the products to meet industry standards and customer expectations. Suppliers should provide certifications for materials used and safety compliance. Regular audits and inspections during the manufacturing process can help ensure consistent quality. Establishing a clear return policy for defective products is also crucial to maintaining customer satisfaction and loyalty.

Top 6 Smart Feeder Manufacturers & Suppliers List

1. Petlibro – Automatic Pet Feeders

Domein: petlibro.com

Registered: 2019 (6 years)

Inleiding: Automatic Pet Feeders for Cats and Dogs – Petlibro includes various models such as Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Space Smart Feeder. Key features include RFID pet recognition, app control, vacuum-sealing technology, and dual food trays. Capacities range from 2L to 8L. Prices vary from $89.99 to $449.97. Free shipping on orders over $75 in the U.S. Discounts av…

2. Petkit – YumShare Dual-hopper Automatic Feeder

Domein: petkit.com

Registered: 2003 (22 years)

Inleiding: {“products”:[{“name”:”YumShare Dual-hopper Automatic Feeder with Camera”,”sale_price”:”$159.00″,”capacity”:”5L (2L+3L)”,”material”:”Bowl: 304 stainless steel, Container: Food-grade ABS”,”portion_control”:”10-100g”,”fresh_lock_systems”:”Quadruple”,”camera_ai”:”✓”,”app_control”:”✓”,”two_way_audio”:”✓”,”anti_blockage_technology”:”✓”,”weight_sensor”:”✓”,”proximity_sensors”:”✓”,”personalized_meal_call”…

3. PetSafe® – Smart Feed Automatic Dog and Cat Feeder

Domein: petsafe.com

Registered: 1996 (29 years)

Inleiding: {‘product_name’: ‘Smart Feed Automatic Dog and Cat Feeder, 2nd Generation’, ‘brand’: ‘PetSafe®’, ‘price’: ‘$134.99’, ‘capacity’: ’24 cups’, ‘number_of_meals’: ’12’, ‘meal_scheduler’: ‘Customize meal times’, ‘features’: [‘Wi-Fi’, ‘Alexa enabled’, ‘iPhone & Android compatible’], ‘refill_type’: ‘Automatic’, ‘dishwasher_safe’: ‘Top-rack dishwasher safe’, ‘sensors’: [‘Low food sensor’, ‘Empty food sens…

4. PawSync – Smart Pet Feeder

Domein: pawsync.com

Registered: 2022 (3 years)

Inleiding: Slimme voederbak voor huisdieren

– Sale Price: $79.99 (Regular Price: $99.99)

– Features:

– Low Food Detection Sensor

– Backup Power Supply

– Meal Calls

– 304 Stainless Steel Bowl

– Slow Feeding Mode

– BPA-Free Tank

– Schedule Feedings

– Moisture Control

– Free Shipping: Fast, hassle-free delivery at no extra cost.

– 90-Day Trial: Try it risk-free; love it or return it within 90 days.

– Free Retur…

5. Feed Smart – Automatic Horse Feeder

Domein: feed-smart.com

Geregistreerd: 2008 (17 jaar)

Inleiding: Automatic Horse Feeder by Feed Smart for Horses, Cattle, Sheep and other Livestock. Designed for durability with heavy-duty materials, made of galvanized steel, and solar-powered for reliability. Offers up to six feed times per day, recommended at least four. Hopper design keeps feed fresh for weeks. Suitable for loose, dry feed like uncoated pellets or oats. Available in two sizes: large (500-550…

6. Invisible Fence – Smart Feed Automatic Dog and Cat Feeder

Domein: invisiblefence.com

Registered: 1999 (26 years)

Inleiding: Product Name: Smart Feed Automatic Dog and Cat Feeder, 2nd Generation

Capacity: Holds 24 cups of dry or semi-moist food

Feeding Schedule: Schedule up to 12 meals daily in sizes from 1/8 cup to 4 cups per meal

Features:

– Slow Feed option dispenses meals larger than 1/8 cup in small amounts over 15 minutes

– Feed Now option for instant feeding

– Low food sensor sends notifications when running low…

Strategic Sourcing Conclusion and Outlook for smart feeder

In the evolving landscape of pet care, smart feeders represent a significant opportunity for international B2B buyers seeking innovative solutions that enhance both pet well-being and consumer convenience. The integration of advanced technologies, such as app connectivity, RFID recognition, and real-time monitoring, not only optimizes feeding schedules but also ensures that pets receive the appropriate nutrition tailored to their needs.

Strategic sourcing of smart feeders can yield substantial benefits, including improved customer satisfaction, reduced operational costs, and enhanced product differentiation in competitive markets. By partnering with reputable manufacturers, buyers can ensure a steady supply of high-quality products that align with market demands, particularly in regions like Africa, South America, the Middle East, and Europe, where pet ownership is on the rise.

Looking ahead, the smart feeder market is poised for growth, driven by increasing consumer awareness of pet health and the convenience offered by technology. International B2B buyers are encouraged to explore partnerships that not only meet current demand but also anticipate future trends. Embrace the opportunity to lead in this dynamic sector, and invest in smart feeding solutions that cater to a growing, tech-savvy customer base.

Illustrative image related to smart feeder

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.