Introduction: Navigating the Global Market for automatic canned food feeder

The global market for automatic canned food feeders is rapidly evolving, presenting both opportunities and challenges for international B2B buyers. As pet ownership continues to rise in regions such as Africa, South America, the Middle East, and Europe, the demand for innovative feeding solutions is surging. However, sourcing reliable automatic canned food feeders that meet diverse consumer needs can be daunting due to varying quality standards and regional preferences. This guide is designed to address these challenges by providing a comprehensive overview of the types of automatic canned food feeders available, their applications, and key considerations for supplier vetting and cost analysis.

In this guide, B2B buyers will find detailed insights into the latest technologies in automatic feeding systems, including features like RFID recognition, app-controlled feeding, and vacuum-sealed food storage options. We will explore how these innovations not only enhance pet care but also streamline operations for distributors and retailers. Furthermore, our guide will equip buyers with actionable strategies for evaluating suppliers, ensuring that they can make informed purchasing decisions that align with market demands and consumer expectations. By navigating the complexities of the automatic canned food feeder market, businesses can position themselves for success in an increasingly competitive landscape.

Spis treści

- Top 4 Automatic Canned Food Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automatic canned food feeder

- Understanding automatic canned food feeder Types and Variations

- Key Industrial Applications of automatic canned food feeder

- 3 Common User Pain Points for ‘automatic canned food feeder’ & Their Solutions

- Strategic Material Selection Guide for automatic canned food feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic canned food feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic canned food feeder’

- Comprehensive Cost and Pricing Analysis for automatic canned food feeder Sourcing

- Alternatives Analysis: Comparing automatic canned food feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for automatic canned food feeder

- Navigating Market Dynamics and Sourcing Trends in the automatic canned food feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic canned food feeder

- Strategic Sourcing Conclusion and Outlook for automatic canned food feeder

- Ważne zastrzeżenia i warunki użytkowania

Understanding automatic canned food feeder Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Refrigerated Wet Food Feeders | Maintains optimal temperature for wet food; often includes ice packs | Pet care facilities, veterinary clinics | Plusy: Keeps food fresh; ideal for multiple pets. Wady: Higher cost; requires power source. |

| RFID Smart Feeders | Uses RFID technology for personalized feeding; app-controlled | Pet technology companies, high-end retailers | Plusy: Customizable feeding; reduces food waste. Wady: Complex setup; may require tech support. |

| Multi-Meal Dry Food Feeders | Dispenses dry food for multiple meals; features digital timers | Pet boarding services, shelters | Plusy: Versatile for various pet sizes; easy to use. Wady: Limited to dry food; potential battery issues. |

| Automated Self-Cleaning Feeders | Automatically cleans feeding area; designed for wet food | Luxury pet product retailers, subscription services | Plusy: Low maintenance; promotes hygiene. Wady: Higher upfront investment; specific food compatibility. |

| Smart Monitoring Feeders | Tracks eating habits and health; connects to mobile apps | Veterinary practices, tech-savvy pet owners | Plusy: Health monitoring; alerts for dietary issues. Wady: Requires app; potential data privacy concerns. |

What Are the Characteristics of Refrigerated Wet Food Feeders?

Refrigerated wet food feeders are specifically designed to keep canned food at safe temperatures, often incorporating ice packs or refrigeration technology. These feeders are particularly suited for environments where multiple pets are fed simultaneously, such as pet care facilities and veterinary clinics. When considering a purchase, B2B buyers should evaluate the capacity, energy efficiency, and ease of cleaning, as well as the potential need for power sources.

How Do RFID Smart Feeders Enhance Pet Feeding?

RFID smart feeders leverage technology to recognize individual pets, allowing for personalized feeding schedules through mobile apps. This feature is highly beneficial for businesses that cater to multiple pets, such as pet technology companies and high-end retailers. B2B buyers should consider the integration capabilities with existing systems, the cost of RFID tags, and the technical support required for setup and maintenance.

What Advantages Do Multi-Meal Dry Food Feeders Offer?

Multi-meal dry food feeders are designed to dispense dry food at scheduled intervals, making them ideal for boarding services and shelters. These feeders often include digital timers for easy programming. When purchasing, businesses should focus on the feeder’s capacity, the ease of use, and the durability of the materials, particularly if they will be used in a high-traffic environment.

Why Choose Automated Self-Cleaning Feeders?

Automated self-cleaning feeders provide a significant advantage in maintaining cleanliness, especially for wet food. These feeders are popular among luxury pet product retailers and subscription services. Buyers should assess the initial investment costs, the types of food compatible with the feeder, and the overall maintenance requirements to ensure it meets their business needs.

How Do Smart Monitoring Feeders Support Pet Health?

Smart monitoring feeders track pets’ eating habits and can alert owners to potential health issues, making them valuable tools for veterinary practices and tech-savvy pet owners. When considering these feeders, B2B buyers should evaluate the software’s reliability, data privacy measures, and the feeder’s compatibility with various pet diets to ensure it aligns with their services.

Key Industrial Applications of automatic canned food feeder

| Przemysł/sektor | Specific Application of automatic canned food feeder | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Pet Care | Automated feeding in veterinary clinics | Improved pet health monitoring and care efficiency | Reliability, ease of cleaning, and remote monitoring capabilities |

| Animal Shelters | Feeding multiple animals simultaneously | Streamlined operations and reduced labor costs | Capacity for bulk feeding, durability, and safety features |

| E-commerce & Retail | Smart feeders for subscription-based pet food delivery | Enhanced customer experience and loyalty | Compatibility with various food types and subscription logistics |

| Research Institutions | Controlled feeding for animal behavior studies | Accurate data collection and animal welfare | Customization options and precise portion control |

| Hospitality & Boarding | Automated feeding in pet boarding facilities | Consistent feeding schedules and reduced staff workload | Versatility in food types and ease of maintenance |

How is the Automatic Canned Food Feeder Used in the Pet Care Industry?

In veterinary clinics, automatic canned food feeders are used to manage the feeding schedules of pets in recovery or those requiring special diets. These feeders can be programmed to dispense specific amounts of food at designated times, helping veterinarians monitor intake and adjust diets as needed. This technology not only enhances the efficiency of care but also alleviates the burden on staff, allowing them to focus on other critical tasks. Buyers in this sector should prioritize reliability and features like remote monitoring to ensure optimal pet health management.

What Role Does the Automatic Canned Food Feeder Play in Animal Shelters?

Animal shelters utilize automatic canned food feeders to streamline the feeding process for multiple animals. By programming feeders to dispense food at regular intervals, shelters can ensure that all animals receive adequate nutrition without requiring constant human oversight. This efficiency can significantly reduce labor costs and improve the overall welfare of the animals. When sourcing feeders for shelters, considerations should include capacity for bulk feeding, durability to withstand heavy use, and safety features to prevent tampering.

How Can E-commerce and Retail Benefit from Automatic Canned Food Feeders?

In the e-commerce and retail sector, smart automatic feeders enhance subscription-based pet food services. These feeders can be integrated with apps that track inventory and usage, allowing businesses to offer personalized delivery schedules based on customer preferences. This capability not only improves customer satisfaction but also fosters loyalty through a seamless user experience. Retailers should consider compatibility with various food types and the logistics of subscription fulfillment when sourcing these feeders.

Why are Automatic Canned Food Feeders Essential for Research Institutions?

Research institutions often require precise feeding control for animal behavior studies. Automatic canned food feeders provide a means to deliver specific food portions consistently, which is crucial for experimental integrity and animal welfare. The data collected from these feeders can help researchers gain insights into feeding behaviors and health outcomes. Buyers in this sector should look for customization options that allow for different feeding protocols and precise portion control to meet their specific research needs.

What Advantages Do Automatic Canned Food Feeders Offer in Hospitality and Boarding Facilities?

In pet boarding facilities, automatic canned food feeders are invaluable for maintaining consistent feeding schedules for multiple animals. These feeders reduce the workload on staff, allowing them to manage more animals efficiently while ensuring that each pet receives its meals on time. The versatility to handle various types of food, along with ease of maintenance, makes these feeders a practical choice. Facilities should focus on sourcing feeders that can accommodate different food types and are easy to clean to ensure high standards of hygiene.

3 Common User Pain Points for ‘automatic canned food feeder’ & Their Solutions

Scenario 1: Managing Inventory and Spoilage Concerns in Automatic Canned Food Feeders

Problem: Many B2B buyers, especially those in the pet care industry, face the challenge of managing inventory effectively while ensuring the freshness of wet food in automatic canned food feeders. Canned food has a limited shelf life, and without proper management, businesses risk spoilage, leading to waste and increased costs. This is particularly pressing for suppliers catering to markets with varying demand patterns, where stock levels must be closely monitored to avoid both surplus and shortages.

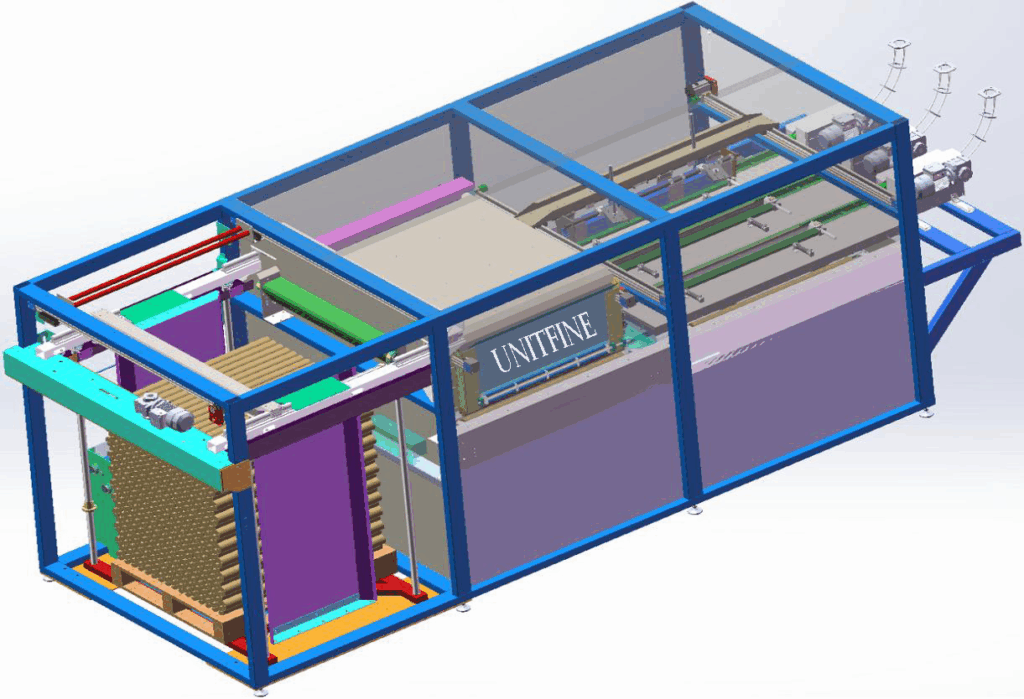

Illustrative image related to automatic canned food feeder

Rozwiązanie: To combat spoilage and manage inventory effectively, businesses should invest in automatic canned food feeders that incorporate smart inventory management features. These feeders can track food levels and alert users when stock is low or nearing expiration. Moreover, implementing a just-in-time inventory system, combined with predictive analytics, can help forecast demand trends based on historical data. Suppliers should also consider establishing partnerships with manufacturers that offer compatible feeder systems, ensuring that the feeders can accommodate various can sizes and types. This strategic sourcing allows for flexibility and adaptability in meeting consumer needs while minimizing waste.

Scenario 2: Ensuring Pet Health and Compliance with Feeding Standards

Problem: Compliance with health standards and ensuring the nutritional well-being of pets is crucial for B2B buyers in the pet care sector. Automatic canned food feeders that do not provide accurate portion control or fail to maintain food freshness can lead to overfeeding or serving spoiled food, risking pet health and violating regulatory standards. This challenge is particularly acute in regions with strict pet food regulations, where businesses must ensure that feeding practices meet safety guidelines.

Rozwiązanie: To ensure compliance and promote pet health, buyers should prioritize automatic canned food feeders that feature precise portion control mechanisms and built-in freshness preservation technologies. For instance, feeders equipped with vacuum-sealing capabilities can maintain food freshness longer, reducing the risk of spoilage. Additionally, selecting feeders that allow for programmable feeding schedules can help regulate portion sizes based on individual pet needs. B2B buyers should also invest in training for staff on the proper usage and monitoring of these feeders to ensure adherence to feeding guidelines and enhance pet care practices.

Scenario 3: Integrating Technology for Seamless Operations

Problem: Many businesses struggle with integrating technology into their operations, particularly when it comes to automatic feeding systems. The lack of interoperability between different feeder brands and the associated apps can lead to inefficiencies and increased labor costs. This is a common pain point for distributors and retailers who wish to offer a streamlined experience for their customers but face challenges in ensuring that all devices work cohesively.

Rozwiązanie: To achieve seamless operations, B2B buyers should seek automatic canned food feeders that are compatible with a wide range of smart devices and offer integration with popular pet care applications. Choosing systems that support cloud connectivity can facilitate remote monitoring and adjustments, allowing businesses to manage multiple feeders from a single interface. Furthermore, buyers should consider suppliers that provide robust customer support and training for their technology, ensuring that staff can effectively troubleshoot issues and maximize the feeders’ capabilities. Investing in feeders with user-friendly apps can also enhance customer experience, leading to higher satisfaction and retention rates.

Strategic Material Selection Guide for automatic canned food feeder

What Are the Key Materials for Automatic Canned Food Feeders?

When selecting materials for automatic canned food feeders, it’s essential to consider properties that affect performance, durability, and compliance with international standards. The following analysis covers four common materials: stainless steel, plastic, aluminum, and silicone.

How Does Stainless Steel Perform in Automatic Canned Food Feeders?

Stainless steel is a popular choice for automatic canned food feeders due to its excellent corrosion resistance and durability. It can withstand a wide range of temperatures, making it suitable for both wet and dry food applications. The material is also easy to clean, which is critical for maintaining hygiene in pet feeding.

Plusy: Stainless steel is highly durable and resistant to rust, ensuring a long lifespan. Its non-porous surface prevents bacterial growth, making it a hygienic option.

Wady: The initial manufacturing cost can be high, and the complexity of shaping stainless steel can increase production times.

For international buyers, compliance with food safety standards is crucial. Stainless steel must meet specific regulations, such as ASTM A240 for food-grade materials, which ensures safety and performance.

What Are the Benefits of Plastic in Automatic Canned Food Feeders?

Plastic is widely used in automatic feeders due to its lightweight nature and versatility. It can be molded into various shapes, allowing for innovative designs that enhance user experience.

Plusy: Plastic is generally less expensive than metals and can be produced quickly, making it a cost-effective solution for manufacturers. It also offers good resistance to impact and is available in various colors and finishes.

Wady: Plastic may not be as durable as metals, particularly under high temperatures or when exposed to certain chemicals. Over time, it can become brittle or discolored.

For buyers in regions like Africa and South America, where temperature fluctuations can be significant, selecting high-quality, food-safe plastics compliant with standards such as FDA regulations is essential.

Why Choose Aluminum for Automatic Canned Food Feeders?

Aluminum is another viable option for automatic canned food feeders. It is lightweight and has good thermal conductivity, making it suitable for maintaining food temperatures.

Plusy: Aluminum is relatively inexpensive and can be anodized for added corrosion resistance. Its lightweight nature makes it easier to handle and transport.

Wady: While aluminum is resistant to rust, it can corrode if exposed to acidic foods over time. This material may also require additional coatings or treatments to enhance its durability.

International buyers should ensure that aluminum components comply with regulations such as ISO 9001 for quality management systems, particularly when exporting to Europe.

Illustrative image related to automatic canned food feeder

What Role Does Silicone Play in Automatic Canned Food Feeders?

Silicone is often used for seals and gaskets in automatic feeders due to its flexibility and high-temperature resistance. It can withstand extreme temperatures without degrading, making it ideal for both hot and cold food applications.

Plusy: Silicone is highly durable and resistant to UV light, ensuring that it maintains its properties over time. It is also easy to clean and can be manufactured in various colors.

Wady: Silicone can be more expensive than other materials and may not be as rigid, which can affect the structural integrity of feeder components.

Illustrative image related to automatic canned food feeder

For international buyers, it is important to verify that silicone materials meet food safety standards, such as FDA approval, to ensure they are safe for use in pet feeding applications.

Summary Table of Material Selection for Automatic Canned Food Feeders

| Materiał | Typical Use Case for automatic canned food feeder | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Stainless Steel | Food bowls, feeder bodies | Highly durable and hygienic | High initial cost and manufacturing complexity | Wysoki |

| Tworzywo sztuczne | Feeder components, trays | Cost-effective and versatile | Less durable, can degrade over time | Niski |

| Aluminum | Structural components, food trays | Lightweight and inexpensive | Can corrode with acidic foods | Średni |

| Silicone | Seals, gaskets | Flexible and high-temperature resistant | More expensive and less rigid | Średni |

This material selection guide provides actionable insights for international B2B buyers seeking to optimize their automatic canned food feeder offerings, ensuring compliance with relevant standards while balancing performance and cost.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic canned food feeder

What are the Key Stages in the Manufacturing Process of Automatic Canned Food Feeders?

The manufacturing process for automatic canned food feeders involves several critical stages, ensuring that the final product meets quality standards and consumer expectations. Each stage is designed to optimize efficiency and maintain the integrity of the materials used.

Material Preparation: How are Raw Materials Processed?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality components such as plastic, metal, electronics, and sensors. Suppliers often conduct rigorous testing of these materials to ensure compliance with international standards, such as ISO 9001. This testing includes assessing the durability and safety of plastics and ensuring metals are free from corrosion.

Illustrative image related to automatic canned food feeder

Once materials are sourced, they are subjected to cleaning and inspection processes. This step is crucial for eliminating contaminants that could affect the feeder’s functionality. B2B buyers should inquire about the supplier’s material sourcing policies and whether they conduct regular audits of their suppliers.

What Techniques are Used for Forming and Shaping Components?

Following material preparation, the forming stage begins. This can involve various techniques depending on the component. For plastic parts, injection molding is commonly used, while metal components may undergo stamping or machining. Each technique has its own set of specifications and tolerances that must be adhered to, ensuring parts fit together seamlessly.

In this stage, advanced technologies such as computer numerical control (CNC) machining are often employed to enhance precision. This is particularly important for parts that require intricate designs, such as the dispensing mechanisms and electronic housings. B2B buyers should look for manufacturers that utilize these modern techniques, as they often yield higher-quality products.

How is Assembly Conducted for Automatic Feeders?

The assembly stage integrates all the formed components into a cohesive unit. This process typically involves manual labor and automated systems to ensure efficiency. Skilled technicians assemble the feeder, ensuring that all electronic components, such as timers and motors, are installed correctly.

During assembly, quality control checkpoints are established. These checkpoints help identify any defects early in the process, reducing waste and ensuring that only fully functional units proceed to the next stage. B2B buyers should verify that their suppliers have documented assembly processes and checklists to maintain consistent quality.

What Finishing Techniques are Applied to Enhance the Product?

The finishing stage includes painting, coating, and labeling the automatic feeders. These processes not only enhance aesthetic appeal but also provide protection against wear and tear. For example, UV-resistant coatings can be applied to protect against sunlight degradation.

Additionally, during this stage, manufacturers often conduct final inspections to ensure that all components meet quality standards. Buyers should inquire about the types of finishes used and their respective durability, as these can impact the feeder’s longevity and performance.

What Quality Assurance Practices are in Place for Automatic Canned Food Feeders?

Quality assurance (QA) is a critical component of the manufacturing process for automatic canned food feeders. The goal is to ensure that each feeder meets regulatory standards and customer expectations.

Illustrative image related to automatic canned food feeder

What International and Industry-Specific Standards Should B2B Buyers Consider?

Manufacturers must comply with various international standards, such as ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer follows established quality control procedures throughout production. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the feeder’s use and geographic market.

B2B buyers should ask potential suppliers for their certifications and the scope of these certifications. Understanding these standards is crucial for ensuring that the products will meet the regulatory requirements of the buyer’s market.

How are Quality Control Checkpoints Established?

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival.

- In-Process Quality Control (IPQC): Regular checks during production ensure that any deviations from specifications are addressed immediately.

- Final Quality Control (FQC): Before shipping, finished products undergo comprehensive testing to verify functionality and safety.

Each checkpoint serves as a safeguard to maintain product integrity. Buyers should inquire about the specific QC processes their suppliers employ and request access to quality reports.

What Common Testing Methods are Used to Ensure Product Quality?

Testing methods vary based on the components and intended use of the automatic feeders. Common methods include:

- Functional Testing: Ensures that all electronic components, such as timers and sensors, operate correctly.

- Durability Testing: Assesses the feeder’s resistance to wear and tear under normal usage conditions.

- Safety Testing: Verifies that the product meets safety standards, particularly regarding electrical components and materials used.

B2B buyers should request information on the testing methods used and the results of any tests conducted on the products.

How Can B2B Buyers Verify a Supplier’s Quality Assurance Processes?

To ensure that potential suppliers adhere to strict quality assurance processes, B2B buyers can take several steps:

Illustrative image related to automatic canned food feeder

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes and quality control measures in place. This allows buyers to see firsthand how products are made and the standards maintained.

- Quality Reports: Request documentation of past quality control tests and outcomes. This data can provide insights into the supplier’s consistency and reliability.

- Third-Party Inspections: Engage third-party inspection services to evaluate the supplier’s operations and product quality independently. This adds an extra layer of verification.

What Should International Buyers from Diverse Regions Know About Quality Control Nuances?

For international buyers, understanding the nuances of quality control is vital. Different regions may have varying standards and practices. For instance, buyers from Africa or South America may encounter suppliers who prioritize cost-saving measures, potentially compromising quality. Conversely, European manufacturers may have stricter regulatory compliance due to EU standards.

It is essential for buyers to conduct thorough research on regional practices and engage suppliers who demonstrate a commitment to quality. This may include reviewing customer testimonials and industry reviews to gauge the supplier’s reputation in their respective markets.

By being informed about manufacturing processes and quality assurance practices, B2B buyers can make educated decisions when selecting suppliers for automatic canned food feeders. This knowledge not only helps in securing high-quality products but also fosters long-term business relationships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic canned food feeder’

In the competitive landscape of pet care products, sourcing an automatic canned food feeder requires a strategic approach. This guide provides a step-by-step checklist to help B2B buyers efficiently navigate the procurement process, ensuring you secure a reliable and high-quality product that meets your market needs.

Illustrative image related to automatic canned food feeder

Krok 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific features you require in an automatic canned food feeder. Consider factors such as capacity, compatibility with different food types (wet or dry), and smart features like app control or portion management. Clearly defined specifications will streamline your search and help you communicate your needs effectively to potential suppliers.

Krok 2: Research Market Trends and Competitors

Understanding current market trends is crucial for making informed purchasing decisions. Analyze competitors’ offerings to identify popular features and pricing strategies. This insight can guide your product selection, ensuring that your offering aligns with market demand and customer preferences.

Krok 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making any commitments. Request detailed company profiles, product catalogs, and case studies to assess their experience and reliability. It’s also beneficial to ask for references from other B2B buyers in your region or industry to gain insights into their performance and customer service.

Krok 4: Assess Compliance and Certifications

Verify that suppliers adhere to relevant industry standards and regulations. Look for certifications such as ISO, CE, or FDA approval, which indicate compliance with quality and safety requirements. Ensuring that products meet these standards is vital for safeguarding your business and maintaining customer trust.

Illustrative image related to automatic canned food feeder

Krok 5: Request Samples for Quality Testing

Once you have shortlisted suppliers, request samples of the automatic canned food feeders. Testing these samples allows you to evaluate the build quality, functionality, and ease of use. Pay attention to aspects like durability, noise levels, and user-friendliness, as these factors can significantly impact customer satisfaction.

Krok 6: Negotiate Pricing and Terms

Engage in negotiations with your chosen suppliers to secure favorable pricing and terms. Consider not only the unit price but also shipping costs, payment terms, and bulk order discounts. Establishing clear terms upfront can prevent misunderstandings and ensure a smoother procurement process.

Krok 7: Plan for After-Sales Support and Maintenance

After selecting a supplier, discuss after-sales support and maintenance options. Understanding the warranty, availability of spare parts, and customer service can help you manage any issues that may arise post-purchase. A supplier that offers robust after-sales support can enhance your operational efficiency and customer satisfaction.

Illustrative image related to automatic canned food feeder

By following these steps, B2B buyers can effectively navigate the sourcing process for automatic canned food feeders, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for automatic canned food feeder Sourcing

What Are the Key Cost Components for Sourcing Automatic Canned Food Feeders?

Understanding the cost structure of automatic canned food feeders is essential for B2B buyers aiming to optimize their sourcing strategies. The primary components include:

-

Materiały: The cost of raw materials like plastics, metals, and electronic components significantly impacts overall pricing. High-quality materials often lead to higher durability and better performance, which can justify a premium price.

-

Praca: Labor costs can vary widely based on geographic location and the complexity of the assembly process. Regions with lower labor costs might offer cheaper products, but this can sometimes come at the expense of quality.

-

Koszty ogólne produkcji: This encompasses costs related to factory operations, utilities, and administrative expenses. Suppliers with efficient production processes may be able to pass savings onto buyers.

-

Oprzyrządowanie: Custom tooling for specialized designs can be a significant upfront cost. Buyers seeking unique features or branding might face higher initial expenses, which should be factored into the total cost.

-

Kontrola jakości (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Buyers should evaluate the supplier’s QC practices to gauge the expected quality level.

-

Logistyka: Shipping costs, including freight and handling, can vary based on distance and shipping methods. International buyers must consider customs duties and tariffs, which can further influence the final price.

-

Margines: Supplier margins can vary, impacting the end price. Understanding typical markups in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect the Sourcing of Automatic Canned Food Feeders?

Several factors influence the pricing of automatic canned food feeders, and awareness of these can lead to better purchasing decisions:

-

Objętość/MOQ: Suppliers often provide discounts based on order volume. Minimum Order Quantities (MOQs) can affect pricing, and larger purchases generally yield better pricing per unit.

-

Specifications/Customization: Custom features can increase costs. Buyers should weigh the benefits of customization against the additional expenses incurred.

-

Materials and Quality/Certifications: High-quality materials and certifications (e.g., CE, ISO) can enhance product credibility and performance but also raise costs. Buyers should assess the importance of these factors relative to their market needs.

-

Czynniki dostawcy: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their brand value and proven track record.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect shipping costs and risk allocation. Understanding these terms is vital for budgeting and cost management.

What Are the Best Negotiation Tips for International Buyers?

Negotiation is a critical skill in sourcing automatic canned food feeders, especially for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Here are effective strategies:

-

Research Market Prices: Familiarizing yourself with market rates helps establish a baseline for negotiations. Having comparative pricing data from multiple suppliers can strengthen your position.

-

Leverage Volume Discounts: If your business can guarantee larger orders, use this as leverage to negotiate lower prices or better payment terms.

-

Discuss Total Cost of Ownership (TCO): Emphasize the long-term value and savings associated with quality products, as opposed to focusing solely on the initial purchase price. This approach can justify higher upfront costs.

-

Build Relationships: Cultivating strong supplier relationships can lead to better terms and pricing. Regular communication and trust can facilitate smoother negotiations.

-

Be Culturally Aware: Understanding cultural nuances in negotiation styles can enhance interactions. Tailoring your approach to align with regional practices can foster goodwill and cooperation.

What Pricing Nuances Should International Buyers Consider?

International buyers must navigate various pricing nuances when sourcing automatic canned food feeders. Fluctuations in currency exchange rates can affect purchasing costs. Additionally, understanding local market dynamics and consumer preferences can help tailor product offerings to specific regions, potentially improving sales and profitability.

Disclaimer

The prices mentioned throughout this analysis are indicative and can vary based on supplier negotiations, market conditions, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing automatic canned food feeder With Other Solutions

Exploring Alternative Solutions to Automatic Canned Food Feeders

In the rapidly evolving market of pet care, automatic canned food feeders have gained prominence for their convenience and efficiency. However, businesses should also consider alternative solutions that may better fit specific operational needs or budgets. This analysis compares automatic canned food feeders with two viable alternatives: traditional manual feeding and automatic dry food feeders.

Tabela porównawcza

| Aspekt porównawczy | Automatic Canned Food Feeder | Traditional Manual Feeding | Automatic Dry Food Feeder |

|---|---|---|---|

| Wydajność | High; delivers precise portions and maintains food freshness | Variable; depends on owner’s schedule | High; consistently dispenses measured portions |

| Koszt | Moderate to High ($50 – $500+) | Low; minimal equipment needed | Moderate ($30 – $200) |

| Łatwość wdrożenia | Requires initial setup and occasional maintenance | Simple; no setup required | Moderate; requires setup but generally user-friendly |

| Konserwacja | Regular cleaning and occasional part replacement | Minimal; occasional cleaning | Moderate; needs regular cleaning and may require battery changes |

| Najlepszy przypadek użycia | Ideal for multi-pet households or when owners are away | Best for owners who prefer direct feeding | Suitable for busy owners needing a consistent feeding schedule |

Detailed Breakdown of Alternatives

Traditional Manual Feeding

Manual feeding is the most straightforward method, where pet owners provide food at scheduled times. This approach offers the flexibility to adjust portions based on the pet’s immediate needs and dietary preferences. However, it requires a consistent commitment from the owner, which may not always be feasible. The primary advantages include low cost and minimal equipment. On the downside, it can lead to irregular feeding schedules and potential overeating if not monitored closely.

Automatic Dry Food Feeders

These feeders provide a solution for consistent portion control, utilizing a timer to dispense dry food at predetermined intervals. They often feature easy-to-clean components and can handle a range of food types. Automatic dry food feeders are particularly beneficial for busy pet owners or those managing multiple pets, ensuring that pets receive their meals on time. However, they may lack the ability to dispense wet food, which could be a significant drawback for pets requiring moisture-rich diets. Additionally, while they are generally less expensive than automatic canned food feeders, their performance can vary based on the quality of the device.

Conclusion: How to Choose the Right Feeding Solution

When selecting the appropriate feeding solution, B2B buyers should assess their specific needs, including the type of food, the number of pets, and the owner’s lifestyle. Automatic canned food feeders excel in maintaining food freshness and accommodating various dietary requirements, making them ideal for businesses focusing on premium pet care. Conversely, traditional manual feeding might suit businesses with limited budgets or those emphasizing a hands-on approach. Automatic dry food feeders represent a middle ground, offering convenience and consistency at a moderate cost. Ultimately, understanding these alternatives enables businesses to make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for automatic canned food feeder

What are the Key Technical Properties of Automatic Canned Food Feeders?

When considering the purchase of automatic canned food feeders, several technical properties are essential for ensuring reliability, efficiency, and user satisfaction. Here are some critical specifications that B2B buyers should evaluate:

-

Material Grade

The material used in the construction of the feeder significantly impacts its durability and safety. Common materials include food-grade plastics, stainless steel, and silicone. Food-grade plastics are lightweight and resistant to moisture, while stainless steel is known for its durability and ease of cleaning. Ensuring that the materials meet safety standards is crucial, especially when dealing with food products. -

Capacity

The capacity of the feeder refers to how much food it can hold at one time, typically measured in liters or ounces. For instance, a feeder with a capacity of 2L can hold enough food to serve multiple meals. B2B buyers must consider the feeding needs of their target market (e.g., pet shops, veterinary clinics) to choose a feeder with an appropriate capacity that minimizes frequent refilling. -

Dispensing Mechanism

Different feeders utilize various dispensing mechanisms, such as gravity-fed or motorized systems. A motorized feeder allows for more precise control over portion sizes and feeding schedules, which is essential for maintaining pet health. Evaluating the dispensing mechanism is vital for ensuring that the product meets customer expectations for reliability and ease of use. -

Power Source

Automatic feeders can be powered by batteries, AC power, or even solar energy. Battery-operated models offer flexibility and ease of placement, while AC-powered feeders may provide a more consistent power supply. Understanding the power source is critical for buyers who want to ensure that the feeder operates reliably in various environments. -

Smart Technology Integration

Many modern feeders come with smart technology features, such as app connectivity, timers, and health monitoring systems. These features allow users to control feeding schedules remotely and receive alerts about their pet’s eating habits. B2B buyers should assess the technological capabilities of feeders to cater to a growing market of tech-savvy consumers.

What are Common Trade Terminology and Jargon Related to Automatic Canned Food Feeders?

Understanding industry terminology is essential for B2B transactions in the automatic canned food feeder market. Here are some common terms:

-

OEM (producent oryginalnego sprzętu)

This term refers to companies that manufacture products or components that are sold under another company’s brand name. For B2B buyers, partnering with OEMs can provide access to high-quality feeders without the need for extensive manufacturing capabilities. -

MOQ (minimalna ilość zamówienia)

MOQ denotes the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for inventory planning and ensuring that the purchase aligns with demand forecasts. Buyers should negotiate MOQs that suit their business model to optimize stock levels. -

RFQ (zapytanie ofertowe)

An RFQ is a document sent by a buyer to suppliers requesting pricing and other terms for a specific quantity of goods. This process helps buyers compare costs and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (międzynarodowe warunki handlowe)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk management, and cost allocation, ensuring smooth logistics. -

Czas realizacji

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times is vital for inventory management and planning sales strategies. Buyers should inquire about lead times to align their operations with customer demands. -

Warranty Period

This term indicates the duration for which a product is guaranteed against defects or malfunctions. A longer warranty period often reflects the manufacturer’s confidence in the product’s quality. B2B buyers should consider warranty periods when evaluating suppliers to mitigate risks associated with product failures.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions regarding automatic canned food feeders, enhancing their purchasing strategy and ensuring better alignment with market needs.

Navigating Market Dynamics and Sourcing Trends in the automatic canned food feeder Sector

What are the Current Market Dynamics and Key Trends in the Automatic Canned Food Feeder Sector?

The automatic canned food feeder market is experiencing robust growth driven by several global factors. As pet ownership continues to rise, particularly in emerging markets in Africa, South America, and the Middle East, demand for innovative feeding solutions is surging. B2B buyers are increasingly seeking products that offer convenience, efficiency, and advanced technology features such as app connectivity, portion control, and smart monitoring capabilities. Notably, the integration of RFID technology for pet identification is becoming a key trend, allowing for personalized feeding schedules and reducing food wastage.

Illustrative image related to automatic canned food feeder

In regions like Europe and South America, where urbanization is leading to busier lifestyles, automatic feeders are seen as essential tools for pet owners who wish to ensure their pets receive proper nutrition without compromising their time. Moreover, sustainability is becoming a significant concern. Buyers are looking for manufacturers who prioritize eco-friendly materials and processes, making it essential for suppliers to adapt to these expectations. The market is also witnessing a shift towards subscription-based models, where consumers can receive regular deliveries of compatible food products, enhancing customer loyalty and recurring revenue for B2B partners.

How is Sustainability and Ethical Sourcing Shaping the Automatic Canned Food Feeder Market?

Sustainability has emerged as a critical consideration in the sourcing of automatic canned food feeders. The environmental impact of manufacturing processes and packaging materials is under scrutiny, prompting buyers to prioritize suppliers that demonstrate a commitment to reducing their carbon footprint. Ethical sourcing practices, including the use of recyclable materials and environmentally friendly manufacturing processes, are increasingly influencing purchasing decisions.

B2B buyers are now more inclined to partner with manufacturers that possess ‘green’ certifications, such as ISO 14001 or those recognized for using sustainable materials. This not only aligns with global sustainability goals but also appeals to consumers who are increasingly conscious of their purchasing choices. Furthermore, transparency in supply chains is becoming paramount; buyers are demanding detailed information about sourcing practices to ensure ethical compliance. As the market evolves, those suppliers who embrace sustainable practices and ethical sourcing will not only enhance their market position but also attract a loyal customer base.

What is the Brief Evolution and History of Automatic Canned Food Feeders?

The evolution of automatic canned food feeders dates back to the early 20th century, when simple mechanical devices began to emerge, allowing pet owners to automate feeding schedules. However, it wasn’t until the late 1990s and early 2000s that significant advancements in technology began to shape the market. The introduction of digital timers and portion control features made these devices more user-friendly and efficient.

Illustrative image related to automatic canned food feeder

As technology continued to evolve, the integration of smart technology into automatic feeders transformed the landscape. Features such as app connectivity, RFID pet recognition, and real-time monitoring became standard, appealing to tech-savvy pet owners. Today, the market is characterized by a diverse range of products that cater to various needs, from basic timed feeders to sophisticated systems that provide health monitoring and personalized feeding experiences. This evolution reflects the growing recognition of pets as family members and the increasing demand for solutions that enhance their care and well-being.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic canned food feeder

1. How do I solve issues with inconsistent feeding schedules in automatic canned food feeders?

To ensure consistent feeding schedules, choose feeders equipped with programmable timers and reliable dispensing mechanisms. Look for models that allow multiple meal settings and can accommodate various portion sizes. Additionally, consider feeders with backup battery options to prevent disruptions during power outages. Regular maintenance and testing of the timer functionality are essential to ensure it operates smoothly. Consulting with suppliers about their product reliability and customer reviews can also help in selecting a feeder that minimizes such issues.

2. What is the best automatic canned food feeder for multi-pet households?

For multi-pet households, feeders with multiple compartments and customizable portion sizes are ideal. Look for models that allow you to program individual feeding schedules for each pet, ensuring they receive the correct amount of food without interference. Features like RFID recognition can also prevent one pet from eating another’s food. Brands that offer dual or multi-bowl configurations, as well as those with smart monitoring capabilities, are particularly suitable. Always confirm compatibility with the type of canned food you plan to use.

3. How can I vet suppliers of automatic canned food feeders?

When vetting suppliers, consider their manufacturing certifications, product quality standards, and customer testimonials. Request samples to assess the feeder’s build quality and functionality. It’s also beneficial to check their production capacity and lead times to ensure they can meet your demand. Engage in direct communication to evaluate their responsiveness and willingness to accommodate custom orders or specific needs. Additionally, researching their history and reputation in the industry can provide insights into their reliability and professionalism.

Illustrative image related to automatic canned food feeder

4. What are the typical minimum order quantities (MOQs) for automatic canned food feeders?

MOQs for automatic canned food feeders can vary widely based on the supplier and the complexity of the product. Generally, you might expect MOQs to range from 50 to 500 units, depending on factors like customization options and pricing tiers. Discussing your specific needs with suppliers can sometimes lead to flexibility in MOQs, especially for first-time orders or long-term partnerships. It’s advisable to clarify these terms upfront to avoid any surprises during the ordering process.

5. What payment terms should I expect when purchasing automatic canned food feeders internationally?

Payment terms for international purchases can vary based on the supplier’s policies and the relationship established. Common terms include a 30% deposit upon order confirmation with the remaining balance due before shipment. Some suppliers may offer net 30 or net 60 payment terms for established clients. Always confirm acceptable payment methods, which may include wire transfers, letters of credit, or online payment platforms. Negotiating favorable terms can help manage cash flow effectively, especially when dealing with larger orders.

6. How do I ensure quality assurance (QA) for automatic canned food feeders?

Quality assurance can be ensured by implementing a multi-step process, including selecting suppliers with recognized quality certifications (e.g., ISO 9001). Request detailed product specifications and compliance documentation to verify materials and safety standards. Conduct pre-shipment inspections or audits to evaluate production quality. Establishing a good relationship with suppliers allows for ongoing communication regarding quality issues and improvements. Consider engaging third-party inspection services if necessary to provide an unbiased assessment of the products.

7. What logistics considerations should I keep in mind when sourcing automatic canned food feeders?

Logistics considerations include shipping methods, delivery times, and customs regulations. Choose suppliers who have experience with international shipping and can provide accurate lead times. Discussing freight options, such as air or sea, based on urgency and cost can help optimize logistics. Ensure the supplier provides proper documentation for customs clearance to avoid delays. Additionally, consider warehousing solutions if you plan to manage stock levels or distribute feeders across multiple regions.

Illustrative image related to automatic canned food feeder

8. How do I customize automatic canned food feeders to meet specific market needs?

Customization options can include size, color, branding, and functionality. Engage with suppliers who offer tailored solutions and are open to product modifications based on your specifications. Discuss your target market’s preferences, such as specific dietary needs or technological features like app connectivity or smart monitoring. Providing detailed requirements during initial discussions can help align your vision with the supplier’s capabilities. Always request prototypes or samples to evaluate the modifications before proceeding with bulk orders.

Top 4 Automatic Canned Food Feeder Manufacturers & Suppliers List

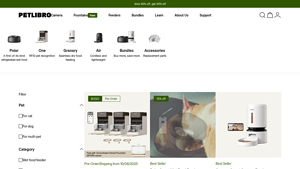

1. Petlibro – Smart Automatic Pet Feeders

Domena: petlibro.com

Registered: 2019 (6 years)

Wprowadzenie: Automatic Pet Feeders for Cats and Dogs – Petlibro offers a variety of feeders including: 1. Polar Smart Wet Food Feeder – Refrigerated wet food feeder with RFID pet recognition, priced at $149.99. 2. Granary Smart Camera Feeder – Dual bowl feeder with surveillance capabilities, priced at $139.99. 3. Granary Smart Feeder – App-controlled automatic feeder, priced at $89.99. 4. Granary Automatic Fee…

2. Petlibro – Granary Smart Camera Feeder

Domena: wired.com

Registered: 1992 (33 years)

Wprowadzenie: {“Best Dry Feeder”: {“Name”: “Petlibro Granary Smart Camera Feeder”, “Price”: “$160”, “Discounted Price”: “$105 (34% off)”, “Capacity”: “5 liters”, “Camera”: “1080p HD with night vision”, “App”: “Yes”, “Power Source”: “Power cord, three D backup batteries”, “Warranty”: “Two years”, “Food Type”: “Dry only”}, “Best Wet Feeder”: {“Name”: “Petlibro Polar Wet Food Feeder”, “Price”: “$150”, “Discounted …

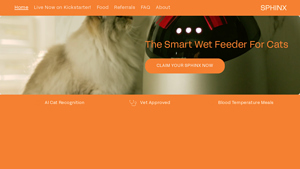

3. Sphinx Cat Feeder – Automatic Wet Food Dispenser

Domena: sphinxcatfeeder.com

Registered: 2022 (3 years)

Wprowadzenie: Sphinx Cat Feeder is an automatic wet cat food feeder designed for optimal cat health and behavior. Key features include:

1. Tailored meal plans for cats’ optimal health.

2. Effortless feeding and control via the Sphinx App, even when away from home.

3. Extended wet food storage for up to 2 weeks.

4. Two-way audio and video communication with cats.

5. Flexible food options with gourmet cat food cr…

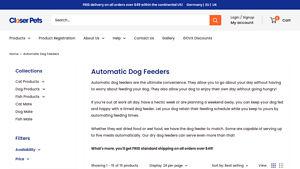

4. Closer Pets – Automatic Dog Feeders

Domena: closerpets.com

Registered: 2020 (5 years)

Wprowadzenie: Automatic dog feeders provide convenience by allowing pet owners to automate feeding times, ensuring dogs are fed even when owners are busy or away. They can accommodate both dry and wet food, with some models capable of serving up to five meals automatically. Key features include: 1. Free standard shipping on orders over $49 within the continental US. 2. Various models available, including the Mi…

Strategic Sourcing Conclusion and Outlook for automatic canned food feeder

As the demand for automatic canned food feeders grows, strategic sourcing becomes essential for B2B buyers looking to capitalize on this trend. Understanding product features—such as RFID recognition, app-controlled feeding, and dual food trays—enables businesses to select solutions that meet the diverse needs of pet owners. By prioritizing suppliers that offer high-quality, innovative products at competitive prices, buyers can enhance their offerings while ensuring customer satisfaction.

Moreover, the increasing emphasis on convenience and health monitoring in pet care products presents a unique opportunity for businesses to differentiate themselves in the market. Buyers should consider sourcing products that not only simplify feeding but also integrate health tracking features, as these elements resonate well with modern pet owners.

Looking ahead, the landscape for automatic canned food feeders is poised for significant growth, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Engaging with reliable manufacturers now will position businesses advantageously as they prepare to meet escalating demand. Take action today—evaluate your sourcing strategy and align with innovative suppliers to stay ahead in this competitive market.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Illustrative image related to automatic canned food feeder

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.