Introduction: Navigating the Global Market for how often to change sugar water for hummingbirds

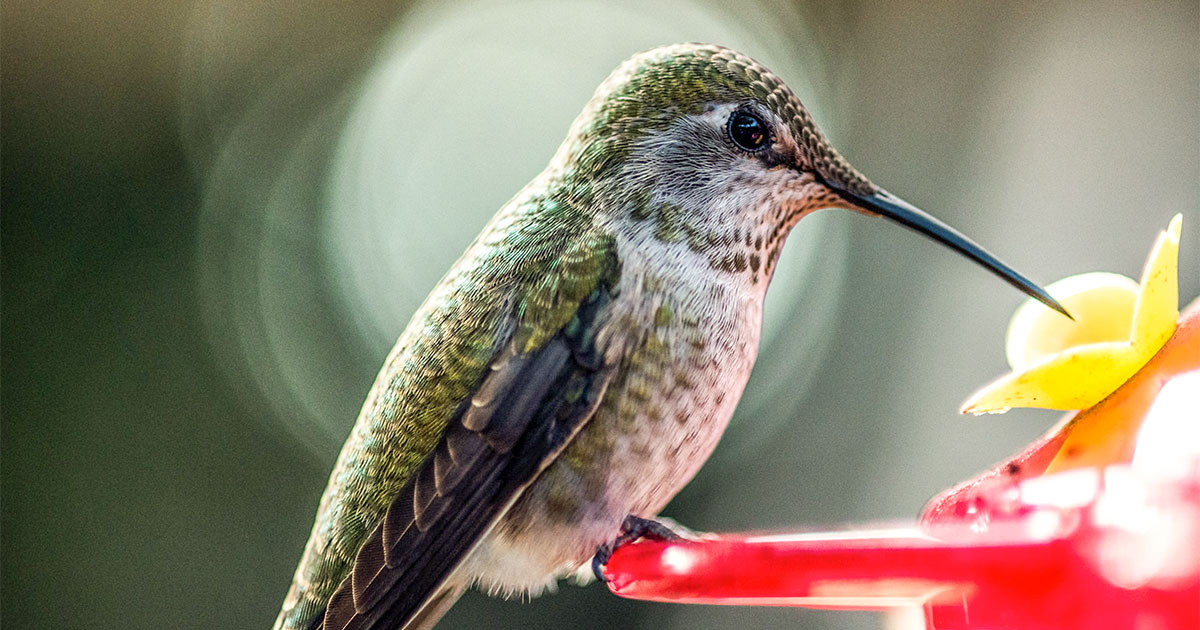

In the vibrant world of birding, understanding how often to change sugar water for hummingbirds is pivotal for both the health of these delicate creatures and the satisfaction of your customers. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers for hummingbird nectar solutions, they face challenges in ensuring product quality and freshness. This comprehensive guide delves into critical aspects such as the optimal frequency for nectar changes based on climatic conditions, the impact of feeder design, and effective supplier vetting processes.

By addressing the nuances of nectar maintenance, this guide equips buyers with actionable insights that empower informed purchasing decisions. Whether you are sourcing high-quality nectar products or exploring innovative feeder designs, understanding the interplay between environmental factors and nectar longevity is essential. Additionally, we will cover cost considerations and supplier reliability, ensuring that your business can thrive in a competitive marketplace.

With this knowledge at your fingertips, you can confidently cater to the needs of hummingbird enthusiasts, fostering a healthier ecosystem for these fascinating birds while enhancing your product offerings. Join us in navigating the global market for hummingbird nectar solutions, where informed decisions lead to sustainable success.

Spis treści

- Top 4 How Often To Change Sugar Water For Hummingbirds Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often to change sugar water for hummingbirds

- Understanding how often to change sugar water for hummingbirds Types and Variations

- Key Industrial Applications of how often to change sugar water for hummingbirds

- 3 Common User Pain Points for ‘how often to change sugar water for hummingbirds’ & Their Solutions

- Strategic Material Selection Guide for how often to change sugar water for hummingbirds

- In-depth Look: Manufacturing Processes and Quality Assurance for how often to change sugar water for hummingbirds

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change sugar water for hummingbirds’

- Comprehensive Cost and Pricing Analysis for how often to change sugar water for hummingbirds Sourcing

- Alternatives Analysis: Comparing how often to change sugar water for hummingbirds With Other Solutions

- Essential Technical Properties and Trade Terminology for how often to change sugar water for hummingbirds

- Navigating Market Dynamics and Sourcing Trends in the how often to change sugar water for hummingbirds Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often to change sugar water for hummingbirds

- Strategic Sourcing Conclusion and Outlook for how often to change sugar water for hummingbirds

- Ważne zastrzeżenia i warunki użytkowania

Understanding how often to change sugar water for hummingbirds Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Temperature-Based Changes | Nectar change frequency based on ambient temperature. | Retailers of hummingbird feeders and nectar supplies. | Plusy: Tailored to climate; ensures freshness. Wady: Requires constant monitoring of temperatures. |

| Seasonal Adjustments | Nectar change frequency varies with seasonal changes. | Suppliers targeting seasonal birdwatching markets. | Plusy: Aligns with bird migration; optimizes feeding. Wady: May confuse users unfamiliar with seasonal habits. |

| Humidity Considerations | Change frequency increases in humid conditions. | Manufacturers of specialized feeders for humid climates. | Plusy: Protects against spoilage; enhances feeder use. Wady: Limited applicability in dry regions. |

| Feeder Design Influence | Certain feeder designs prolong nectar freshness. | Vendors focusing on innovative feeder technology. | Plusy: Reduces maintenance; encourages bird visits. Wady: Higher initial investment for advanced designs. |

| User Experience Education | Emphasis on educating users about nectar spoilage signs. | Companies offering educational resources and guides. | Plusy: Increases customer loyalty; fosters engagement. Wady: Requires ongoing effort to educate customers. |

What Are Temperature-Based Changes for Nectar Frequency?

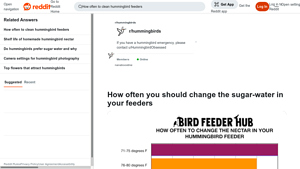

Temperature-based changes dictate how often sugar water should be refreshed in hummingbird feeders. In warmer climates, nectar may need to be replaced every 1-2 days, while cooler temperatures allow for a longer interval of up to 7 days. B2B buyers should consider this approach when stocking seasonal products, as it encourages sales of nectar solutions tailored to specific climates, ensuring optimal bird health and feeder efficiency.

How Do Seasonal Adjustments Affect Nectar Changes?

Seasonal adjustments in nectar change frequency are crucial for adapting to bird migration patterns and environmental changes. During peak migration seasons, nectar may require more frequent changes to attract birds. Suppliers can leverage this knowledge to develop marketing campaigns or seasonal product lines that cater to birdwatchers and nature enthusiasts, enhancing sales during these critical periods.

Why Are Humidity Considerations Important for Nectar Freshness?

Humidity plays a significant role in nectar spoilage, necessitating more frequent changes in humid regions. B2B companies that manufacture or sell feeders can benefit from educating customers about the effects of humidity on nectar. This knowledge can guide product development, such as creating specialized feeders designed to minimize spoilage, thus appealing to buyers in humid climates.

How Does Feeder Design Influence Nectar Freshness?

The design of hummingbird feeders can significantly impact how often nectar needs to be changed. Feeders that minimize nectar exposure to sunlight and are easy to clean can prolong freshness. B2B vendors should focus on promoting innovative feeder designs that enhance user experience and attract more hummingbirds, ultimately driving sales and customer satisfaction.

What Role Does User Experience Education Play in Nectar Management?

Educating users about the signs of spoiled nectar—such as cloudiness or unusual odors—can enhance their experience and encourage regular feeder maintenance. B2B companies can create informative resources, guides, or workshops to help customers understand nectar care. This approach not only fosters customer loyalty but also positions the company as a knowledgeable authority in the birding community, leading to increased sales and brand recognition.

Key Industrial Applications of how often to change sugar water for hummingbirds

| Przemysł/sektor | Specific Application of how often to change sugar water for hummingbirds | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Ornithology Research | Regular nectar changes for study of hummingbird feeding habits | Accurate data on feeding patterns and preferences | Quality and freshness of nectar; availability of feeders |

| Ekoturystyka | Maintaining feeders in wildlife parks to attract visitors | Enhanced visitor experience and birdwatching opportunities | Durable feeder designs; ease of cleaning and maintenance |

| Agriculture & Farming | Use of hummingbird feeders for pollination in fruit orchards | Improved crop yields through enhanced pollination | Nectar formulation; feeder placement for optimal attraction |

| Retail & E-commerce | Selling hummingbird feeders and nectar solutions | Increased sales through informed customers | Competitive pricing; supplier reliability; product education |

| Landscaping & Gardening | Incorporating hummingbird feeders in garden designs | Aesthetic appeal and biodiversity enhancement | Design compatibility; seasonal nectar supply considerations |

How Can Ornithology Research Benefit from Regular Nectar Changes?

In ornithology research, understanding hummingbird feeding habits is crucial. Regularly changing sugar water ensures that researchers collect accurate data on feeding frequency and preferences. Spoiled nectar can lead to misleading results, impacting studies on bird behavior and health. International buyers in this sector should prioritize sourcing high-quality feeders that facilitate easy cleaning and nectar replacement to maintain the integrity of their research.

Why is Eco-Tourism Enhanced by Hummingbird Feeders?

Eco-tourism businesses often rely on attracting wildlife to enhance visitor experiences. By maintaining fresh nectar in hummingbird feeders, these establishments can draw in more birds, providing excellent opportunities for birdwatching. This not only increases customer satisfaction but can also lead to repeat visits. Buyers in this industry must consider feeder durability and ease of maintenance to ensure long-term attraction of hummingbirds in various climates.

How Does Agriculture and Farming Benefit from Hummingbird Feeders?

In agriculture, particularly in fruit orchards, hummingbirds play a vital role in pollination. By strategically placing feeders with fresh nectar, farmers can enhance the presence of these birds, leading to improved crop yields. International buyers in agriculture should focus on sourcing high-quality nectar formulations that mimic natural flower nectar, as well as understanding the optimal placement of feeders to maximize pollination benefits.

What Role Does Retail and E-commerce Play in Hummingbird Nectar Solutions?

Retailers and e-commerce platforms can capitalize on the growing interest in backyard birding by offering hummingbird feeders and nectar solutions. Providing customers with clear guidelines on how often to change sugar water can enhance customer satisfaction and loyalty. Sourcing considerations for these businesses should include competitive pricing, supplier reliability, and the availability of educational resources that help customers maintain their feeders effectively.

How Can Landscaping and Gardening Incorporate Hummingbird Feeders?

Landscapers and gardeners can significantly enhance the aesthetic appeal of outdoor spaces by incorporating hummingbird feeders. Regularly changing the nectar not only attracts these beautiful birds but also promotes biodiversity. Buyers in this sector should consider the design compatibility of feeders with various garden styles and the seasonal availability of nectar to ensure a vibrant and inviting environment for both birds and people.

3 Common User Pain Points for ‘how often to change sugar water for hummingbirds’ & Their Solutions

Scenario 1: Understanding Nectar Freshness Across Diverse Climates

Problem: B2B buyers operating in regions with extreme weather variations, such as the Middle East or parts of Africa, struggle to determine the optimal frequency for changing sugar water in hummingbird feeders. The challenge lies in balancing the freshness of the nectar with the environmental conditions, which can accelerate spoilage due to high temperatures or humidity. This inconsistency can lead to health risks for the hummingbirds, causing potential reputational damage for businesses that rely on birdwatching tourism or hummingbird-related products.

Rozwiązanie: To effectively manage nectar freshness, B2B buyers should implement a climate-responsive strategy. Start by establishing a clear schedule based on local weather conditions: in cooler climates, nectar can be changed every 3-4 days, while in hotter climates, daily changes may be necessary. Invest in quality feeders that limit sunlight exposure and use insulated containers to store nectar, reducing spoilage. Providing training for staff on monitoring temperature and signs of spoilage—such as cloudiness or odor—can further enhance the quality of the nectar. By creating a systematic approach to nectar management, businesses can ensure the health of the hummingbirds and maintain their brand integrity.

Scenario 2: The Challenge of Educating Customers on Nectar Maintenance

Problem: Many businesses selling hummingbird feeders and nectar face the issue of customers being unaware of the importance of regular nectar changes. This lack of understanding can lead to poor feeder maintenance, resulting in moldy or spoiled nectar that deters hummingbirds and damages the business’s reputation. International buyers, especially in developing markets, may have limited knowledge about best practices, complicating the sales process.

Rozwiązanie: To tackle this educational gap, B2B buyers should develop comprehensive educational materials tailored to their target markets. This could include multilingual guides, video tutorials, and infographics detailing the importance of nectar freshness and maintenance routines. Hosting workshops or webinars can also engage customers directly, allowing for interactive learning. Providing a simple checklist for nectar maintenance—detailing how often to change the nectar based on local weather conditions and signs of spoilage—can empower customers. This proactive approach not only enhances customer satisfaction but also fosters brand loyalty and encourages repeat business.

Scenario 3: Managing Supply Chain for Nectar Ingredients

Problem: B2B buyers sourcing sugar for hummingbird nectar often encounter supply chain challenges that impact the consistency and quality of their products. Fluctuations in sugar prices, variations in quality, and delivery delays can disrupt operations, leading to inconsistent nectar offerings. This inconsistency can affect customer trust and impact sales, especially in competitive markets.

Rozwiązanie: Establishing reliable supplier relationships is critical for maintaining a steady supply of high-quality sugar. B2B buyers should conduct thorough market research to identify suppliers who offer consistent quality and competitive pricing. Forming partnerships with local sugar producers can reduce transportation costs and lead times, ensuring timely deliveries. Additionally, implementing a just-in-time inventory system can help manage stock levels more effectively, reducing waste and maintaining product freshness. Regular communication with suppliers regarding demand forecasts will further enhance supply chain reliability, allowing businesses to offer consistent, high-quality nectar to their customers. By optimizing the supply chain, companies can ensure a steady flow of quality ingredients, fostering customer trust and loyalty.

Strategic Material Selection Guide for how often to change sugar water for hummingbirds

What Materials are Best for Hummingbird Feeders?

When selecting materials for hummingbird feeders, particularly in relation to how often to change sugar water, it’s essential to consider factors such as durability, ease of cleaning, and resistance to environmental conditions. Here, we analyze four common materials used in hummingbird feeders: glass, plastic, metal, and silicone.

How Does Glass Perform in Hummingbird Feeders?

Key Properties: Glass is non-porous, which prevents the absorption of sugars and other contaminants. It can withstand a range of temperatures, making it suitable for both hot and cold climates.

Pros & Cons: Glass feeders are durable and easy to clean, providing a hygienic option for nectar storage. However, they can be heavier and more fragile than other materials, increasing the risk of breakage during transport or handling. Additionally, they may be more expensive due to manufacturing costs.

Impact on Application: Glass feeders maintain nectar freshness longer than plastic due to their insulating properties. They are ideal for regions with fluctuating temperatures, as they do not warp or degrade under heat.

Considerations for International Buyers: Buyers in regions like Europe may prefer glass due to its aesthetic appeal and recyclability. Compliance with safety standards, such as those set by ASTM or DIN, is essential, especially in countries with strict environmental regulations.

What Role Does Plastic Play in Hummingbird Feeders?

Key Properties: Plastic feeders are lightweight and often designed with UV-resistant materials to prevent degradation from sunlight exposure.

Pros & Cons: The primary advantage of plastic is its affordability and variety of designs. However, cheaper plastics may warp or discolor over time, especially in high temperatures. They can also retain odors and flavors from previous nectar, potentially affecting the quality of the sugar water.

Impact on Application: Plastic feeders are suitable for warmer climates where frequent nectar changes are necessary. Their lightweight nature makes them easy to transport, which is beneficial for international shipping.

Considerations for International Buyers: Buyers from Africa and South America may prefer plastic for its cost-effectiveness. However, it’s crucial to ensure that the materials meet local safety and environmental standards to avoid regulatory issues.

How Does Metal Influence Hummingbird Feeders?

Key Properties: Metal feeders, typically made from aluminum or stainless steel, are highly durable and resistant to corrosion, making them suitable for outdoor use.

Pros & Cons: The main advantage of metal feeders is their longevity and resistance to damage from birds or weather. However, they can heat up quickly in direct sunlight, potentially spoiling the nectar. Additionally, metal feeders may require more maintenance to prevent rusting.

Impact on Application: Metal feeders are best suited for regions with stable climates, as they can retain heat. They are less ideal for areas with high humidity where condensation may lead to mold growth.

Considerations for International Buyers: Buyers in the Middle East may appreciate the durability of metal feeders, but should consider the potential for heat retention. Ensuring compliance with local standards for food safety is critical, especially in areas with strict regulations.

What Benefits Does Silicone Offer in Hummingbird Feeders?

Key Properties: Silicone is flexible, heat-resistant, and can be molded into various shapes, making it a versatile material for feeder components.

Pros & Cons: Silicone feeders are easy to clean and can withstand extreme temperatures without degrading. However, they may not be as visually appealing as glass or metal options, and some lower-quality silicones can leach chemicals into the nectar.

Impact on Application: Silicone is beneficial in regions with extreme temperature fluctuations, as it maintains its integrity under varying conditions. Its flexibility allows for unique designs that can enhance feeder functionality.

Considerations for International Buyers: Buyers from Europe may be more inclined to invest in silicone feeders due to their innovative designs. Ensuring that the silicone is food-grade and compliant with relevant safety standards is essential for market acceptance.

Summary Table of Material Properties

| Materiał | Typical Use Case for how often to change sugar water for hummingbirds | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Szkło | Ideal for maintaining nectar freshness in varying climates | Durable and easy to clean | Heavy and fragile | Wysoki |

| Tworzywo sztuczne | Cost-effective for frequent nectar changes | Lightweight and affordable | May warp or retain odors | Niski |

| Metal | Long-lasting in stable climates | Highly durable and corrosion-resistant | Can heat up quickly | Średni |

| Silicone | Flexible design for extreme temperatures | Heat-resistant and easy to clean | Lower aesthetic appeal | Średni |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their hummingbird feeder offerings while considering the unique needs of different international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for how often to change sugar water for hummingbirds

What are the Main Stages of Manufacturing Hummingbird Nectar?

When it comes to the production of sugar water for hummingbirds, several critical manufacturing processes ensure that the product meets quality and safety standards. These stages can generally be broken down into material preparation, formulation, assembly, and finishing.

How is Material Prepared for Hummingbird Nectar?

The manufacturing process begins with sourcing high-quality ingredients, primarily sugar and water. The sugar must be of food-grade quality, often refined to a superfine texture to ensure easy dissolution. Water quality is also paramount; ideally, it should be purified to remove any chlorine or contaminants. In regions like Africa and South America, where access to clean water can vary, manufacturers often use advanced filtration systems to ensure purity.

What Formulation Techniques are Commonly Used?

Once the materials are prepared, the next stage is formulation. This involves carefully measuring the sugar-to-water ratio, typically a 1:4 ratio, which mimics natural flower nectar. This process may include boiling the water to dissolve the sugar fully, ensuring a uniform mixture. In some cases, manufacturers might add electrolytes to the nectar to enhance its nutritional value.

Techniques such as vacuum mixing can also be employed to reduce the introduction of air, which can lead to oxidation and spoilage. This is particularly important for products intended for export to markets in the Middle East and Europe, where the shelf life of the product is critical.

How is the Nectar Assembled for Packaging?

The assembly stage encompasses the bottling and packaging of the nectar. Bottles must be made from food-grade materials that are UV-resistant to limit light exposure, which can cause spoilage. Automated filling lines are often used to ensure consistency and speed. Labels must comply with local and international regulations, providing essential information such as ingredients, nutritional content, and usage instructions.

What Finishing Techniques Ensure Product Quality?

Finishing techniques include quality checks and sealing processes. Each bottle is typically sealed to prevent contamination and preserve freshness. In addition, some manufacturers use nitrogen flushing techniques before sealing to displace oxygen, further extending shelf life. The final product is then subjected to thorough inspections to ensure it meets quality standards before it reaches the market.

What Quality Assurance Measures are Essential for Hummingbird Nectar?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, particularly for products intended for international markets. Ensuring that the nectar is safe, effective, and consistent in quality is crucial for maintaining customer trust.

Which International Standards Apply to Hummingbird Nectar Production?

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to quality and continuous improvement. In addition to ISO, products may also need to comply with specific industry standards like CE marking for the European market or API standards for the Middle Eastern market.

What are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

Illustrative image related to how often to change sugar water for hummingbirds

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are tested for quality upon receipt. Sugar and water are both examined for purity and adherence to specifications.

-

In-Process Quality Control (IPQC): During the formulation and bottling processes, various parameters such as temperature, mixing time, and filling volumes are monitored to ensure they meet predefined standards.

-

Final Quality Control (FQC): After packaging, samples from each batch are tested for consistency, taste, and safety. This often includes microbial testing to ensure the absence of harmful bacteria or mold.

W jaki sposób nabywcy B2B mogą weryfikować kontrolę jakości dostawców?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can be done through:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices in place.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the methodologies and results of testing conducted at various checkpoints.

-

Third-Party Inspections: Engaging third-party inspectors can offer an unbiased evaluation of the supplier’s quality control practices, ensuring compliance with international standards.

What are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, understanding local regulations and quality standards is vital. Each region may have unique requirements regarding product labeling, ingredient sourcing, and safety testing.

How Do Regional Regulations Impact Quality Assurance?

In the Middle East, for instance, buyers may need to ensure that products comply with halal certification, while European buyers must be aware of stringent EU regulations regarding food safety. Understanding these nuances can significantly impact the decision-making process when selecting a supplier.

What Role Does Traceability Play in Quality Assurance?

Traceability is another critical factor in quality assurance. B2B buyers should ensure that their suppliers can trace the origin of their ingredients and the processes used in manufacturing. This is particularly important for organic or specialty products, where consumers demand transparency about sourcing and production methods.

Wnioski

Manufacturing high-quality hummingbird nectar involves a meticulous process that spans several stages, from material preparation to final quality assurance checks. For B2B buyers, particularly in international markets, understanding these manufacturing processes and quality control measures is essential for selecting reliable suppliers. By prioritizing quality and compliance with international standards, buyers can ensure that they provide safe and effective products to their customers, thereby fostering trust and loyalty in their brand.

Illustrative image related to how often to change sugar water for hummingbirds

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often to change sugar water for hummingbirds’

To effectively maintain hummingbird feeders, it is crucial for B2B buyers to understand the optimal practices for changing sugar water. This checklist serves as a practical guide to ensure the health and well-being of hummingbirds, which in turn can enhance the attractiveness of your products to customers.

Krok 1: Determine Local Climate Conditions

Understanding the climate in which your feeders will be used is essential. Warmer climates may require more frequent nectar changes due to faster spoilage rates. For instance, in tropical regions, nectar should be changed every 1-2 days, while in cooler areas, a weekly change may suffice.

Krok 2: Establish a Nectar Change Schedule

Create a consistent schedule for changing nectar based on temperature and humidity levels. A guideline is to change nectar every 2-4 days; however, adjust this according to environmental conditions. For example:

– Above 86°F (30°C): Change every day to every other day.

– 71°F to 80°F (22°C to 27°C): Change every 3-4 days.

This schedule will help maintain freshness and prevent spoilage.

Krok 3: Use Quality Ingredients for Nectar Preparation

Ensure that the sugar used in the nectar is of high quality and free from additives. A standard ratio is 1 part sugar to 4 parts water, boiled to eliminate impurities. Avoid using dyes or preservatives, as these can be harmful to hummingbirds. Prioritizing quality ingredients will reflect positively on your brand’s commitment to wildlife health.

Krok 4: Invest in Effective Feeder Design

Select feeders that minimize nectar exposure to sunlight and heat. Look for feeders made from materials that offer insulation or come with built-in shade. The design should also facilitate easy cleaning, as cleanliness is crucial to prevent mold and bacteria growth that can harm hummingbirds.

Krok 5: Implement Regular Cleaning Protocols

Establish a protocol for cleaning feeders before refilling them with fresh nectar. Use a mixture of water and vinegar or mild soap, ensuring all residues are thoroughly rinsed. Regular cleaning will prevent the buildup of harmful substances, ensuring that the nectar remains safe for consumption.

Krok 6: Monitor Nectar for Signs of Spoilage

Educate your team to regularly check nectar for signs of spoilage such as cloudiness, discoloration, or foul odors. Mold growth can occur quickly, especially in humid conditions, so routine inspections are critical. Promptly replacing spoiled nectar will help maintain hummingbird visitation rates and customer satisfaction.

Krok 7: Educate Customers on Best Practices

Provide your customers with educational materials on how often to change nectar and the importance of proper feeder maintenance. Consider including these guidelines in product packaging or as part of customer service outreach. Well-informed customers are more likely to have positive experiences and recommend your products to others.

By following this step-by-step checklist, B2B buyers can ensure that their hummingbird feeders are optimally maintained, enhancing the health of the birds and the satisfaction of their customers.

Comprehensive Cost and Pricing Analysis for how often to change sugar water for hummingbirds Sourcing

What Are the Key Cost Components for Sourcing Hummingbird Nectar?

When sourcing sugar water for hummingbirds, several cost components must be considered to effectively manage the financial aspects of the supply chain. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materiały: The primary raw material is sugar, which varies in price based on global market fluctuations. The type of sugar—granulated, superfine, or organic—can also impact costs. Water quality and any additives (e.g., electrolytes for enhanced nutrition) may contribute additional expenses.

-

Praca: Labor costs encompass the wages of workers involved in the production, packaging, and distribution processes. This can vary significantly by region, with labor costs in Africa and South America generally lower compared to Europe and the Middle East.

-

Koszty ogólne produkcji: This includes utilities, rent, and equipment maintenance associated with production facilities. Efficient manufacturing processes can help minimize overhead costs.

-

Oprzyrządowanie: Investment in specialized equipment for bottling and packaging can lead to significant upfront costs but may result in long-term savings through efficiency and reduced waste.

-

Kontrola jakości (QC): Ensuring the nectar meets safety and quality standards is crucial. This requires investment in testing and compliance processes, which can be a notable part of the overall cost structure.

-

Logistyka: Transportation and distribution costs vary by region and can be influenced by distance, mode of transport, and local infrastructure. For international buyers, understanding Incoterms is essential to clarify responsibilities for shipping and handling.

-

Margines: Suppliers typically aim for a profit margin that reflects the risks and investments involved. Negotiating favorable terms can help buyers secure better pricing.

How Do Price Influencers Affect Sourcing Decisions for Hummingbird Nectar?

Several price influencers come into play when sourcing hummingbird nectar, impacting both the initial price and the overall Total Cost of Ownership (TCO).

-

Objętość/MOQ: Suppliers often provide tiered pricing based on the minimum order quantity (MOQ). Higher volumes can lead to substantial discounts, making it beneficial for businesses that plan to scale.

-

Specyfikacje i personalizacja: Custom formulations (e.g., organic or fortified nectar) may incur higher costs. Buyers should assess their specific needs against standard offerings to identify potential cost savings.

-

Materiały: The choice between conventional and premium materials (like organic sugar) can affect pricing. Buyers should weigh the benefits of higher-quality inputs against their budget constraints.

-

Quality and Certifications: Products that meet specific certifications (e.g., organic or non-GMO) often come at a premium. Buyers in regions with stringent regulations should factor in these costs when sourcing.

-

Czynniki dostawcy: Reliability, reputation, and previous experience with suppliers can influence pricing. Long-term partnerships may lead to better terms and pricing stability.

-

Incoterms: Understanding the implications of different Incoterms is vital for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) can significantly affect the landed cost of goods.

What Are the Best Practices for International B2B Buyers Sourcing Hummingbird Nectar?

International buyers must navigate various challenges when sourcing hummingbird nectar. Here are some actionable tips:

-

Negocjacje: Always negotiate terms, especially on pricing and delivery schedules. Establishing a long-term relationship can lead to better rates and terms.

-

Efektywność kosztowa: Consider the TCO when evaluating suppliers. Look beyond the sticker price to understand logistics, quality, and potential waste.

-

Local Sourcing: When possible, source from local suppliers to reduce logistics costs and support local economies, especially in regions like Africa and South America.

-

Zapewnienie jakości: Implement stringent QC processes to ensure that the nectar remains fresh and safe for hummingbirds. This can prevent losses due to spoilage and enhance customer satisfaction.

-

Badania rynku: Stay informed about market trends and fluctuations in sugar prices to make informed purchasing decisions.

-

Flexibility: Be prepared to adapt sourcing strategies based on seasonal availability and changing market conditions.

Wnioski

While sourcing sugar water for hummingbirds involves various cost components and price influencers, strategic planning and informed decision-making can yield significant benefits. By understanding the dynamics of the market and employing best practices, international B2B buyers can optimize their sourcing strategies, ensuring both profitability and sustainability in their operations.

Illustrative image related to how often to change sugar water for hummingbirds

Alternatives Analysis: Comparing how often to change sugar water for hummingbirds With Other Solutions

Exploring Alternatives to Changing Sugar Water for Hummingbirds

In the quest to attract and nourish hummingbirds, maintaining fresh nectar is essential. However, there are various alternatives and methods that can complement or replace the traditional approach of changing sugar water. This analysis compares the frequency of changing sugar water with two viable alternatives: commercial hummingbird nectar and automatic nectar dispensing systems. Each solution has its unique advantages and considerations, making it important for B2B buyers to evaluate them carefully.

| Aspekt porównawczy | How Often To Change Sugar Water For Hummingbirds | Commercial Hummingbird Nectar | Automatic Nectar Dispensing Systems |

|---|---|---|---|

| Wydajność | Requires changing every 2-4 days, more often in heat | Long shelf life; consistent quality | Provides continuous feeding; reduces spoilage |

| Koszt | Low initial cost; sugar and water are inexpensive | Higher upfront cost; depends on brand | High initial investment; requires maintenance |

| Łatwość wdrożenia | Simple preparation; requires regular attention | Easy to use; no mixing needed | Requires setup; may need technical expertise |

| Konserwacja | Frequent cleaning needed; easy to manage | Minimal; depends on storage | Regular maintenance; cleaning required |

| Najlepszy przypadek użycia | Ideal for casual bird watchers; low volume setups | Suitable for high-traffic feeders; consistent availability | Best for commercial setups; high visitation rates |

Understanding Commercial Hummingbird Nectar

Commercial hummingbird nectar is a pre-mixed solution that eliminates the need for DIY preparation. The pros include a long shelf life and consistent quality, as these products are often formulated to mimic natural nectar without harmful additives. However, they can be more expensive than making nectar at home, and some brands may contain artificial colors or preservatives. For businesses looking to maintain high visitation rates with minimal effort, this option can be appealing, though it may not be as cost-effective in the long run.

Assessing Automatic Nectar Dispensing Systems

Automatic nectar dispensing systems represent a technological advancement in bird feeding. These systems can provide a continuous supply of nectar, reducing the risk of spoilage and ensuring that hummingbirds have access to food at all times. The main advantage is efficiency, particularly for businesses like nature reserves or commercial properties that experience high foot traffic. However, the initial investment can be significant, and these systems may require technical know-how for setup and maintenance. Additionally, regular cleaning is still necessary to prevent mold and bacteria buildup.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When evaluating the best solution for attracting hummingbirds, B2B buyers should consider their specific needs, such as the volume of visitors, budget constraints, and available resources for maintenance. For casual birdwatchers or small businesses, regularly changing sugar water may suffice, offering a low-cost and straightforward approach. Conversely, businesses with higher traffic or those seeking to streamline operations might benefit from commercial nectar or automatic dispensing systems, despite the higher costs. Ultimately, the choice hinges on balancing performance, cost, and ease of use to ensure a thriving environment for hummingbirds.

Essential Technical Properties and Trade Terminology for how often to change sugar water for hummingbirds

What Are the Essential Technical Properties for Hummingbird Nectar Management?

When dealing with hummingbird feeders, understanding the technical properties associated with nectar management is crucial for ensuring the health of these birds and the efficiency of your operations. Here are several key specifications to consider:

1. Nectar Composition

The standard recipe for hummingbird nectar is a 1:4 ratio of sugar to water, which must be free from dyes and preservatives. This composition is vital as it mimics natural flower nectar, essential for attracting hummingbirds. B2B buyers should prioritize products that meet this specification to ensure customer satisfaction and bird health.

2. Storage Temperature

Proper storage of nectar before use can significantly impact its freshness. It is recommended to store prepared nectar in a refrigerator to delay spoilage. Understanding the temperature tolerance helps in maintaining product quality, especially in warmer climates where spoilage rates increase.

3. Shelf Life

The shelf life of homemade nectar is approximately one week when stored in a cool place. However, once placed in a feeder, the nectar should be changed every 2 to 4 days, depending on environmental conditions. B2B buyers need to communicate these specifications to their customers, ensuring they understand the importance of timely nectar changes to prevent health risks to hummingbirds.

4. Feeder Material Durability

The materials used in hummingbird feeders (glass, plastic, etc.) can affect their ability to retain nectar freshness. For instance, glass feeders are generally more durable and less prone to retain odors compared to plastic. B2B suppliers should emphasize the benefits of using high-quality materials in their products to maintain customer trust and satisfaction.

What Trade Terminology Should B2B Buyers Know Regarding Hummingbird Nectar?

Understanding common trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are several key terms relevant to the hummingbird nectar industry:

1. OEM (producent oryginalnego sprzętu)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hummingbird feeders, buyers may work with OEMs to ensure that the nectar and feeder components meet specific quality standards.

Illustrative image related to how often to change sugar water for hummingbirds

2. MOQ (minimalna ilość zamówienia)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. For hummingbird nectar and feeder suppliers, understanding MOQ is crucial for managing inventory and ensuring that they can meet demand without overstocking.

3. RFQ (zapytanie ofertowe)

An RFQ is a business process in which a company solicits price quotes from suppliers for specific products or services. When sourcing hummingbird nectar or feeders, buyers may issue RFQs to compare prices and terms from various suppliers.

4. Incoterms (międzynarodowe warunki handlowe)

These are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers importing or exporting hummingbird feeders and nectar, as they determine shipping responsibilities and risks.

5. Czas realizacji

Lead time refers to the time taken from placing an order until it is received. Understanding lead times is essential for B2B buyers to manage their inventory levels effectively, especially during peak seasons when demand for hummingbird feeders may surge.

6. Sustainability Standards

In today’s market, sustainability is increasingly important. Buyers should inquire about the environmental impact of the materials used in feeders and nectar production. Adhering to sustainability standards can enhance brand reputation and meet consumer demand for eco-friendly products.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that not only enhance the well-being of hummingbirds but also improve operational efficiency and customer satisfaction in their businesses.

Navigating Market Dynamics and Sourcing Trends in the how often to change sugar water for hummingbirds Sector

What Are the Key Market Drivers Influencing Nectar Change Frequency for Hummingbirds?

The global market for hummingbird feeders and associated nectar solutions is increasingly influenced by several key drivers. The rise in birdwatching as a leisure activity has sparked a demand for quality feeding products, particularly in regions such as Africa, South America, the Middle East, and Europe. As urbanization progresses, more individuals are seeking ways to connect with nature, thus creating a burgeoning market for hummingbird-related products.

Emerging trends point towards the integration of technology in feeding solutions. Smart feeders equipped with sensors can monitor nectar levels and freshness, notifying users when it’s time to change the nectar. This is particularly appealing to international buyers who are looking for advanced, user-friendly solutions. Additionally, the increasing awareness of biodiversity and wildlife conservation is leading to a preference for high-quality, natural nectar solutions that mimic the nutritional value found in flowers, further driving market growth.

In the context of sourcing, international buyers are also encouraged to consider regional climatic variations. For instance, in warmer climates, the frequency of nectar changes may need to be higher, suggesting a localized approach to sourcing nectar products that can accommodate these dynamics.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in Nectar Products?

Sustainability is paramount in the modern B2B landscape, especially for products associated with wildlife. The environmental impact of sugar production is significant, prompting buyers to seek ethically sourced sugar options for hummingbird nectar. By prioritizing suppliers who offer organic and fair-trade sugars, businesses can contribute to sustainable agricultural practices while ensuring the health of local ecosystems.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should look for certifications such as USDA Organic or Fair Trade, which indicate a commitment to environmentally friendly practices and social responsibility. Such certifications not only enhance brand reputation but also appeal to a growing consumer base that values sustainability.

In addition to sugar sourcing, the materials used in the production of hummingbird feeders and associated products should also be scrutinized. Recycled or biodegradable materials can reduce the environmental footprint, making them more appealing to eco-conscious buyers. This commitment to sustainability can differentiate brands in a competitive market.

What Is the Historical Context Behind Nectar Change Practices for Hummingbirds?

The practice of changing sugar water for hummingbirds has evolved significantly over the years. Initially, bird enthusiasts relied on basic knowledge and anecdotal evidence regarding nectar freshness. However, as awareness of the importance of bird health and nutrition grew, so did the understanding of nectar management.

In recent decades, research has illuminated the detrimental effects of spoiled nectar on hummingbird populations, leading to more standardized practices. Today, it is widely accepted that nectar should be changed every 2 to 4 days, with adjustments based on climatic conditions. This evolution reflects a broader trend in wildlife care, where best practices are continually refined to enhance the well-being of species that rely on human-provided resources.

Illustrative image related to how often to change sugar water for hummingbirds

As international B2B buyers navigate this sector, understanding the historical context can provide valuable insights into current best practices and consumer expectations, ultimately influencing sourcing and product development strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of how often to change sugar water for hummingbirds

-

How often should I change the sugar water for hummingbirds in different climates?

The frequency of changing sugar water for hummingbirds largely depends on the climate. In warmer or humid conditions, it’s advisable to change the nectar every 1-2 days to prevent spoilage. For moderate temperatures (around 60-70°F), changing it every 2-4 days is suitable. Buyers should consider local temperature variations and humidity levels when determining the optimal frequency for nectar replacement to ensure the health of the birds and the effectiveness of their feeders. -

What is the best sugar-to-water ratio for hummingbird nectar?

The recommended sugar-to-water ratio for hummingbird nectar is 1 part sugar to 4 parts water. This mimics the natural nectar found in flowers. For optimal results, use white granulated sugar and avoid using any dyes or additives. This simple recipe ensures that the nectar is palatable for hummingbirds, promoting their health and encouraging frequent visits to feeders. -

How can I assess the quality of hummingbird nectar before changing it?

Regularly inspect the nectar for signs of spoilage. Look for cloudiness, discoloration, or any mold growth around the feeder ports. If the nectar has an off odor or appears thick, it’s time for a change. Maintaining high-quality nectar is crucial for attracting and retaining hummingbirds, as spoiled nectar can deter them from returning to the feeder. -

What logistics should I consider when sourcing hummingbird nectar supplies internationally?

When sourcing hummingbird nectar supplies, consider shipping times, customs regulations, and potential tariffs. Ensure that suppliers can provide timely delivery and that their products comply with local regulations in your region. Additionally, evaluate the reliability of logistics partners to prevent delays that could impact the freshness of the nectar upon arrival. -

How can I vet suppliers for hummingbird nectar and feeders?

To vet suppliers, research their reputation within the industry, including customer reviews and feedback. Request samples to assess product quality, and inquire about their sourcing practices and ingredient transparency. It’s also beneficial to verify certifications and compliance with international quality standards, ensuring that the products meet safety and health regulations. -

What are common minimum order quantities (MOQs) for hummingbird nectar products?

MOQs can vary widely among suppliers. Typically, MOQs for hummingbird nectar may range from 100 to 1,000 units, depending on the supplier’s production capacity and market strategy. When negotiating, inquire about flexibility in order sizes, especially if you’re just starting or testing the market, to ensure that you can meet your inventory needs without excessive upfront investment. -

What payment terms should I negotiate with suppliers?

When negotiating payment terms, consider options such as net 30, net 60, or even payment upon delivery, depending on your relationship with the supplier. It’s also wise to discuss potential discounts for early payments or bulk orders. Establishing clear payment terms can help manage cash flow and ensure a smooth transaction process. -

How can I ensure quality assurance (QA) for hummingbird nectar products?

To ensure quality assurance, establish clear quality standards with your suppliers, including product testing for sugar content and microbial contamination. Request documentation of quality control procedures and certifications. Regular audits and inspections can also help maintain consistent product quality, ensuring that the nectar remains safe and appealing for hummingbirds.

Top 4 How Often To Change Sugar Water For Hummingbirds Manufacturers & Suppliers List

1. Reddit – Hummingbird Feeder Care

Domena: reddit.com

Registered: 2005 (20 years)

Wprowadzenie: Change sugar-water in feeders every day when temperatures exceed 80 degrees; change every two days in cooler weather. Fresh nectar is essential for hummingbird health.

2. Facebook – Nectar Feeder Care

Domena: facebook.com

Zarejestrowany: 1997 (28 lat)

Wprowadzenie: This company, Facebook – Nectar Feeder Care, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Perky-Pet® – Clear Hummingbird Nectar Concentrate

Domena: perkypet.com

Zarejestrowany: 1996 (29 lat)

Wprowadzenie: Perky-Pet® offers a variety of instant hummingbird nectars made with 100% sucrose, containing no artificial flavors or sweeteners. The products include:

1. **Perky-Pet® Clear Hummingbird Nectar Concentrate** – 64 oz bottle, makes up to 256 oz of hummingbird food, mimics natural flower nectar.

2. **Perky-Pet® Instant Clear Hummingbird Nectar** – 2 lb bag, makes up to 192 oz of clear hummingbird nec…

4. Birdwatching Daily – Hummingbird Nectar Care

Domena: birdwatchingdaily.com

Registered: 2010 (15 years)

Wprowadzenie: Change hummingbird nectar every 1 to 2 days in hot weather (above 70°F) and every 3 to 5 days in cooler weather. Clean the feeder every time you change the nectar, with a more thorough cleaning at least once a week. Use hot tap water, mild dish soap, a bottle brush or pipe cleaners, and optionally white vinegar or a diluted bleach solution for cleaning. Prepare nectar using 1 part white table suga…

Strategic Sourcing Conclusion and Outlook for how often to change sugar water for hummingbirds

How Can Regularly Changing Hummingbird Nectar Benefit Your Business?

In summary, maintaining the freshness of hummingbird nectar is crucial for attracting and supporting these delicate creatures. For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, understanding the optimal frequency for changing sugar water is essential to ensure the health of hummingbirds and the effectiveness of your feeders. The general guideline of changing nectar every 2 to 4 days, or more frequently in warmer climates, highlights the importance of careful monitoring and timely action.

Strategic sourcing of high-quality nectar solutions, such as dye-free commercial products or well-formulated homemade recipes, can enhance your offerings and increase customer satisfaction. As the demand for hummingbird feeders rises, aligning your inventory with best practices in nectar management will position your business as a trusted resource in the market.

Looking ahead, consider investing in educational campaigns or resources that inform customers about the significance of nectar freshness. By doing so, you not only promote responsible feeding practices but also strengthen customer loyalty and drive sales. Embrace the opportunity to lead in this niche market, ensuring that both your business and the hummingbirds thrive.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.