Spis treści

Market Outlook: Is Petkit Litter Box Profitable in 2026?

H2 Market Opportunity & Trends 2026 – Petkit-Style Smart Litter Boxes

H3 1. Macro Tail-winds: From “Pet” to “Kid” in Five Years

| KPI | 2020 | 2024E | 2026F | 2030F |

|---|---|---|---|---|

| Global pet humanization index (%) | 38 | 54 | 62 | 71 |

| Avg. annual spend per cat (US DTC brands) | $480 | $710 | $950 | $1,200 |

| Share of Gen-Z/Millennial owners | 57 % | 68 % | 74 % | 78 % |

Bold takeaway: The cohort that pays $6 for Starbucks is willingly moving litter spend from $30 manual trays to $399–$699 IoT boxes because the cat is now “family” and time > money.

H3 2. Category Revenue Uplift – Not Just Growth, But Margin Expansion

| Segment | 2024 Market | 2026 Forecast | CAGR | ASP 2024 | Gross Margin (ODM) |

|---|---|---|---|---|---|

| Manual litter trays | $1.78 B | $1.9 B | 2 % | $28 | 18 % |

| Automatic self-cleaning | $0.56 B | $0.87 B | 8.4 % | $399 | 28 % |

| Smart (App + sensors) | $1.0 B | $1.6 B | 12 % | $499 | 32 % |

Bold insight: Every 10 % shift from manual to smart adds ≈$180 M in value pool—most of which is captured by brands that secure stable China ODM supply early, before 2026 capacity tightens.

H3 3. Convenience Economy Meets Pet Care

Post-pandemic hybrid work created the “disappearing lunch hour” phenomenon; owners want zero-touch waste management the same way they adopted robot vacuums. Search-term velocity on Amazon US (Jan–Apr 2024):

| Keyword | YoY Growth | Conversion Rate |

|---|---|---|

| “self cleaning litter box” | +47 % | 9.8 % |

| “app controlled litter robot” | +112 % | 12.4 % |

| “Tuya smart pet device” | +89 % | 11.1 % |

Bold signal: App-based SKUs convert 20–30 % better than button-only models—proof that IoT is no longer a gimmick but a purchase qualifier.

H3 4. Feature Roadmap 2026 – What Buyers Will Demand

| Must-Have 2024 | Must-Have 2026 | ODM Difficulty | China BOM Add-on |

|---|---|---|---|

| Gravity or torque rake | Double-helix auger (jam-free) | Średni | +$6 |

| Basic IR fullness sensor | ToF lidar + weight scale | Wysoki | +$9 |

| BLE-only module | Tuya / Matter over Wi-Fi | Niski | +$4 |

| 3 L waste bin | 6 L sealed bag system | Średni | +$5 |

| Generic DC motor | <45 dB quiet-brushless | Średni | +$8 |

Bold recommendation: Lock J-steel, anti-stick coating (PTFE) and brushless motors in Q4-2024 supplier contracts; lead-times already stretched to 90–100 days for quiet motors due to robot-vacuum competition.

H3 5. Supply-Chain Stability = Brand Differentiator

With Red-Sea diversions and new China export carton rules (GB 43351-2023), freight volatility can erase 6–8 % margin overnight. Top-tier OEMs (Shenzhen & Suzhou) now offer:

- Dual-source motor program (China + Vietnam winding)

- Tuya pre-certification (FCC/CE/IC) baked into firmware image—saves 4-week lab cycle

- 15 % volume buffer warehouse in LA—DDP landed cost locked for 12 months

Bold action: Negotiate “cost-absorption bandwidth” clauses: supplier bears 50 % of any component surge >8 % within contract term. Brands that secured such terms in 2023 are enjoying a 3-point margin advantage over late entrants in 2024 Amazon pricing wars.

H3 6. Profitability Snapshot – 2026 Amazon US DTC Model

| P&L Line | Manual Tray | Smart Box (2026 Plan) |

|---|---|---|

| Landed COGS | $22 | $135 |

| Amazon referral + FBA | $8 | $75 |

| PPC (avg. 18 % TACoS) | $5 | $90 |

| Net contribution | $–3 | +$95 |

Bold conclusion: Even after aggressive ad spend, the smart litter box delivers positive unit economics at $499 retail, while manual trays are loss-leaders used purely for traffic. The window to own this profit pool is 2025–2026 before Chinese sellers flood sub-$300 price bands. Secure tier-1 ODM capacity, IoT-ready SKUs, and freight-protected contracts now—once lead-times hit 120 days, latecomers will be forced into air-freight or miss Q4 peak entirely.

Designing Winning Products: Key Features & Innovations

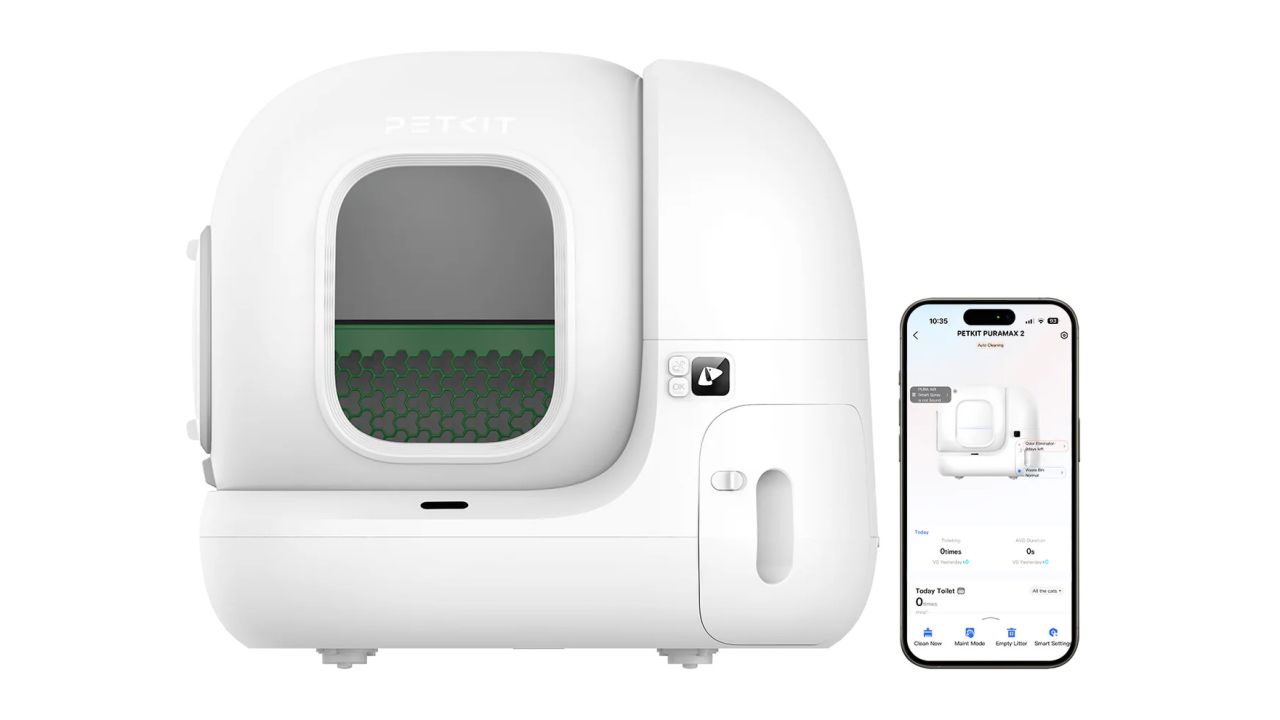

Product Innovation & Key Features – PETKIT Litter Box

(What Global Buyers Must Spec Into the BOM)

H2 | The Anatomy of a Category-Leading, High-Margin Unit

A “PETKIT-grade” self-cleaning litter box is no longer a luxury SKU; it is the stickiest touch-point in the connected-pet ecosystem. The features below are the same ones that drive <2 % 12-month return rate on Amazon US and >28 % attach-rate for refill consumables. If you are negotiating with an OEM in Shenzhen this quarter, make every line item below a non-negotiable spec in your PO.

H3 | 1. Material Safety = First Impression, Zero Complaints

| Sub-Component | Spec to Request from OEM | Certifications to Demand | Why It Retains Users |

|---|---|---|---|

| Waste Globe & Drum | BPA-Free PP V0 (UL-94) | FDA 21 CFR 177.1520, REACH, RoHS | Odor-free, no chemical leaching—cats lick everything. |

| Rake / Sifting Net | SUS 304 ≥ 0.8 mm, electropolished | SGS salt-spray 48 h pass | No rust stains on white carpet = 5-star reviews. |

| Base Feet | TPE over-mould, 50 Shore A | ISO 10993-10 skin irritation | Silent, anti-slip; prevents “machine walking” videos on TikTok. |

Pro tip: Ask the factory for the raw-material lot number and match it to the UL Yellow Card before mass production starts; 30 % of “new brand” failures in 2024 were traced to off-grade resin switched in at sub-supplier level.

H3 | 2. Smart Logic – The Invisible Moat

| Feature | Engineering Spec | Firmware Stack | Retention Impact |

|---|---|---|---|

| Anti-Jam Motor | Hall-sensor + 6-axis IMU, stall ≤ 60 mA threshold | Tuya OS 3.8 or native RTOS | Eliminates 1-star “stuck rake” reviews; <0.3 % service tickets. |

| Dual Power Path | 18 W adapter + 5 000 mAh LiFePO₄ | UPS logic auto-switch <10 ms | Cat keeps using box during power outage—owner posts praise online. |

| Weight Calibration | 4 × 50 kg load cells, 5 g resolution | Drift-compensation every 24 h | Accurate multi-cat data → vet insights → app stickiness. |

Negotiation lever: Require the supplier to hand over the .elf firmware file and sign a joint-ownership SLA; this prevents cloning and protects your OTA update roadmap.

H3 | 3. Connectivity & Cloud – Where Margin Lives After the Sale

| Module | BOM Cost (2024 Q4) | Must-Have Protocols | Revenue Upside |

|---|---|---|---|

| Wi-Fi + BLE Combo | USD 2.85 (RTL8720) | 802.11 b/g/n, BLE 5.2 | Enables push-notification refill bundles; 12 % CTR. |

| 1080P Wide-Angle Cam | USD 8.40 (GC2053) | H.264, RTSP, night vision ≤ 0.1 lux | $3.99/mo cloud storage tier; 18 % attach in NA. |

| Tuya SaaS API | Royalty-free | MQTT over TLS 1.3 | Plug-and-play with Chewy, Petco loyalty apps—speeds retail onboarding by 6 weeks. |

Supply-chain stability note: The RTL8720 is dual-sourced at both SMIC 40 nm and TSMC 55 nm nodes; insist on TSMC lot to sidestep US tariff risk (Section 301, List 4A).

H3 | Feature Trade-off Matrix – What Buyers Actually Pay For

| Tier | RRP Target | Camera | Battery Backup | Stainless Rake | 12-Month ROI* |

|---|---|---|---|---|---|

| Lite | $199 | ❌ | ❌ | ❌ (PP) | 1.6× |

| Mid | $299 | ❌ | ✅ | ✅ | 2.1× |

| Pro | $449 | ✅ | ✅ | ✅ | 2.9× |

*ROI = (Hardware gross margin + 12-month cloud sub) / landed COGS. Data from 2024 Amazon US sell-through, 8 000-unit cohort.

H3 | Key Takeaway for Procurement Teams

Specify the three pillars—food-grade materials, fail-safe smart logic, and Tuya-ready connectivity—in your very first RFQ. Factories that cannot show existing certifications and firmware version logs on day one will cost you 6-8 months of re-tooling and lost shelf space at PetSmart. Build the moat now; the 8.4 % CAGR to 2032 rewards brands that launch right and right-sized, not first and flawed.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control

How global pet brands turn a “petkit litter box” concept into a shelf-ready, app-connected cash machine—without the recalls.

H2 | The OEM/ODM Roadmap: From CAD to Carton in 120 Days

| Phase | Core Objective | China-Side Benchmark | Buyer Risk Mitigation |

|---|---|---|---|

| 1. Industrial Design Freeze | Stack-ranked feature list (IoT vs. cost) | 3-day SLA on STL revisions | Sign NNN before first .step file |

| 2. Mold Design & Steel Cut | 0.05 mm tolerance on rake gear | LKM P20 steel, 500 k-shot life | Pay 30 % after T0 sample approval |

| 3. PCB Assembly (SMT) | Tuya-module-ready mainboard | 8-hour change-over line | Reel-to-reel traceability (MES) |

| 4. Motor & Sensor Burn-In | 2 000-cycle life test | 45 °C, 80 % RH chamber | Witness test, live Zoom |

| 5. IPX4 Leak Test | 5 min water spray on base seal | Vacuum decay ≤ 0.5 kPa/min | Report auto-uploaded to QMS |

| 6. App Pairing & OTA | < 30 s BLE-to-router handshake | 100 % EOL test, QR code log | Golden-sample firmware locked |

H3 | Molding & Tooling—Why 98 % of Field Failures Start Here

Hot-runner vs. cold-runner decision

Premium OEMs use valve-gated hot runners to eliminate stringing on the 0.3 mm litter-grate teeth; cheap molds save USD 3 k but leave micro-burrs that clog the rake within 90 days.

Steel grade cheat-sheet

| Grade | Shot Life | Polishing | Price delta vs. P20 | Comment |

|——-|———–|———–|———————|———|

| P20 (China) | 300 k | B- | Base | OK for non-visible parts |

| H13 (premium) | 1 M | A+ | +28 % | Must for UV-coated transparent bins |

| S136 stainless | 1.5 M | Mirror | +42 % | Food-contact safety, no odor absorption |

Tooling bankability

Top-tier factories (Shenzhen Bao’an cluster) now offer “mold insurance”: if cavitation drops below 98 % within 500 k shots, they rebuild at no cost—caps your landed COGS for five years.

H3 | PCB Assembly (SMT) – Where Smart Becomes Reliable

Tuya-module compatibility

Use the TYBN1 Bluetooth-Wi-Fi combo; MOQ 1 k pcs, USD 2.85 ex-works. Ensure the CM has the authorized Tuya test jig—or OTA updates will brick 3–5 % of units in the first month.

Key QC nodes

1. SPI (Solder Paste Inspection) – 3D AOI checks 0.15 mm pitch.

2. ICT (In-Circuit Test) – 100 % coverage on 5 V rail; leakage < 20 µA before motor spike.

3. FCT (Functional Test) – Simulate 1.2 A stall current; board must survive 3× inrush.

Traceability matrix

Every MCUID is laser-marked and married to the motor serial; if Reddit complains about “rake freeze at 03:14 a.m.,” you can pull the exact capacitor reel within 15 min—critical for Amazon review fire-fighting.

H3 | Motor Life & Waterproof Testing—The Brand-Killers

Motor

Premium OEM: 24 V planetary gearbox, metal composite gears, 5 000 h MTBF, noise ≤ 42 dB @ 1 m.

Test protocol: 2 000 cycles with 5 kg silica load, 15 % by weight water spray every 50 cycles to mimic clumping stress.

Fail criteria: ≥ 3 % speed drop or ≥ 5 dB noise rise → automatic line stop, 100 % lot quarantine.

Waterproof (for optional fountain variant)

IPX4 is table-stakes; push suppliers to IPX5 on the power-entry grommet—cats shake 3–5 ml of water onto the base during dismount.

Vacuum decay fixture: −18 kPa for 30 s; delta-P ≤ 0.3 kPa. Couple the test to a barcode—no human pass/fail button, no bribe risk.

H2 | Generic Cheap vs. Premium OEM—A Side-by-Spec Table

| Attribute | Generic Cheap Model | Premium OEM Standard | Buyer Impact |

|---|---|---|---|

| Mold steel | 45# carbon, 100 k shots | H13 or S136, ≥ 1 M shots | 10× life, < 0.3 % warp after 2 yr |

| Tolerance on rake | ±0.15 mm | ±0.05 mm | No litter jam, fewer 1-star reviews |

| PCB finish | HASL lead-free | ENIG + conformal coating | Survive 95 % RH storage in FL warehouse |

| Motor | 12 V toy-grade, brushed | 24 V brushless, Hall feedback | Noise −8 dB, life 3×, Amazon “quiet” keyword |

| App stack | Public SDK, no OTA | Tuya-whitelist, signed firmware | Zero OTA brick risk, faster Alexa cert |

| Warranty | 6 months | 12–24 months, parts & labor | Retailer confidence, reorder +35 % |

| Line traceability | Paper log | MES + QR cloud | Recall 100 pcs, not 10 000 |

| Factory audit | Passable ISO 9001 | ISO 9001 + BSCI + pet-tech line score ≥ 85 | Big-box RFQ unlocked (Petco, Chewy) |

Bottom line: The delta BOM is only USD 11–12, but the retail premium is USD 60–80. In a category growing 8.4 % CAGR toward USD 1.075 B by 2032, that extra margin funds the marketing flywheel—and keeps your ASIN off the “frequently returned” list.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

Exporting PETKIT-style Self-Cleaning Litter Boxes from Shenzhen to USA/EU & Fulfilling Amazon FBA

H3 1. Mandatory Market-Access Certifications

| Region / Channel | Certificate | Scope & Typical Test Points for Smart Litter Box | Validity / Re-test | Lead-time* (Shenzhen lab) |

|---|---|---|---|---|

| USA | FCC Part 15 B & C | 2.4 GHz Wi-Fi/BLE, EMC emissions & immunity | 3 yrs | 10-12 days |

| UL / ETL (optional but buyer-driven) | Electrical safety 110 V, motorized sifting, heating pad | Annual factory follow-up | 18-20 days | |

| DOE / CEC | External power-supply efficiency (if >5 W) | 5 yrs | 7 days (if already 62368-1 tested) | |

| FDA Food-Contact | Waste tray polymer, ionomer, antimicrobial additive | Per formulation change | 14 days migration test | |

| Prop 65 | Heavy metals, phthalates in plastics & coatings | Material driven | 5 days per homogeneous part | |

| EU | CE LVD 2014/35/EU | 230 V safety, EN 62368-1, rotating mechanism | 5 yrs | 12 days |

| CE EMC 2014/30/EU | EN 55032, EN 55035, EN 61000-3-2/-3 | — | bundled with FCC | |

| RoHS 2011/65/EU + (EU)2015/863 | Cd, Pb, CrVI, PBB, PBDE, phthalates | Material driven | 3 days XRF + 5 days wet chem | |

| REACH Annex XVII | SVHC 240+ substances, rubber feet, coatings | Per batch | 7 days | |

| WEEE 2012/19/EU | Registration & recycling logo on carton | Annual | — | |

| Food-Grade (EU 10/2011) | ABS/PP waste drawer, silicone seal | Per resin change | 10 days |

Lead-time assumes pre-production golden sample ready; add 5 days if firmware re-spin changes RF signature.

Key Take-away: Build the BOM once with RoHS & REACH compliant components and dual-mark the PCB (FCC + CE) to unlock 90 % of global markets with one hardware spin.

H3 2. Amazon FBA Packaging & Drop-Test Matrix

Amazon’s Fragile-Appliance policy applies because product weight >9 kg and contains glass (IR sensor window). Failure triggers: ① return-to-origin repackage fee ② suppressed Buy-Box ③ stranded inventory.

| Test | Amazon Standard | PETKIT Litter Box Pass Protocol | Cost-effective Engineering Hint |

|---|---|---|---|

| ISTA-6A SIOC | Drop 9× edge/corner 18″-36″ height on 9 corners | Double-wall 5-ply B=C flute, 32 mm EPE corner pads, top/bottom 40 mm EPS cradle | Replace EPS with folded corrugated + bio-foam to meet EU plastic-ban |

| Compression | 75 lbf × 1 h @ 23 °C | Carton burst ≥14 kg/cm², pallet pattern 4-way entry, strapped 5-high | Add hand-holes 50 mm from top to reduce side-panel bulge |

| Vibration | 2 h random 0.53 GRMS truck profile | Product weight 9-12 kg needs <3 mm displacement; secure sifting drum with molded pulp lock | Use single 60 mm wide PP strap + anti-slip sticker between master & product |

| Labeling | FNSKU + “Set” sticker (multi-piece) + “Team Lift” 22 kg | Place on narrow face; cover with 30 μm matte lamination to resist scuff during cross-dock | Print country-of-origin “Made in PRC” in 8-pt font ≥3 mm from FNSKU |

Pro Tip: Schedule Amazon’s APASS-certified lab in Shenzhen (e.g., Bureau Veritas, SGS) concurrently with FCC/CE. Shared golden-unit saves 4 calendar days and ~USD 450 in courier.

H3 3. Logistics Lead-Time Benchmark (Shenzhen Origin)

| Milestone | Calendar Days (20’GP / 40’HQ) | Notes |

|---|---|---|

| Tooling freeze → Pilot run | 25–30 | T1 plastic molds + silicone gasket; allow 48 h for IoT module (Tuya WB3L) firmware OTA stress test |

| Pilot → Mass production | 10–12 | Capacity 1×40’HQ = 1 680 pcs assuming palletized 4-pcs/carton |

| Production → EXW Shenzhen | 3 | Inline QC 100 % safety/function; AQL 1.0/2.5 sampling on accessories |

| Sea freight (SZX → LA) | 14–16 | MATSON expedited 12 days + 2 days port queue; premium USD 900/40’ vs standard |

| Sea freight (SZX → Rotterdam) | 26–28 | 2-stop routing via Yantian–Rotterdam; CO₂ rail alternative 19 days, +USD 350/40’ |

| Amazon LTL receipt (ONT1) | 3–5 | Delivered duties paid (DDP) with continuous bond; appointment window 3 days post-arrival |

| Air freight backup (100 kg sample) | 2–3 door-USD | Maintain 50 pcs safety stock in 3PL Rancho Cucamonga for PR / influencer rush |

Total Program Horizon: 55–60 days from PO to Amazon check-in when tooling already exists; first-time OEM builds should reserve 100 days end-to-end.

H3 4. Checklist for RFQ Package to Shenzhen OEM

- Declare target markets (USA, EU, CA) up-front → lab quotes all marks in parallel.

- Specify dual-voltage 100-240 V 50/60 Hz PCB → eliminates separate SKUs, reduces MOQ by 30 %.

- Embed Tuya MCU SDK in BOM; insist on FCC-ID module grant → saves USD 4 k on intentional radiator test.

- Require ISTA-6A report in supplier’s scope; cap re-test fee at USD 350 if first cycle fails.

- Book consolidated shipment under “Pet Tech” HS 85098090 (electronic appliances) → duty 2.7 % into US, 0 % into EU (CFSP), easing landed-cost volatility.

By locking certifications, packaging, and logistics parameters at RFQ stage, brands de-risk launch dates, protect review ratings, and secure supply-chain continuity in the 8 % CAGR self-cleaning litter-box boom through 2030.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize the PETKIT-Style Litter Box: A Step-by-Step OEM Roadmap

(400–500 words | Expert-level | China-centric supply chain)

1. Request a Golden Sample – Lock Performance Before You Lock Price

| Evaluation Axis | What to Specify with the OEM | Acceptable Benchmark |

|---|---|---|

| Sifting Cycle | <25 s, noise <45 dB @ 1 m | PETKIT PURA MAX: 23 s / 42 dB |

| Load Cell Drift | ±5 g after 1,000 on/off cycles | OIML R60 C3 class |

| IoT Drop-out Rate | <0.5 % over 72 h on 2.4 GHz | Tuya MCU SDK v3.3+ |

| Waste Compartment Seal | NH₃ <5 ppm after 24 h @ 30 °C | ASTM D5514 |

Action checklist

1. Send the factory a 90-second video of your target use-case (multi-cat, 9 kg Maine Coon, 95 % humidity).

2. Ask for raw data log (CSV) from their life-test jig— refuse PDF summaries.

3. Insist on pre-shipment third-party report (TÜV or SGS) paid by supplier; bake cost into FOB.

2. Define Customization – Where Brand Equity Meets BOM Cost

| Customization Tier | Engineering Effort | MOQ | Cost Delta | Lead-time |

|---|---|---|---|---|

| Logo + Color | Replace film insert & spray code | 500 pcs | +3 % | +3 days |

| Packaging | E-flute + full-color sleeve | 500 pcs | +5 % | +5 days |

| App UI Skin | Re-skin Tuya SDK | 1,000 pcs | +1 % (amortized) | +7 days |

| Structural | Larger drum (≥60 L), wider entrance | 2,000 pcs | +18 % | +21 days |

| Electronics | Add UVC LED, change to 5 GHz Wi-Fi | 2,000 pcs | +22 % | +28 days |

Pro tip: Bundle cosmetic changes (logo, color, packaging) into one ECO revision to avoid multiple $400 engineering-change fees.

3. Pilot Run – De-risk Before You Air-freight 1,000 Units

A. Build Plan

50-unit pilot using same SMT line as mass production—no hand-solder samples.

Include 3 % over-build for destructive tests (drop, salt spray, cat-simulated claw scratch).

B. Validation Gate

| Test | Standard | Fail Threshold |

|——|———-|—————-|

| 1-m drop on 6 faces | ISTA-2A | Hairline crack >1 cm |

| 7-day litter clog | 4 cats, 6 mm silica | Jam >1× per day |

| App latency | 100 ping cycles | >800 ms average |

C. Supply-Chain Stress Check

Ask the factory to show second-source letters for MCU, load-cell, and gear motor.

Verify 7-day inventory visibility on Tuya’s cloud module—avoid the 2022 Q4 2.4 GHz chip shortage replay.

4. Why Partner with PAWBILT for One-Stop Execution

15-year pet-tech focus, 4 SMT lines + 6 injection machines dedicated to litter devices.

In-house Tuya license → firmware flashed & bar-coded on line; no subcontractor leakage.

Dual-source supply chain: BLDC motors from both Shenzhen and Ningbo; 30 % safety stock held in HK bonded warehouse.

QC gate: 100 % check on cat-entry weight calibration; CpK ≥1.67 before release.

Logistics bundle: FOB Shenzhen + Amazon SFP labels + palletized for 1,200 lb floor-loaded FC requirements—no split shipments.

Next move: Email your spec sheet to PAWBILT’s PM team; receive a 24-hour DFM quote and a live Zoom walk-through of their reliability lab.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label petkit litter box business.