Introduction: Navigating the Global Market for replace water fountain pump

In today’s competitive landscape, sourcing the right replacement water fountain pump can pose significant challenges for international B2B buyers. With a multitude of options available, from energy-efficient models to those equipped with advanced features like low water shut-off systems, making an informed decision is crucial to ensure optimal performance and longevity of water features. This comprehensive guide is designed to empower buyers from diverse regions—including Africa, South America, the Middle East, and Europe—by providing critical insights into the types of pumps available, their specific applications, and the essential criteria for vetting suppliers.

Navigating the global market for replacement water fountain pumps involves understanding various factors such as flow rates, sizing requirements, and installation considerations. This guide will delve into these aspects, helping you identify the best solutions that meet your operational needs while aligning with your budget. Additionally, we will cover effective strategies for evaluating suppliers, ensuring that you can procure high-quality products that comply with international standards.

By leveraging the information presented here, you will be equipped to make strategic purchasing decisions that enhance your fountain installations, ultimately driving customer satisfaction and business success. Whether you’re managing a hotel, a commercial property, or a public space, finding the right replacement pump is key to maintaining the aesthetic and functional integrity of your water features.

Spis treści

- Top 4 Replace Water Fountain Pump Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for replace water fountain pump

- Understanding replace water fountain pump Types and Variations

- Key Industrial Applications of replace water fountain pump

- 3 Common User Pain Points for ‘replace water fountain pump’ & Their Solutions

- Strategic Material Selection Guide for replace water fountain pump

- In-depth Look: Manufacturing Processes and Quality Assurance for replace water fountain pump

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘replace water fountain pump’

- Comprehensive Cost and Pricing Analysis for replace water fountain pump Sourcing

- Alternatives Analysis: Comparing replace water fountain pump With Other Solutions

- Essential Technical Properties and Trade Terminology for replace water fountain pump

- Navigating Market Dynamics and Sourcing Trends in the replace water fountain pump Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of replace water fountain pump

- Strategic Sourcing Conclusion and Outlook for replace water fountain pump

- Ważne zastrzeżenia i warunki użytkowania

Understanding replace water fountain pump Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Low Water Shut-Off Pumps | Automatically shuts off when water levels are low | Landscaping companies, municipal parks | Plusy: Prevents pump damage, reduces maintenance. Wady: May have higher upfront costs. |

| Premium Fountain Pumps | Enhanced low-water pickup, longer pre-filters | Large water features, commercial spaces | Plusy: Longer lifespan, reduced clogging. Wady: Higher price point, may require more complex installation. |

| Standard Fountain Pumps | Basic functionality with adjustable flow control | Residential gardens, small parks | Plusy: Cost-effective, easy to install. Wady: Limited features, may need frequent replacements. |

| In-line Capable Pumps | Can operate outside of water, connected via tubing | Fountains with limited space | Plusy: Flexible installation, suitable for various setups. Wady: Requires additional tubing, may complicate maintenance. |

| Tabletop Fountain Pumps | Designed for smaller, indoor fountains | Offices, small retail spaces | Plusy: Compact size, easy to relocate. Wady: Limited pumping height, lower flow rates. |

What Are Low Water Shut-Off Pumps and Their Applications?

Low Water Shut-Off Pumps are designed to automatically stop operation when water levels drop, protecting the pump from damage. This feature is particularly beneficial for B2B buyers managing fountains in environments with fluctuating water levels, such as outdoor parks or landscaping projects. By preventing dry running, these pumps can significantly reduce maintenance costs and extend the lifespan of the equipment, making them a smart investment for businesses concerned about operational efficiency.

How Do Premium Fountain Pumps Stand Out?

Premium Fountain Pumps offer advanced features like low-water pickup and longer pre-filters, which minimize clogging from debris. They are ideal for large water features or commercial spaces where consistent performance is crucial. B2B buyers should consider these pumps for their durability and efficiency, despite the higher initial investment. Their ability to maintain flow even at low water levels can enhance the aesthetic appeal of fountains in busy public areas.

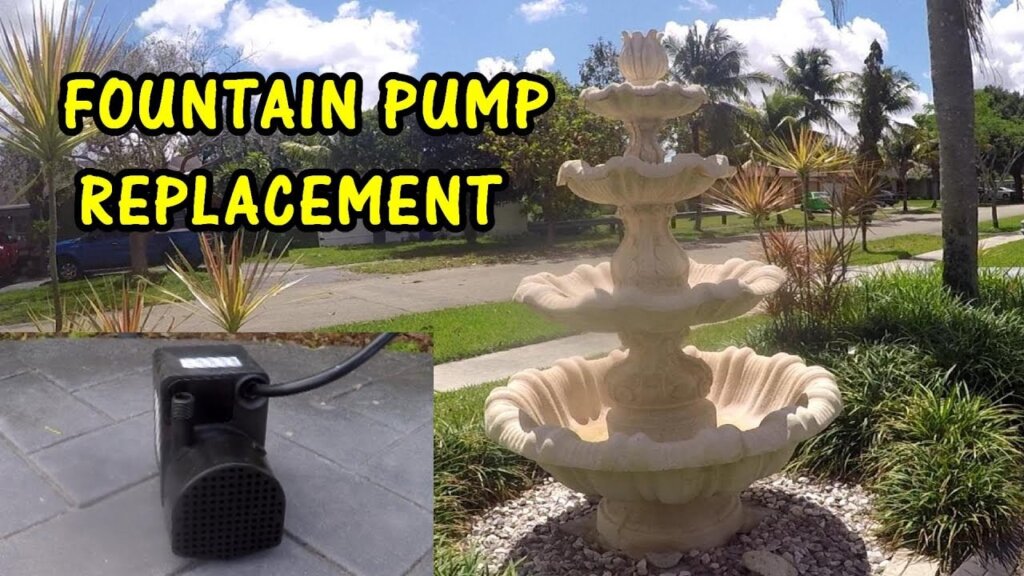

Illustrative image related to replace water fountain pump

What Should Buyers Know About Standard Fountain Pumps?

Standard Fountain Pumps provide basic functionality with adjustable flow control, making them suitable for residential gardens and small parks. Their affordability makes them a popular choice among B2B buyers looking for cost-effective solutions. However, it’s important to note that while they are easy to install, they may require more frequent replacements due to their simpler design and lack of advanced features.

Why Choose In-line Capable Pumps for Your Fountain?

In-line Capable Pumps can operate outside of the water, connected through tubing, which offers flexibility in installation. This makes them particularly useful for fountains with limited space or unconventional designs. B2B buyers should evaluate their specific needs, as these pumps can complicate maintenance due to the additional tubing required. However, their adaptability can be a significant advantage in diverse setups.

What Are the Benefits of Tabletop Fountain Pumps?

Tabletop Fountain Pumps are specifically designed for smaller indoor fountains, making them ideal for office spaces and small retail environments. Their compact size allows for easy relocation and setup, catering to B2B buyers with limited space. However, they typically have lower flow rates and pumping heights, so it’s essential to consider the specific requirements of the intended application when making a purchase.

Key Industrial Applications of replace water fountain pump

| Przemysł/sektor | Specific Application of replace water fountain pump | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Hospitality | Outdoor fountains in hotels and resorts | Enhances guest experience and property aesthetics | Energy efficiency, flow rate, and durability in various climates |

| Landscaping & Garden Design | Decorative water features in public parks | Attracts visitors, enhances ambiance, and promotes tranquility | Size compatibility, installation ease, and maintenance requirements |

| Aquaculture | Water circulation in fish farms | Ensures optimal oxygenation and water quality for aquatic life | Pump capacity, reliability, and resistance to corrosion |

| Municipal Infrastructure | Fountains in urban spaces and public squares | Provides recreational spaces and improves urban aesthetics | Compliance with local regulations, energy efficiency, and ease of maintenance |

| Retail | Fountain displays in shopping malls | Creates a welcoming atmosphere, encouraging foot traffic | Customization options, size and power requirements, and aesthetic appeal |

How Are Replacement Water Fountain Pumps Used in the Hospitality Industry?

In the hospitality sector, outdoor fountains serve as focal points in hotels and resorts, enhancing the aesthetic appeal and overall guest experience. Replacement water fountain pumps ensure these features operate efficiently, providing consistent water flow and preventing stagnation. International buyers from regions like the Middle East and Africa should consider energy-efficient models that can withstand local climate conditions, as well as pumps with low water shut-off features to prevent damage during dry spells.

What Role Do Replacement Pumps Play in Landscaping and Garden Design?

In landscaping and garden design, decorative water features, such as fountains and ponds, are pivotal in creating serene and inviting environments. Replacement pumps are essential for maintaining water circulation, which prevents algae growth and ensures the fountain remains visually appealing. Buyers in South America and Europe should prioritize pumps that are easy to install and maintain, especially in public parks where accessibility and durability are critical for long-term use.

Illustrative image related to replace water fountain pump

How Are Replacement Fountain Pumps Beneficial to Aquaculture?

Aquaculture relies heavily on water quality management, where replacement fountain pumps facilitate water circulation and aeration in fish farms. These pumps help maintain optimal oxygen levels, crucial for the health of aquatic life. B2B buyers in this sector must focus on pumps with high reliability and corrosion resistance, particularly in regions with varying water quality, ensuring longevity and minimal downtime.

Why Are Replacement Pumps Important for Municipal Infrastructure?

Municipalities utilize decorative fountains in urban spaces to create recreational areas and enhance public aesthetics. Replacement pumps are vital for keeping these installations functional and visually appealing. Buyers should consider compliance with local environmental regulations and energy efficiency to reduce operational costs, particularly in Europe, where sustainability is a significant concern. Additionally, ease of maintenance is crucial for municipal applications to ensure minimal disruption in public spaces.

How Do Replacement Fountain Pumps Enhance Retail Environments?

In retail settings, fountain displays create a welcoming atmosphere, encouraging customers to linger and explore. Replacement water fountain pumps are essential for maintaining the flow and visual appeal of these features. Retail buyers should look for customizable options that fit their specific design needs, as well as pumps that can handle variable power requirements, ensuring the fountain complements the overall shopping experience.

3 Common User Pain Points for ‘replace water fountain pump’ & Their Solutions

Scenario 1: Sizing the Replacement Pump Correctly

Problem: One of the most common challenges faced by B2B buyers when replacing a water fountain pump is ensuring that they select the correct size. A pump that is too small will result in insufficient water flow or spray, leading to a lackluster fountain display. Conversely, a pump that is too large may operate inefficiently, overworking itself and potentially burning out due to low water levels. This can cause operational downtime and increased maintenance costs, which are particularly concerning for businesses relying on fountains for aesthetic or functional purposes.

Rozwiązanie: To avoid these pitfalls, it is essential for buyers to understand the specifications of their existing fountain system. Begin by measuring the fountain’s water reservoir and determining the required flow rate, typically expressed in gallons per hour (GPH). For instance, if the fountain has a height of three feet, a pump with an appropriate GPH rating should be selected to achieve the desired height and spray effect. Buyers can consult manufacturer guidelines or product data sheets to find the ideal pump size. Additionally, utilizing adjustable flow control features in pumps allows for customization of water flow, accommodating changes in water levels or seasonal variations. Engaging with suppliers who provide technical support can further streamline the selection process.

Scenario 2: Dealing with Clogging Issues

Problem: Clogging is a frequent issue that can lead to the premature failure of fountain pumps. Debris such as leaves, dirt, or even small stones can obstruct the pump intake, leading to reduced efficiency and increased wear on the pump. For businesses, this not only disrupts the visual appeal of the fountain but can also result in costly repairs and replacements if left unaddressed. Regular maintenance is often overlooked, especially in larger installations where the fountain is part of a broader landscape.

Rozwiązanie: To mitigate clogging issues, businesses should invest in fountain pumps equipped with built-in pre-filters and low-water pickup features. These pumps are designed to handle debris more effectively and can operate at lower water levels without risk of damage. Regular maintenance schedules should be established, including routine cleaning of the pump and reservoir to prevent build-up. Implementing a proactive maintenance strategy, such as installing screens or mesh covers over the fountain openings, can also help minimize debris ingress. Educating staff about the importance of maintaining the water quality and cleanliness of the fountain will further enhance the lifespan of the pump and the overall fountain system.

Scenario 3: Electrical Compatibility and Installation Challenges

Problem: Another significant hurdle B2B buyers encounter is ensuring that the new pump is electrically compatible with existing systems. Different pumps may operate on varying voltage levels and may have specific wiring requirements, which can complicate the installation process. This is particularly challenging for businesses in regions where access to technical expertise is limited, leading to potential delays and increased costs associated with hiring external electricians for installation.

Rozwiązanie: To facilitate a smooth replacement process, buyers should start by reviewing the electrical specifications of both the existing and replacement pumps. It is critical to confirm the voltage and phase of the new pump to ensure compatibility with the existing electrical setup. Buyers should also seek pumps that come with comprehensive installation guides or customer support services. For those less experienced with electrical work, opting for pumps with plug-and-play designs can simplify the installation process. Additionally, forming partnerships with local suppliers who can provide on-site assistance or training can empower businesses to handle installations internally, reducing reliance on external contractors and enhancing operational efficiency.

Strategic Material Selection Guide for replace water fountain pump

What Are the Key Materials for Replacement Water Fountain Pumps?

When selecting a replacement water fountain pump, understanding the materials used in its construction is crucial for ensuring optimal performance and durability. Here, we analyze four common materials: plastic, stainless steel, bronze, and cast iron, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Plastic Perform in Water Fountain Pumps?

Plastic is a popular choice for many fountain pumps due to its lightweight and corrosion-resistant properties. Typically made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), plastic pumps can withstand moderate temperatures and pressures, making them suitable for various water features.

Illustrative image related to replace water fountain pump

Plusy: Plastic pumps are generally less expensive to manufacture, which translates to lower costs for buyers. They are also resistant to rust and corrosion, making them ideal for outdoor applications where exposure to water and elements is a concern.

Wady: However, plastic may not be as durable as metal alternatives. It can become brittle over time, especially under UV exposure, and may not perform well in high-pressure applications.

Impact on Application: Plastic pumps are suitable for freshwater applications but may not be compatible with saltwater or chemically treated water, limiting their use in certain environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the plastic used complies with local environmental regulations regarding material safety and durability.

What Are the Benefits of Stainless Steel Pumps?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for replacement fountain pumps. With a high-temperature and pressure rating, stainless steel pumps can handle demanding environments.

Illustrative image related to replace water fountain pump

Plusy: The primary advantage of stainless steel is its durability; it can withstand harsh conditions and is less likely to rust or corrode. This longevity often justifies a higher upfront cost.

Wady: The main drawback is the higher manufacturing complexity and cost associated with stainless steel pumps. They may also require more maintenance to prevent surface corrosion if not properly cared for.

Impact on Application: Stainless steel pumps are suitable for both freshwater and saltwater applications, providing versatility for various fountain designs.

Considerations for International Buyers: Buyers in Europe and South America should look for pumps that meet ASTM or DIN standards for quality assurance, particularly in environments with varying water quality.

Why Choose Bronze for Fountain Pumps?

Bronze, an alloy of copper and tin, offers excellent corrosion resistance, particularly in saltwater environments. This material is often used in high-end fountain pumps due to its aesthetic appeal and durability.

Plusy: Bronze pumps are highly resistant to corrosion and can operate effectively in both freshwater and saltwater applications. They also have a longer lifespan compared to plastic pumps.

Wady: The primary disadvantage is the cost; bronze pumps are typically more expensive than both plastic and stainless steel options. Additionally, they can be heavier, which may complicate installation.

Impact on Application: Bronze is particularly suitable for decorative fountains in coastal areas, where saltwater exposure is a concern.

Illustrative image related to replace water fountain pump

Considerations for International Buyers: Buyers should ensure that bronze pumps comply with local standards, especially in regions like Saudi Arabia, where environmental regulations may dictate material use.

What Role Does Cast Iron Play in Fountain Pumps?

Cast iron is known for its strength and durability, often used in larger, more industrial fountain applications. It can withstand high pressures and is less prone to damage from physical impacts.

Plusy: The key advantage of cast iron is its robustness; it can handle heavy-duty applications and has a long lifespan when properly maintained.

Wady: However, cast iron is susceptible to rust if not coated or maintained properly, and it is typically heavier, making installation more challenging.

Impact on Application: Cast iron pumps are ideal for large fountains or water features that require a significant flow rate and pressure.

Illustrative image related to replace water fountain pump

Considerations for International Buyers: Buyers in regions with high humidity or rainfall, such as parts of Africa, should consider protective coatings to prevent rust and ensure longevity.

Summary Table of Material Selection for Replacement Water Fountain Pumps

| Materiał | Typical Use Case for replace water fountain pump | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Tworzywo sztuczne | Small to medium fountains | Lightweight and corrosion-resistant | Less durable, can become brittle | Niski |

| Stainless Steel | Medium to large fountains | High durability and corrosion resistance | Higher cost and maintenance | Wysoki |

| Bronze | Decorative and coastal fountains | Excellent corrosion resistance in saltwater | Higher cost, heavier for installation | Wysoki |

| Cast Iron | Large industrial fountains | Robust and long-lasting | Susceptible to rust, heavier | Średni |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to replace water fountain pumps. By understanding the properties and implications of each material, buyers can make informed decisions that align with their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for replace water fountain pump

What Are the Key Stages in the Manufacturing Process of Replacement Water Fountain Pumps?

The manufacturing process of replacement water fountain pumps involves several critical stages, each designed to ensure the final product meets performance and durability standards. These stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to replace water fountain pump

Material Preparation: How Are Components Selected and Processed?

The first step in manufacturing replacement water fountain pumps is the selection and preparation of materials. Common materials include high-grade plastics for the pump casing, stainless steel for impellers, and durable rubber for seals. Each material is chosen for its resistance to corrosion, wear, and environmental factors.

Once selected, materials undergo rigorous quality checks to ensure they meet industry standards. This may involve testing for tensile strength, temperature resistance, and chemical compatibility. Suppliers often provide certificates of analysis (CoA) for their materials, which B2B buyers can request to verify compliance.

What Techniques Are Used in the Forming Process?

The forming stage is crucial in shaping the components of the fountain pump. Techniques like injection molding and die casting are commonly employed. Injection molding allows for precise shaping of plastic components, ensuring tight tolerances and consistent quality. In contrast, die casting is used for metal parts, creating robust and lightweight components.

Advanced technologies such as computer numerical control (CNC) machining may also be utilized to achieve intricate designs and specifications. This precision is vital for the efficient operation of the pump, as even minor deviations can affect performance.

Illustrative image related to replace water fountain pump

How Are Components Assembled into a Finished Product?

Assembly is where individual components come together to form the complete pump. This process often involves both automated and manual techniques. Automated assembly lines can significantly enhance efficiency and consistency, while skilled technicians may handle sensitive components requiring careful installation, such as electrical wiring and seals.

Quality control checks are integrated throughout the assembly line, ensuring that each component fits correctly and functions as intended. Common practices include visual inspections, functional tests, and performance evaluations to identify any defects before the product moves to the finishing stage.

What Finishing Processes Ensure Product Readiness?

The finishing stage involves several processes aimed at enhancing the pump’s durability and aesthetic appeal. This can include surface treatments, such as painting or coating, to protect against environmental wear. Additionally, pumps may undergo final testing to ensure they meet flow rate and pressure specifications.

Final packaging is also a critical aspect of the finishing process. Proper packaging not only protects the product during transportation but also provides essential information, including installation instructions and warranty details.

Illustrative image related to replace water fountain pump

What Quality Assurance Standards Are Relevant to Water Fountain Pump Manufacturing?

Quality assurance (QA) is vital in ensuring that replacement water fountain pumps meet both customer expectations and regulatory requirements. Several international and industry-specific standards govern this process.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized international standards for quality management systems. It emphasizes a process-oriented approach, ensuring that manufacturers maintain consistency in their products and services. Compliance with ISO 9001 can provide B2B buyers with confidence in a supplier’s commitment to quality.

Additionally, CE marking is critical for products sold in the European market. It indicates that the product meets EU safety, health, and environmental protection standards. For buyers in the Middle East or Africa, understanding local regulations and certifications is equally essential to ensure compliance and avoid costly delays.

What Are the Checkpoints in the Quality Control Process?

Quality control in the manufacturing of fountain pumps typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials and components before they enter the production process. Suppliers must provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): As components are manufactured and assembled, IPQC involves continuous monitoring of production processes. This can include measuring tolerances and conducting functional tests to identify any issues early.

-

Final Quality Control (FQC): Before products are packaged and shipped, FQC ensures that the final assembled pumps meet all performance specifications and safety standards. This may include flow tests, pressure tests, and other performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to verify the quality control practices of potential suppliers. Here are several effective strategies:

Illustrative image related to replace water fountain pump

What Auditing Practices Should Be Implemented?

Conducting audits is a proactive approach to verifying a supplier’s quality assurance processes. Buyers can request to see the results of internal audits or even conduct their own. This provides insights into the supplier’s operations, adherence to quality standards, and overall reliability.

How Important Are Third-Party Inspections?

Third-party inspections can serve as an independent verification of a supplier’s quality control measures. Engaging a reputable inspection agency can provide detailed reports on manufacturing practices, compliance with industry standards, and product performance.

What Documentation Is Crucial for Quality Verification?

Documentation plays a crucial role in quality assurance. B2B buyers should request quality control reports, certificates of compliance, and testing results. This documentation serves as evidence of a supplier’s commitment to maintaining high standards and can be invaluable in case of disputes or quality issues.

What Nuances Should International Buyers Be Aware Of Regarding Quality Control?

International buyers must navigate various nuances in quality control that can affect their purchasing decisions. Understanding local standards, cultural differences in manufacturing practices, and logistical challenges is essential.

How Do Cultural Differences Impact Quality Assurance?

Cultural attitudes toward quality and workmanship can vary significantly across regions. Buyers should be aware of these differences and consider them when evaluating suppliers. Establishing clear communication and expectations can help bridge these gaps and ensure alignment on quality standards.

Illustrative image related to replace water fountain pump

What Logistical Challenges Should Be Anticipated?

Logistical challenges, including transportation and customs regulations, can impact the timely delivery of replacement water fountain pumps. Buyers should factor in these potential delays when negotiating contracts and timelines with suppliers, ensuring that quality assurance processes are not compromised.

By understanding the manufacturing processes and quality assurance practices specific to replacement water fountain pumps, B2B buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replace water fountain pump’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers looking to procure replacement water fountain pumps. Whether you are operating in the hospitality industry, landscaping, or municipal services across Africa, South America, the Middle East, or Europe, understanding how to select the right pump is essential for ensuring operational efficiency and enhancing the aesthetic appeal of water features.

Krok 1: Define Your Technical Specifications

Before initiating the procurement process, clearly define the technical specifications of the pump you need. Consider factors such as the fountain size, desired flow rate (GPH), and pumping height. These specifications will directly influence the performance and longevity of the fountain.

Illustrative image related to replace water fountain pump

- Flow Rate: Ensure you calculate the required gallons per hour (GPH) based on your fountain’s design.

- Pumping Height: Assess the vertical distance from the water level to the highest point of the fountain’s spray.

Krok 2: Research Different Pump Types

Familiarize yourself with the various types of fountain pumps available in the market. Each type has unique features that cater to different needs, such as energy efficiency, noise levels, and maintenance requirements.

- Low Water Shut-Off Pumps: Ideal for areas where water levels fluctuate; they prevent pump damage by shutting off automatically.

- In-line Pumps: Suitable for fountains with limited space; these can be placed below the fountain, connected via tubing.

Krok 3: Evaluate Supplier Certifications

When sourcing pumps, it’s crucial to verify that potential suppliers hold relevant certifications and comply with international quality standards. This step ensures that you are purchasing a reliable product that meets safety and performance benchmarks.

- ISO Certifications: Look for suppliers with ISO 9001 or other relevant certifications, indicating quality management practices.

- Environmental Standards: Ensure compliance with local environmental regulations, especially if the pump will be used in public spaces.

Krok 4: Request Product Samples and Specifications

Before finalizing any orders, request product samples and detailed specifications from shortlisted suppliers. This step allows you to assess the pump’s quality and compatibility with your existing fountain system.

Illustrative image related to replace water fountain pump

- Technical Data Sheets: Examine flow rates, energy consumption, and installation requirements.

- Sample Testing: If possible, test the pump in a similar application to evaluate performance.

Krok 5: Compare Pricing and Warranty Options

Pricing can vary significantly among suppliers, so it’s essential to compare costs while also considering warranty options. A lower price may not always equate to better value if the warranty and support services are lacking.

- Warranty Length: Look for pumps with a minimum one-year warranty to cover potential defects.

- Total Cost of Ownership: Factor in the energy efficiency of the pump, as this can lead to significant savings over time.

Krok 6: Assess Supplier Support and Service

Strong post-purchase support can significantly impact your satisfaction and operational efficiency. Assess the level of customer service offered by the supplier, including technical support and parts availability.

- Technical Assistance: Ensure the supplier provides comprehensive guidance on installation and troubleshooting.

- Parts Availability: Confirm that spare parts are readily available for maintenance and repairs.

Krok 7: Finalize Your Order and Confirm Logistics

Once you have selected a supplier and product, finalize your order by confirming logistics, including shipping times and delivery options. Effective logistics management is vital to ensure timely installation and minimize downtime.

- Lead Times: Understand the expected delivery times and plan your installation schedule accordingly.

- Shipping Costs: Factor in shipping costs to avoid unexpected expenses that could impact your budget.

By following this checklist, B2B buyers can confidently navigate the procurement process for replacement water fountain pumps, ensuring they make informed decisions that enhance their water features and meet their operational needs.

Comprehensive Cost and Pricing Analysis for replace water fountain pump Sourcing

When considering the replacement of water fountain pumps, understanding the comprehensive cost structure is crucial for B2B buyers looking to optimize their sourcing strategy. The costs involved can be broken down into several key components, each influencing the overall price of the pump.

What Are the Key Cost Components in Fountain Pump Sourcing?

-

Materiały: The primary cost driver in fountain pump manufacturing is the materials used. Common materials include durable plastics, metals for the pump casing, and electrical components. Higher-quality materials often lead to increased durability and efficiency, which may justify a higher initial cost.

-

Praca: Labor costs encompass the wages paid to workers involved in the manufacturing process. This includes assembly line workers, engineers, and quality control inspectors. The labor cost can vary significantly depending on the region, with labor-intensive manufacturing being more expensive in developed countries compared to emerging markets.

-

Koszty ogólne produkcji: This includes costs associated with facilities, utilities, and indirect labor. Overhead can vary based on the production scale and location of the manufacturing facility. Larger manufacturers may have economies of scale that reduce per-unit overhead costs.

-

Oprzyrządowanie: Custom tooling for specific pump designs can add to the initial cost. If a buyer requires a unique design or specifications, the tooling costs can be significant. Standardized pumps typically have lower tooling costs due to existing molds.

-

Kontrola jakości (QC): Ensuring product quality involves additional costs for testing and inspection. Pumps with certifications (like ISO or CE) often come at a premium due to the rigorous QC processes required to meet international standards.

-

Logistyka: Transporting pumps from the manufacturer to the buyer’s location incurs shipping and handling costs. Factors such as distance, shipping method, and import tariffs can significantly affect logistics costs, especially for international buyers.

-

Margines: Suppliers will factor in their desired profit margin, which can vary widely based on market competition, brand reputation, and distribution costs.

How Do Price Influencers Affect Fountain Pump Costs?

-

Objętość/MOQ: Bulk orders typically lead to lower per-unit prices. Manufacturers often offer discounts for larger orders, making it essential for buyers to evaluate their needs and consider economies of scale.

-

Specyfikacje i personalizacja: Custom features or higher performance specifications can lead to increased costs. Buyers should balance the need for specific features with budget constraints, opting for standard models when possible.

-

Materiały i certyfikaty jakości: Pumps made from higher-grade materials or those that have undergone stringent certification processes will generally command a higher price. Buyers should assess the long-term benefits of investing in quality against upfront costs.

-

Czynniki dostawcy: The reliability and reputation of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge a premium, but they can also reduce risk for buyers.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Buyer Tips for Cost-Efficiency in Fountain Pump Sourcing?

-

Negotiate: Engage suppliers in discussions about pricing, especially for larger orders. Negotiating can uncover discounts or better payment terms that enhance cost-efficiency.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate operational costs, maintenance, and potential downtime associated with lower-quality pumps to make a more informed decision.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should be aware of additional costs related to customs duties and taxes. Researching local regulations can prevent unexpected expenses.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can help ensure that the selected pump meets performance expectations, potentially saving costs on replacements or repairs later.

-

Stay Informed on Market Trends: Keeping abreast of market trends and technological advancements in pump design can provide insights into potential future cost reductions and efficiency gains.

By understanding these cost components and price influencers, B2B buyers can make informed decisions, ensuring they source the right fountain pump that meets both their operational needs and budget constraints.

Alternatives Analysis: Comparing replace water fountain pump With Other Solutions

Exploring Alternative Solutions to Replacing Water Fountain Pumps

When it comes to maintaining the functionality of water fountains, replacing the pump is often a primary solution. However, there are alternative methods and technologies that can also achieve similar outcomes. This analysis explores these alternatives, helping B2B buyers make informed decisions based on their specific needs.

Tabela porównawcza

| Aspekt porównawczy | Replace Water Fountain Pump | Solar-Powered Fountain System | Water Circulation System |

|---|---|---|---|

| Wydajność | High flow rate, consistent water movement | Variable flow, dependent on sunlight | Continuous water movement, adjustable flow |

| Koszt | Moderate initial cost, ongoing maintenance | Higher upfront cost, lower operational costs | Moderate to high cost, depending on system size |

| Łatwość wdrożenia | Straightforward, requires basic plumbing skills | Requires installation of solar panels, may need structural support | Can be complex, requires plumbing and electrical knowledge |

| Konserwacja | Regular checks needed, potential for clogging | Low maintenance, occasional cleaning of solar panels | Regular checks needed, filters must be replaced periodically |

| Najlepszy przypadek użycia | Ideal for traditional fountains needing reliable operation | Best for eco-friendly installations in sunny areas | Suitable for larger water features or ponds requiring circulation |

Detailed Breakdown of Alternatives

What Are the Advantages of a Solar-Powered Fountain System?

Solar-powered fountain systems utilize renewable energy, making them an environmentally friendly option. They often come with built-in batteries that store energy for use during cloudy days. The primary downside is that their performance can be inconsistent in areas with limited sunlight, which may affect water flow rates. Additionally, the initial installation can be more complex due to the need for solar panels and potential structural support.

Illustrative image related to replace water fountain pump

How Does a Water Circulation System Function as an Alternative?

Water circulation systems are designed to promote constant water flow, which is essential for maintaining water quality in larger ponds or fountains. These systems can be adjusted for flow rates and are effective for larger installations. However, they can be more expensive to install and maintain than a standard pump replacement. Regular maintenance is also required, including filter changes and system checks to ensure optimal performance.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between replacing a water fountain pump and exploring alternative solutions, B2B buyers should consider several factors. Evaluate the specific operational demands of the fountain or water feature, the availability of resources such as sunlight, and the budget for both initial setup and ongoing maintenance. By aligning these considerations with the unique requirements of their projects, buyers can select the solution that best meets their operational goals and sustainability objectives.

Essential Technical Properties and Trade Terminology for replace water fountain pump

What Are the Essential Technical Properties for Selecting a Replacement Water Fountain Pump?

When sourcing a replacement water fountain pump, understanding its technical properties is critical for ensuring optimal performance and longevity. Here are several key specifications to consider:

1. Flow Rate (GPH)

The flow rate, measured in gallons per hour (GPH), indicates how much water the pump can move in a given timeframe. This is crucial for determining the pump’s suitability for a specific fountain size. Pumps with higher GPH ratings provide stronger water flow, which is essential for achieving desired aesthetic effects. In B2B transactions, accurately matching flow rates to fountain specifications can prevent costly inefficiencies.

2. Pump Height (Pumping Height)

Pumping height refers to the vertical distance the pump can effectively move water, measured from the water level in the reservoir to the fountain’s highest spray point. Understanding this specification ensures that the pump can deliver the desired water display without strain. For buyers, knowing the required pumping height helps in selecting a pump that meets operational requirements while avoiding potential damage from inadequate performance.

3. Power Consumption (Wattage)

Energy efficiency is an important consideration for B2B buyers, particularly in regions where energy costs can significantly impact operational budgets. The wattage rating indicates how much power the pump consumes during operation. Selecting a pump with lower wattage yet adequate performance can lead to substantial cost savings over time, making it a critical factor in procurement decisions.

4. Material Composition

The materials used in pump construction influence durability and resistance to environmental factors such as corrosion, especially in outdoor settings. Common materials include thermoplastics and stainless steel. Understanding the material grade helps buyers assess the pump’s longevity and maintenance needs, which is essential for planning long-term investments in fountain systems.

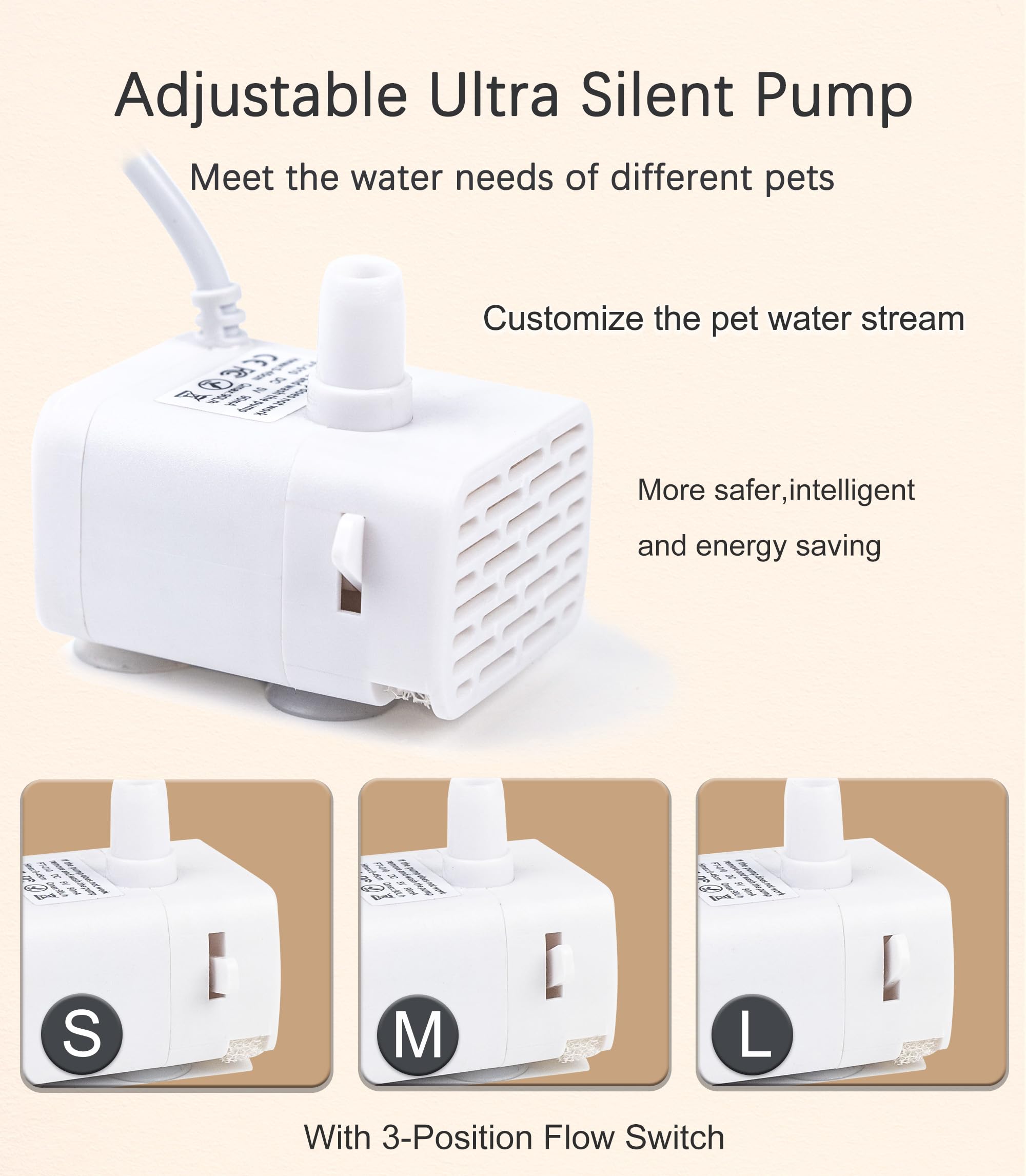

5. Noise Level

Noise levels, typically measured in decibels (dB), are especially important for commercial applications where ambient sound matters, such as hotels or restaurants. A pump with a low noise output enhances the customer experience and can be a deciding factor in B2B purchases. Buyers should consider this specification to align with the desired ambiance of the installation site.

Illustrative image related to replace water fountain pump

What Trade Terminology Should B2B Buyers Know When Replacing a Water Fountain Pump?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fountain pumps, understanding whether a supplier is an OEM can help buyers gauge quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers, as it can affect inventory management and cost efficiency. Suppliers may impose MOQs to ensure production efficiency, so understanding this term aids in planning purchases.

Illustrative image related to replace water fountain pump

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. Crafting a detailed RFQ can help buyers obtain competitive pricing and terms, making it an essential tool for effective procurement processes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery obligations, which is crucial for international transactions.

5. Warranty and Service Agreements

Understanding warranty terms and available service agreements is critical for B2B buyers. Warranties provide assurance regarding the longevity and performance of the pump, while service agreements outline maintenance responsibilities. Clarity on these terms can safeguard investments and ensure ongoing operational efficiency.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, negotiate effectively, and ensure they procure the right water fountain pump for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the replace water fountain pump Sector

What Are the Current Market Dynamics and Key Trends for Replacement Water Fountain Pumps?

The replacement water fountain pump market is experiencing a surge, driven by increasing urbanization and a growing emphasis on aesthetic outdoor spaces in both residential and commercial sectors. In regions like Africa, South America, the Middle East, and Europe, the demand for decorative water features is on the rise, resulting in a parallel need for efficient and reliable replacement pumps. Key trends include the adoption of energy-efficient pumps that not only reduce operational costs but also align with sustainability goals. Additionally, advancements in pump technology, such as smart sensors and adjustable flow rates, are becoming increasingly popular among international buyers seeking customized solutions.

Illustrative image related to replace water fountain pump

Emerging B2B tech trends are reshaping sourcing strategies in this sector. The proliferation of e-commerce platforms allows buyers from diverse regions to access a broader range of products and suppliers. Moreover, the integration of IoT technology into pump systems enables real-time monitoring, enhancing maintenance efficiency and reducing downtime. This trend is particularly relevant for markets in Saudi Arabia and Nigeria, where infrastructure investment is a priority. As a result, international buyers must remain vigilant about these dynamics to capitalize on opportunities for cost-effective and innovative pump solutions.

How Is Sustainability and Ethical Sourcing Shaping the Replacement Water Fountain Pump Market?

Sustainability is becoming a critical focal point in the replacement water fountain pump sector. The environmental impact of manufacturing and operating pumps necessitates a shift towards sustainable practices. Buyers are increasingly prioritizing products made from recycled materials and those that are energy-efficient, as these options significantly reduce the carbon footprint of water features. Additionally, the importance of ethical supply chains is gaining traction; B2B buyers are now more inclined to partner with suppliers who adhere to fair labor practices and environmental regulations.

Certifications such as Energy Star and Green Seal are becoming essential for buyers looking to ensure their sourcing aligns with eco-friendly standards. These certifications not only provide assurance of a product’s environmental impact but also enhance brand reputation in markets that value sustainability. As a result, B2B buyers in regions like Europe and the Middle East, where environmental regulations are stringent, should seek suppliers that emphasize sustainable practices in their manufacturing processes.

What Has Been the Evolution of Replacement Water Fountain Pumps in the B2B Context?

The evolution of replacement water fountain pumps has been marked by significant technological advancements and a shift in consumer preferences. Initially, pumps were basic mechanical devices with limited functionality. However, as the demand for decorative water features grew, so did the complexity and efficiency of pumps. The introduction of low-water shut-off features and energy-efficient models has revolutionized the market, allowing for greater flexibility and reliability in various settings.

Illustrative image related to replace water fountain pump

Furthermore, the rise of e-commerce and digital platforms has transformed the way B2B buyers source these pumps. Buyers now have the ability to compare products, read reviews, and access technical specifications from multiple suppliers, leading to more informed purchasing decisions. This evolution reflects a broader trend within the B2B landscape, where technology continues to drive efficiency and innovation, ultimately benefiting international buyers looking for high-quality replacement water fountain pumps.

Frequently Asked Questions (FAQs) for B2B Buyers of replace water fountain pump

-

How do I troubleshoot a malfunctioning water fountain pump?

To troubleshoot a malfunctioning water fountain pump, first, check for any blockages at the pump intake, such as debris or leaves. Ensure the power cord is securely connected and delivering power. If the pump is still unresponsive, inspect the pump for any visible signs of damage or wear. If basic troubleshooting doesn’t resolve the issue, it may be time to replace the pump. Consider consulting the manufacturer’s guidelines for specific troubleshooting steps related to your pump model. -

What is the best type of replacement fountain pump for my needs?

The best type of replacement fountain pump depends on the fountain’s size and water flow requirements. For smaller tabletop fountains, a pump with a flow rate of 55-80 GPH is ideal. Medium to large fountains may require pumps with flow rates ranging from 155 to 500 GPH. Additionally, consider features such as low water shut-off for added protection against damage. Assess the specific needs of your fountain to choose a pump that ensures optimal water flow and efficiency. -

How can I ensure I am sourcing from a reputable supplier for fountain pumps?

To source from a reputable supplier, conduct thorough research on potential vendors. Look for certifications, customer reviews, and case studies that demonstrate their reliability. Engage with suppliers who provide clear information about their products, warranties, and return policies. It’s also beneficial to request samples before placing a bulk order to assess product quality. Establishing a good rapport and communication with suppliers can also provide insights into their credibility and service. -

What are the typical minimum order quantities (MOQs) for fountain pumps?

Minimum order quantities (MOQs) for fountain pumps can vary widely depending on the supplier and the specific model. Some manufacturers may offer MOQs as low as 10 units, while others may require orders of 100 units or more. It’s essential to discuss your needs with suppliers and negotiate terms that align with your purchasing strategy. Consider the balance between your inventory needs and the supplier’s production capacity when evaluating MOQs. -

What payment terms should I expect when ordering fountain pumps internationally?

Payment terms for international orders can vary based on the supplier and the nature of the transaction. Common terms include a 30% upfront payment with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger orders to ensure security for both parties. Always clarify payment methods, currency, and any additional fees that may apply, such as transaction fees or duties, to avoid surprises. -

How can I customize fountain pumps to meet specific project requirements?

Customization options for fountain pumps often include adjustments to flow rates, sizes, and additional features like LED lights or specific voltage requirements. Communicate your specifications clearly to potential suppliers and inquire about their capacity for customization. Many manufacturers are willing to accommodate special requests, but it’s important to confirm lead times and any potential impact on pricing when ordering custom products. -

What quality assurance measures should I look for in fountain pump suppliers?

When evaluating suppliers, inquire about their quality assurance (QA) processes. Reputable manufacturers often have standardized testing protocols to ensure pumps meet performance and safety standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Request documentation regarding testing procedures and quality control measures to ensure that the pumps you receive will perform reliably in your applications. -

What logistics considerations are important when importing fountain pumps?

Logistics considerations for importing fountain pumps include shipping methods, customs clearance, and delivery timelines. Choose a shipping method that balances cost and speed based on your urgency. Familiarize yourself with the customs regulations in your country to avoid unexpected delays or fees. Additionally, work with logistics partners who have experience in handling international shipments to streamline the process and ensure that your products arrive safely and on time.

Top 4 Replace Water Fountain Pump Manufacturers & Suppliers List

1. The Pond Boss – 170 GPH Low Water Auto Shut-Off Fountain Pump

Domena: thepondboss.net

Registered: 2011 (14 years)

Wprowadzenie: [{‘name’: ’50 GPH Fountain Pump’, ‘sale_price’: ‘$17.99’}, {‘name’: ’90 GPH Fountain Pump’, ‘sale_price’: ‘$23.99’}, {‘name’: ‘150 GPH Fountain Pump’, ‘sale_price’: ‘$24.99’}, {‘name’: ‘170 GPH Low Water Auto Shut-Off Fountain Pump’, ‘sale_price’: ‘$60.99’, ‘discount’: ‘Save 50%’}, {‘name’: ‘170 GPH Low Water Auto Shut-Off Fountain Pump Plus Light’, ‘sale_price’: ‘$36.00’, ‘regular_price’: ‘$71.99…

2. Smart Pond – Replacement Fountain Pumps

Domena: smart-pond.com

Registered: 2007 (18 years)

Wprowadzenie: Replacement fountain pumps come in three types: 1) Fountain Pumps with Low Water Shut Off – automatically shut off when water levels are low; 2) Premium Fountain Pumps – have low-water pickup and longer pre-filters to prevent clogging; 3) Standard Pumps. Pumps are sized based on flow rate (GPH) and pumping height: Tabletop Fountains (up to 2 ft, 55-80 GPH), Small Fountains (up to 3 ft, 80-155 GPH)…

3. Water Pump – Essential Replacement Guide

Domena: reddit.com

Registered: 2005 (20 years)

Wprowadzenie: The user is looking to replace a broken pump for a water feature left by the previous homeowner. Key considerations include finding a pump rated for the vertical lift height of the fountain, ensuring the pump is placed slightly above the bottom of the pond to avoid debris intake, and using a hose clamp to attach the internal pipe piece. Recommendations include using a 90-degree attachment piece wi…

4. TotalPond – Fountain Pumps

Domena: totalpond.com

Registered: 2006 (19 years)

Wprowadzenie: TotalPond Fountain Pumps are energy-efficient pumps designed for fountains and water features. They feature a built-in adjustable flow control and suction cups for easy installation. All pumps come with a 1-year manufacturer warranty. Available models include: 70 GPH Fountain Pump ($21.99), 140 GPH Fountain Pump ($25.99), 300 GPH Fountain Pump ($43.99), 500 GPH Fountain Pump ($50.99), and a 45 GPH…

Strategic Sourcing Conclusion and Outlook for replace water fountain pump

In summary, selecting the right replacement water fountain pump is crucial for maintaining the aesthetic and functional appeal of your water feature. Key considerations include pump size, type, and energy efficiency. By understanding the specific needs of your fountain, such as flow rate and pumping height, you can ensure optimal performance while minimizing operational costs. Additionally, the integration of advanced features like low water shut-off technology can enhance reliability and prolong pump life, reducing the frequency of replacements.

Strategic sourcing plays a vital role in this process, enabling international buyers from regions such as Africa, South America, the Middle East, and Europe to identify reliable suppliers and quality products. By leveraging strategic partnerships, you can access a wider range of options, ensuring that your fountain operates at peak efficiency and aligns with your sustainability goals.

As you move forward in your procurement efforts, consider establishing long-term relationships with trusted suppliers who can provide not only pumps but also ongoing support and maintenance advice. This proactive approach will not only enhance your fountain’s longevity but also contribute to your organization’s overall operational success.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Illustrative image related to replace water fountain pump

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.