Introduction: Navigating the Global Market for husky tracking

In today’s fast-paced global market, navigating the complexities of husky tracking can present significant challenges for international B2B buyers. From managing logistics to ensuring timely deliveries, the stakes are high, particularly in regions like Africa, South America, the Middle East, and Europe. This guide is designed to empower you with the knowledge needed to make informed purchasing decisions regarding husky tracking solutions, addressing critical aspects such as supplier vetting, cost implications, and various applications across diverse industries.

The landscape of husky tracking encompasses a range of technologies and services that enable real-time monitoring and management of logistics operations. By exploring different types of tracking systems, understanding their applications, and learning how to evaluate potential suppliers, you will gain insights that can streamline your operations and enhance your supply chain efficiency. Additionally, this guide will delve into cost considerations, helping you budget effectively while maximizing value.

Whether you are a procurement officer in Brazil seeking reliable tracking solutions or a logistics manager in Nigeria aiming to improve operational efficiency, this comprehensive resource equips you with actionable insights. By leveraging the information provided, you can confidently navigate the global market for husky tracking, ensuring your business remains competitive and responsive to market demands.

Spis treści

- Top 5 Husky Tracking Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for husky tracking

- Understanding husky tracking Types and Variations

- Key Industrial Applications of husky tracking

- 3 Common User Pain Points for ‘husky tracking’ & Their Solutions

- Strategic Material Selection Guide for husky tracking

- In-depth Look: Manufacturing Processes and Quality Assurance for husky tracking

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘husky tracking’

- Comprehensive Cost and Pricing Analysis for husky tracking Sourcing

- Alternatives Analysis: Comparing husky tracking With Other Solutions

- Essential Technical Properties and Trade Terminology for husky tracking

- Navigating Market Dynamics and Sourcing Trends in the husky tracking Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of husky tracking

- Strategic Sourcing Conclusion and Outlook for husky tracking

- Ważne zastrzeżenia i warunki użytkowania

Understanding husky tracking Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Real-Time Container Tracking | Provides live updates on container status and location | Shipping logistics, inventory management | Plusy: Immediate visibility, proactive issue resolution; Wady: May require integration with existing systems. |

| Last Free Day Tracking | Indicates the last day a container can stay at the terminal without incurring fees | Cost management, budget planning | Plusy: Helps avoid unexpected charges; Wady: Limited to specific terminals and may not cover all scenarios. |

| Dwell Time Analytics | Analyzes the time containers spend at the terminal | Operational efficiency, resource allocation | Plusy: Identifies bottlenecks; Wady: Requires historical data for accurate analysis. |

| API Integration Services | Allows businesses to integrate tracking data into their systems | Custom software solutions, automated reporting | Plusy: Seamless data flow; Wady: May involve upfront development costs. |

| Container Availability Tracking | Provides updates on when containers are ready for pickup | Inventory management, logistics planning | Plusy: Optimizes pickup schedules; Wady: Dependent on terminal reporting accuracy. |

What Are the Key Characteristics of Real-Time Container Tracking?

Real-time container tracking systems offer live updates on the status and location of containers throughout their journey. This type of tracking is essential for businesses that rely on timely deliveries and effective logistics management. By leveraging advanced technologies like GPS and RFID, companies can monitor their shipments and respond swiftly to any disruptions. For B2B buyers, investing in real-time tracking solutions can significantly enhance supply chain visibility and operational efficiency.

How Does Last Free Day Tracking Benefit Businesses?

Last Free Day (LFD) tracking is a specialized service that alerts businesses to the final day they can keep a container at a terminal without incurring additional fees. This information is crucial for cost management and budget planning, as it helps companies avoid unexpected charges associated with extended storage. While LFD tracking can save money, buyers should consider its limitations, such as coverage only at specific terminals and varying policies.

Why Is Dwell Time Analytics Important for Operational Efficiency?

Dwell time analytics focuses on measuring the duration containers remain at terminals. By analyzing this data, businesses can identify inefficiencies and bottlenecks in their logistics processes. This type of tracking is particularly beneficial for optimizing resource allocation and improving overall operational performance. However, B2B buyers must ensure they have access to historical data to derive meaningful insights from dwell time metrics.

What Advantages Do API Integration Services Offer for Tracking?

API integration services enable businesses to incorporate tracking data directly into their existing systems, facilitating automated reporting and real-time updates. This capability is particularly valuable for companies that require customized software solutions to manage their logistics. While API integration can streamline operations and enhance data accuracy, buyers should be prepared for potential upfront development costs associated with implementation.

How Does Container Availability Tracking Enhance Logistics Planning?

Container availability tracking provides timely updates regarding when containers are ready for pickup at terminals. This information is vital for effective logistics planning and inventory management, as it allows businesses to optimize their pickup schedules. However, the effectiveness of this tracking type hinges on the accuracy of terminal reporting, which can vary. B2B buyers should weigh the benefits of improved scheduling against potential reporting discrepancies.

Key Industrial Applications of husky tracking

| Przemysł/sektor | Specific Application of husky tracking | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Logistics and Shipping | Real-time Container Tracking | Enhanced visibility into shipment status reduces delays and improves planning. | Integration with existing logistics management systems. |

| Retail and E-commerce | Inventory Management and Stock Replenishment | Optimized inventory levels ensure product availability and reduce excess stock. | Reliable data accuracy for forecasting and inventory needs. |

| Agriculture and Food Supply | Temperature-Controlled Shipment Monitoring | Ensures product quality and compliance with safety standards during transport. | Robust tracking capabilities for perishable goods. |

| Manufacturing | Supply Chain Optimization | Streamlined operations lead to cost savings and improved production schedules. | Ability to track multiple shipments across various carriers. |

| Construction | Equipment and Material Tracking | Improved project timelines and reduced equipment loss or theft. | Detailed reporting and alerts for timely project management. |

How is ‘husky tracking’ utilized in the logistics and shipping industry?

In the logistics and shipping sector, husky tracking is vital for real-time container tracking. This application allows businesses to monitor the location and status of their shipments continuously. By providing visibility into the supply chain, husky tracking helps reduce delays and optimize planning, which is crucial for international B2B operations. For buyers in regions like Africa and South America, ensuring timely deliveries is essential to maintain competitive advantage, making reliable tracking systems a priority.

What role does husky tracking play in retail and e-commerce?

Retail and e-commerce businesses utilize husky tracking for effective inventory management and stock replenishment. By tracking containers and shipments, retailers can optimize inventory levels, ensuring that products are available when customers demand them while minimizing excess stock. For international buyers, particularly in Europe, accurate tracking data is essential for forecasting demand and making informed purchasing decisions, thus enhancing overall business efficiency.

How does husky tracking benefit the agriculture and food supply chain?

In the agriculture and food supply chain, husky tracking facilitates temperature-controlled shipment monitoring. This application is critical for ensuring the quality and safety of perishable goods during transport. It allows businesses to comply with health standards and avoid losses due to spoilage. Buyers in the Middle East and Africa, where food safety regulations are stringent, must prioritize robust tracking systems to maintain product integrity and market access.

How can manufacturers leverage husky tracking for supply chain optimization?

Manufacturers leverage husky tracking to optimize their supply chains by monitoring the movement of raw materials and finished goods. This capability helps streamline operations, reduce costs, and improve production schedules. For international buyers, particularly in regions with complex supply chains, the ability to track multiple shipments across various carriers is crucial for timely production and delivery.

Illustrative image related to husky tracking

In what ways does husky tracking support the construction industry?

In the construction sector, husky tracking is employed for equipment and material tracking. By providing real-time updates on the location of critical resources, businesses can improve project timelines and minimize losses due to theft or misplacement. For buyers operating in emerging markets like Nigeria and Brazil, detailed reporting and alerts from husky tracking systems are essential for effective project management and resource allocation.

3 Common User Pain Points for ‘husky tracking’ & Their Solutions

Scenario 1: Unpredictable Container Availability Disrupts Supply Chains

Problem: B2B buyers often face challenges with the unpredictability of container availability at terminals like Husky. When containers are delayed or not available for pickup as scheduled, it can lead to significant disruptions in supply chains. This unpredictability can result in lost sales opportunities, increased costs due to demurrage fees, and strained relationships with customers who rely on timely deliveries. Buyers are left scrambling to find alternative solutions, which can be both time-consuming and costly.

Rozwiązanie: To mitigate this issue, B2B buyers should leverage advanced container tracking systems that provide real-time updates on container availability and status. Implementing a robust tracking solution, such as those offered by Terminal49, allows businesses to monitor their containers from port to destination. By regularly checking the tracking information and setting up alerts for key milestones—like when a container is released from the terminal—buyers can plan their logistics accordingly. Additionally, establishing strong communication with the terminal operators can help in understanding potential delays and proactively managing inventory levels, ultimately ensuring a smoother supply chain operation.

Scenario 2: Lack of Transparency in Shipping Costs Leads to Budget Overruns

Problem: Many international buyers encounter the challenge of opaque shipping costs when using husky tracking services. Unexpected fees for container handling, terminal charges, and customs duties can quickly accumulate, leading to budget overruns. This lack of transparency can create financial strain and complicate financial forecasting, making it difficult for businesses to maintain competitive pricing.

Rozwiązanie: To address this pain point, buyers should ensure they have access to comprehensive fee structures before finalizing shipping arrangements. This involves researching terminal fees and understanding the full scope of potential charges associated with husky tracking. Buyers can request detailed breakdowns from shipping providers and terminal operators to clarify any ambiguous costs. Utilizing platforms that offer fee information, such as Terminal49, can also help in obtaining accurate, up-to-date pricing data. By maintaining a clear line of communication with logistics partners and consistently reviewing shipping costs, businesses can better predict their expenses and align them with their budgets.

Scenario 3: Difficulty in Tracking Container Status Leads to Operational Inefficiencies

Problem: A common pain point for B2B buyers is the difficulty in tracking the status of containers once they leave the terminal. When buyers lack visibility into their shipments, it leads to operational inefficiencies, missed delivery windows, and challenges in coordinating with freight forwarders. This lack of tracking can hinder a company’s ability to respond quickly to delays or issues, ultimately affecting customer satisfaction and business reputation.

Rozwiązanie: To overcome this challenge, businesses should invest in a centralized tracking system that consolidates data from multiple sources, including terminals like Husky. By utilizing integrated software solutions that provide visibility into the entire shipping process, from terminal departure to final delivery, buyers can significantly enhance their operational efficiency. Additionally, implementing automated notifications for container status changes can keep all stakeholders informed in real-time. This proactive approach allows for quicker decision-making and the ability to address issues before they escalate, ensuring smoother operations and improved service levels for customers.

Illustrative image related to husky tracking

Strategic Material Selection Guide for husky tracking

What Are the Key Materials for Husky Tracking?

When selecting materials for husky tracking applications, it’s crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact performance, durability, and overall effectiveness in various environments. Below, we analyze four common materials used in husky tracking systems.

How Does Aluminum Perform in Husky Tracking Applications?

Aluminum is a lightweight, corrosion-resistant metal commonly utilized in the construction of tracking equipment. Its key properties include a high strength-to-weight ratio and excellent thermal conductivity, making it suitable for outdoor applications where temperature variations occur.

Plusy: Aluminum is durable and resistant to rust, which is essential for tracking devices exposed to various weather conditions. Additionally, it is relatively easy to manufacture and can be extruded into complex shapes.

Wady: The primary limitation of aluminum is its susceptibility to scratching and denting, which can affect the aesthetic and functional aspects of the tracking equipment. Furthermore, while aluminum is generally cost-effective, prices can fluctuate based on market demand.

What Role Does Stainless Steel Play in Husky Tracking?

Stainless steel is another prevalent choice for husky tracking applications due to its exceptional strength and corrosion resistance. It can withstand high temperatures and pressures, making it ideal for environments that may involve extreme conditions.

Plusy: Stainless steel is highly durable and can endure harsh environments without significant degradation. Its aesthetic appeal is also a plus, as it maintains a polished look over time.

Wady: The main drawback is that stainless steel is heavier than aluminum, which may not be ideal for all tracking applications. Additionally, it is more expensive, which could be a concern for budget-conscious buyers.

Why Consider Polycarbonate for Husky Tracking?

Polycarbonate is a high-performance plastic known for its impact resistance and lightweight properties. It is often used in housings for tracking devices, offering excellent protection against physical damage.

Plusy: Polycarbonate is highly durable and can withstand significant impact, making it suitable for rugged outdoor conditions. It is also transparent, allowing for visibility of internal components, which can be advantageous for monitoring purposes.

Wady: However, polycarbonate can be prone to scratching and may degrade under prolonged exposure to UV light unless treated. Its manufacturing process can also be more complex, leading to higher production costs.

How Does Rubber Contribute to Husky Tracking Solutions?

Rubber is frequently used in seals and gaskets within husky tracking systems, providing essential protection against moisture and dust ingress. Its flexible nature allows it to conform to various shapes and surfaces.

Plusy: Rubber is excellent for vibration dampening, making it ideal for mobile tracking applications. It is also relatively inexpensive and easy to work with, which can lower manufacturing costs.

Wady: The primary limitation of rubber is its susceptibility to degradation from ozone and UV exposure, which can shorten its lifespan. Additionally, it may not perform well under extreme temperature variations, potentially affecting tracking performance.

Illustrative image related to husky tracking

Summary Table of Material Properties for Husky Tracking

| Materiał | Typical Use Case for husky tracking | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Aluminum | Tracking equipment housings | Lightweight and corrosion-resistant | Susceptible to scratches | Średni |

| Stainless Steel | Structural components | High strength and durability | Heavier and more expensive | Wysoki |

| Polycarbonate | Protective casings | Impact-resistant and lightweight | Prone to scratching and UV degradation | Średni |

| Rubber | Seals and gaskets | Excellent vibration dampening | Degrades under ozone and UV exposure | Niski |

This analysis provides a comprehensive overview of the materials commonly used in husky tracking applications. Understanding the properties, advantages, and limitations of each material helps international B2B buyers make informed decisions tailored to their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for husky tracking

What Are the Main Stages in the Manufacturing Process for Husky Tracking?

The manufacturing process for husky tracking systems typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring the quality and reliability of the final product.

-

Przygotowanie materiału: The initial step involves sourcing high-quality materials that meet industry standards. Common materials include robust plastics, metals, and electronic components. Suppliers must ensure that the materials are free from defects and meet specifications, which often requires extensive documentation and certification.

-

Formowanie: This stage involves shaping the materials into the desired components. Techniques such as injection molding for plastics or stamping for metals are commonly used. Precision during this phase is essential, as any discrepancies can lead to failures in the final product.

-

Montaż: Once the components are formed, they are assembled into the tracking system. This may involve manual assembly or automated processes, depending on the complexity of the product. Effective assembly techniques include the use of jigs and fixtures to maintain alignment and reduce errors.

-

Wykończenie: The final stage includes surface treatments, painting, or coating to enhance durability and aesthetics. Quality checks are performed throughout the manufacturing process to ensure adherence to specifications.

Which Key Techniques Are Utilized in Husky Tracking Manufacturing?

Several advanced manufacturing techniques are employed to ensure the reliability and performance of husky tracking systems.

-

Automated Manufacturing: Automation enhances efficiency and precision. Robotic arms can perform repetitive tasks, ensuring consistent quality across batches.

-

Quality Control Techniques: Statistical Process Control (SPC) is often implemented to monitor the manufacturing process in real-time. This technique helps identify variations and mitigate defects before they escalate.

-

Additive Manufacturing: For prototyping and low-volume production, 3D printing can be used. It allows for rapid iteration and testing of designs without the need for extensive tooling.

What International Standards and Quality Assurance Practices Are Relevant to Husky Tracking?

International standards play a crucial role in ensuring the quality of husky tracking systems. Adhering to these standards not only enhances product reliability but also builds trust with international B2B buyers.

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

Oznaczenie CE: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

Standardy API: For certain tracking devices used in industrial applications, adherence to American Petroleum Institute (API) standards may be necessary, especially for products used in hazardous environments.

What Are the Key Quality Control Checkpoints in Husky Tracking Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that the final product meets the required standards. Key checkpoints in QC include:

Illustrative image related to husky tracking

-

Przychodząca kontrola jakości (IQC): This initial checkpoint assesses the quality of incoming materials. Suppliers are often required to provide certificates of compliance, which verify that materials meet specified standards.

-

Kontrola jakości w trakcie procesu (IPQC): During the manufacturing process, continuous monitoring is conducted to ensure that production adheres to established quality standards. Random sampling and testing of components can help catch defects early.

-

Końcowa kontrola jakości (FQC): Before products are shipped, a thorough inspection is conducted. This includes functional testing, visual inspections, and performance evaluations to ensure that the tracking systems meet all operational requirements.

W jaki sposób nabywcy B2B mogą weryfikować kontrolę jakości dostawców?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, must take proactive steps to verify the quality control measures of their suppliers. Here are effective strategies:

-

Audyty dostawców: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes and QC practices firsthand. This can provide insights into their adherence to international standards and internal quality measures.

-

Żądanie raportów jakości: Buyers should request detailed quality reports that outline the QC processes, including IQC, IPQC, and FQC results. These documents should include metrics such as defect rates and corrective actions taken.

-

Kontrole osób trzecich: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly important for international transactions where trust is a concern.

What Common Testing Methods Are Employed in Quality Assurance for Husky Tracking?

To ensure that husky tracking systems meet stringent quality standards, various testing methods are utilized throughout the manufacturing process. These include:

-

Functional Testing: This involves evaluating the product’s performance under expected operating conditions. For tracking systems, this may include GPS accuracy tests and range testing.

-

Environmental Testing: Products are subjected to extreme temperature, humidity, and vibration tests to ensure durability in diverse environments. This is particularly relevant for systems used in rugged terrains or harsh climates.

-

Electrical Testing: For electronic components, electrical testing ensures that the systems function correctly and safely. This includes checking for proper voltage, current flow, and resistance.

How Do Quality Control and Certification Nuances Affect International B2B Buyers?

For international B2B buyers, particularly those in emerging markets like Brazil and Nigeria, understanding the nuances of quality control and certification is critical.

-

Regulatory Compliance: Different regions have specific regulations that products must meet. Buyers must ensure that their suppliers are compliant with local regulations, which may differ significantly from international standards.

-

Cultural Differences: Communication about quality expectations may vary across cultures. It’s essential for buyers to establish clear quality criteria and ensure that suppliers understand these expectations.

-

Documentation and Traceability: Maintaining proper documentation throughout the supply chain is vital for quality assurance. Buyers should insist on traceability records that detail the manufacturing process, materials used, and quality checks performed.

By understanding these manufacturing processes, quality assurance practices, and verification strategies, B2B buyers can make informed decisions when sourcing husky tracking systems, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘husky tracking’

In the rapidly evolving landscape of logistics and supply chain management, sourcing effective husky tracking solutions is essential for optimizing operations. This guide serves as a comprehensive checklist for B2B buyers aiming to procure husky tracking systems that enhance visibility, efficiency, and reliability in their supply chains.

Krok 1: Identify Your Tracking Needs

Understanding your specific tracking requirements is crucial before engaging with suppliers. Determine the types of containers or cargo you need to monitor, the frequency of updates required, and the geographical regions involved. This clarity will help you communicate your expectations effectively to potential suppliers.

- Considerations:

- What types of cargo will you be tracking? (e.g., standard containers, refrigerated units)

- How frequently do you need updates? (e.g., real-time, daily summaries)

Krok 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in husky tracking solutions. Look for companies with a proven track record in the industry and positive reviews from existing clients. Supplier reliability is paramount, as it directly impacts your operational efficiency.

Illustrative image related to husky tracking

- Key Actions:

- Explore online reviews and case studies.

- Attend industry trade shows or webinars to meet potential suppliers.

Krok 3: Evaluate Technology and Features

Assess the technology used by potential suppliers to ensure it meets your operational needs. Look for systems that provide real-time tracking, easy integration with your existing systems, and user-friendly interfaces. Advanced features like automated alerts and analytics tools can greatly enhance your tracking capabilities.

- Focus Areas:

- Compatibility with your current logistics software.

- Availability of mobile applications for on-the-go access.

Krok 4: Verify Supplier Certifications and Compliance

Ensure that your chosen supplier adheres to relevant industry standards and regulations. This not only validates their credibility but also ensures that your tracking operations remain compliant with local and international laws.

- Important Certifications:

- ISO certifications related to quality management.

- Compliance with data protection regulations (e.g., GDPR).

Krok 5: Request Demonstrations and Trials

Before making a commitment, request demonstrations or trial periods of the tracking systems. This hands-on experience will allow you to assess the usability and effectiveness of the technology in a practical setting.

- What to Look For:

- Ease of use for your team.

- Responsiveness of customer support during the trial.

Krok 6: Discuss Pricing and Contract Terms

Engage in transparent discussions regarding pricing structures and contract terms. Understanding the total cost of ownership, including setup fees, subscription models, and potential hidden costs, is crucial for budgeting.

- Key Considerations:

- Are there additional costs for features or support?

- What are the terms for contract renewal or cancellation?

Krok 7: Establish Clear Communication Channels

Once you select a supplier, establish clear lines of communication for ongoing support and issue resolution. Regular check-ins can facilitate proactive problem-solving and ensure that your tracking needs continue to be met effectively.

- Communication Strategies:

- Schedule regular performance reviews.

- Set up dedicated support contacts for immediate assistance.

By following this structured checklist, B2B buyers can ensure they make informed decisions in sourcing husky tracking solutions, ultimately enhancing their operational efficiency and supply chain visibility.

Comprehensive Cost and Pricing Analysis for husky tracking Sourcing

What Are the Key Cost Components in Husky Tracking Sourcing?

In the husky tracking sourcing ecosystem, understanding the cost structure is pivotal for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materiały: The choice of materials significantly impacts the final product’s cost. For husky tracking systems, durable and weather-resistant materials are preferred, which can lead to higher initial costs but lower long-term maintenance.

-

Praca: Labor costs vary by region and can be influenced by local wage standards and the complexity of the tracking system. Skilled labor is essential for assembly and quality assurance, which can drive up costs.

-

Koszty ogólne produkcji: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Oprzyrządowanie: Initial investment in tooling can be substantial, especially if the husky tracking systems require specialized equipment. Buyers should consider this when assessing total costs.

-

Kontrola jakości (QC): Ensuring the tracking systems meet international standards requires a robust QC process, which adds to the overall expense but is crucial for reliability.

-

Logistyka: Shipping and handling costs are particularly important for international buyers. The choice of shipping method (air vs. sea) and the distance from the supplier can significantly affect logistics costs.

-

Margines: Suppliers will add a profit margin on top of the costs incurred. This margin can vary based on the supplier’s market position and the competition in the industry.

What Price Influencers Should Buyers Consider for Husky Tracking Solutions?

Several factors can influence pricing for husky tracking solutions, which buyers should keep in mind:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce the per-unit cost due to economies of scale. Buyers should evaluate their needs and negotiate terms that reflect their purchasing power.

-

Specyfikacje i personalizacja: Custom features or specifications can drive up costs. Buyers should weigh the necessity of these customizations against their budget constraints.

-

Materiały: Premium materials can enhance durability and reliability but will increase costs. Buyers should seek a balance between quality and price.

-

Quality and Certifications: Products certified to international standards often come at a premium. Buyers in regions such as Africa and South America may need to consider local compliance requirements and the associated costs.

-

Czynniki dostawcy: The reputation, location, and capacity of suppliers can influence pricing. Buyers should conduct thorough due diligence and consider multiple quotes to understand the market rates.

-

Incoterms: The terms of shipping and delivery can significantly affect total costs. Understanding Incoterms will help buyers calculate their total landed costs effectively.

What Buyer Tips Can Help Optimize Costs in Husky Tracking Procurement?

For international B2B buyers, particularly in emerging markets like Brazil and Nigeria, optimizing procurement costs requires strategic planning:

-

Negocjacje: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building strong relationships can lead to better pricing and service agreements.

-

Efektywność kosztowa: Focus on the Total Cost of Ownership (TCO) rather than just the upfront price. Consider maintenance, operational costs, and potential downtime when evaluating options.

-

Niuanse cenowe: Be aware of regional pricing variations. Factors such as currency fluctuations, import tariffs, and local market conditions can impact costs.

-

Supplier Diversification: Avoid reliance on a single supplier by sourcing from multiple vendors. This strategy can enhance competition and lead to better pricing and service levels.

-

Long-Term Contracts: If a supplier offers favorable terms, consider long-term contracts to lock in prices and secure consistent supply, especially in volatile markets.

While prices can fluctuate based on various factors, understanding these components and influencers will empower buyers to make informed decisions and negotiate effectively in the husky tracking sourcing landscape.

Alternatives Analysis: Comparing husky tracking With Other Solutions

In today’s competitive logistics landscape, businesses are constantly seeking effective solutions for tracking shipments and managing supply chains. Husky tracking, a prominent service in this field, offers unique advantages, but it’s essential to evaluate it against other viable alternatives to identify the best fit for specific operational needs. Below, we compare Husky tracking with two notable alternatives: RFID tracking and GPS-based tracking systems.

| Aspekt porównawczy | Husky Tracking | RFID Tracking | GPS Tracking |

|---|---|---|---|

| Wydajność | High accuracy and reliability in container movement tracking | Effective for short-range tracking; limited by line of sight | Excellent real-time location updates globally |

| Koszt | Moderate setup and operational costs | Generally low-cost for implementation but may require additional infrastructure | Higher initial investment for hardware; operational costs vary |

| Łatwość wdrożenia | Requires integration with existing terminal operations | Relatively easy to set up, especially in controlled environments | Requires installation of devices and software; can be complex |

| Konserwacja | Moderate; relies on terminal infrastructure and regular updates | Low; tags are durable, but readers need maintenance | Moderate; devices may require regular updates and battery replacements |

| Najlepszy przypadek użycia | Ideal for port and terminal operations with high container volumes | Best for inventory management in warehouses and retail | Optimal for real-time tracking of vehicles and assets over long distances |

What Are the Pros and Cons of RFID Tracking?

RFID (Radio-Frequency Identification) technology utilizes tags and readers to track items within a defined range. The primary advantage of RFID is its cost-effectiveness for short-range tracking, making it suitable for inventory management in warehouses or retail environments. Its ease of setup and low maintenance needs further enhance its appeal. However, RFID is limited by its line-of-sight requirement, which can hinder tracking efficiency in large or cluttered spaces.

How Does GPS Tracking Compare to Husky Tracking?

GPS tracking systems provide real-time location updates and are capable of tracking assets globally. This technology excels in scenarios where assets are mobile, such as vehicles or shipping containers in transit. Its strength lies in its ability to offer precise, continuous tracking regardless of distance. However, the initial investment for GPS devices can be substantial, and ongoing operational costs may vary depending on the service provider. The complexity of installation and maintenance can also pose challenges for businesses without technical expertise.

Illustrative image related to husky tracking

Choosing the Right Solution for Your Business Needs

When selecting a tracking solution, B2B buyers should consider factors such as the scale of operations, specific tracking requirements, and budget constraints. Husky tracking offers robust capabilities for terminal operations, making it a strong contender for companies focused on high-volume container management. Alternatively, businesses requiring flexibility in tracking mobile assets may benefit more from GPS solutions, while those managing inventory in confined environments might find RFID technology to be the most effective option. Ultimately, the choice should align with operational goals, cost considerations, and the desired level of tracking precision.

Essential Technical Properties and Trade Terminology for husky tracking

What Are the Critical Technical Properties for Husky Tracking?

When evaluating husky tracking solutions, understanding the essential technical properties is crucial for making informed decisions. Here are some key specifications that directly impact operational efficiency and service quality:

-

Container Capacity

This refers to the total number of containers that can be handled at a terminal. For example, Husky Terminal boasts a capacity for over 600 refrigerated containers. Understanding capacity is vital for businesses to ensure that their logistics needs are met, particularly during peak shipping seasons. -

Refrigerated Capacity (Reefer Plugs)

The number of reefer plugs available indicates how many temperature-sensitive goods can be stored. This is particularly important for businesses dealing in perishables. A higher number of reefer plugs allows for more flexibility in managing inventory and reducing spoilage. -

Crane Specifications

The type and number of cranes, such as Super Post-Panamax cranes, determine the terminal’s ability to efficiently load and unload cargo. For instance, having eight cranes with a 24-wide reach allows for swift handling of large vessels, minimizing turnaround time and enhancing supply chain efficiency. -

Water Depth

The depth of water at the berth (e.g., -51 feet Mean Lower Low Water) is critical for accommodating various vessel sizes. A sufficient water depth ensures that larger ships can dock without risk, which is essential for international shipping operations. -

Gate Operations

The number of inbound and outbound gates affects how quickly containers can be processed. For example, eight inbound and four outbound gates facilitate efficient entry and exit of cargo. This is crucial for reducing congestion and ensuring timely deliveries. -

Intermodal Connections

Facilities that offer seamless rail and road connections can significantly streamline logistics. Husky Terminal’s on-dock rail ramps provide easy access to rail services, which can be a competitive advantage for businesses looking to optimize their transport routes.

What Are the Common Trade Terms in Husky Tracking?

Familiarity with industry jargon is essential for effective communication and negotiation in the husky tracking sector. Here are some commonly used trade terms:

-

OEM (producent oryginalnego sprzętu)

This term refers to companies that produce components or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps businesses ensure compatibility and quality in their tracking solutions. -

MOQ (minimalna ilość zamówienia)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage inventory costs and avoid overstock situations. -

RFQ (zapytanie ofertowe)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It’s essential for businesses to draft clear RFQs to ensure they receive accurate and competitive pricing for their tracking needs. -

Incoterms (międzynarodowe warunki handlowe)

These are standardized international trade terms that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps businesses understand their obligations regarding shipping, insurance, and freight costs. -

LFD (Last Free Day)

This term refers to the last day a container can remain at a terminal without incurring additional charges. Knowing the LFD is crucial for managing storage costs and planning timely pickups. -

Dwell Time

Dwell time measures the duration a container remains at a terminal before being picked up. Understanding dwell time can help businesses optimize their logistics operations and reduce costs associated with delays.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making processes, leading to improved efficiency and cost-effectiveness in husky tracking operations.

Navigating Market Dynamics and Sourcing Trends in the husky tracking Sector

What Are the Current Market Dynamics and Key Trends in Husky Tracking?

The husky tracking sector is experiencing significant transformation driven by globalization, technological advancements, and evolving consumer expectations. As businesses increasingly rely on efficient supply chain management, the demand for real-time tracking and monitoring solutions has surged. This trend is particularly prominent among international B2B buyers from regions like Africa, South America, the Middle East, and Europe. The integration of IoT devices, AI, and blockchain technology is facilitating enhanced visibility and operational efficiency across the supply chain. Companies are utilizing data analytics for predictive insights, which is critical for optimizing inventory management and reducing costs.

Illustrative image related to husky tracking

Moreover, the rise of e-commerce and the need for faster delivery options are pushing businesses to adopt advanced tracking solutions. In emerging markets such as Brazil and Nigeria, where logistics infrastructure is developing, there is a growing appetite for innovative tracking solutions that can offer competitive advantages. As a result, suppliers must be agile and responsive to the fluctuating demands and preferences of these diverse markets, making strategic partnerships and collaborations essential for success.

How Is Sustainability and Ethical Sourcing Shaping the Husky Tracking Sector?

Sustainability has become a central pillar in the husky tracking sector, with an increasing emphasis on minimizing environmental impact and fostering ethical sourcing practices. International B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable operations, which includes using eco-friendly materials and adopting green certifications. The use of biodegradable packaging, energy-efficient tracking devices, and sustainable logistics practices are becoming critical factors in supplier selection.

Furthermore, businesses are recognizing the importance of ethical supply chains, particularly in regions where labor practices may be scrutinized. Buyers are increasingly demanding transparency in sourcing, pushing companies to ensure that their materials are ethically obtained and that labor conditions meet international standards. Embracing sustainability not only aligns with corporate social responsibility goals but also enhances brand reputation, making it a competitive advantage in the global marketplace.

What Is the Historical Context of Husky Tracking and Its Evolution?

The evolution of husky tracking can be traced back to the early days of container shipping, where the need for efficient cargo management became paramount. Initially, tracking relied heavily on manual processes and paper-based systems, which were often prone to errors and delays. However, with the advent of technology in the late 20th century, tracking methods began to shift towards electronic systems, paving the way for real-time monitoring capabilities.

As globalization expanded, so did the complexity of supply chains, prompting the development of sophisticated tracking solutions that leverage GPS, RFID, and IoT technologies. Today, husky tracking stands at the forefront of logistics innovation, integrating advanced technologies that enable seamless operations and improved customer satisfaction. For B2B buyers, understanding this historical context underscores the importance of selecting suppliers that not only embrace technological advancements but also align with sustainable and ethical practices, ensuring long-term viability in a rapidly evolving market.

Illustrative image related to husky tracking

Frequently Asked Questions (FAQs) for B2B Buyers of husky tracking

-

How do I solve issues with husky tracking delays?

To address delays in husky tracking, first, ensure that you have accurate and up-to-date tracking information. Utilize real-time tracking systems offered by providers like Terminal49, which can give insights into container availability and dwell time. If delays persist, contact your shipping line or the terminal operator directly for clarification on the status of your shipment. Having a proactive approach to communication can help mitigate issues and provide solutions faster. -

What is the best method for tracking husky shipments internationally?

The most effective method for tracking husky shipments internationally is to use a robust tracking platform that integrates with major shipping lines. Look for services that offer real-time updates, notifications for key milestones, and analytics on container performance. APIs can also enhance your logistics operations by automating data retrieval, ensuring you have the latest information at your fingertips. -

How can I vet suppliers for husky tracking solutions?

To vet suppliers for husky tracking solutions, conduct thorough research on their reputation and reliability. Check for certifications, customer testimonials, and case studies that demonstrate their experience in handling international logistics. Engage in direct communication to assess their customer service responsiveness and willingness to customize solutions based on your business needs. Additionally, consider requesting references from current clients to gauge satisfaction. -

What customization options are available for husky tracking systems?

Customization options for husky tracking systems often include tailored dashboards, alerts based on specific triggers, and integration with existing inventory management systems. Some providers may also offer bespoke reporting features that align with your business metrics. When discussing potential solutions, clearly outline your operational requirements to ensure the supplier can deliver a system that meets your unique needs. -

What are the minimum order quantities (MOQ) for husky tracking services?

Minimum order quantities (MOQ) for husky tracking services can vary significantly based on the provider and the scope of services required. Some suppliers may have flexible MOQs, especially for trial periods, while others might set specific thresholds based on the volume of shipments. It’s advisable to discuss your anticipated shipping volumes with potential suppliers to negotiate favorable terms. -

What payment terms should I expect when sourcing husky tracking services?

Payment terms for husky tracking services typically vary by provider but generally include options such as upfront payments, net 30, or net 60 days. Some suppliers may also offer discounts for early payments or bulk orders. Always clarify the payment structure, including any applicable fees or taxes, before finalizing agreements to avoid unexpected costs. -

How does quality assurance work in husky tracking services?

Quality assurance in husky tracking services is crucial for ensuring data accuracy and reliability. Most reputable providers implement rigorous QA processes, including regular audits of tracking data, monitoring for discrepancies, and maintaining compliance with industry standards. Request information on the supplier’s QA protocols and any certifications they possess to ensure their service meets your expectations. -

What logistics challenges should I be aware of when using husky tracking?

When utilizing husky tracking, you may encounter logistics challenges such as customs clearance delays, inaccurate data reporting, and communication breakdowns between multiple stakeholders. To mitigate these risks, establish clear communication channels with all parties involved, leverage technology for real-time updates, and ensure all documentation is complete and accurate. Being proactive and informed can significantly enhance the efficiency of your logistics operations.

Top 5 Husky Tracking Manufacturers & Suppliers List

1. Husky Terminal – Global Shipping Hub

Domena: huskyterminal.com

Registered: 2010 (15 years)

Wprowadzenie: Husky Terminal is a premier terminal located in Tacoma, WA, serving as a key hub in the global marketplace. It facilitates the movement of thousands of containers daily via sea, rail, and road. The terminal emphasizes its commitment to customer success and prides itself on being a trusted partner. Key highlights include recognition as the Terminal Operator of the Year at the 2025 North Star Awards…

2. Husky Liners – All-Weather Floor Mats

Domena: huskyliners.com

Zarejestrowany: 1997 (28 lat)

Wprowadzenie: Free Shipping on All Orders; Order via phone, chat, or online; 24/7 online store; Payment methods: Affirm, Apple Pay, Credit Cards, Debit Cards, Google Pay, PayPal; Accepted cards: American Express, Discover, MasterCard, PayPal, Visa; Payment charged upon order completion; Order status can be checked online or via customer service; Orders cannot be modified once placed; Refunds available for eligi…

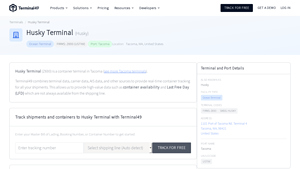

3. Husky Terminal – Real-time Container Tracking

Domena: terminal49.com

Registered: 2014 (11 years)

Wprowadzenie: {“terminal_name”:”Husky Terminal”,”terminal_code”:”Z693″,”facility_type”:”Ocean Terminal”,”location”:”Tacoma, WA, United States”,”address”:”1101 Port of Tacoma Rd. Terminal 4 Tacoma, WA, 98421 United States”,”port_name”:”Tacoma”,”UN/LOCODE”:”USTIW”,”services”:”Real-time container tracking, container availability, last free day information, container holds information, fee information, container lo…

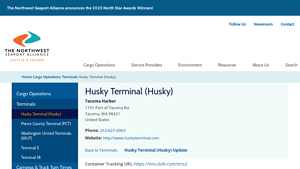

4. Husky Terminal – Container Handling

Domena: nwseaportalliance.com

Registered: 2015 (10 years)

Wprowadzenie: Terminal Name: Husky Terminal (Husky)\nLocation: Tacoma Harbor, 1101 Port of Tacoma Rd., Tacoma, WA 98421, United States\nPhone: 253-627-6963\nWebsite: http://www.huskyterminal.com\nTerminal Operator: Husky Terminal & Stevedoring\nCargo Type: Containers\nRefrigerated Capacity: 600 reefer plugs\nOcean Carriers: Hapag-Lloyd, HMM, Maersk, Ocean Network Express (ONE), Yang Ming Line\nRail Ramps: North…

5. Husky – Husky Tracks Tool

Domena: huskynet.husky.com

Registered: 1992 (33 years)

Wprowadzenie: Husky Tracks tool allows users to manage orders online, including placing orders, viewing shipping dates, and getting tracking numbers.

Strategic Sourcing Conclusion and Outlook for husky tracking

Why is Strategic Sourcing Vital for Successful Husky Tracking Operations?

In the rapidly evolving landscape of global logistics, effective strategic sourcing is essential for businesses looking to optimize husky tracking operations. Key takeaways emphasize the importance of selecting reliable partners, leveraging advanced tracking technologies, and ensuring real-time visibility throughout the supply chain. By prioritizing these elements, B2B buyers can enhance operational efficiency, reduce costs, and improve customer satisfaction.

Moreover, international buyers from regions such as Africa, South America, the Middle East, and Europe must recognize the strategic advantages of aligning with reputable terminal operators like Husky Terminal. Their commitment to safety, sustainability, and customer success positions them as a valuable partner in navigating the complexities of global shipping.

What’s Next for International Buyers?

As we look to the future, international B2B buyers should actively explore partnerships that facilitate seamless tracking and logistics management. Embracing innovative solutions and investing in strategic sourcing will be critical in maintaining competitiveness in the marketplace. By prioritizing these strategies, businesses can not only adapt to changing market conditions but also capitalize on new opportunities for growth and expansion. Engage with trusted partners today to secure a more efficient and transparent supply chain for tomorrow.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.