Introduction: Navigating the Global Market for blitz automatic dog feeder

The global market for the Blitz automatic dog feeder presents a unique opportunity for B2B buyers looking to enhance pet care solutions in diverse regions, including Africa, South America, the Middle East, and Europe. Sourcing a reliable automatic dog feeder that meets the needs of various pet owners and kennel operations can be challenging, especially given the multitude of options and specifications available. This guide is designed to equip international buyers with the necessary insights to navigate this market effectively.

In this comprehensive resource, we explore different types of Blitz automatic dog feeders, their applications in both residential and commercial settings, and the critical aspects of supplier vetting. We will also delve into cost considerations, ensuring that buyers can make financially sound decisions while prioritizing quality and reliability. By understanding the unique features and benefits of various models, buyers can select products that not only satisfy consumer demands but also enhance operational efficiency.

With insights tailored to the specific needs of buyers from regions such as Brazil and Vietnam, this guide empowers stakeholders to make informed purchasing decisions. Whether you are a retailer, distributor, or kennel operator, understanding the intricacies of the Blitz automatic dog feeder market will help you provide superior pet care solutions that meet the evolving expectations of pet owners worldwide.

Spis treści

- Top 3 Blitz Automatic Dog Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for blitz automatic dog feeder

- Understanding blitz automatic dog feeder Types and Variations

- Key Industrial Applications of blitz automatic dog feeder

- 3 Common User Pain Points for ‘blitz automatic dog feeder’ & Their Solutions

- Strategic Material Selection Guide for blitz automatic dog feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for blitz automatic dog feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘blitz automatic dog feeder’

- Comprehensive Cost and Pricing Analysis for blitz automatic dog feeder Sourcing

- Alternatives Analysis: Comparing blitz automatic dog feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for blitz automatic dog feeder

- Navigating Market Dynamics and Sourcing Trends in the blitz automatic dog feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of blitz automatic dog feeder

- Strategic Sourcing Conclusion and Outlook for blitz automatic dog feeder

- Ważne zastrzeżenia i warunki użytkowania

Understanding blitz automatic dog feeder Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Gravity Feeders | Simple design, uses gravity to dispense food | Pet stores, kennels, veterinary clinics | Plusy: Low maintenance, cost-effective. Wady: Limited portion control, may not suit all pet sizes. |

| Programmable Timed Feeders | Allows scheduling of feeding times and portions | Pet care services, grooming salons | Plusy: Customizable feeding schedules, ideal for busy pet owners. Wady: Higher initial cost, requires power. |

| Combination Feeders | Integrates food and water dispensing | Animal shelters, boarding facilities | Plusy: Space-saving design, convenient for users. Wady: Complexity may lead to maintenance issues. |

| Smart Feeders | Connects to mobile apps for monitoring and control | Pet tech retailers, online marketplaces | Plusy: Remote operation, real-time monitoring. Wady: Dependence on technology, potential connectivity issues. |

| Large Capacity Feeders | Designed for bulk storage and dispensing | Kennels, breeders, large pet facilities | Plusy: Reduces frequent refills, durable construction. Wady: Bulkiness may limit placement options. |

What Are the Key Characteristics of Gravity Feeders?

Gravity feeders are among the simplest designs in automatic dog feeders, relying on gravity to dispense food as pets consume it. Typically constructed from durable materials like high-density polyethylene, they are ideal for environments where minimal maintenance is desired. B2B buyers should consider gravity feeders for retail settings or veterinary clinics, where ease of use and cost-effectiveness are paramount. However, their lack of portion control may be a drawback for specific dietary needs.

How Do Programmable Timed Feeders Enhance Feeding Management?

Programmable timed feeders offer the advantage of scheduling specific feeding times and portion sizes, catering to various pet dietary requirements. These feeders are particularly beneficial for pet care services and grooming salons, where multiple pets are managed simultaneously. B2B buyers should evaluate the initial investment against the convenience and improved feeding management that these devices provide. However, they do require a power source, which may limit placement options.

What Makes Combination Feeders Ideal for Boarding Facilities?

Combination feeders streamline the feeding and watering process by integrating both functions into one unit. This design is particularly advantageous for animal shelters and boarding facilities where space is at a premium. Buyers should weigh the convenience of having a dual-purpose device against the potential for increased complexity in maintenance. Despite these considerations, the practicality of combination feeders can significantly enhance operational efficiency.

How Do Smart Feeders Change the Game for Pet Owners?

Smart feeders represent a technological advancement in pet care, allowing remote operation and real-time monitoring through mobile applications. This feature is especially appealing to tech-savvy consumers and is gaining traction in online marketplaces. B2B buyers should consider the appeal of smart feeders in retail settings, as they cater to modern pet owners looking for innovative solutions. However, the reliance on technology may introduce challenges related to connectivity and user comfort.

Why Choose Large Capacity Feeders for Commercial Use?

Large capacity feeders are specifically designed for bulk storage and dispensing, making them ideal for kennels, breeders, and large pet facilities. These feeders minimize the need for frequent refills, enhancing operational efficiency. Buyers should assess the durability and construction quality, as these factors directly impact long-term use in high-demand environments. However, the bulkiness of these feeders may pose placement challenges, necessitating careful planning in facility layouts.

Key Industrial Applications of blitz automatic dog feeder

| Przemysł/sektor | Specific Application of blitz automatic dog feeder | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Pet Care Facilities | Used in kennels and shelters to feed multiple dogs efficiently | Reduces labor costs and ensures consistent feeding schedules | Durability, capacity for large volumes, and ease of cleaning |

| Veterinary Clinics | Provides a controlled feeding environment for post-operative care | Enhances patient recovery by regulating food intake | Compliance with health standards and ease of monitoring intake |

| Dog Training Centers | Supports structured feeding times to reinforce training routines | Improves training effectiveness through consistent feeding | Adjustability in portion sizes and robust construction |

| Retail Pet Supply Stores | Display units for automatic feeders to attract customers | Increases sales through product demonstration | Aesthetic design and compatibility with various dog sizes |

| Agricultural Enterprises | Serves as a feeding solution for working dogs on farms | Streamlines feeding processes in rural settings | Weather resistance and mobility for outdoor use |

How is the Blitz Automatic Dog Feeder Used in Pet Care Facilities?

In pet care facilities such as kennels and shelters, the blitz automatic dog feeder is instrumental in managing feeding schedules for multiple dogs. By automating the feeding process, facilities can significantly reduce labor costs while ensuring that dogs receive their meals at regular intervals. This consistency not only promotes better health among the animals but also frees up staff to focus on other critical tasks, such as socialization and care. International buyers should consider the feeder’s durability and capacity to hold large volumes of food, as these factors are vital in high-demand environments.

What Role Does the Blitz Automatic Dog Feeder Play in Veterinary Clinics?

Veterinary clinics utilize the blitz automatic dog feeder to provide a controlled feeding environment for dogs recovering from surgery or illness. By regulating the amount of food dispensed, clinics can better monitor the intake of each patient, which is essential for recovery. The feeder’s design must comply with health standards, ensuring that it can be easily cleaned and sanitized. For B2B buyers in this sector, features such as precise portion control and the ability to adapt to different dietary needs are crucial.

How Can Dog Training Centers Benefit from the Blitz Automatic Dog Feeder?

Dog training centers leverage the blitz automatic dog feeder to establish structured feeding times that align with training routines. This synchronization helps reinforce behavioral training by associating meal times with specific commands or activities. The feeder’s adjustability in portion sizes allows trainers to tailor diets based on individual dog needs, thereby enhancing training outcomes. Buyers in this sector should prioritize feeders that are robust and able to withstand frequent use in a busy training environment.

Why are Retail Pet Supply Stores Interested in the Blitz Automatic Dog Feeder?

Retail pet supply stores recognize the blitz automatic dog feeder as an attractive display unit that can enhance customer engagement. By demonstrating the feeder’s capabilities in-store, retailers can increase sales and customer interest. The aesthetic design of the feeder is also important, as it needs to appeal to a wide range of pet owners. When sourcing, retailers should consider compatibility with various dog sizes and the overall marketing potential of the product.

How Does the Blitz Automatic Dog Feeder Assist Agricultural Enterprises?

In agricultural settings, the blitz automatic dog feeder serves as an effective feeding solution for working dogs, such as herding or hunting dogs. This device streamlines the feeding process, allowing farmers to manage food distribution efficiently, especially in rural areas where time and resources may be limited. Buyers in this sector should look for feeders that are weather-resistant and mobile, ensuring they can withstand outdoor conditions while being easily transportable across different locations.

3 Common User Pain Points for ‘blitz automatic dog feeder’ & Their Solutions

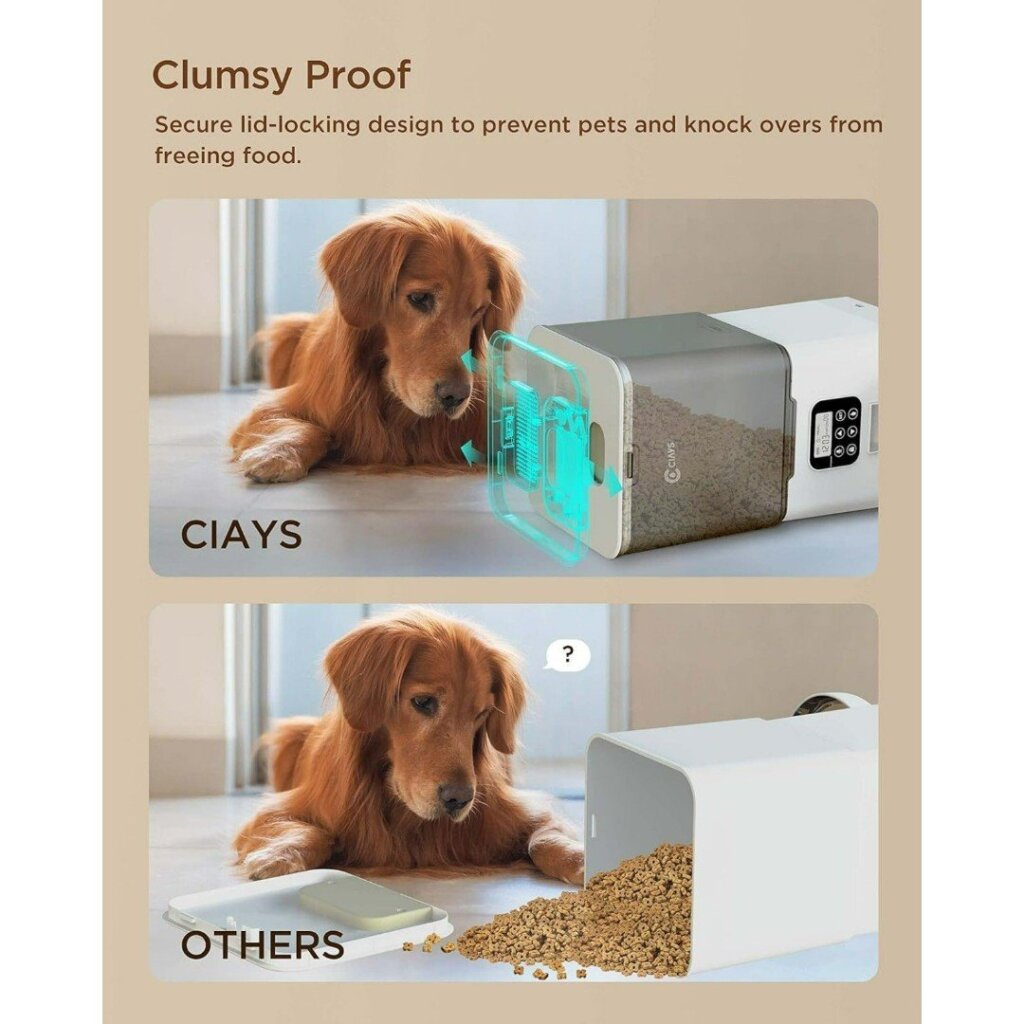

Scenario 1: Ensuring Consistent Food Dispensing for Large Breeds

Problem: B2B buyers catering to kennel operations or pet care businesses often face the challenge of ensuring that larger dog breeds receive adequate and timely meals. Automatic feeders can sometimes malfunction, leading to inconsistent food dispensing. This can result in dogs either being overfed or underfed, affecting their health and behavior. Additionally, the variability in food types may cause clogs or blockages in the feeder, further complicating the feeding process.

Rozwiązanie: To mitigate these issues, buyers should carefully evaluate the specifications of the blitz automatic dog feeder, particularly its capacity and dispensing mechanism. Opt for feeders designed specifically for larger breeds, ensuring they can handle the volume and type of food intended for these pets. When sourcing, prioritize models with a robust design that prevents clogs, such as those featuring an advanced dispensing system that accommodates different kibble sizes. Regular maintenance checks and cleaning schedules should also be established to ensure that the feeder operates smoothly, which can include inspecting the feeding chute for blockages and cleaning the internal components to prevent food buildup.

Scenario 2: Addressing Power Supply and Connectivity Issues

Problem: In regions where power supply can be unreliable, B2B buyers may encounter issues with automatic feeders that rely solely on electricity or Wi-Fi connectivity. Power outages or weak signals can prevent the feeder from dispensing food at scheduled times, which is especially problematic for businesses that depend on punctual feeding schedules to maintain their operations.

Rozwiązanie: Buyers should seek blitz automatic dog feeders that offer dual power options, such as battery backup alongside standard electrical operation. This ensures that even during power outages, the feeder continues to function. Additionally, buyers should consider models with manual override settings that allow for feeding in case of connectivity issues. When implementing these feeders, it’s advisable to conduct thorough testing in the intended operational environment to identify potential connectivity issues ahead of time. Consider integrating a monitoring system that alerts staff in case of malfunction, enabling prompt action to maintain feeding schedules.

Scenario 3: Managing Food Freshness and Hygiene Concerns

Problem: Maintaining the freshness and hygiene of pet food is critical for B2B buyers managing dog daycares or pet hotels. Automatic feeders can inadvertently expose food to elements that compromise its quality, such as moisture or pests. This can lead to health risks for pets and potential liability for businesses.

Rozwiązanie: When selecting the blitz automatic dog feeder, buyers should prioritize models that feature airtight compartments to keep food secure from moisture and pests. Additionally, incorporating food-grade materials in the feeder’s design can enhance hygiene. To further ensure food freshness, consider implementing a rotation system where food is regularly replenished, and older stock is used first. Establishing standard operating procedures for cleaning the feeder and inspecting food quality can also minimize health risks. Training staff to monitor the freshness of stored food and replace it regularly will help maintain high standards of hygiene and quality in the feeding process.

Strategic Material Selection Guide for blitz automatic dog feeder

What are the Key Materials for the Blitz Automatic Dog Feeder and Their Properties?

When selecting materials for the Blitz Automatic Dog Feeder, it is essential to consider properties such as durability, resistance to environmental factors, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of automatic dog feeders.

Illustrative image related to blitz automatic dog feeder

High-Density Polyethylene (HDPE): A Versatile Choice

Key Properties:

HDPE is known for its high strength-to-density ratio, excellent impact resistance, and low moisture absorption. It can withstand temperatures ranging from -40°F to 120°F, making it suitable for various climates.

Pros & Cons:

The durability of HDPE makes it a preferred choice for outdoor feeders. It is resistant to corrosion and UV radiation, which is vital for products exposed to the elements. However, HDPE can be more expensive than other plastics, and its manufacturing process may require specialized equipment.

Impact on Application:

HDPE is compatible with dry dog food and can easily be cleaned, ensuring hygiene. Its lightweight nature facilitates easy transport, which is advantageous for international shipping.

Considerations for International Buyers:

HDPE complies with various international standards, including ASTM and ISO. Buyers in regions like Africa and South America should ensure that suppliers meet local regulations regarding food safety.

Illustrative image related to blitz automatic dog feeder

Stainless Steel: The Premium Option

Key Properties:

Stainless steel is renowned for its exceptional corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It is also non-reactive, which is crucial for food safety.

Pros & Cons:

While stainless steel offers superior durability and a premium appearance, it is more expensive than plastic options. The manufacturing process can be complex, requiring specialized welding and finishing techniques.

Impact on Application:

Stainless steel is ideal for feeders that may be exposed to moisture or harsh cleaning chemicals. Its robustness ensures a long lifespan, making it suitable for high-demand environments like kennels.

Considerations for International Buyers:

International buyers should verify that the stainless steel used meets standards such as ASTM A240 for food-grade materials. Compliance with local regulations regarding metal safety is also essential.

Polypropylene: A Cost-Effective Alternative

Key Properties:

Polypropylene is lightweight, flexible, and resistant to chemical corrosion. It has a melting point of around 320°F, making it suitable for various applications.

Pros & Cons:

Polypropylene is cost-effective and easy to mold, making it a popular choice for manufacturers. However, it is less durable than HDPE and stainless steel, which may limit its use in extreme conditions.

Impact on Application:

This material is suitable for indoor feeders and can handle dry dog food without issues. Its lightweight nature aids in reducing shipping costs.

Considerations for International Buyers:

Polypropylene complies with various international standards, but buyers should ensure that it meets food safety regulations in their respective countries, especially in Europe and the Middle East.

Aluminum: Lightweight Yet Strong

Key Properties:

Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It can withstand a range of temperatures, making it suitable for various environments.

Pros & Cons:

Aluminum is relatively inexpensive and easy to work with, but it is softer than stainless steel, which may lead to dents and scratches over time. Its surface can oxidize, potentially affecting food safety if not properly coated.

Impact on Application:

Aluminum feeders are suitable for moderate use and can be designed in various shapes and sizes. However, they may require protective coatings to enhance durability.

Considerations for International Buyers:

Buyers should ensure that aluminum used in feeders complies with food safety standards, particularly in regions with stringent regulations, such as Europe.

Summary Table of Material Selection for Blitz Automatic Dog Feeder

| Materiał | Typical Use Case for blitz automatic dog feeder | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Outdoor feeders, high-impact environments | Excellent UV and moisture resistance | Higher manufacturing costs | Średni |

| Stainless Steel | Premium feeders, high-demand environments | Exceptional durability and safety | Complex manufacturing process | Wysoki |

| Polypropylene | Indoor feeders, cost-sensitive applications | Cost-effective and lightweight | Less durable than alternatives | Niski |

| Aluminum | Moderate use feeders, lightweight designs | Lightweight and easy to work with | Susceptible to dents and scratches | Średni |

This strategic material selection guide provides insights into the properties and considerations of various materials used in the Blitz Automatic Dog Feeder, helping international B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for blitz automatic dog feeder

What Are the Main Stages of Manufacturing the Blitz Automatic Dog Feeder?

The manufacturing process for the Blitz Automatic Dog Feeder involves several critical stages to ensure the final product meets quality and performance standards.

1. Material Preparation

The first stage in the manufacturing process is material preparation. High-density polyethylene (HDPE) is commonly used due to its durability and resistance to breakage, rust, and corrosion. Suppliers must source HDPE that meets specific industry standards, ensuring that the material is free from contaminants. Before production, materials undergo quality checks to confirm that they meet the required specifications.

Illustrative image related to blitz automatic dog feeder

2. Forming

Once the materials are prepared, the next stage is forming. This involves molding the HDPE into the specific shapes required for the feeder. Injection molding is a prevalent technique used in this phase. It allows for the creation of complex shapes with high precision, ensuring that all parts fit together seamlessly. The molds used in this process are meticulously crafted to ensure consistency across batches.

3. Assembly

After forming, the components are assembled. This stage may involve manual labor or automated assembly lines, depending on the scale of production. Key elements such as the feed inlet lid, outlet lid, and the internal divider wall are integrated at this stage. The assembly process must adhere to strict guidelines to ensure that the feeders are easy to use and operate effectively. Any misalignment or improper fitting can lead to product failures, which manufacturers must avoid.

4. Finishing

The final stage of manufacturing is finishing, which includes cleaning, polishing, and applying any necessary coatings. This step is essential to ensure the product is visually appealing and free from manufacturing residues. Quality checks during this phase might include visual inspections and tests to ensure that surfaces are smooth and free from defects.

How Is Quality Assurance Implemented in the Manufacturing of Blitz Automatic Dog Feeders?

Quality assurance (QA) is a critical component of the manufacturing process for the Blitz Automatic Dog Feeder. It ensures that every unit produced meets specific international standards and industry requirements.

Illustrative image related to blitz automatic dog feeder

What International Standards Are Relevant for Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that the manufacturer has established processes to consistently provide products that meet customer and regulatory requirements. In addition to ISO standards, CE marking is essential for products sold in the European market, ensuring compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality Control (QC) checkpoints are integrated into various stages of production to maintain high standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. The purpose is to ensure that all materials meet specified quality criteria before they enter production.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring and inspecting products at various stages. This helps identify defects early, reducing waste and ensuring that only quality products proceed to the next stage.

-

Final Quality Control (FQC): This is the last checkpoint before products are packaged and shipped. FQC includes comprehensive testing of finished units to verify that they function correctly and meet all specifications.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods play a vital role in ensuring that the Blitz Automatic Dog Feeder is safe and functional. Common testing methods include:

-

Functional Testing: Ensures that the feeder operates as intended, including dispensing food accurately and consistently.

-

Durability Testing: Evaluates how well the product withstands wear and tear, often simulating long-term usage conditions.

-

Safety Testing: Assesses potential hazards, including sharp edges or materials that may be harmful to pets.

W jaki sposób nabywcy B2B mogą weryfikować kontrolę jakości dostawców?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring reliable products.

What Are Effective Verification Methods?

-

Supplier Audits: Conducting on-site audits can provide buyers with firsthand insight into the manufacturing processes and quality control measures in place. Audits should assess compliance with international standards and the effectiveness of the QA system.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC processes and any issues that may have arisen during production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing facility and product quality. These inspections often yield certifications that can assure buyers of the product’s quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When engaging with international suppliers, B2B buyers must navigate various certification requirements and quality control nuances.

Illustrative image related to blitz automatic dog feeder

How Do Regional Regulations Affect Quality Assurance?

Different regions may have varying standards and regulations. For example, products sold in Europe must meet CE marking requirements, while some countries in Africa may have their own local standards. It is crucial for buyers to familiarize themselves with these regulations to ensure compliance.

What Are the Implications of Quality Standards on Supply Chain Management?

Understanding quality standards can significantly impact supply chain management. Buyers should consider how quality assurance processes affect lead times, costs, and overall product availability. A supplier with a robust QC process may have higher upfront costs but could lead to lower long-term expenses due to reduced returns and warranty claims.

In summary, the manufacturing processes and quality assurance protocols for the Blitz Automatic Dog Feeder are designed to ensure high-quality, durable products that meet international standards. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers and ensure they receive reliable and safe products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blitz automatic dog feeder’

To assist international B2B buyers in sourcing the Blitz Automatic Dog Feeder effectively, the following practical checklist outlines essential steps to ensure a successful procurement process.

Krok 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for aligning your procurement needs with the capabilities of the Blitz Automatic Dog Feeder. Consider factors such as capacity, material durability, and design features that cater to your target market, including larger breeds or kennel environments. Knowing your requirements upfront will streamline communication with suppliers and help avoid mismatches.

Krok 2: Research Market Trends and Demand

Understanding market trends in pet care and feeding solutions will guide your procurement strategy. Analyze data on pet ownership rates, consumer preferences, and technological advancements in automatic feeders. This insight will not only inform your purchasing decisions but also help you anticipate future demand in regions like Africa, South America, and Europe.

Krok 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request detailed company profiles, product catalogs, and references from existing clients. Assess their production capacity, quality control measures, and compliance with international standards to ensure reliability and consistency in product delivery.

- Consider Supplier Certifications: Ensure that suppliers hold relevant certifications (e.g., ISO, CE) that demonstrate adherence to quality and safety standards.

- Review Customer Feedback: Look for testimonials or reviews from other B2B buyers to gauge supplier reputation and product performance.

Krok 4: Assess Logistics and Distribution Capabilities

Logistics play a vital role in the timely delivery of products. Discuss with potential suppliers their shipping options, lead times, and distribution networks, particularly in your target regions. Effective logistics management will minimize delays and ensure that you can meet customer demand promptly.

Illustrative image related to blitz automatic dog feeder

Krok 5: Negotiate Pricing and Payment Terms

Once you have shortlisted suppliers, engage in negotiations to secure favorable pricing and payment terms. Consider factors such as bulk discounts, payment schedules, and potential for long-term partnerships. Transparent discussions will help build trust and establish a mutually beneficial relationship.

Krok 6: Request Samples for Quality Assurance

Before finalizing your order, request samples of the Blitz Automatic Dog Feeder. This step is crucial for assessing the product’s quality, functionality, and suitability for your market. Testing the samples will help ensure that the product meets your specifications and customer expectations.

Krok 7: Finalize Contracts and Terms of Agreement

After selecting a supplier and validating product quality, finalize contracts that clearly outline terms of agreement, including delivery timelines, warranty provisions, and return policies. A well-structured contract protects both parties and establishes a clear framework for future transactions.

Illustrative image related to blitz automatic dog feeder

By following this checklist, B2B buyers can effectively navigate the sourcing process for the Blitz Automatic Dog Feeder, ensuring they make informed decisions that align with their business goals and customer needs.

Comprehensive Cost and Pricing Analysis for blitz automatic dog feeder Sourcing

What Are the Key Cost Components for Sourcing Blitz Automatic Dog Feeders?

When sourcing blitz automatic dog feeders, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The use of high-density polyethylene (HDPE) for the feeder’s body is common, as it is durable, weather-resistant, and non-corrosive. The cost of materials can vary based on global resin prices and supplier relationships.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with lower labor costs, such as parts of Asia and South America, may offer significant savings compared to European production.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and facility costs associated with production. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Initial tooling costs for molds and fixtures can be substantial, especially for custom designs. Buyers should be aware of these costs when negotiating initial orders.

-

Quality Control (QC): Implementing robust QC processes adds to the cost but ensures product reliability, which is crucial for maintaining brand reputation.

-

Logistics: Shipping costs depend on the origin, destination, and shipping method. Incoterms will dictate who is responsible for various costs and risks during transport.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect the Sourcing of Automatic Dog Feeders?

Several factors influence pricing for blitz automatic dog feeders. Understanding these can help buyers make informed decisions.

Illustrative image related to blitz automatic dog feeder

-

Volume/MOQ: Manufacturers often offer better pricing for larger orders. Minimum order quantities (MOQs) can lead to economies of scale, reducing the per-unit cost.

-

Specifications/Customization: Custom features or specific branding requirements may increase costs. Clear communication about specifications can help avoid unexpected expenses.

-

Materials: The choice of materials can significantly affect the price. Higher-quality materials may incur additional costs but can enhance product durability and customer satisfaction.

-

Quality and Certifications: Products that meet international standards or have specific certifications (e.g., ISO) might come at a premium but can also enhance marketability.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can influence pricing. Building long-term relationships with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is crucial for budgeting. Different terms can significantly impact total landed costs.

What Are the Best Negotiation Tips for International B2B Buyers?

B2B buyers should adopt strategic approaches to enhance cost-efficiency and negotiate better deals.

-

Leverage Volume: If possible, consolidate orders to meet MOQs and negotiate discounts based on larger purchase volumes.

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, tariffs, and potential warranty or repair costs. A lower initial price may lead to higher long-term costs.

-

Research Market Prices: Knowledge of current market prices can provide leverage in negotiations. Being well-informed about competitors’ offerings can strengthen your negotiating position.

-

Build Relationships: Establishing a rapport with suppliers can lead to more favorable terms and increased flexibility in negotiations.

-

Be Culturally Aware: In regions like Africa, South America, and the Middle East, understanding cultural nuances can facilitate smoother negotiations and build trust.

Wnioski

Navigating the cost and pricing landscape for blitz automatic dog feeders requires a comprehensive understanding of various factors. By focusing on key cost components, price influencers, and effective negotiation strategies, B2B buyers can optimize their sourcing decisions and enhance their competitive edge in the market. Remember, pricing can fluctuate, so it is advisable to request indicative prices and conduct regular market assessments.

Alternatives Analysis: Comparing blitz automatic dog feeder With Other Solutions

Understanding Alternative Solutions for Automatic Dog Feeding

In the competitive landscape of pet care products, the blitz automatic dog feeder stands out due to its innovative features and design. However, various alternative solutions can also serve the needs of pet owners and businesses alike. This analysis aims to provide B2B buyers with a comprehensive comparison of the blitz automatic dog feeder against other viable options, helping them make informed purchasing decisions.

Tabela porównawcza

| Aspekt porównawczy | Blitz Automatic Dog Feeder | Bergan Aut-O-Dine Dog Feeder | Gravity-Feed Dog Feeder |

|---|---|---|---|

| Wydajność | Highly programmable, allows for portion control and scheduled feeding | Dispenses up to 25 lbs of food, suitable for larger dogs | Uses gravity to dispense food automatically as the bowl empties |

| Koszt | Moderate price point, typically ranges from $70 to $100 | Priced at approximately $86.49 | Generally low-cost, around $30 to $60 depending on size |

| Łatwość wdrożenia | Requires initial setup and programming, user-friendly interface | Simple installation, easy to load food | Minimal assembly, straightforward to use |

| Konserwacja | Requires periodic cleaning and battery replacement | Easy to clean, dishwasher safe parts | Low maintenance, occasional cleaning needed |

| Najlepszy przypadek użycia | Ideal for tech-savvy pet owners needing precise feeding schedules | Best for kennels or larger dogs needing bulk feeding | Suitable for pet owners seeking a budget-friendly solution |

Detailed Breakdown of Alternatives

Bergan Aut-O-Dine Dog Feeder

The Bergan Aut-O-Dine is a robust alternative designed specifically for larger breeds. With a capacity of 25 lbs, it automatically dispenses food based on the owner’s preferences. The feeder is made of high-density polyethylene, making it durable and easy to clean. However, its lack of advanced programming features means it may not suit pet owners looking for precise feeding schedules. Its value lies in simplicity and reliability, making it a great choice for kennels or busy households.

Gravity-Feed Dog Feeder

The gravity-feed dog feeder represents a cost-effective solution for pet owners who prefer a no-fuss feeding method. Utilizing gravity, it dispenses food as the dog eats, ensuring a continuous supply. This type of feeder requires minimal assembly and is generally low-cost, making it accessible for budget-conscious buyers. However, it lacks the programmability and portion control that the blitz feeder offers, which may lead to overeating in some pets. This solution is best for casual pet owners who prioritize simplicity over technology.

Conclusion: How to Choose the Right Automatic Dog Feeder

When selecting an automatic dog feeder, B2B buyers should assess their specific needs and the unique requirements of their clientele. For businesses catering to tech-savvy pet owners, the blitz automatic dog feeder offers advanced features that can enhance customer satisfaction. In contrast, for those serving a broader market with varying budgets, the Bergan Aut-O-Dine and gravity-feed options provide reliable, effective feeding solutions without the complexities of technology. Ultimately, the decision should be based on factors such as performance, cost, ease of use, and maintenance requirements to ensure the chosen solution aligns with the target market’s demands.

Essential Technical Properties and Trade Terminology for blitz automatic dog feeder

What Are the Essential Technical Properties of the Blitz Automatic Dog Feeder?

When considering the Blitz Automatic Dog Feeder for B2B purchasing, understanding its technical properties is crucial for making informed decisions. Here are the key specifications that define the product’s quality and functionality:

-

Material Grade: The Blitz Automatic Dog Feeder is typically constructed from high-density polyethylene (HDPE). This material is known for its durability, resistance to impact, and non-corrosive nature. For B2B buyers, selecting feeders made from HDPE ensures longevity and less frequent replacement, ultimately leading to cost savings.

-

Capacity: A critical specification is the feeder’s capacity, which often holds approximately 25 pounds or 100 cups of dry dog food. This capacity is ideal for larger breeds and kennel operations. Understanding capacity helps buyers gauge whether the feeder meets their operational needs, especially in high-demand environments.

-

Weather Resistance: The feeder is designed with weatherproof features, including a lid that prevents rain and pests from contaminating the food. This property is particularly important for buyers in regions with fluctuating climates, as it ensures the integrity of the food stored within.

-

Ease of Cleaning: The design of the Blitz Automatic Dog Feeder emphasizes easy maintenance, with features that facilitate quick cleaning. For B2B buyers, this property is essential as it reduces labor costs associated with sanitation, a critical aspect in pet care facilities.

-

Mounting Options: Many models come with easy mounting capabilities, allowing for flexibility in placement. This feature is beneficial for businesses that may have limited space or specific layout requirements, enabling efficient use of available areas.

-

Safety Features: The feeder often includes mechanisms to prevent overfeeding and ensure portion control. This is vital for maintaining pet health and managing food costs, particularly in commercial settings where numerous animals are fed.

Which Trade Terminology Should B2B Buyers Understand?

Navigating the purchasing landscape involves familiarity with specific trade terms that can impact business operations. Here are some essential terms relevant to the Blitz Automatic Dog Feeder:

-

OEM (producent oryginalnego sprzętu): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can clarify product origin and ensure quality standards are met.

-

MOQ (minimalna ilość zamówienia): MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses looking to stock products efficiently.

-

RFQ (zapytanie ofertowe): An RFQ is a standard business process where a company solicits price quotes from suppliers. For B2B buyers, issuing an RFQ for the Blitz Automatic Dog Feeder allows for competitive pricing and helps in evaluating supplier offers effectively.

-

Incoterms (międzynarodowe warunki handlowe): These are international rules that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is essential for B2B transactions involving international shipping, as it clarifies costs and risks associated with transportation.

-

Czas realizacji: This refers to the time taken from placing an order to receiving the goods. Understanding lead time is critical for B2B buyers to manage inventory levels and ensure timely availability of products, especially in fast-paced markets.

-

Warranty Terms: Warranty terms outline the conditions under which the supplier will repair or replace defective products. For B2B buyers, knowing these terms can provide peace of mind regarding product reliability and support, making it an essential consideration during the purchasing process.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding the Blitz Automatic Dog Feeder, ultimately leading to better outcomes for their businesses.

Navigating Market Dynamics and Sourcing Trends in the blitz automatic dog feeder Sector

What Are the Key Market Dynamics and Trends Affecting the Blitz Automatic Dog Feeder Sector?

The global market for automatic dog feeders, particularly the blitz automatic dog feeder, is witnessing significant growth driven by an increase in pet ownership, particularly in emerging economies across Africa, South America, the Middle East, and Europe. The rise in dual-income households has led to a demand for convenient pet care solutions, with automatic feeders offering a practical way to manage pet feeding schedules. Furthermore, advancements in technology are enabling the integration of smart features, such as app connectivity and portion control, which are appealing to tech-savvy consumers.

Emerging B2B trends indicate a shift towards products that cater to larger dog breeds, as evidenced by models that can dispense significant quantities of food, such as those holding up to 25 pounds. Additionally, the need for durable and easy-to-clean designs is becoming a priority for buyers, especially in commercial settings like kennels and pet hotels. International buyers are increasingly looking for suppliers who can provide comprehensive support, including product training and after-sales service, to ensure seamless integration into their operations.

How Is Sustainability Influencing Sourcing Trends for Blitz Automatic Dog Feeders?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the blitz automatic dog feeder sector. The environmental impact of manufacturing processes and materials used in pet products is under increasing scrutiny. Buyers are now favoring suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and production methods. For instance, dog feeders made from recycled plastics or biodegradable components are becoming increasingly popular.

Moreover, certifications such as ISO 14001 for environmental management systems or the Forest Stewardship Council (FSC) label for sustainably sourced materials are becoming essential for suppliers looking to differentiate themselves in the market. Buyers in regions like Europe and North America are particularly inclined to partner with companies that prioritize ethical supply chains, as these align with broader corporate social responsibility goals. Additionally, the demand for transparency in sourcing practices is prompting suppliers to provide detailed information on the lifecycle of their products, enhancing trust and credibility in the market.

What Is the Brief Evolution of the Blitz Automatic Dog Feeder Market?

The evolution of the blitz automatic dog feeder market can be traced back to the increasing recognition of the need for convenience in pet care. Initial models were basic in function, primarily focusing on the mechanical dispensing of food. Over time, technological advancements have transformed these devices into sophisticated feeders equipped with timers, portion control settings, and even smartphone connectivity, allowing pet owners to manage feeding schedules remotely.

As the market has matured, there has been a notable shift towards more user-friendly designs that prioritize hygiene and ease of use, catering to both individual pet owners and commercial establishments. Today, the blitz automatic dog feeder not only serves the functional purpose of feeding pets but also reflects the growing consumer demand for sustainable and ethically produced pet care products. This evolution underscores the importance of innovation and adaptability in meeting the changing needs of pet owners and the broader market.

Frequently Asked Questions (FAQs) for B2B Buyers of blitz automatic dog feeder

-

How do I ensure the quality of blitz automatic dog feeders before making a purchase?

To ensure quality, request samples from potential suppliers to evaluate the materials and functionality firsthand. Additionally, check for certifications that meet international standards, such as ISO or CE marking. Consider visiting the manufacturing facility, if feasible, to witness production processes and quality control measures. Engage with past clients of the supplier to gain insights into their reliability and product performance. -

What is the best automatic dog feeder for large breeds?

The blitz automatic dog feeder is specifically designed to cater to larger dog breeds, offering a capacity of up to 25 pounds of dry food. Its robust construction ensures durability, while the automatic dispensing feature allows for convenient feeding schedules. When selecting a feeder, consider the ease of cleaning and food storage options to maintain hygiene and food quality. -

What customization options are available for blitz automatic dog feeders?

Many suppliers offer customization options such as color, branding, and specific features tailored to your market needs. You can also request modifications in the design to accommodate local preferences or regulations. Discuss your requirements during initial negotiations to understand what is feasible and the associated costs. -

What are the minimum order quantities (MOQ) for blitz automatic dog feeders?

MOQs can vary significantly between suppliers, typically ranging from 100 to 1,000 units for bulk orders. It’s advisable to discuss your purchasing needs early in the negotiation process. Some suppliers may offer lower MOQs for initial orders, especially if you are a new customer, to foster long-term relationships. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms often vary by supplier and may include options like letters of credit, advance payments, or net 30/60/90 days terms. For first-time transactions, suppliers may require partial upfront payment to mitigate risks. Be sure to clarify payment terms during negotiations to ensure they align with your cash flow and financial policies. -

How can I vet suppliers for blitz automatic dog feeders effectively?

Conduct thorough research on potential suppliers by reviewing their business licenses, certifications, and customer feedback. Utilize platforms like Alibaba or Global Sources for supplier ratings and reviews. Additionally, consider arranging factory visits or using third-party inspection services to assess manufacturing capabilities and compliance with quality standards. -

What logistics considerations should I keep in mind when importing dog feeders?

When importing blitz automatic dog feeders, consider shipping methods, costs, and transit times. Evaluate the reliability of logistics partners, customs clearance processes, and potential tariffs or duties applicable in your country. It’s also wise to have contingency plans for delays and ensure that the packaging is robust to prevent damage during transit. -

What are the common issues faced during the importation of dog feeders, and how can they be mitigated?

Common issues include customs delays, product compliance failures, and shipping damage. To mitigate these risks, ensure that all paperwork is accurate and complete, comply with local regulations, and choose reputable logistics providers. Additionally, investing in quality packaging can help prevent damage, and maintaining open communication with suppliers will help address any issues promptly.

Top 3 Blitz Automatic Dog Feeder Manufacturers & Suppliers List

1. Bergan – Aut-O-Dine Dog Feeder

Domena: upco.com

Zarejestrowany: 1996 (29 lat)

Wprowadzenie: Bergan Aut-O-Dine Dog Feeder & Storage, Rated 5.00 out of 5 based on 2 customer ratings, Price: $86.49, SKU: 11894, Made of high density polyethylene, non-breakable, pest proof door, weather proof lid, Non-rusting, non-corrosive, easy mounting, Holds 25 lbs, automatically dispenses up to 100 cups or 25 pounds of dry dog food, Designed for larger dogs, Food loads from the top, Excellent for kennel …

2. Facebook – Blitz Automatic Dog Feeder

Domena: facebook.com

Zarejestrowany: 1997 (28 lat)

Wprowadzenie: blitz automatic dog feeder for sale

3. Blitz – Automatic Dog Feeder

Domena: 1bid.us

Registered: 2011 (14 years)

Wprowadzenie: {“name”:”Blitz Automatic Dog Feeder”,”material”:”Plastic”,”capacity”:”Holds approx. 25 lbs of food”,”condition”:”Needs cleaning but still in good condition”,”dimensions”:”14w x 14d x 21h”}

Strategic Sourcing Conclusion and Outlook for blitz automatic dog feeder

As the demand for innovative pet care solutions grows globally, the Blitz Automatic Dog Feeder stands out as a strategic asset for B2B buyers seeking to enhance their product offerings. This feeder not only simplifies the feeding process but also ensures optimal food storage and distribution, addressing key concerns such as hygiene and efficiency. Its robust design caters to larger breeds, making it an ideal choice for kennels and pet care facilities.

Strategic sourcing of the Blitz Automatic Dog Feeder can yield significant advantages, including competitive pricing, reliable supply chains, and enhanced customer satisfaction. Buyers from diverse markets—especially in Africa, South America, the Middle East, and Europe—should consider establishing partnerships with suppliers that prioritize quality and innovation. This approach will not only meet local demands but also position businesses favorably in an increasingly competitive landscape.

Looking ahead, international B2B buyers are encouraged to leverage the growing trend of automated pet care solutions. By integrating products like the Blitz Automatic Dog Feeder into their offerings, businesses can cater to evolving consumer preferences, ultimately driving growth and profitability. Now is the time to act—explore strategic sourcing opportunities to elevate your product portfolio and meet the needs of discerning pet owners worldwide.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.